Device for reducing metal rhenium and molybdenum through radiation dissociation of rhenium and molybdenum gas electrode

A metal and dissociation technology, applied in the field of high melting point rare metal and high melting point scattered metal production, can solve the problems of high production cost, complicated process and high loss of rhenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

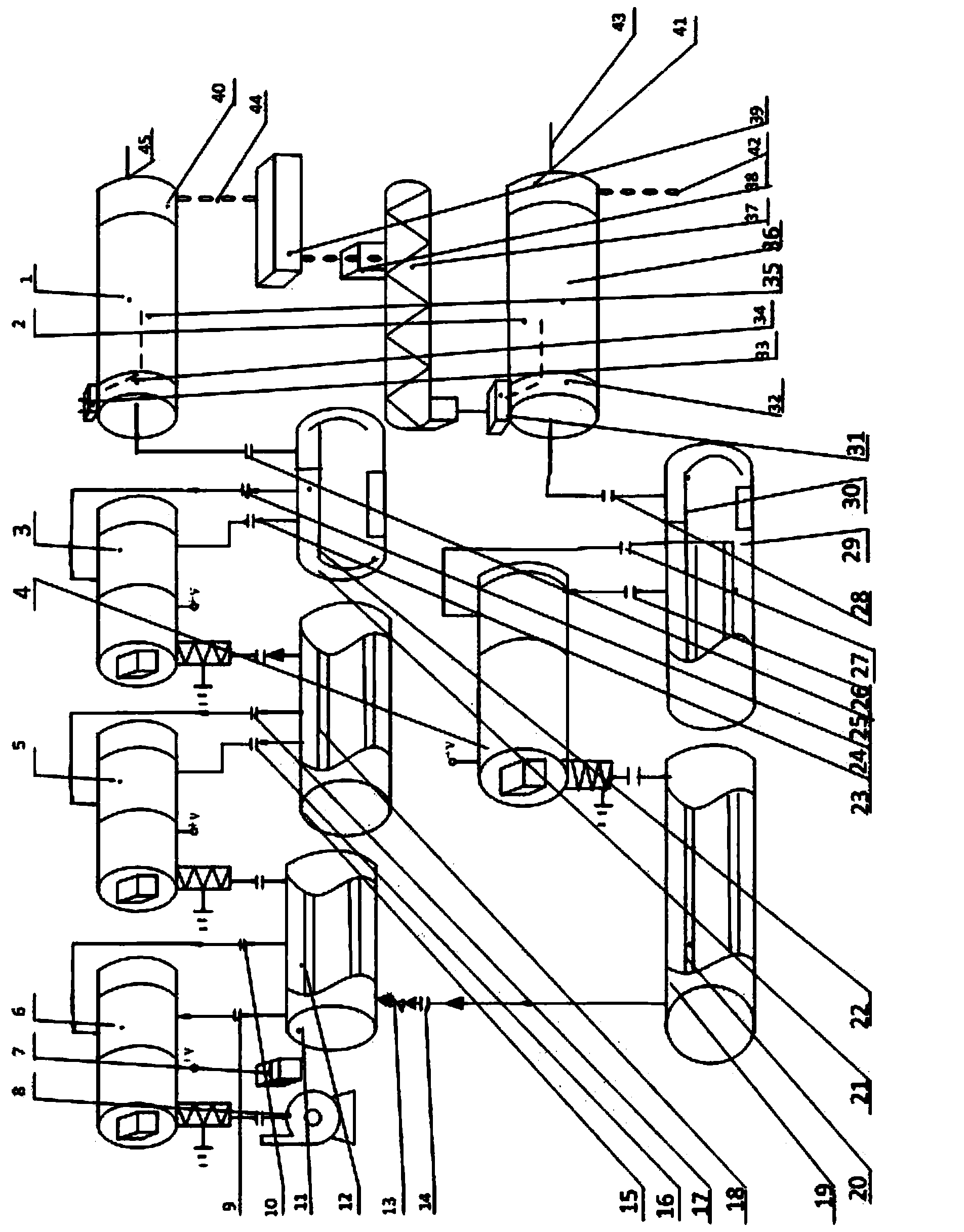

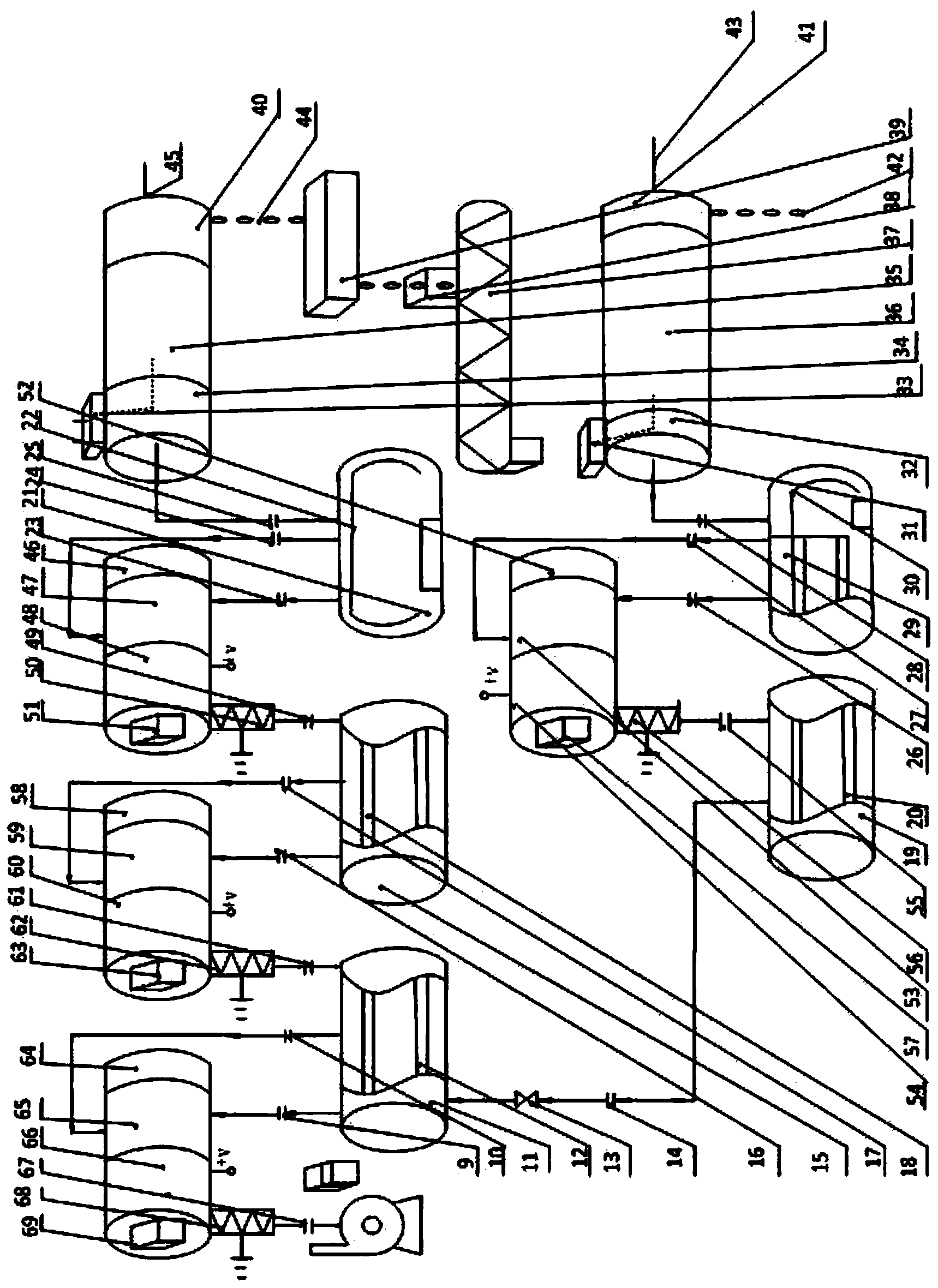

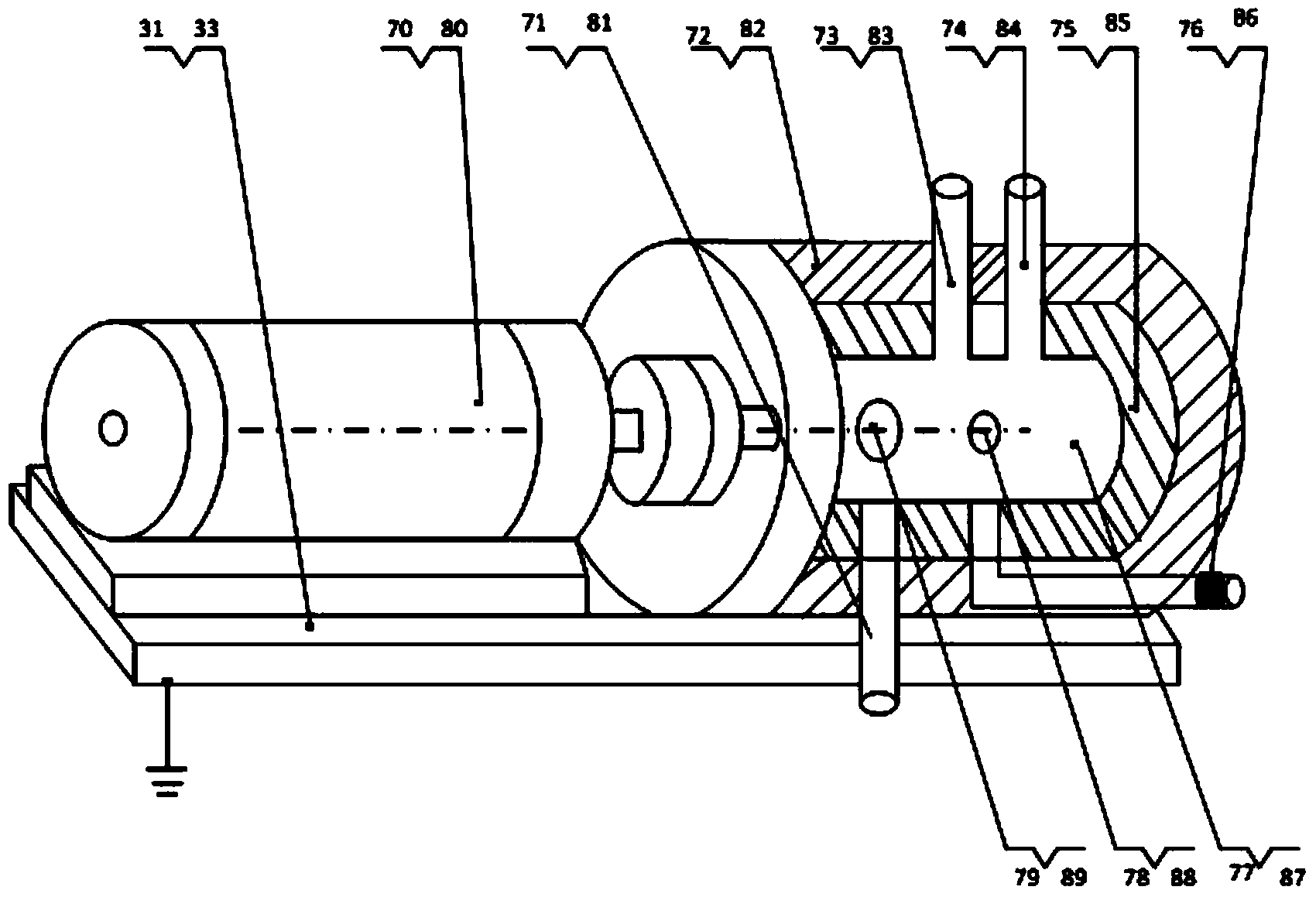

[0036] Relevant data show that molybdenite (MoS 2 ) with a melting point of 1185°C, solid molybdenum trioxide MoO 3 (s) The melting point is 795°C; according to the chemical and chemical principle that volatile oxide gas will be produced by oxidative roasting in the atmosphere above the melting point of the compound, the present invention uses an anhydrous process to divide the overall device into radiation dissociation volatile rhenium gas molybdenum The complex system of making rhenium and molybdenum gas and the single molybdenum system of radiation dissociation volatile molybdenum gas; the use of smokeless oxidation roasting process to make molybdenite (MoS 2) into gaseous molybdenum trioxide MoO 3 (g) process, will release a large amount of sulfur dioxide gas SO 2 (g), nitrogen oxide gas NO X (g) and carbon dioxide CO 2 (g) etc., the present invention according to A · Einstein photoelectric effect law τ a = СZ ef 4 lambda 3 The room temperature nuclear energy desul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com