Patents

Literature

119results about How to "Reduce reaction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

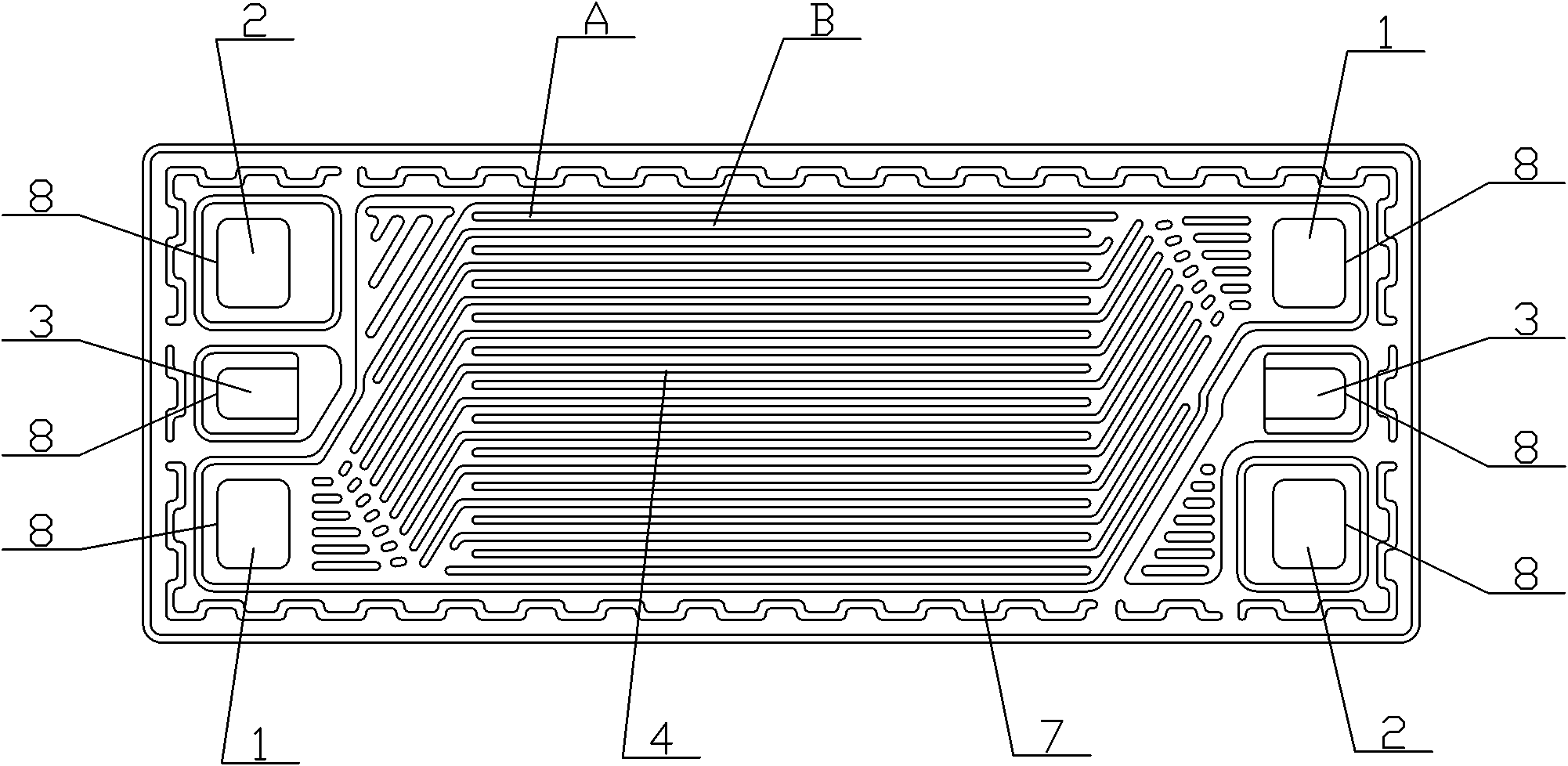

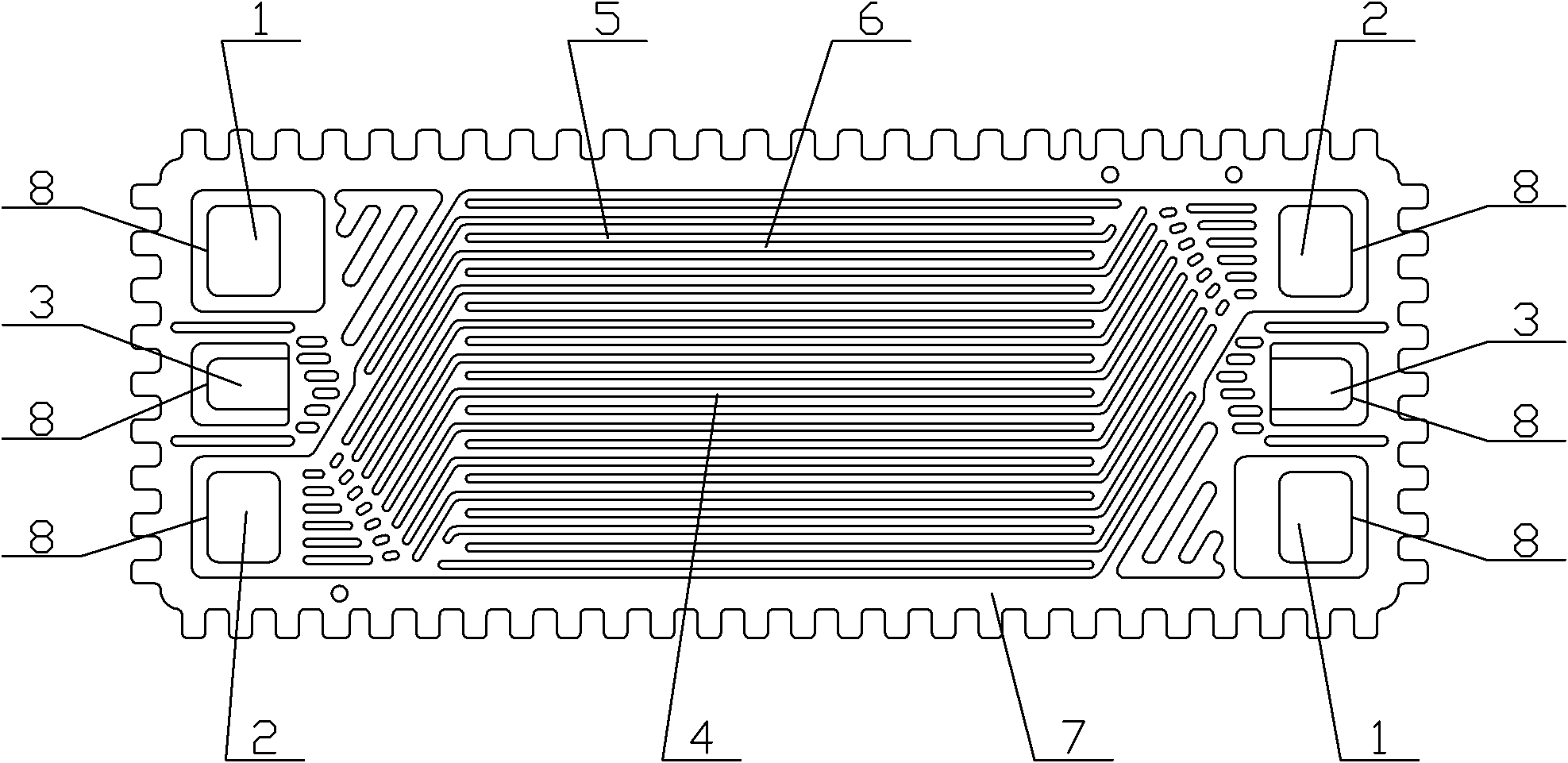

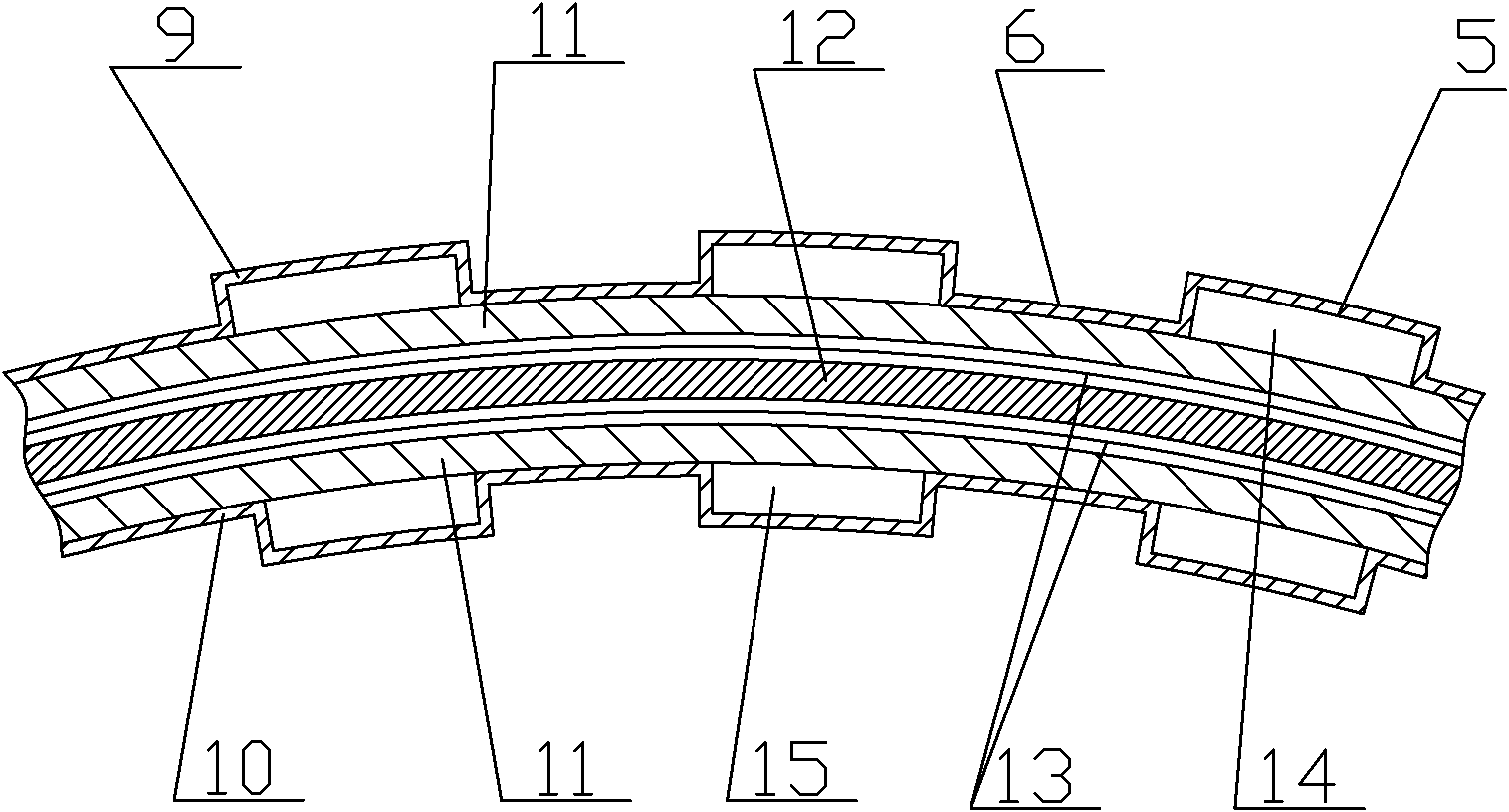

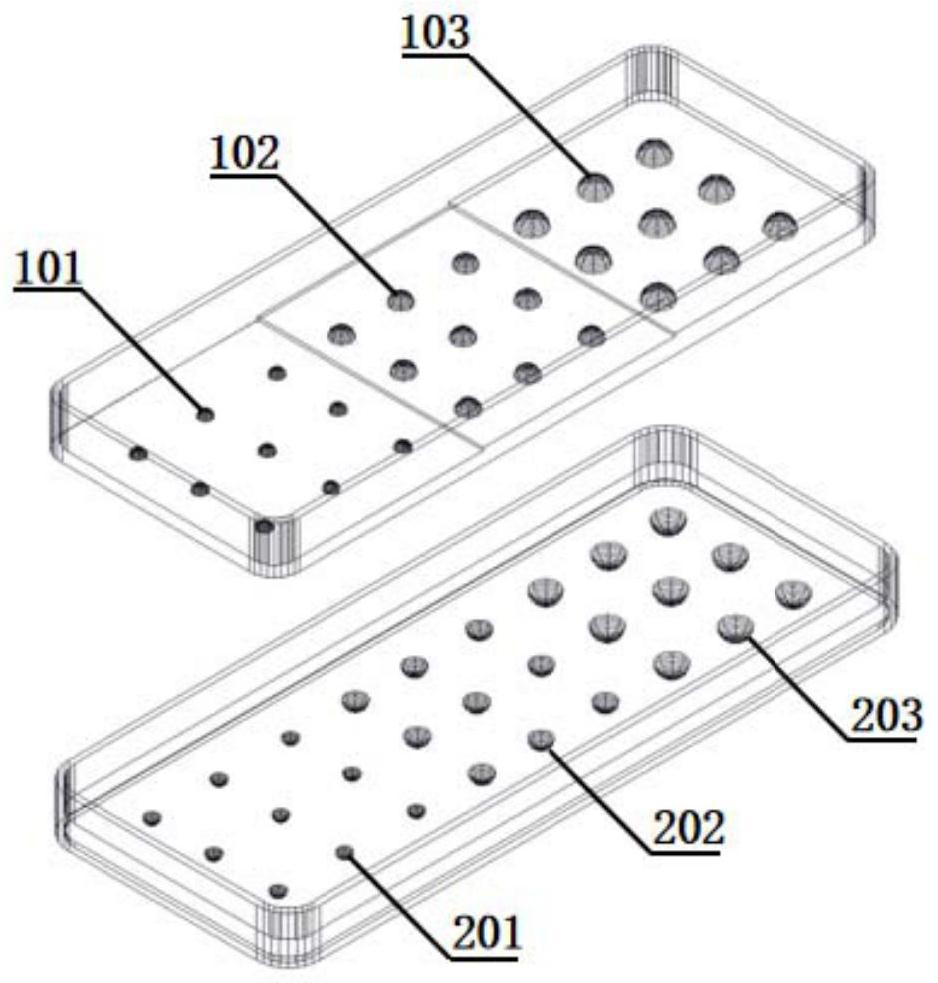

Metallic bipolar plate of proton exchange membrane fuel cell and single cell and electric stack formed by same

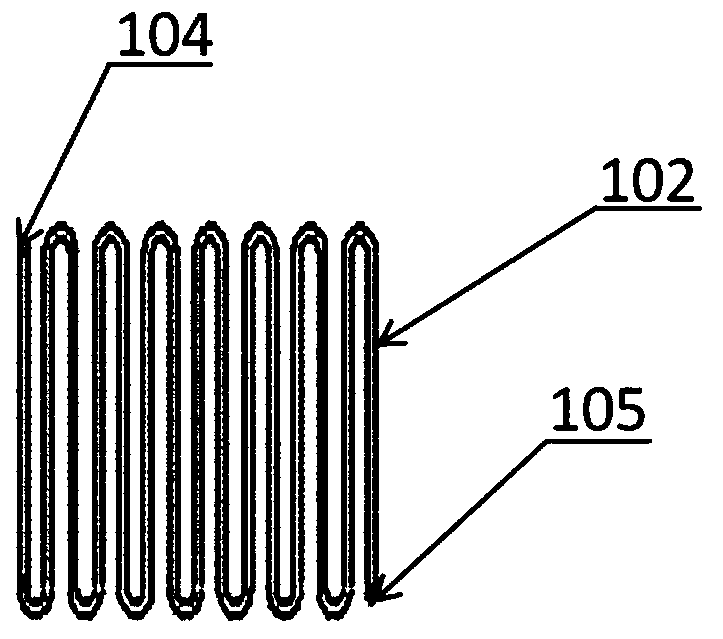

ActiveCN101937997AIncrease contactReduce reaction efficiencyFuel cells groupingCell electrodesInternal resistanceEngineering

The invention discloses a metallic bipolar plate of a proton exchange membrane fuel cell and a single cell and an electric stack formed by the same. The metallic bipolar plate is a non-planar arc plate with certain curvature, and is formed by relatively combining a cathode monopolar plate and an anode monopolar plate which are made of metal sheets; cathode and anode cavities, cooling medium cavities, flow field area grooves and lug bosses of the two plates have mutual corresponding convex-concave shapes and form a fuel gas passage, an oxidant gas passage and a cooling medium passage respectively; and a membrane electrode and single bipolar plate can be combined into single fuel cell, and a plurality of single cells can be superposed and connected to form the electric stack. Compared with a common metallic bipolar plate, the bipolar plate has better mechanical property, is not easy to deform or dislocated after assembly, and has high stability; and because the contact between the bipolar plate and a diffusion layer of the membrane electrode is good, the internal resistance is low, the energy consumption is low, and the formed electric stack can provide higher output voltage and higher output power.

