Patents

Literature

88results about How to "Oxidation stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of converting rendered triglyceride oil from marine sources into bland, stable oil

Triglyceride oil derived from marine sources, mammalian and fish, is treated with a silica at relatively low temperature under vacuum and is then further treated with a bleaching clay under vacuum and at higher temperature. The silica and the bleaching clay are then separated from the oil. The oil treated by this method is essentially free of proteinaceous materials, phosphatides and mucilage, pro-oxidant metals and very low in colored compounds, and is suitable for deodorizing. The deodorized oil is completely bland, unchanged in the concentration of the long-chain highly unsaturated fatty acids (EPA, DPA and DHA), very low in color, peroxides and secondary oxidation products, free of pesticides and has very good flavor stability. The method avoids the use of any chemicals, such as in the acid and base treatments required in conventional degumming and alkali refining of oils of marine origin. This avoids the formation of artifacts in the oil and trace contamination with chemicals. It also reduces the number of process steps required to produce deodorized food oil from marine sources, which is advantageous in respect to oil quality, process losses and processing costs. The method is especially environmentally advantageous, since it avoids the need for soapstock and waste water processing entirely. Refined oil produced by the method is useful as a nutritional supplement and in methods of therapy or medical treatment.

Owner:MAG TED

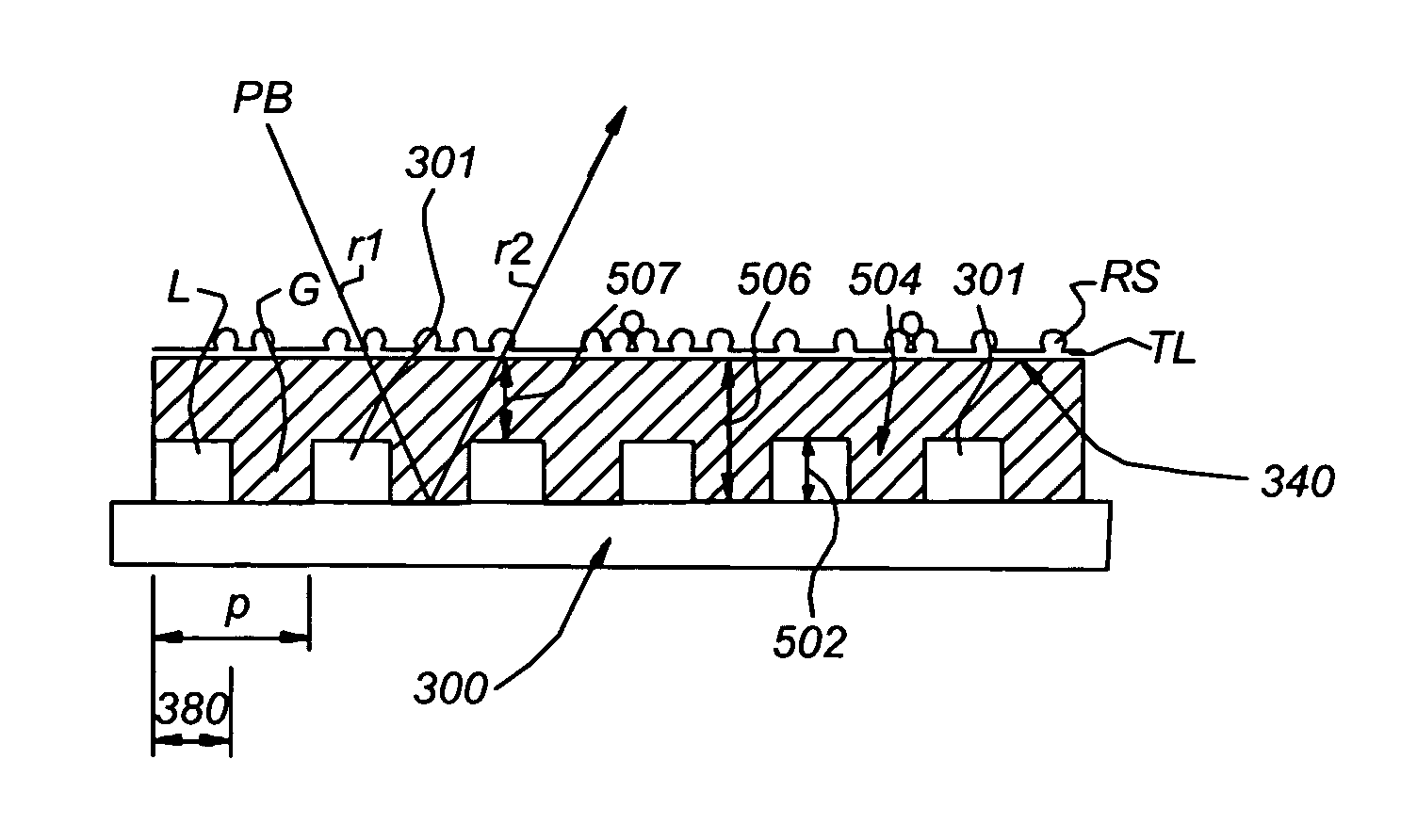

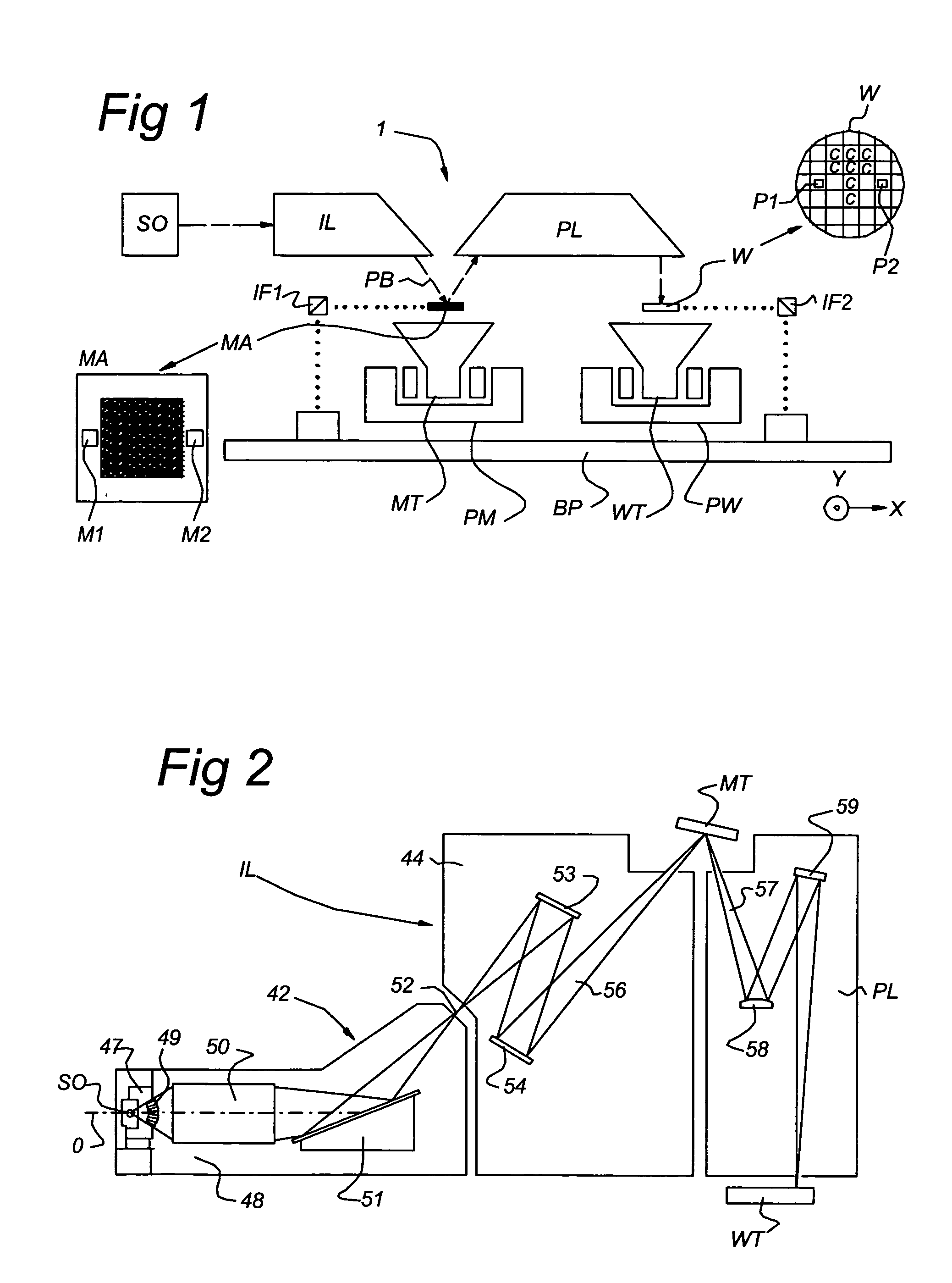

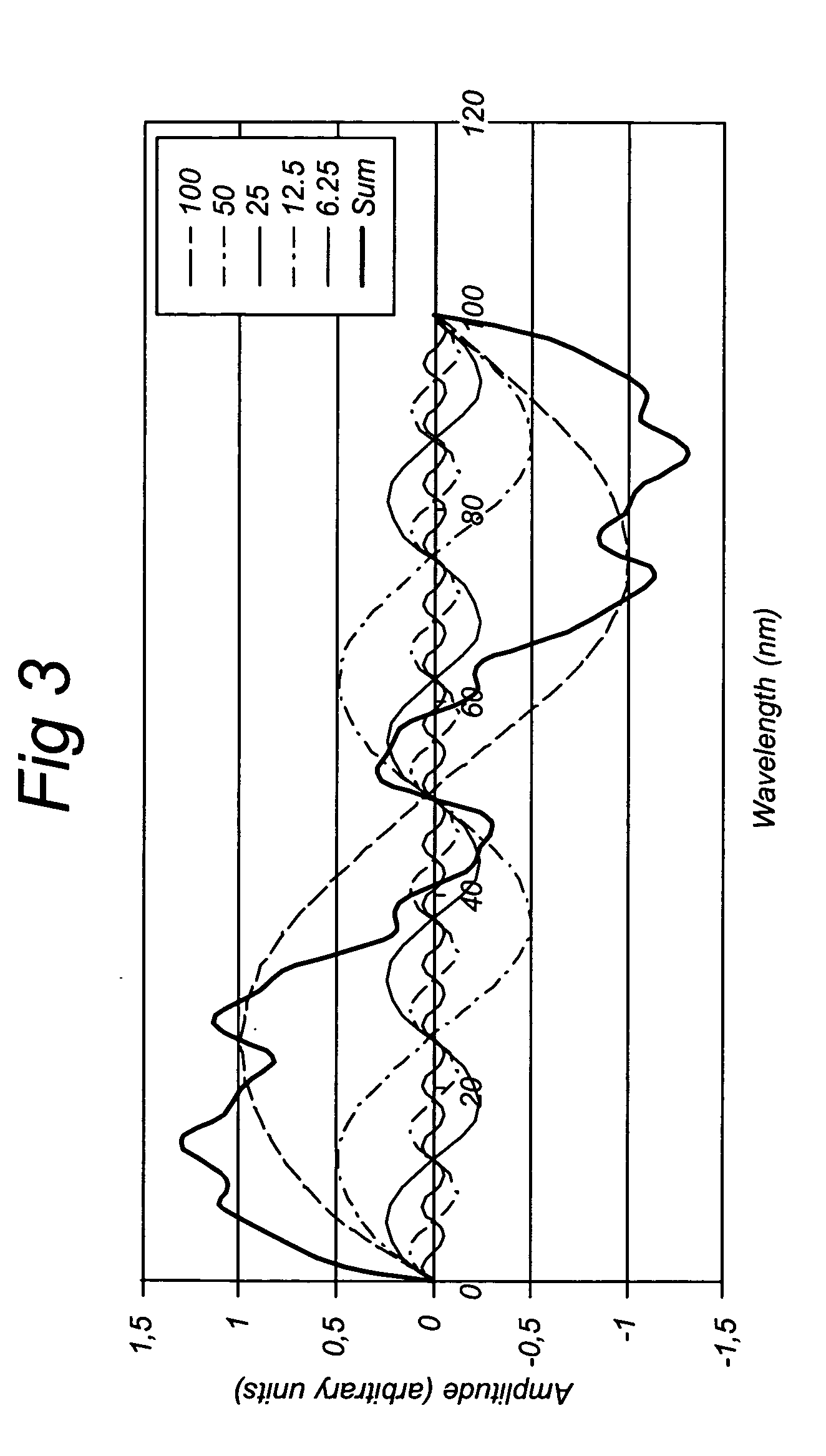

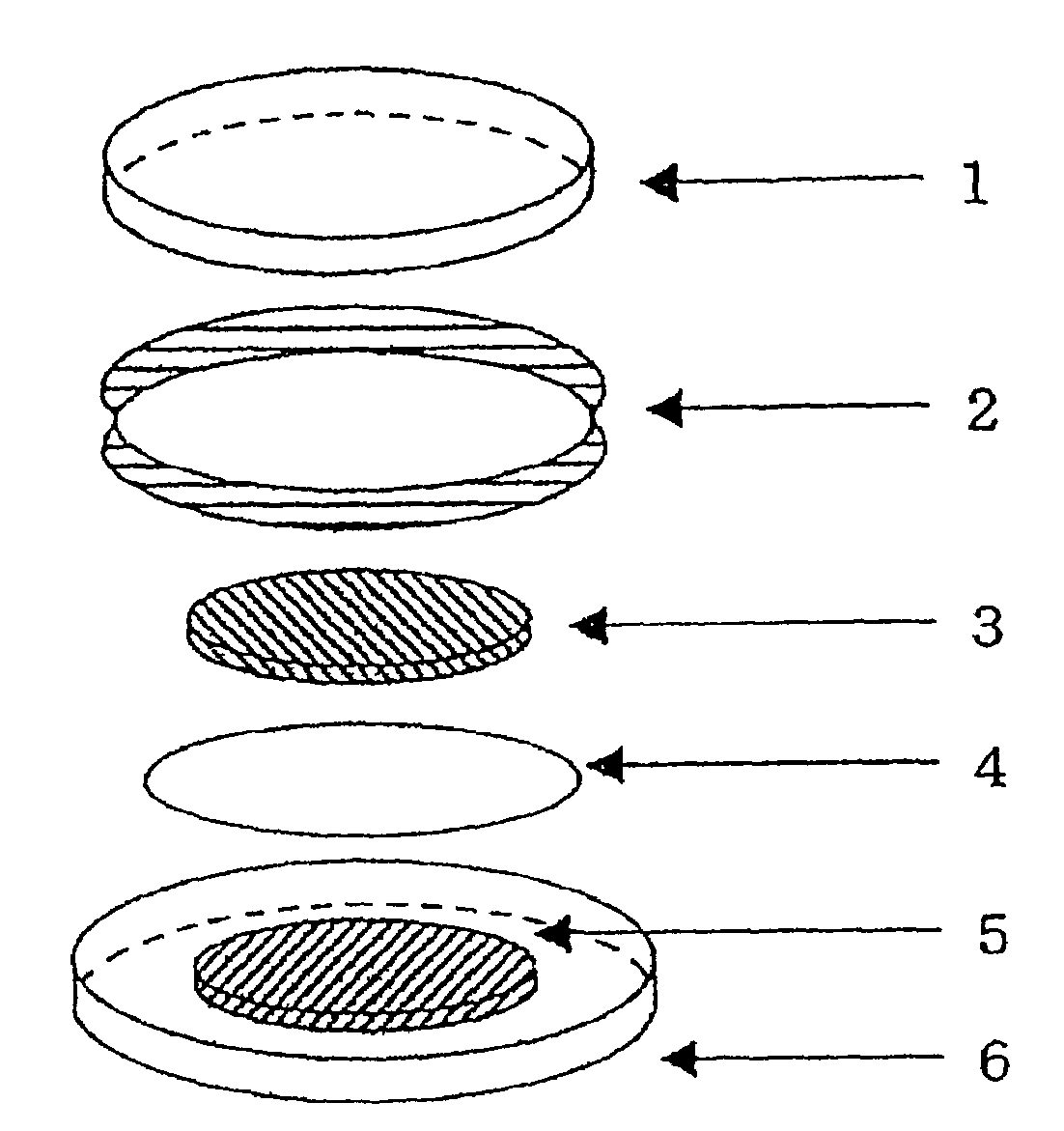

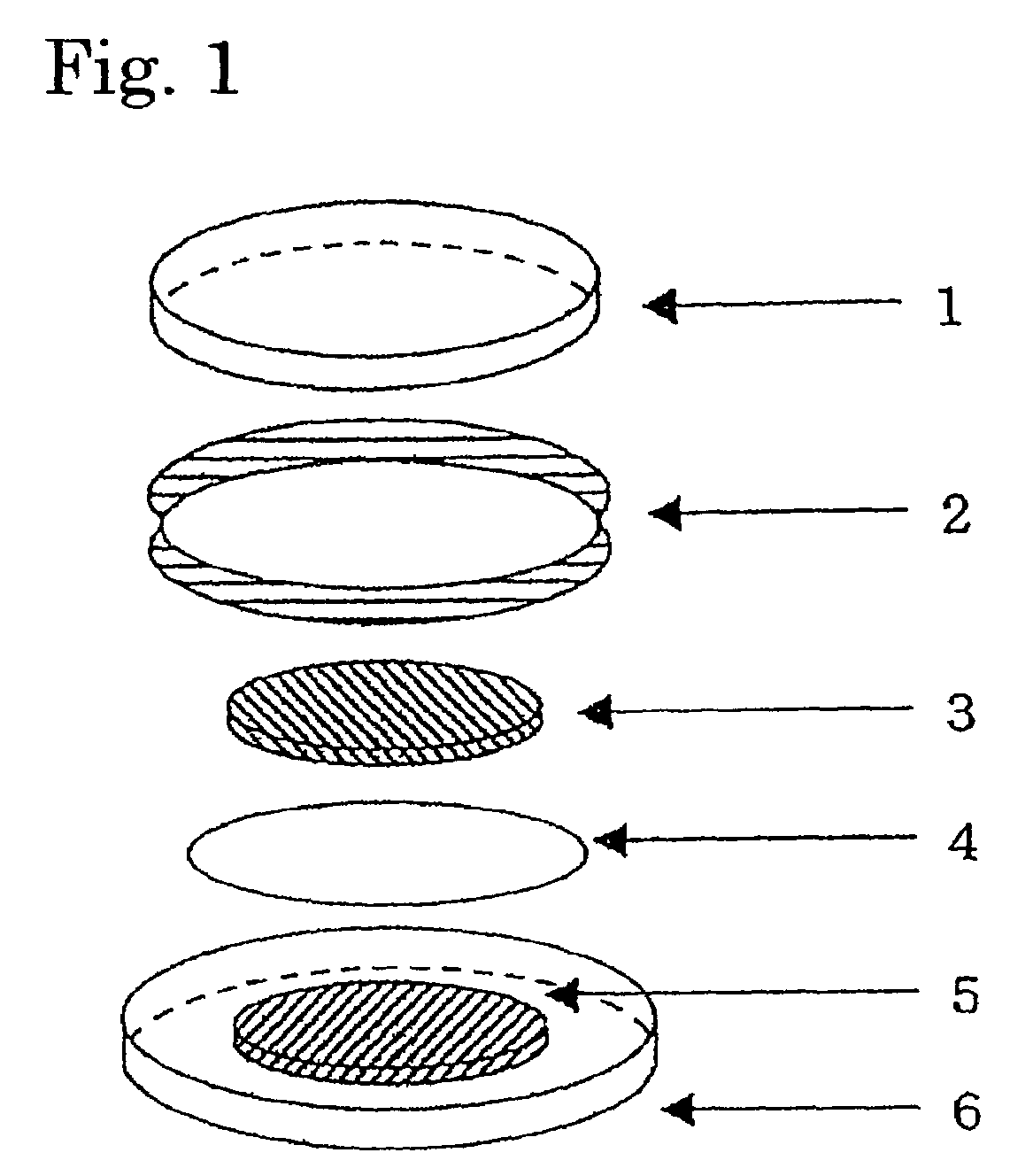

Optical element, lithographic apparatus including such optical element and device manufacturing method, and device manufactured thereby

InactiveUS20050122589A1Stable to oxidationIncrease reflectionMirrorsDiffusing elementsPhysicsEngineering

An optical element includes a top layer which is transmissive for EUV radiation with wavelength λ in the range of 5-20 nm, and a structure of the top layer is a structure having an rms roughness value equal to or larger than λ / 10 for spatial periods equal to or smaller than λ / 2. The structure promotes transmission through the top layer to the optical element.

