Ceramic glaze, processing device, and ceramic glaze processing method

A ceramic glaze and processing device technology, which is applied to chemical instruments and methods, transportation and packaging, mixers, etc., can solve the problems of inability to heat and stir ceramic glaze raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

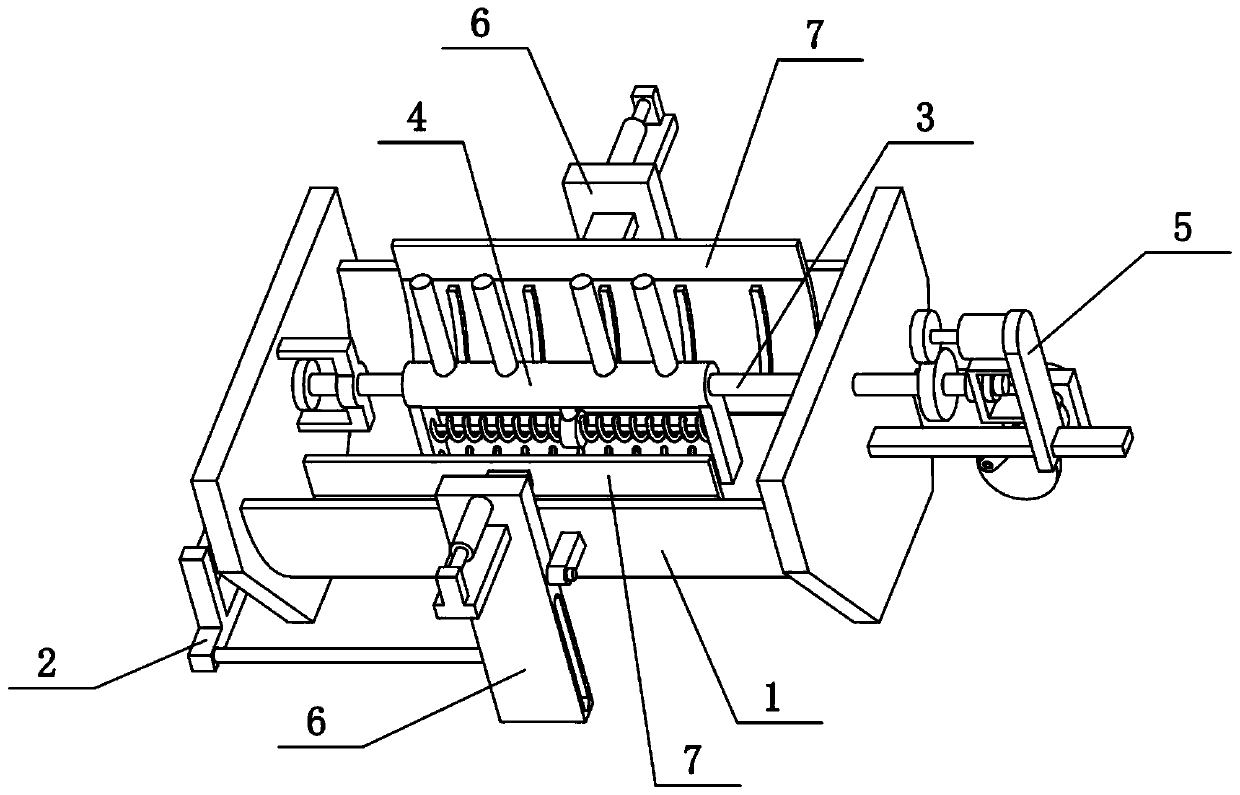

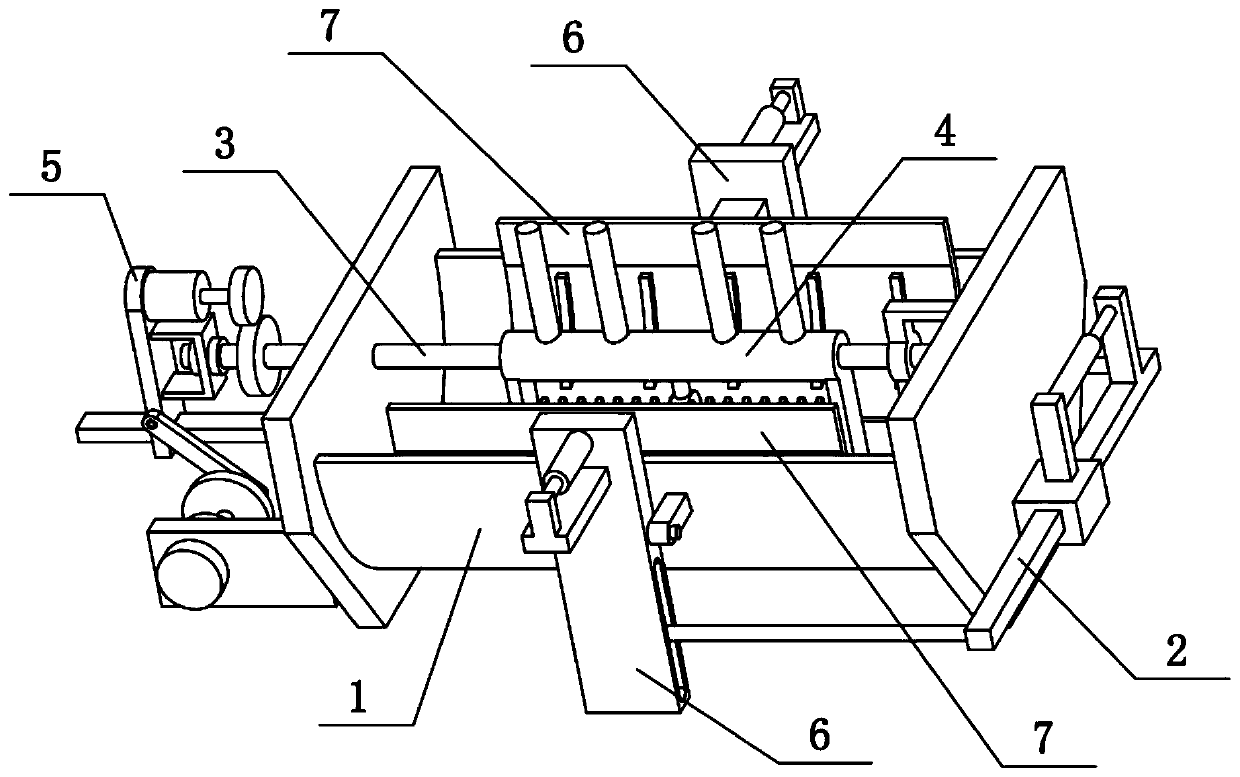

[0033] Combine below Figure 1-10 Describe this embodiment mode. The present invention relates to the field of ceramic glazes, more specifically, a ceramic glaze and a processing device and a ceramic glaze processing method, including a horizontal shaft 3, a circular sleeve 303, a connecting column 304, a sleeve 4, a stirring Rod 401, transverse groove 402, side plate 403 and spring sleeve column II405, the present invention can fully heat and stir the ceramic glaze material.

[0034]The middle part of the horizontal shaft 3 is fixedly connected with a connecting column 304, and the outer end of the connecting column 304 is fixedly connected with a round sleeve 303, and the sleeve 4 is slidably connected on the horizontal shaft 3, and the sleeve 4 is provided with a transverse groove 402, and the connecting column 304 is slidably connected to the transverse groove 402, a plurality of stirring rods 401 are fixedly connected to the sleeve 4, side plates 403 are fixedly connected...

specific Embodiment approach 2

[0036] Combine below Figure 1-10 To illustrate this embodiment, the ceramic glaze processing device further includes a spring sleeve I404, a spring sleeve I404 is fixedly connected between the two side plates 403, and a compression spring I is sleeved on the spring sleeve I404. Between the two side plates 403, a spring sleeve column I404 and a compression spring I are arranged again, and the spring sleeve column I404 and the compression spring I will also rotate with the axis of the horizontal shaft 3 along with the horizontal shaft 3, and the spring sleeve column II405 and The two compression springs II on the spring sleeve column II405 will also rotate with the axis of the horizontal axis 3 along with the horizontal axis 3, and the compression spring I and the compression spring II respectively increase the stirring of the spring sleeve column I404 and the spring sleeve column II405 scope.