Owner:WUHAN UNIV OF TECH

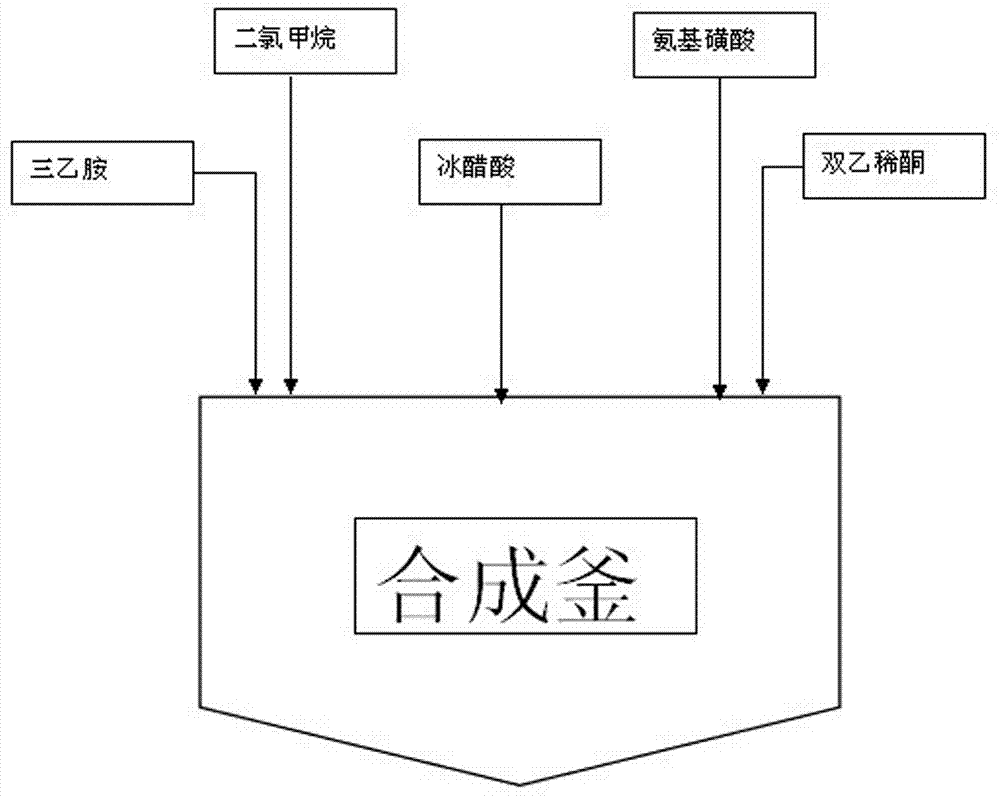

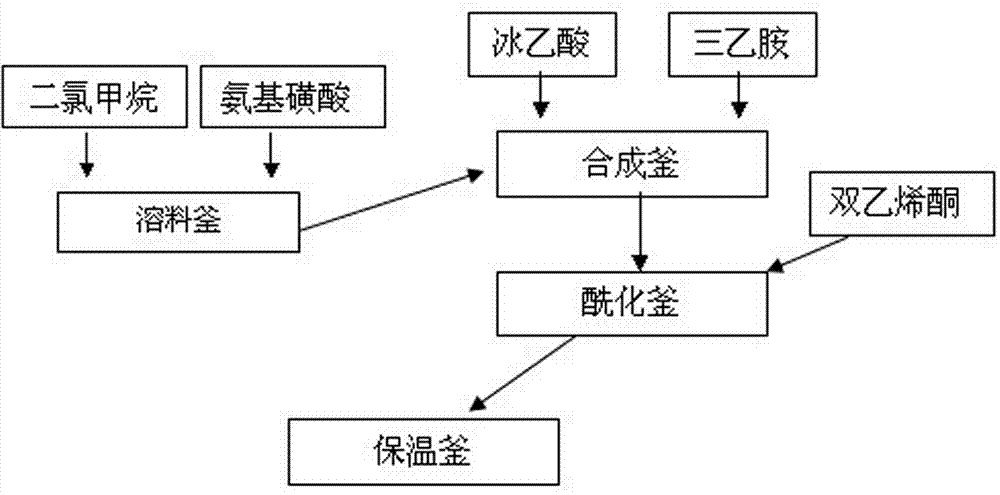

Acesulfame synthesis and acylation production process

InactiveCN103570592AReduce labor intensityImprove continuitySulfuric acid amide preparationAcetic acidEconomic benefits

The invention relates to an acesulfame synthesis and acylation production process, which comprises the following steps of a, putting a sulfamic acid and dichloromethane into a dissolving kettle, and pumping a mixture into a synthesis kettle; b, adding dropwise triethylamine into the synthesis kettle, adding dropwise a glacial acetic acid, and performing natural reaction for 1 hour after the glacial acetic acid is added dropwise; c, placing reactants in the synthesis kettle into an acylation kettle, and adding dropwise diketene for an acylation reaction; and d, after the diketene is added dropwise, circulating a product subjected to the acylation reaction for 1 hour in the acylation kettle, placing into a heat-preservation kettle, performing natural reaction for 1 hour to generate an acetoacetyl-N-sulfonate intermediate, and feeding the acetoacetyl-N-sulfonate intermediate to a sulfonation section for use. The acesulfame synthesis and acylation production process has the advantages that 1, a stepwise reaction mode is adopted, so that compared with a conventional single-kettle production process, the method has the characteristics of production operation continuity and high reaction stability; 2, a multi-kettle stepwise production mode is adopted, so that the production efficiency is greatly improved, the reaction efficiency of the whole production flow is optimized, and the economic benefits of an enterprise are significantly improved.

Owner:ANHUI JINGHE IND

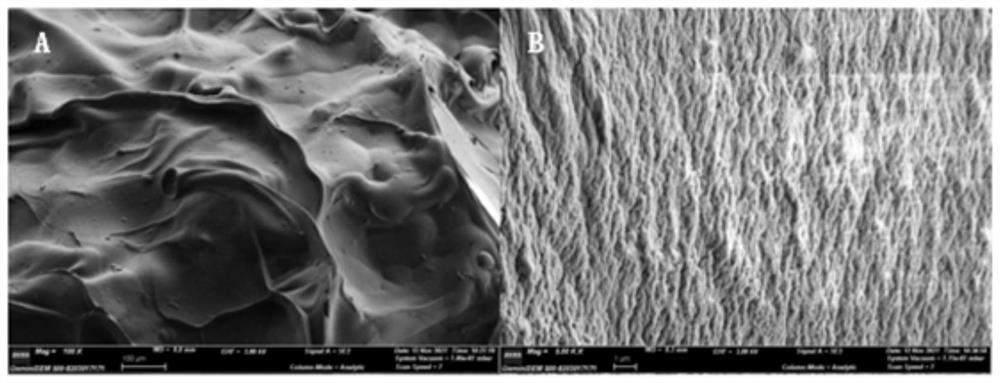

Support having protein immobilized thereon and method of producing the same

InactiveUS20100105879A1Reduce reaction efficiencyHigh in proteinPeptide preparation methodsDepsipeptidesChemistryBasic amino acids

A method of producing a protein-immobilized support includes immobilizing a protein having a tag sequence on a support, the tag sequence including a sequence that includes three or more consecutive basic amino acids.

Owner:JSR CORPORATIOON

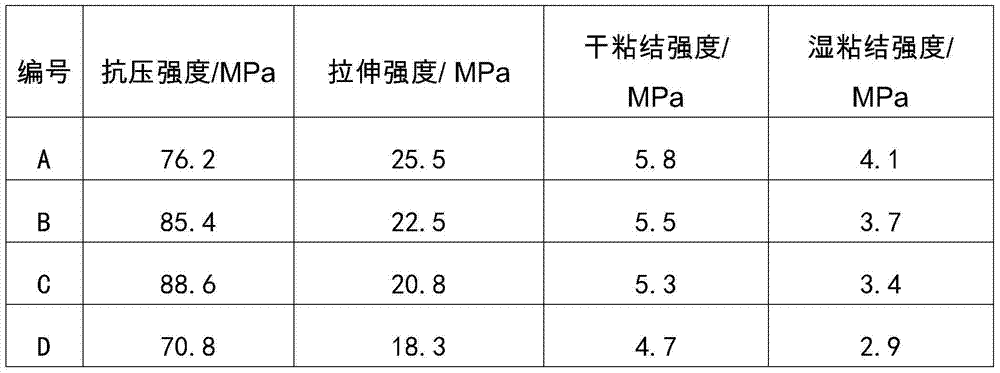

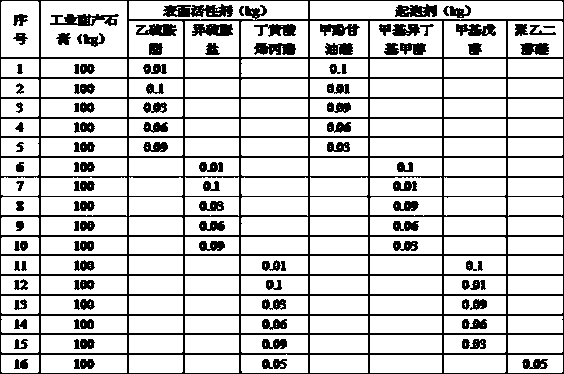

Preparation method of polyurethane modified epoxy resin and grouting material based on resin

The invention provides a preparation method of polyurethane modified epoxy resin. The preparation method comprises the following steps: firstly performing reaction on isocyanate and a hydroxyl group on epoxy resin to obtain polyurethane graft epoxy resin, further terminating isocyanate on the polyurethane graft epoxy resin with monohydric alcohol, and further grafting a polyurethane short branch chain on the epoxy resin by utilizing the unit termination of isocyanate so as to increase the intermolecular distance of the epoxy resin, reduce the intermolecular action force, improve the motion ability of a chain segment and simultaneously realize the effects of reducing viscosity of slurry and toughening; furthermore, a grouting material based on the polyurethane modified epoxy resin provided by the invention can effectively reduce the intermolecular physical crosslinking and realize strong permeability and good toughness; data shows that the compressive strength exceeds 70MPa, the tensile strength is more than 20MPa, the dry bonding strength is more than 5MPa, and the wet bonding strength is more than 3MPa.