Owner:ASML NETHERLANDS BV

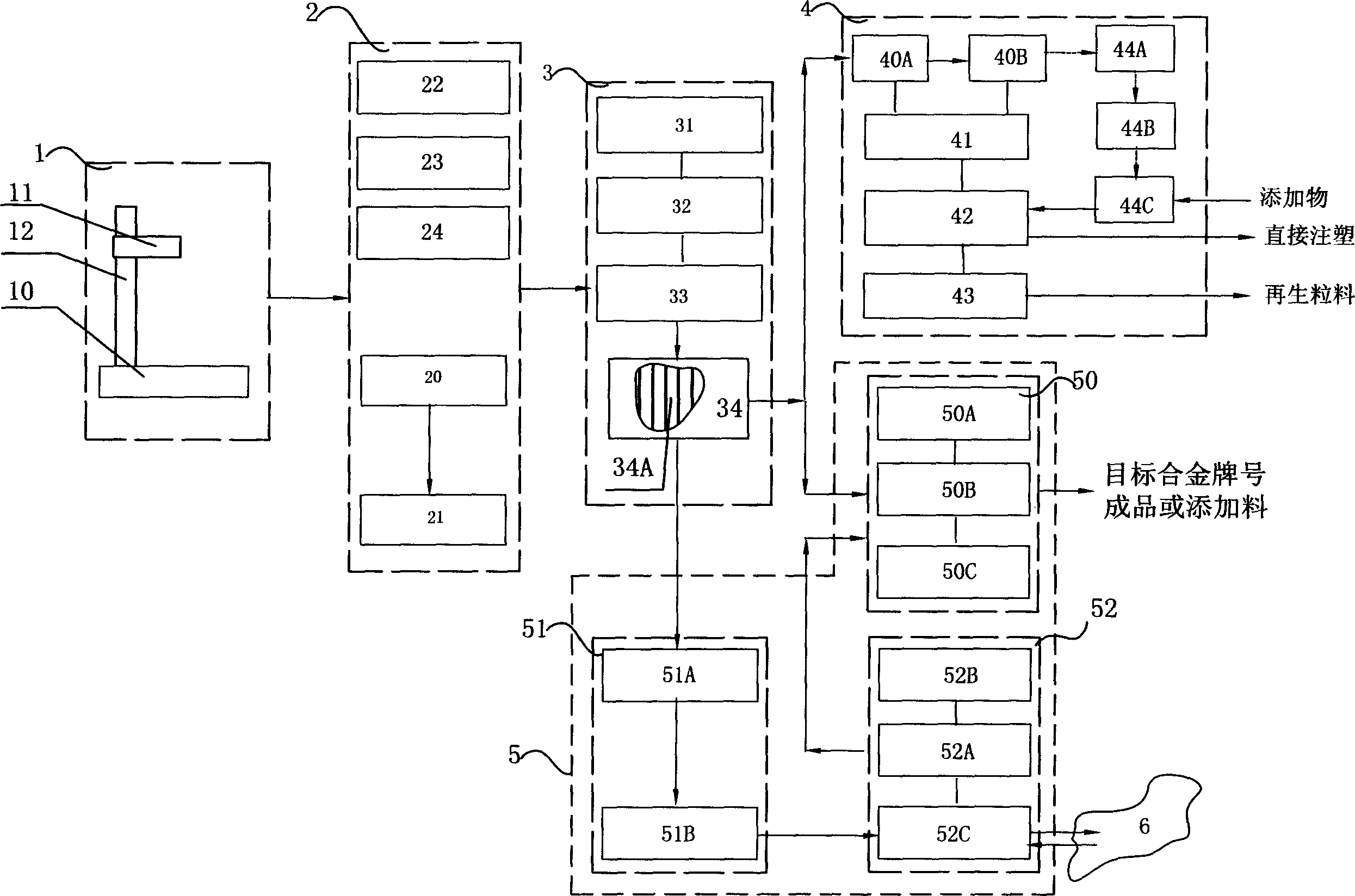

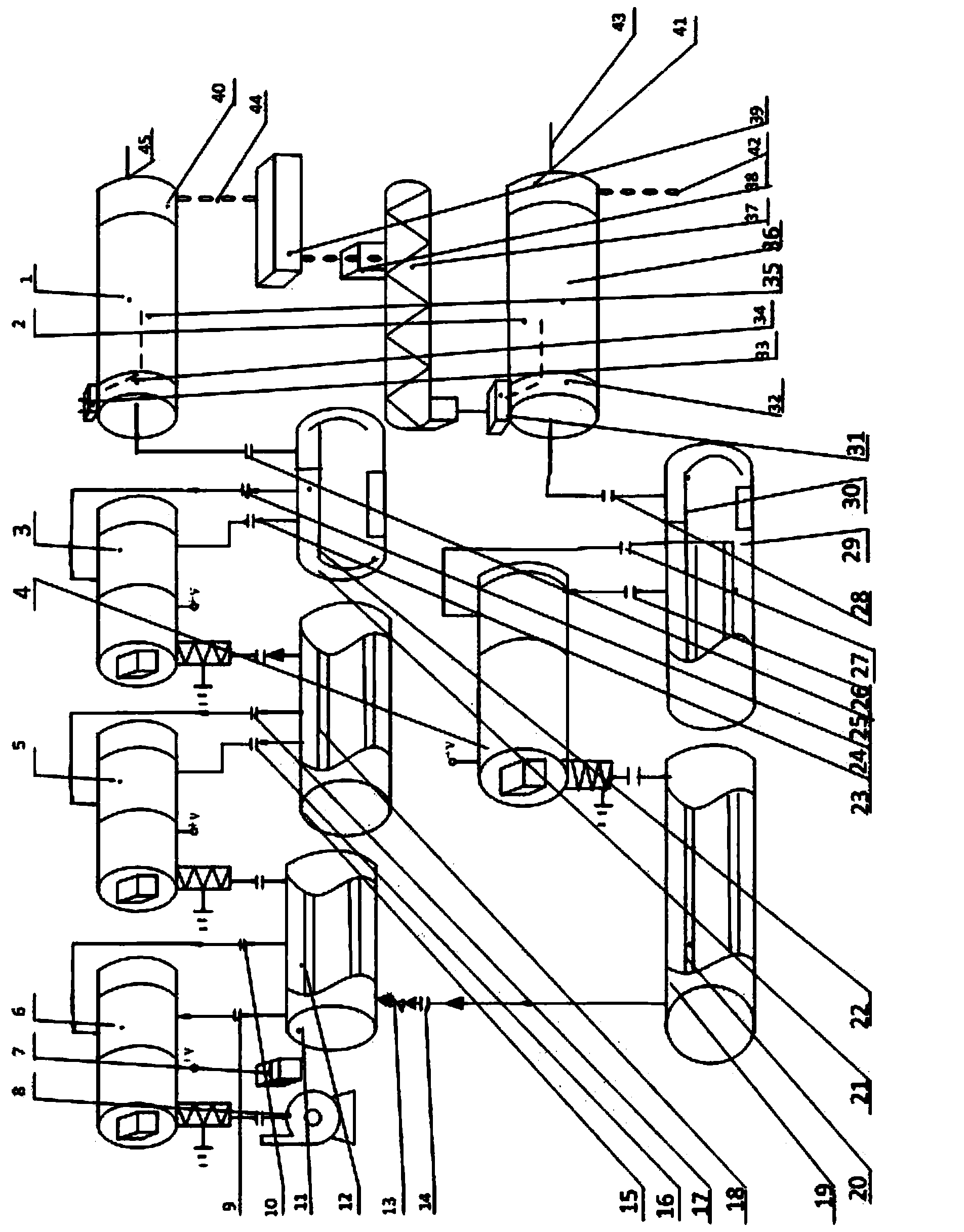

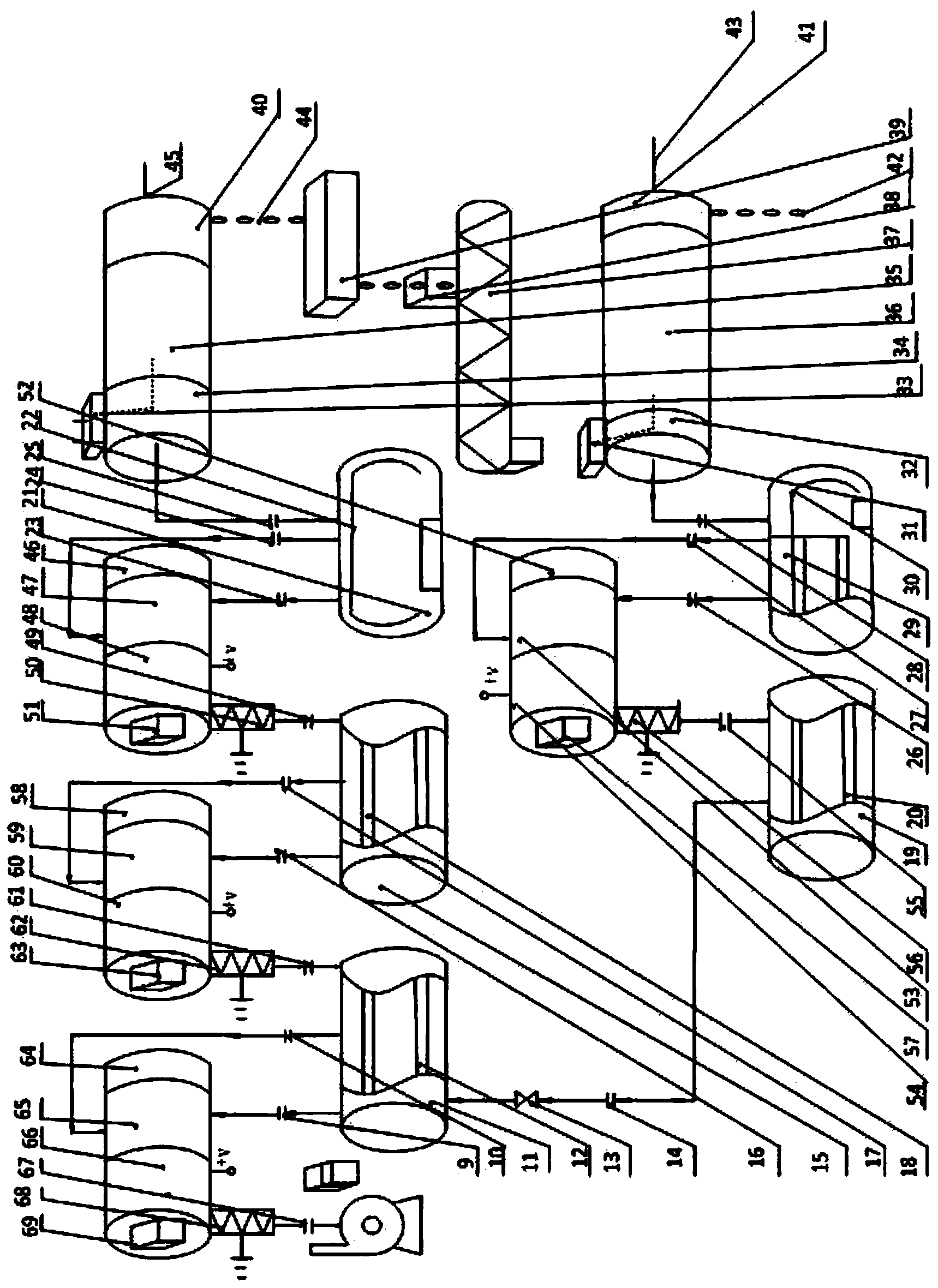

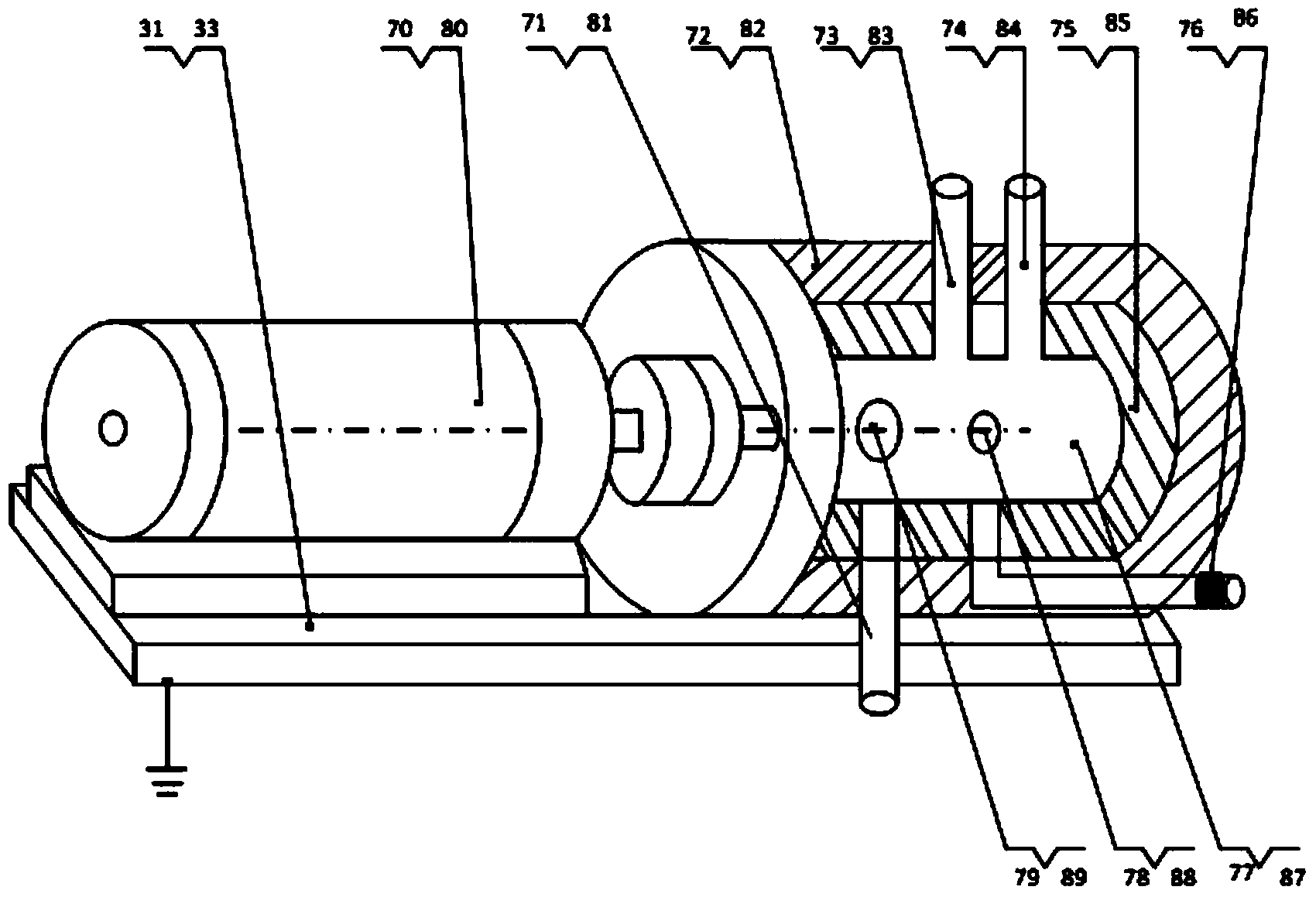

Automobile and electronic waste recovery process and its system

ActiveCN1775388AChange surface propertiesOxidation safetySolid waste disposalPlastic recyclingElement analysisAlloy

The present invention relates to a recovery technological process of car and electronic wastes and its recovery system. Said system includes removing equipment, breaking equipment, sorting equipment, plastics regeneration treatment equipment and metal component deep-processing equipment. Said plastics regeneration treatment equipment includes oxidation device, granular material drying device, mixing device and granulating machine. Besides, said invention also includes a data processing equipment, including data base, memory, analysis module and comparison and operation module, etc.

Owner:GEM CO LTD

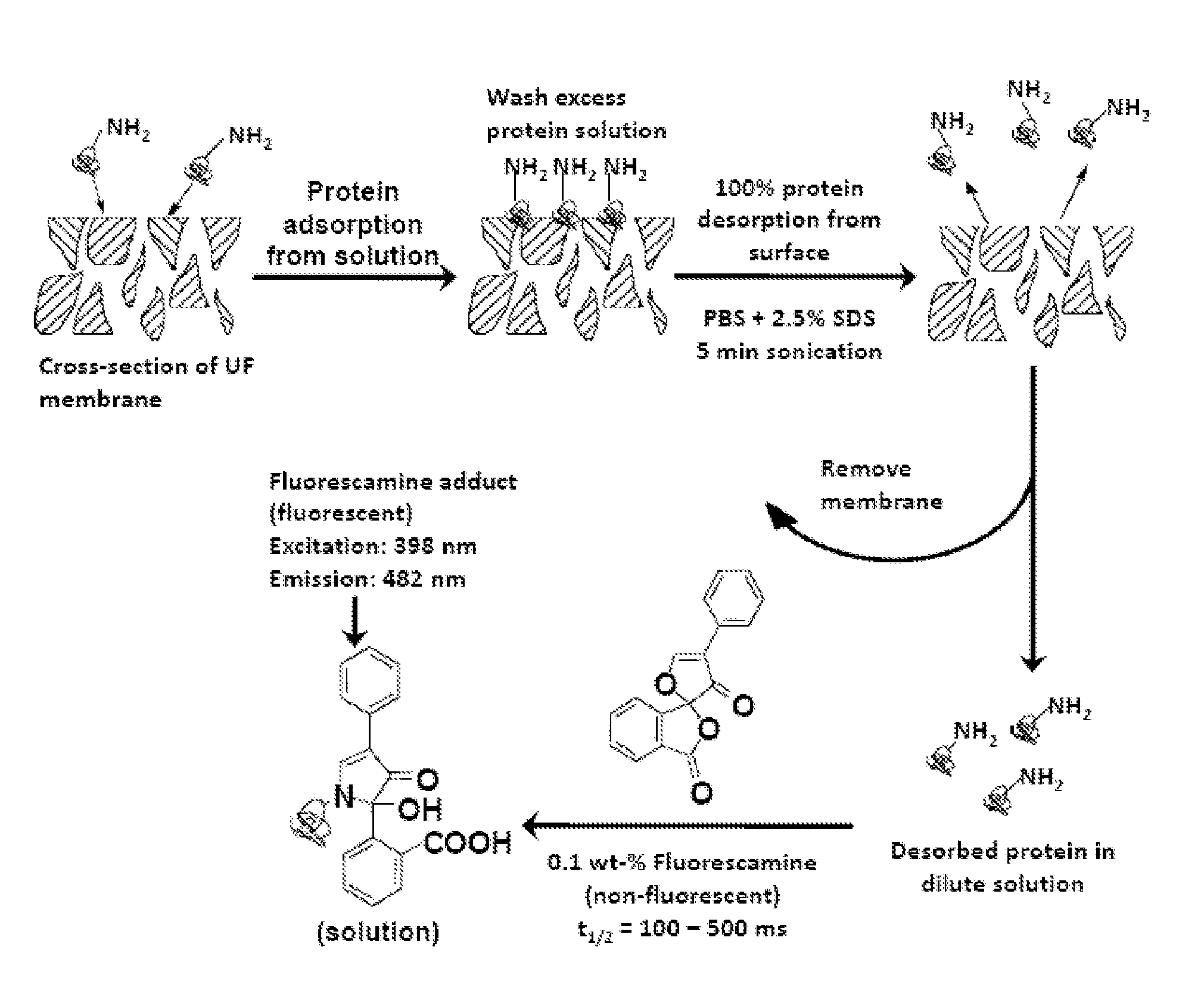

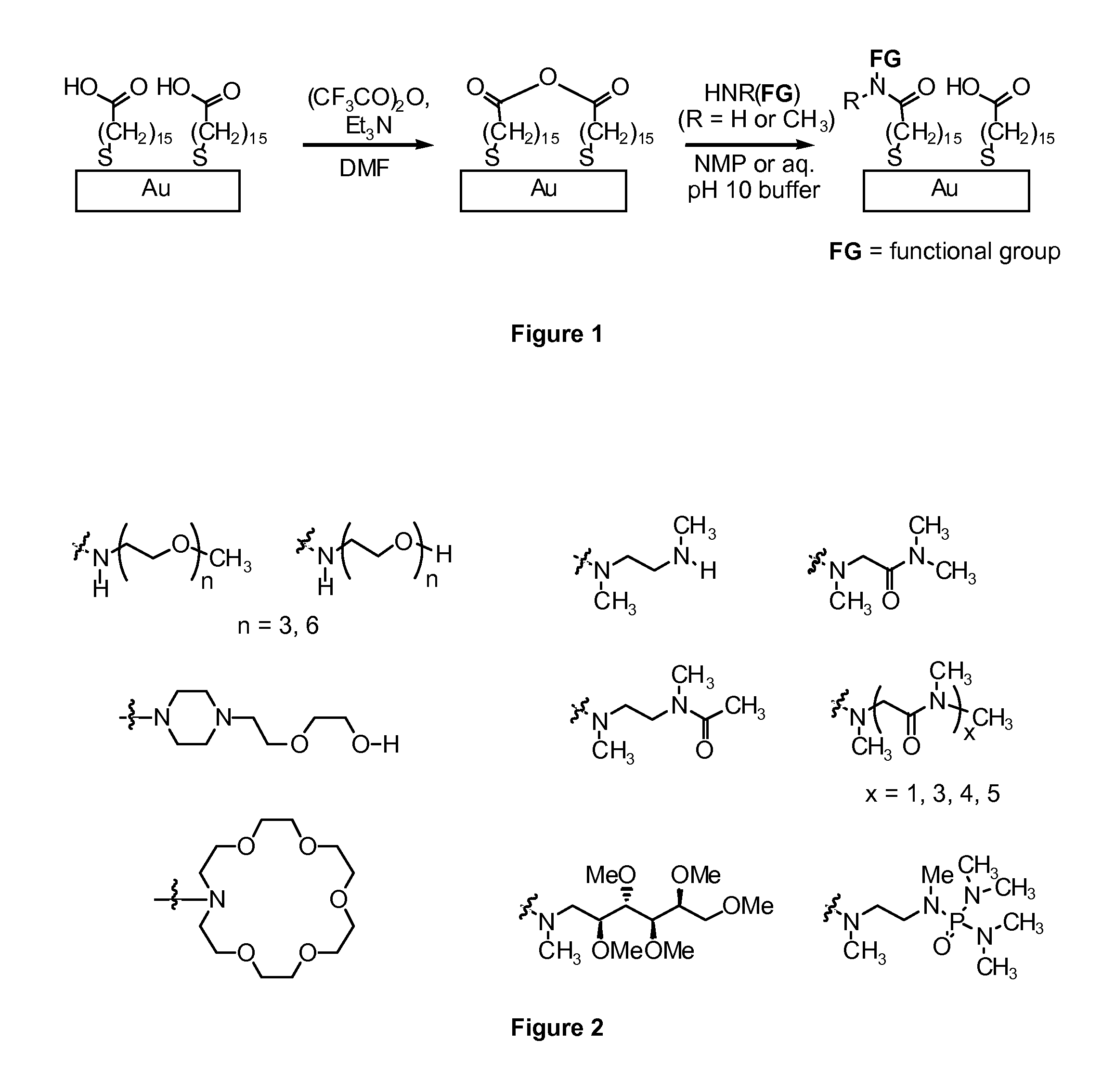

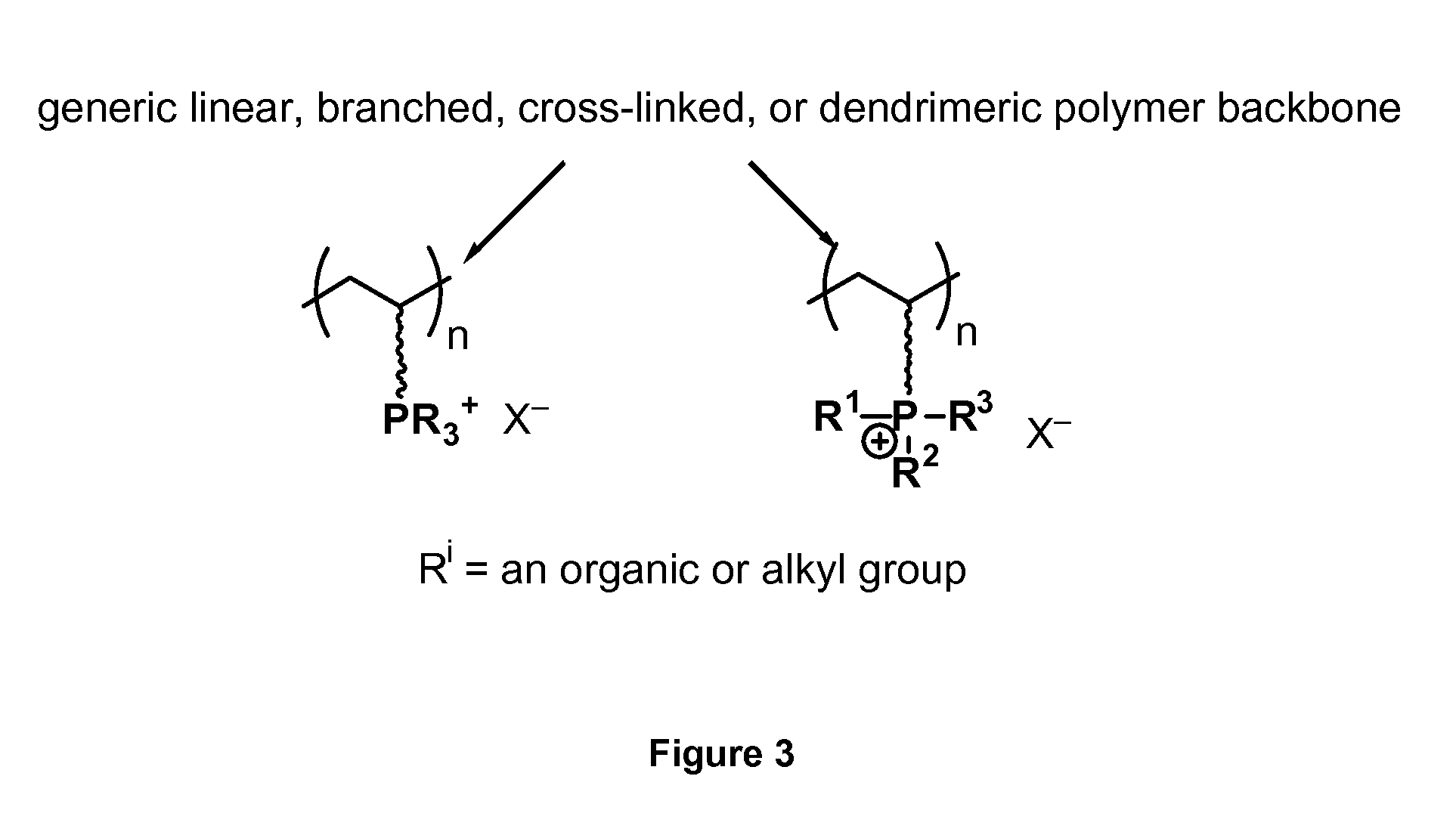

Polymer coatings that resist adsorption of proteins

InactiveUS20100096327A1Easy to synthesizeOxidation stabilityMembranesUltrafiltrationPhosphoniumFiltration

The invention provides membranes useful for filtration of water and other liquids. The membrane may be a composite membrane having a polymer layer incorporating quaternary phosphonium or ammonium groups. The polymer layer may be resistant to protein adsorption in an aqueous environment. The membrane may also be a surface-modified membrane in which a polymer having quaternary phosphonium or ammonium groups is covalently attached to the membrane surface. Methods for making and using the membranes of the invention are also provided.

