Patents

Literature

88results about How to "Satisfactory yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

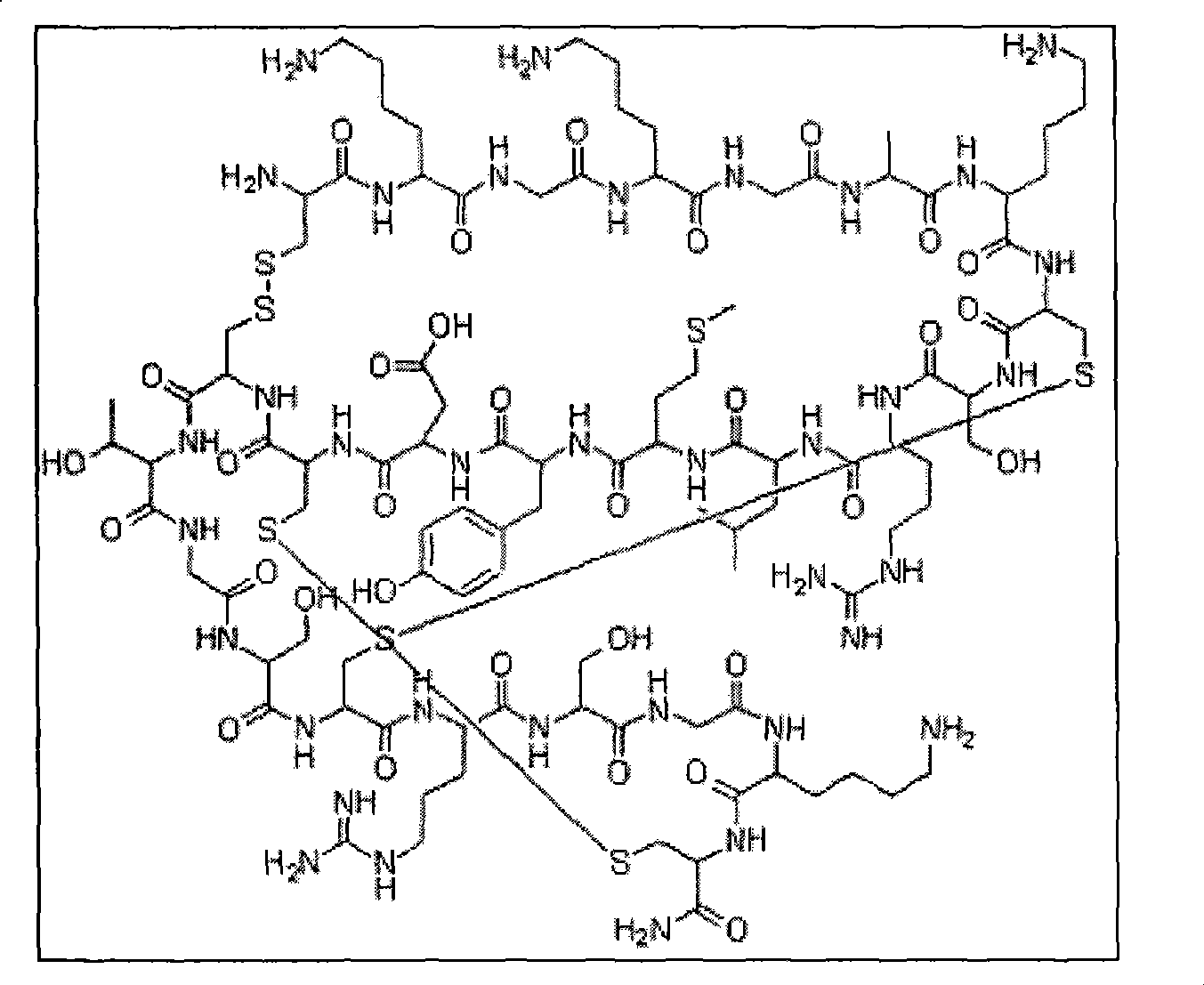

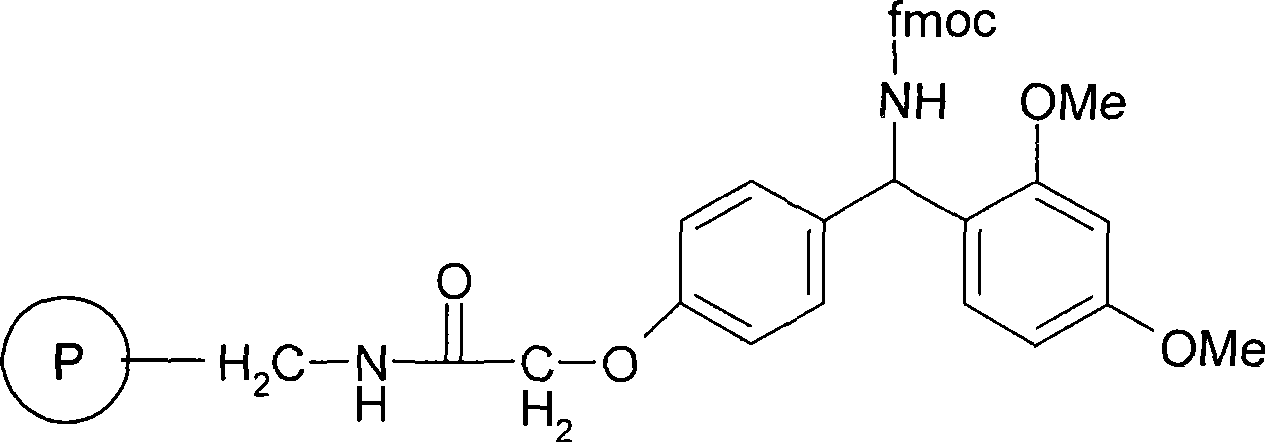

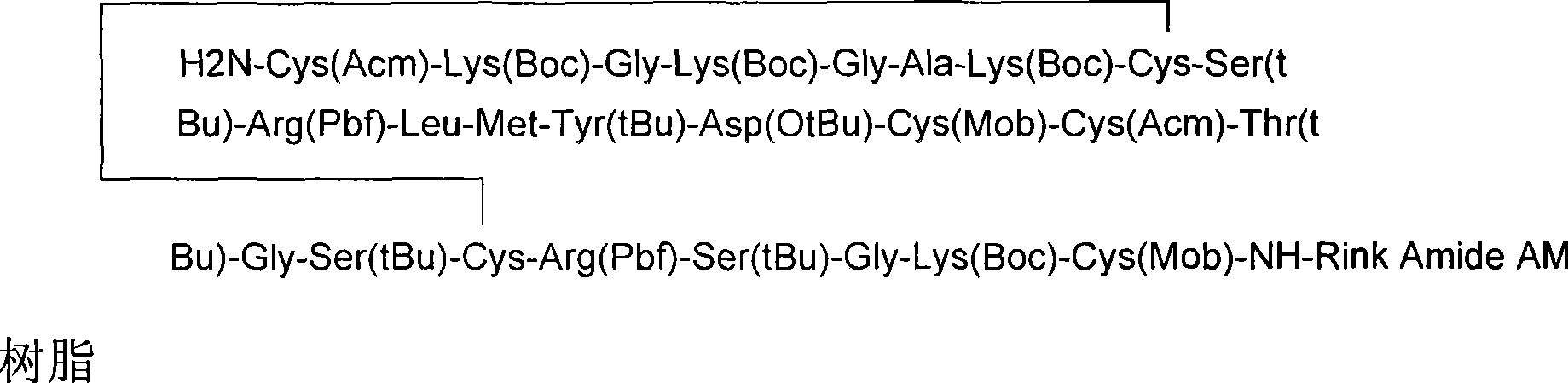

Solid phase synthesis method of ziconotide

InactiveCN101412752AIncrease the speed of cyclizationImprove reaction efficiencyPeptide preparation methodsAnimals/human peptidesSide chainCombinatorial chemistry

The invention relates to a solid phase synthesis method for ziconotide, which comprises the following steps: an Fmoc-Rink Amide-MBHA resin is taken as a solid phase carrier for program reaction; condensation reactions are orderly performed to link 25 amino acids with protecting groups to obtain a linear peptide complete-protection resin of the 25 amino acids,wherein in three groups of Cyses which form a disulfide bond, the Cyses in the same group are simultaneously linked with one of a Trt, Acm or Mob protecting group, and different groups of the Cyses are linked with different protecting groups; the protecting groups of the three groups of the Cyses are orderly removed; a cyclization reaction is performed to form a disulfide ring bond; a side chain protecting group is removed; and the resin is cut to obtain the ziconotide containing three disulfide rings. The method has the main advantages of few side products, high directive efficiency, simplicity, convenience, high yield of products, and favorability for the purification of the products.