Owner:BEIJING TIEKE SHOUGANG RAIL TECH CO LTD

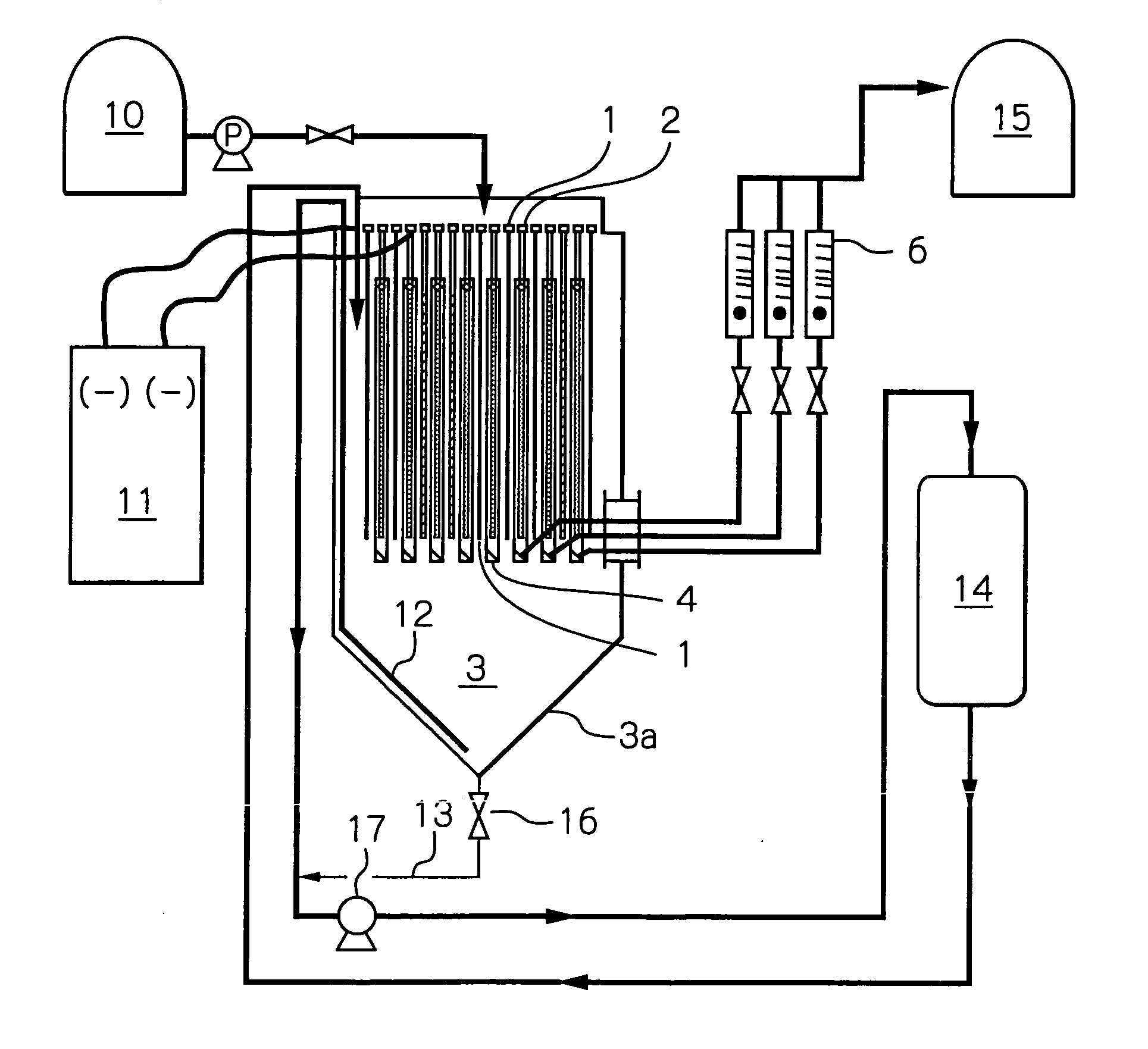

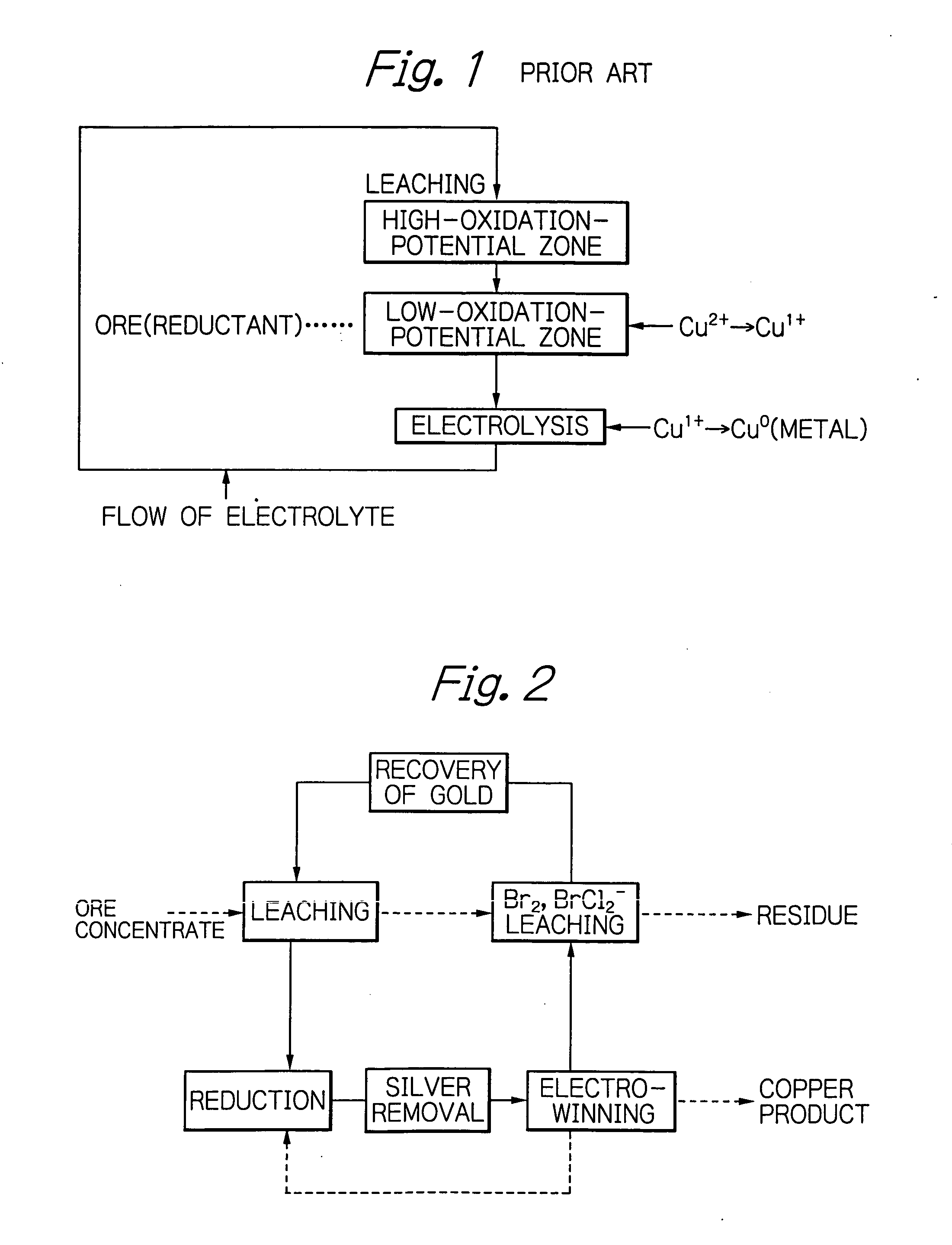

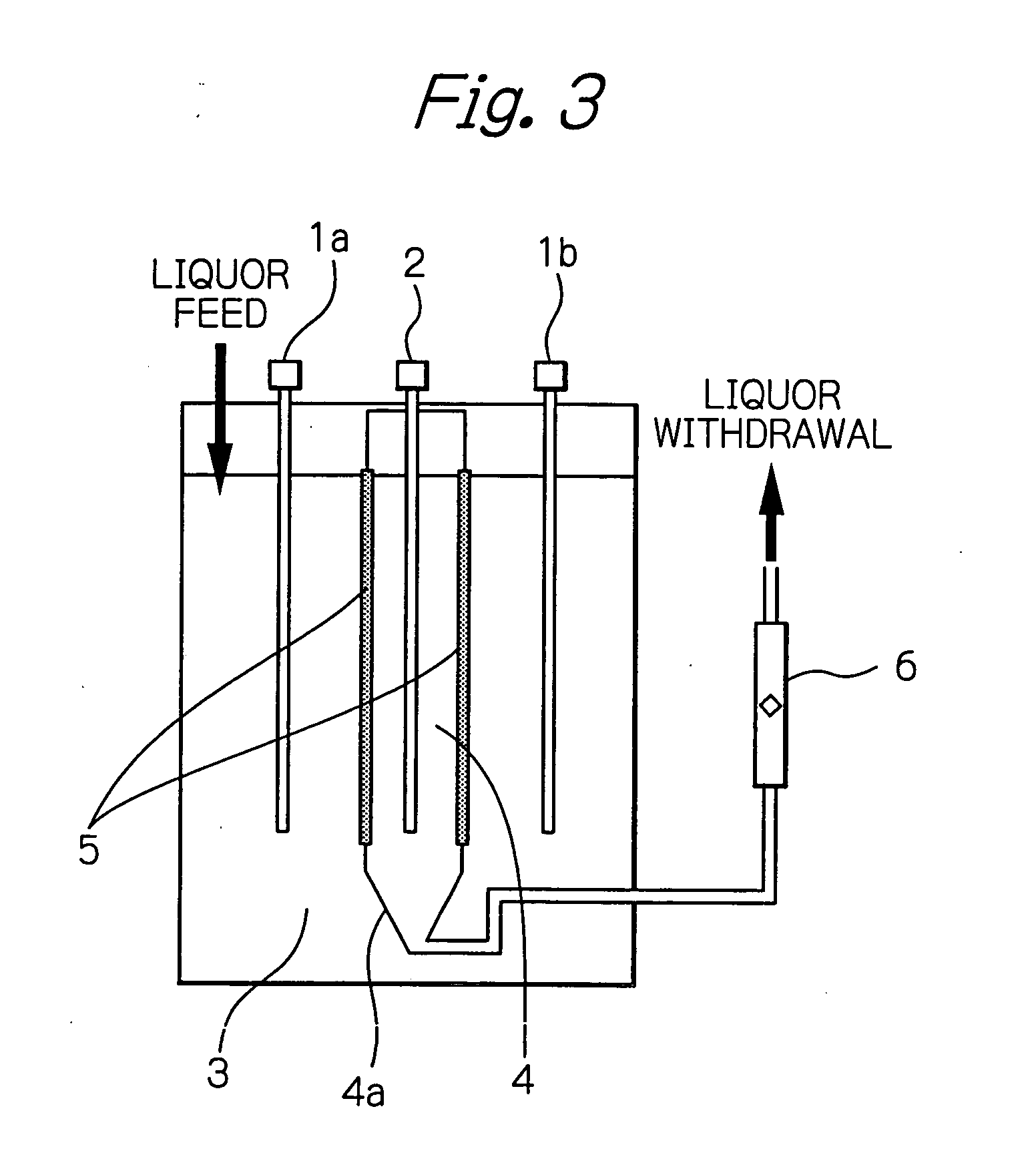

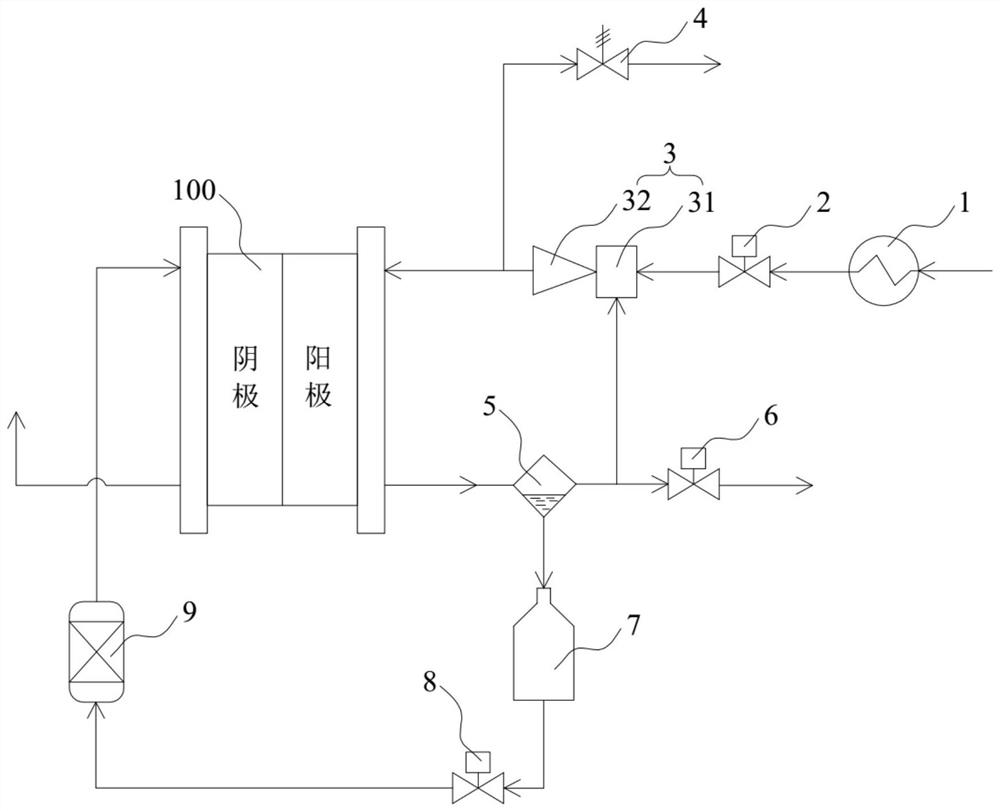

Electrolytic method in diaphragm-type cell

InactiveUS20050067299A1Improve leaching efficiencyReduce reaction efficiencyPhotography auxillary processesElectrolysis componentsPregnant leach solutionChloride electrolytes

In a metal-winning method, copper ore or copper-ore concentrates is effectively hydraulically leached in a chloride leach liquor and the resultant leached liquor is diaphragm-electrolyzed. A chloride electrolyte containing Br− ions and the leached metals is subjected to a diaphragm-electrolysis in an electrolytic cell comprising an anode compartment (4) and a cathode compartment (3). A portion of the electrolyte in the anode compartment (4) is withdrawn from below an anode (2) of the anode compartment (4) and is returned to the leaching step so as to increase the oxidation potential of the chloride leach liquor.

