Passivation method for surface of black silicon solar cell

A technology on the surface of solar cells and silicon wafers, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve problems such as high production costs, complex process equipment conditions, etc., to improve minority carrier life and open circuit voltage, and improve photoelectric conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

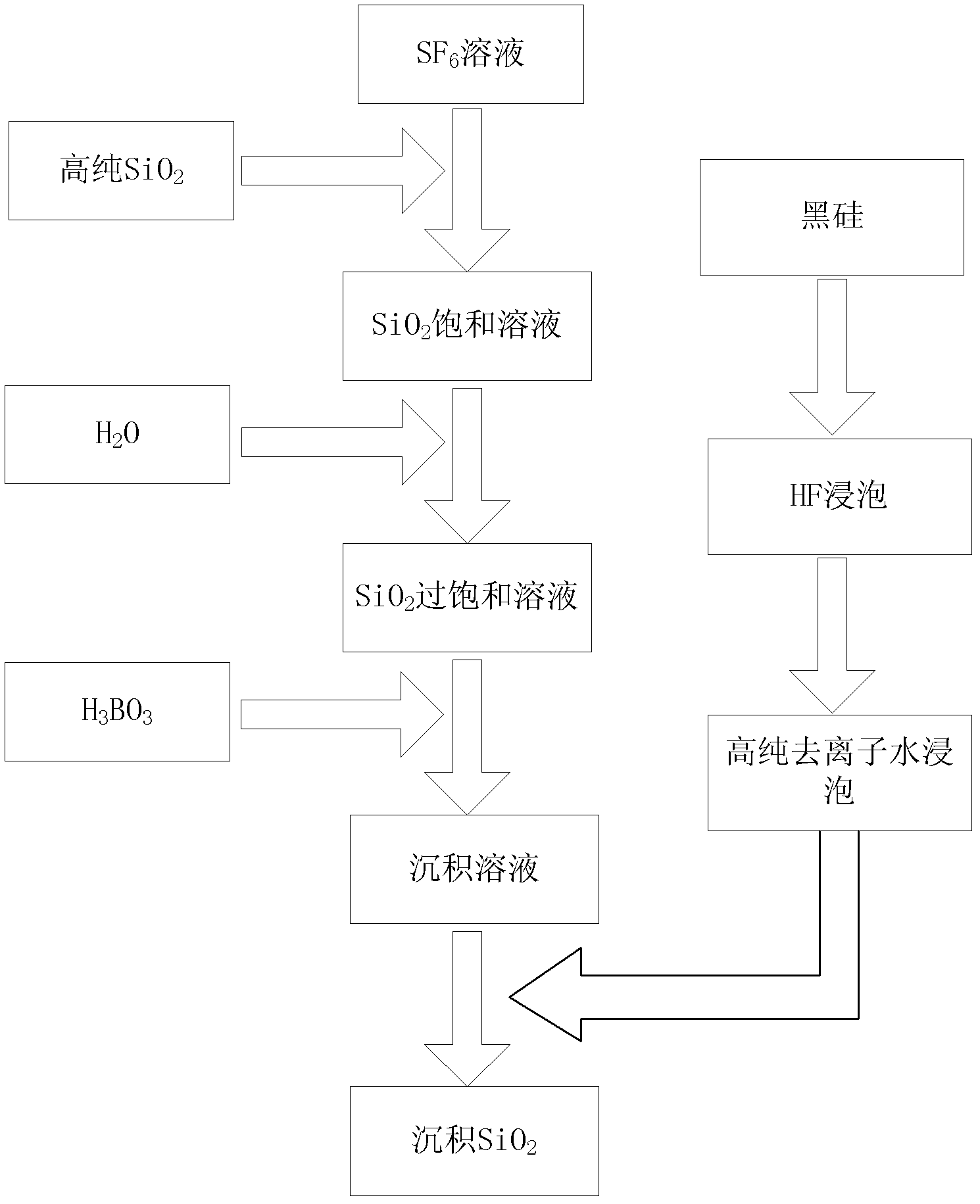

[0030] see figure 1 , the embodiment of the present invention provides a method for passivating the surface of a black silicon solar cell, the method includes the preparation of a silicon dioxide deposition solution, the cleaning of the diffused black silicon wafer and the deposition of a silicon dioxide film, which will be described in detail below The above three processes are as follows:

[0031] Step 101: select a hexafluorosilicate solution with a concentration of 30-35 wt%, and heat it to 40°C;

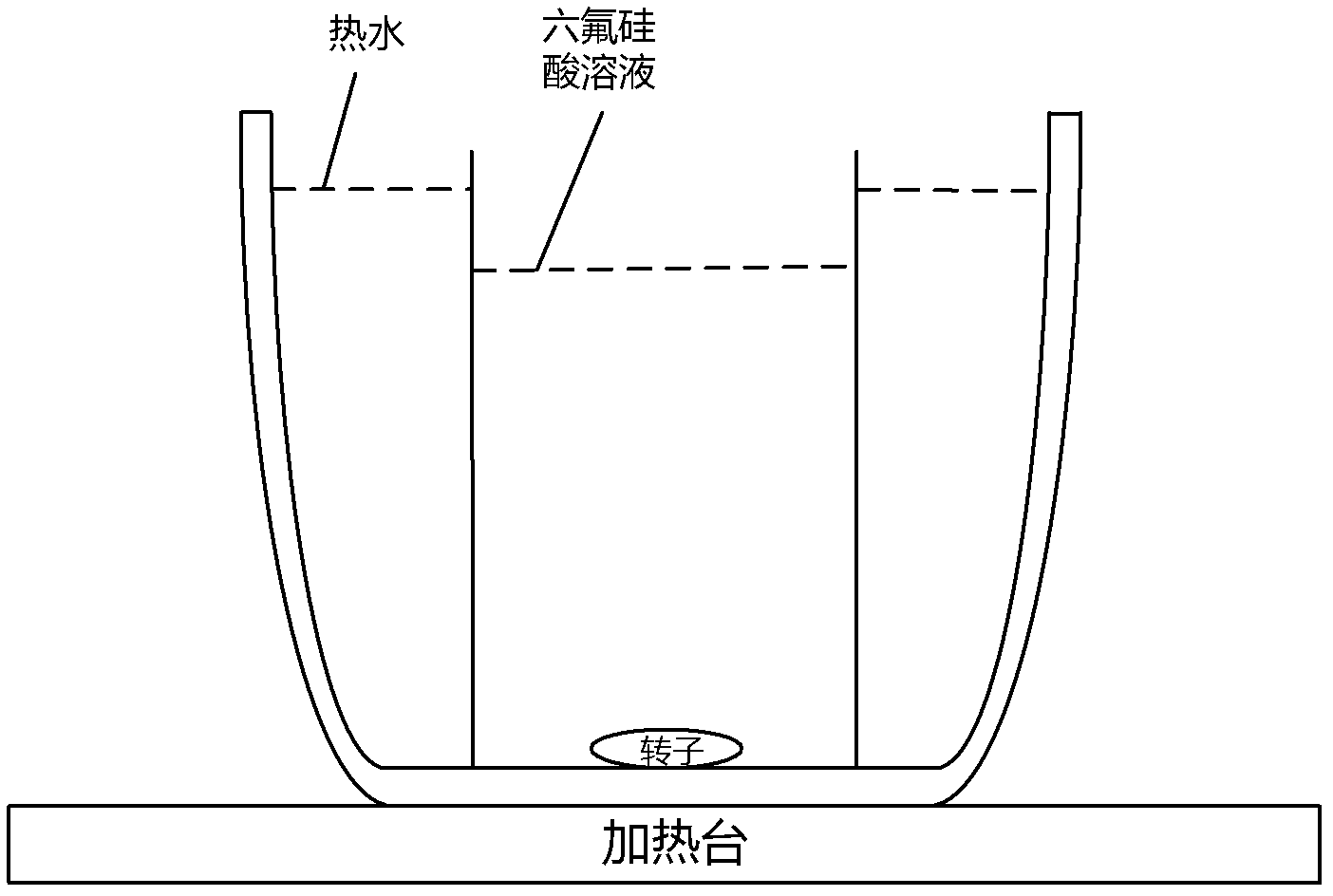

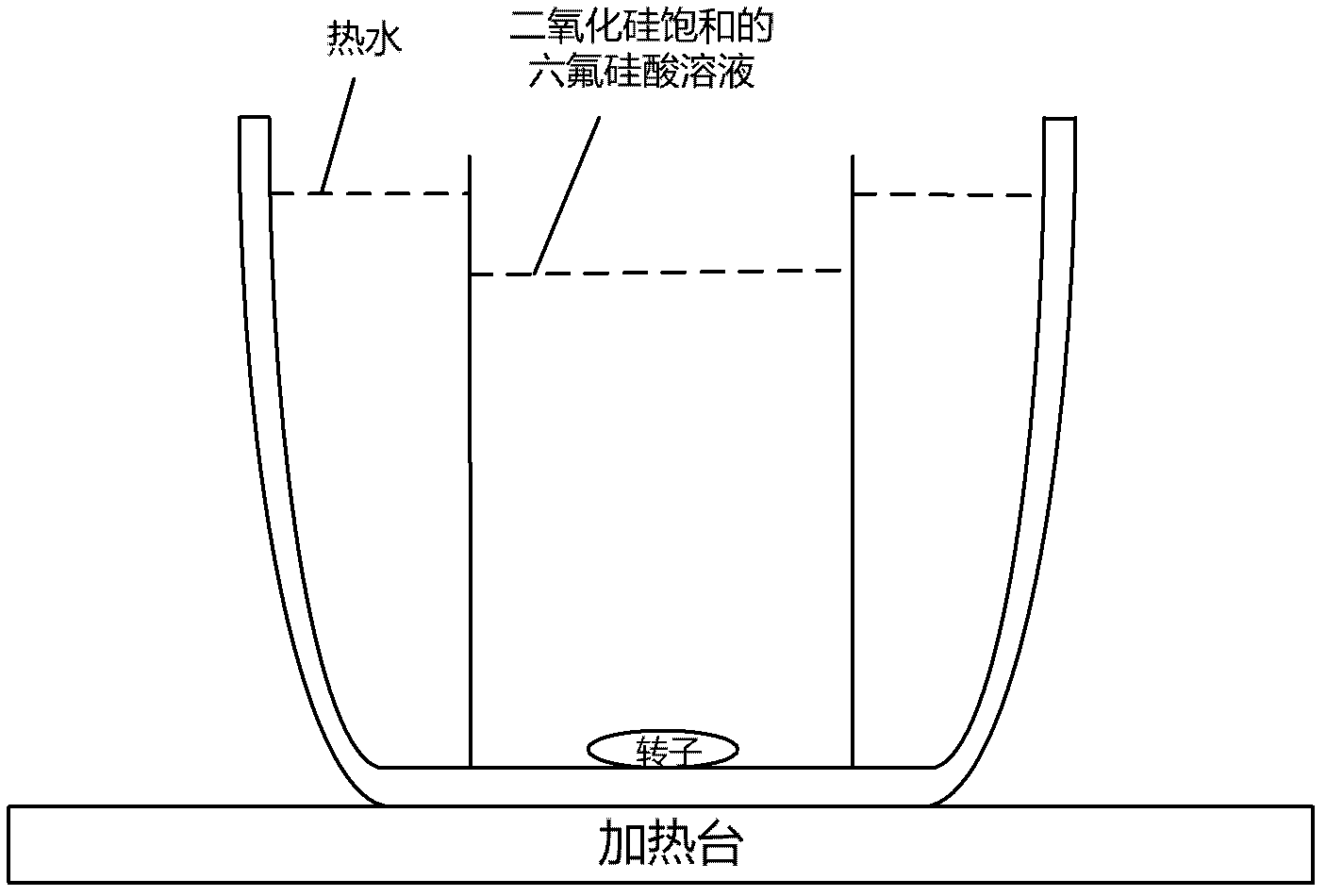

[0032] Such as figure 2 As shown, in this embodiment, the water bath heating method is used to heat the hexafluorosilicate solution. The main instruments used include a heating platform, a liquid container with a heat conduction chamber inside, and a stirring tank located at the bottom center of the heat conduction chamber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com