Owner:ADLAI NORTYE BIOPHARMA CO LTD

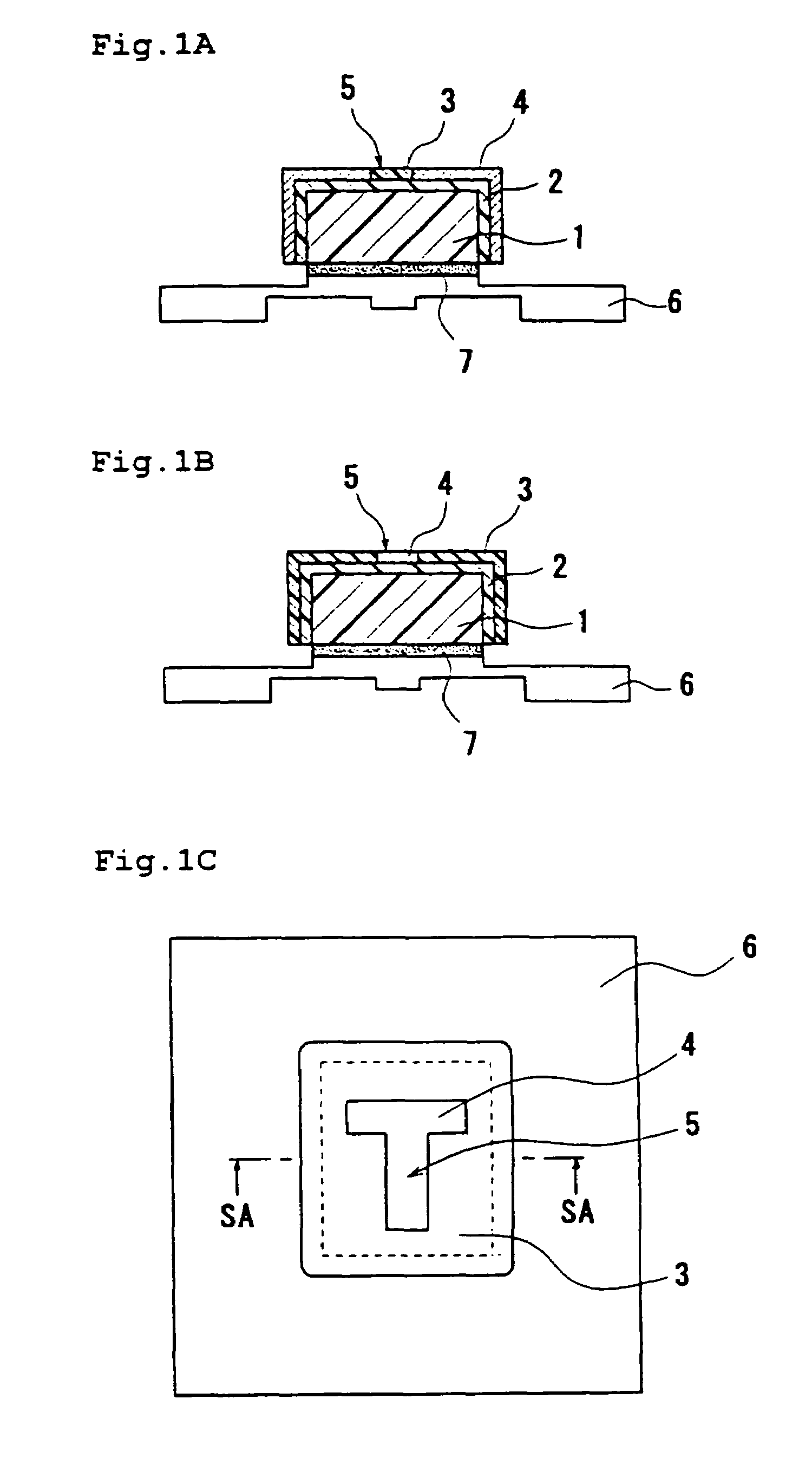

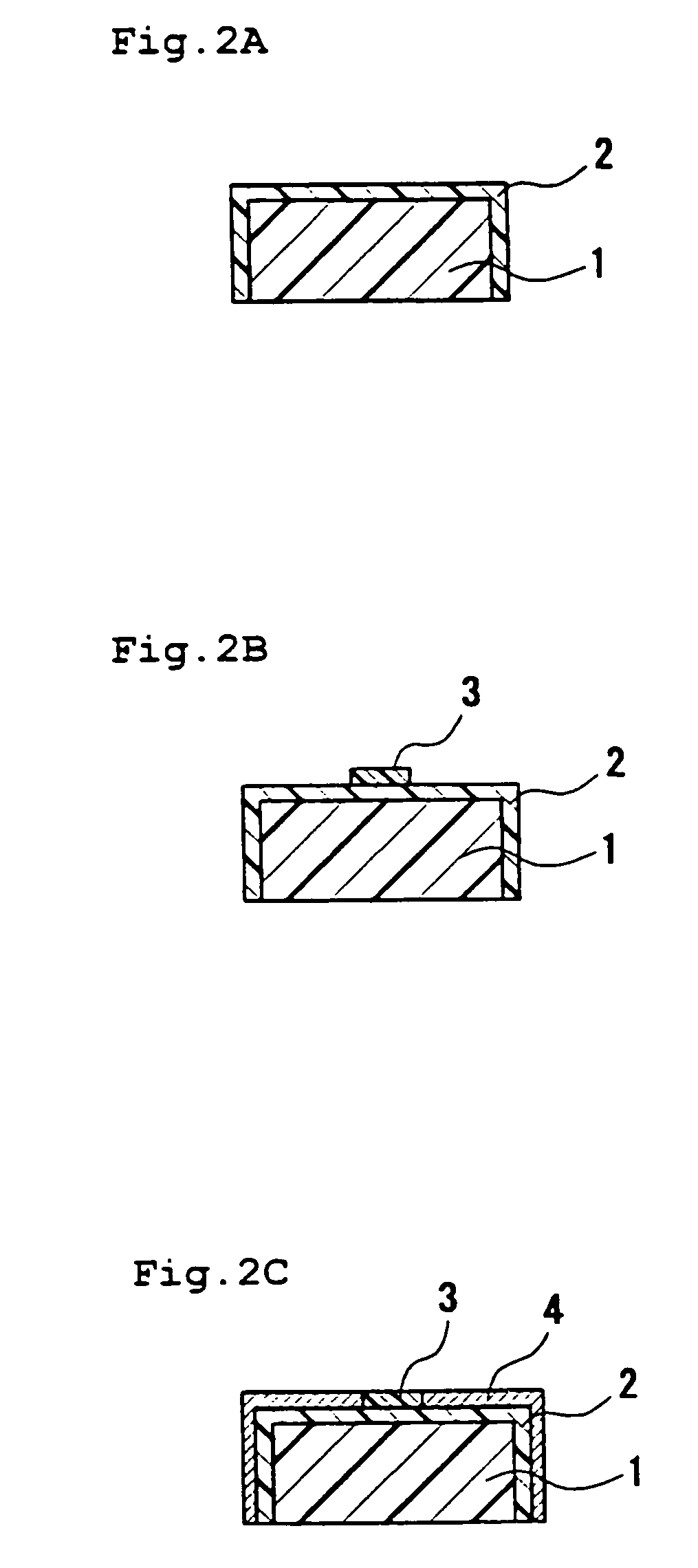

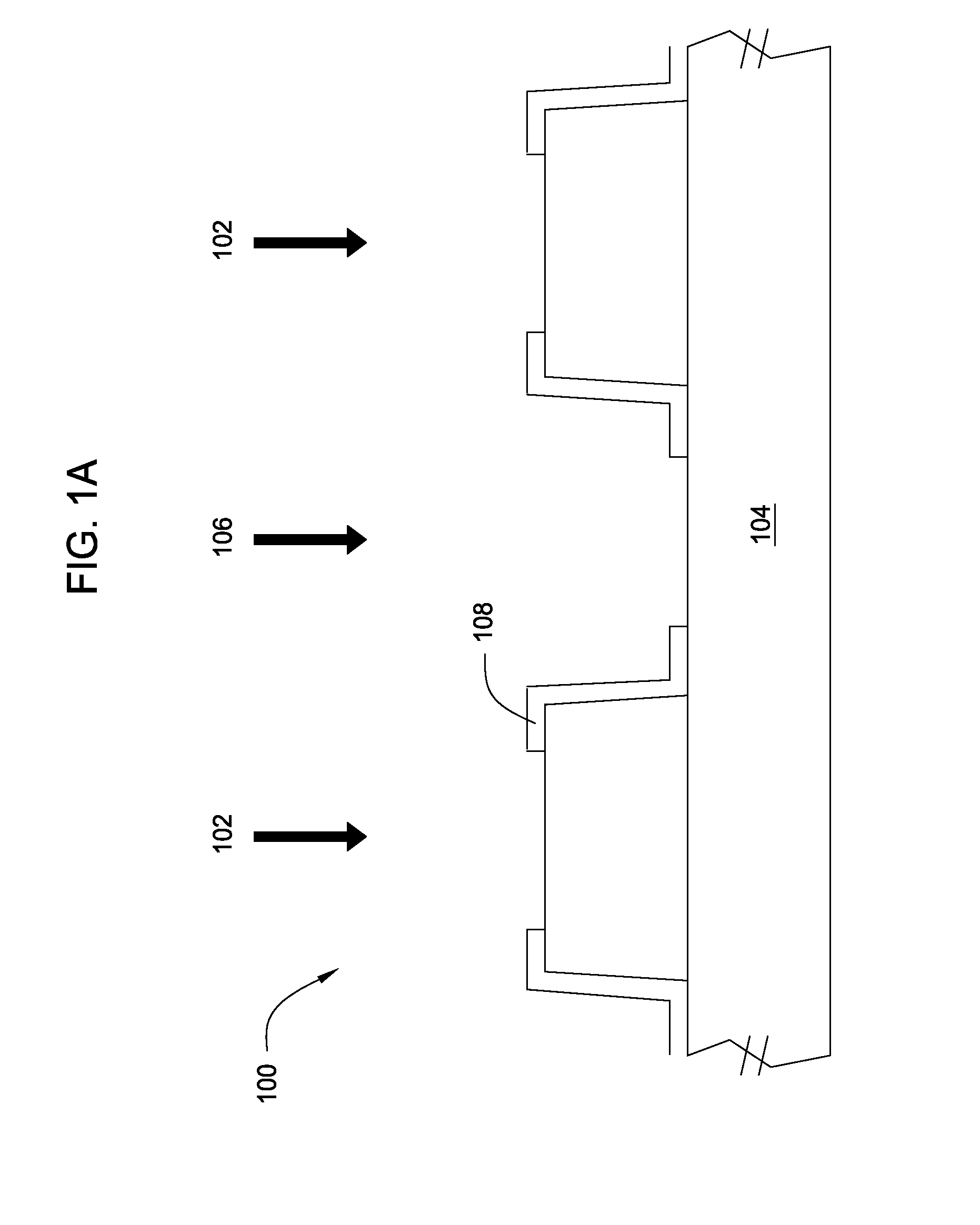

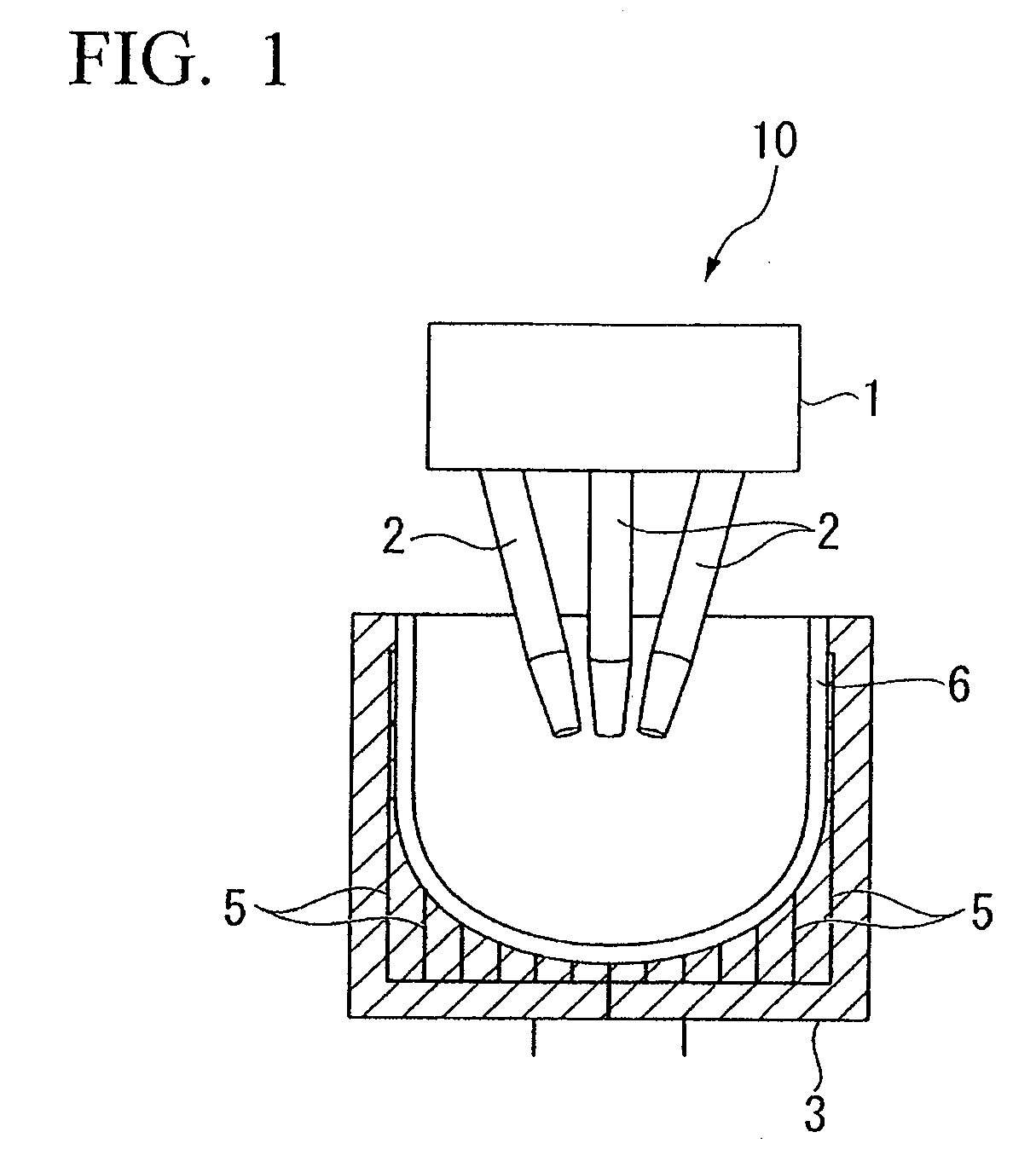

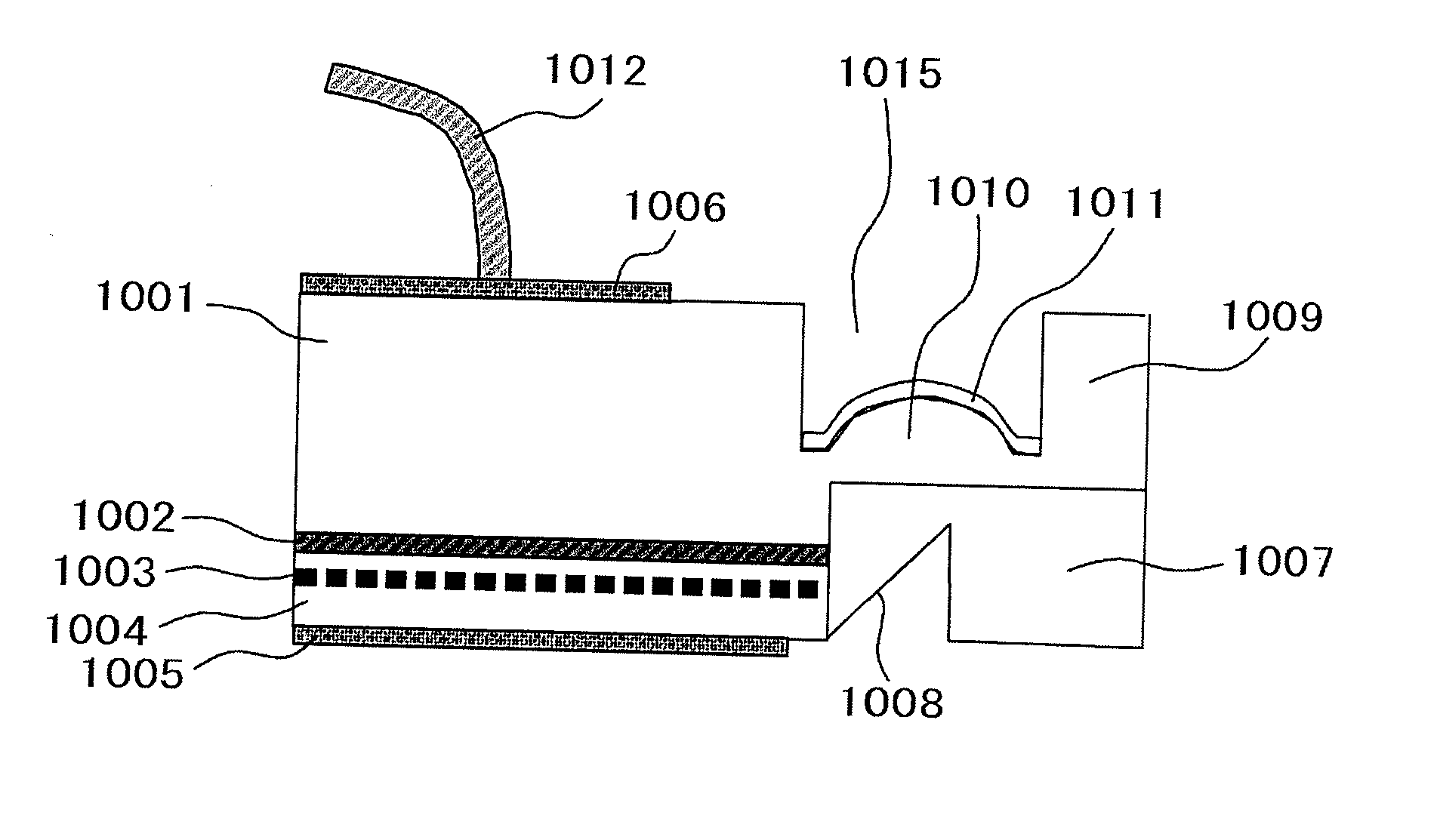

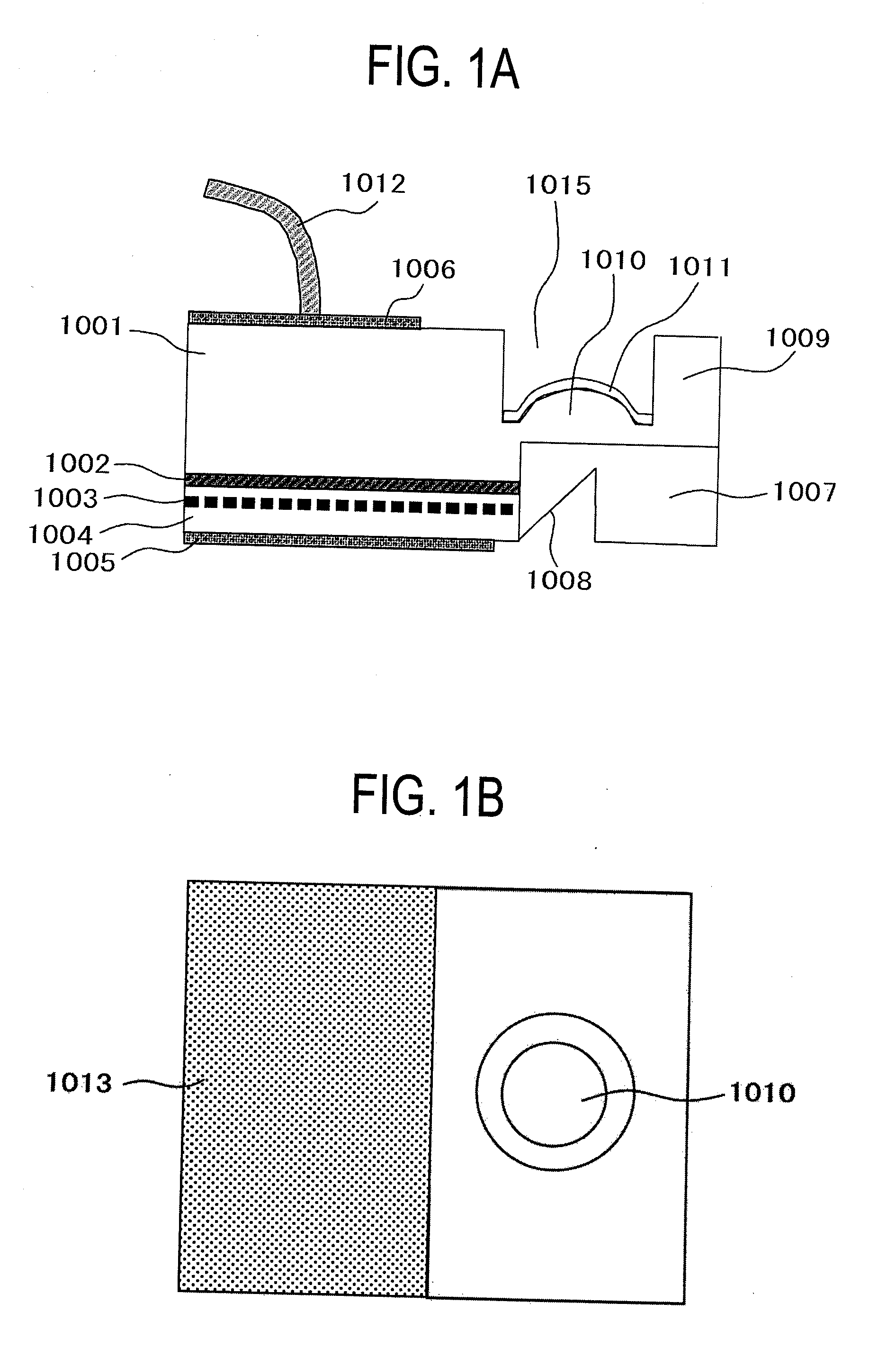

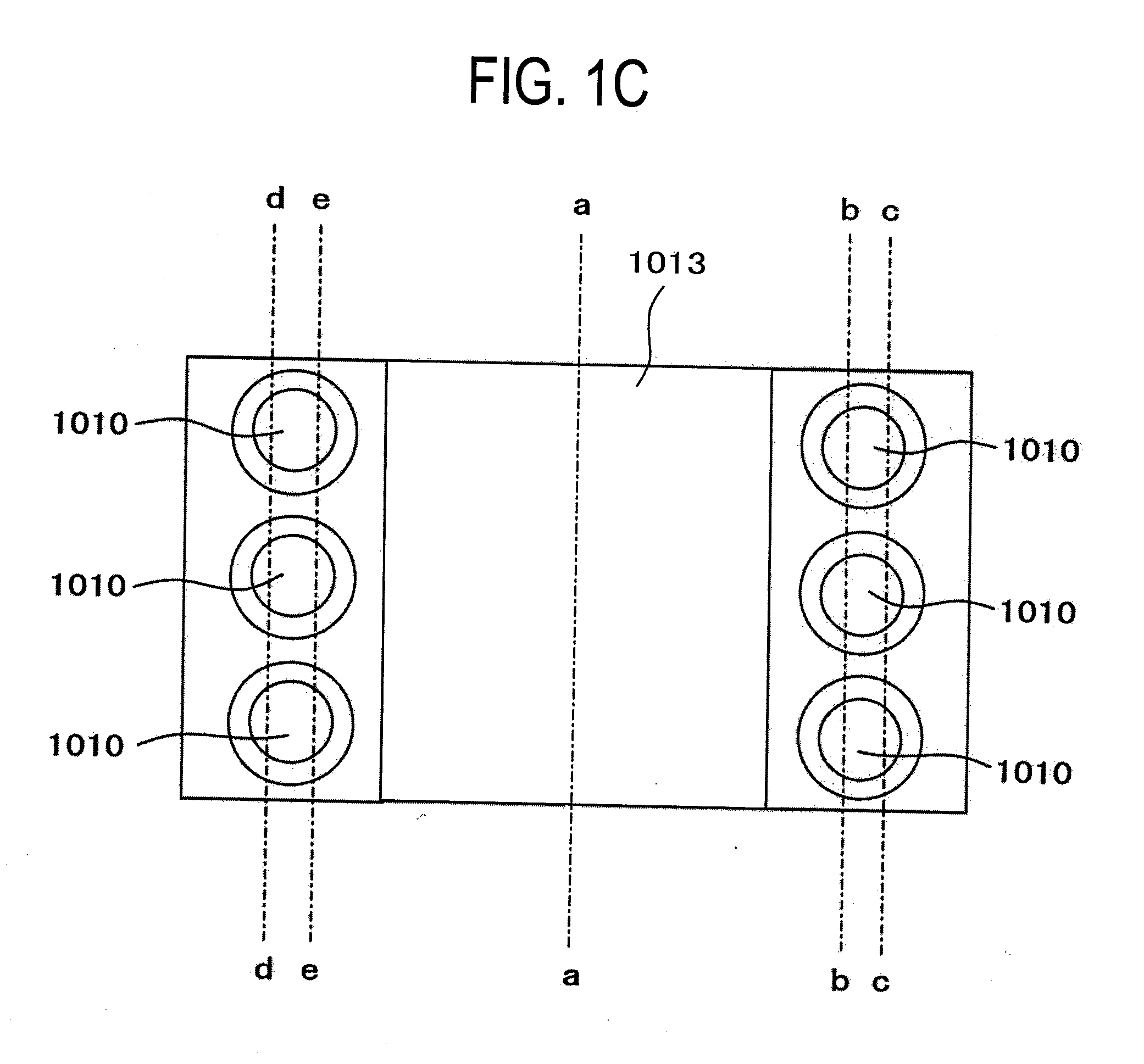

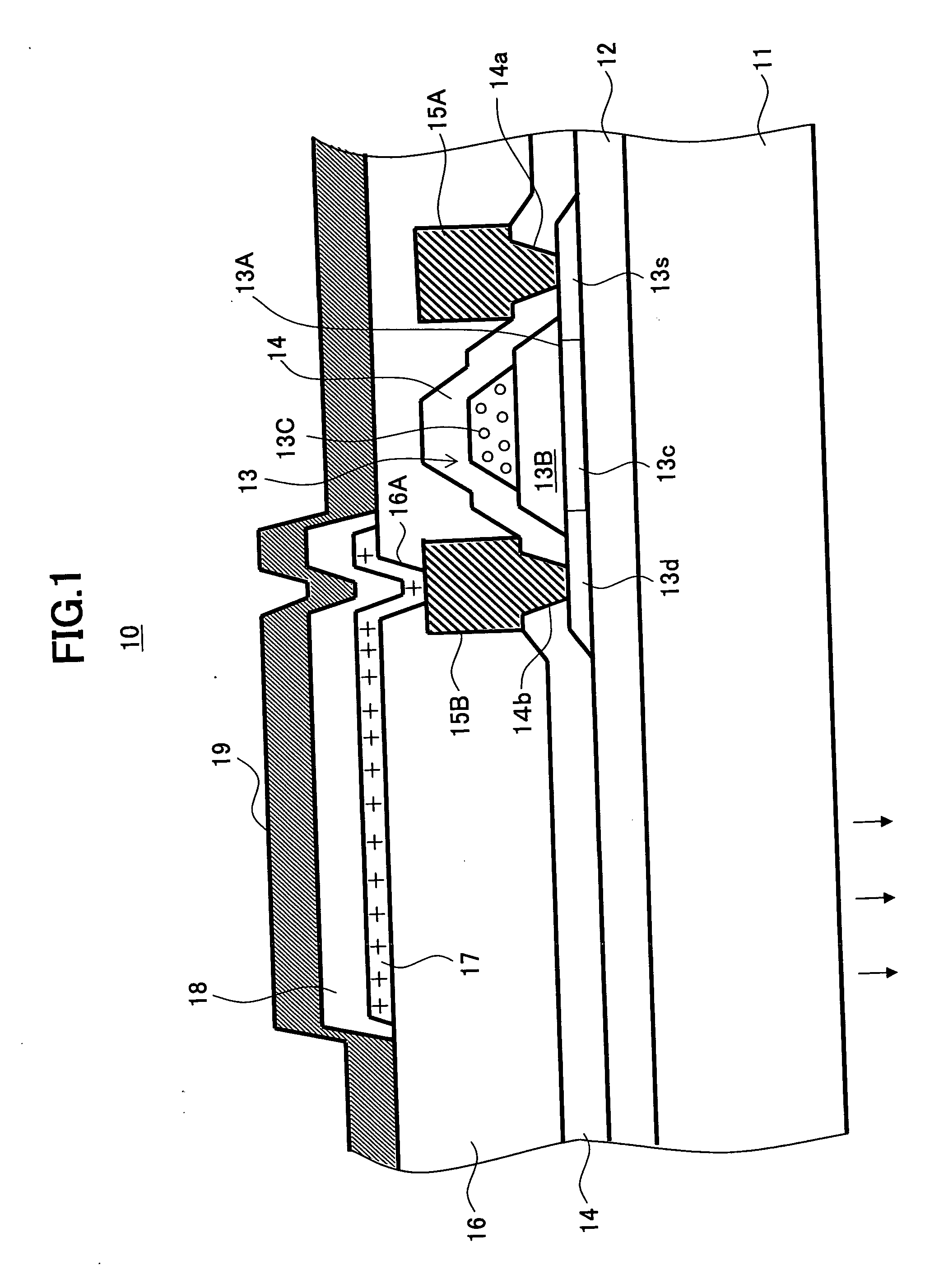

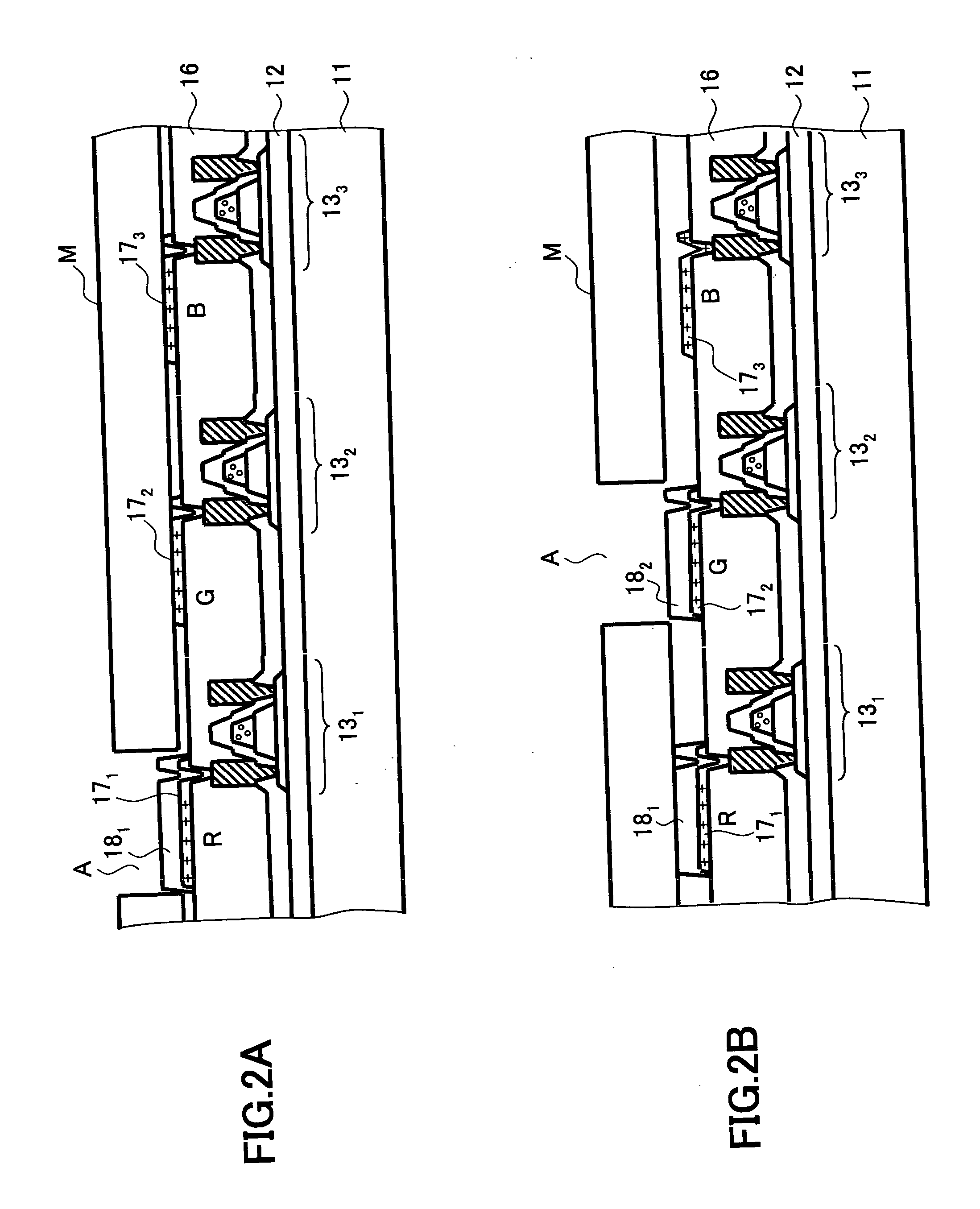

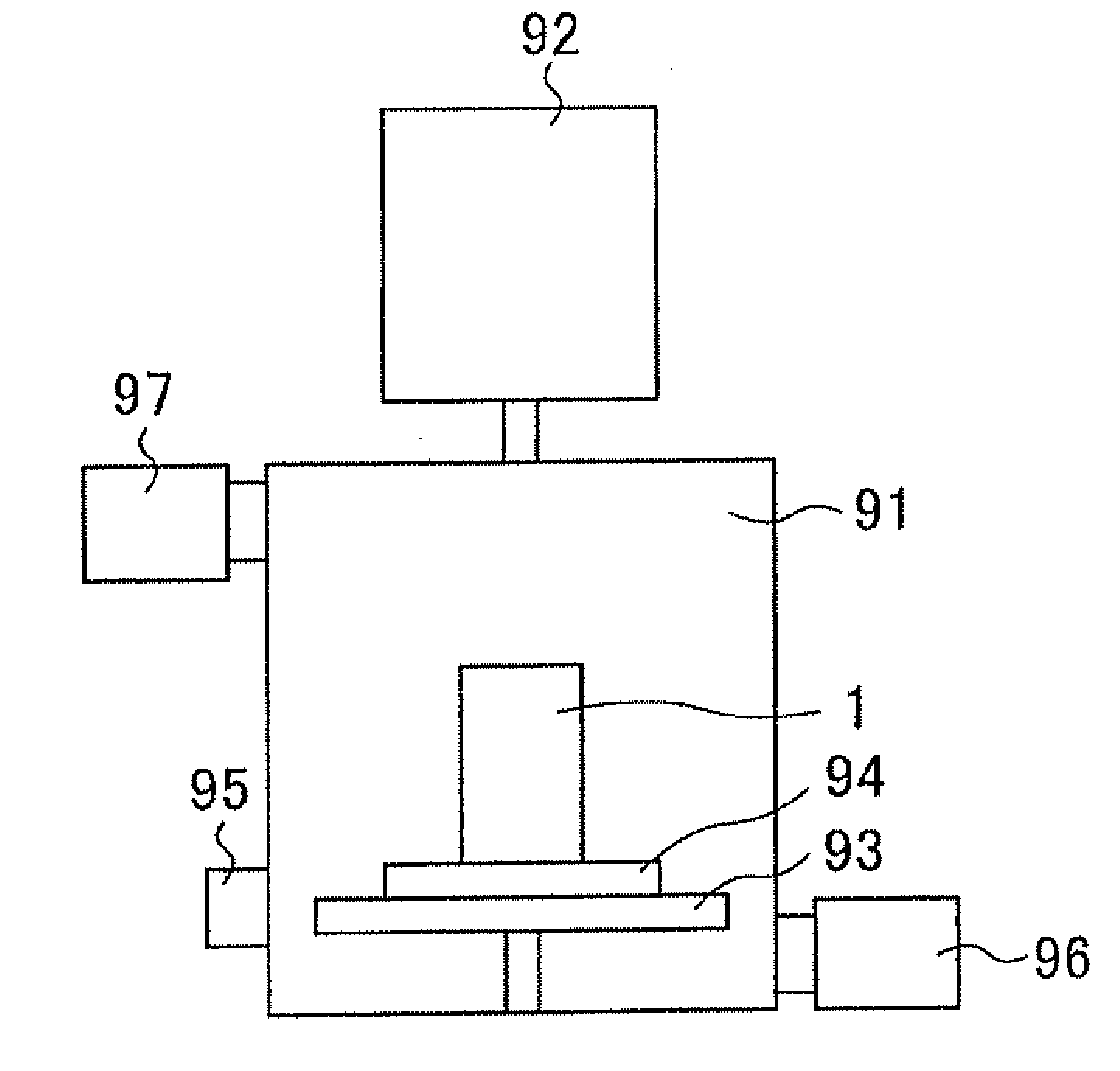

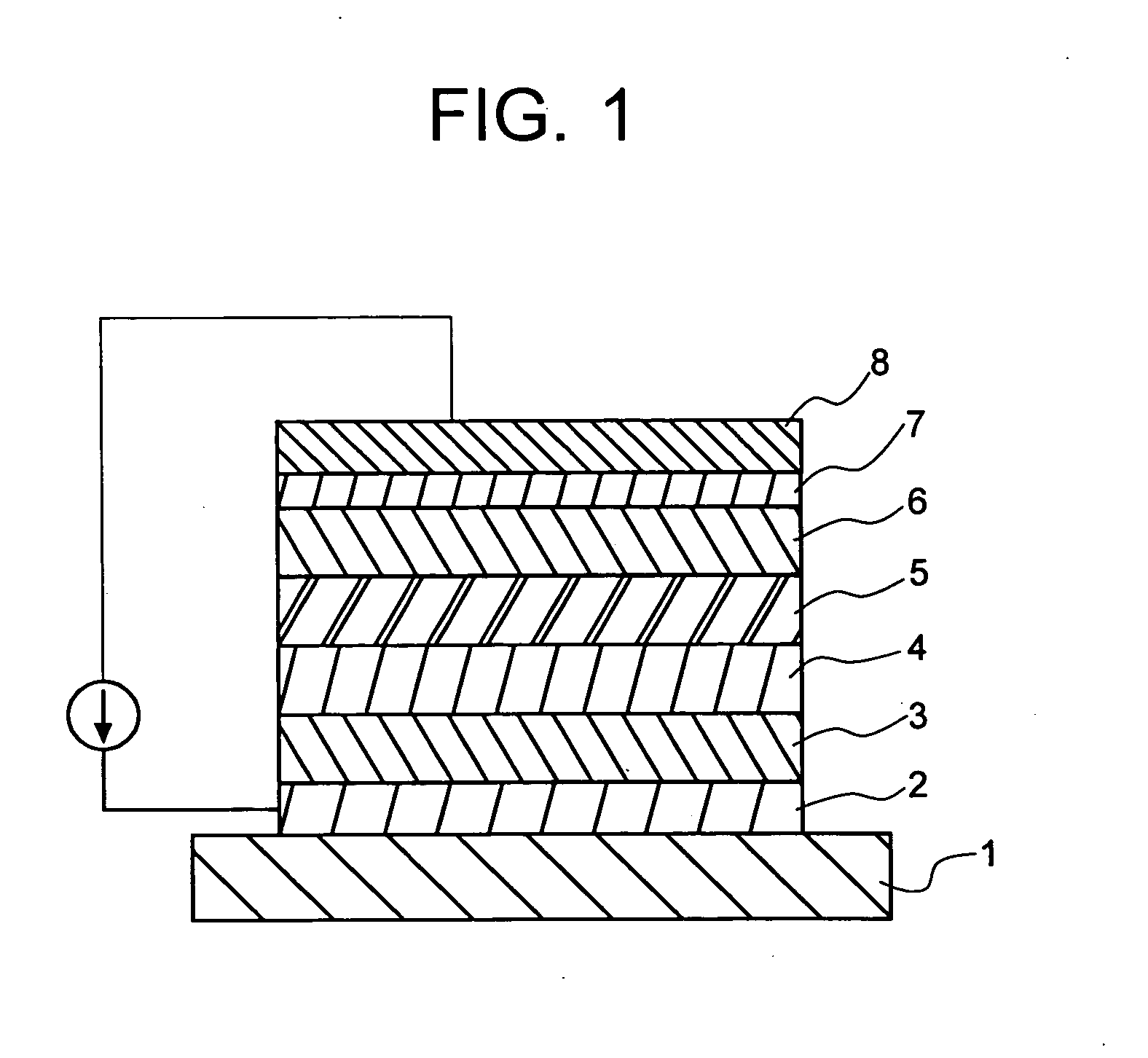

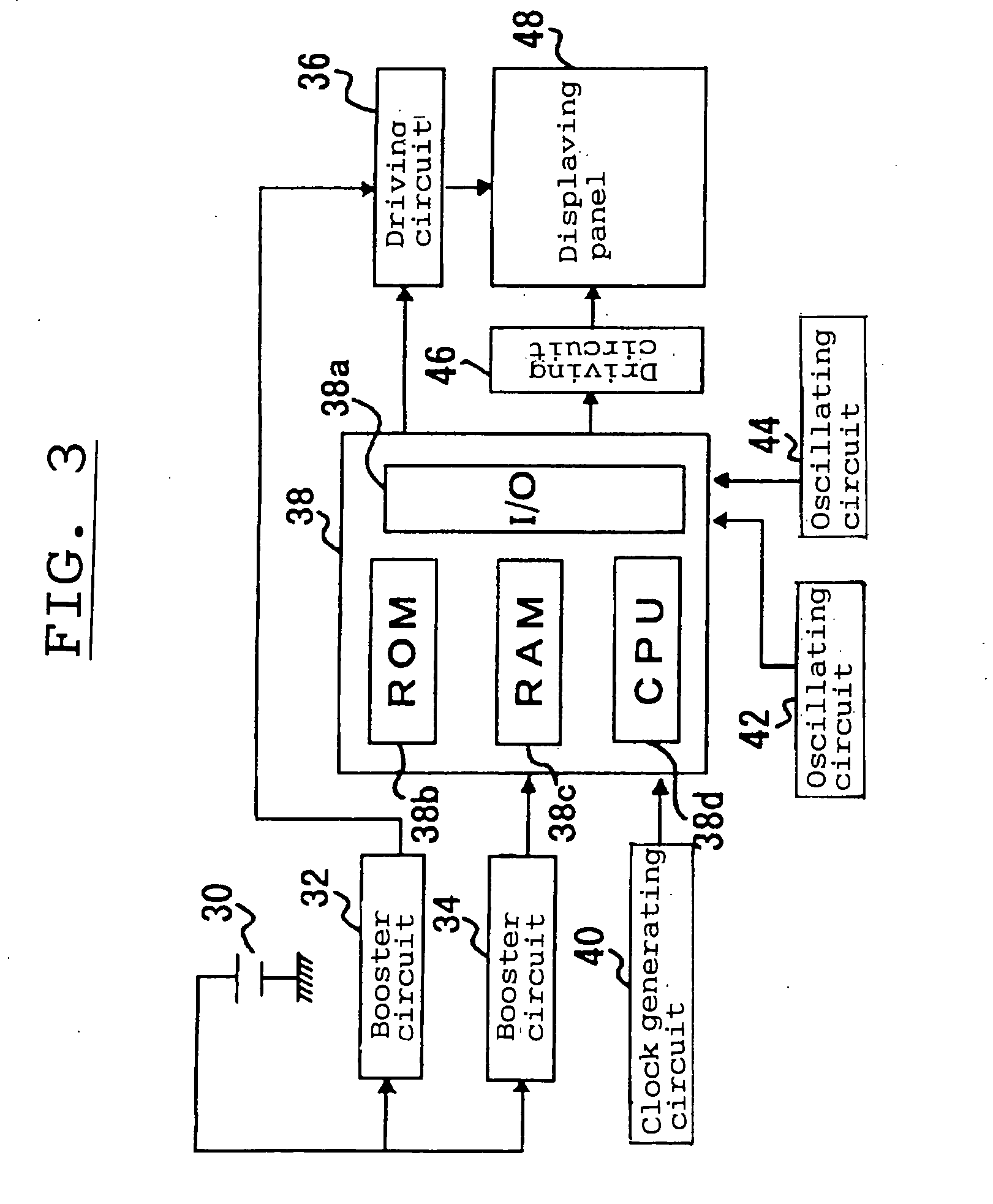

Horizontal cavity surface emitting laser diodes, vertical illuminated photodiodes, and methods of their fabrication

InactiveUS20120183009A1Satisfactory yieldReduce manufacturing costLaser optical resonator constructionSolid-state devicesWaveguidePhotodiode

The horizontal cavity surface emitting laser includes a cavity structure portion including a stacked structure of a first conduction type clad layer, an active layer and a second conduction type clad layer stacked over a semiconductor substrate and causing light generated by the active layer to be reflected or resonated, an optical waveguide layer provided at part of the semiconductor substrate and guiding the light, a reflector provided in the optical waveguide layer, for reflecting the light and emitting the light from the back surface of the semiconductor substrate, and a condensing lens provided at the back surface thereof and focusing the reflected light. The back surface thereof has a groove provided with the condensing lens and a terrace-like portion disposed below the cavity structure portion and has a terrace shape with the cleavage direction along a longitudinal direction thereof provided along a cleavage direction of the semiconductor substrate.