Owner:UNIV OF COLORADO THE REGENTS OF +1

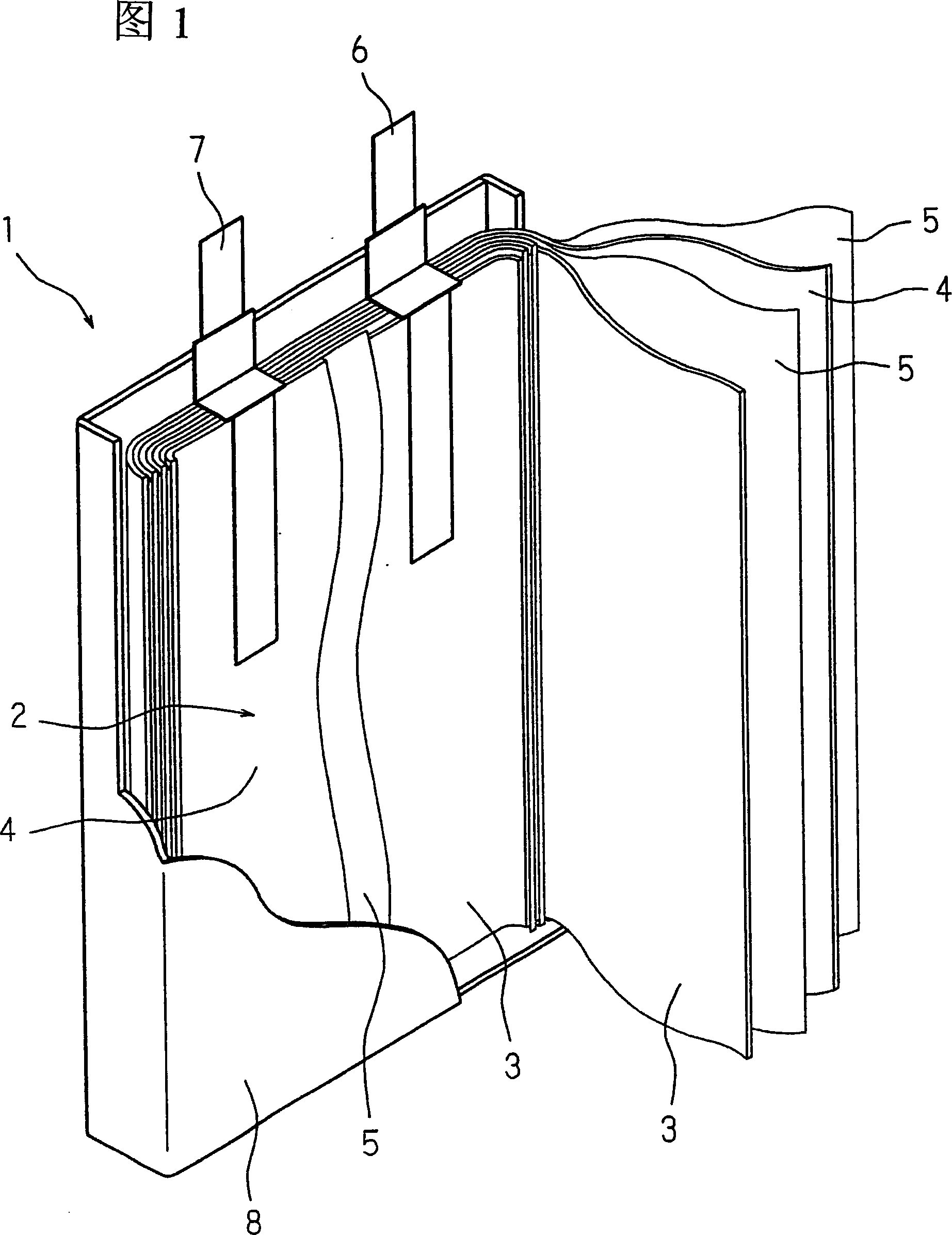

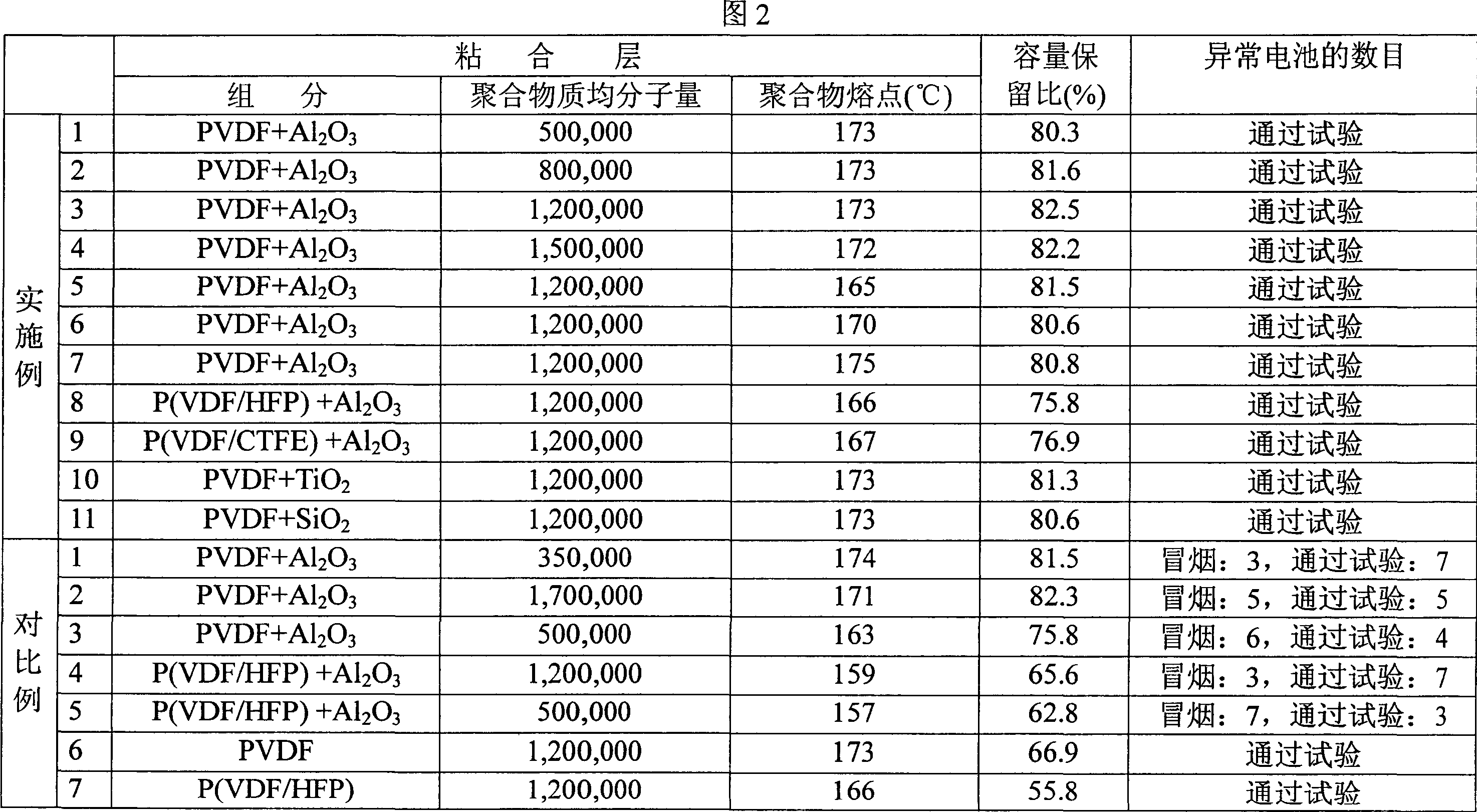

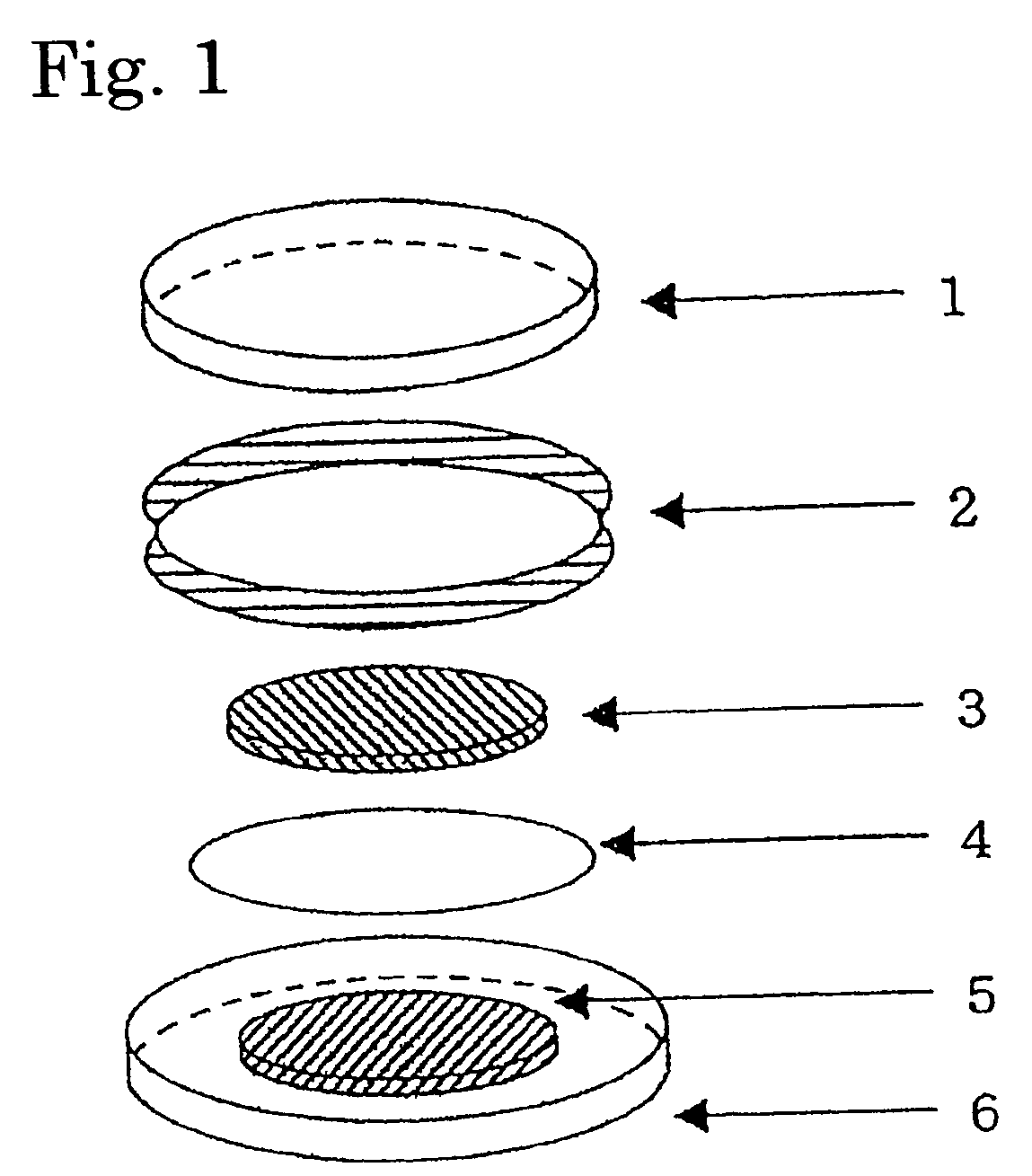

Non-aqueous electrolyte battery

InactiveCN1953268AStay porousImprove securityCell electrodesFinal product manufacturePolyvinylidene difluorideEthylene Homopolymers

In a non-aqueous electrolyte battery including a generating element having a separator bonded with an adhesive layer between a positive electrode plate and a negative electrode plate, the adhesive layer contains a fluorine-based polymer having a mass average molecular weight of from 500,000 to 1,500,000 and a melting point of from 165° C. to 175° C., and an inorganic-solid filler. The fluorine-based polymer is a polyvinylidene fluoride-based polymer such as a polyvinylidene fluoride homopolymer.

Owner:SANYO ELECTRIC CO LTD +1

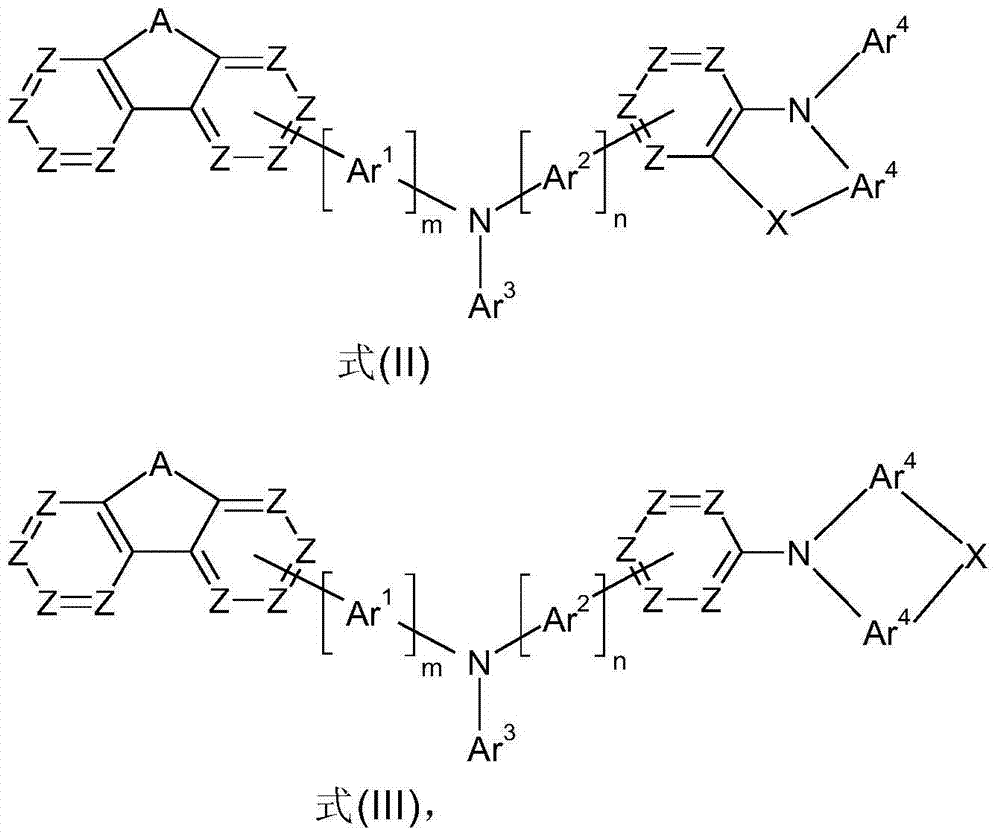

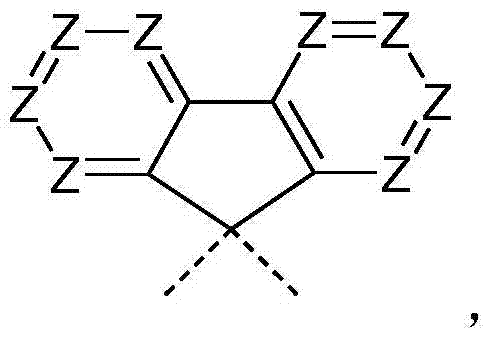

Materials for electronic devices

ActiveCN103718317AImprove efficiencyLow working voltageOrganic compound preparationSolid-state devicesCombinatorial chemistry

Owner:MERCK PATENT GMBH

Flame retardant hydraulic oil containing a synthetic ester formed by reaction of a polyol and a mixture of carboxylic acids including oleic acid and isostearic acid

InactiveUS6361711B1Oxidation stabilityA large amountLiquid carbonaceous fuelsHeat-exchange elementsGlycerolFlash point

Disclosed herein is a flame retardant hydraulic oil excellent in the flame retardancy, heat stability and oxidative stability, unaccompanied by the dangers of pinhole fire and giving rise to no environmental contamination.This flame retardant hydraulic oil contains a hydraulic base oil including as the essential component a synthetic ester, which is a product formed by reacting (A) at least one polyol selected from the group consisting of neopentyl glycol, 2,2-dimethyl-3-hydroxypropyl-2',2'-dimethyl-3'-hydroxypropionate, glycerin and trimethylolpropane with (B) a carboxylic acid including 15 to 85% by mole of oleic acid based on the total carboxylic acid and 15 to 85% by mole of isostearic acid based on the total carboxylic acid or a carboxylic acid obtained by incorporating into the carboxylic acid 85% by mole or less of monocarboxylic acid having 6 to 22 carbon atoms (excluding oleic acids and isostearic acids) based on the total carboxylic acid. The synthetic ester has a kinematic viscosity of 40 to 80 cSt at 40° C. and a flash point of 290° C. or higher.

Owner:IDEMITSU KOSAN CO LTD

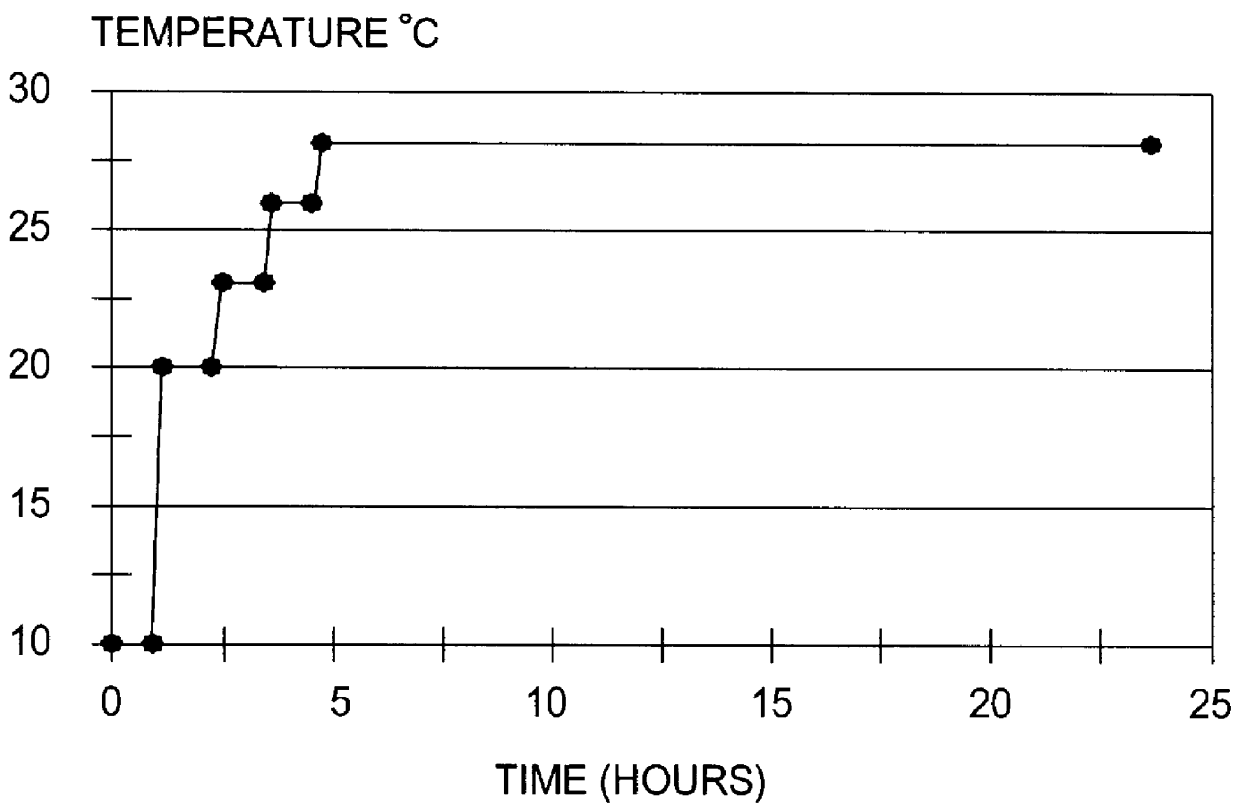

Crystallization of a protein with a sulphur salt

InactiveUS6066481AOxidation stabilityHydrolasesPeptide preparation methodsCrystallographySAA protein

The present invention relates to a method for crystallization of a protein obtained from a protein-containing solution which involves (a) treating the protein-containing solution with a salt containing a sulphur atom having an oxidation state less than 6, and (b) recovering the protein in crystalline form.

