Efficient treatment, recycling and zero emission method and system for shale gas flowback fluid

A technology for flowback liquid and shale gas, applied in mining wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. The effect of good separation effect and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

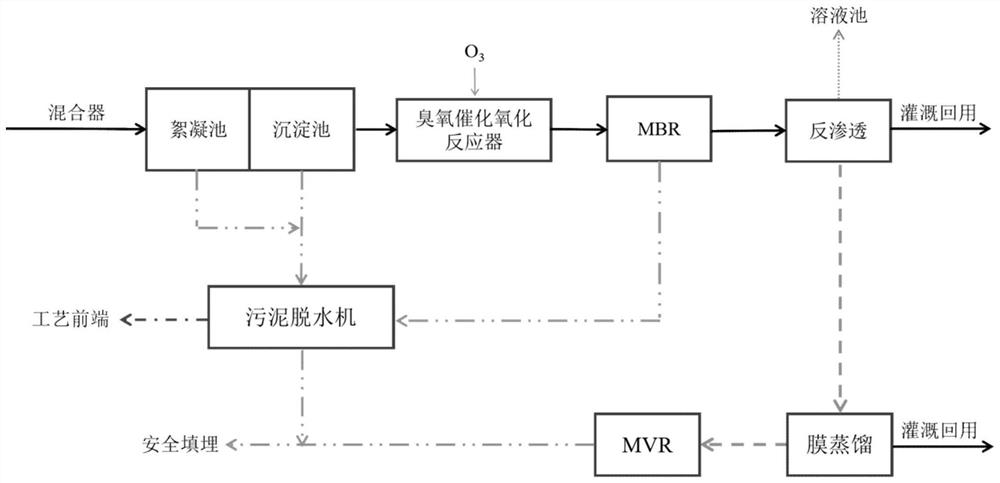

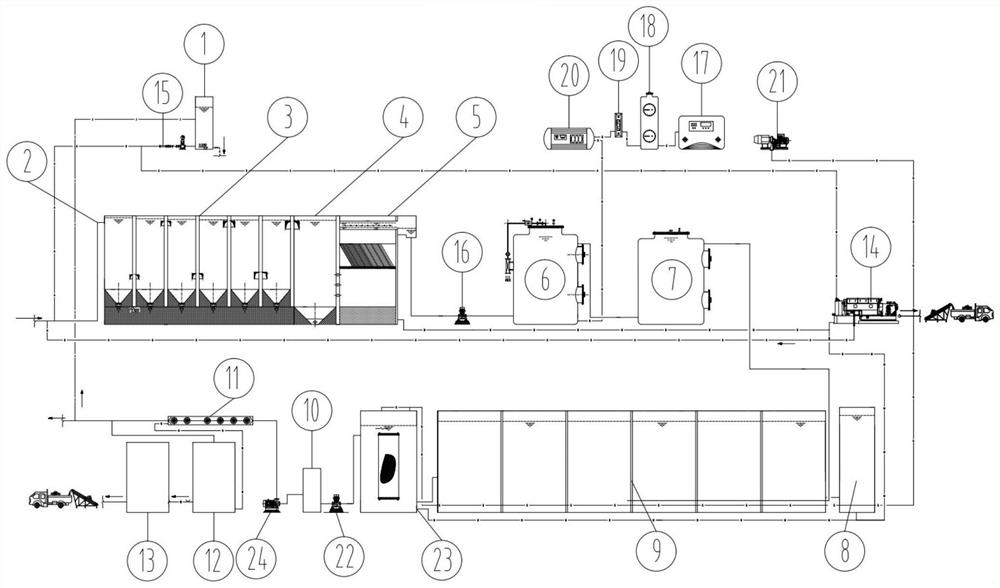

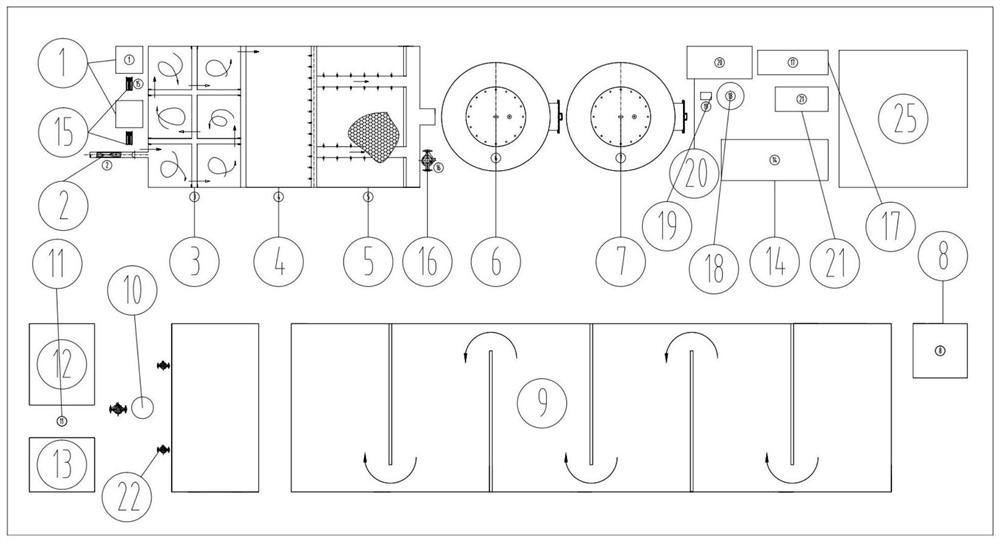

[0076] Such as figure 2 As shown, the high-efficiency treatment, reuse, and zero discharge system of shale gas flowback fluid described in this implementation includes a primary processing unit, a secondary processing unit, an advanced processing unit, a concentrated liquid processing unit, a sludge processing unit, and a PLC control unit.

[0077] The primary treatment unit includes a solution pool, a tubular static mixer, a perforated swirl flocculation tank, a transition section, and an inclined tube sedimentation tank; the flocculation tank, transition section, and sedimentation tank are connected in sequence, and the bottom of the flocculation tank is set The steel frame structure is raised to raise the water level to ensure gravity flow and good hydraulic conditions; the perforated swirl flocculation tank is divided into 6 grids; the inclined tube sedimentation tank includes the bottom mud discharge area, water distribution area, There are four divisions in the incline...

Embodiment 2

[0085] The system described in Example 1 was used to treat shale gas flowback fluid.

[0086] The pH of the shale gas flowback fluid at a well site in Sichuan is 6.76, the color is yellowish, and there is no pungent smell. The specific parameters are shown in Table 1:

[0087] Table 1 Water quality of shale gas flowback fluid at a wellsite in Sichuan

[0088]

[0089] A method for treating shale gas flowback liquid with high-efficiency treatment, reuse, and zero discharge system, comprising the following steps:

[0090] According to the actual amount of treated water and the actual application scenario, the shale gas flowback liquid outside the system is continuously and stably transported to the inside of the system by means of pressurized water delivery by the pump;

[0091] For the first preparation of coagulant agent, it is necessary to manually inject tap water into the solution pool to the design liquid level, add the agent to the solution pool through the automatic ...

Embodiment 3

[0120] It is basically the same as in Example 1, the only difference is that the mixing and flocculation devices respectively select a mechanical mixing tank and a mechanical flocculation tank, which have better adaptability to changes in water quality and quantity, and occupy a larger area, but can obtain Better processing effect. The working principle and method of the system are the same as those in Implementation 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com