Owner:HITACHI LTD

Perylene derivative synthesis process, perylene derivative and organic EL device

InactiveUS20030137241A1Satisfactory yieldImprove production efficiencyDischarge tube luminescnet screensCarboxylic acid nitrile preparationPerylene derivativesPhotochemistry

Owner:FUTABA CORPORATION

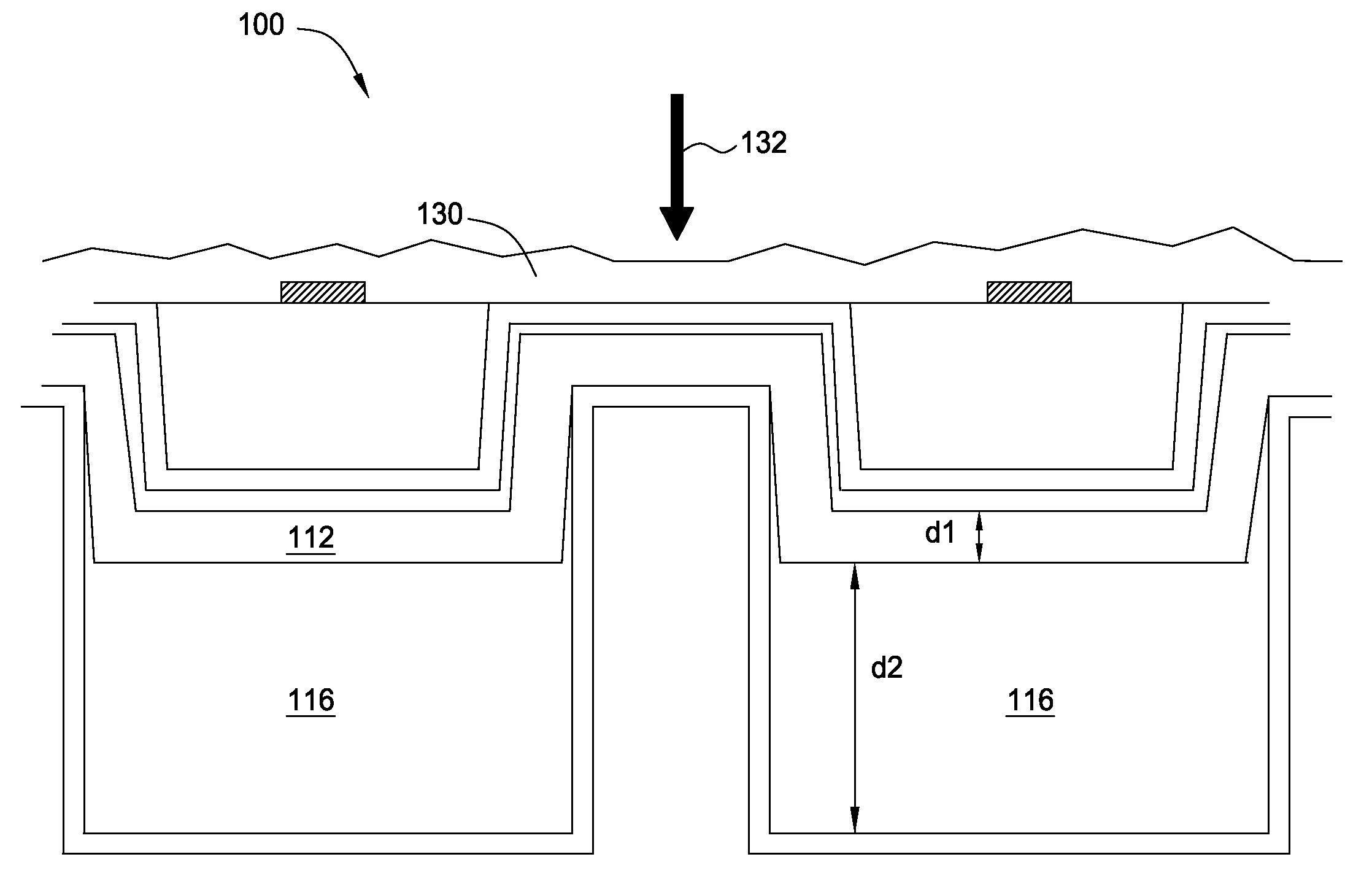

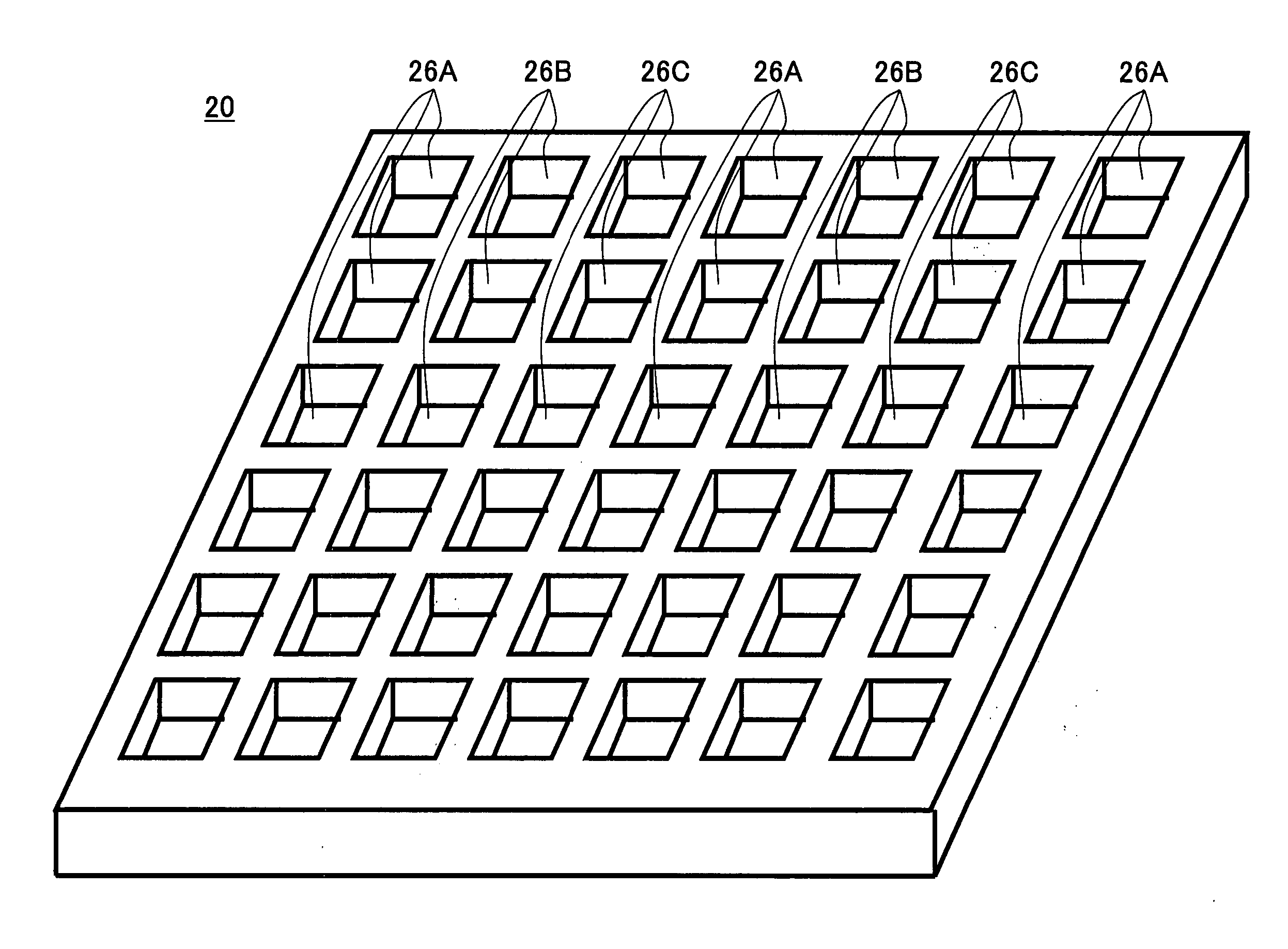

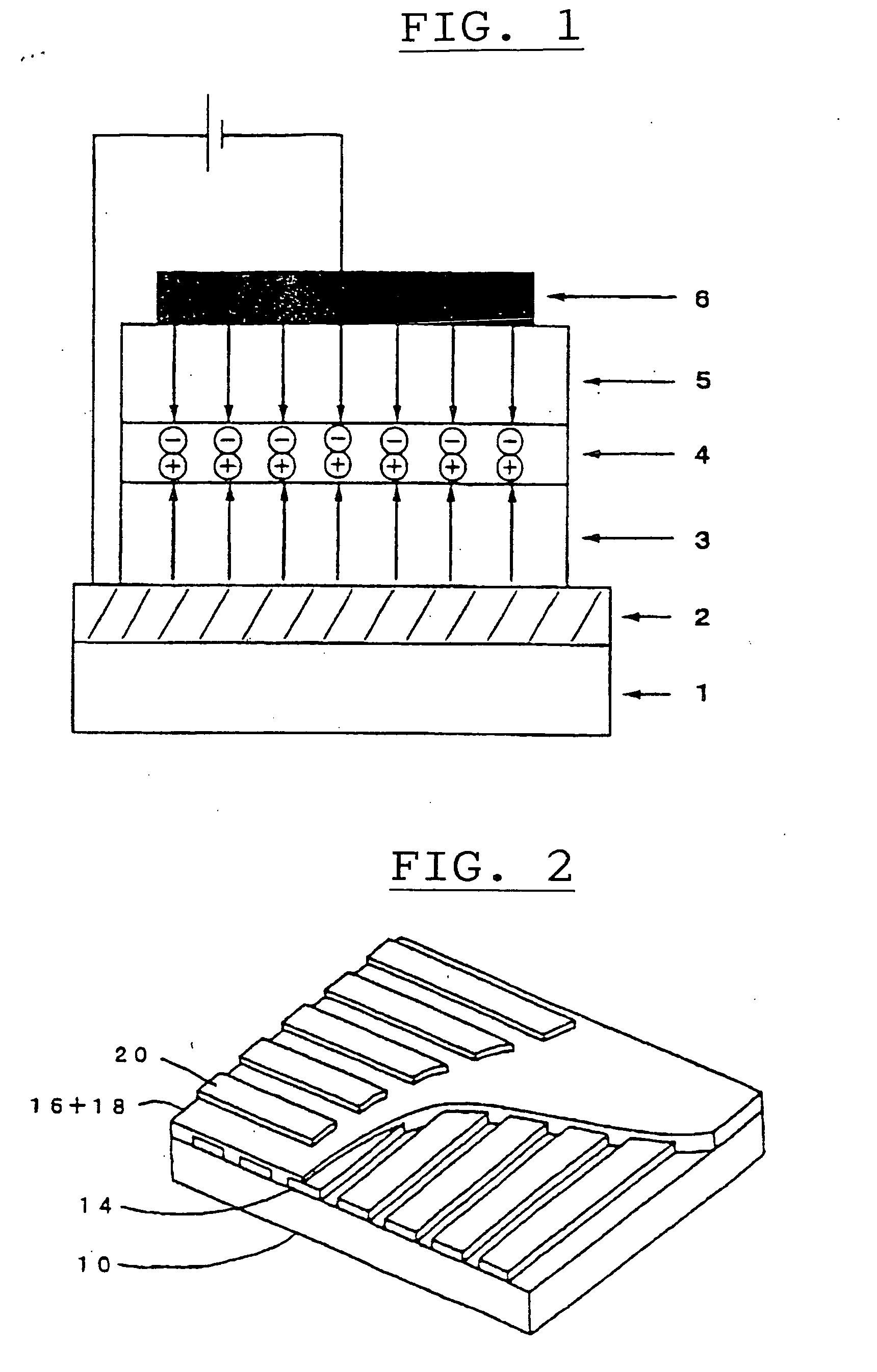

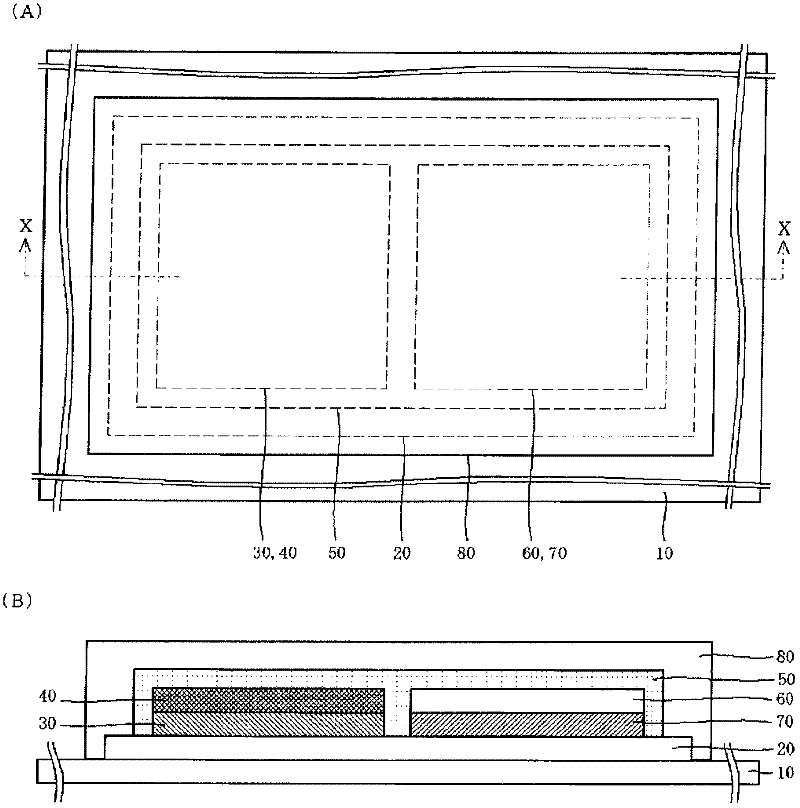

Organic electroluminescence display apparatus

InactiveUS20050162080A1Increase productionAvoid contactDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringOrganic electroluminescence

An organic EL display apparatus is disclosed that includes a substrate, a thin film transistor formed on the substrate, an insulation film formed on the substrate in a manner covering the thin film transistor, and an organic EL element formed on the insulation film. The insulation film is formed with a recess portion. The organic EL element is formed in a manner contacting the thin film transistor via the recess portion formed in the insulation film.

Owner:UDC IRELAND +1

Method for increasing crop yield

InactiveUS20120096912A1Increase productionEliminating and reducing useBiocideAmmonium nitratesAmmonium sulfateNutrient

The method for increasing yield of crop plants uses foliar application to the plants during the plant growth stage of a granular fertilizer consisting essentially of urea, ammonium sulfate and a fertilizer stabilizing agent. The stabilizing agent regulates and slows down decomposition nitrogen in urea and / or ammonium sulfate to maximize use thereof. The granular fertilizer has a urea / ammonium sulfate weight ratio of about 4 / 1 and contains at least 40% nitrogen and at least 4% sulfur. The relatively high N—S fertilizer is applied at relatively high rates of about 100 to 150 pounds per acre to ensure that the fertilizer nutrients are always available to the plants at several stages of growth.

Owner:RIZZO JOHN M

Process for the manufacture of a starch hydrolysate with high dextrose content

InactiveUS6126754AAccelerates hydrolysis reactionReduce in quantityPurification using adsorption agentsOrganic compound preparationHydrolysateD-Glucose

The invention concerns a process for the manufacture of a starch hydrolysate with high dextrose content comprising the stages of: (a) liquefying starch milk with the aid of an alpha -amylase so as to obtain a liquefied starch milk; (b) saccharifying the liquefied starch milk, with the aid of a glucogenic enzyme, to obtain a raw saccharified hydrolysate; (c) separating the raw saccharified hydrolysate by nanofiltration over membranes so as to collect a nanofiltration permeate constituting said starch hydrolysate with high dextrose content and a nanofiltration retentate.

Owner:ROQUETTE FRERES SA

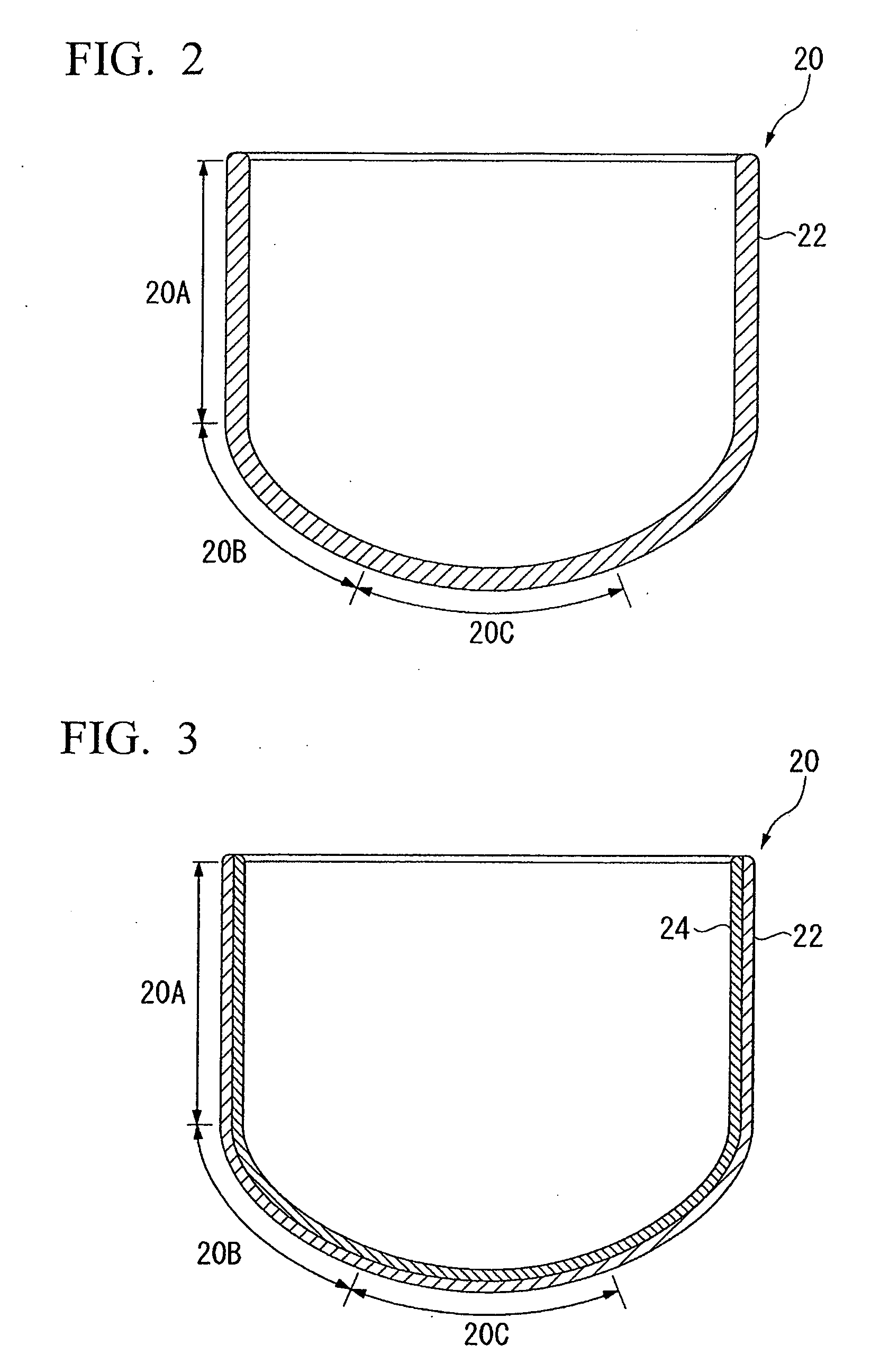

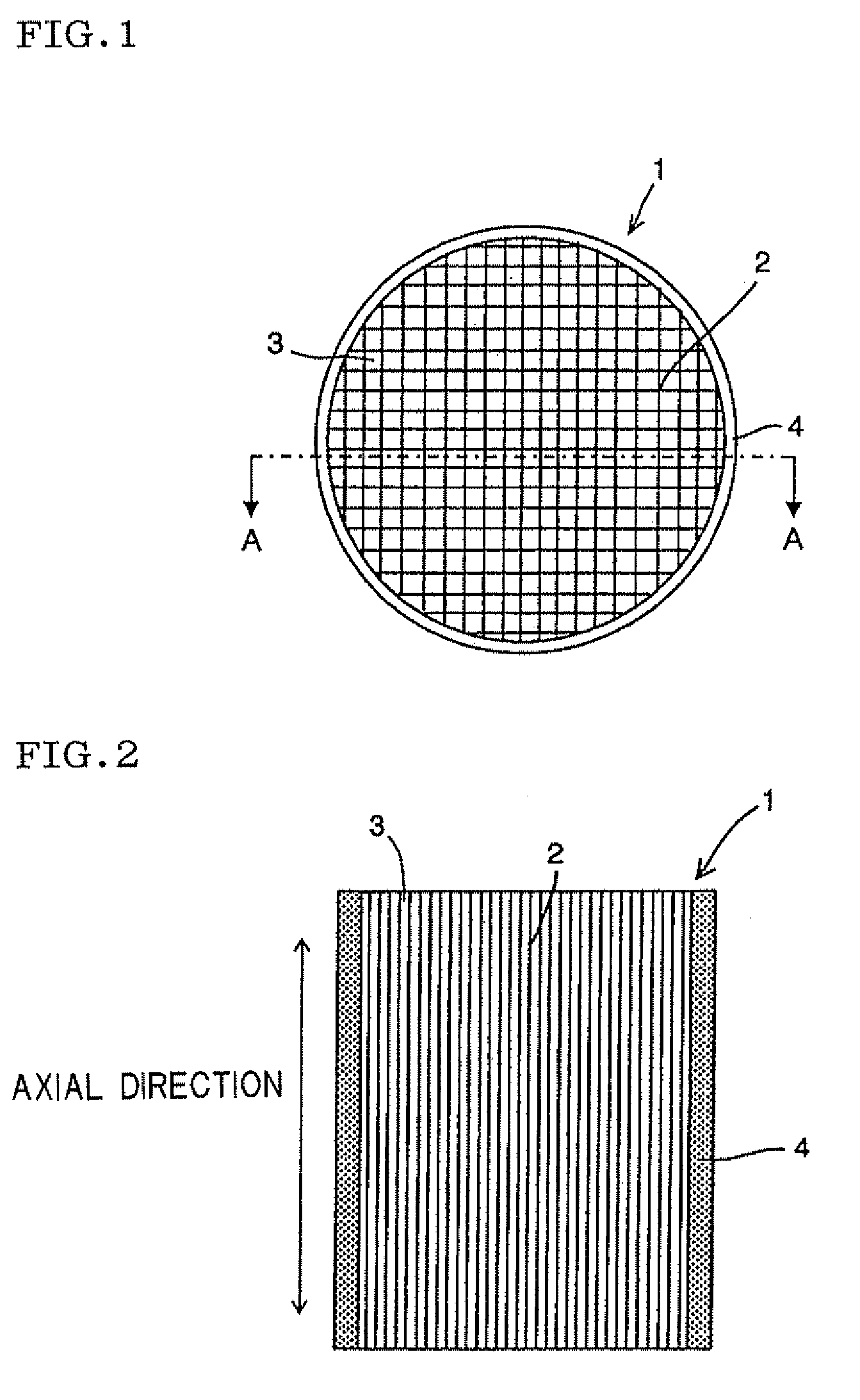

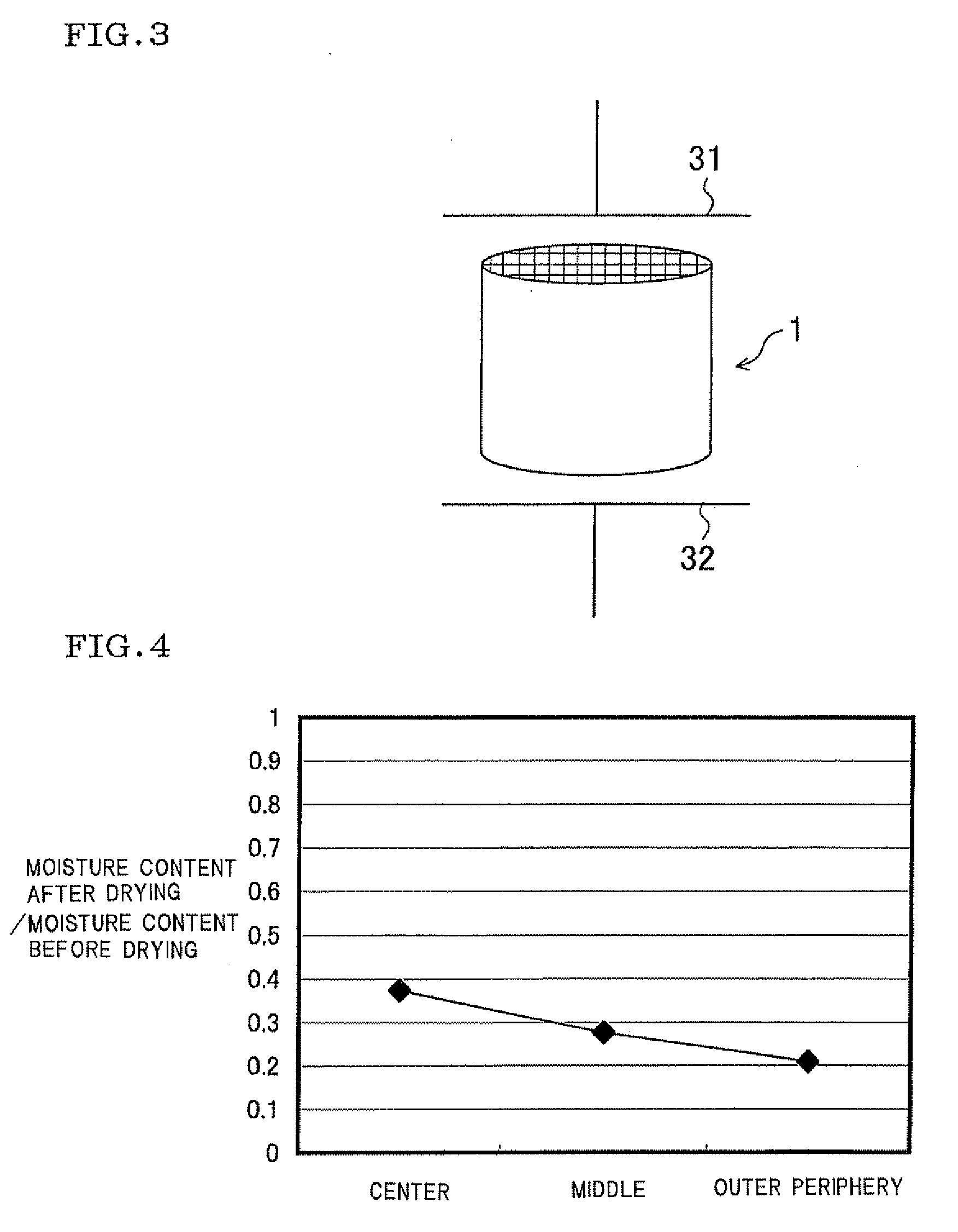

Drying method of formed ceramic article

InactiveUS20090235552A1High qualityHigh yieldDrying using combination processesCeramic shaping apparatusMicrowaveMetallurgy

There is disclosed formed ceramic article drying means capable of evenly and uniformly drying even a large formed ceramic article containing much moisture as a drying target for a short time without causing any crack or deformation, to efficiently obtain a dry formed ceramic article having a high quality with a satisfactory yield. There is provided a drying method of a formed ceramic article including the steps of subjecting an unfired formed ceramic article formed of a ceramic material as a main material to dielectric drying and then microwave drying.