Owner:NOVOZYMES AS

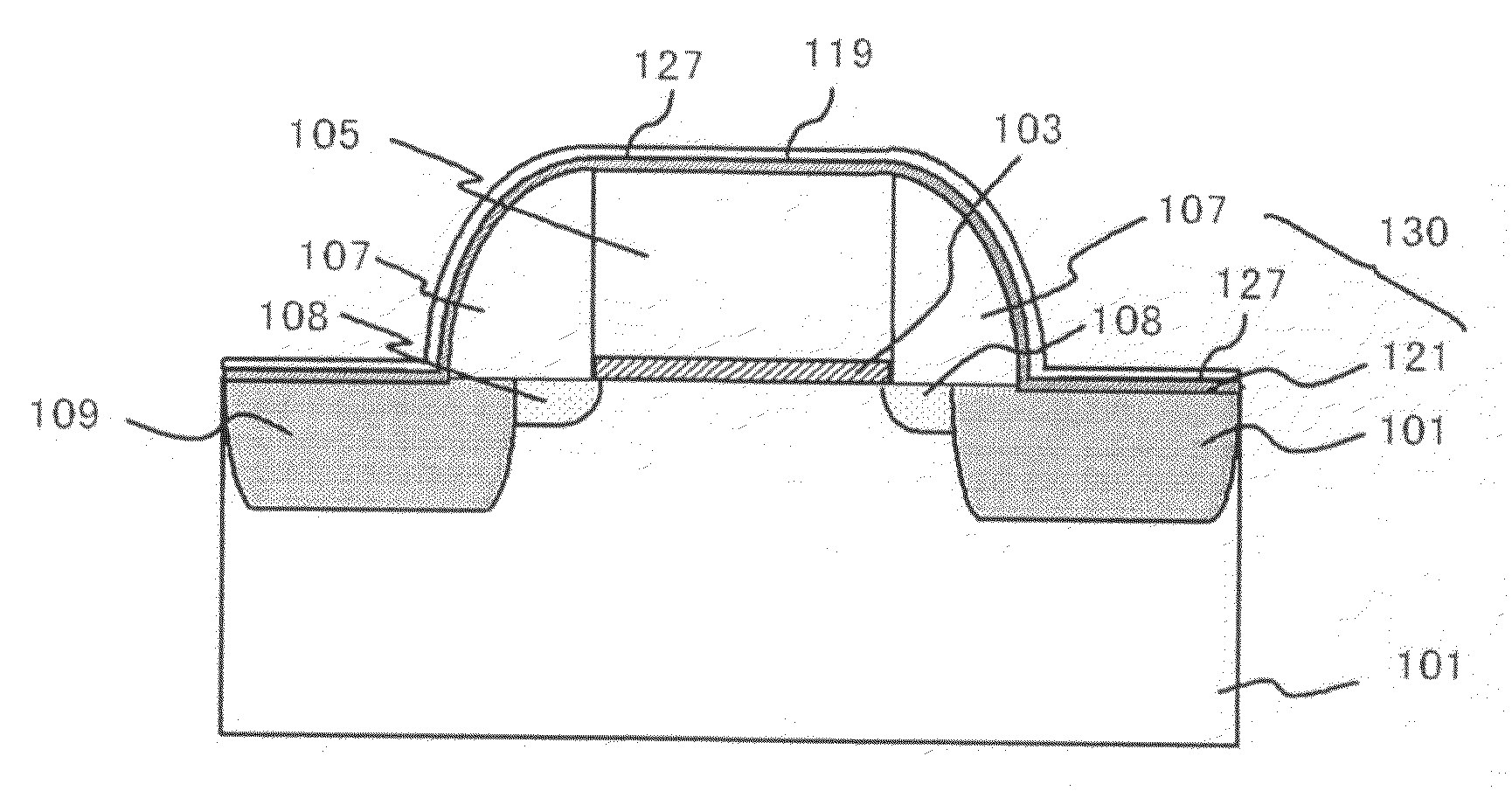

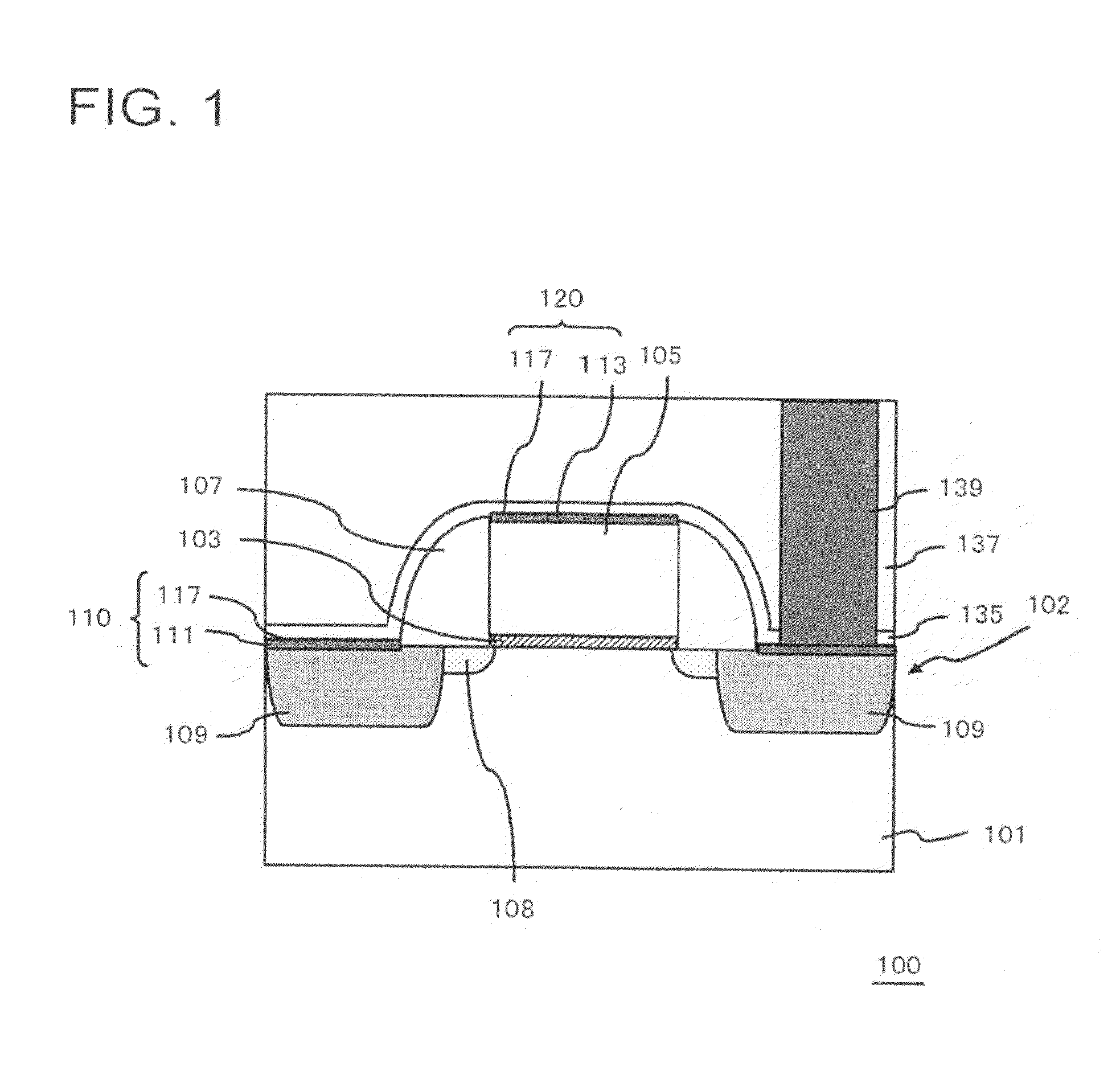

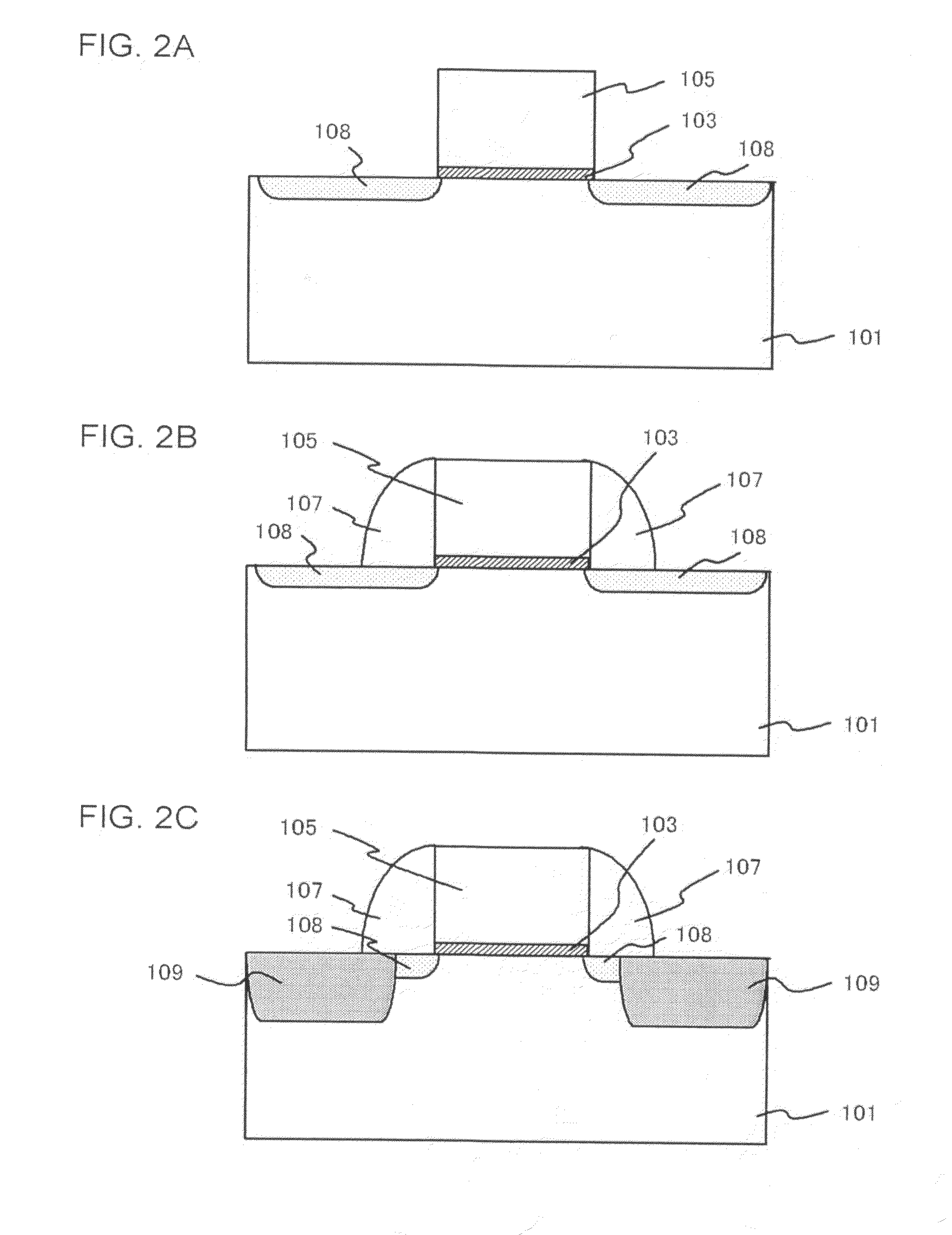

Semiconductor device and method of manufacturing the same

ActiveUS20070254480A1Increase influenceLow process temperatureTransistorSemiconductor/solid-state device detailsNitrogenTotal thickness

A semiconductor device includes a silicon substrate, and a NiSi layer provided on the silicon substrate aiming to suppress oxidation of the surface of a NiSi layer and the resistivity increase. The NiSi layer includes a bottom NiSi region and a top NiSi region. The bottom NiSi region provided in contact with silicon surface, and containing substantially no nitrogen. The top NiSi region is a nitrided NiSi region provided in contact with the bottom NiSi region, and containing nitrogen. The NiSi layer has a total thickness of 50 nm or below.

Owner:RENESAS ELECTRONICS CORP

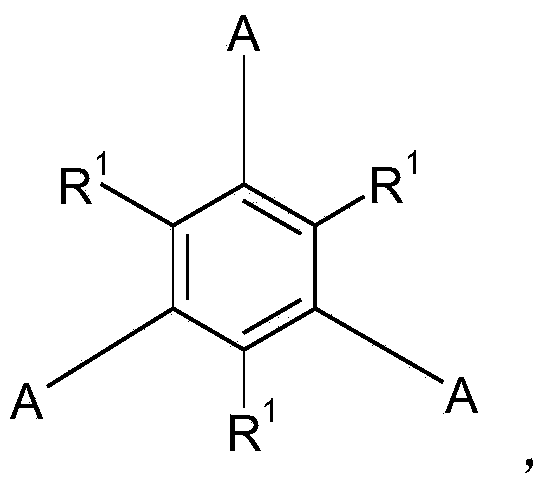

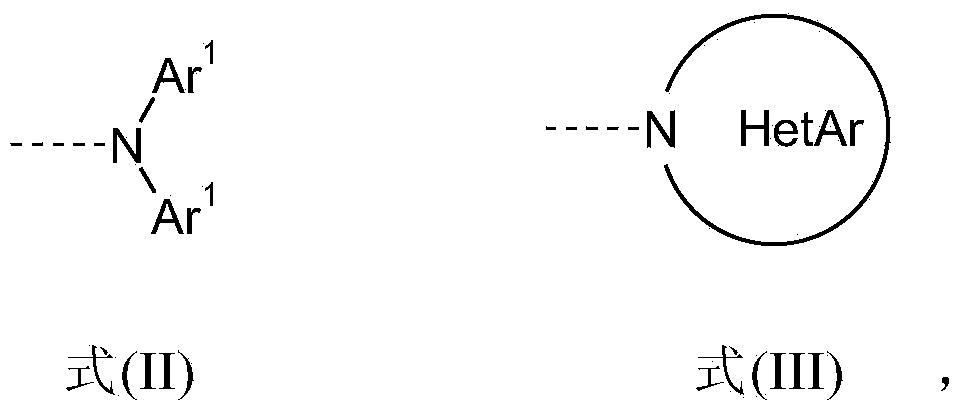

Compounds for electronic devices

ActiveCN103502388AImprove power efficiencyLow working voltageCarboxylic acid nitrile preparationOrganic compound preparationEngineeringCombinatorial chemistry

Owner:MERCK PATENT GMBH

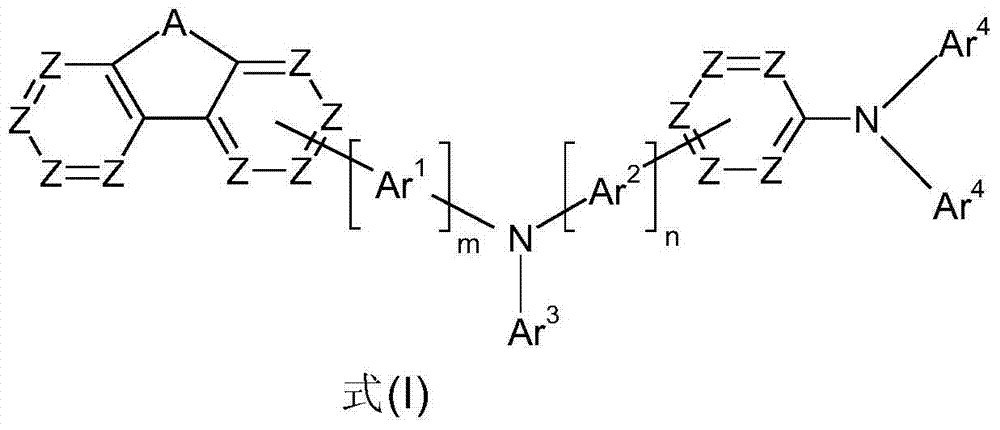

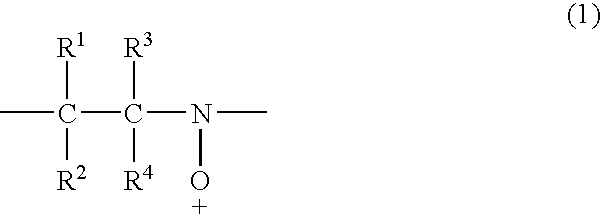

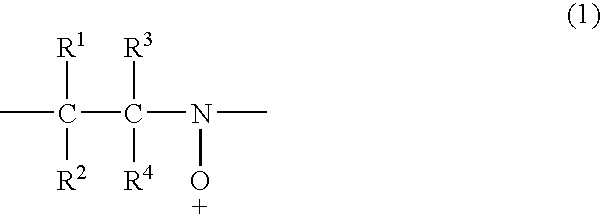

Secondary battery

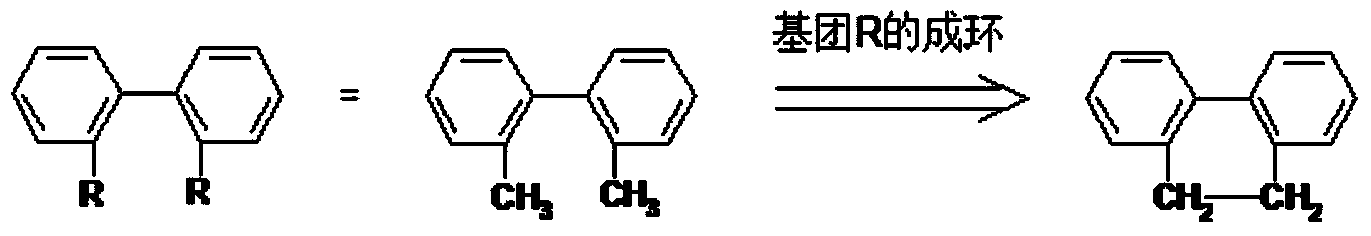

InactiveUS20050260500A1Improve charge and discharge cycle characteristicsIncrease energy densitySolid electrolyte cellsPositive electrodesHydrogen atomAromatic hydrocarbon

A secondary battery, that has an excellent charge and discharge cycle characteristics, with a larger capacity, is provided. The secondary battery having a positive electrode, negative electrode and electrolyte, includes a polymer having a repeating unit represented by a formula (1) as an active material of at least one of positive electrode and negative electrode. According to formula (1), R1, R2, R3 and R4 each independently represents hydrogen atom, substituted or unsubstituted alkyl group, substituted or unsubstituted aromatic hydrocarbons, substituted or unsubstituted hetroaromatic groups, halogen atom, or alkylene group that may be coupled to the ring form either one or both of R1 and R3, R2 and R4.

Owner:NEC CORP

Cashmere blanching method

InactiveCN105177983AHigh activityReduce effectivenessBleaching apparatusAnimal fibresSulfonateWarm water

The invention provides a cashmere blanching method which is characterized by comprising the following steps: soaking cashmere in clear water with the bath ratio of 1:50, and then adding 2-5g / L alkyl sodium sulfonate and 0.1-2g / L detergent LS to obtain treating fluid; adjusting the pH value of the treating fluid to be 7-7.5, then heating to 55-65 DEG C at the heating rate of 1-2 DEG C / min, and keeping for 10min; then cooling and washing with water three times, namely washing with warm water at 45 DEG C once and washing with cold water twice, wherein the bath ratio is respectively 1:45; and then wiping.

Owner:耿云花

Method for collaboratively degrading 666 soil by Fe (II)/sodium percarbonate

InactiveCN106513431ASimple process conditionsReduced operating requirementsContaminated soil reclamationSulfateProcess conditions

The invention belongs to the technical field of repair of organic-polluted soil, and discloses a method for collaboratively degrading 666 polluted soil by citric acid assisted Fe (II) / sodium percarbonate. The method comprises the following steps: the 666 polluted soil is mixed as mud-state soil mixed solution according to a certain water-soil ratio; ferrous sulfate and sodium percarbonate are fed in the solution by a certain ratio to oscillate by 6-24 h in a constant-temperature oscillator at normal temperature; and the degrading rate of the treated 666 reaches above 50%. The method has such advantages as simple process conditions, low operation requirements and high treatment efficiency, and is suitable for repairing organic chlorine pesticide polluted soil.

Owner:CHANGZHOU UNIV

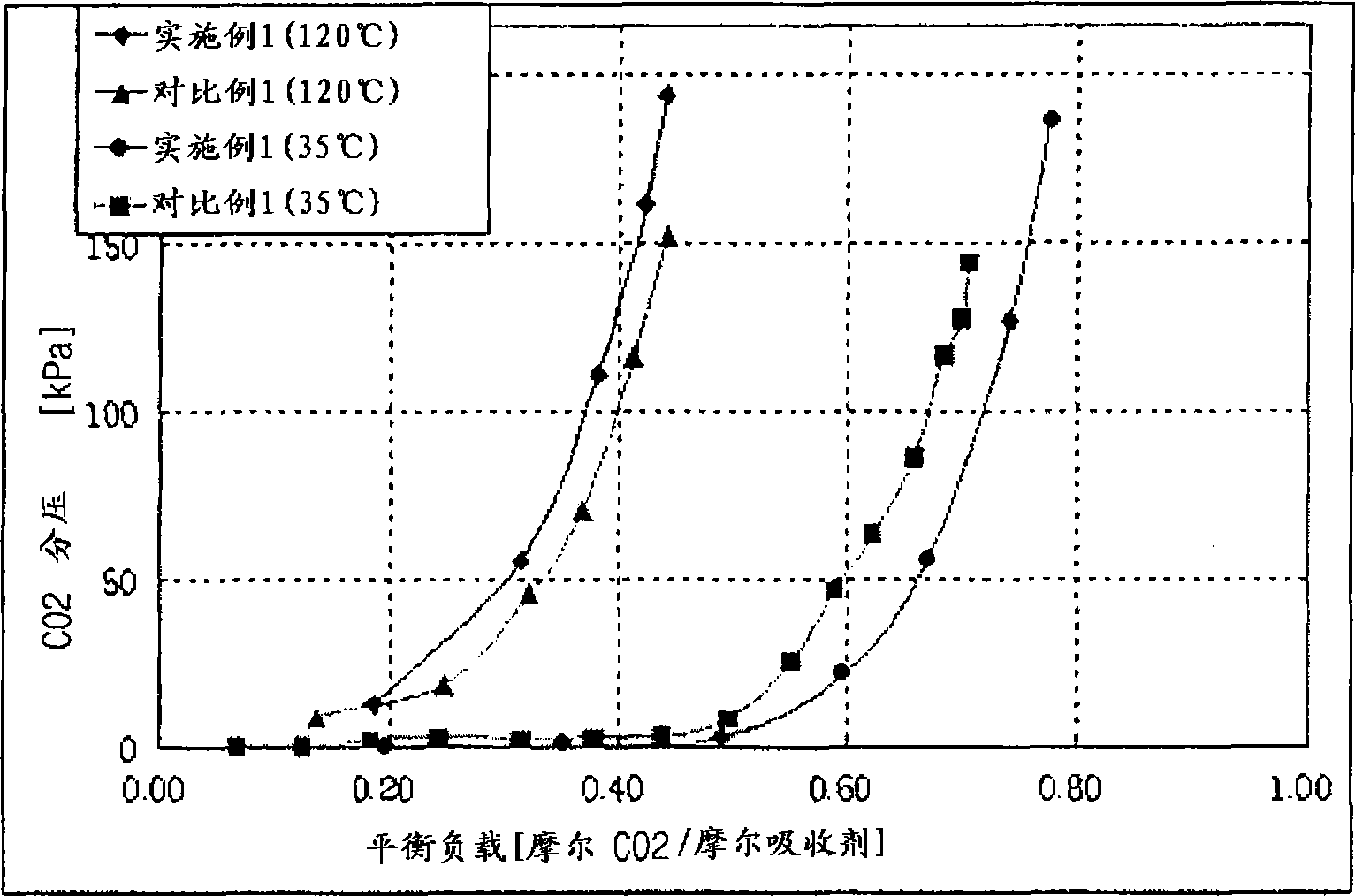

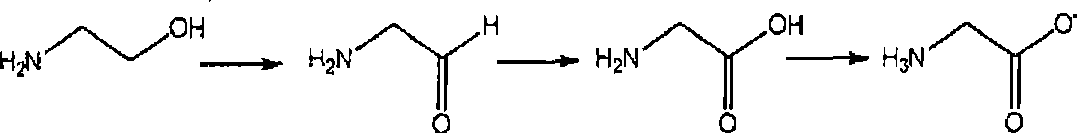

High effective absorbent for separating acid gas

InactiveCN101396636AIncrease reaction rateSave energyCarbon compoundsChemical industryAbsorption capacityLower risk

Provided is a high-efficiency, low-energy type mixed absorbent for separation of carbon dioxide, which has a rapid reaction rate with carbon dioxide and a high-carbon dioxide absorption capacity and does not require a large amount of energy for regeneration of the absorbent, in conjunction with low risk of absorbent oxidation. The absorbent comprises a mixed aqueous solution of: 100 parts by weight of a compound of Formula 1 having one alcoholic hydroxyl group and one primary amine in the molecular structure with no substituent being on the alpha carbon adjacent to the amine and both of an alkyl substituent and an alcoholic hydroxyl group being on the beta carbon, and 1 to 60 parts by weight of a heterocyclic compound of Formula 2 having at least one amine in the ring: (See formula 1) (See formula 2) wherein R1, R2, R3, R4, R5, and X are as defined in the specification.

Owner:KOREA ELECTRIC POWER CORP

Fat containing polyunsaturated fatty acid

InactiveUS20160255852A1Promote oxidationGreat tasteEdible oils/fats ingredientsFatty substance preservation using additivesFlavorFatty acids.polyunsaturated

Provided are a highly versatile fat containing a polyunsaturated fatty acid and a foodstuff in which said fat is used, said fat having good flavor and exceptional oxidation stability. A fat containing a polyunsaturated fatty acid, the fat containing water-soluble tea polyphenol added when the fat is dissolved in an aqueous solution.

Owner:FUJI OIL CO LTD

Method for cleaning liquid-crystal display screen electrochemically

InactiveCN1895798APromote decompositionRealize cyclic applicationCleaning using liquidsLiquid-crystal displayWater soluble

An electrochemical cleaning method for the LCD screen includes such steps as preparing detergent from amine alkali, non-ionic surfactant and water, cleaning with diamond film along with said detergent, washing with said detergent, cleaning with diamond film, ultrasonic rinsing in water twice, showering and baking.