Owner:JX NIPPON MINING& METALS CORP +1

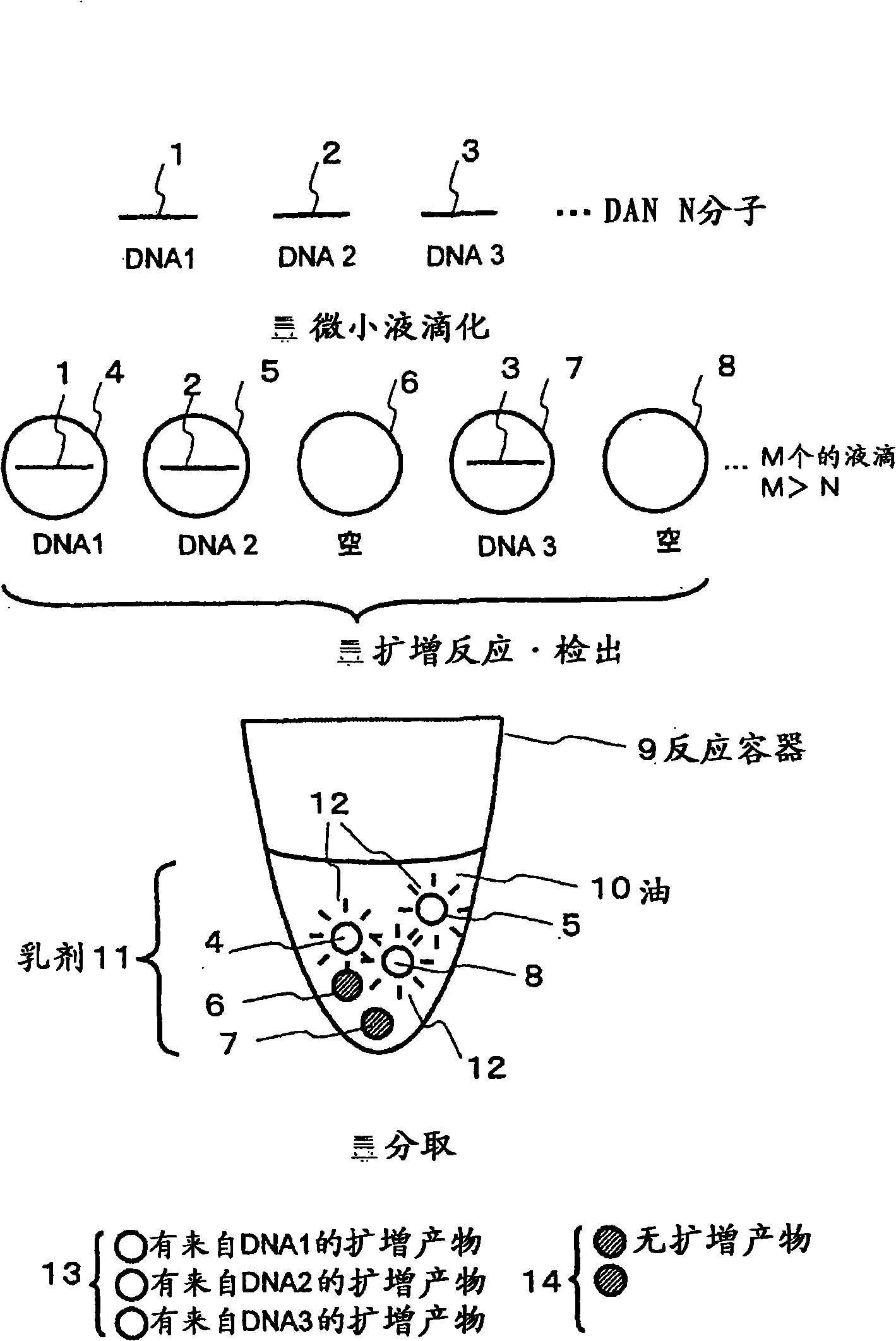

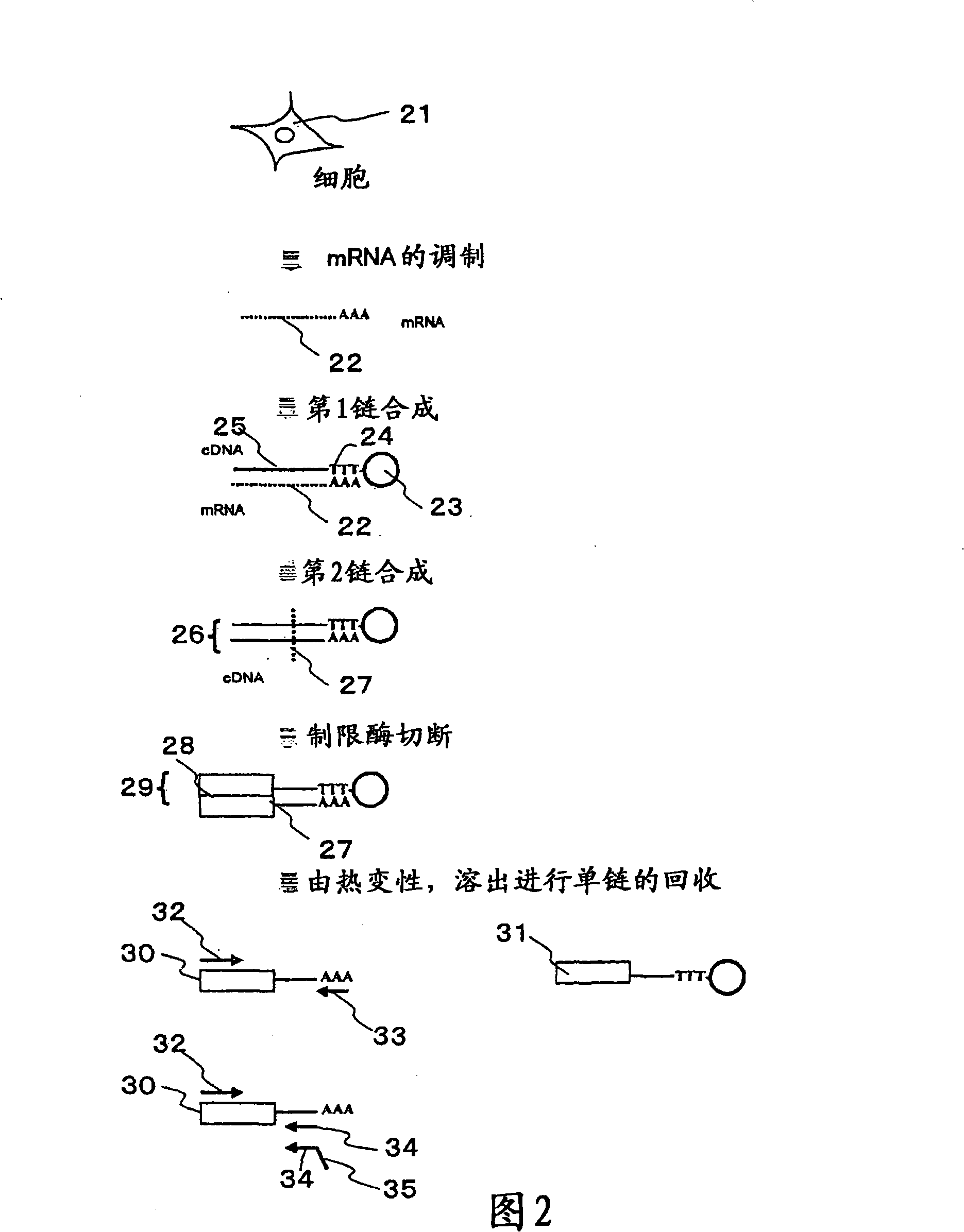

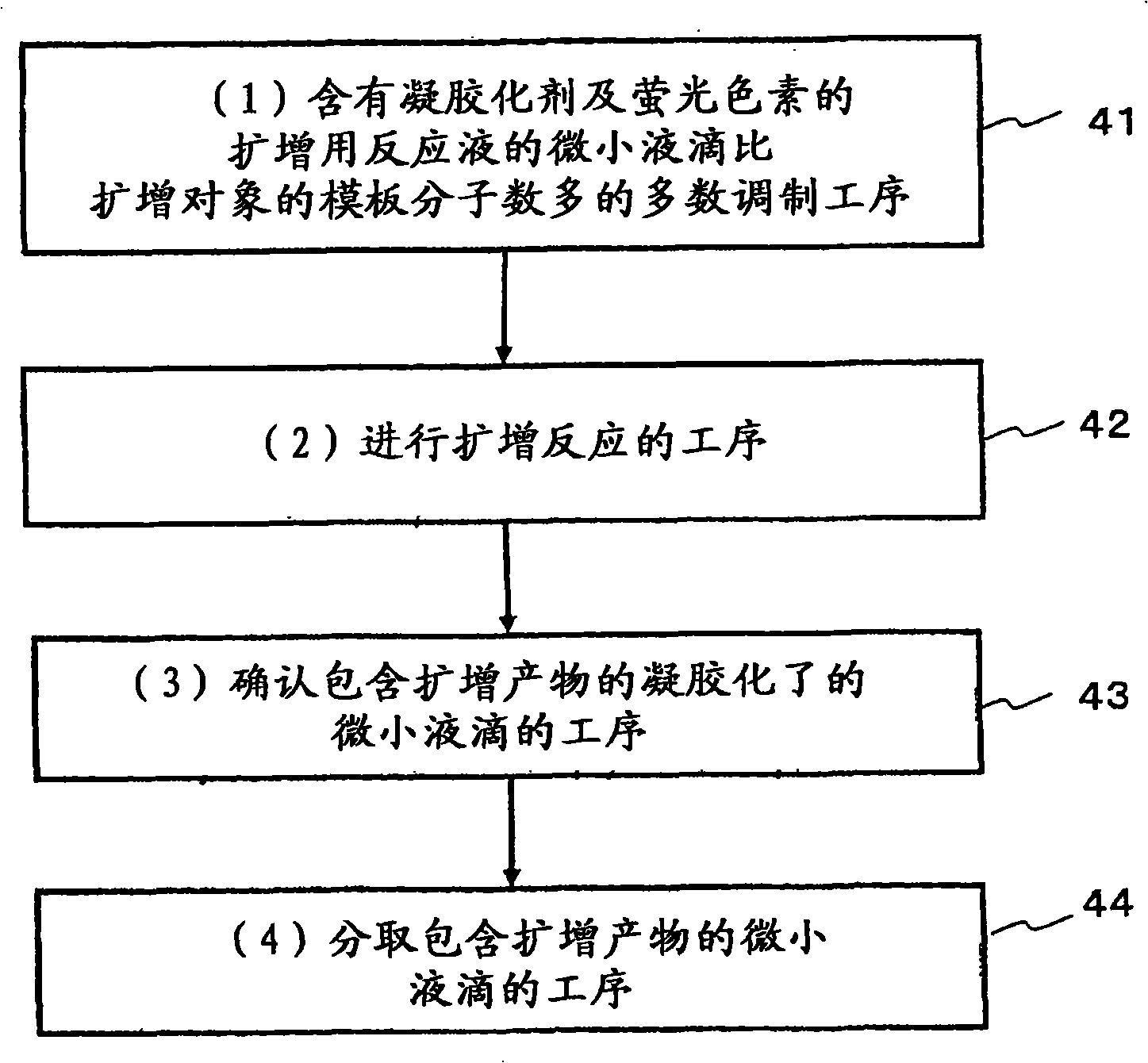

Method and apparatus for sample preparation

InactiveCN101275164AReduce lossesReduce reaction efficiencyMicrobiological testing/measurementFluorescence/phosphorescenceAnalyteSmall droplet

A method of the present invention comprises fractionating a sample solution containing analyte DNA molecules into small droplets, wherein the number M of the droplets is greater than the total number N of the DNA molecules, subjecting an emulsion containing the droplets to, for example, PCR amplification, and detecting the presence or absence (amount) of an amplicon obtained in each droplet by fluorescent detection using an intercalator or the like.