Owner:NGK INSULATORS LTD

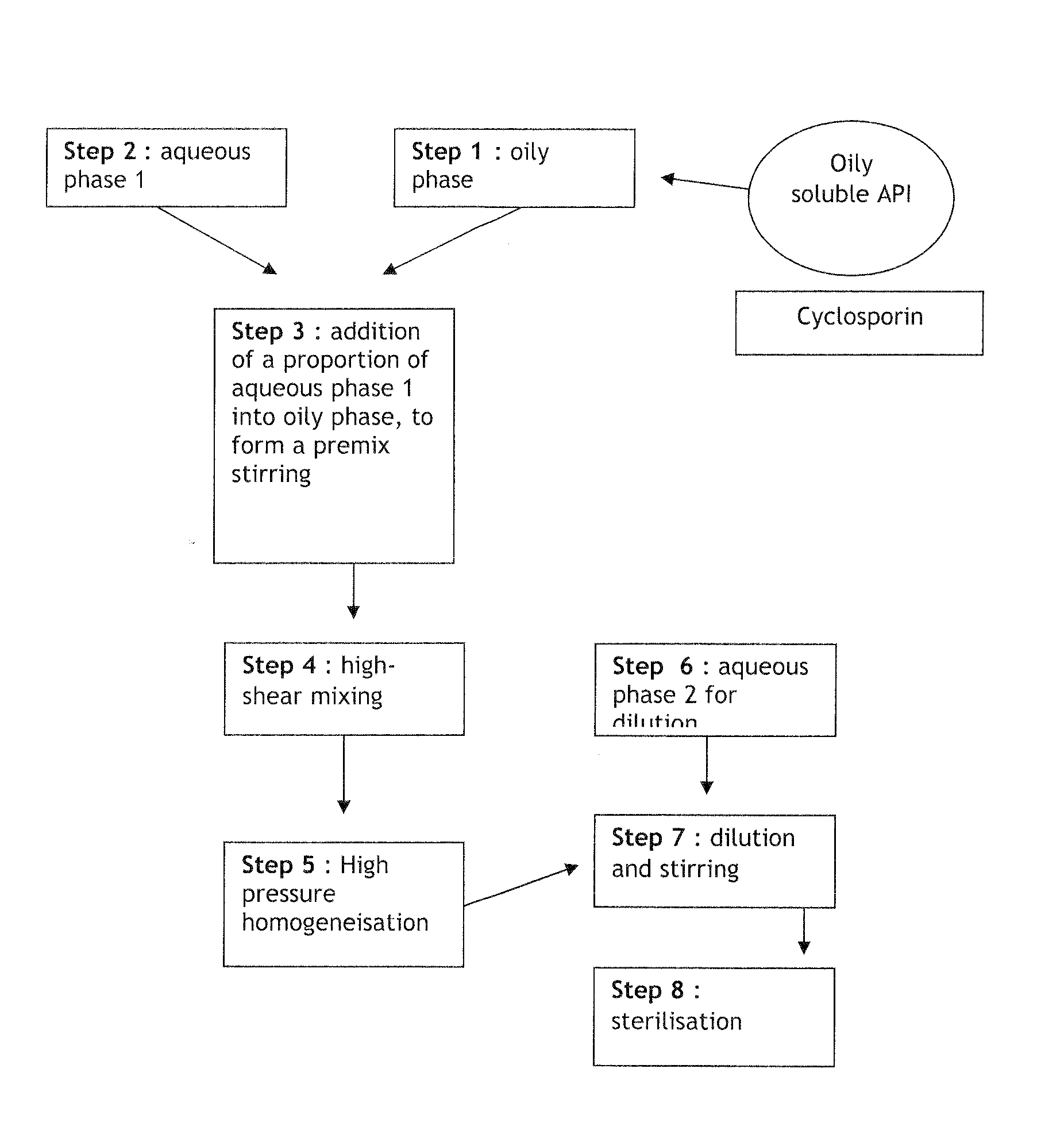

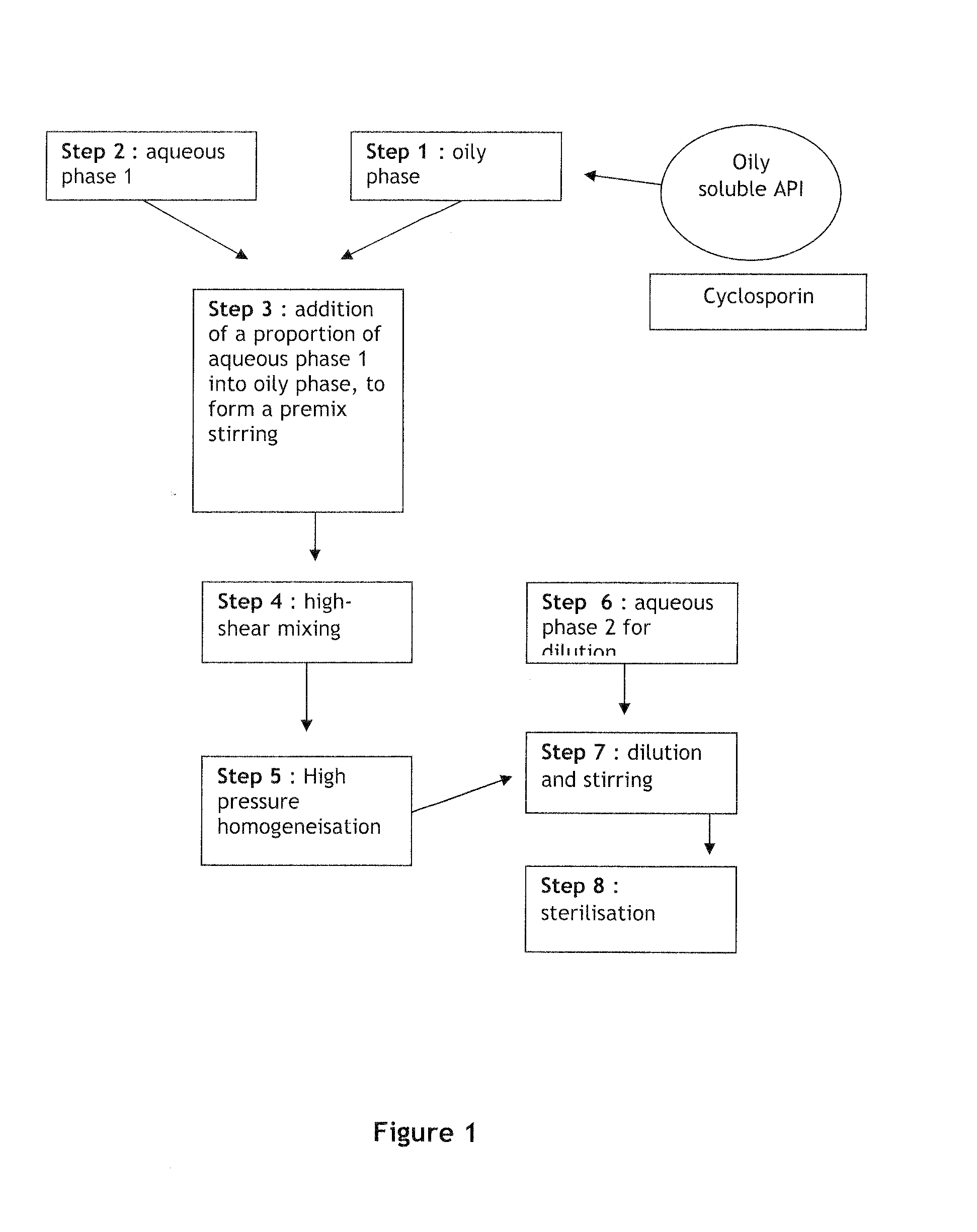

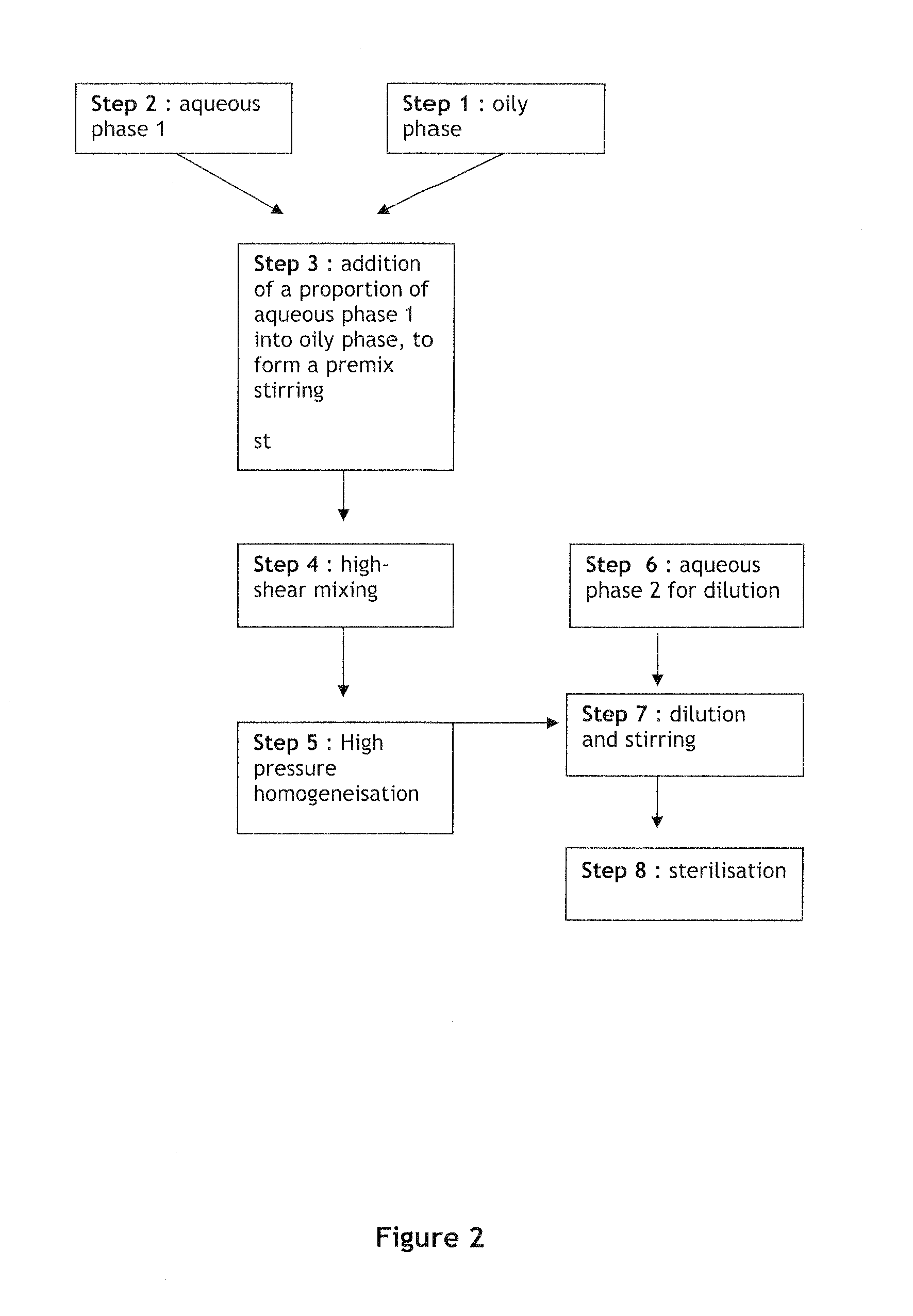

Process for manufacturing ophthalmic oil-in-water emulsions

ActiveUS20080181867A1Limited amount of energySatisfactory yieldOrganic active ingredientsSenses disorderMedicineOil in water

The present invention relates to new processes for the preparation of oil-in-water emulsions useful in ophthalmic applications. In particular, processes are provided that include preparing a pre-concentrate of the oil-in-water emulsion, and diluting the pre-concentrate obtained to form the desired oil-in-water emulsion. The present invention also provides pharmaceutical compositions comprising an oil-in-water emulsion prepared by an inventive process, and methods of using these compositions for the treatment of an eye disease or condition.

Owner:SANTEN SAS

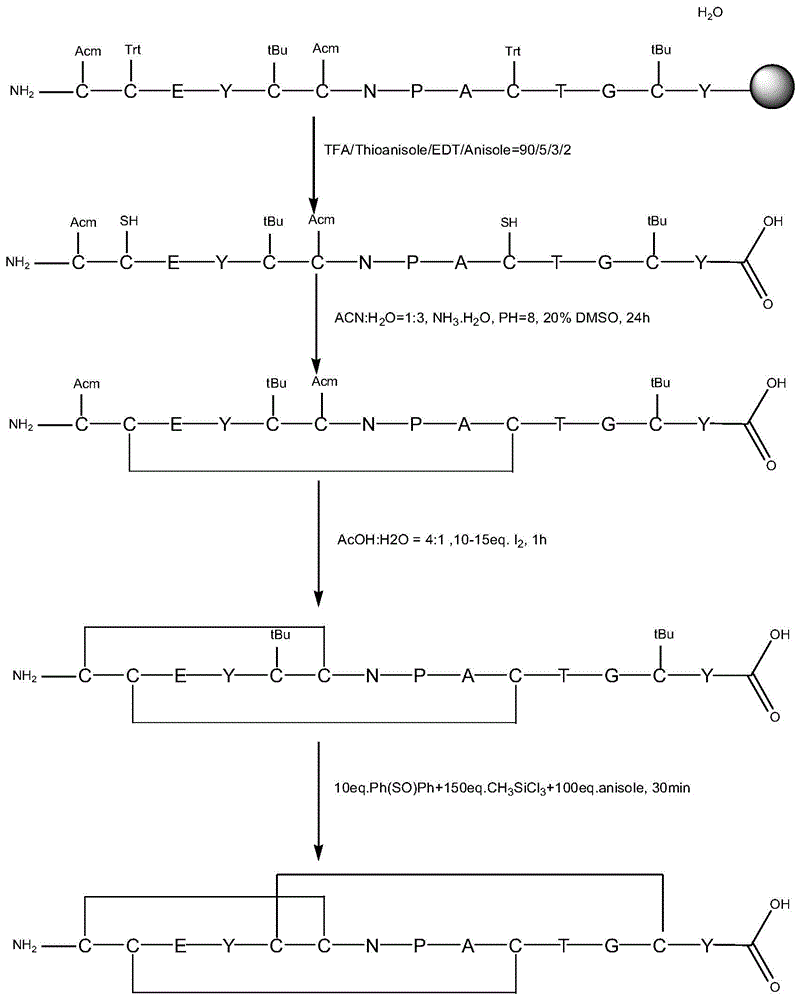

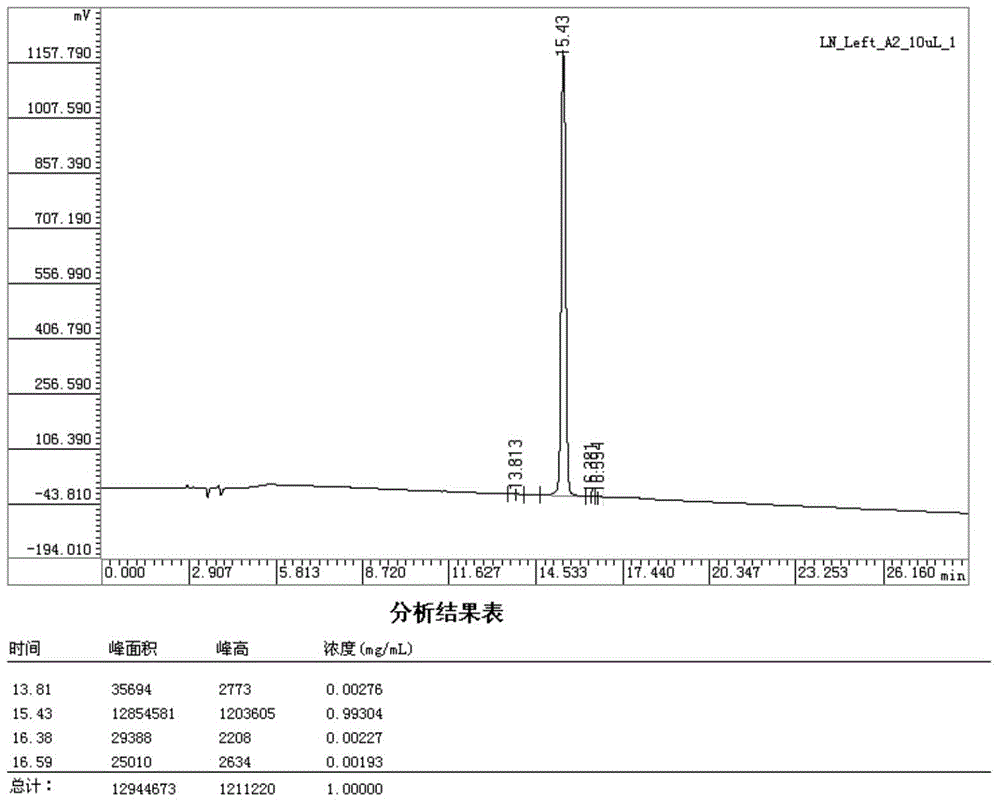

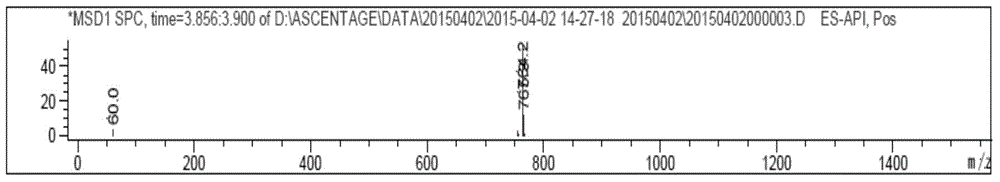

Linaclotide solid-phase synthesis method

InactiveCN104974229AGood effectPrecise positioningPeptide preparation methodsBulk chemical productionFreeze-dryingSolid-phase synthesis

The invention discloses a linaclotide solid-phase synthesis method, and belongs to the biochemical technical field. The method includes the following steps: (1) preparation of linaclotide resin; (2) cutting the linaclotide linear peptide resin obtained in the step (1), to obtain a protection group linear peptide containing Cys(Acm) and Cys(tBu); (3) oxidizing to form a first disulfide bond, to obtain a monodisulfide cyclopeptide; (4) removing an Acm protection group in the monodisulfide cyclopeptide, to obtain a dual disulfide cyclopeptide; (5) removing a tBu protection group of the dual disulfide cyclopeptide, to obtain a trisdisulfide cyclopeptide; and (6) purifying the trisdisulfide cyclopeptide by HPLC, and freeze-drying to obtain linaclotide. The process has the characteristics of simple reaction operation, easy post-processing, low cost, high yield, and considerable economic and practical values, and besides, has wide application prospect in the polypeptide drug design and synthesis field.

Owner:NANTONG SHIMEIKANG PHARMA CHEM

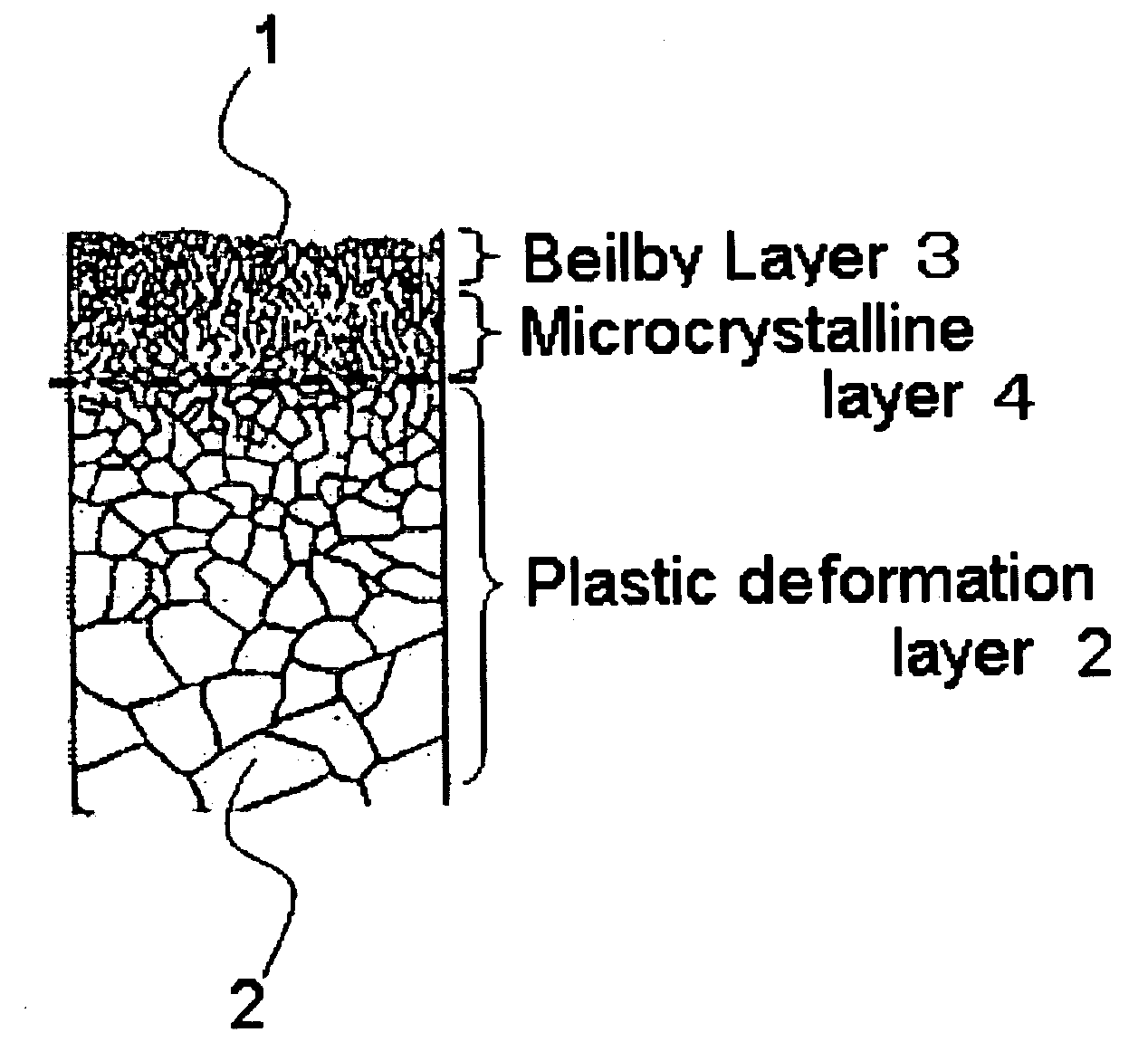

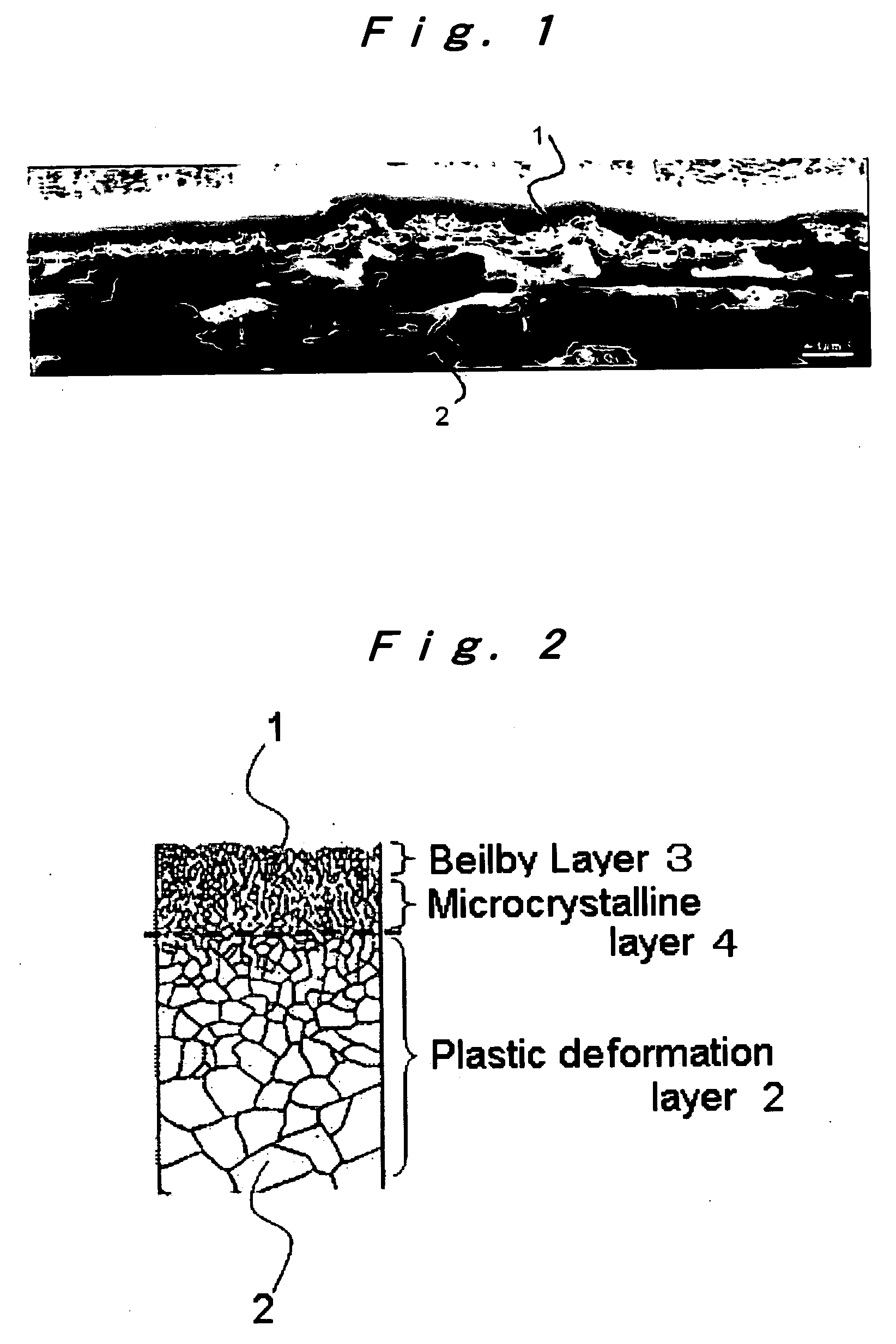

Copper alloy for electronic machinery and tools and method of producing the same

InactiveUS20070015001A1Improve PlatabilityReduce adhesionWave amplification devicesThermometers using material expansion/contactionSurface layerMetallurgy

A copper alloy for electronic machinery and tools, having a surface layer of a work affected layer whose thickness is 0.2 μm or below; and a method of producing the same.

Owner:FURUKAWA ELECTRIC CO LTD

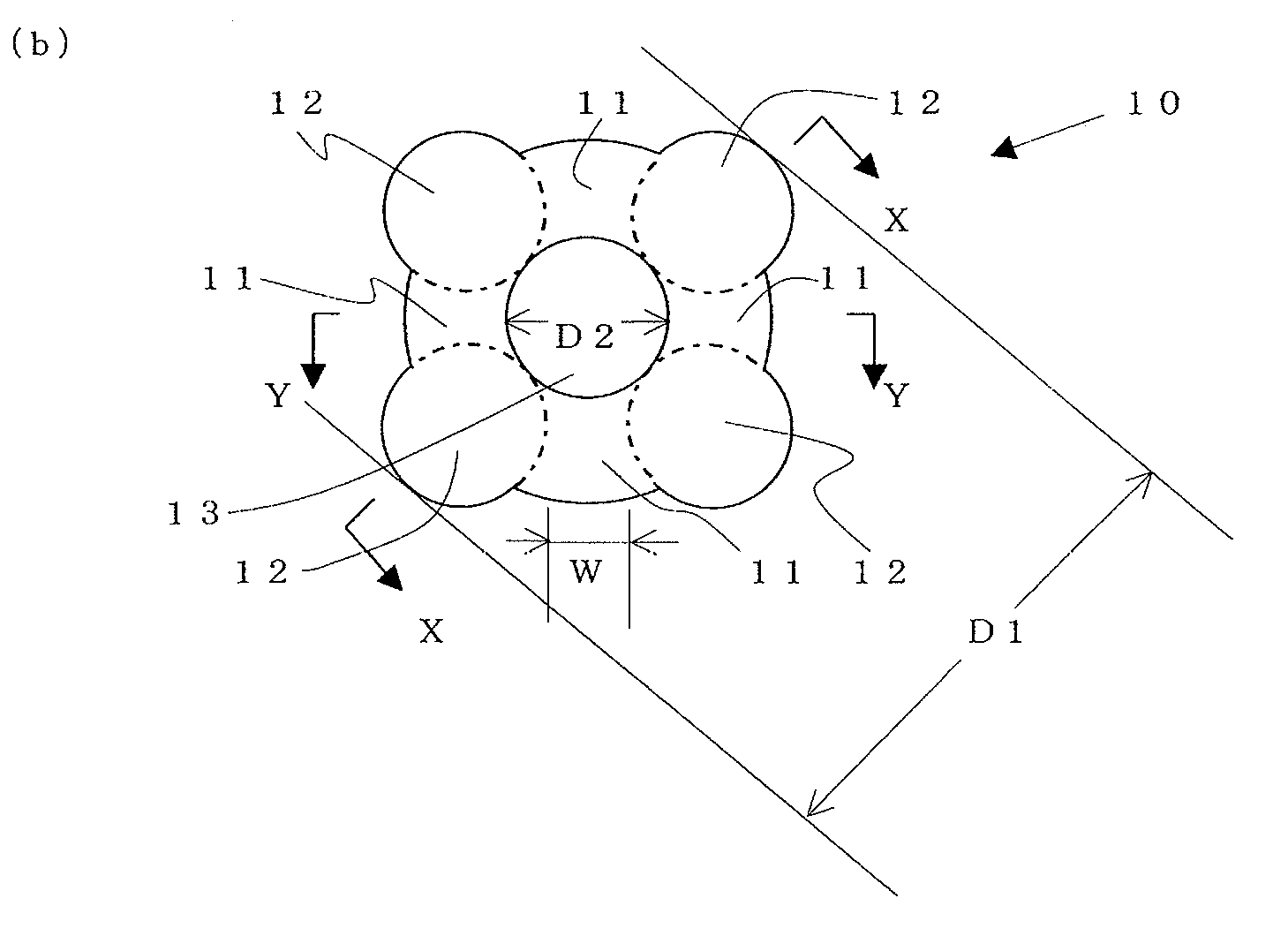

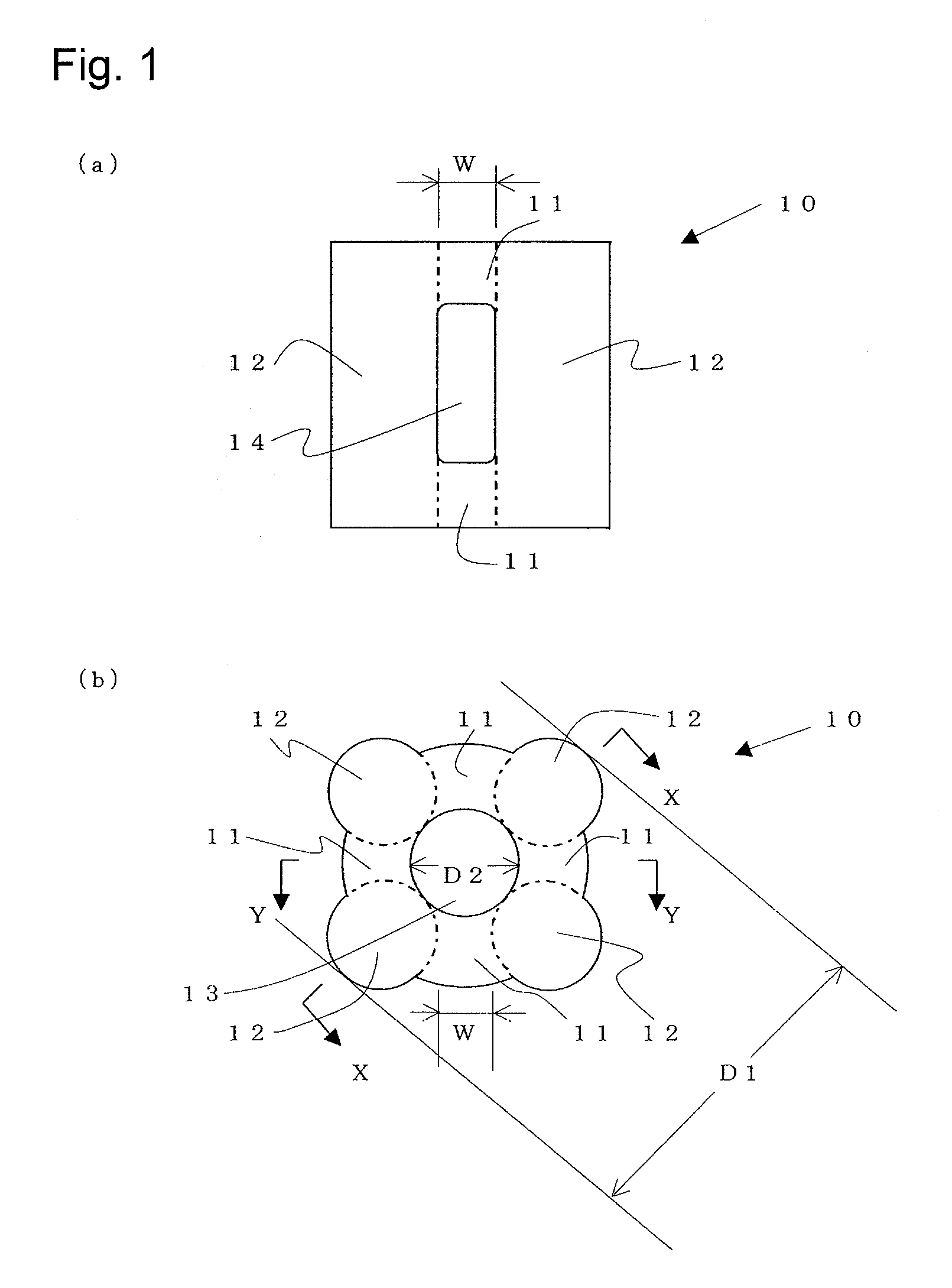

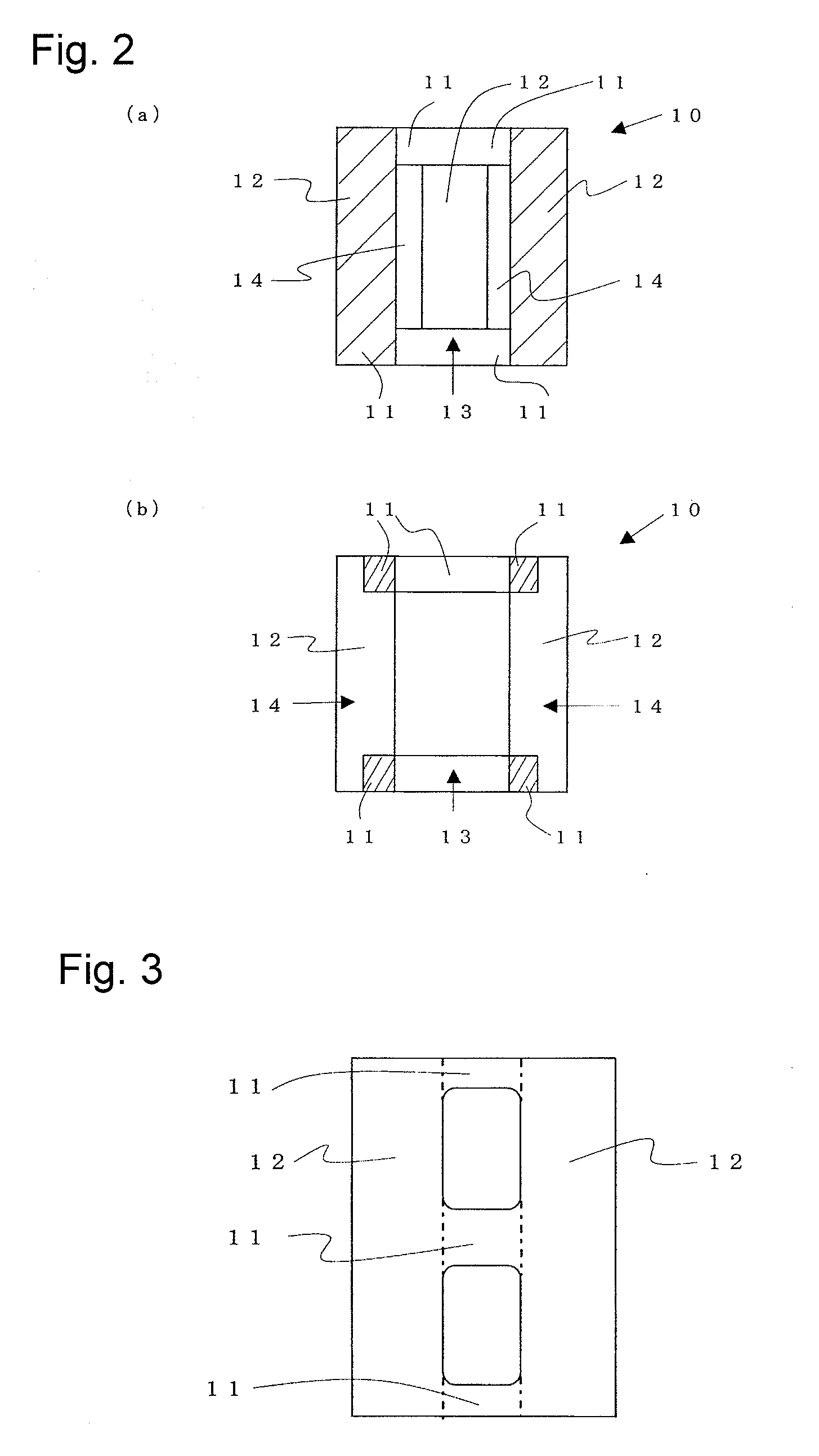

Molding and method for producing the same, and catalyst and method for producing the same

InactiveUS20100331571A1Minimized pressure dropEasy to provideGlass/slag layered productsThin material handlingPolymer sciencePtru catalyst

An object of the present invention is to provide a molding and a method for producing the same; a catalyst for the production of an unsaturated aldehyde and an unsaturated carboxylic acid, and a method for producing the same; and a catalyst for the production of methacrylic acid, and a method for producing the same.The molding of the present invention shows a shape including a plurality of columnar portions disposed with a predetermined gap; and bridge portions which are provided at both ends in longitudinal directions of two adjacent columnar portions and join adjacent columnar portions each other; and including through holes surrounded by a plurality of columnar portions in the longitudinal directions of the columnar portions, and openings formed on a peripheral surface by a gap between the plurality of adjacent columnar portions. This molding can be formed by using an extrusion molding machine including a first die which has a plurality of grooves on an outer peripheral surface, and a ring-shaped or cylindrical second die fitted in the first die which has a plurality of grooves on a peripheral surface, and repeatedly rotating and stopping at least one of the first and second dies.

