Biomass moulded coal and preparation method thereof

A biomass, inferior technology, applied in the direction of biofuels, waste fuels, solid fuels, etc., can solve the problems of slow industrialization of boiler fuel briquette, achieve good desulfurization and waterproofing effect, low ignition point, and protect the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

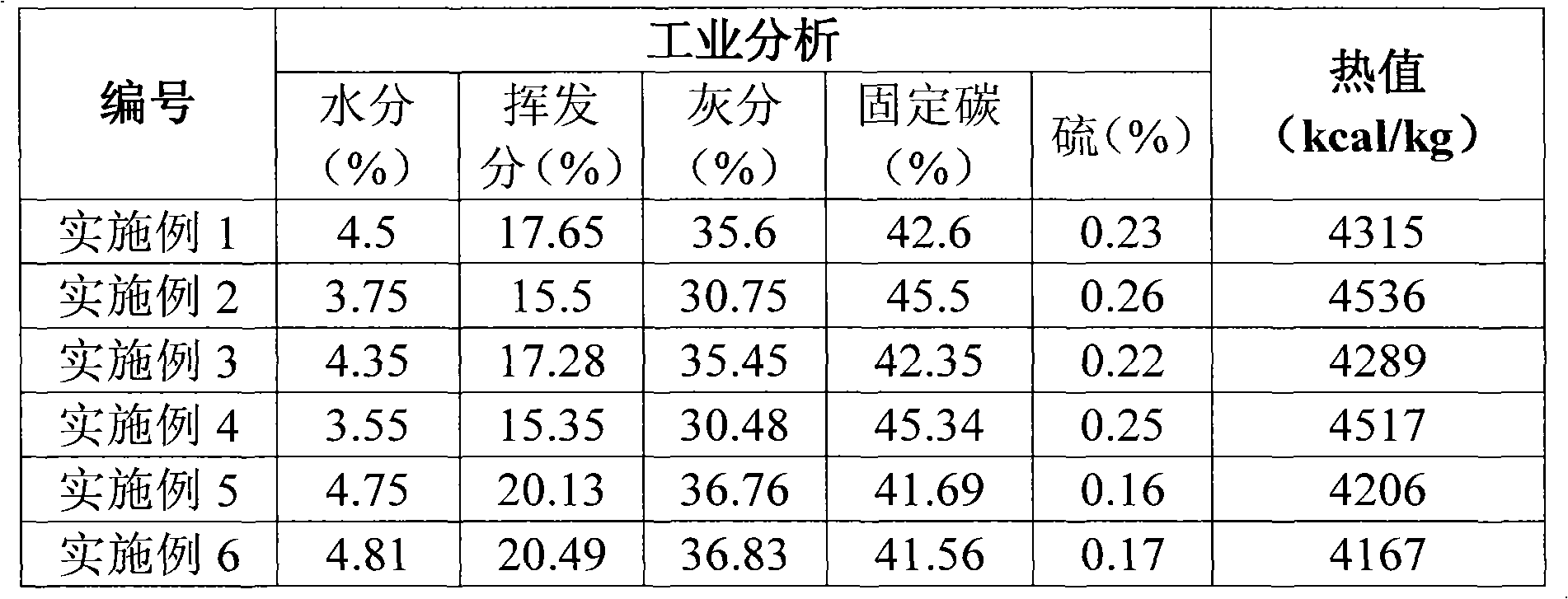

Examples

Embodiment 1

[0022] Sieve the anthracite coal powder and crush the bagasse to ensure that the maximum particle size of the anthracite pulverized coal and bagasse is below 3mm. Take by weighing inferior anthracite pulverized coal 500g, bagasse 400g, both mix homogeneously, then take by weighing sulfur-fixing agent unslaked lime 30g, biomass binding agent 35g (binding agent is to use 5g concentration to be 1% sodium hydroxide solution and 30g of bagasse, mixed with the obtained mixture after stirring for 5 minutes), oxidant potassium permanganate 20g and waterproofing agent tar 15g, after the additives are mixed evenly, then mixed with the mixed raw materials and mixed evenly with water, and then use the self-made mold wet low pressure Shaped to obtain spherical biomass briquettes with a diameter of 50 mm, which are matured at room temperature.

Embodiment 2

[0024] Sieve low-quality anthracite pulverized coal and crush bagasse to ensure that the maximum particle size of anthracite pulverized coal and bagasse is below 3mm. Take by weighing inferior anthracite pulverized coal 600g, bagasse 300g, both mix homogeneously, then take by weighing sulfur-fixing agent unslaked lime 35g, biomass binding agent 30g (binding agent is the sodium hydroxide solution that is 2% with 5g mass concentration Mix with 25g bagasse, stir the obtained mixture after 5 minutes), oxidant potassium permanganate 20g mix evenly, then add water and mix evenly with the mixed raw materials, then mix with 15g waterproofing agent tar and wet with a self-made mold Low-pressure forming method, can obtain spherical biomass briquettes with a diameter of 50mm, and mature at room temperature.

Embodiment 3

[0026] Sieve low-quality anthracite pulverized coal and crush bagasse to ensure that the maximum particle size of anthracite pulverized coal and bagasse is below 3mm. Take by weighing inferior anthracite pulverized coal 500g, bagasse 400g, both mix homogeneously, then take by weighing 40g of sulfur-fixing agent unslaked lime, 25g of biomass binding agent (binding agent is the sodium hydroxide solution of bagasse with mass concentration 1.5%) Gained light yellow viscous matter after treatment), oxidant potassium permanganate 20g and water repellent tar 15g, after the additives are mixed evenly, then add water to mix evenly with the raw materials that have been mixed, then use the self-made mold wet method low-pressure molding, can get the diameter It is a 50mm spherical biomass briquette, matured at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com