Owner:HITACHI LTD

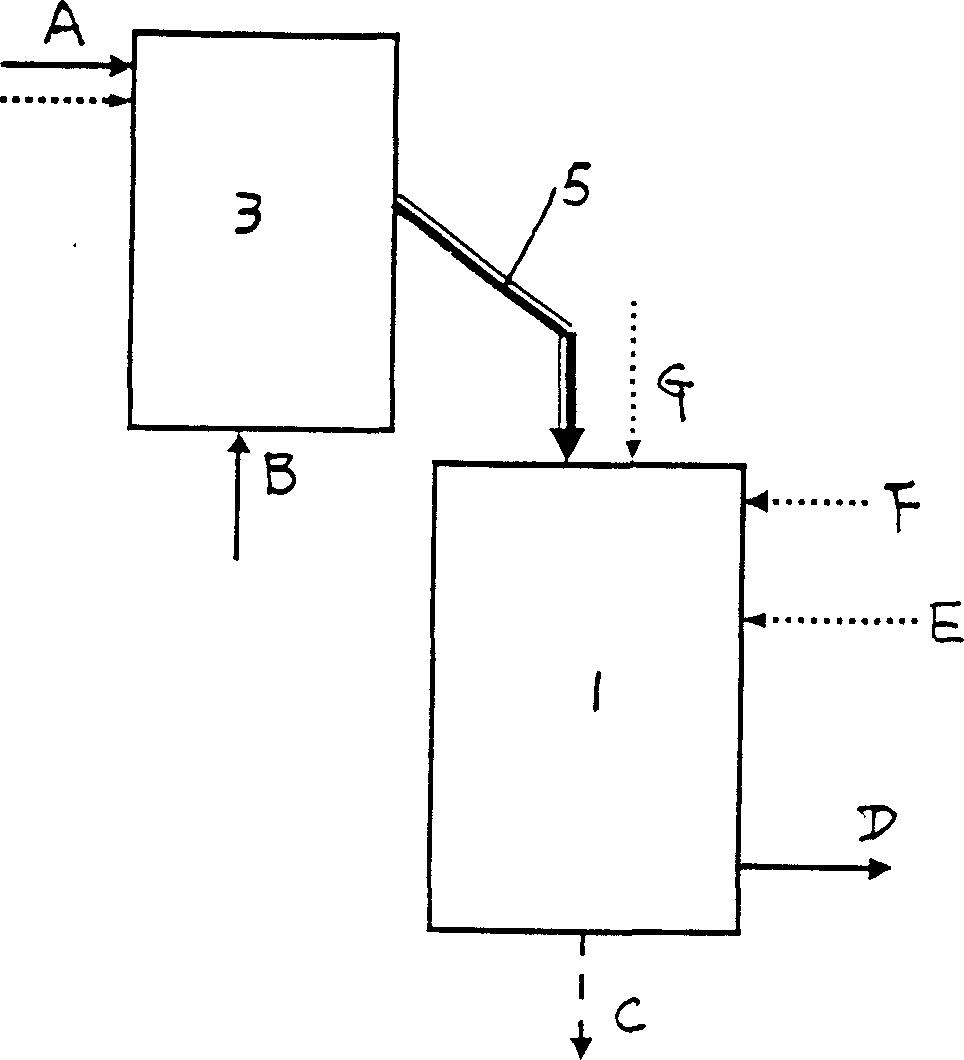

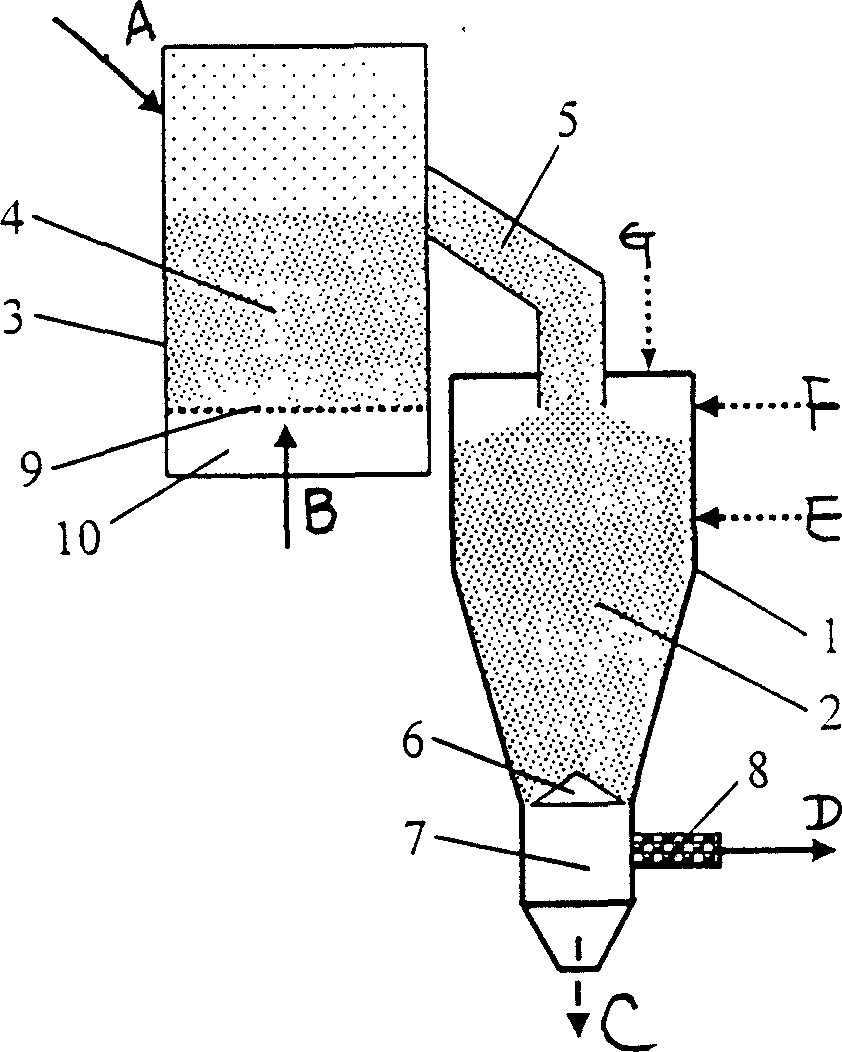

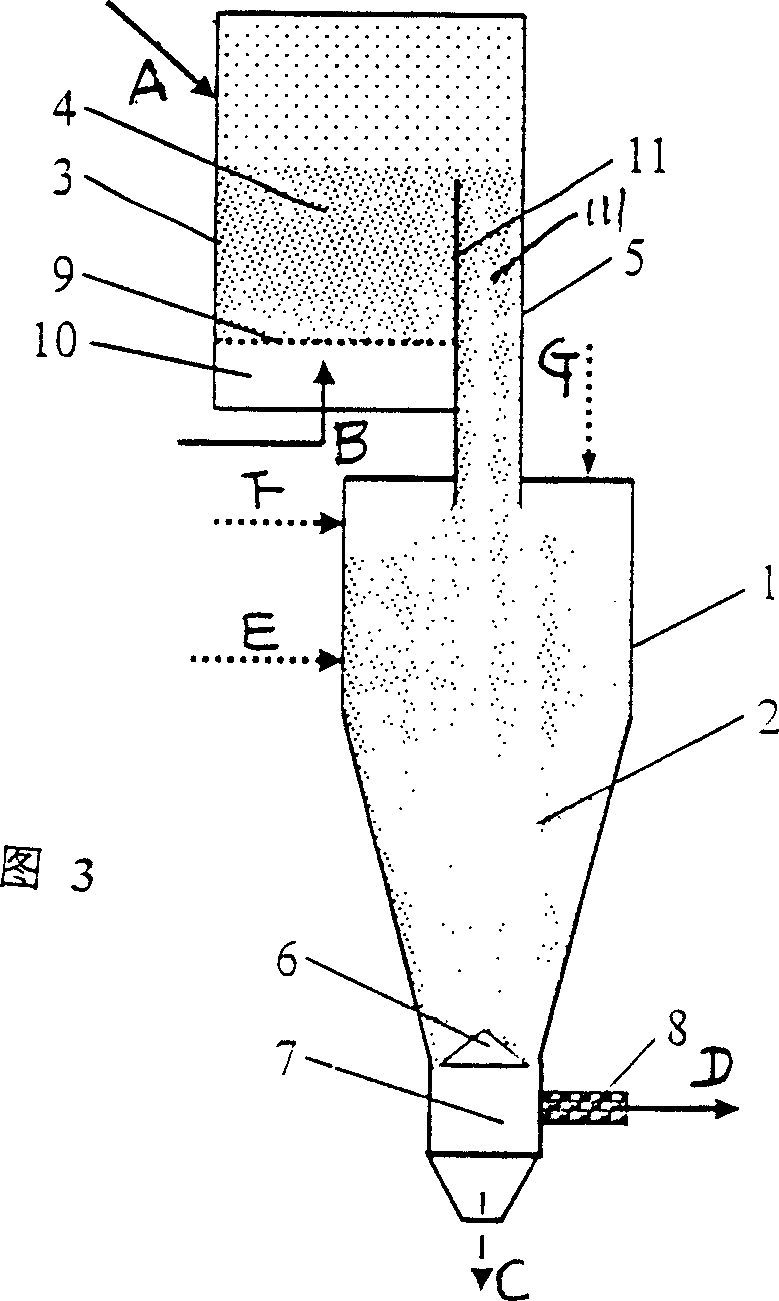

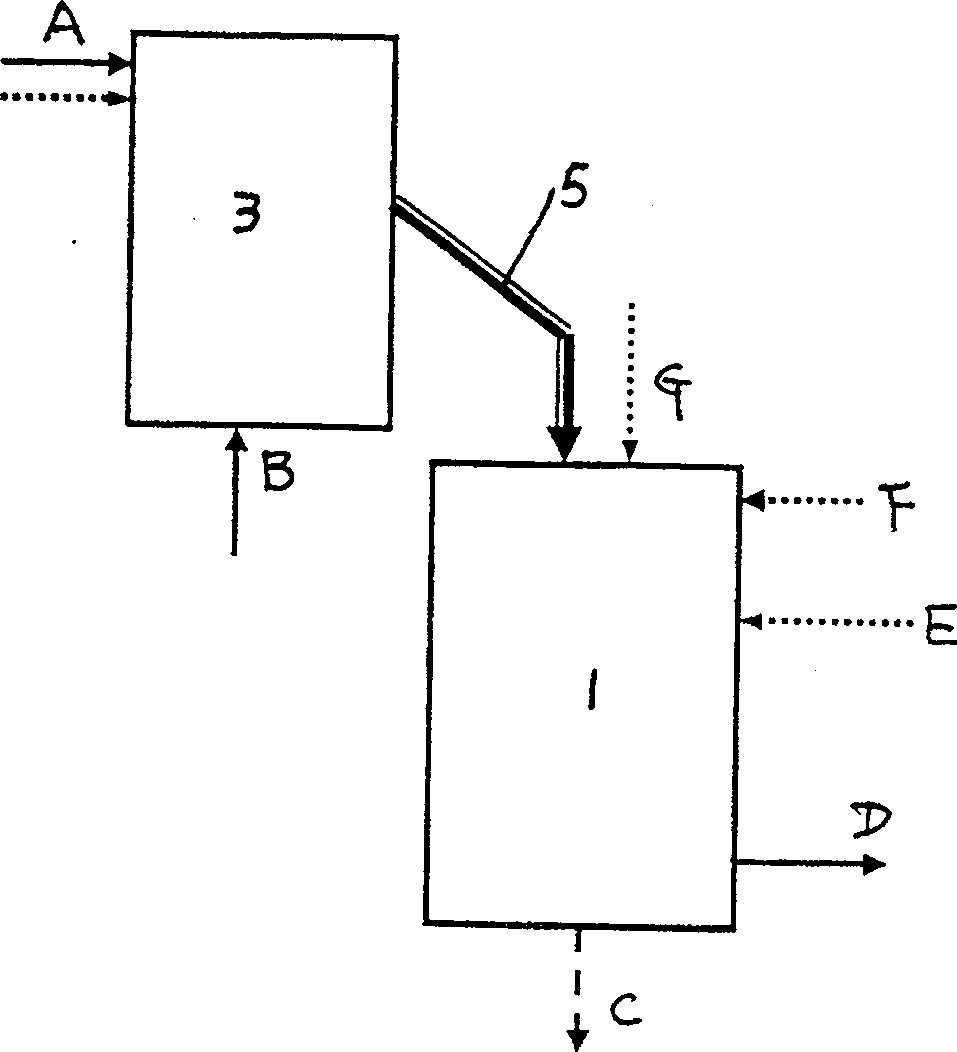

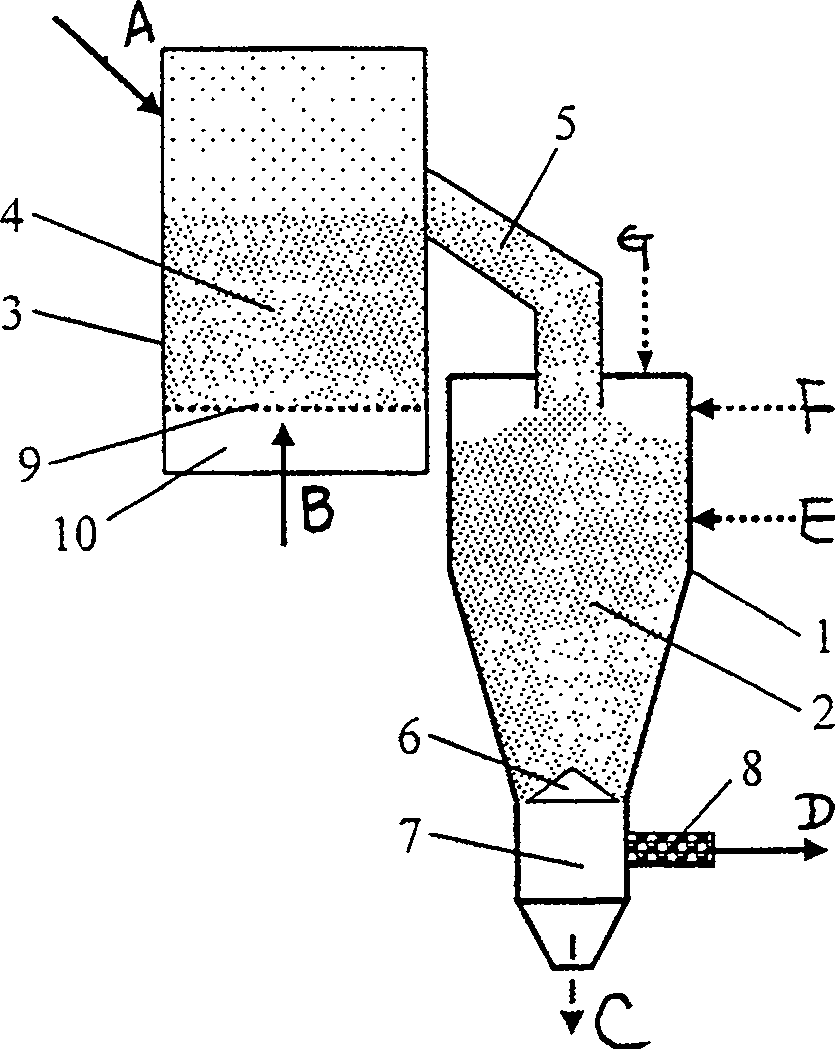

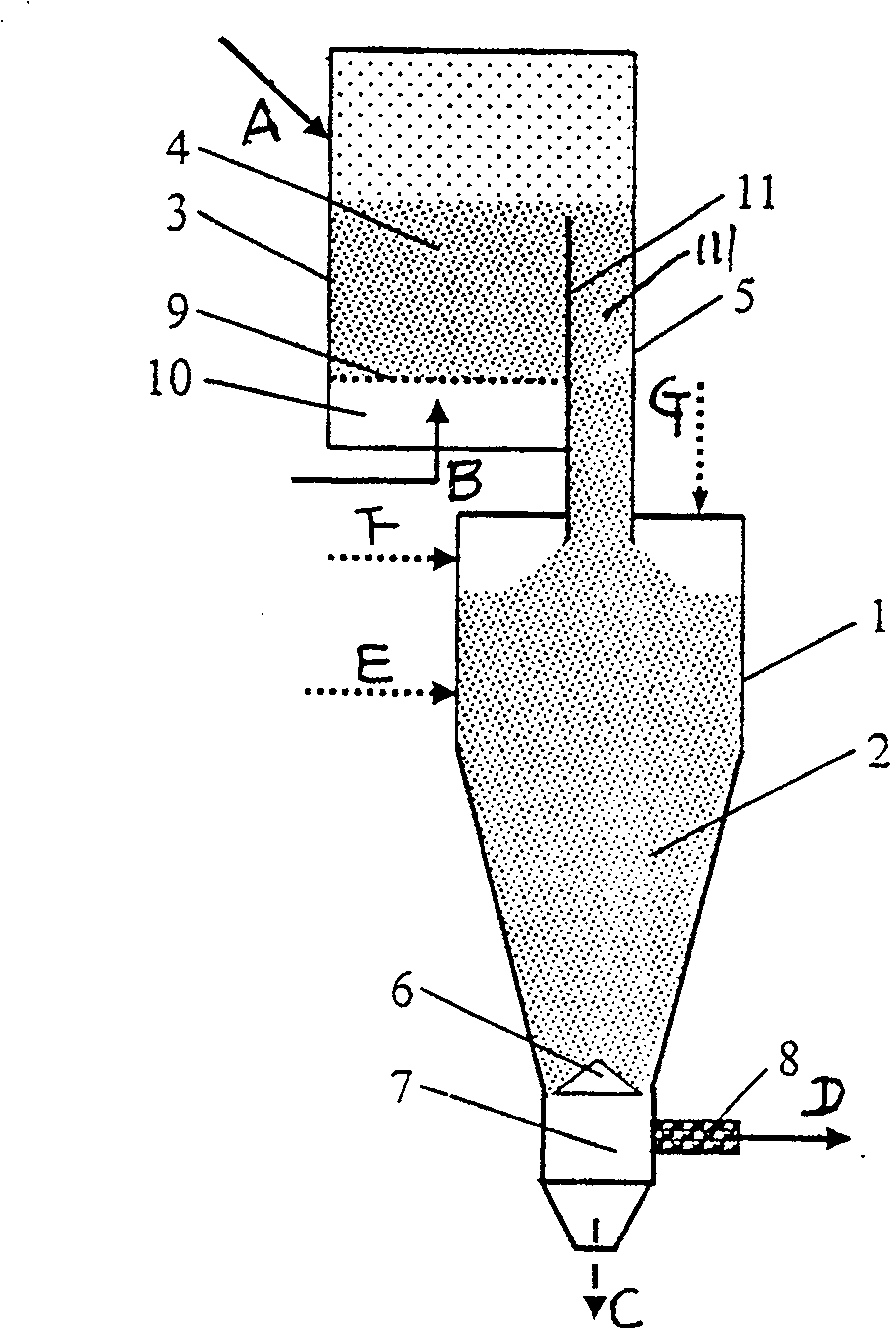

Bottom feed type gas method and equipment for preparing gas with no tar products through oxygendeficient fluid bed combustion

InactiveCN1916123AAccelerate modification/decomposition reactionSimple equipment structureBulk chemical productionGranular/pulverulent flues gasificationTarFluidized bed combustor

This invention relates to downdraft gasification method and equipment for preparing tar-free product gas by oxygen-deficient fluidized burning. The equipment comprised a front fluidized bed burner, a downdraft fixed bed gasifier set lower than the burner, a transporting pipe for carbocoal and semi-finished gas connecting the burner and the gasifying furnace, a fuel inlet and an oxidant inlet. The method comprised: (1) adding fuel through the fuel inlet of the fluidized bed burner, and performing oxygen-deficient fluidized burning with oxidant added through the oxidant inlet at the bottom of the fluidized bed burner to obtain carbocoal and semi-finished gas containing tar, and (2) sending the unseparated carbooal and semi-finished gas containing tar to a down-draft fixed bed gasifier at a high temperature to gasify the carbocoal, and modifying and cracking the tar introduced by the semi-finished gas by the catalytic activity of high-temperature carbocoal to obtain the product gas with tar. The equipment has such advantages as simple structure, easy operation and high gasifying efficiency, and is suitable for a wide variety of fuels and can produce product gas without tar.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