Owner:TIANJIN JINGLING MICROELECTRONIC MATERIALS CO LTD

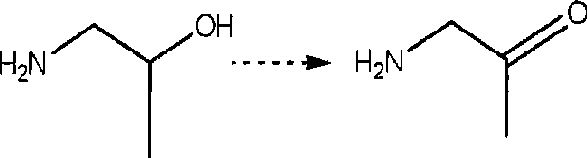

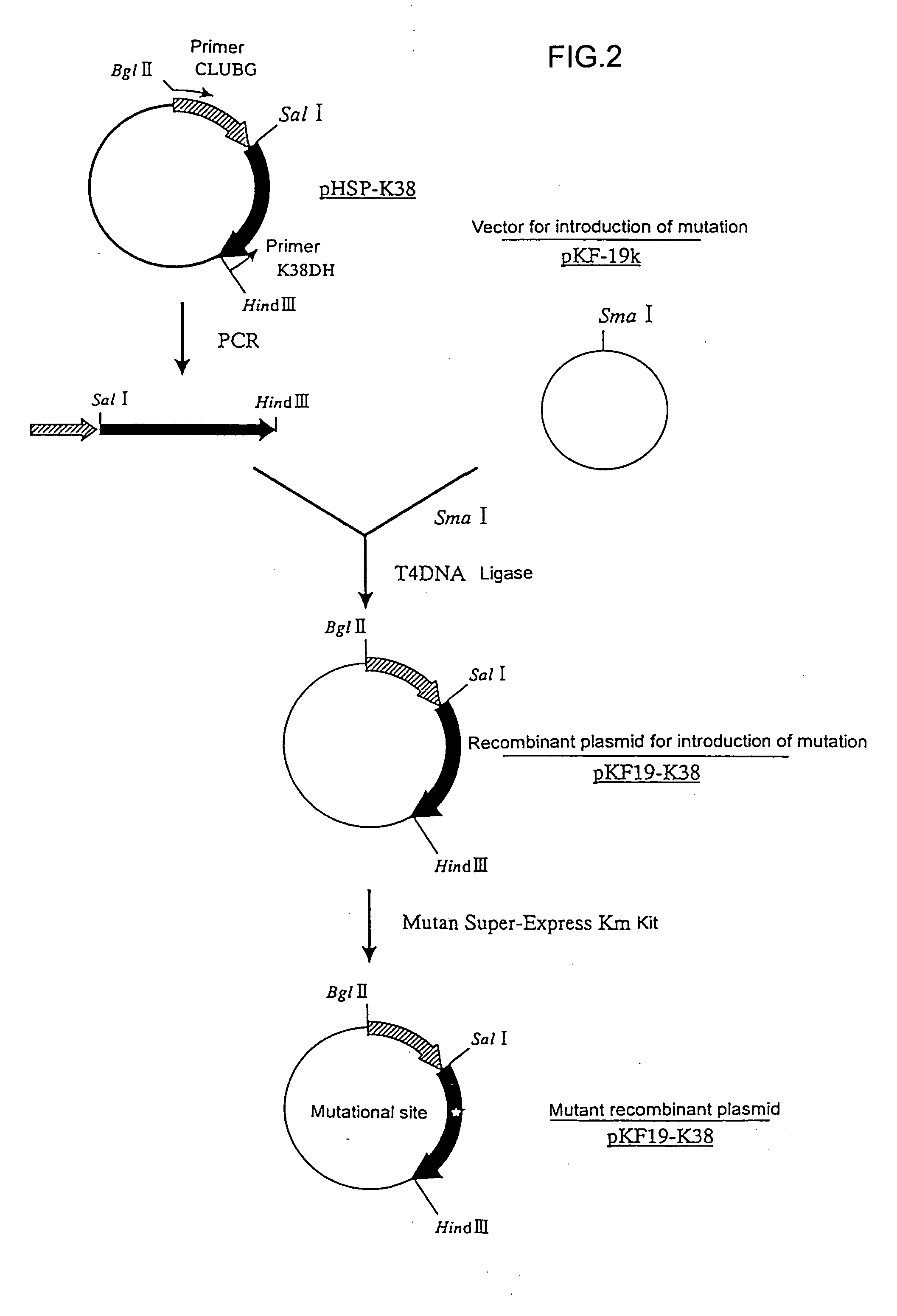

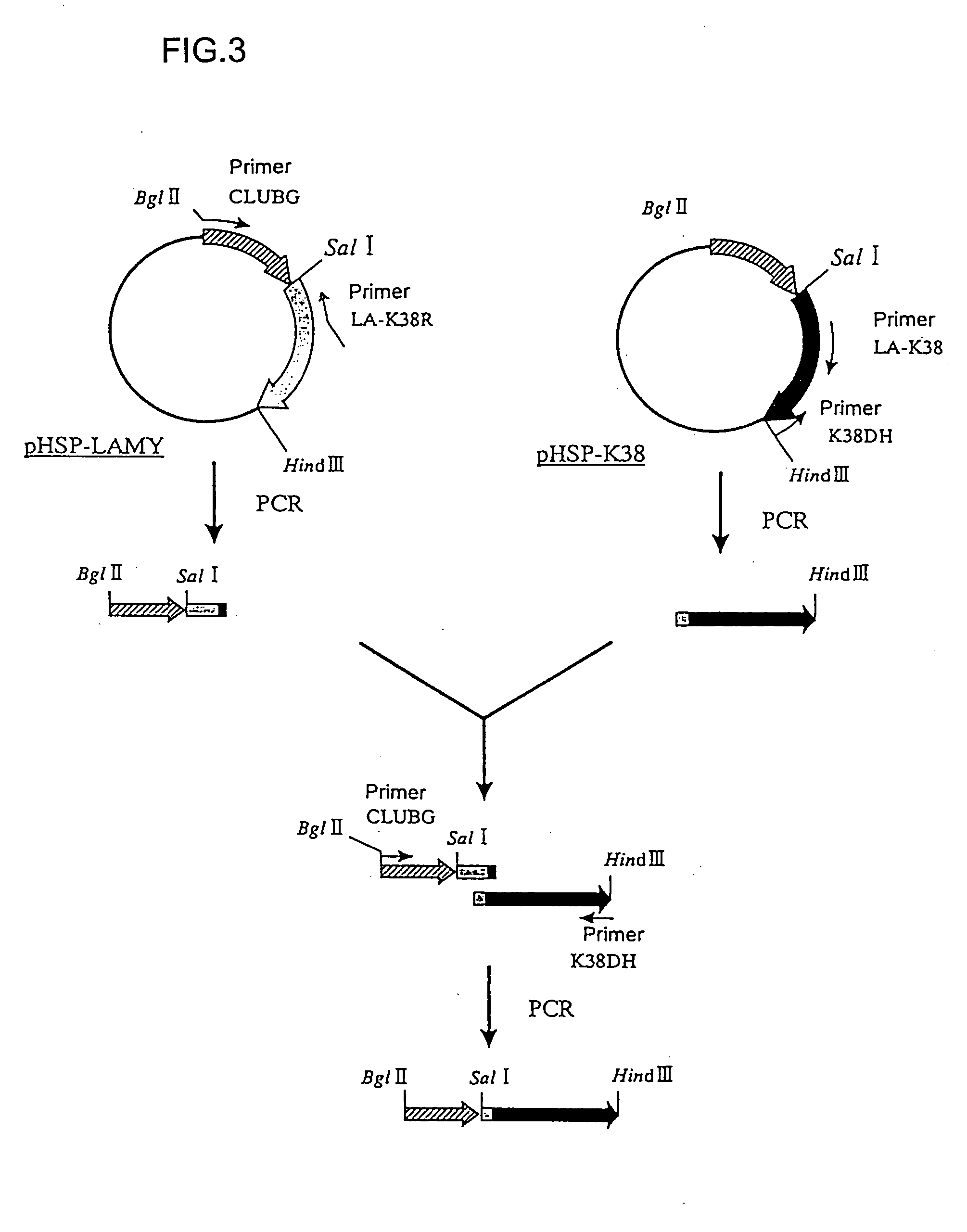

Mutant alpha-amylases

InactiveUS20050181493A1Excellent heat resistanceHigh activityBacteriaNon-surface-active detergent compositionsMutantTransformed cell

The invention relates to a mutant α-amylase obtained by making replacement or deletion of at least one of amino acid residues such as the 167th Gln, 169th Tyr and 178th Ala in the amino acid sequence set forth in SEQ ID NO:1 in an α-amylase having said amino acid sequence, or an α-amylase having a homology of at least 70% to said amino acid sequence, a gene encoding the mutant α-amylase, a vector, transformed cells, a process for producing a mutant α-amylase, comprising culturing the transformed cells, and a detergent composition comprising the mutant α-amylase. The mutant α-amylase of the invention has excellent properties of high resistance to chelating agents, high specific activity in an alkaline region and excellent stability to heat, and is hence useful for detergents for automatic dish washer, laundry detergents and the like.

Owner:KAO CORP

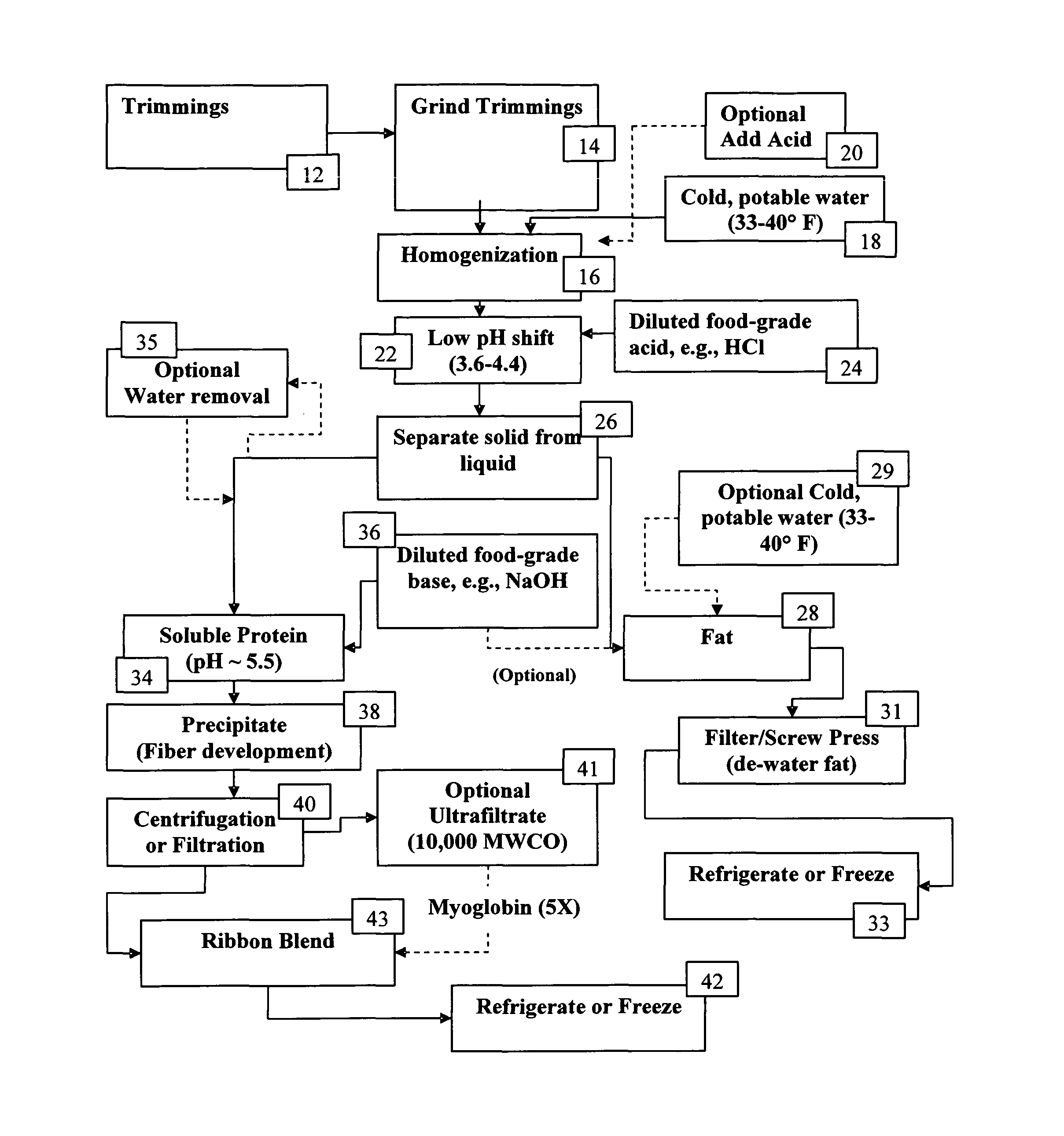

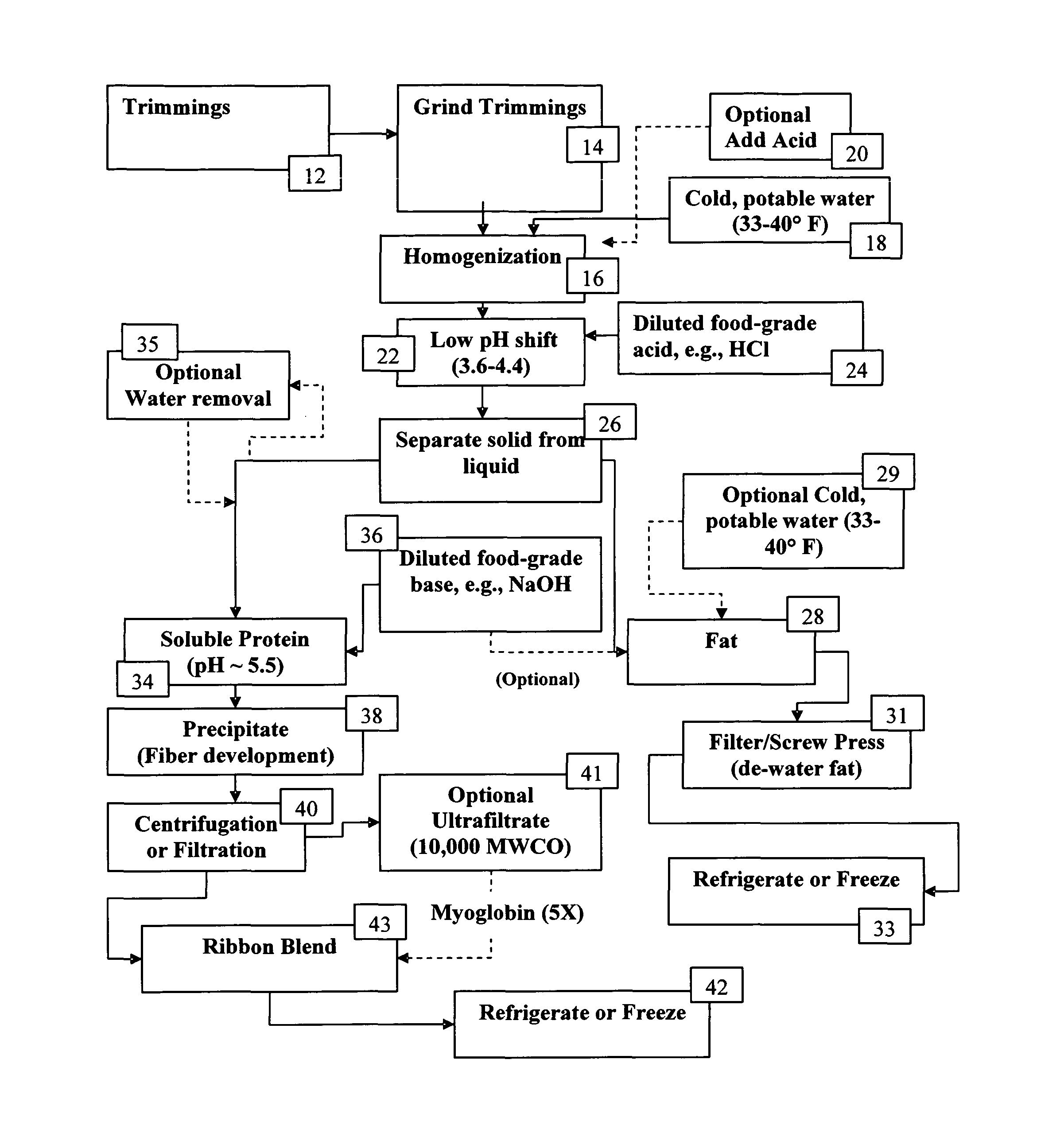

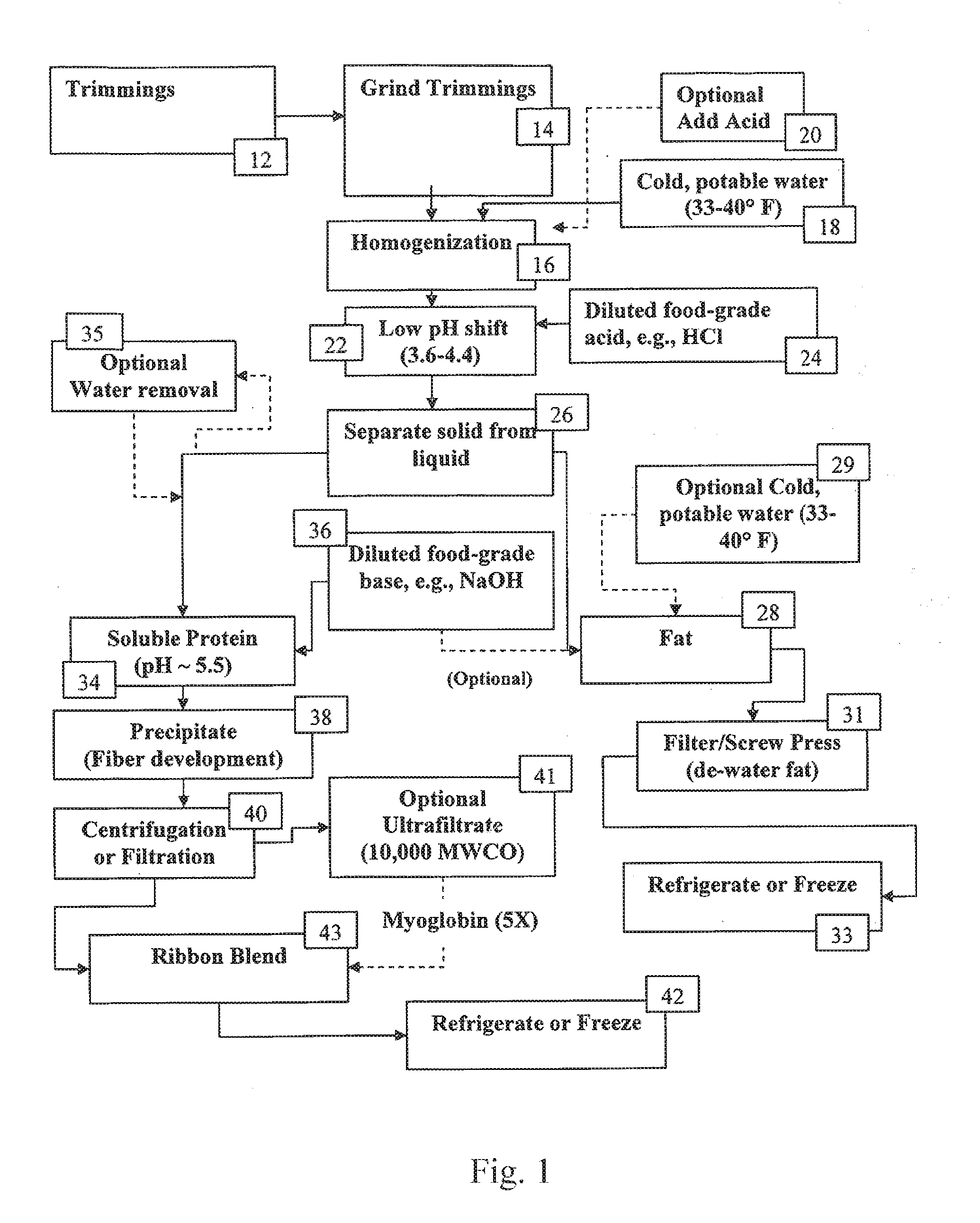

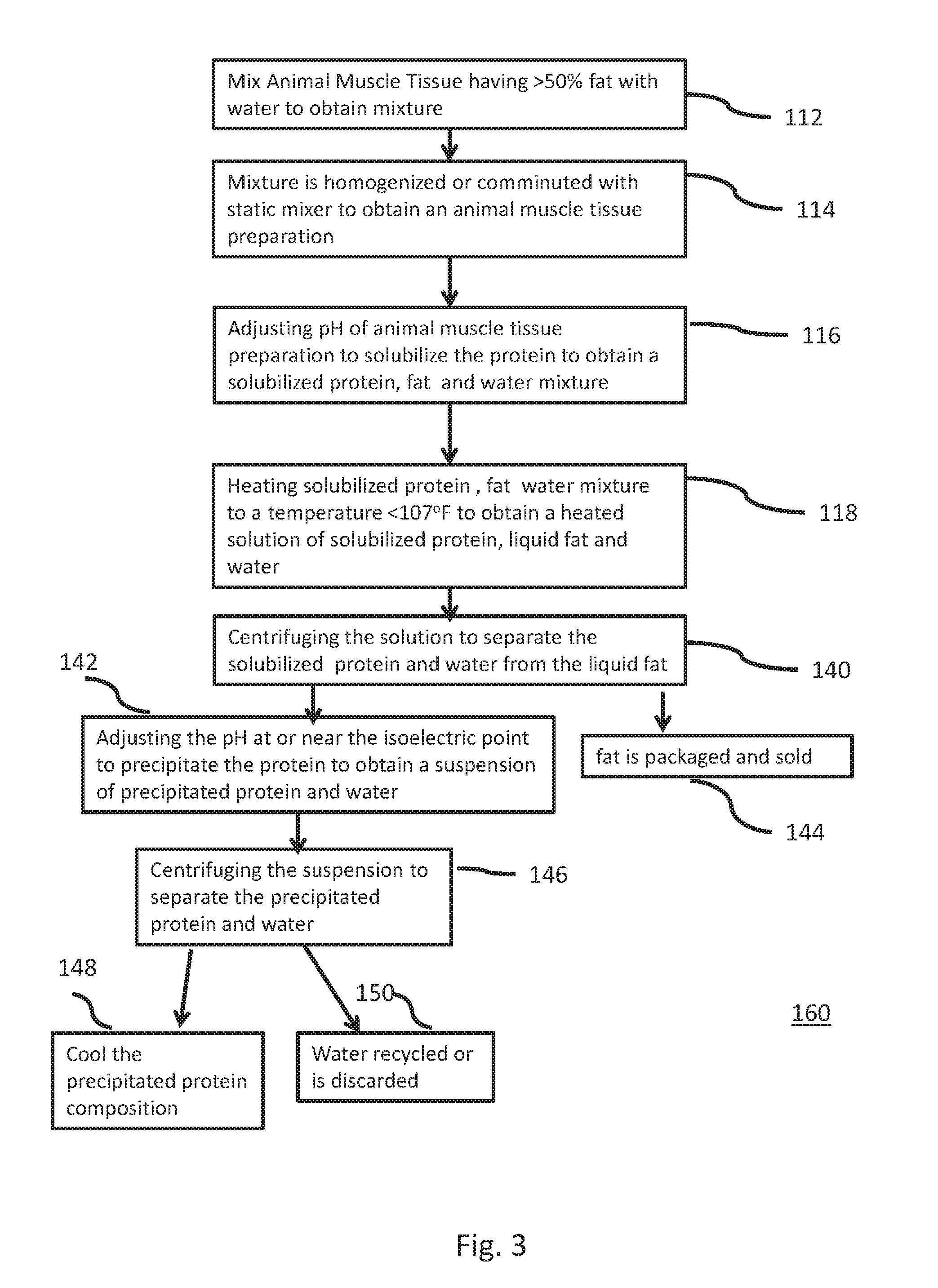

Process for isolating a protein composition and a fat composition from meat trimmings

ActiveUS9161555B2Satisfactory yieldSimplifies subsequent water removalProtein composition from fishFood ingredientsFat compositionChemistry

Owner:KEMIN PROTEINS LLC

Efficient chemical oxidation repairing method for organic polluted soil

ActiveCN108480394AImprove efficiencyPromote dissolutionContaminated soil reclamationPollutantEnvironmental chemistry

The invention discloses an efficient chemical oxidation repairing method for organic polluted soil. The efficient chemical oxidation repairing method for the organic polluted soil comprises the following steps: mixing the organic polluted soil and water to prepare a slurry-state soil mixed solution; adding a binary compound organism-nonionic surfactant into the slurry-state soil mixed solution andthen adding an oxidizing agent; and performing oscillation in an oscillator and degrading the organic pollutant in the soil after oscillation treatment, wherein the oxidizing agent is SPC and the binary compound organism-nonionic surfactant is GLDA and Tween80. The efficient chemical oxidation repairing method for the organic polluted soil has the advantages of simple process condition, low operation requirement, high treatment efficiency and the like, and is suitable for repairing various kinds of organic polluted soil.