Owner:SUMITOMO CHEM CO LTD

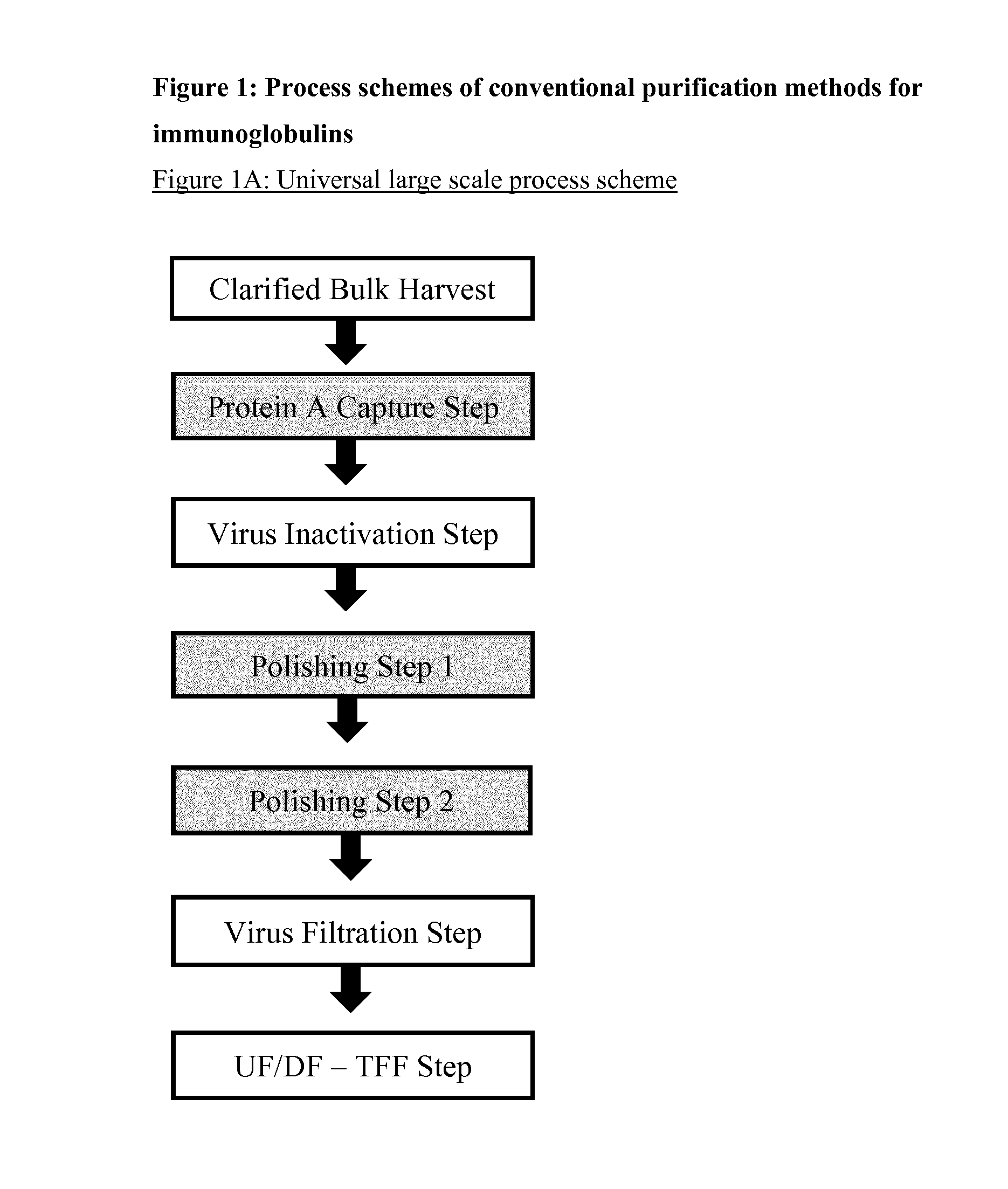

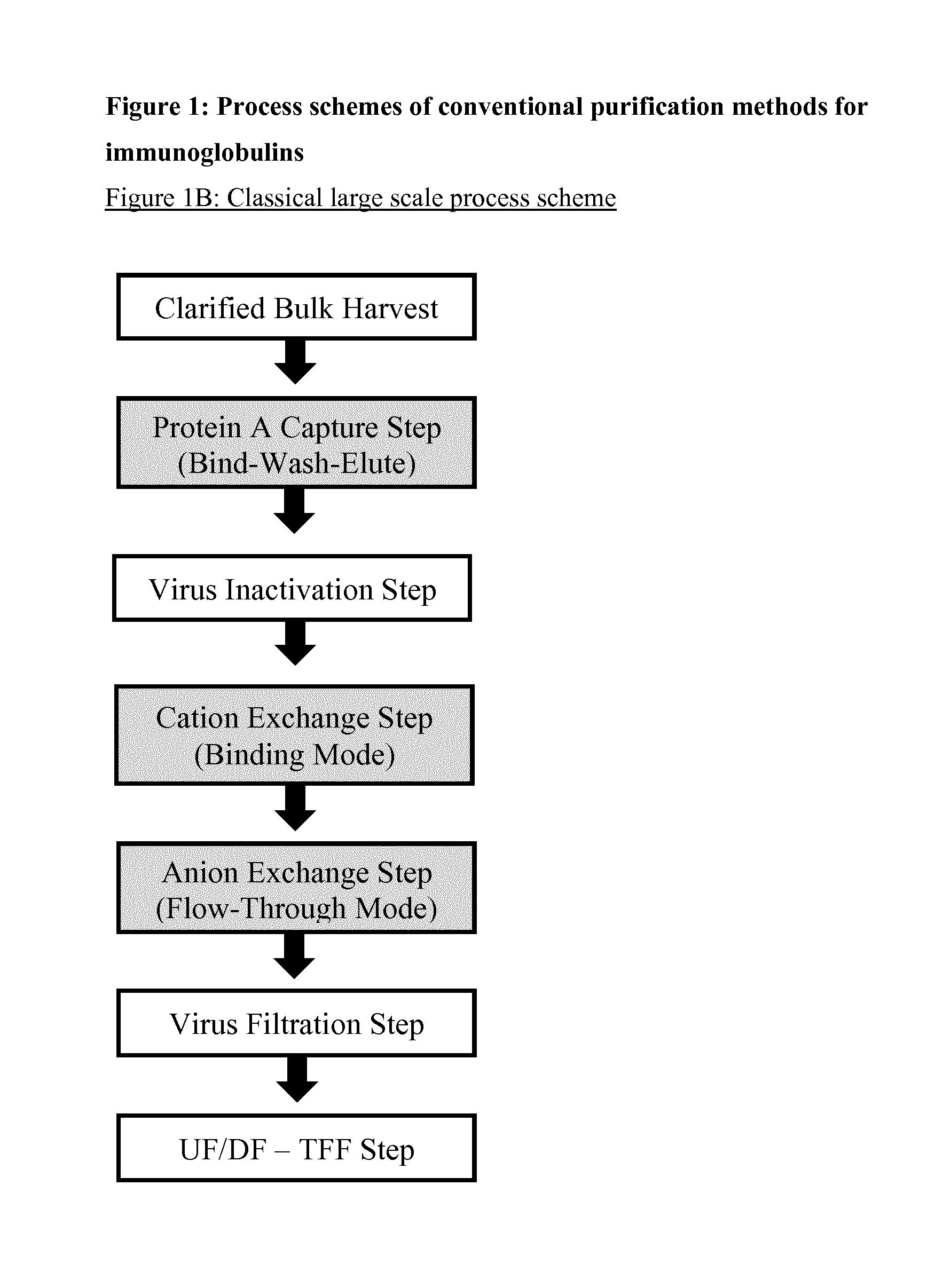

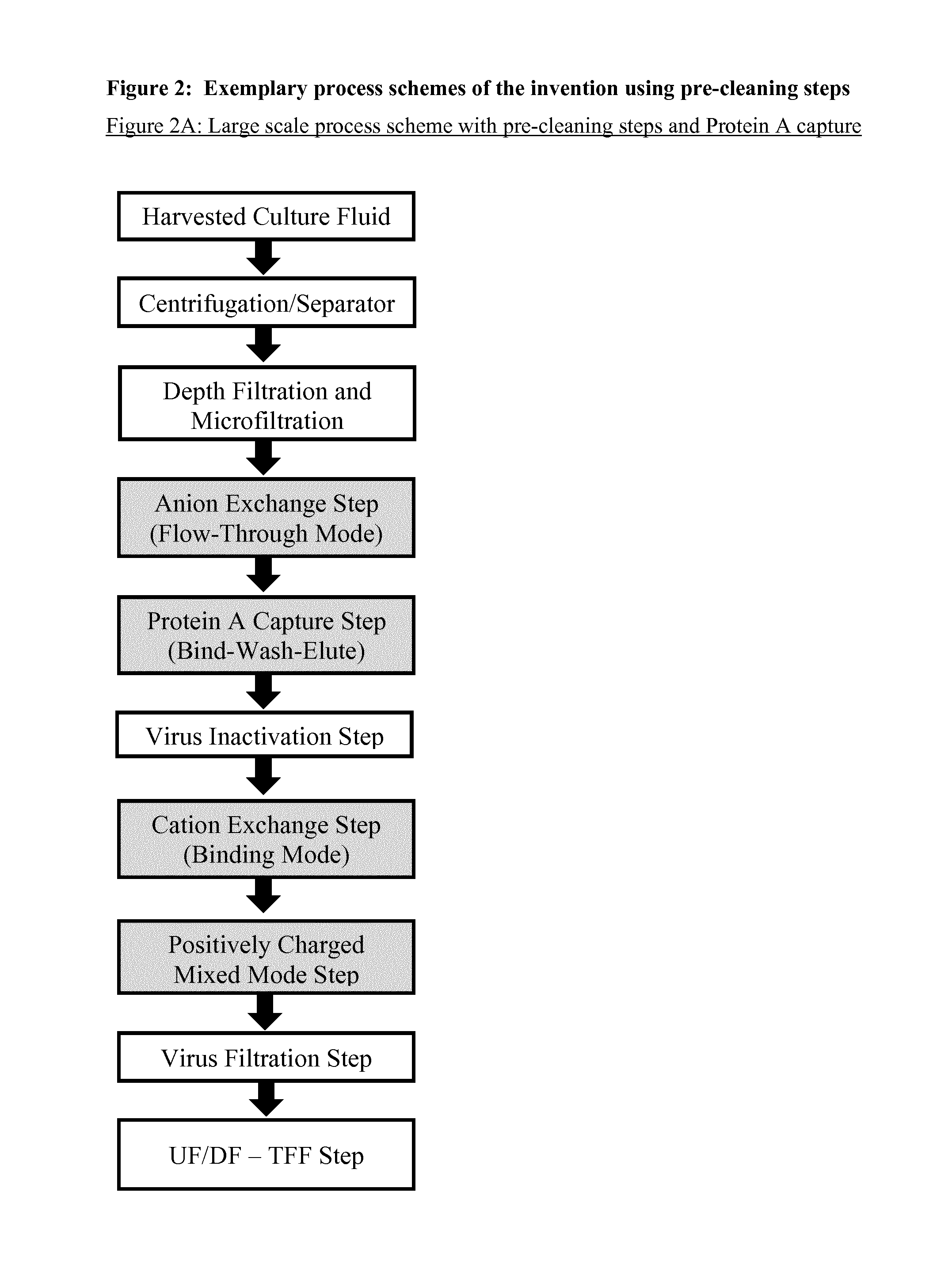

Immunoglobulin purification using pre-cleaning steps

ActiveUS20170058019A1Increasing viral safetyReducing technical complexity of purification processChromatographic cation exchangersSerum immunoglobulinsBiochemical engineeringIntravenous gammaglobulin

The present invention relates to the purification of immunoglobulins and the problem of providing a method for purifying an immunoglobulin in an efficient and cost-effective manner and with satisfactory purity and yield. In particular, the present invention addresses the aspect of the re-use of the rather cost-intensive chromatography materials, in particular the lifetime of the chromatography materials used in the capture step of the downstream process, and how this can be increased while reducing the technical complexity of the purification process.

Owner:RICHTER GEDEON NYRT

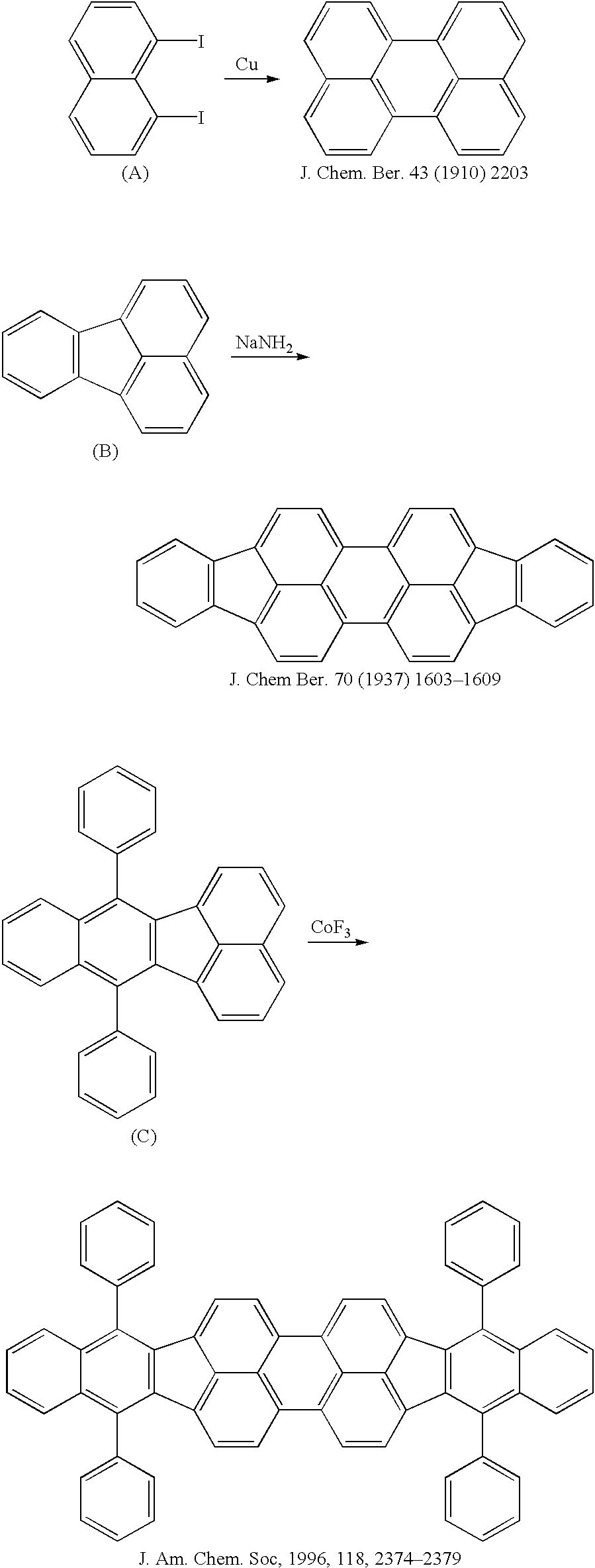

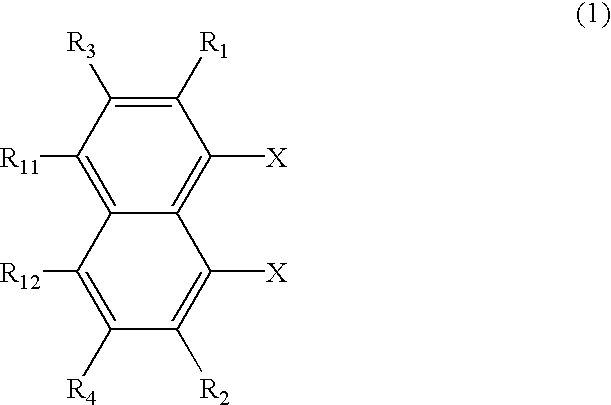

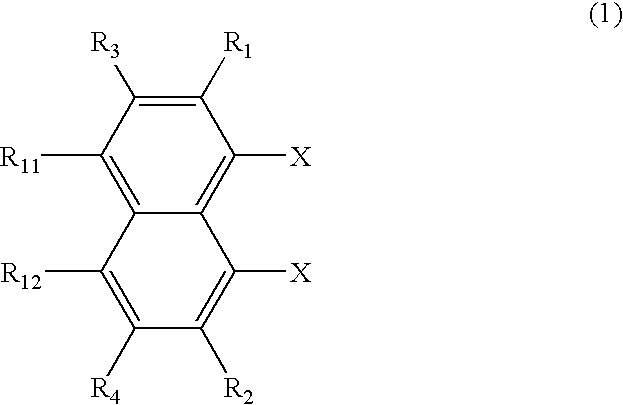

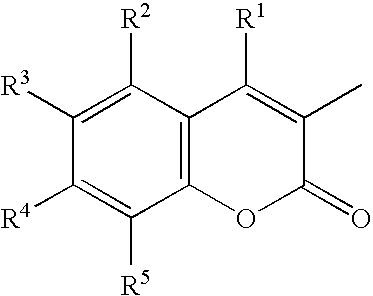

Perylene derivative synthesis process, perylene derivative and organic EL device

InactiveUS20050054852A1Satisfactory yieldImprove production efficiencyOrganic compound preparationSolid-state devicesCyano radicalSulfuryl

The invention aims to provide a perylene derivative preparation process featuring satisfactory yields and improved preparation efficiency, a perylene derivative obtained by the process, and an organic EL device using the same. The object is achieved by a perylene derivative preparation process comprising subjecting to coupling reaction a 1,8-dihalogenated naphthalene derivative of the formula (1): wherein X is Cl, Br or I, R1 to R4, R11 and R12 each are hydrogen, alkyl, alkoxy, alkylthio, alkenyl, alkenyloxy, alkenylthio, aralkyl, aralkyloxy, aralkylthio, aryl, aryloxy, and arylthio radicals which may be substituted, amino radical, cyano radical, hydroxyl radical, —COOM1 radical (wherein M1 is hydrogen, alkyl, alkenyl, aralkyl or aryl), —COM2 radical (wherein M2 is hydrogen, alkyl, alkenyl, aralkyl, aryl or amino), or —OCOM3 radical (wherein M3 is alkyl, alkenyl, aralkyl or aryl), and at least two adjoining radicals selected from among R1 to R4, R11 and R12 may bond or fuse together to form a substituted or unsubstituted carbocyclic aliphatic ring, aromatic ring or fused aromatic ring with the carbon atoms on which they substitute, with the proviso that when the carbocyclic aliphatic ring, aromatic ring or fused aromatic ring has substituent radicals, the substituent radicals are the same as R1 to R4, R11 and R12, to thereby synthesize a perylene derivative of the formula (2): wherein R1′ to R4′, R11′ and R12′ are as defined for R1 to R4, R11 and R12 in formula (1), and R1 to R4, R11 and R12 and R1′ to R4′, R11′ and R12′ may be the same or different.

Owner:FUTABA CORPORATION

Process for the manufacture of a starch hydrolysate with high content

InactiveUS6177265B1Accelerates hydrolysis reactionReduce in quantityNanotechFermentationHydrolysateAlpha-amylase

The invention concerns a process for the manufacture of a starch hydrolysate with high dextrose content comprising the stages of: (a) liquefying a starch milk with the aid of an .alpha.-amylase so as to obtain a liquefied starch milk; (b) saccharifying the liquefied starch milk, with the aid of a glucogenic enzyme, to obtain a raw saccharified hydrolysate having a maximum content of 80% by weight, and preferably 75% by weight; (c) microfiltering the raw saccharified hydrolysate so as to collect a microfiltration permeate and a microfiltration retentate; (d) separating the microfiltration permeate by nanofiltration over membranes so as to collect a nanofiltration permeate constituting said starch hydrolysate with high dextrose content and a nanofiltration retentate.

Owner:ROQUETTE FRERES SA

Coumarin compound

InactiveUS20050275341A1Satisfactory yieldReduce reaction efficiencyOrganic chemistryDischarge tube luminescnet screensCombinatorial chemistryMethyl group

A method for producing a coumarin compound represented by Formula 1, which comprises a step of reacting a coumarin compound represented by Formula 1 with a compound having an aldehyde group and an activated methylene group; luminous agents for organic EL elements and organic EL elements which all comprise the coumarin compound; and displaying panels and information displaying apparatuses using the organic EL elements: ø(Z)m Formula 1 wherein in Formula 1, ø is an aromatic ring, heterocycle, or a combination thereof, each Z is the same or a different coumarin group represented by Formula 2; and m is an integer of two or more; Formula 2:

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

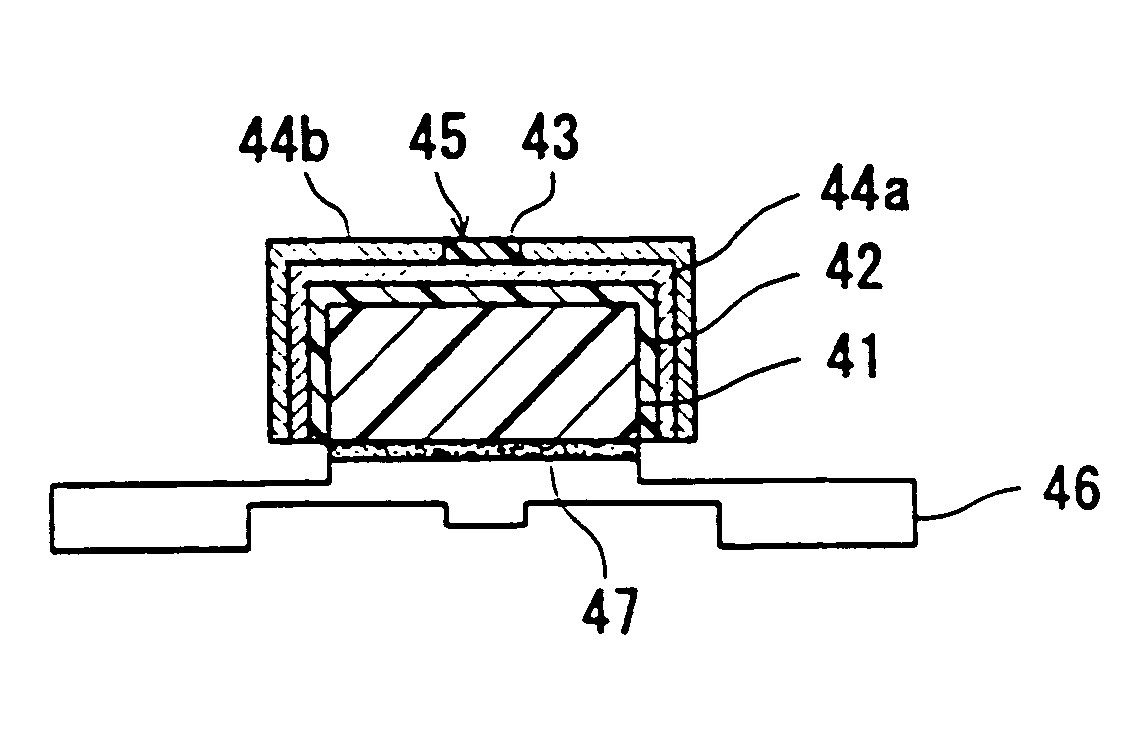

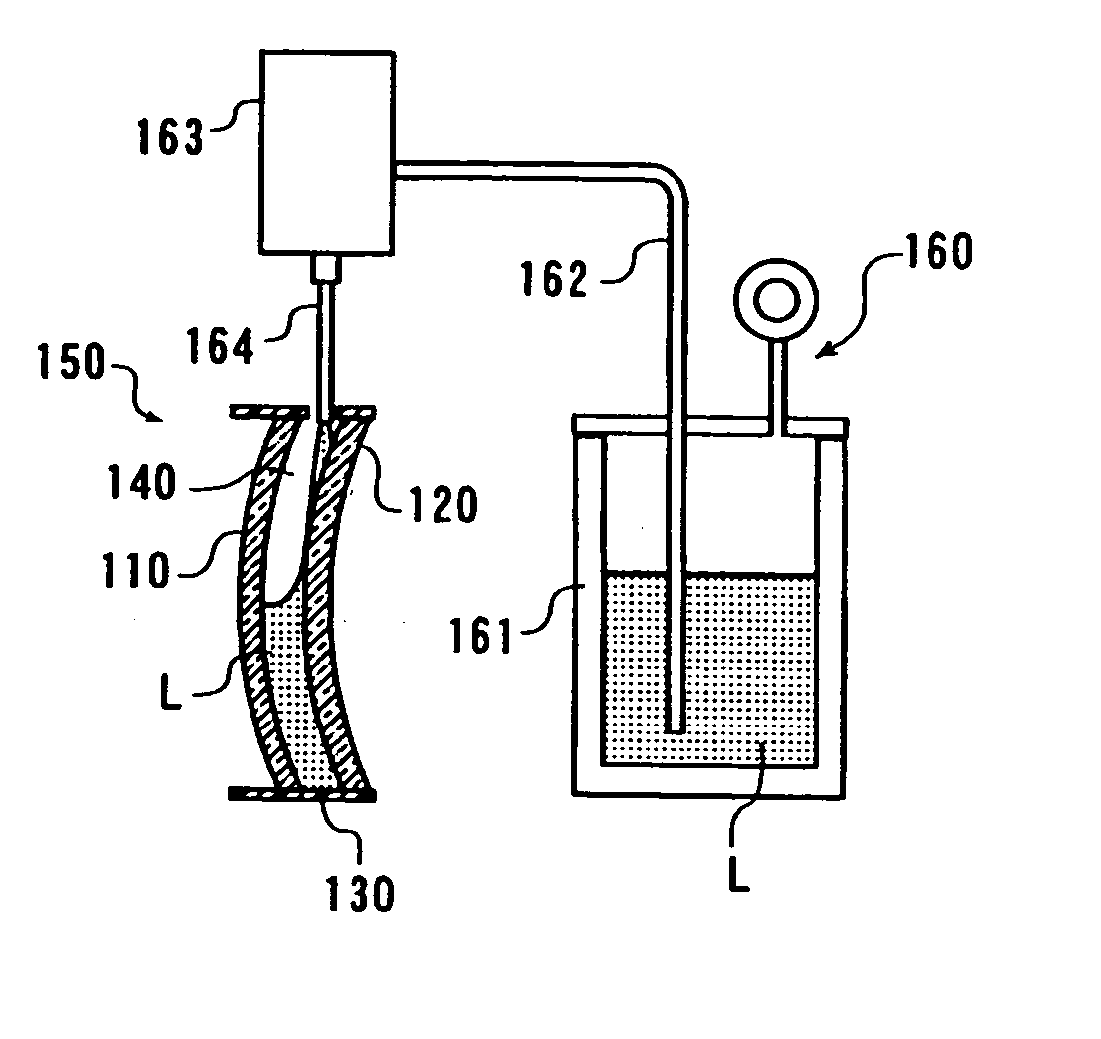

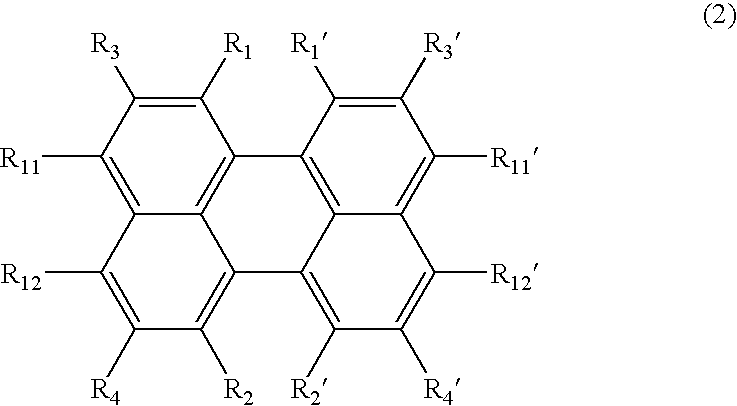

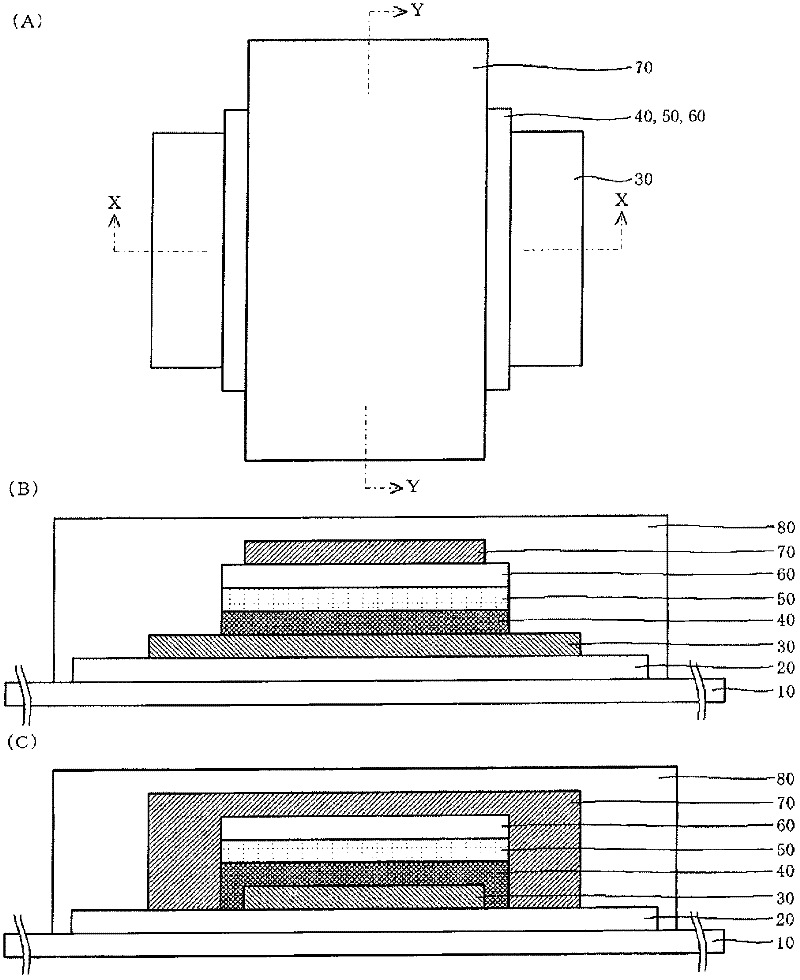

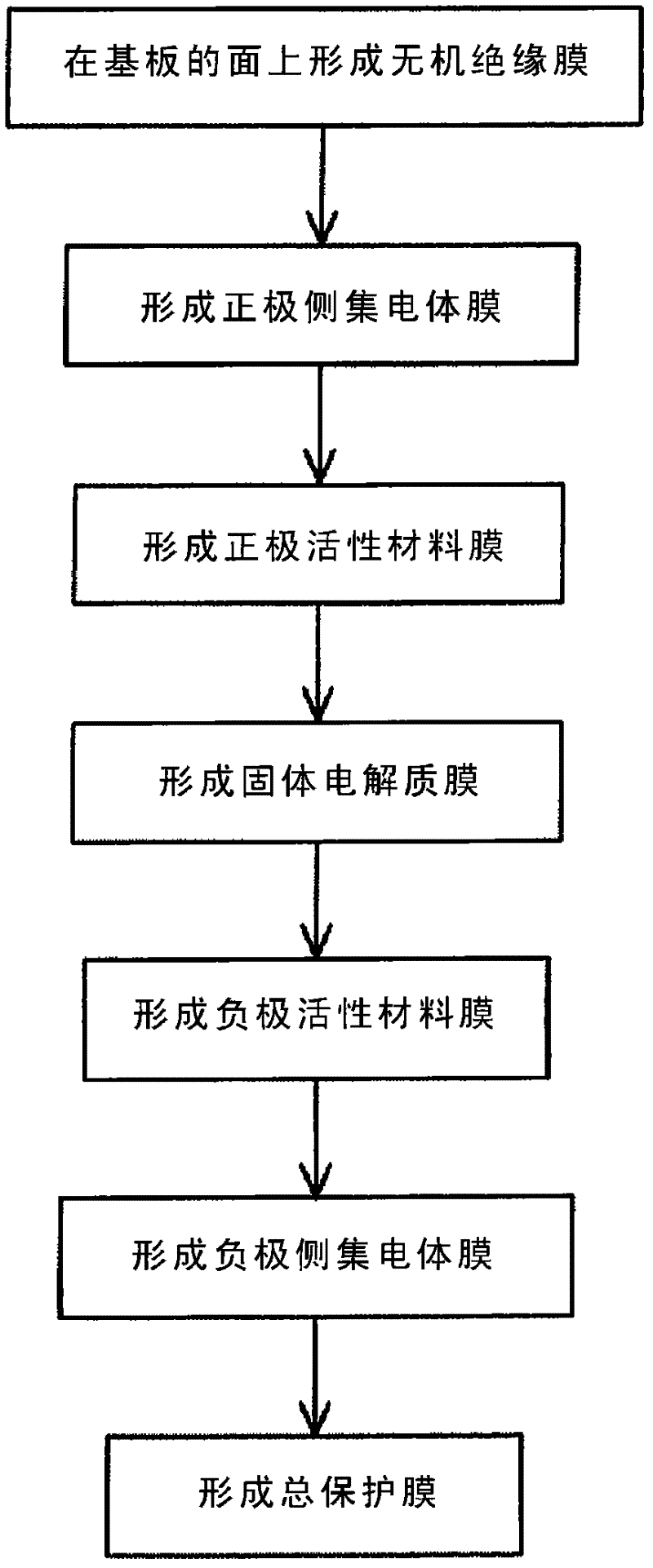

Thin film solid lithium ion secondary battery and manufacturing method thereof

InactiveCN102301519AImprove performanceDrive stabilityFinal product manufactureElectrode carriers/collectorsLithiumEngineering

The present invention discloses a high-performance and inexpensive thin-film solid-state lithium ion secondary battery and a method of manufacturing the battery, which can be charged and discharged in the air and can be stably manufactured with a satisfactory yield. The thin-film solid-state lithium ion secondary battery has: an electrically insulating substrate (10) formed of an organic resin; an insulating film (20) made of an inorganic material and formed on the surface of the substrate; a positive electrode side current collector A membrane (30); a cathode active material membrane (40); a solid electrolyte membrane (50); an anode active material membrane (60); and an anode-side current collector membrane (70). In this thin-film solid-state lithium ion secondary battery, the positive electrode side current collector film and / or the negative electrode side current collector film are formed on the face of the above-mentioned insulating film, and the film thickness of the above-mentioned insulating film is greater than or equal to 10 nm and less than Or equal to 200nm. The insulating film has an area larger than that of the positive electrode-side current collector film or the negative electrode-side current collector film, or larger than the total area of the positive electrode-side current collector film and the negative electrode-side current collector film. The aforementioned inorganic material includes at least one of oxides, nitrides, and sulfides containing any one of Si, Al, Cr, Zr, Ta, Ti, Mn, Mg, and Zn.

Owner:SONY CORP

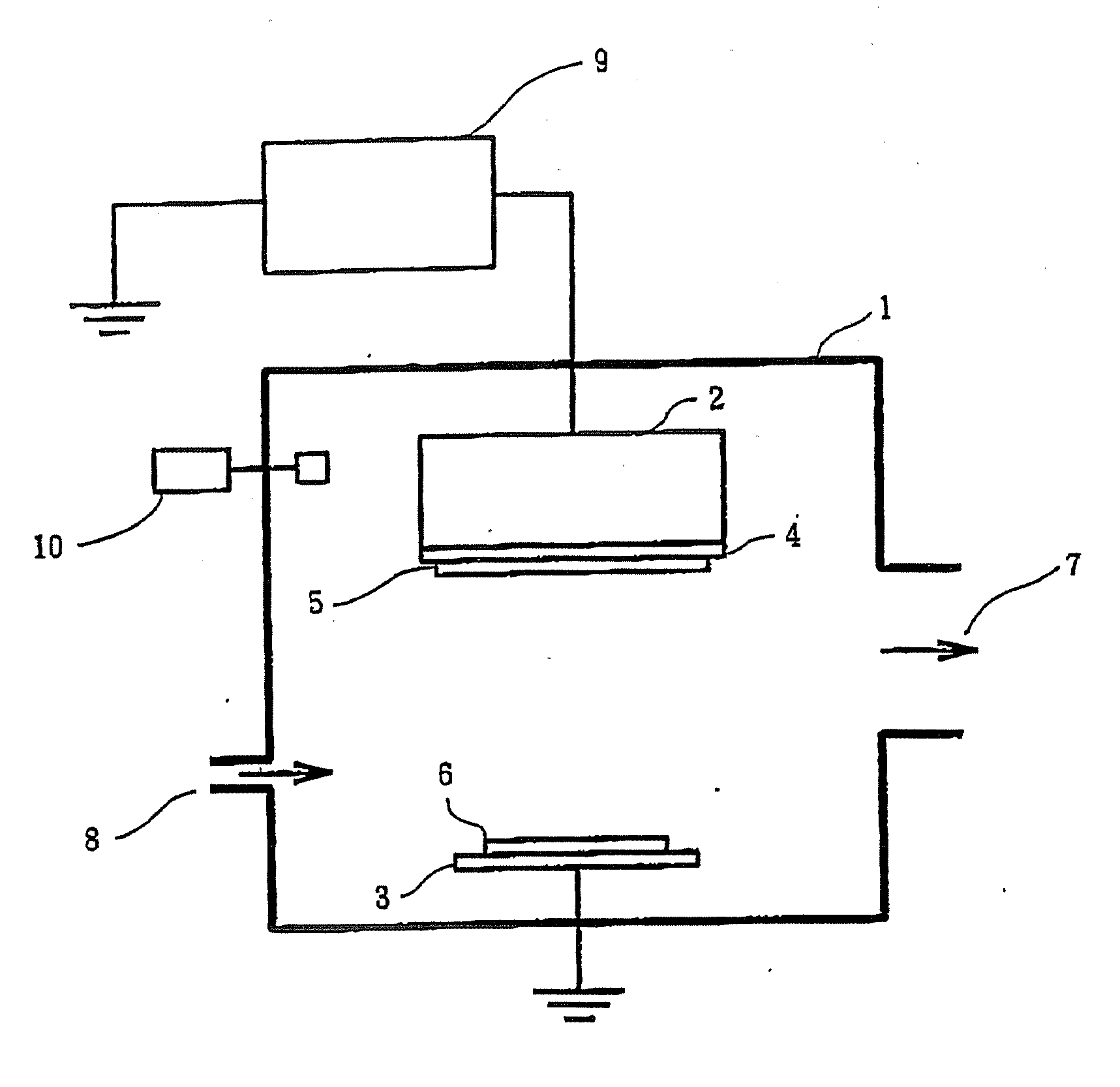

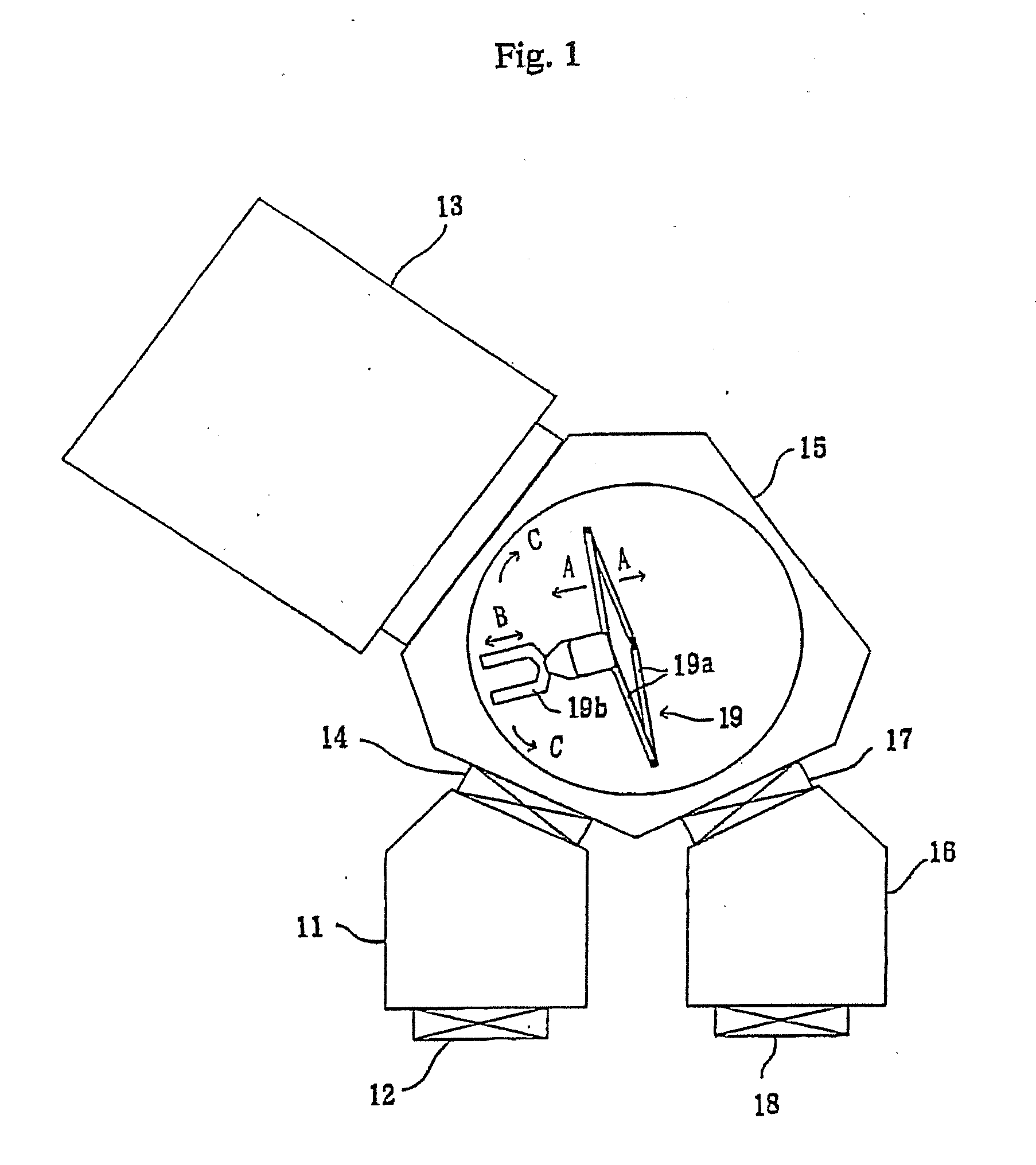

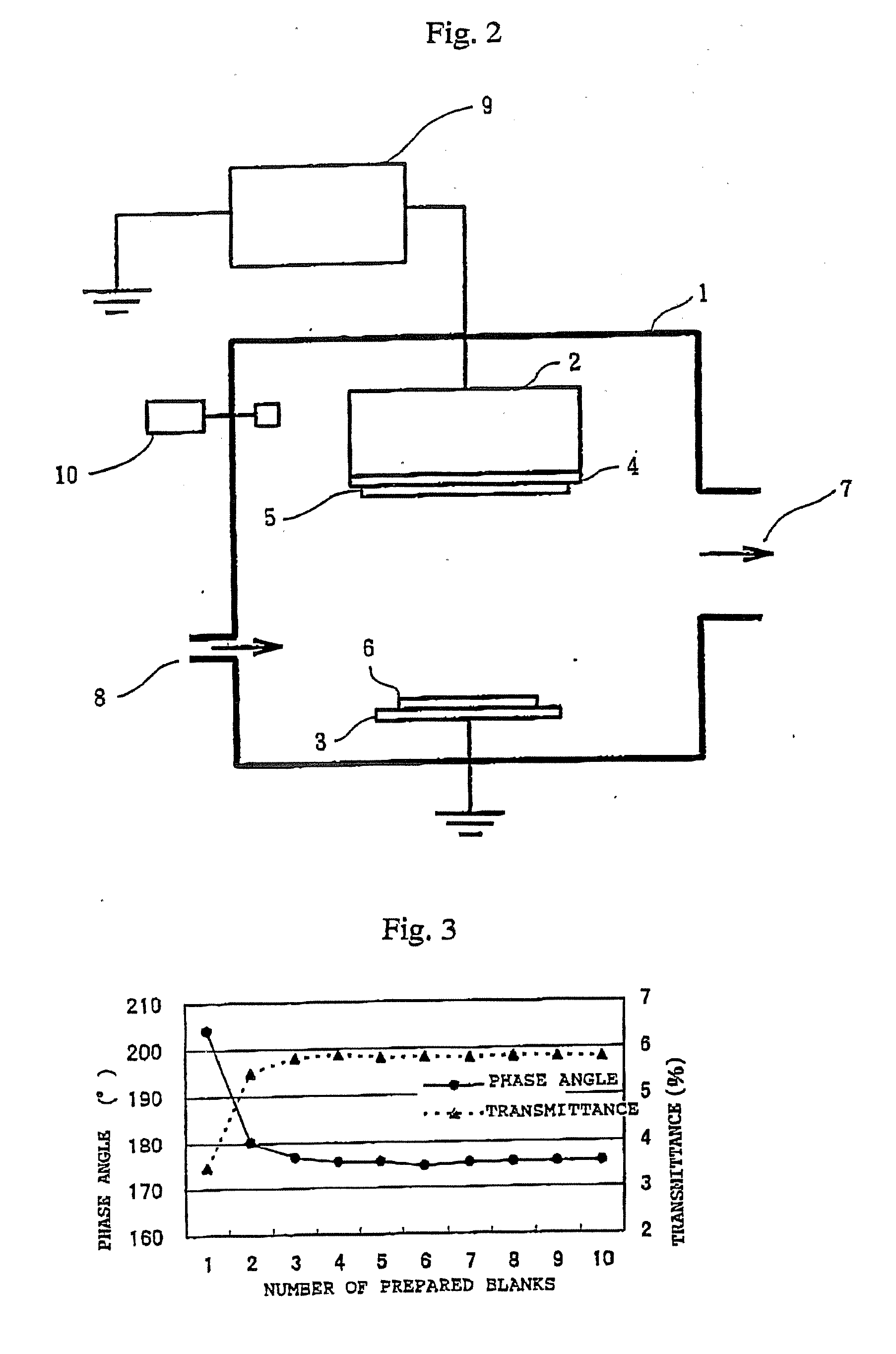

Manufacturing Method and Apparatus of Phase Shift Mask Blank

ActiveUS20070187228A1Satisfactory yieldReduce dispersionCellsVacuum evaporation coatingTransmittancePhase-shift mask

There is disclosed a manufacturing method of a phase shift mask blank in which dispersions of phase angle and transmittance among blanks can be reduced as much as possible and yield is satisfactory. In the manufacturing method of the phase shift mask blank, a process of using a sputtering method to continuously form a thin film on a transparent substrate comprises: successively subjecting a plurality of substrates to a series of process of supplying the transparent substrate into a sputtering chamber, forming the thin film for forming a pattern in the sputtering chamber, and discharging the transparent substrate with the film formed thereon from the sputtering chamber; supplying and discharging the transparent substrate substantially at a constant interval; and setting a film formation time to be constant among a plurality of blanks.

Owner:HOYA CORP

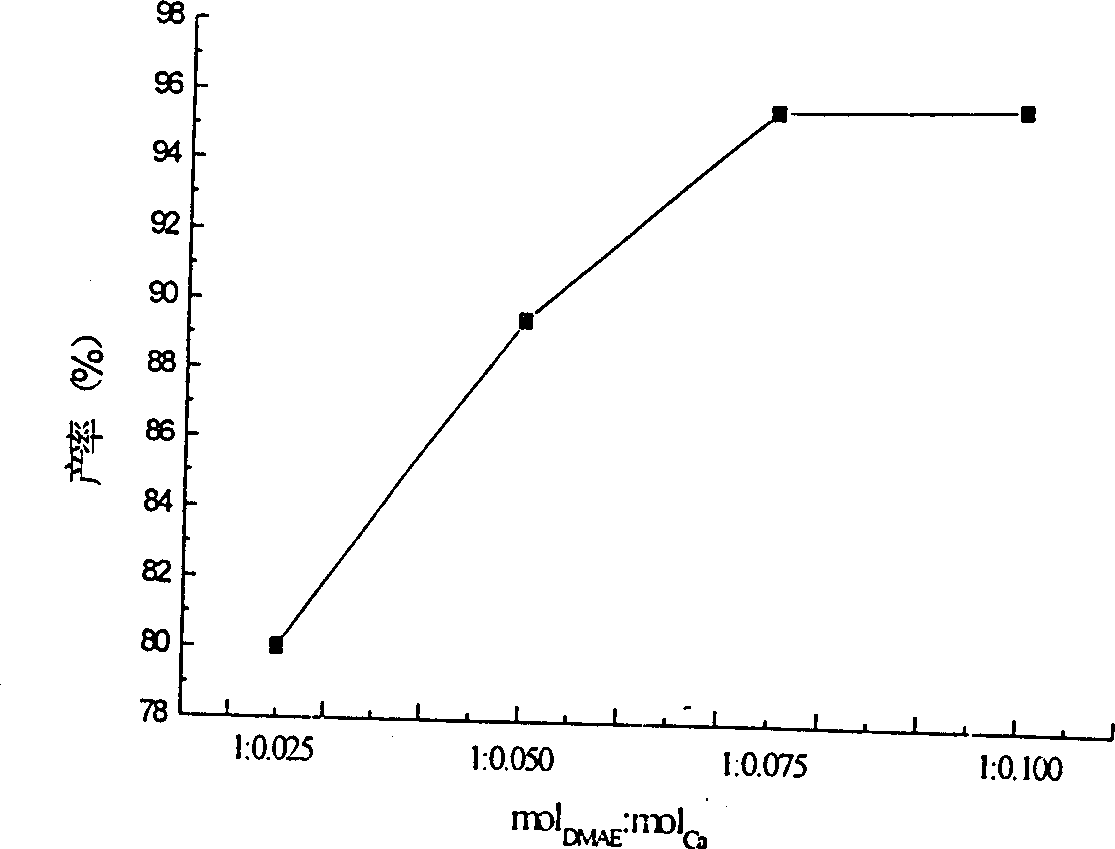

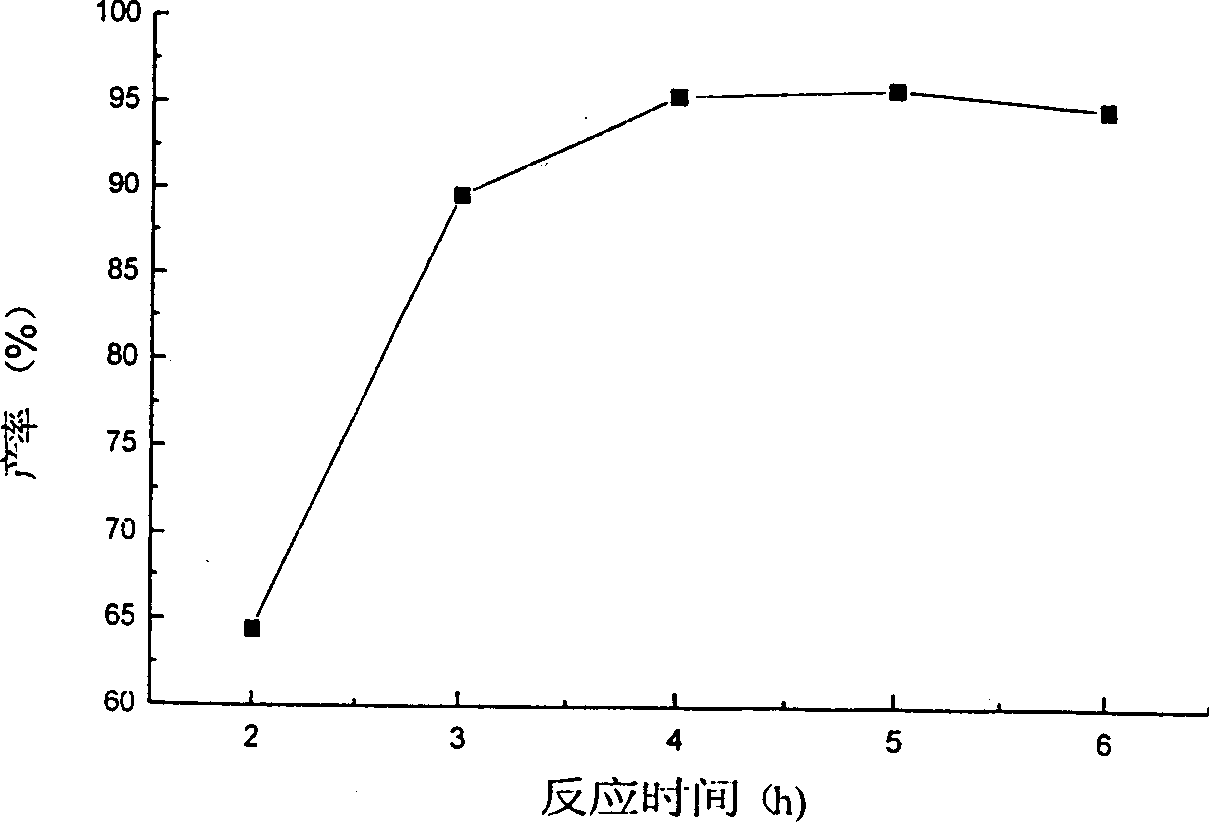

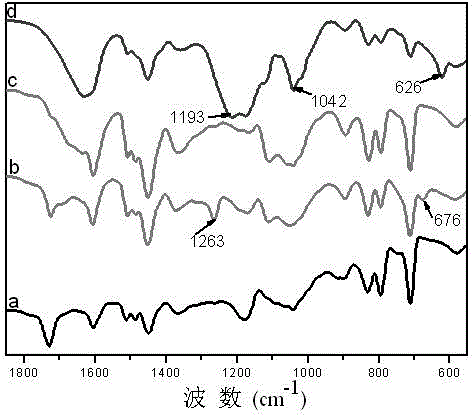

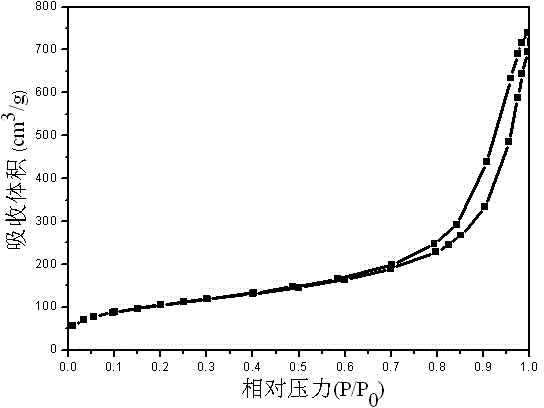

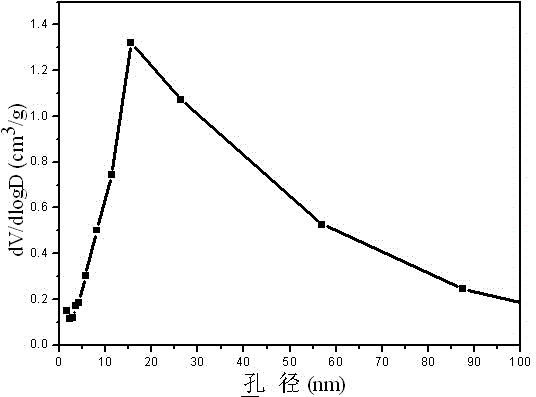

Multi-sulfonic acid funtionalized mesoporous polymeric solid acid catalyst and preparation method and application thereof

ActiveCN104815690ALarge specific surface areaLarge hole volumeFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceBiodiesel

The invention discloses a multi-sulfonic acid funtionalized mesoporous polymeric solid acid catalyst and a preparation method thereof and an application of the catalyst in high-efficiency catalysis of an esterification reaction between free fatty acid and short-chain alcohols (ethanol and methanol) and catalysis of one-pot preparation of biodiesel from high acid-value grease and methanol. The preparation method of the catalyst comprises the following steps: mesoporous polydivinylbenzene is used as a carrier, and the carrier firstly reacts with chloromethyl methyl ether to introduce the carrier into chloromethylene; then, a product reacts with ethene diamine to make the carrier to be linked in the form of a covalent bond with ethene diamine; and finally, chlorosulfonic acid is used to carry out sulfonation so as to obtain the multi-sulfonic acid funtionalized mesoporous polymeric solid acid catalyst. The mesoporous polymeric solid acid catalyst obtained by the preparation method has a lot of mesoporous pore structures, large specific surface area and pore volume and high acid density. The catalyst is applied in catalysis of an esterification reaction between free fatty acid and short-chain alcohols (ethanol and methanol) and catalysis of one-pot preparation of biodiesel from high acid-value grease and methanol, and has a high catalytic activity. Thus, the catalyst has good industrial application value.