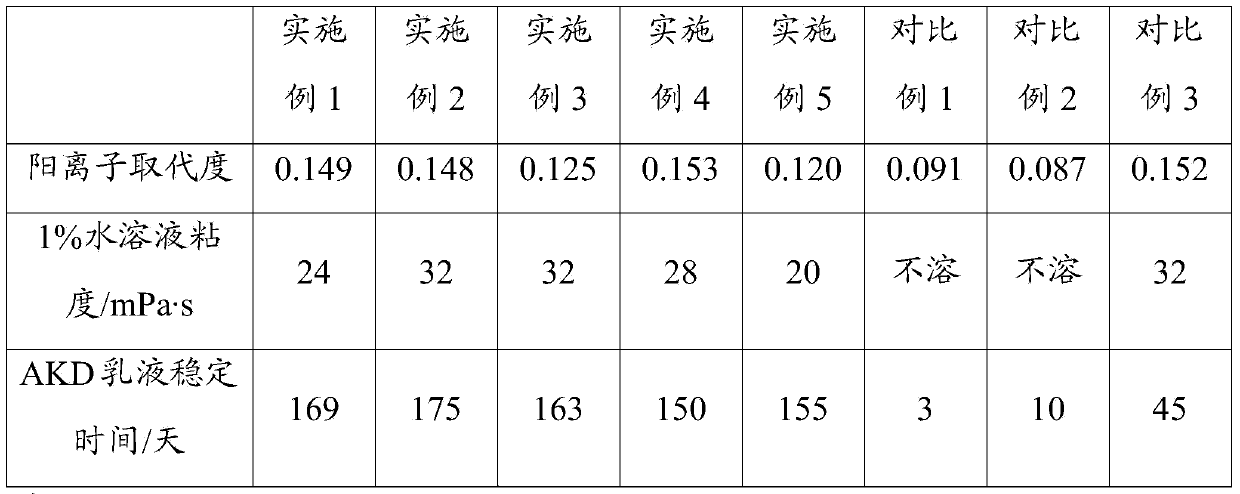

Cationic starch as well as preparation method and application of cationic starch

ActiveCN104193839AHigh degree of cationic substitutionImprove emulsion stabilityWater-repelling agents additionPaper coatingOrganic solventAqueous solution

The invention discloses a cationic starch as well as a preparation method and application of the cationic starch. The preparation method comprises the steps of (1) mixing starch and a water solution of 50-90% of organic solvent, and then, placing the mixture into a reaction vessel; (2) adding a catalyst, stirring and heating to 50-90 DEG C; (3) adding an etherifying agent, and reacting for 1-5h; (4) adding an oxidant, and reacting for 10-60 minutes; (5) adding acid until the pH value of the reaction system is up to 4-7; and (6) carrying out vacuum drying at the temperature of 50-90 DEG C and the vacuum degree of 0.07-0.1MPa to obtain the cationic starch. If the cationic starch obtained by using the preparation method disclosed by the invention is used as an AKD (Alkyl Ketene Dimer) emulsifier, the stability time of the AKD emulsifier at normal temperature can exceed three months.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

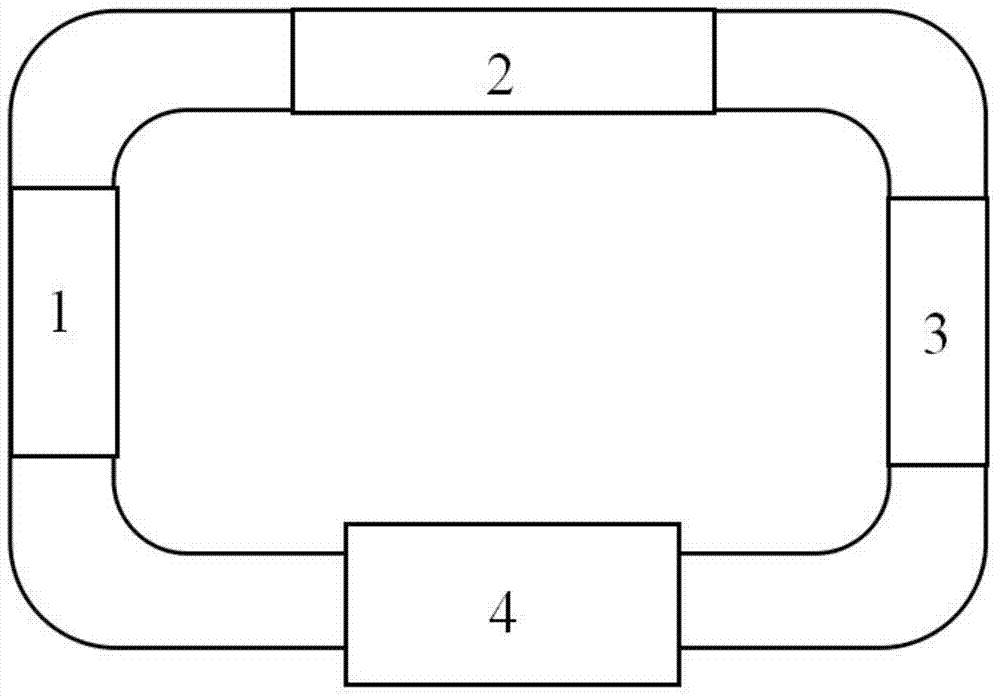

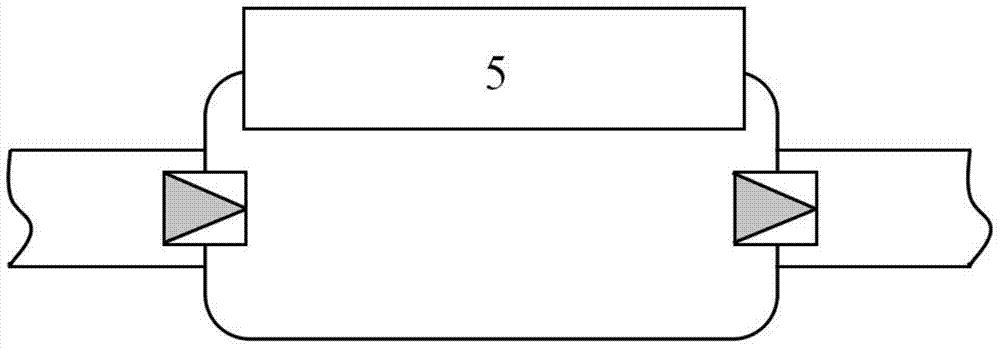

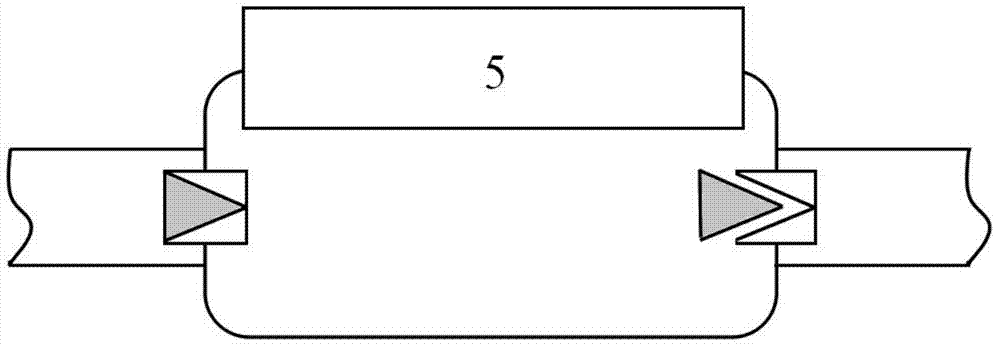

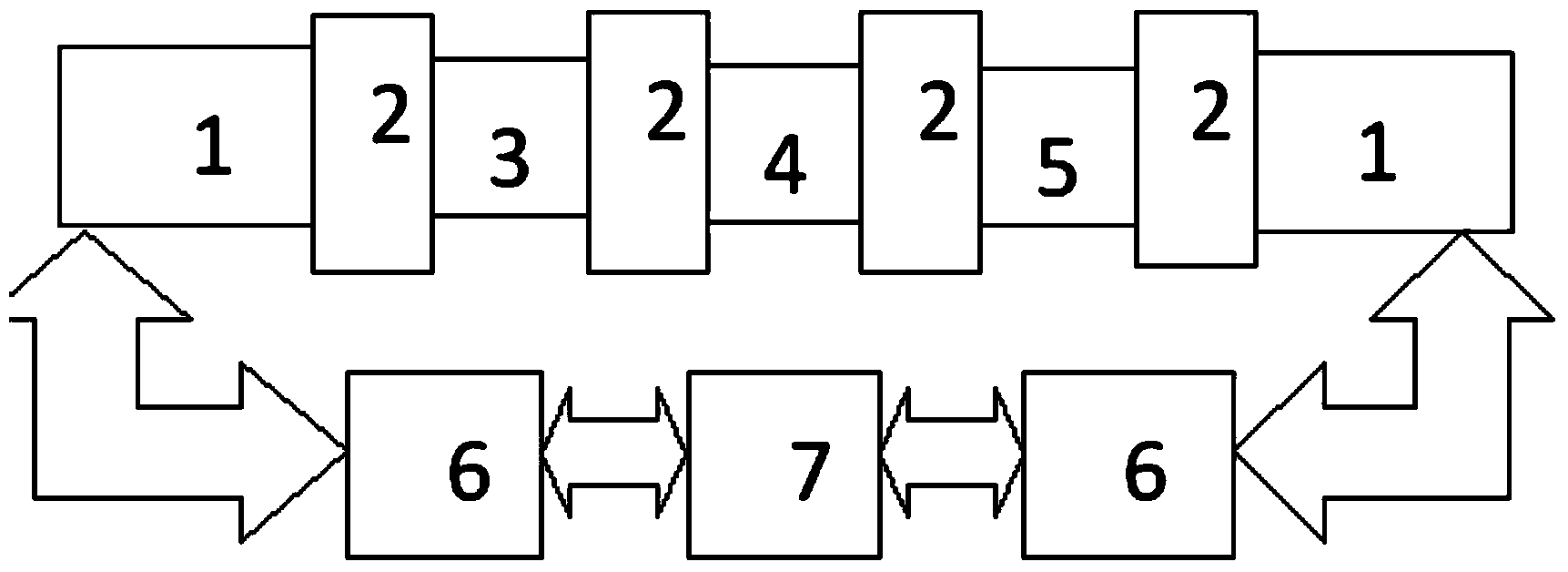

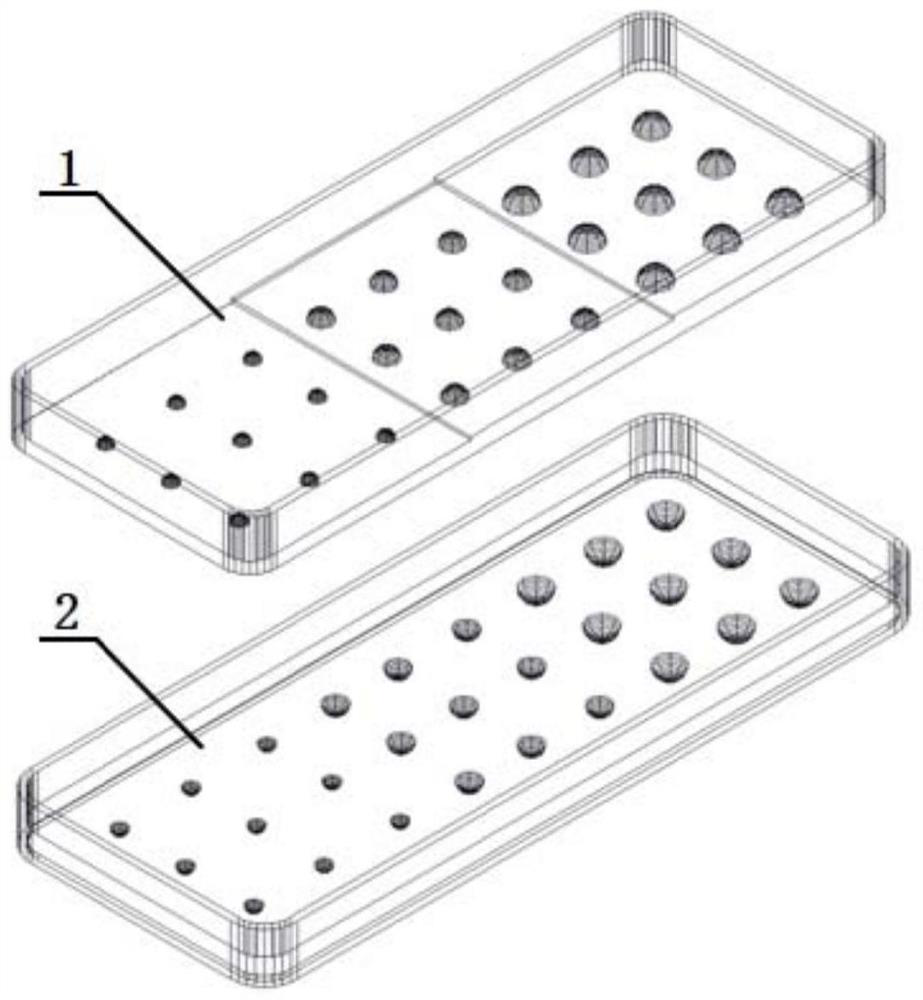

Single-microchannel PCR (Polymerase Chain Reaction) amplification system based on piezoelectric ceramic agitation conveying

InactiveCN103695308AMove preciselyEasy to carryBioreactor/fermenter combinationsBiological substance pretreatmentsMicrocontrollerFluorescence

The invention relates to a single-microchannel PCR (Polymerase Chain Reaction) amplification system based on piezoelectric ceramic agitation conveying. The system comprises a carrier microchannel, power modules and a singlechip control module, wherein the carrier microchannel serves as a biochip; the power of the system is realized by the combined action of piezoelectric ceramics and miniature electromagnetic valves, and the miniature electromagnetic valves are controlled by a singlechip. The system is mainly applied to the subsequent establishment of a real-time fluorescent detection device and an integrated biochip for PCR amplification reaction on a miniature carrier and PCR amplification reaction in a weightless environment, aims to consist of a single-microchannel-cycling PCR amplification reaction module and two kinds of power modules which are respectively applicable to conventional volume and miniature physical check-up, and is suitable for automatically working in a spatial in-orbit weightless environment, so that the aims of functional integration, structure miniaturization, light weight, small size and fully-automatic detection are achieved.