Owner:BEIJING GEOENVIRON ENG & TECH

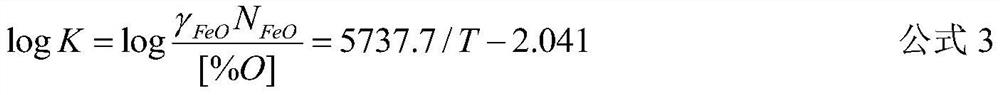

Method for stably controlling oxidability of ultra-low carbon steel top slag

ActiveCN111910040AEffective control of oxidationPrevent mass transferManufacturing convertersSlagCastability

The invention relates to a method for stably controlling the oxidability of ultra-low carbon steel top slag. The method comprises the following steps: S1, calculating the addition amounts of lime andan aluminum-based modifier according to the slag tapping amount and steel tapping amount of a converter, the TFe content in converter final slag and the oxygen content at the end point of the converter; S2, in the RH oxygen blowing temperature rising process, carrying out oxygen blowing and aluminum adding at the same time; S3, in the RH oxygen blowing decarburization process, controlling the oxygen blowing flow of a top lance to be 1,200-2,000 m<3> / h, so that the influence of sharp rising of oxygen in steel on the top slag is prevented; and S4, in the pouring process of a continuous casting machine, sealing a tundish, wherein the oxygen partial pressure in the tundish is controlled to be 0.3% or below. After the treatment measures are adopted, the content of TFe in the RH refining inlet steel ladle top slag can be stably reduced to 4% or below, the content of TFe in the RH refining outlet steel ladle top slag can be stably reduced to 6% or below, then the castability of molten steel is remarkably improved, the pouring service life of a single submerged nozzle can reach that of 6 furnaces or a longer time, and the total oxygen content of the tundish is reduced to 0.002% or below.

Owner:HANDAN IRON & STEEL GROUP +1

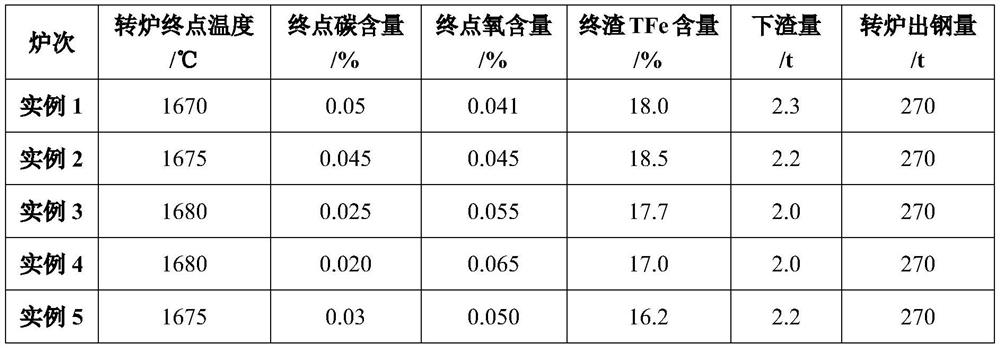

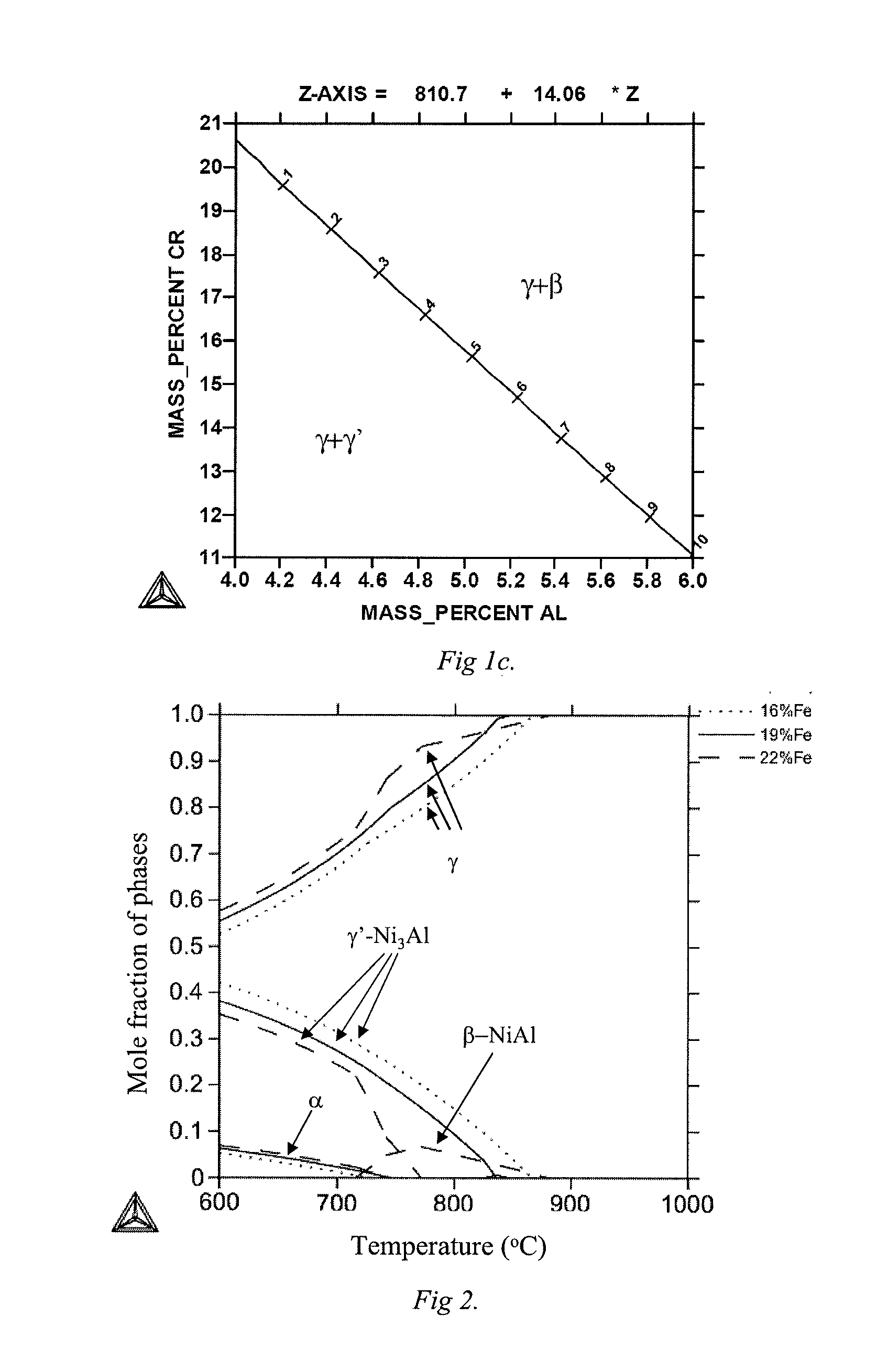

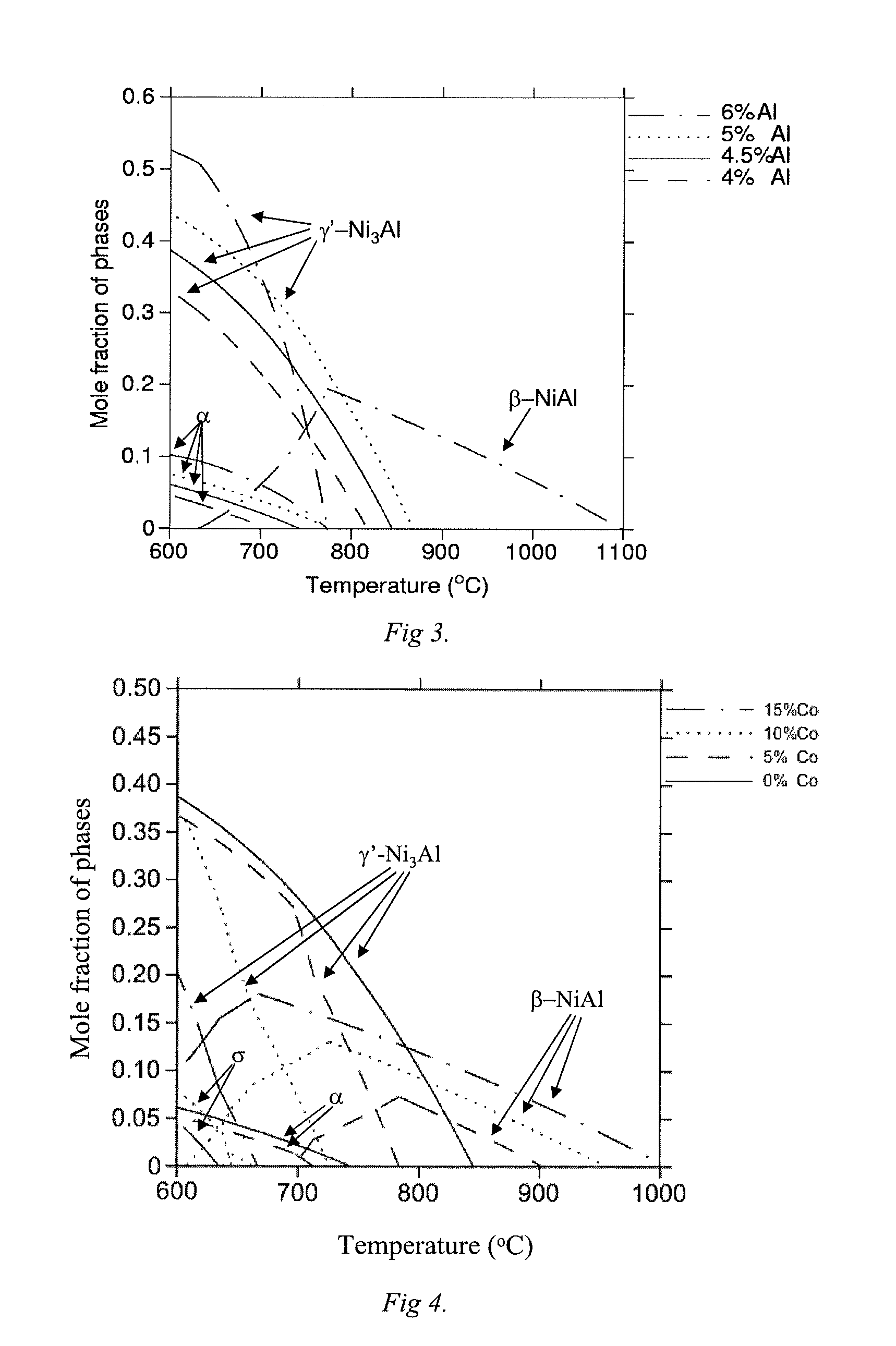

Aluminium oxide forming nickel based alloy

InactiveUS20110250463A1Improve antioxidant capacityImprove creep strengthPig casting plantsIngot casting plantsAlloyImpurity

Nickel based alloy intended for use at high temperatures wherein it comprises in percent by weight (wt-%)C 0.05-0.2Si max 1.5Mn max 0.5Cr 15-20Al 4-6Fe 15-25Co max 10N 0.03-0.15O max 0.5one or more elements selected from the group consisting of Ta, Zr, Hf, Ti and Nb 0.25-2.2one or more elements selected from the group consisting of REM max 0.5balance Ni and normally occurring impurities.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

High-fuel-efficiency biomass fuel

The invention relates to a high-fuel efficiency biomass fuel, and belongs to the field of fuels. According to the invention, octenyl succinic acid modified starch and bacterial cellulose are taken aswall materials, the surface of the wall materials is densified, so that the loss of effective ingredients in the processes of preparation and storage is effectively avoided, the effects of promoting combustion and improving fuel efficiency are achieved, the heat conductivity of the structure of the wall materials is improved; heat can be rapidly led into the inner part in the use process, and micro-explosion occurs to a micro-capsule structure; the occurrence of the micro-explosion, on one side, causes thermoresonance and produces secondary energy, so that the fuel can be completely burned rapidly at high temperature, and the fuel efficiency is further improved; the volume of magnesium oxide expands and shrinks in the use process, so that inner pores and melt materials in a system are redistributed, the excessive expansion of the volume of the fuel is avoided in the combustion process, and the product porosity is also effectively maintained. The invention solves the problems of low combustion efficiency and low use ratio of the current commonly-used biomass fuel.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