specific Embodiment approach 3

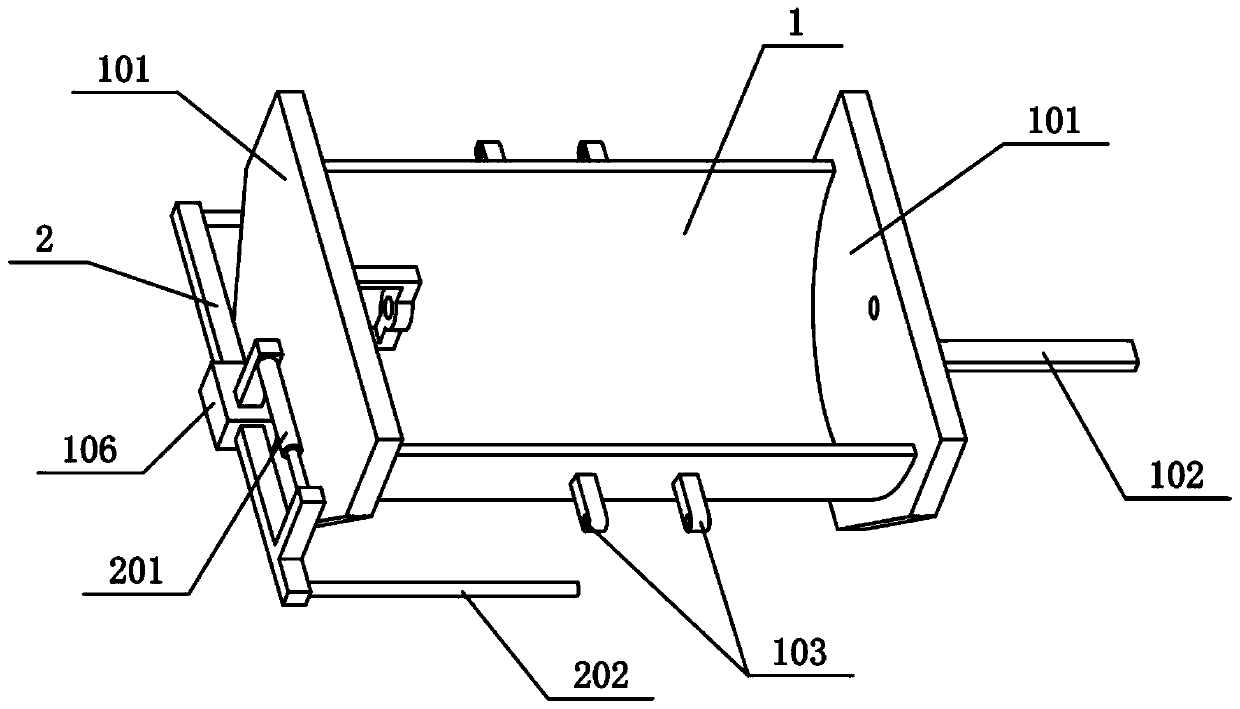

[0038] Combine below Figure 1-10 To illustrate this embodiment, the ceramic glaze processing device also includes a semi-cylindrical container 1, a side plate 101, a bracket 104, a circle 105, a horizontal shaft 3 and a limit piece 305, and the left and right sides of the semi-cylindrical container 1 are provided with side Plate 101, the right side of the side plate 101 at the left end is fixedly connected with a bracket 104, the middle part of the bracket 104 is fixedly connected with a circle 105, the left end of the horizontal shaft 3 is slidably connected with the circle 105, and the left end of the horizontal shaft 3 is fixedly connected with a limiting plate 305, the limiting piece 305 is located on the left side of the circle 105, and the right end of the horizontal shaft 3 is slidably connected to the side plate 101 located at the right end. The semi-cylindrical container 1 provides a container for ceramic glaze raw materials. The horizontal axis 3 can also move left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com