Owner:GUIZHOU UNIV

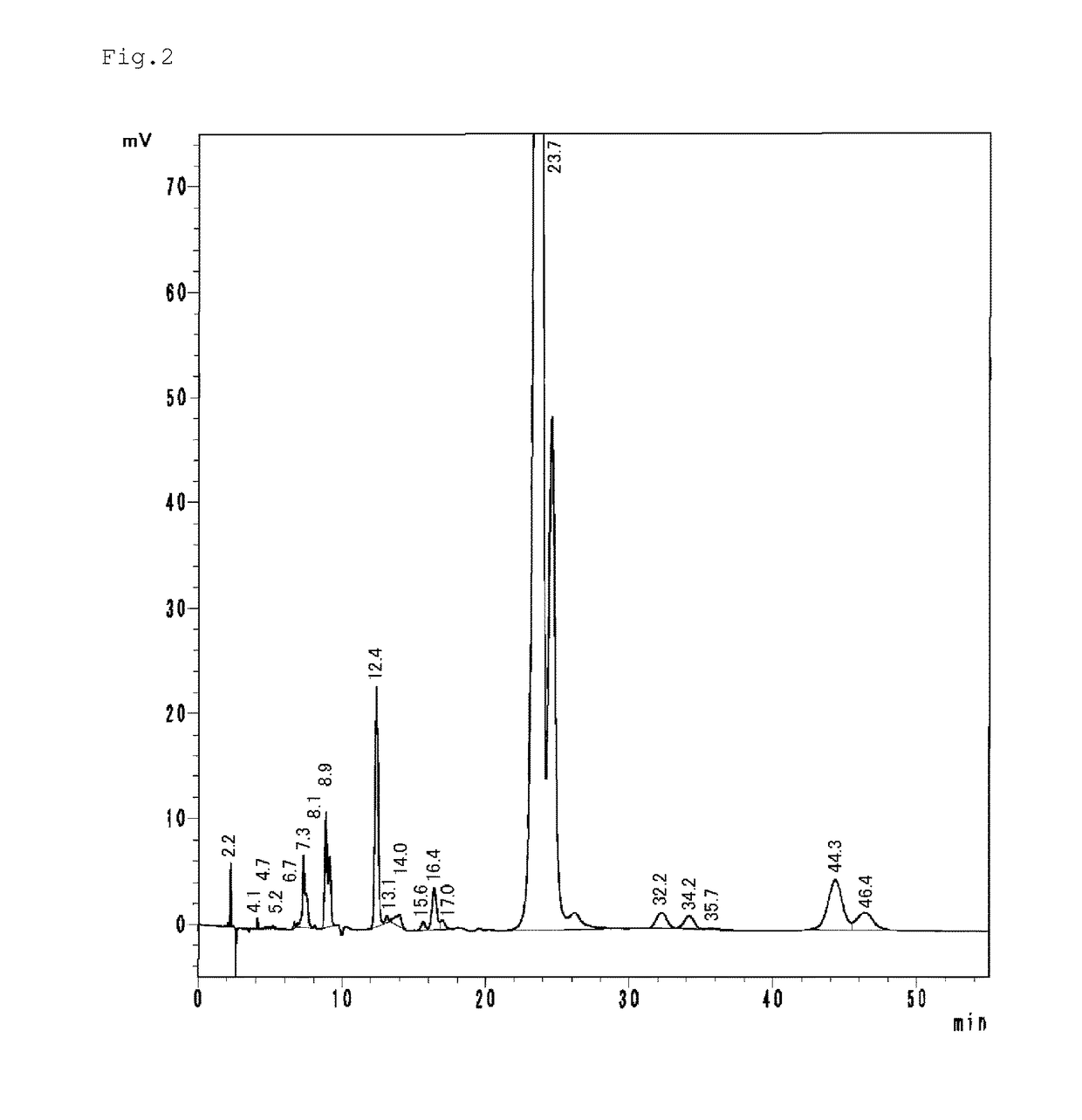

Synthesis method of 2-[(-4-chlorophenyl)(4-piperidinyl-oxy)methyl]pyridine having single optical isomer

InactiveCN104031029ADon't need protectionReduce generationOrganic chemistryChlorobenzeneCombinatorial chemistry

A preparation method of a compound of formula I is characterized in that the compound of formula I is obtained through one step direct condensation ether formation on a raw material of formula II and a raw material of formula III. The protection of reactive hydrogen on the nitrogen atom of the compound of the formula III is not needed in the invention, and a sulfonic acid compound is adopted as a reaction assistant, so the side reaction is reduced, reaction steps are simplified, and a satisfactory product yield can be realized. The compound of formula I having a single optical isomer can be obtained when the raw material of formula II having different isomers is selected.

Owner:CHONGQING HUAPONT PHARMA

Method of producing the keytop for pushbutton switch

InactiveUS7364649B2Simple designSatisfactory yieldContact surface shape/structureContact operating partsPolymer coatingsPush switch

According to a method of producing a key top for a pushbutton switch of the present invention, a base layer made of an insulating resin that can be plated with metal, an electroless plating layer to be formed on the surface of the base layer, and a polymer coating layer, if required, are stacked on the surface of a key top body. Alternatively, an electroplating layer formed by electroplating is further formed on the electroless plating layer. Therefore, a plating layer can be directly and easily formed on the insulating resin, whereby a key top for a pushbutton switch having a sensation of metal and being rich in design is obtained.

Owner:POLYMATECH CO LTD

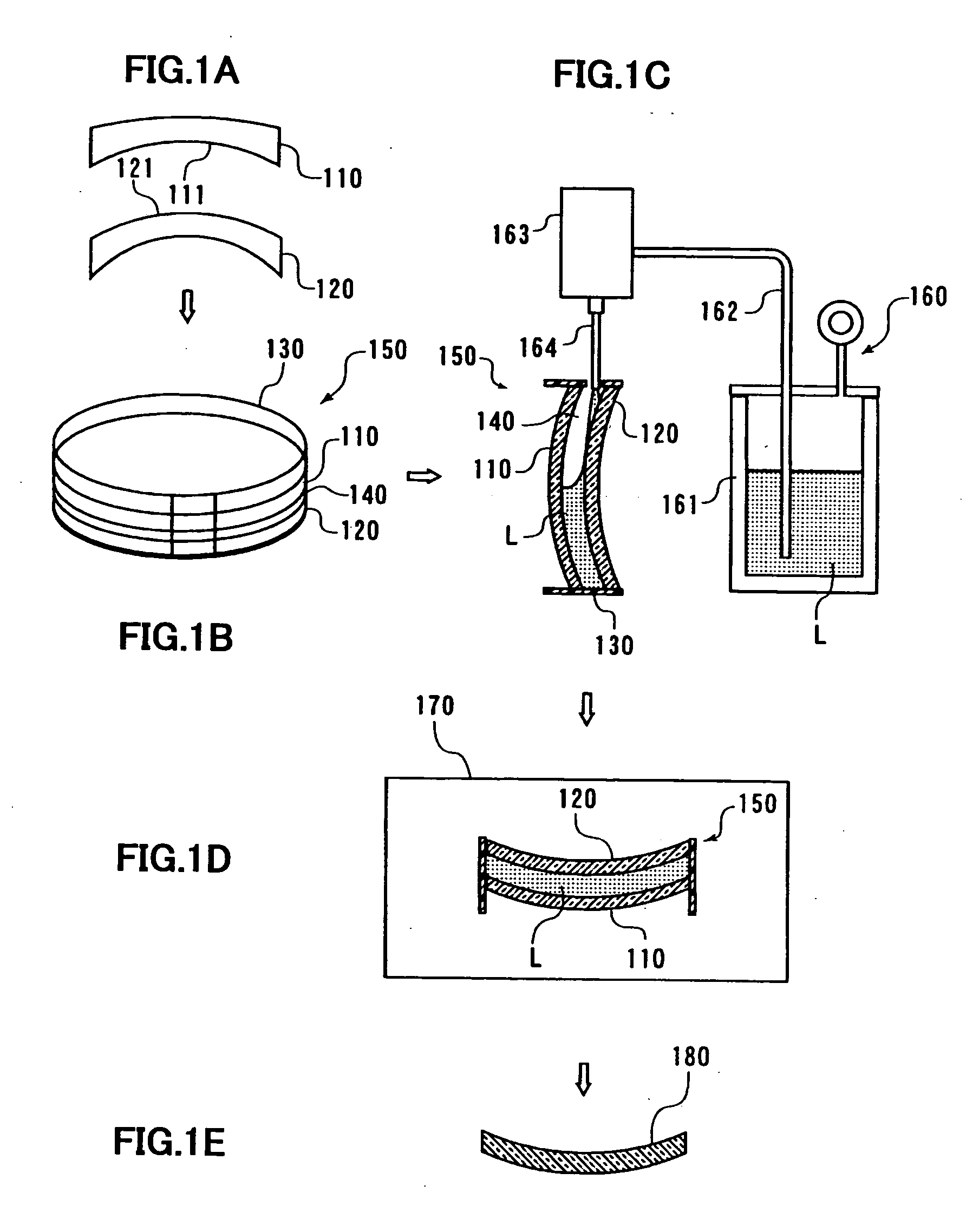

Producing method for plastic lens and raw material storage/supply apparatus

InactiveUS20040178526A1Difficult to dissipateEasy to disassembleOptical articlesLensRoom temperatureEngineering

Provided is a producing method and apparatus for a plastic lens capable of hardening a hardenable composition including a compound having an episulfide group under suppression of generation of an optical strain, and a raw material storage / supply apparatus adapted for storage and supply of such hardenable composition. A raw material storage / supply apparatus is provided by supporting, on a movable base, a storage container capable of storing a liquid raw material. A temperature regulating pipe is included for regulating the temperature of the storage container. Also provided is a temperature regulating apparatus capable of regulating a fluid flowing in the temperature regulating pipe at a temperature less than the room temperature.

Owner:SEIKO EPSON CORP

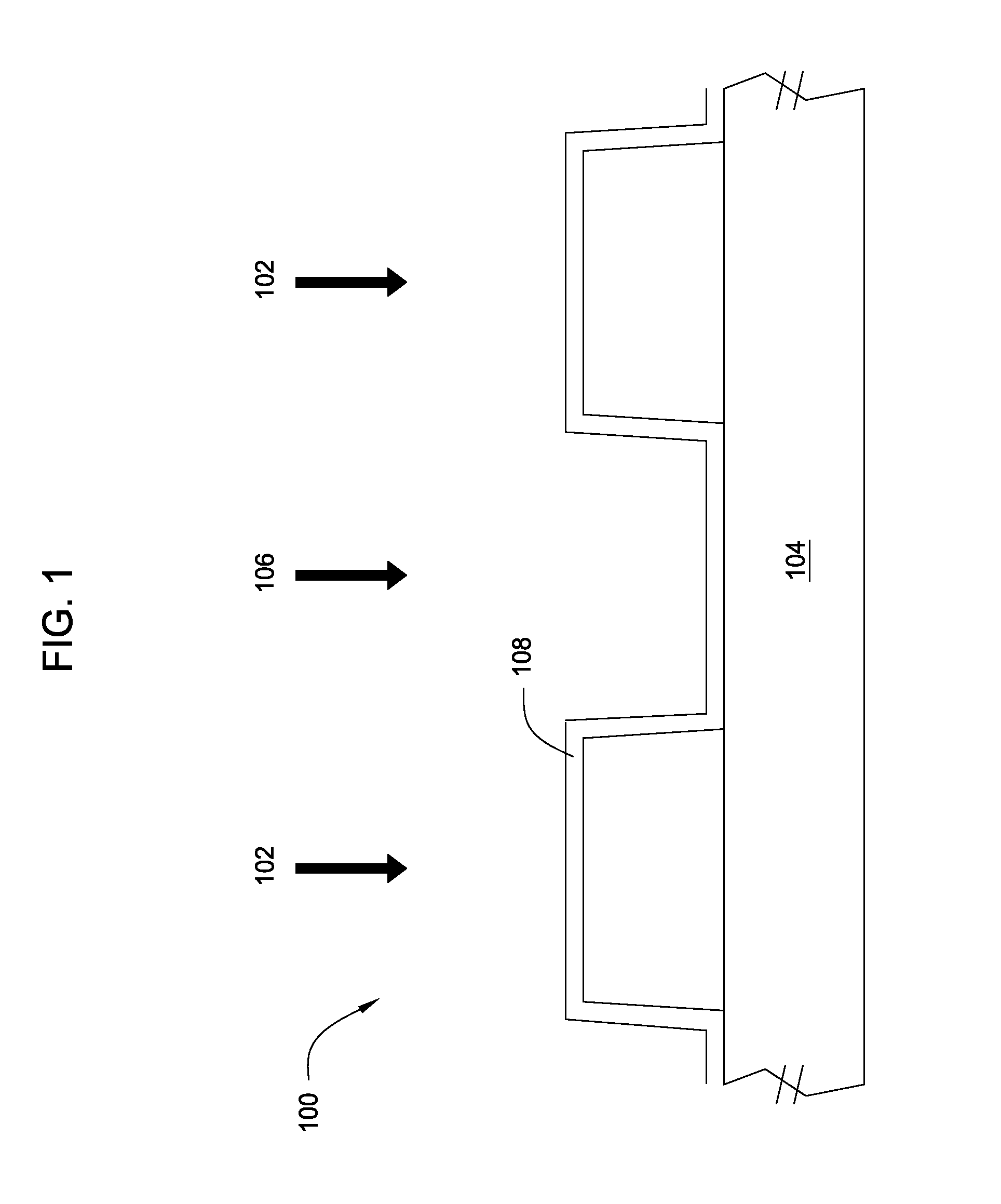

Method of separating semiconductor dies

ActiveUS7829440B2Easy to handleSatisfactory yieldSemiconductor/solid-state device manufacturingSemiconductor devicesLaser cuttingSemiconductor

A method for the separation of multiple dies during semiconductor fabrication is described. On an upper surface of a semiconductor wafer containing multiple dies, a seed metal layer may be used to grow hard metal layers above it for handling. Metal may be plated above these metal layers everywhere except where a block of stop electroplating (EP) material exists. The stop EP material may be obliterated, and a barrier layer may be formed above the entire remaining structure. The substrate may be removed, and the individual dies may have any desired bonding pads and / or patterned circuitry added to the semiconductor surface. The remerged hard metal after laser cutting and heating should be strong enough for handling. Tape may be added to the wafer, and a breaker may be used to break the dies apart. The resulting structure may be flipped over, and the tape may be expanded to separate the individual dies.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

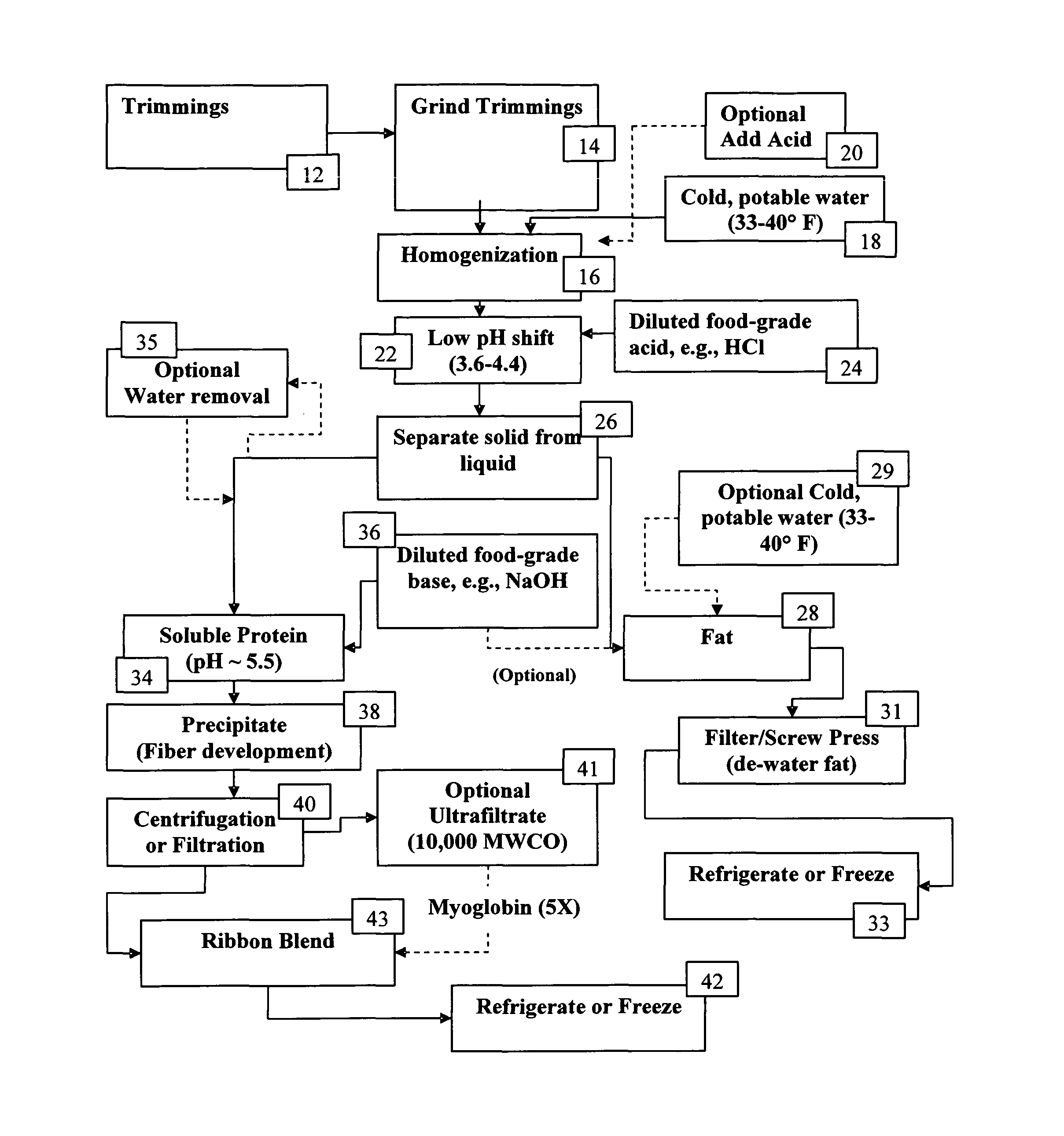

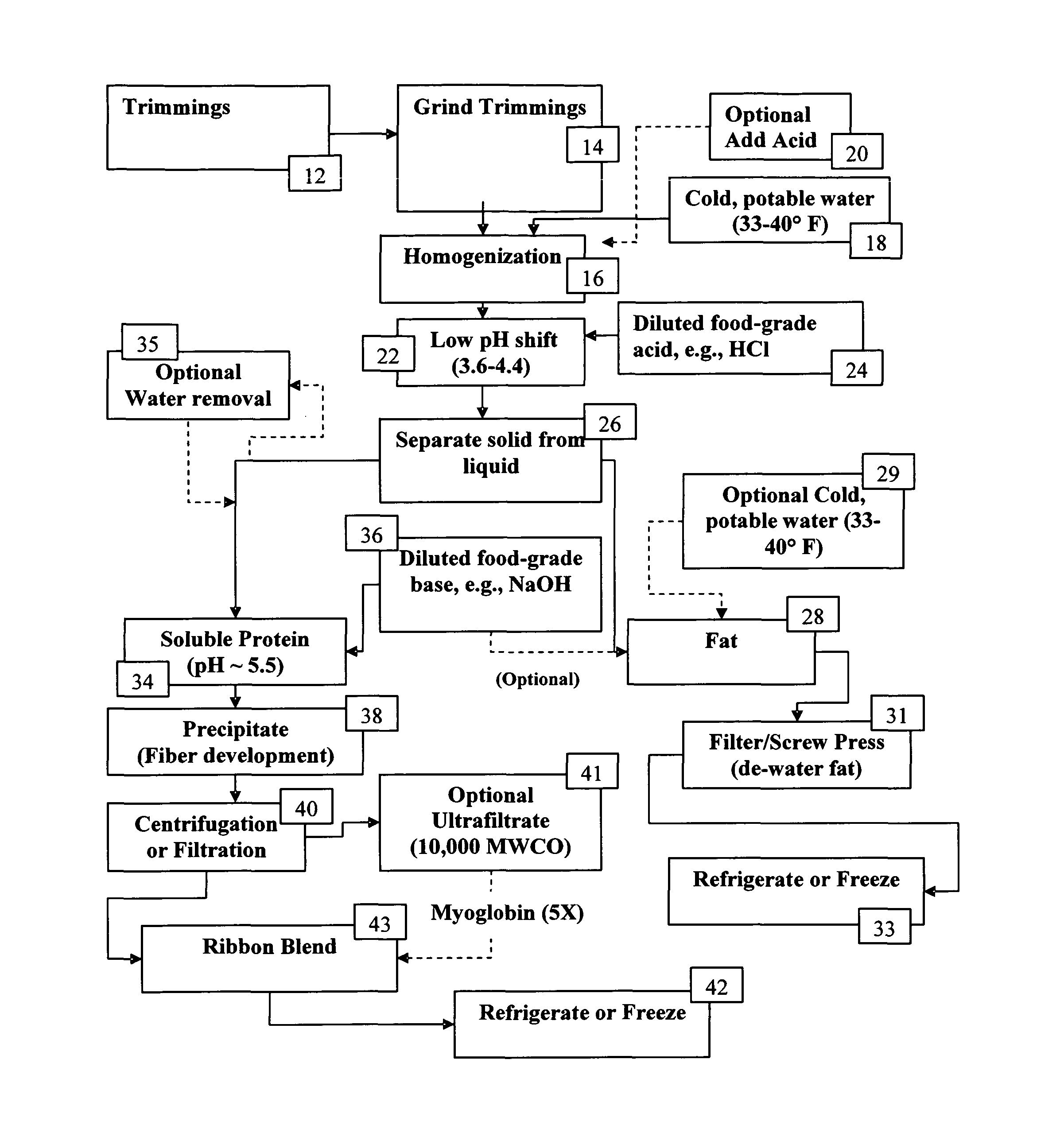

Process for isolating a protein composition and a fat composition from meat trimmings

ActiveUS9161555B2Satisfactory yieldSimplifies subsequent water removalProtein composition from fishFood ingredientsFat compositionChemistry

Owner:KEMIN PROTEINS LLC

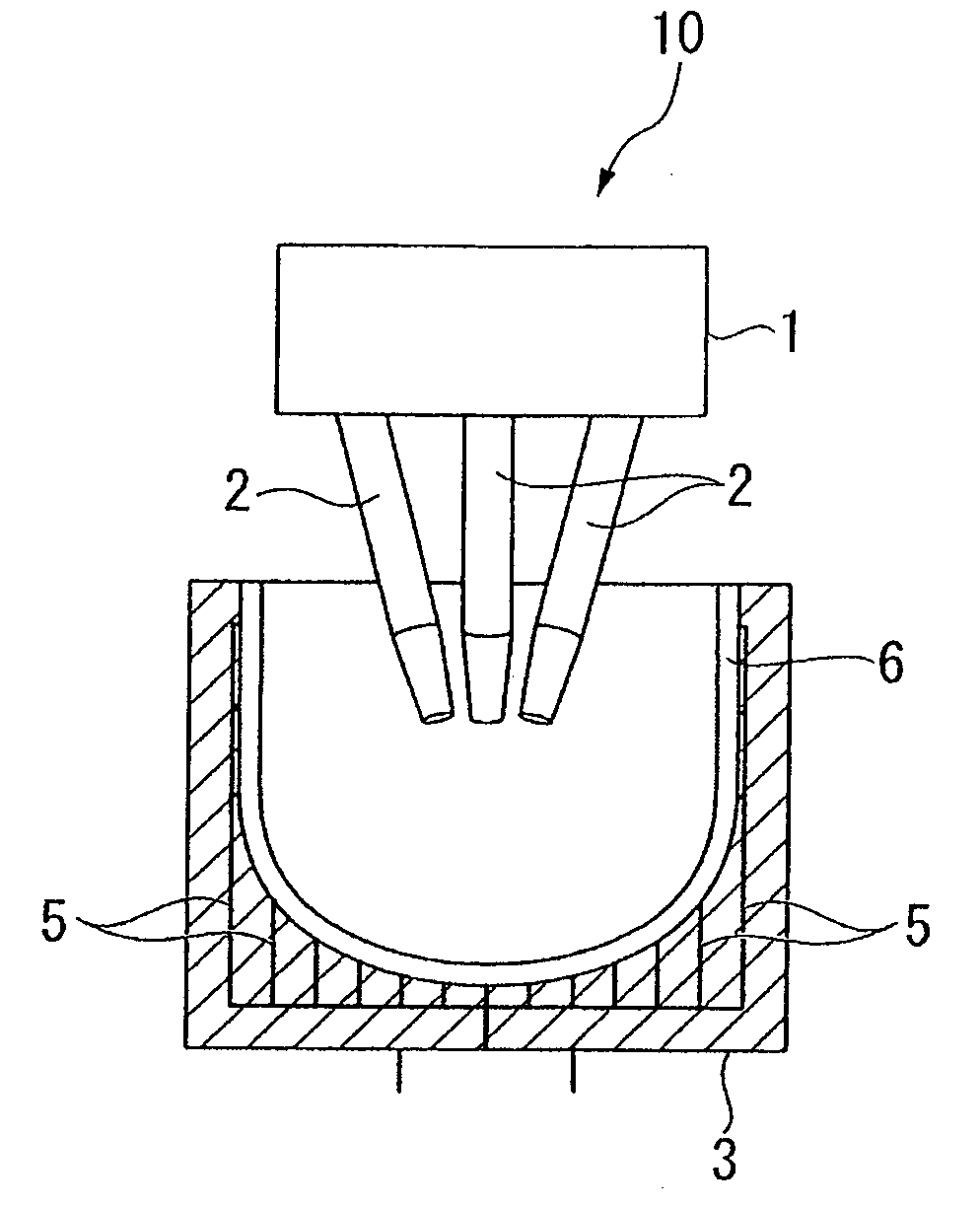

Arc melting high-purity carbon electrode and application thereof

InactiveUS20100095880A1Satisfactory yieldPolycrystalline material growthElectric discharge heatingCrucibleSilicon dioxide

An arc melting high-purity carbon electrode is capable of forming stable arc at the time of arc discharge, and it is possible to produce a vitreous silica crucible with good properties, which does not cause local lack of the electrode and does not create black foreign materials or concave portions on the inner surface of the crucible. The arc melting high-purity carbon electrode is a carbon electrode used to heat and melt silica powder by arc discharge, in which the density of the carbon electrode is equal to or more than 1.60 g / cm3 and equal to or less than 1.80 g / cm3, and is formed of high-purity carbon particles having a diameter of 0.05 mm or less.