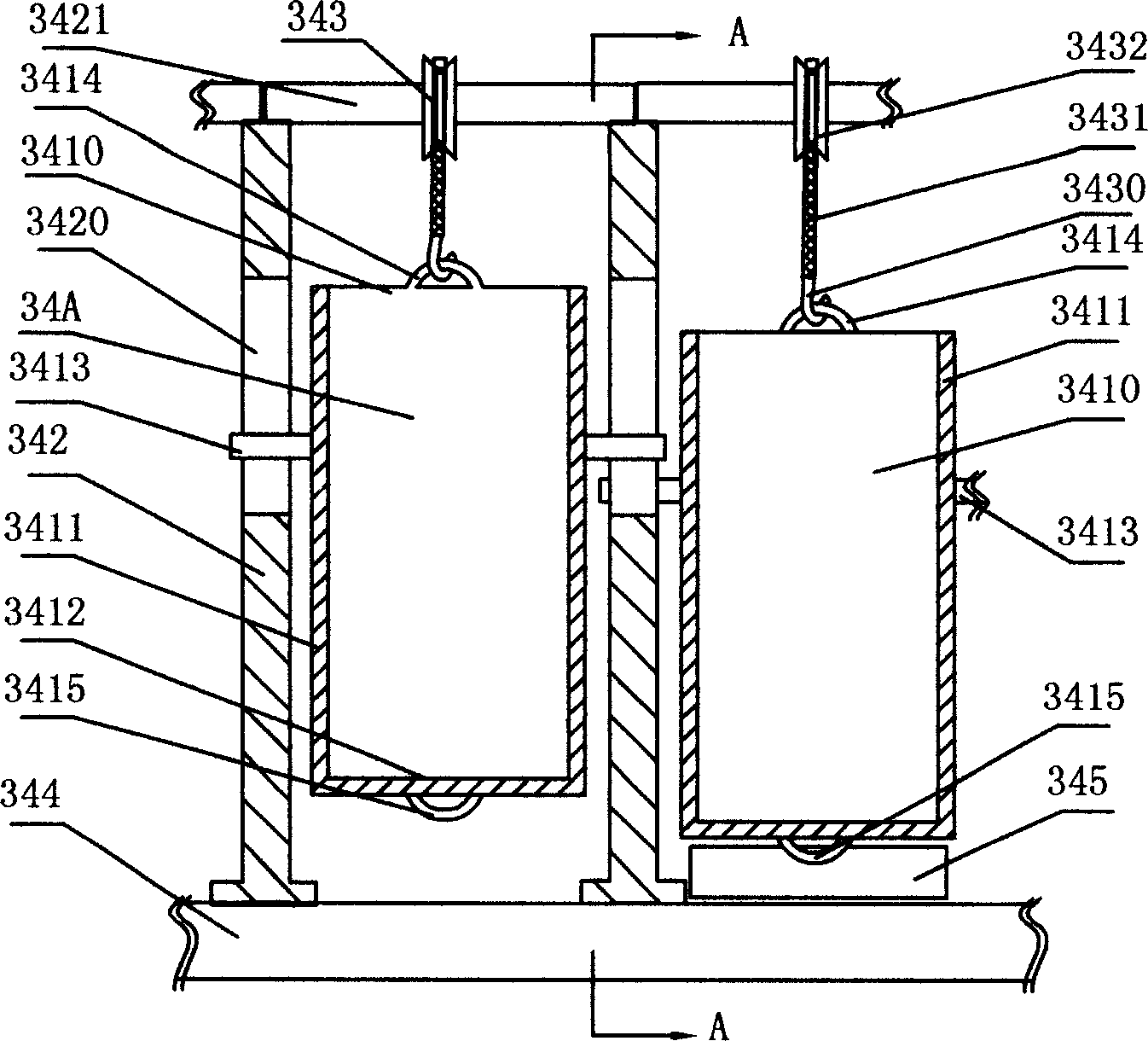

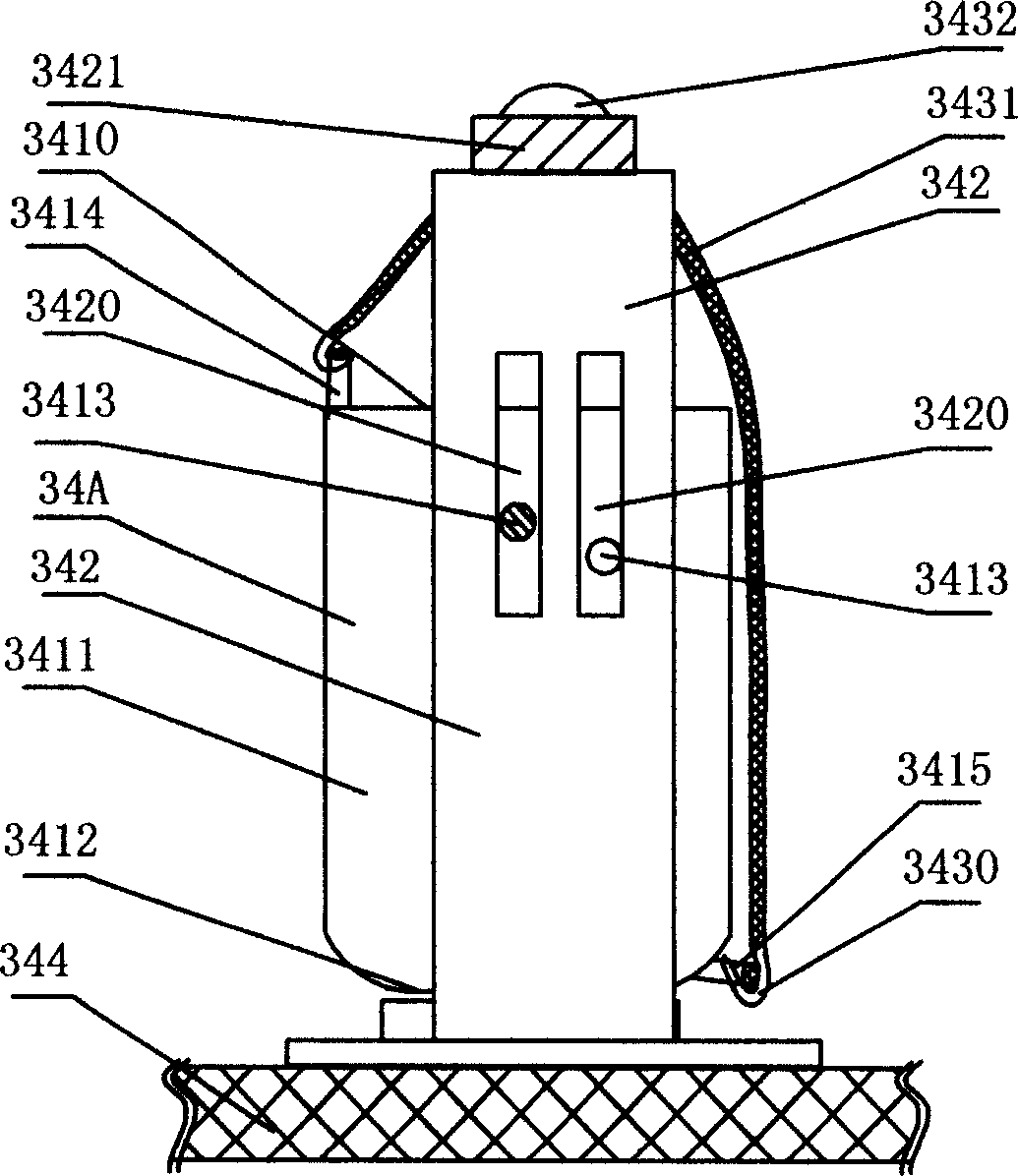

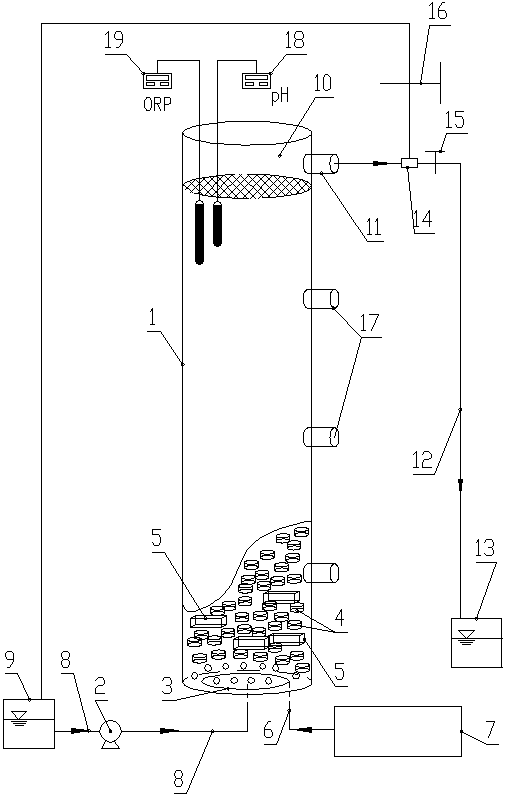

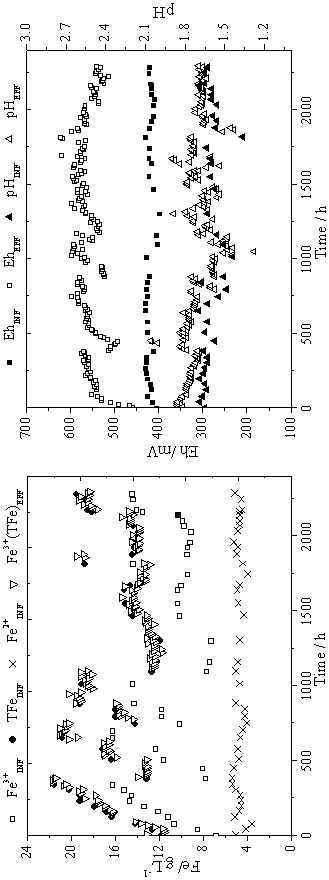

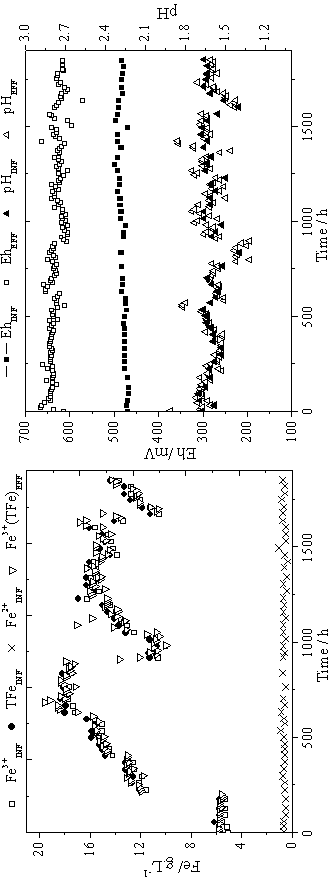

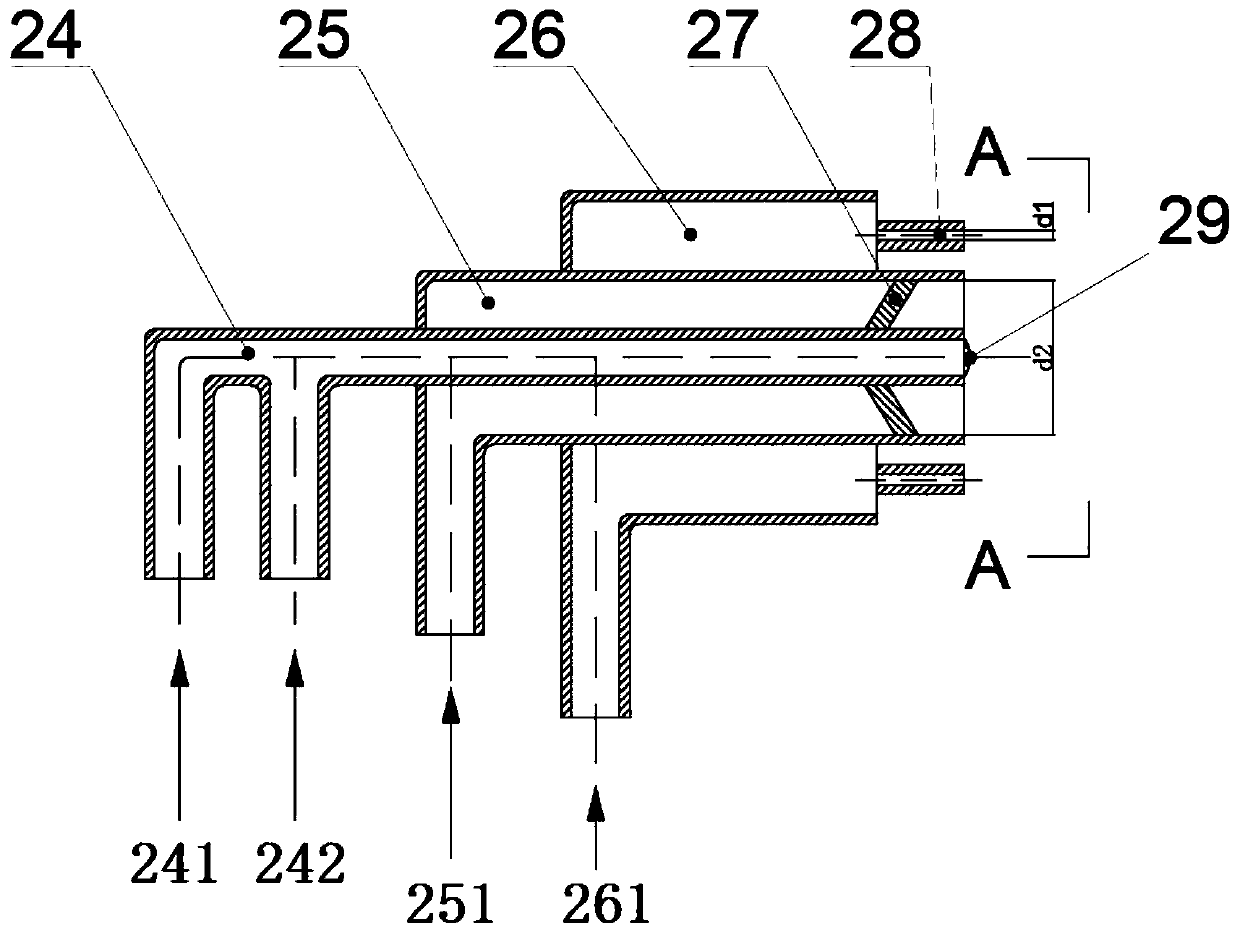

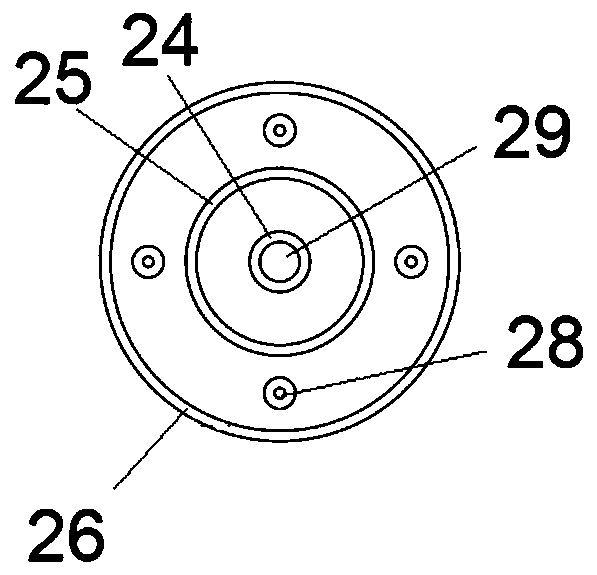

Composite filled column mechanism, method for immobilizing bacteria and method for treating leach liquor

ActiveCN107673486ASolve the problem of clogging the void and reducing the volumetric efficiency of the systemFix stability issuesBiological water/sewage treatmentPregnant leach solutionPeristaltic pump

The invention discloses a composite filled column mechanism which comprises a shell and a peristaltic pump. An annular porous aerator pipe and composite fillers are arranged in the shell from bottom to top, the porous aerator pipe is horizontally arranged, the composite fillers include K3 fillers and modified polyurethane foam fillers which are uniformly mixed with one another, and a stacking volume ratio of the K3 fillers to the modified polyurethane foam fillers is 3:1; an air pump is connected with the porous aerator pipe by a ventilation pipe, the bottom of the shell is connected with an outlet of the peristaltic pump, and a stock solution pond is connected with an inlet of the peristaltic pump; a liquid outlet is formed in a position between the shell and the tops of the composite fillers. The invention further discloses a method for immobilizing acidophilia iron oxide bacteria by the aid of composite filled columns and a method for treating mixed ore tonnage column leaching leachliquor by the aid of the composite filled column mechanism. The composite filled column mechanism and the methods have the advantages that Fe3+ regeneration ponds can be upgraded and transformed, excellent effects of oxidizing Fe2+ in the acidic column leaching leach liquor can be realized by the composite filled column mechanism, and stable effects of oxidizing ferrous iron in various concentration regions can be realized by the composite filled column mechanism.

Owner:EAST CHINA UNIV OF TECH

Secondary battery with a nitroxyl polymer active material

InactiveUS7318981B2Improve charge and discharge cycle characteristicsIncrease energy densitySolid electrolyte cellsPositive electrodesHydrogen atomAromatic hydrocarbon

A secondary battery, that has an excellent charge and discharge cycle characteristics, with a larger capacity, is provided. The secondary battery having a positive electrode, negative electrode and electrolyte, includes a polymer having a repeating unit represented by a formula (1) as an active material of at least one of positive electrode and negative electrode.According to formula (1), R1, R2, R3 and R4 each independently represents hydrogen atom, substituted or unsubstituted alkyl group, substituted or unsubstituted aromatic hydrocarbons, substituted or unsubstituted hetroaromatic groups, halogen atom, or alkylene group that may be coupled to the ring form either one or both of R1 and R3, R2 and R4.

Owner:NEC CORP

Device for reducing metal rhenium and molybdenum through radiation dissociation of rhenium and molybdenum gas electrode

The invention belongs to the technical field of production of a high melting point rare metal and a high melting point scattered metal, in particular to a device for reducing metal rhenium and molybdenum through radiation dissociation of a rhenium and molybdenum gas electrode. The device comprises a rhenium and molybdenum gas smoke-eliminating and dust-removing system, a molybdenum gas smoke-eliminating and dust-removing system, a metal rhenium producing machine, a first metal molybdenum producing machine and a second metal molybdenum producing machine which are arranged at five different altitudes, and a room-temperature desulfurizing, denitrating and decarbonizing device, a direct current power supply and electrical appliance interlocker and an induced draft fan. In the running process, each container and a gas conveying pipeline system maintain a constant negative pressure intensity, and leakage and emission of heavy metal rhenium oxide gas, heavy metal molybdenum oxide gas and sulfur dioxide gas are avoided; the device overcomes the defect that the recycling rate of leaching metal rhenium powder from baking fume is low, directly produces metal rhenium Re(s) and metal molybdenum Mo(s) from sublimated and volatilized rhenium and molybdenum gas through identifying soft X rays, and completely recycles sulfur in molybdenite, thereby greatly reducing pollution of the sulfur dioxide to the environment.

Owner:罗旭 +1

Pulverized coal coupled combustion device and combustion method

PendingCN109827168AReduce generationOxidation stabilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCombustor

The invention discloses a pulverized coal coupled combustion device and a combustion method. The device comprises a gas combustion chamber, and a pulverized coal combustion chamber arranged in the gascombustion chamber; a gas flameless combustor is mounted at the top of the gas combustion chamber; gas is combusted in a flameless mode in a cavity inside the gas combustion chamber and outside the pulverized coal combustion chamber through the gas flameless combustor; a pulverized coal flameless combustor is mounted at the top of the pulverized coal combustion chamber, and penetrates through thetop of the gas combustion chamber; and pulverized coal is combusted in a flameless mode in the pulverized coal combustion chamber through the pulverized coal flameless combustor. The pulverized coalcoupled combustion device can spontaneously maintain the pulverized coal flameless combustion with an uniform temperature field, generated by the gas flameless combustion, as an uniform radiation heatsource, and can stabilize the oxidation under a low-temperature and low-oxygen atmosphere, so that the generation quantity of nitric oxides is greatly reduced, and the ultralow emission of the nitricoxides in the pulverized coal combustion is realized.

Owner:HUAZHONG UNIV OF SCI & TECH +2

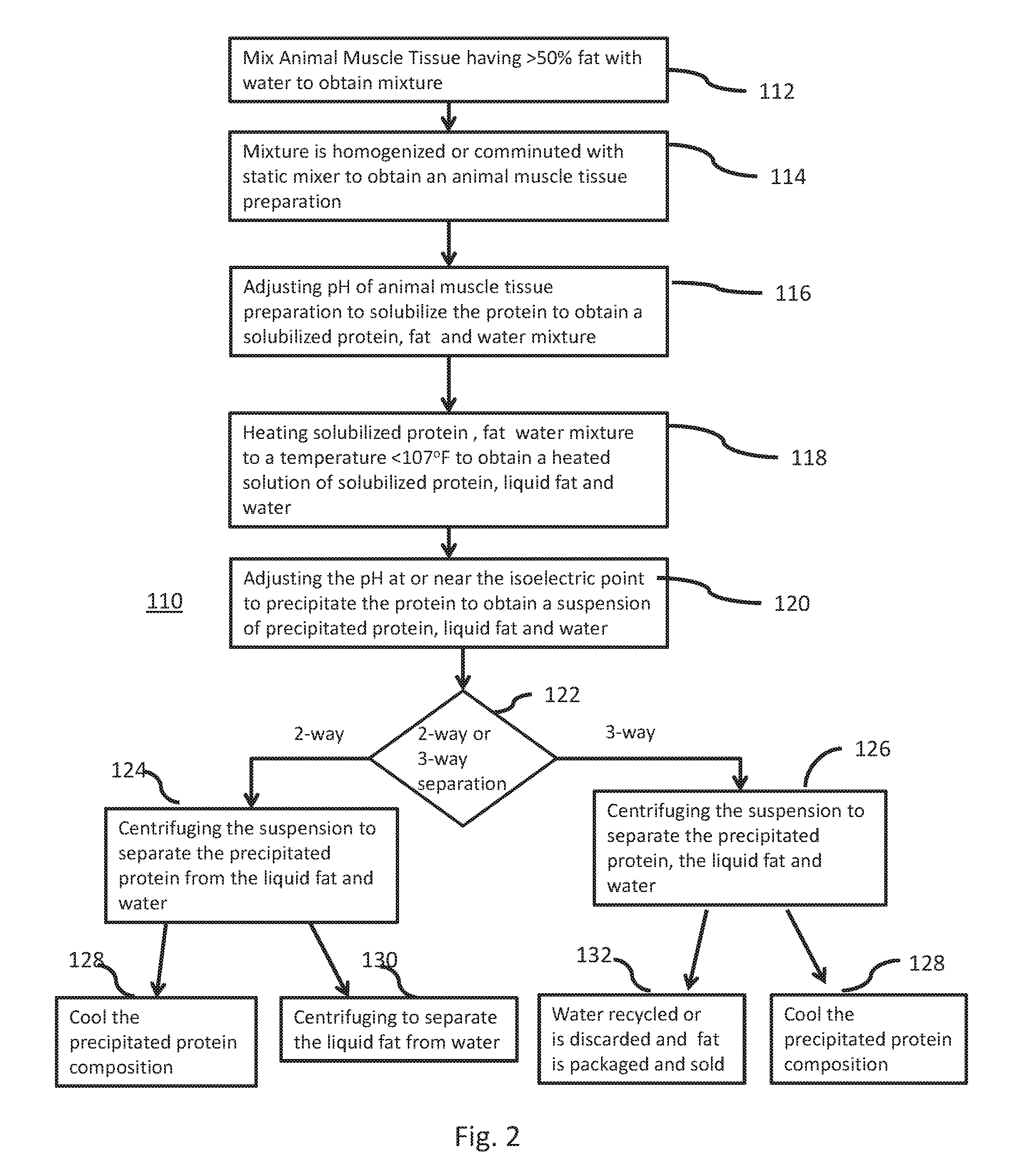

Process for Obtaining Lean Protein

InactiveUS20170013858A1Satisfactory yieldSimplifies subsequent water removalFood ingredientsFood precipitationMuscle tissueFood grade

A protein fraction and an oxidation stable fat fraction are recovered from meat trimmings or a high fat content animal muscle tissue. The trimmings are comminuted, and solubilized with a food grade acid or base. The solubilized protein / fat solution is heated so that the fat transforms into a liquid state. The protein is precipitated and the liquid fat is separated. The process results in a lean protein product that is red in color and can also have characteristics of functional meat.

Owner:KEMIN PROTEINS LLC

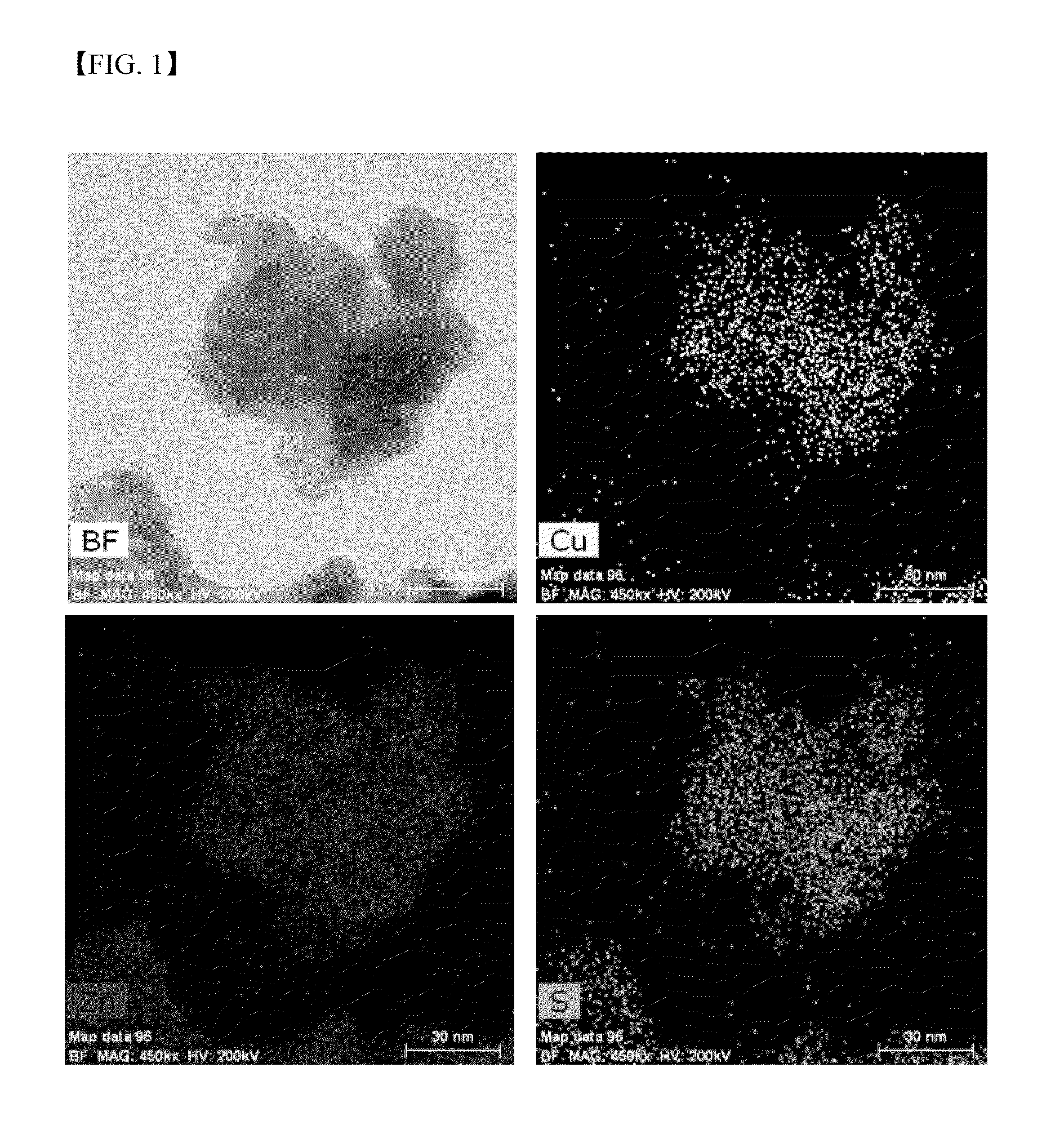

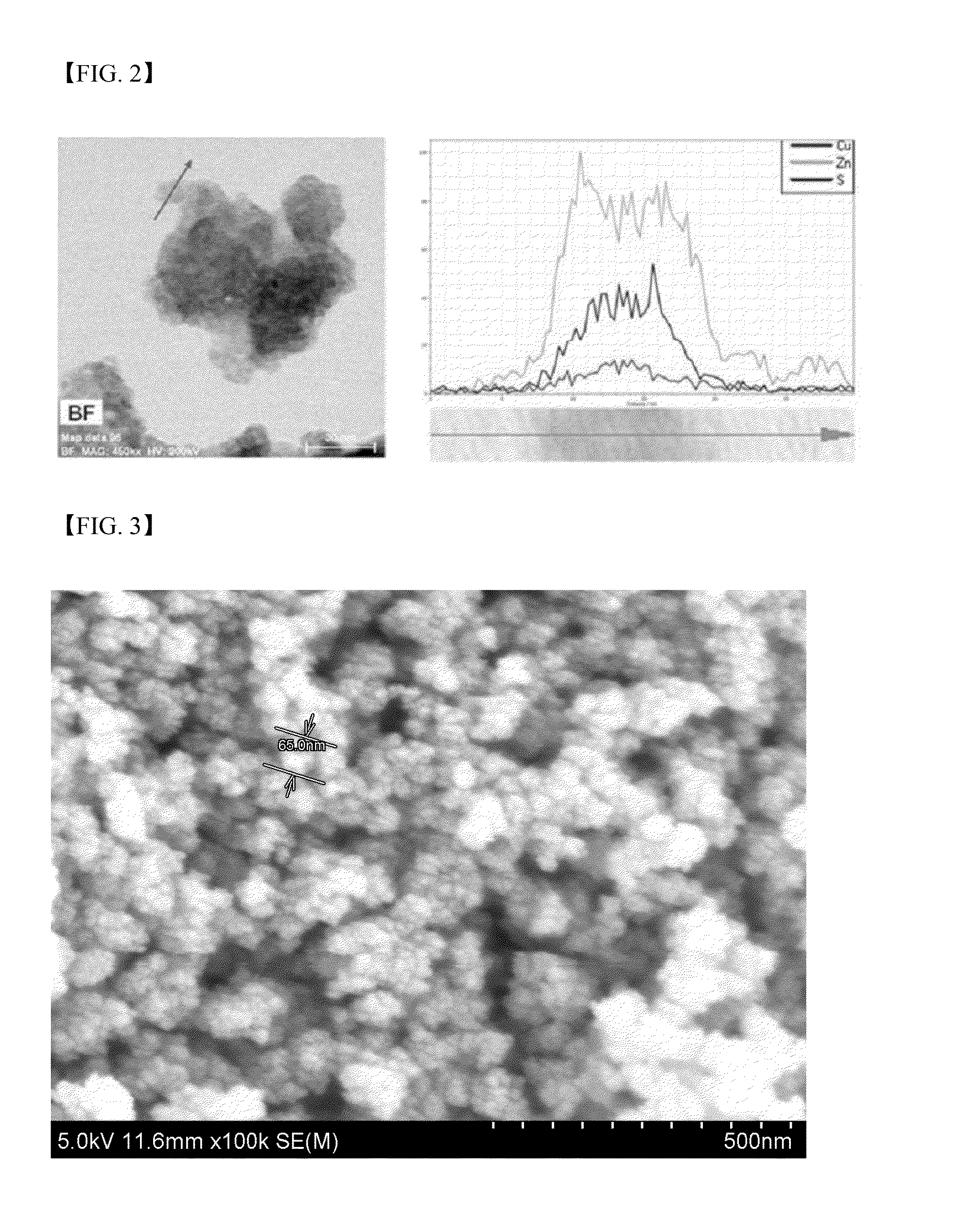

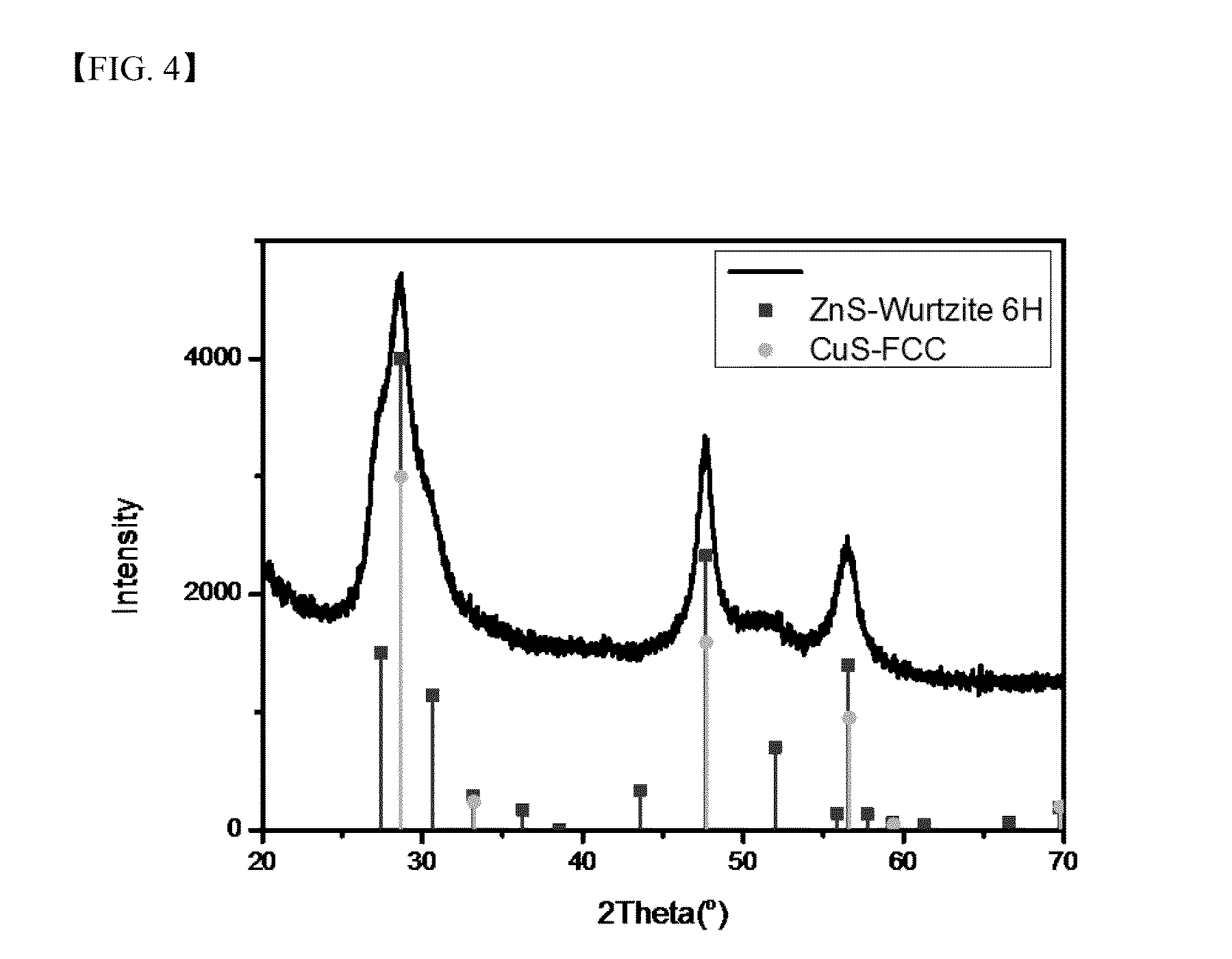

Metal chalcogenide nanoparticles for manufacturing solar cell light absorption layers and method of manufacturing the same

InactiveUS20160149061A1Oxidation stabilityQuality improvementFinal product manufactureConductive materialThird phaseChalcogenide

Disclosed are metal chalcogenide nanoparticles forming light absorption lavers of solar cells including two or more phases selected from a first phase including zinc (Zn)-containing chalcogenide, a second phase including tin (Sn)-containing chalcogenide and a third phase including copper (Cu)-containing chalcogenide, and a method of manufacturing the same.

