Boron extracting device and method

A purification method and technology of elemental boron, which is applied in the direction of boron, boron/boride, etc., can solve the problems of high environmental protection cost, low boron purity, low yield, etc., and achieve the effect of low cost, high product purity and fast purification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

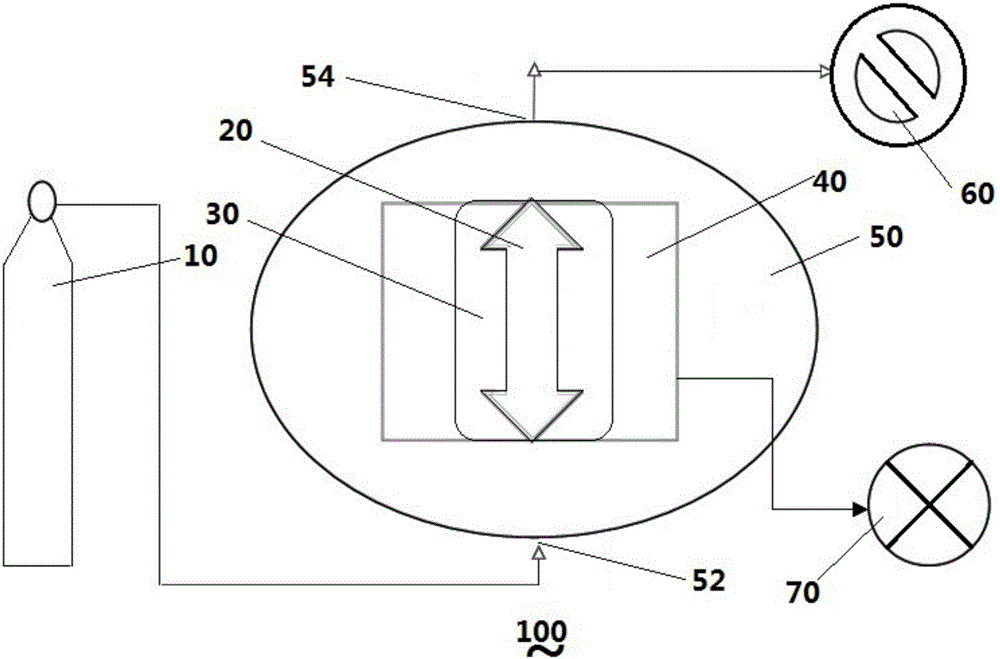

[0038] Put 10 kg of brown amorphous boron with a purity of 92% in figure 1 In the reaction vessel 20 in the container, close the air inlet 54, open the air outlet 52, start the vacuum pump group 60, and vacuumize the airtight cabin 50 to 10 -1 Pa: start the heating control system 70, use the heating coil 40 to heat the brown amorphous boron with a purity of 92% in the reaction vessel 20 to 1700° C. and keep it warm for 60 minutes. Close the gas outlet 54, close the vacuum pump group 60, open the high-purity gas cylinder 10, open the air inlet 52, and fill the high-purity argon (purity is 99.999%) to the airtight chamber 50 to normal pressure. The boron powder is taken out after the temperature of the reaction vessel 20 is lowered to within 100°C. The purity of the analyzed boron powder is greater than 99.9%.

Embodiment 2

[0040] Put 40 kg of brown amorphous boron with a purity of 98% in figure 1 In the reaction vessel 20 in the container, close the air inlet 52, open the air outlet 54, start the vacuum pump group 60, and vacuumize the airtight cabin 50 to 10 -1 Pa; start the heating control system 70, use the heating coil 40 to heat the brown amorphous boron with a purity of 98% in the reaction vessel to 1600° C. and keep it warm for 120 minutes. Close the gas outlet 54, close the vacuum pump group 60, open the high-purity gas cylinder 10, open the air inlet 52, and fill the high-purity argon (99.999%) to the airtight chamber 50 to normal pressure. The boron powder is taken out after the reaction container 20 is cooled to within 100 degrees, and the purity of the obtained boron powder is greater than 99.9%.

Embodiment 3

[0042] 40 kg of brown amorphous boron with a purity of 92% was placed in figure 1 In the reaction vessel 20 in the container, close the air inlet 52, open the air outlet 54, start the vacuum pump group 60, and vacuumize the airtight cabin 50 to 10 -1Pa; start the heating control system 70, use the heating coil 40 to heat the brown amorphous boron with a purity of 92% in the reaction vessel to 1650° C. and keep it warm for 100 minutes. Close the gas outlet 54, close the vacuum pump group 60, open the high-purity gas cylinder 10, open the air inlet 52, and fill the high-purity argon (99.999%) to the airtight chamber 50 to normal pressure. The boron powder is taken out after the reaction container 20 is cooled to within 100 degrees, and the purity of the obtained boron powder is greater than 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com