Owner:JAPAN SUPER QUARTZ CORP +1

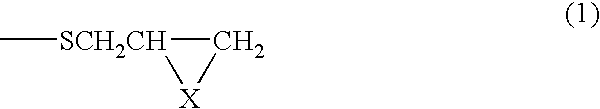

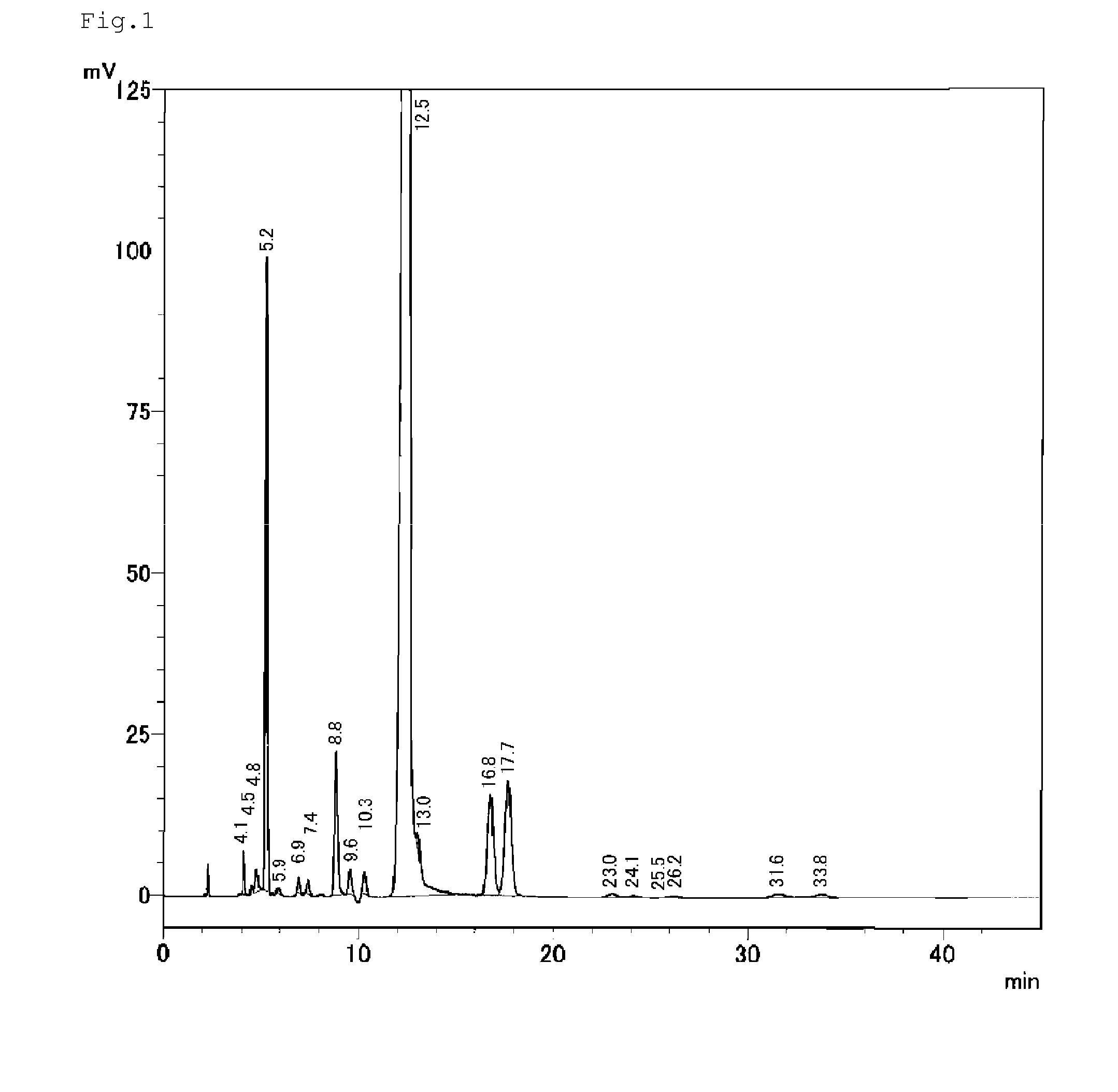

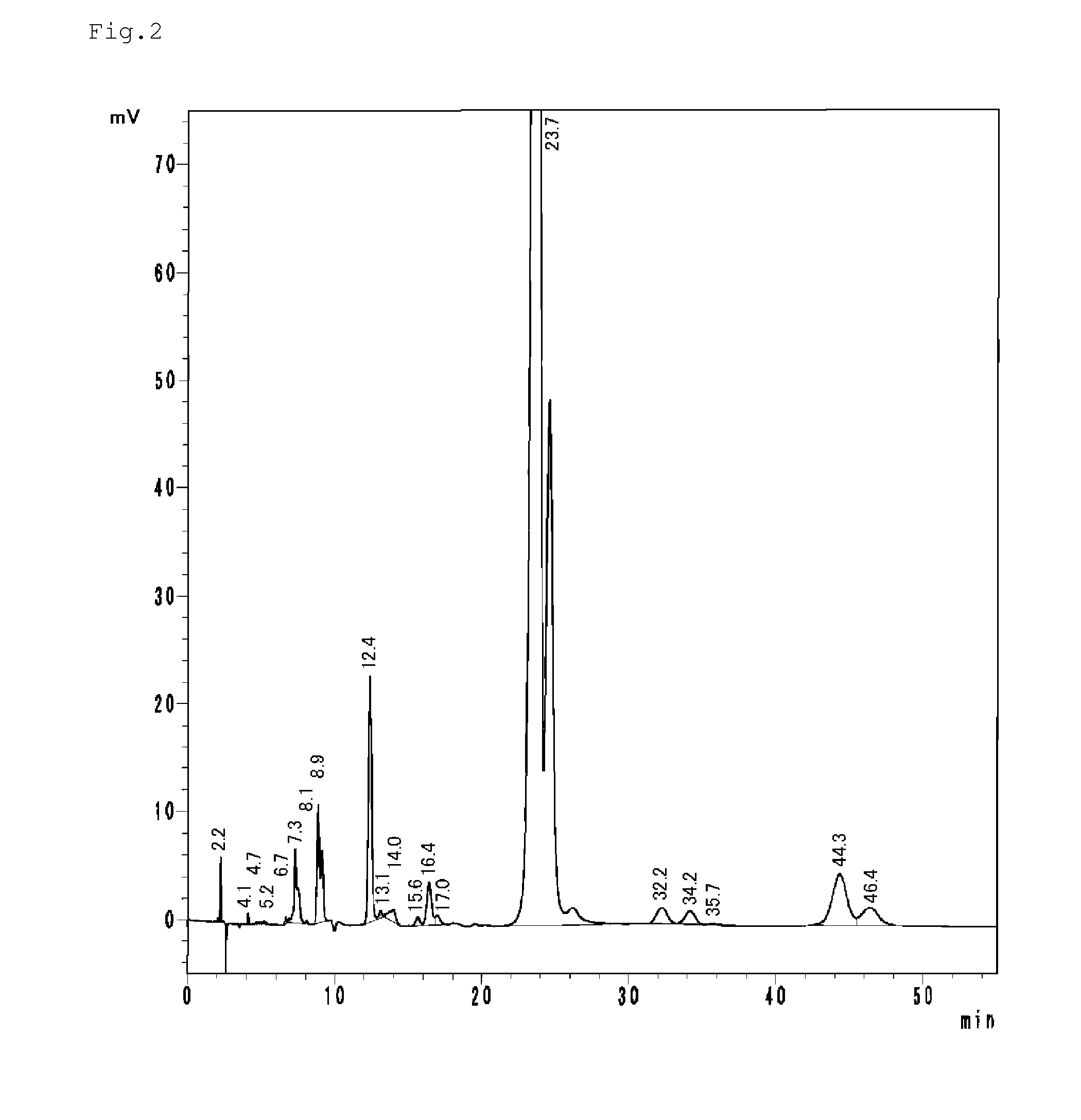

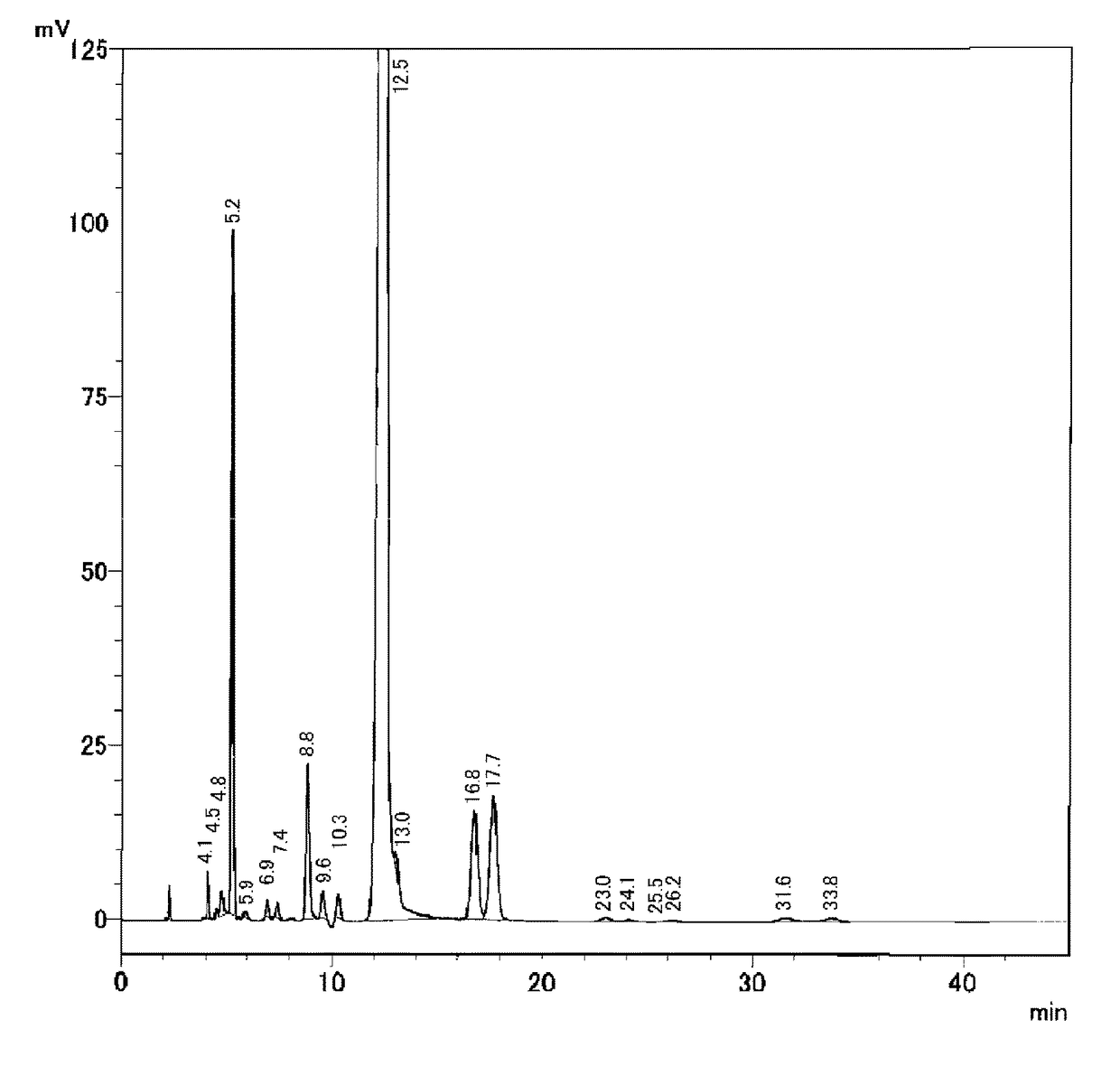

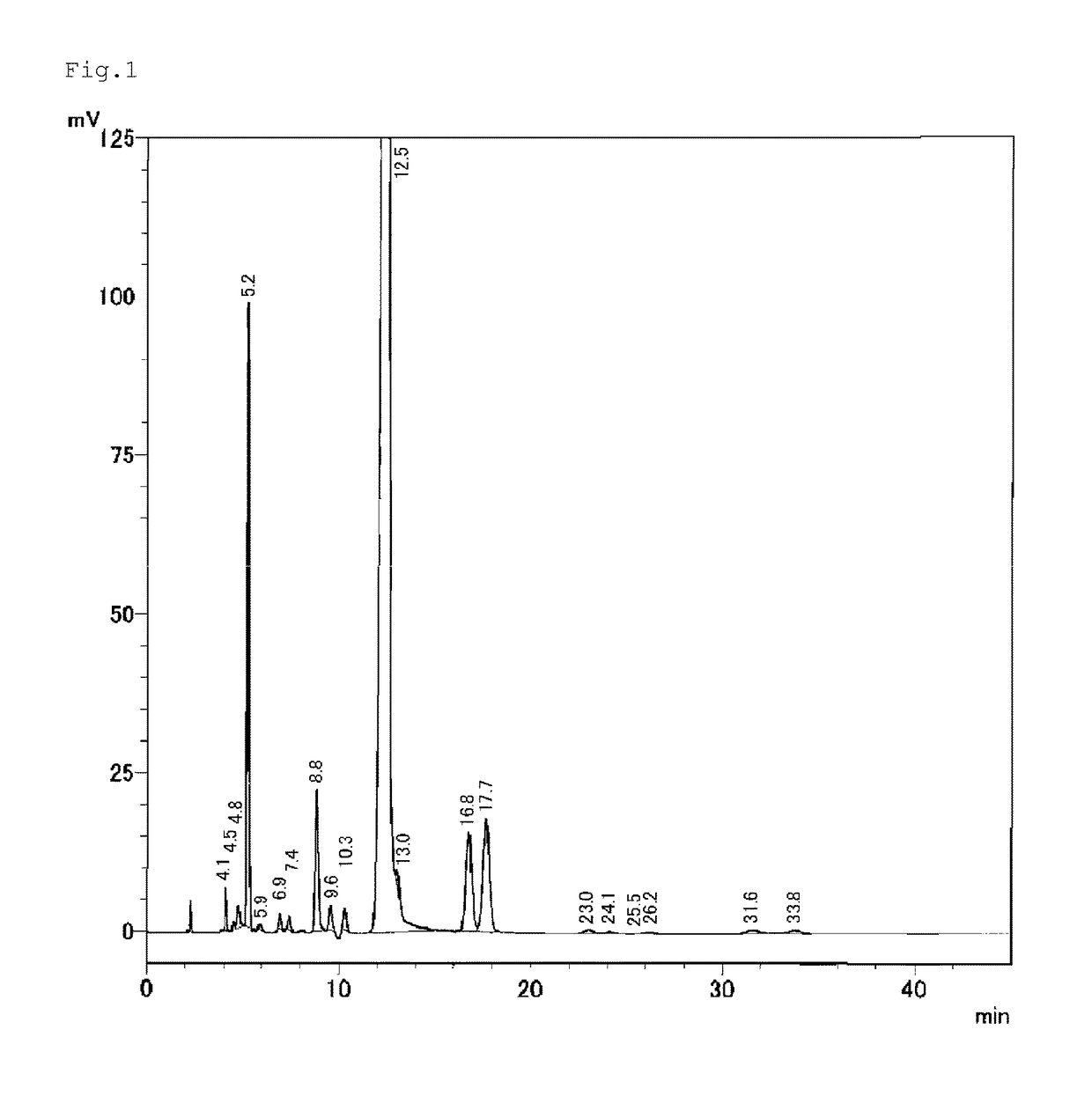

Polythiol composition, polymerizable composition for optical material and use thereof

ActiveUS20150094443A1Quality improvementSatisfactory yieldOrganic chemistryOther chemical processesNitrogenPhotochemistry

A polythiol composition according to the present invention includes a polythiol compound (A) having three or more mercapto groups and a nitrogen-containing compound (B) in which one of a mercapto group of the polythiol compound (A) is replaced with a group represented by the following formula (a) and other one of a mercapto group of the polythiol compound (A) is replaced with a hydroxyl group, in which the peak area of the nitrogen-containing compound (B) is equal to or less than 3.0 with respect to the peak area of 100 of the polythiol compound (A) in a high performance liquid chromatography measurement.

Owner:MITSUI CHEM INC

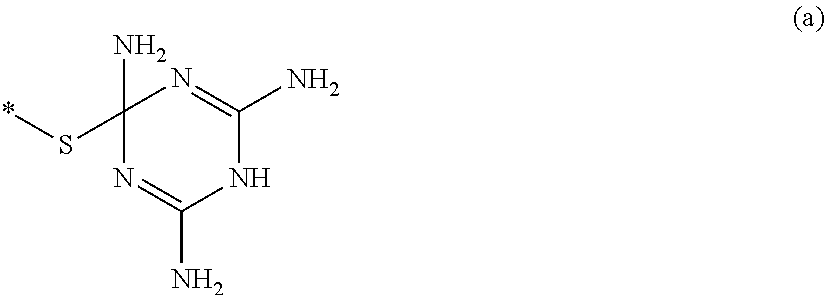

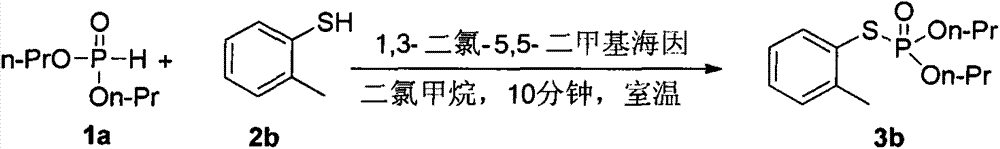

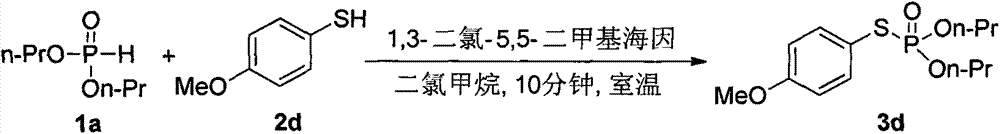

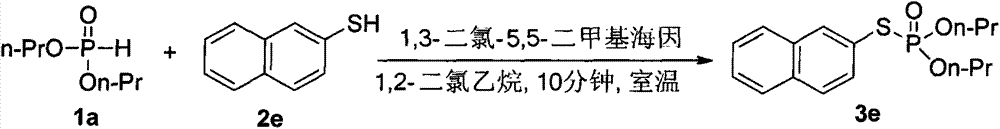

Synthetic method of phosphorothioate compound

ActiveCN104844648AMild reaction conditionsSimple and fast operationGroup 5/15 element organic compoundsThiolNatural product

The present invention relates to a synthetic method of phosphorothioate compound. The preparation method adopts phosphite and thiophenol or mercaptan to synthesize the phosphorothioate under the promotion of a chlorate agent 1,3-dichloro-5,5-dimethylhydantoin / trichloroisocyanuric acid. The method is mild in condition, quick in reaction, free of alkalization and a catalyst in the reaction process, and has wide adaptability to substrates of different functional groups. The phosphite framework which is efficiently constructed by the preparation method provided by the invention is an important framework for many medicines, pesticides, biological active molecules and natural products. The synthetic method provided by the invention provides a widely applied preparation method for synthesizing the compounds.

Owner:中国人民解放军63975部队

Method for increasing crop yield

InactiveUS8617286B2Increase productionEliminating and reducing useBiocideAmmonium nitratesHigh rateDecomposition

The method for increasing yield of crop plants uses foliar application to the plants during the plant growth stage of a granular fertilizer consisting essentially of urea, ammonium sulfate and a fertilizer stabilizing agent. The stabilizing agent regulates and slows down decomposition nitrogen in urea and / or ammonium sulfate to maximize use thereof. The granular fertilizer has a urea / ammonium sulfate weight ratio of about 4 / 1 and contains at least 40% nitrogen and at least 4% sulfur. The relatively high N—S fertilizer is applied at relatively high rates of about 100 to 150 pounds per acre to ensure that the fertilizer nutrients are always available to the plants at several stages of growth.

Owner:RIZZO JOHN M

Polythiol composition, polymerizable composition for optical material and use thereof

ActiveUS9777103B2Quality improvementSatisfactory yieldOrganic chemistryOptical elementsPhotochemistryLiquid phase

A polythiol composition according to the present invention includes a polythiol compound (A) having three or more mercapto groups and a nitrogen-containing compound (B) in which one of a mercapto group of the polythiol compound (A) is replaced with a group represented by the following formula (a) and other one of a mercapto group of the polythiol compound (A) is replaced with a hydroxyl group, in which the peak area of the nitrogen-containing compound (B) is equal to or less than 3.0 with respect to the peak area of 100 of the polythiol compound (A) in a high performance liquid chromatography measurement.

Owner:MITSUI CHEM INC

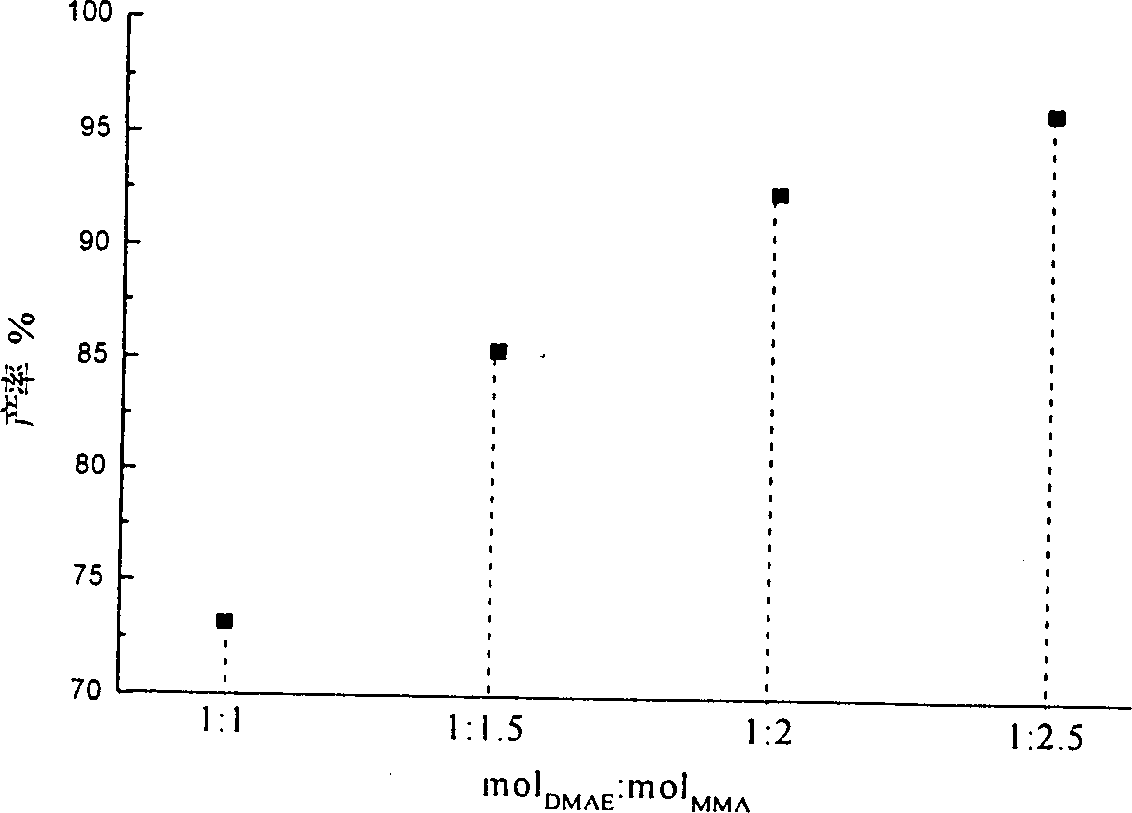

Process for preparing substd. (or unsubstd.) aminoalkyl acrylate

InactiveCN1401628AEasy to useCatalytic activity is not affectedOrganic compound preparationAmino-hyroxy compound preparationAlkaline earth metalAlcohol

Owner:SICHUAN NORMAL UNIVERSITY +1

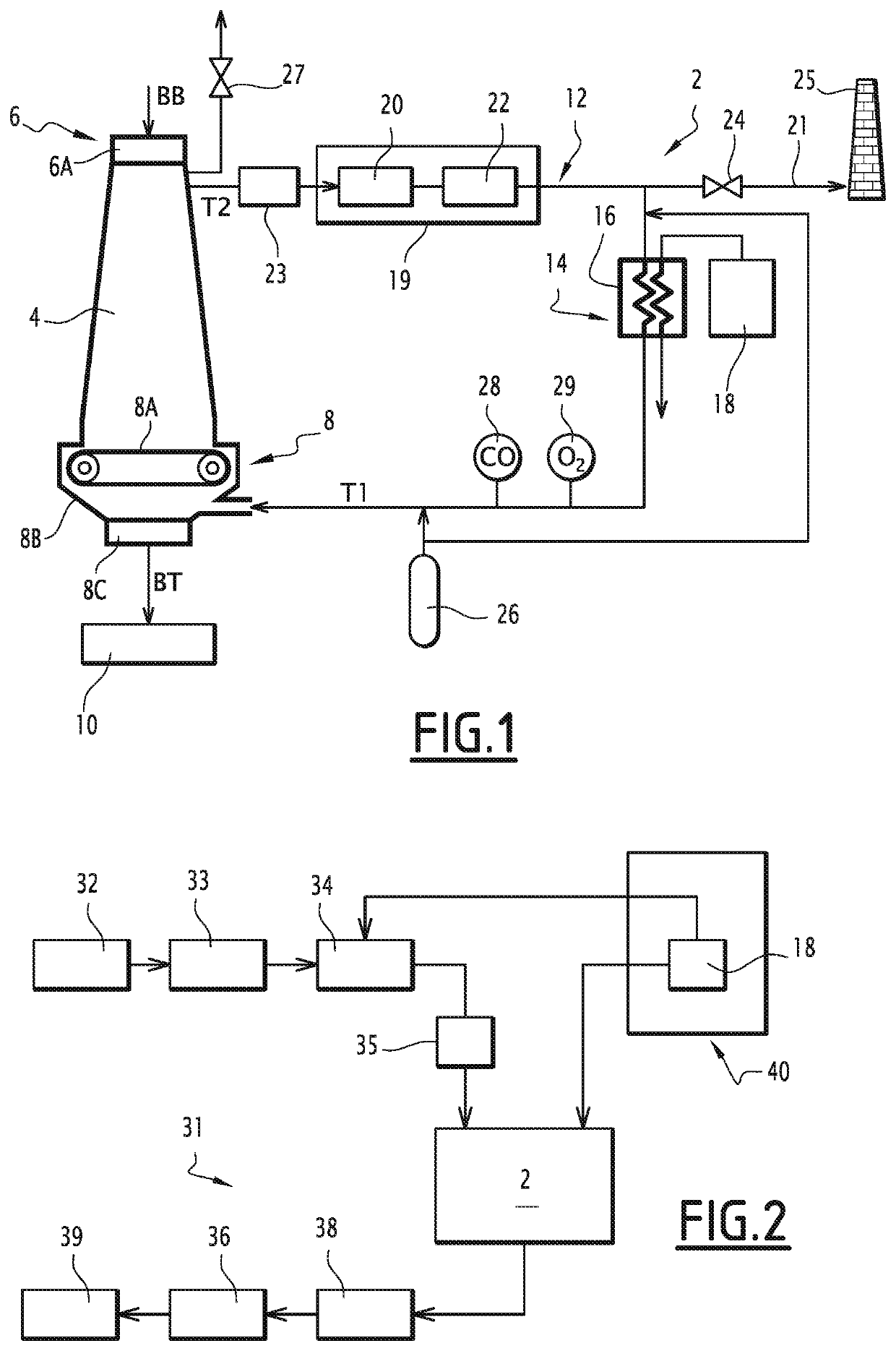

Method and plant for roasting biomass

ActiveUS10526543B2Efficient use ofSatisfactory yieldVertical chamber coke ovensDirect heating destructive distillationGas passingProcess engineering

This method for roasting biomass, including the flow by gravity of the biomass from the top towards the bottom of a column (4) with a counter-current of hot gases flowing from the bottom towards the top of the column (4), with the establishment of an increasing temperature gradient from the top towards the bottom of the column (4), the recovery of the gases at the top of the column and their recycling at the bottom of the column (4) by way of a gas circuit (12) so that the gases flow in a closed loop in the column (4) and the gas circuit (12), and the heating of the gases recovered by passing them through a heat exchanger (16) before their recycling at the bottom of the column (4).

Owner:LMK ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of 2-[(-4-chlorophenyl)(4-piperidinyl-oxy)methyl]pyridine having single optical isomer Synthesis method of 2-[(-4-chlorophenyl)(4-piperidinyl-oxy)methyl]pyridine having single optical isomer](https://images-eureka.patsnap.com/patent_img/b50fa5c1-760d-4f30-a249-27959511c3bd/BDA00002897357400011.PNG)

![Synthesis method of 2-[(-4-chlorophenyl)(4-piperidinyl-oxy)methyl]pyridine having single optical isomer Synthesis method of 2-[(-4-chlorophenyl)(4-piperidinyl-oxy)methyl]pyridine having single optical isomer](https://images-eureka.patsnap.com/patent_img/b50fa5c1-760d-4f30-a249-27959511c3bd/BDA00002897357400012.PNG)

![Synthesis method of 2-[(-4-chlorophenyl)(4-piperidinyl-oxy)methyl]pyridine having single optical isomer Synthesis method of 2-[(-4-chlorophenyl)(4-piperidinyl-oxy)methyl]pyridine having single optical isomer](https://images-eureka.patsnap.com/patent_img/b50fa5c1-760d-4f30-a249-27959511c3bd/BDA00002897357400021.PNG)