Owner:LG CHEM LTD

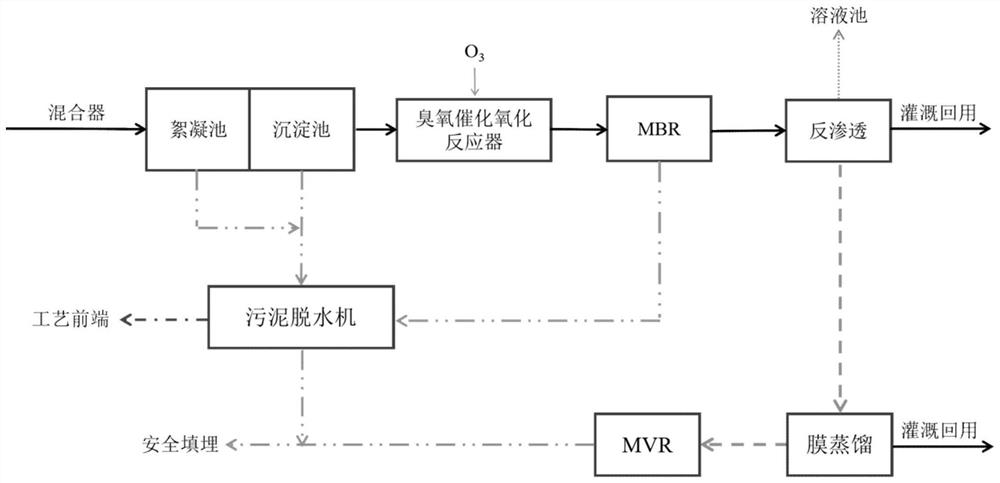

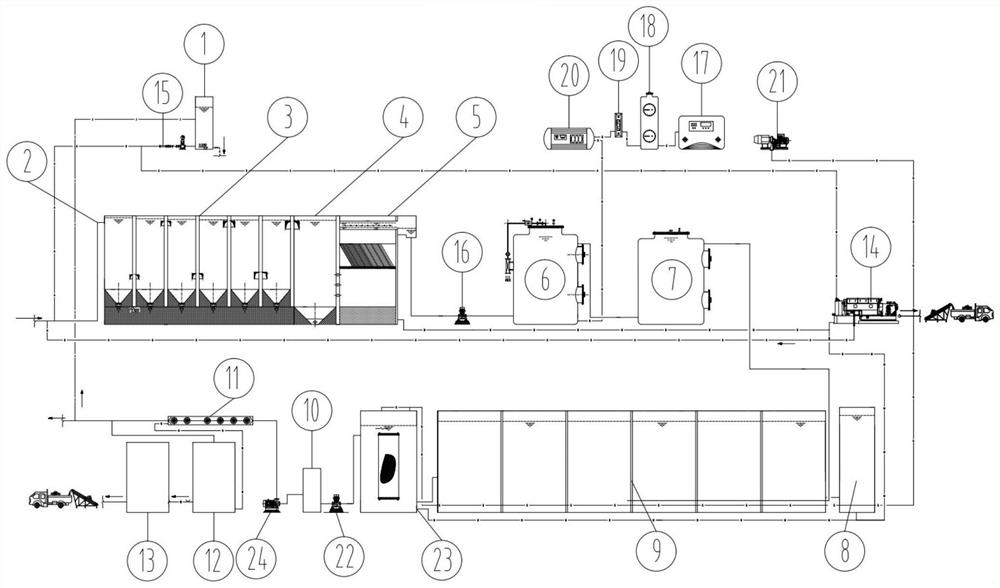

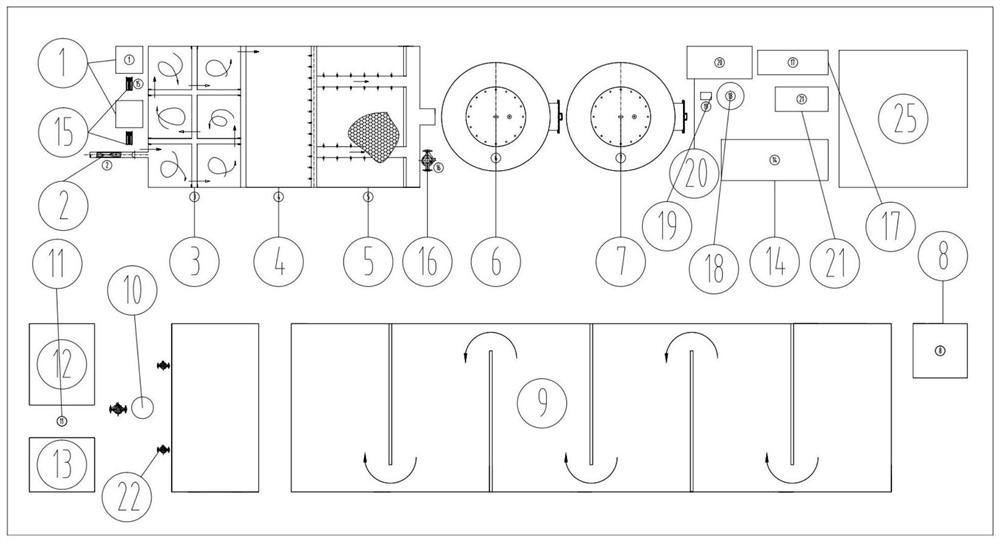

Efficient treatment, recycling and zero emission method and system for shale gas flowback fluid

ActiveCN112441701AEasy to separateImprove water qualityWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningReverse osmosisCatalytic oxidation

The invention provides an efficient treatment, recycling and zero emission method and system for shale gas flowback fluid. The method comprises coagulating sedimentation, catalytic ozonation, an MBR method, reverse osmosis, membrane distillation, a mechanical vapor recompression (MVR) evaporator, sludge dehydration, and safe landfill or resource utilization. The system comprises a primary treatment unit, a secondary treatment unit, an advanced treatment unit, a concentrated solution treatment unit, a sludge treatment unit and an automatic control unit. All the units are arranged in one or morecontainers to form the modular and movable skid-mounted device. By means of the process, suspended solids, colloids, organic matter, salt ions and other pollutants in the shale gas flowback fluid canbe efficiently removed, the effluent quality can meet reinjection, emission and various reuse standards, and meanwhile zero emission of the whole system is achieved. The system is free of environmental pollution, capable of effectively operating for a long time, easy to maintain, small in occupied area, flexible and convenient to use, and the skid-mounted device is quite suitable for treating shale gas flowback fluid.

Owner:刘百仓

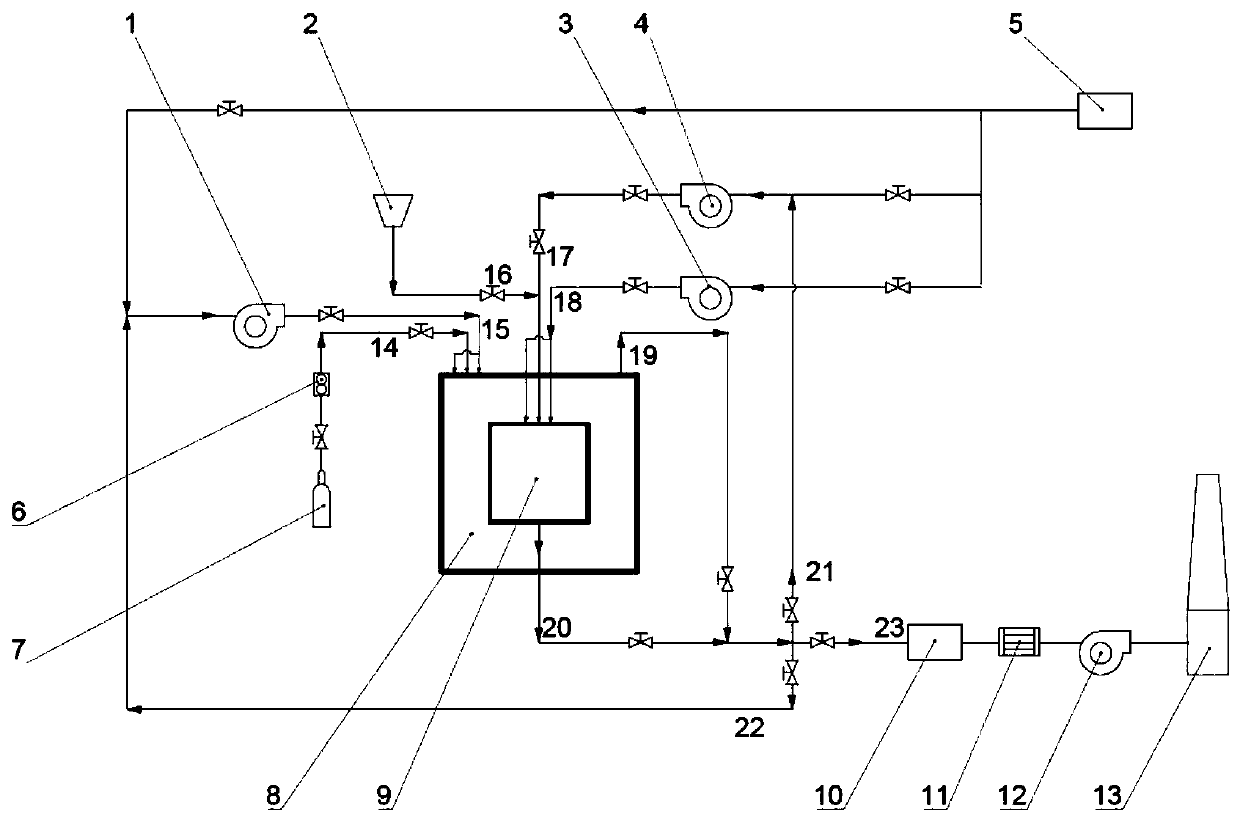

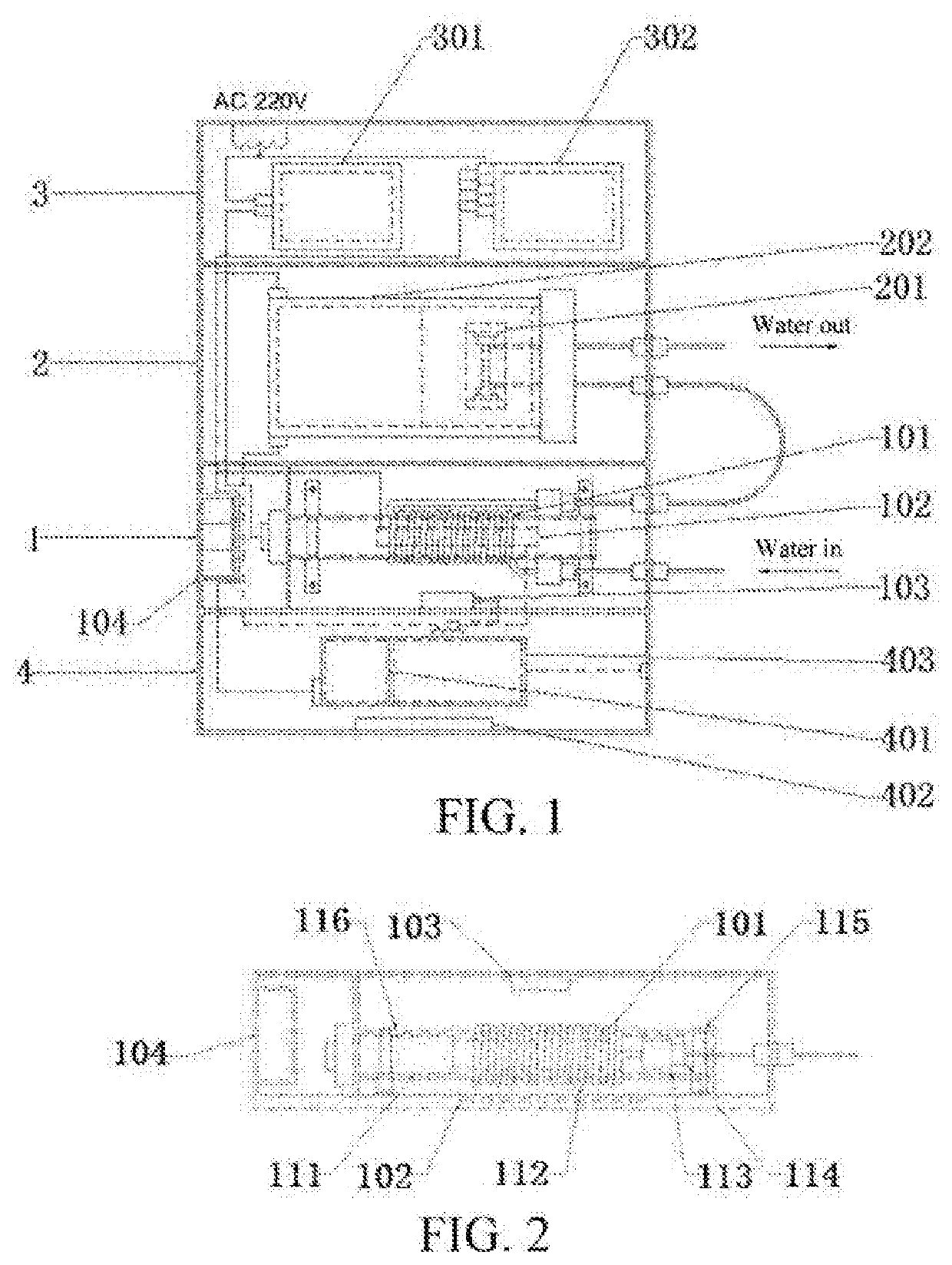

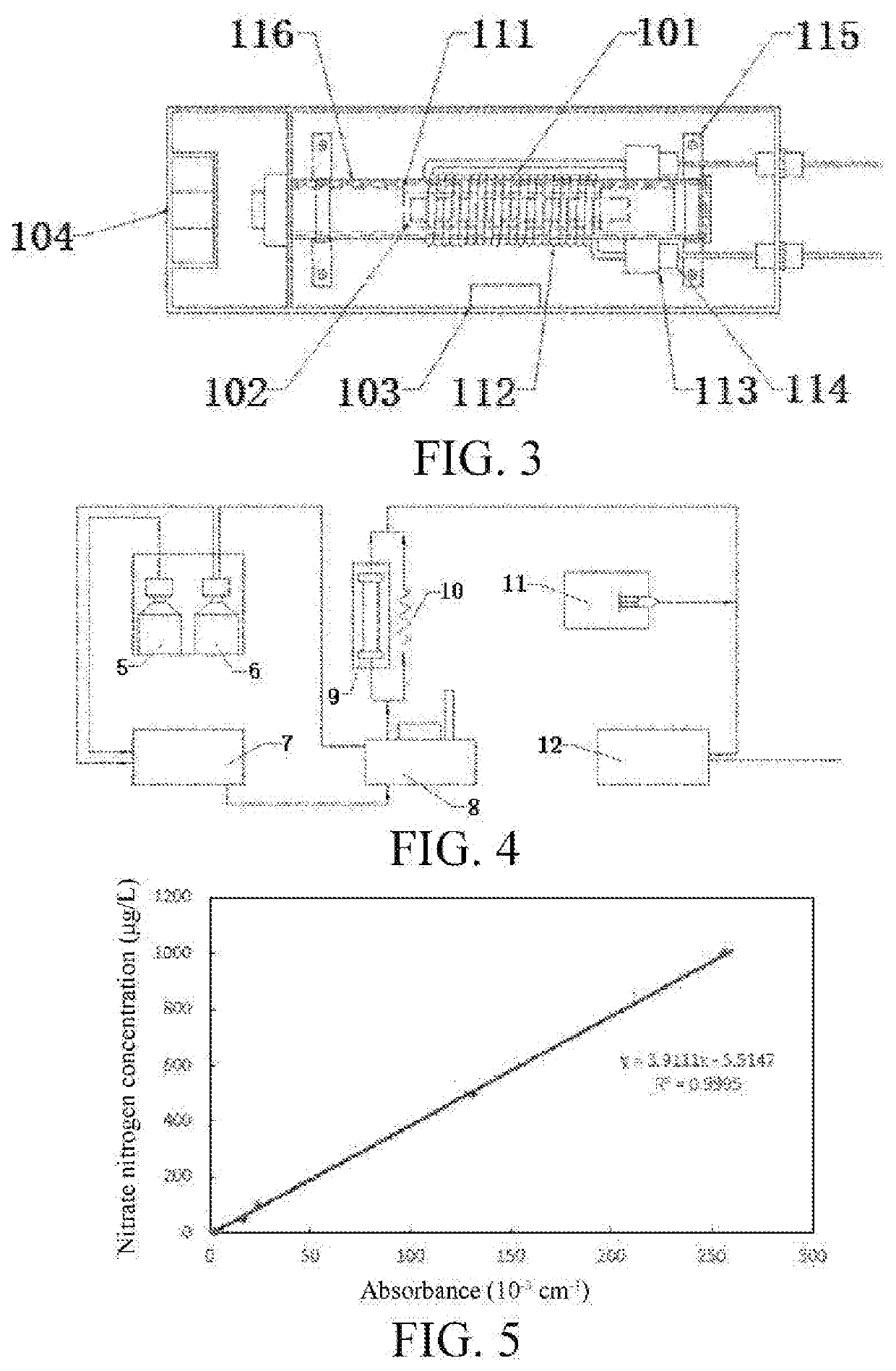

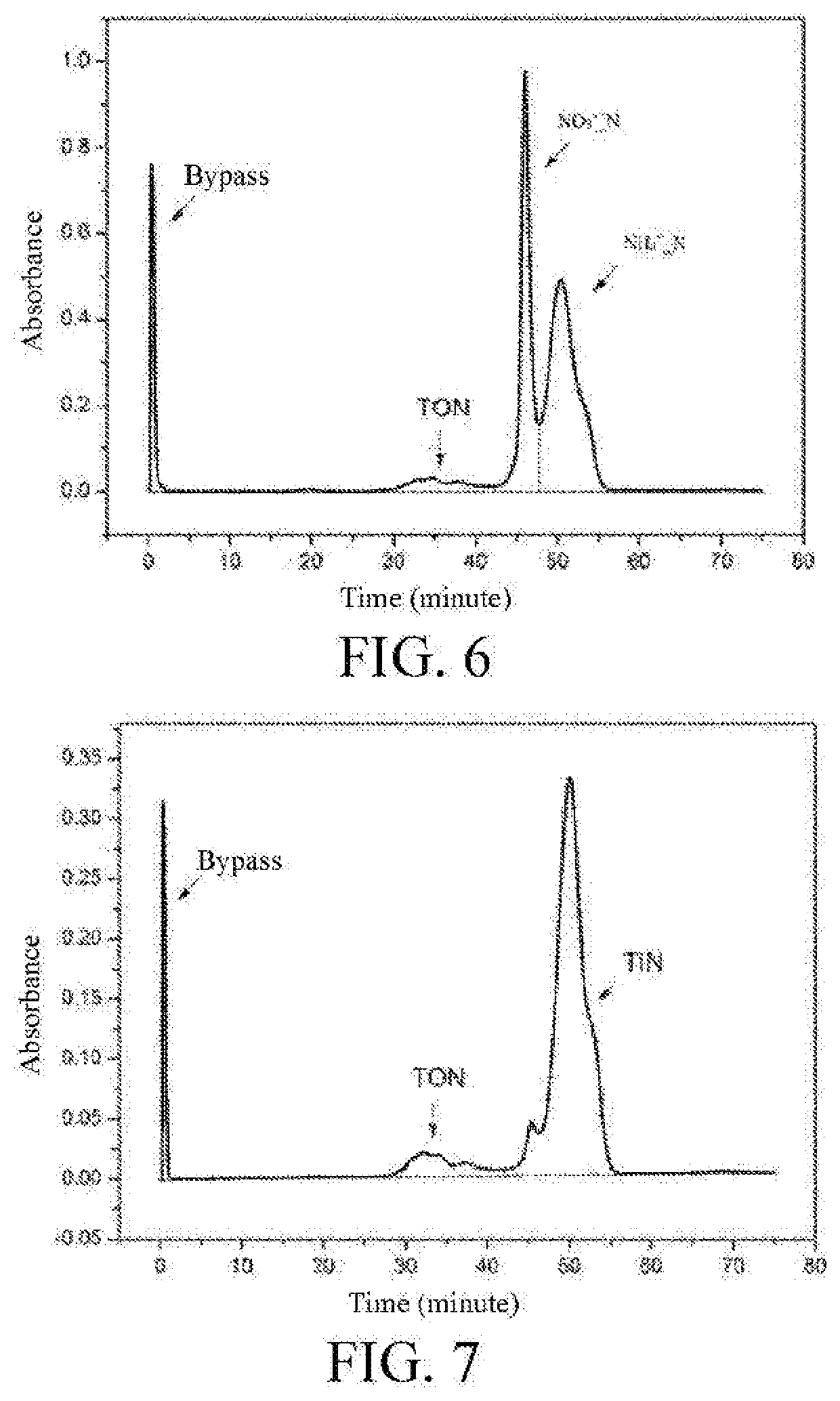

Size exclusion chromatography-combined nitrogen detector and application method

PendingUS20210018476A1Accurate quantitative analysisThe result is accurate and reliableComponent separationColor/spectral properties measurementsChromatographic separationUltraviolet

Disclosed are a size exclusion chromatography-combined nitrogen detector and an application method thereof, which belong to the field of detection and analysis of water quality. The detector comprises an oxidation system (1), a nitrate detection system (2), a power supply system (3), and a signal processing and control system (4), wherein after being separated by size exclusion chromatography, a sample to be detected enters into the oxidation system (1) to undergo oxidation treatment, and after nitrogenous compound in the sample is converted into nitrate, the sample is detected in the nitrate detection system (2) by ultraviolet (UV) absorbance method. The power supply system (3) supplies power to the detector, and the signal processing and control system (4) is responsible for processing and controlling signals of the oxidation system (1) and the nitrate detection system (2). The detector can achieve quantitative analyses of total nitrogen, organic nitrogen, nitrate nitrogen, and ammonia nitrogen, has the advantages of easiness in operation, being rich in information, etc. and thereby effectively prevents the problems of relatively large error and negative value resulting from the subtraction calculation in conventional organic nitrogen analysis methods.

Owner:NANJING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com