Owner:BEIJING UNIV OF TECH

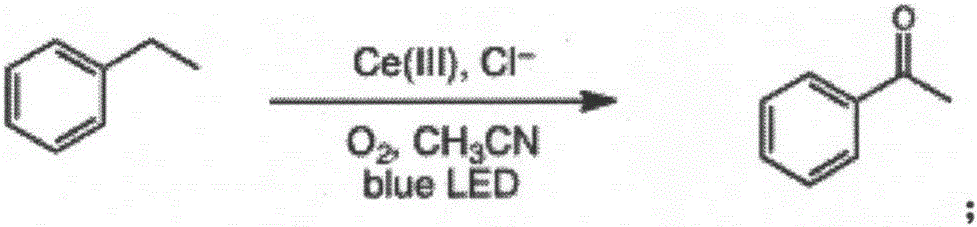

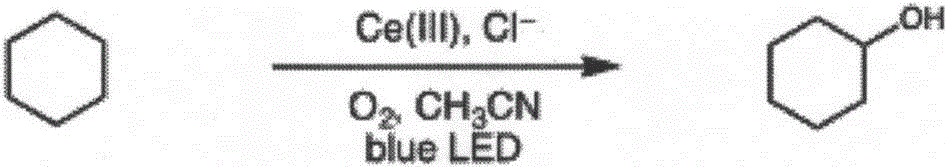

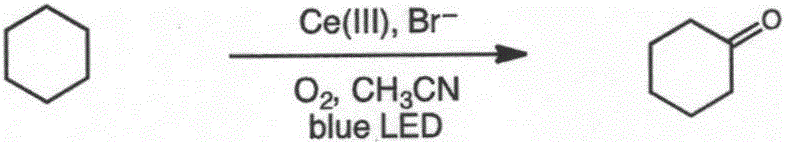

Visible light catalyzed saturated carbon-hydrogen bond direct oxidizing method

ActiveCN106831387ALow costStable in naturePreparation by oxidation reactionsOrganic oxidationCeriumOrganic compound

The invention provides a visible light catalyzed saturated carbon-hydrogen bond direct oxidizing method which is characterized by comprising the following step of performing a reaction on an organic compound and an oxidizing reagent in the presence of a cerium complex in a visible light irradiating condition to oxidize a saturated carbon-hydrogen bond of the organic compound to obtain an oxidized product. According to the method provided by the invention, the reaction is only performed at room temperature, so that the catalytic efficiency is high; energy required by an activating reaction is provided by means of visible light, so that the method is a more mild and green activating mode; and meanwhile, the used catalyst is low in cost, and the used oxidizing reagent is more stable in property, the industrial utilization cost is low, and the practicality of a catalytic system is high; meanwhile, pollution caused by heavy transition metals, peroxides and the like can be avoided.

Owner:SHANGHAI TECH UNIV

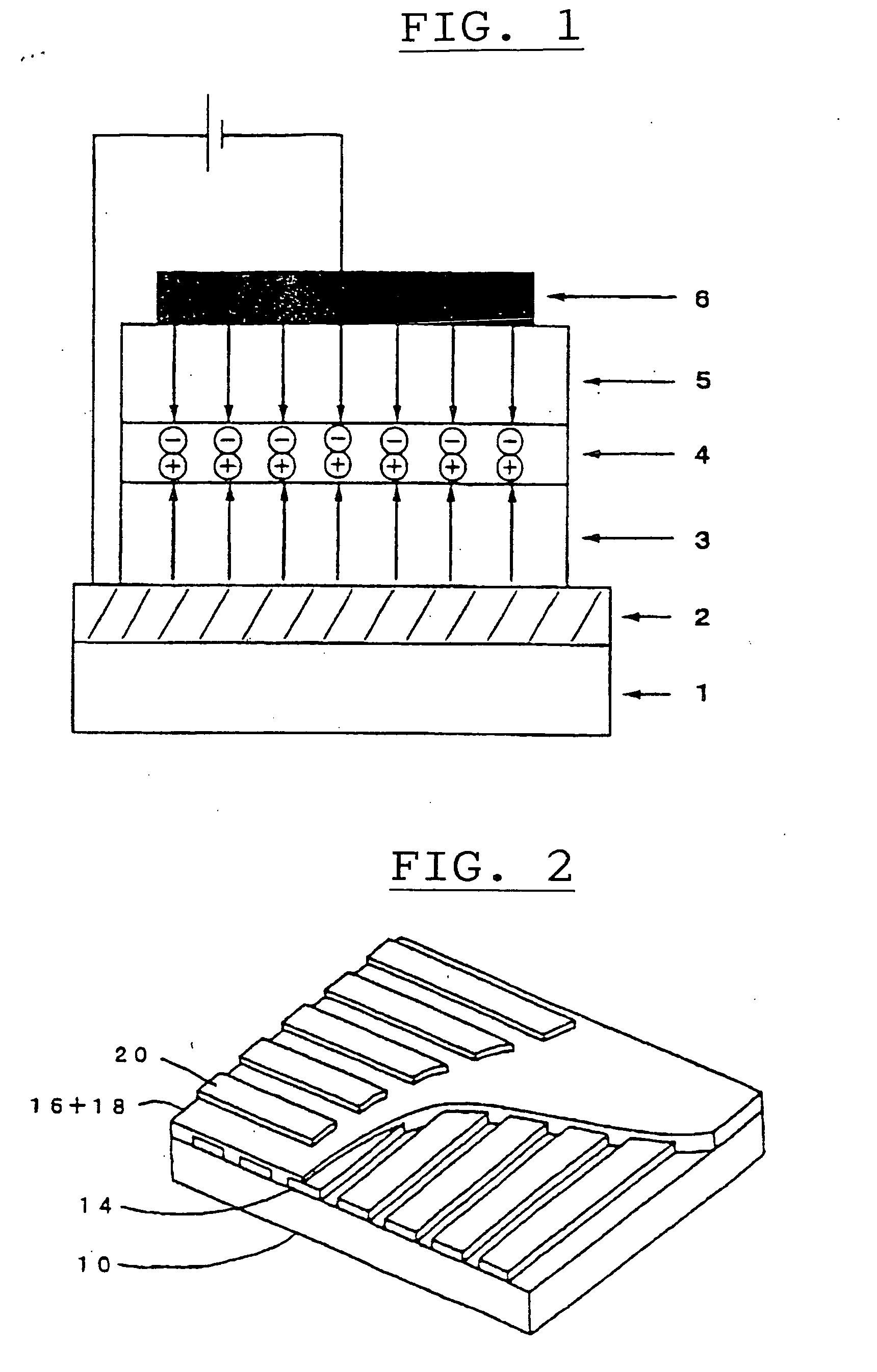

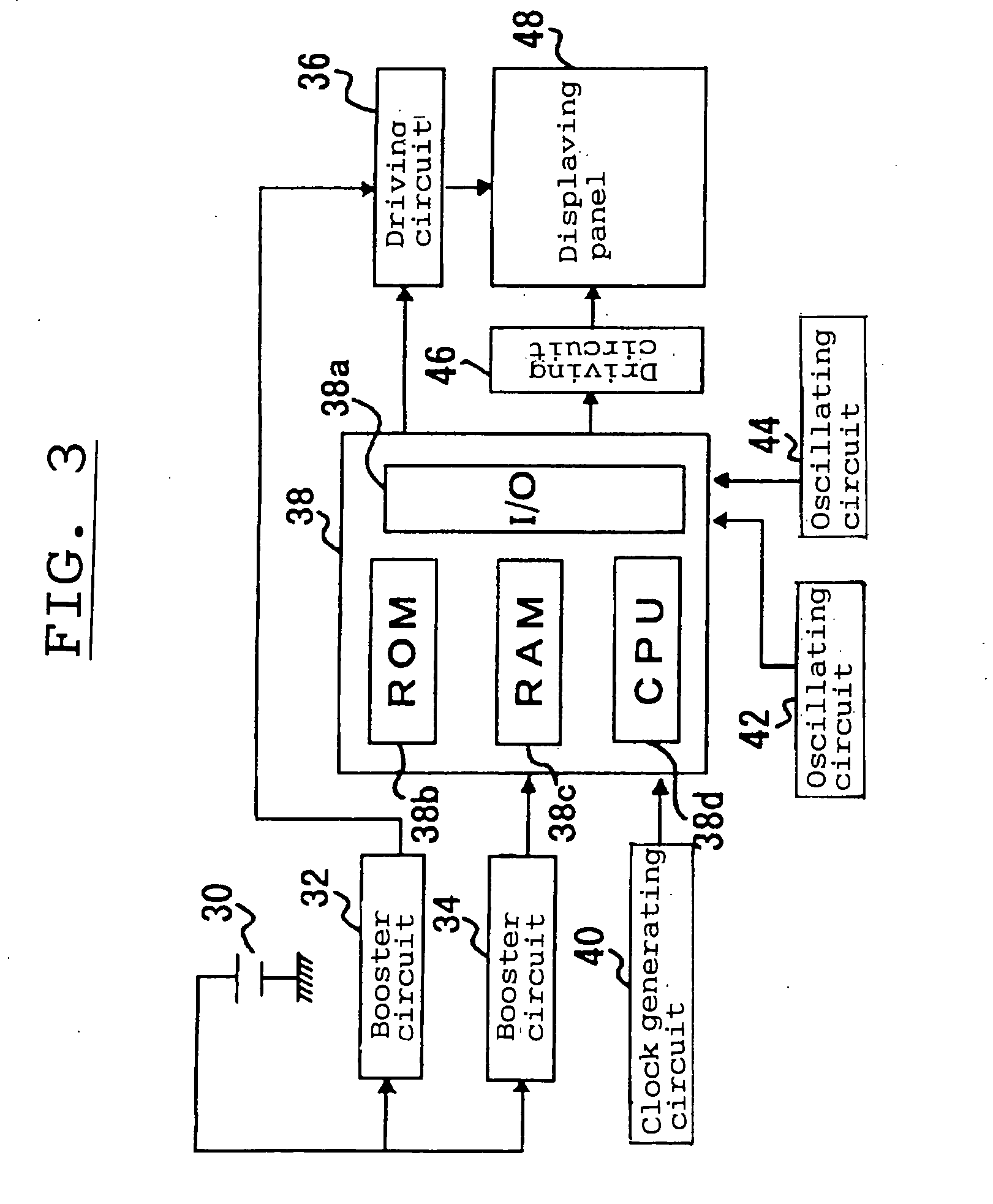

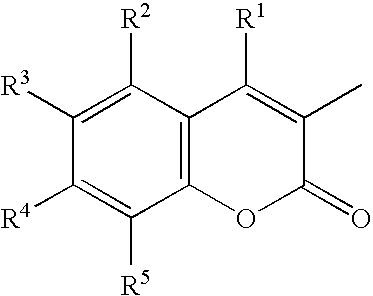

Coumarin compound

InactiveUS20050275341A1Satisfactory yieldReduce reaction efficiencyOrganic chemistryDischarge tube luminescnet screensCombinatorial chemistryMethyl group

A method for producing a coumarin compound represented by Formula 1, which comprises a step of reacting a coumarin compound represented by Formula 1 with a compound having an aldehyde group and an activated methylene group; luminous agents for organic EL elements and organic EL elements which all comprise the coumarin compound; and displaying panels and information displaying apparatuses using the organic EL elements: ø(Z)m Formula 1 wherein in Formula 1, ø is an aromatic ring, heterocycle, or a combination thereof, each Z is the same or a different coumarin group represented by Formula 2; and m is an integer of two or more; Formula 2:

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

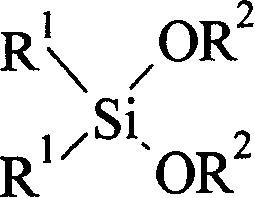

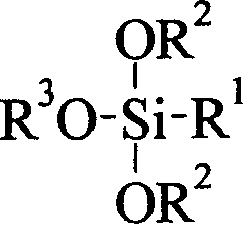

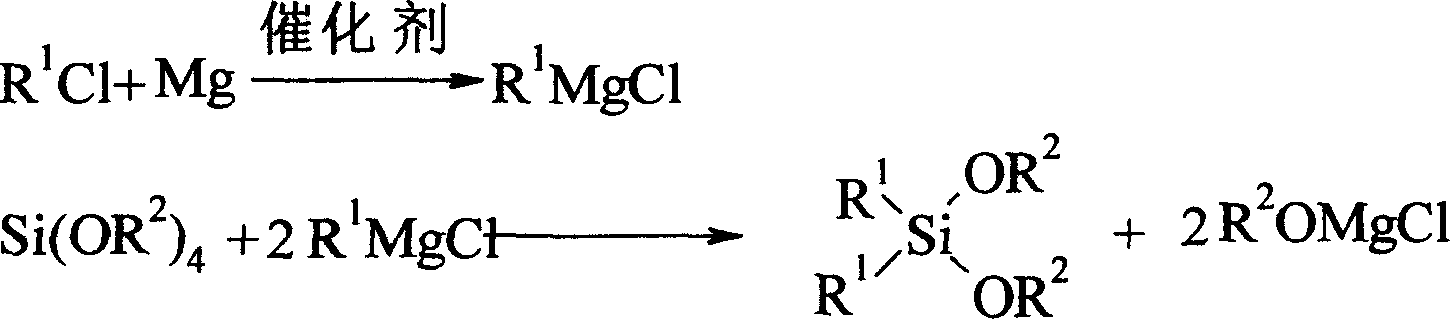

Method for directly synthesizing dialkyl dialkoxy silicane by one-step process

ActiveCN101225090AIncrease production costReduce reaction efficiencyGroup 4/14 element organic compoundsHydrocarbon solventsGrignard reagent

The invention discloses a method, which is characterized in that: reactant 4-alkoxy silicane is used as solvent; grignard reaction is firstly caused by alkyl halide with small amount and metal magnesium powder with particle size less than 150 mesh; then alkyl halide diluted by ethers or hydrocarbon solvent is added through dropping; the preparation method for grignard reagent at the spot enables the grignard reaction and synthesis reaction of dialkyl dialkoxy silicane to be made in the same vessel at the same time, thereby directly synthesizing dialkyl dialkoxy silicane by one step; solid substance separated from reaction suspension is washed using dispersing agent; the filtrate and the lotion are fractionated, thereby getting dispersing agent and reactant successively and finally getting dialkyl dialkoxy silicane with the content of bigger than 99.5%. The preparation method of Grignard reagent at the spot has an advantage of realizing ideal result of more than 85% of product yield and more than 99.5% of product content.

Owner:山东鲁晶化工科技有限公司

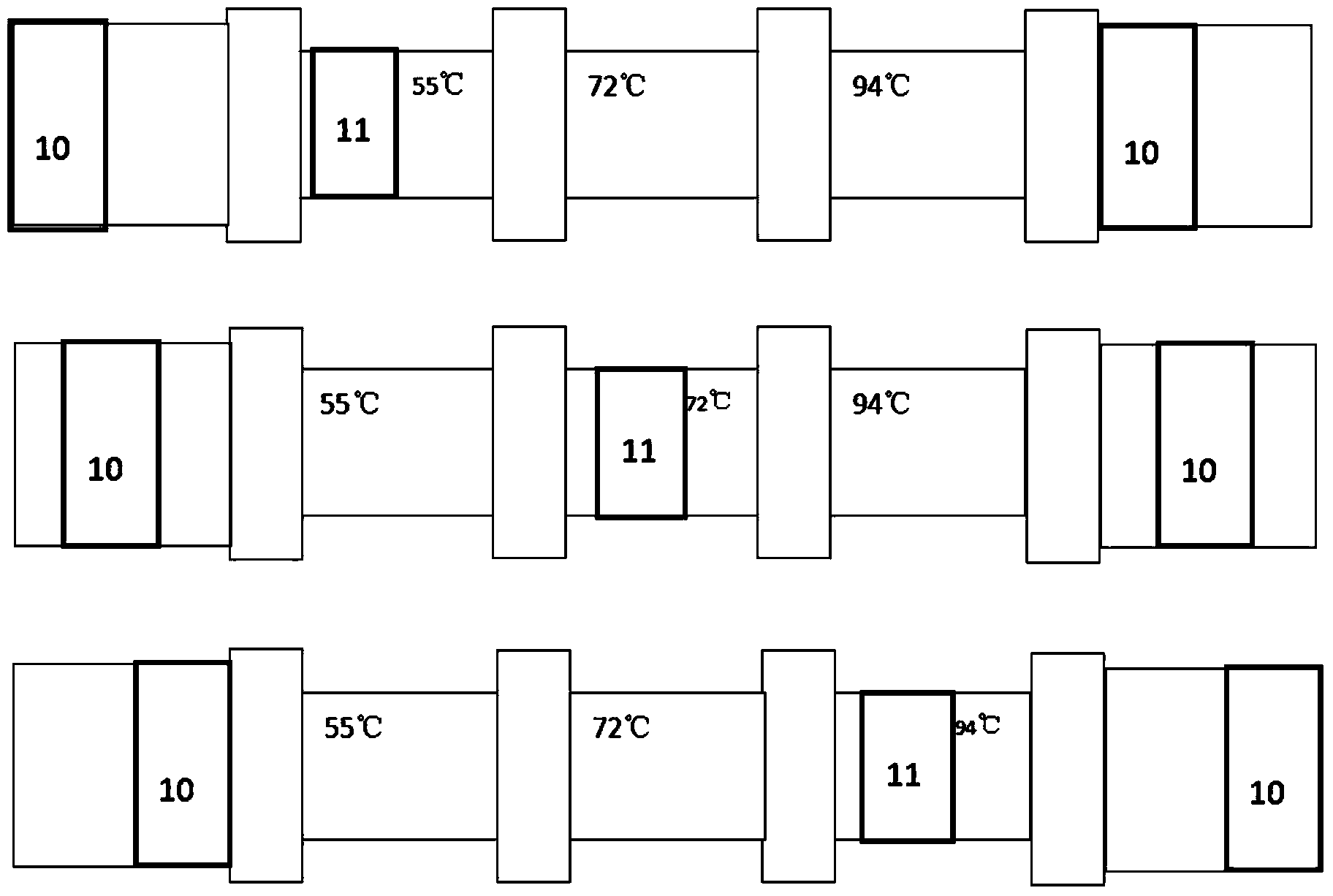

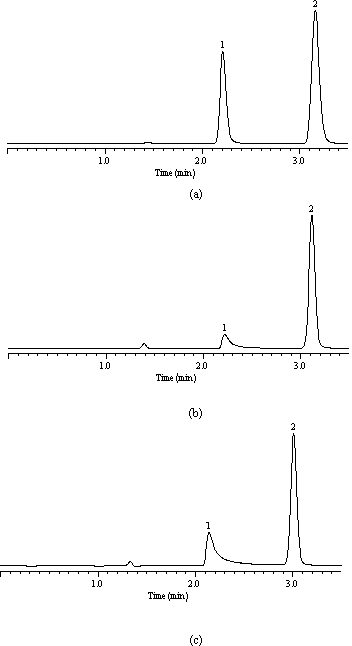

Reciprocating type circulating single micro-channel device facing fluorescent PCR (Polymerase Chain Reaction) micro-system

InactiveCN103614290AFully automated operationAutonomousBioreactor/fermenter combinationsHeating or cooling apparatusFluorescenceEngineering

The invention relates to a reciprocating type circulating single micro-channel device facing a fluorescent PCR (Polymerase Chain Reaction) micro-system and belongs to the detection fields of biology, analytical chemistry and medical science. The reciprocating type circulating single micro-channel device is characterized in that three temperature regions in PCR amplification are composed of metal pipes with good thermal performances; the three metal pipe temperature regions are connected by using ultraviolet laser cure optical colloids; the reciprocating type circulating single micro-channel device not only has the effects of isolating heat, sealing and supporting, but also has the light transmitting property; a mini-type fluorescent detection system can also be arranged to form a real-time fluorescent PCR microfluidic system. The reciprocating type circulating single micro-channel device has the essences that compressed air or silicone oil moves back and forth in a single micro-channel and a small section of a PCR reagent is used for finishing the PCR amplification of forty temperature cycles in the three temperature regions. Therefore, the volume and the weight are reduced, the reagent is saved and the reciprocating type circulating single micro-channel device is suitable for automatically working in a space on-orbit zero-gravity environment.

Owner:BEIJING UNIV OF TECH

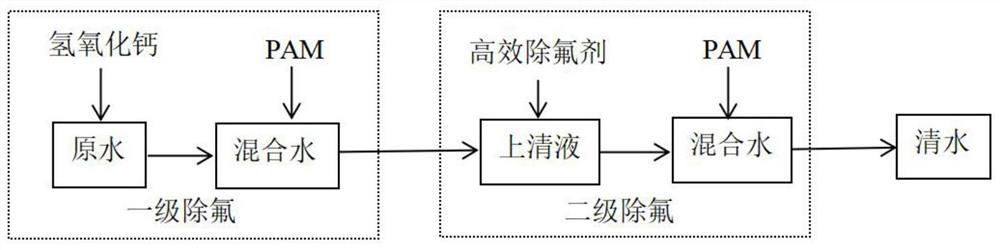

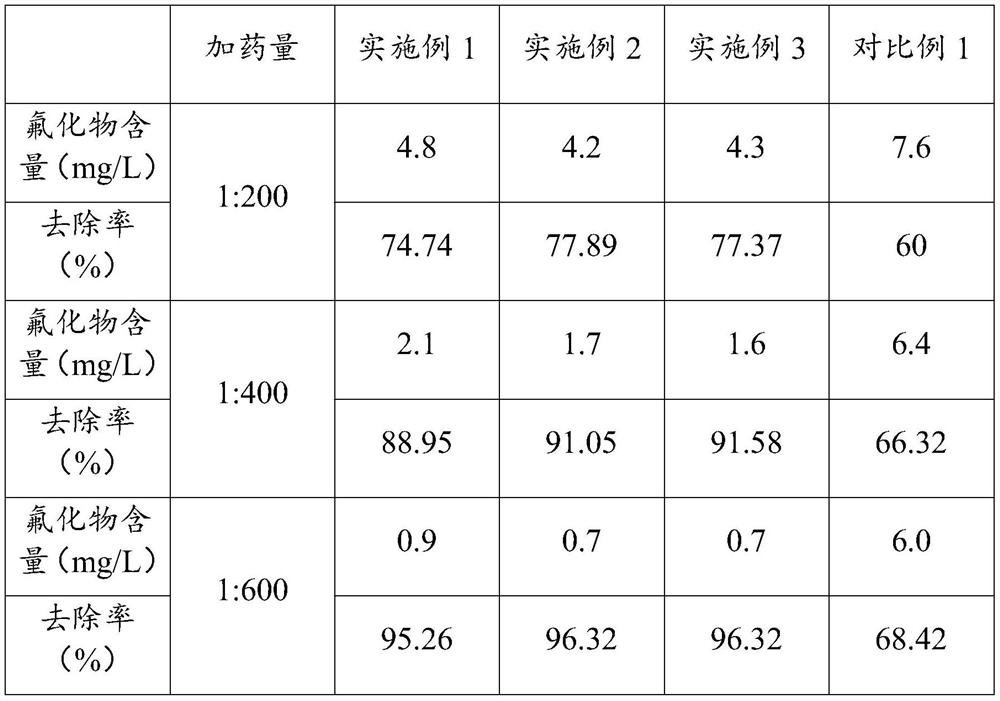

Deep defluorination agent and preparation method thereof

ActiveCN112850867ALarge specific surface areaImprove removal efficiencyWater contaminantsWater/sewage treatment by flocculation/precipitationAluminiumEnvironmental geology

The invention discloses a deep defluorination agent and a preparation method thereof, and belongs to the technical field of chemical materials. According to the technical scheme, the deep defluorination agent is prepared from the following raw materials in weight fraction: 20%-30% of calcium salt, 3%-5% of acid, 10%-15% of ferric salt, 10%-15% of aluminum salt, 2%-3% of magnesium salt, 2%-3% of water glass and the balance water, wherein the ferric salt is nano ferric silicate. Meanwhile, the invention defines a preparation method of the nano iron silicate and the defluorination agent. The nano-scale iron silicate used in the invention has a large specific surface area and can be in good contact with fluorine ions, so that the removal efficiency of the product on fluorine ions in wastewater is improved; and secondly, the preparation method of the raw materials is simple and easy to operate, and industrial production is facilitated.

Owner:北京华德创业环保设备有限公司

Structured catalyst for treating printing and dyeing wastewater and preparation method thereof

InactiveCN103240111ASmall pressure dropSave power inputPhysical/chemical process catalystsWaste water treatment from textile industryCordieriteActivated alumina

The invention discloses a structured catalyst for treating printing and dyeing wastewater and a preparation method thereof. The catalyst comprises a main catalyst, a cocatalyst, activated alumina and cordierite ceramics, wherein the main catalyst is a soluble nitrate of any of Cu, Fe and Mn, and the cocatalyst is a soluble nitrate of any of Ce, Ni and Co. According to the preparation method, a powdery catalyst for treating printing and dyeing wastewater is coated on a cordierite carrier, a dispersant is added during preparation, highly-dispersed catalyst slurry is prepared, and the dispersion and stability of the powdery catalyst are improved. The structured catalyst prepared by the preparation method has the remarkable advantages of difficult active ingredient loss, simple process, reusability, low cost and the like; and when the structured catalyst is applied to the catalytic oxidative degradation of the wastewater, the pressure drop of a reaction system can be reduced, so that the wastewater treating efficiency is increased.

Owner:SOUTHEAST UNIV

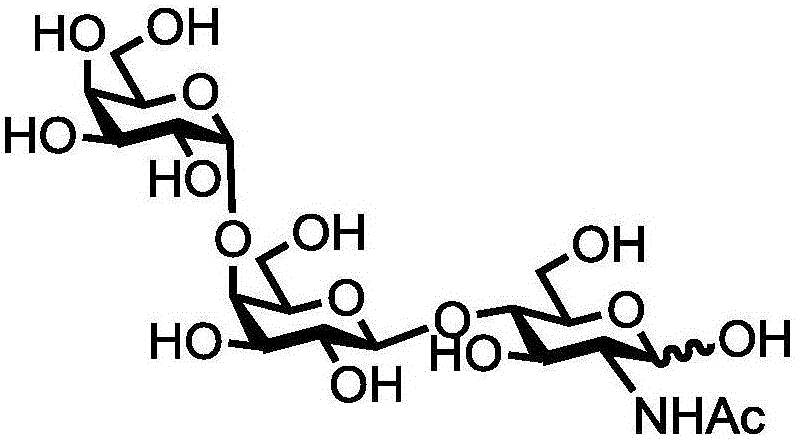

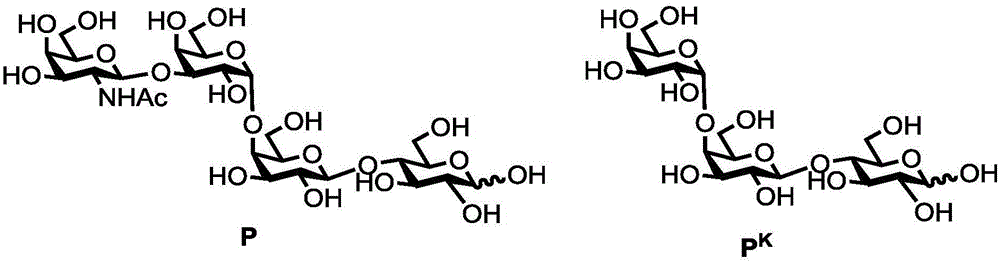

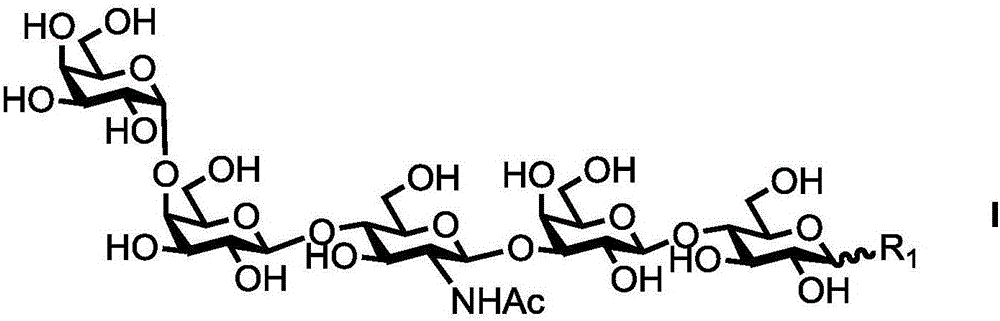

Human blood group antigen P1 pentasaccharide synthesis method

The invention discloses a human blood group antigen P1 pentasaccharide synthesis method. The method includes steps: adopting a one-pot multienzyme system for coupling galactose to trisaccharide as shown in a formula (III) through a beta1-4 glucosidic bond to synthesize tetrasaccharide as shown in a formula (IV); adopting the one-pot multienzyme system for coupling galactose to the tetrasaccharide as shown in the formula (IV) through an alpha1-4 glucosidic bond to synthesize pentasaccharide as shown in a formula (I), wherein in the formula (I), the formula (III) and the formula (IV), R1 refers to hydroxyl, azide substituted alkyl, alkynyl substituted alkyl, sulfydryl substituted alkyl, alpha- or beta- configuration substituted alkyl, alpha- or beta- configuration serine residue and alpha- or beta- configuration threonine residue. By integration of high regioselectivity and high efficiency of enzymatic synthesis, P1 antigen pentasaccharide is synthesized for the first time. Glycosyltransferase, glucose nucleoside generating enzymes and glucokinse adopted in the synthesis method are all derived from prokaryotes, and high protein expression quantity, high substrate adaptability and high catalytic efficiency are realized.

Owner:SHANDONG UNIV

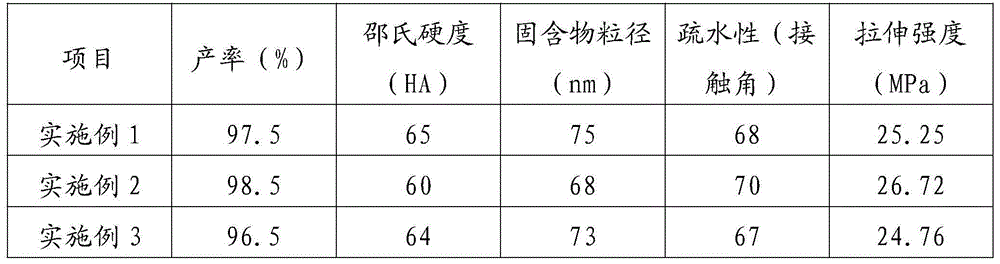

Fabric coating slurry and preparing method thereof

ActiveCN104141231AGood photostability and thermal stabilityGood water and oil resistanceFibre treatmentEmulsionMineralogy

The invention discloses fabric coating slurry which is prepared by the following components, by weight, of 100 parts of epoxidized soybean oil modified waterborne polyurethane, 5-10 parts of crosslink type macromolecule emulsion thickening agents BJ-100 and 5-10 parts of fabric coating extrusion dispersing agents PTFE D-210. The invention discloses a preparing method of the fabric coating slurry at the same time. The fabric coating slurry is well improved in light stability, heat stability, oil resistance and water resistance.

Owner:甄曰菊

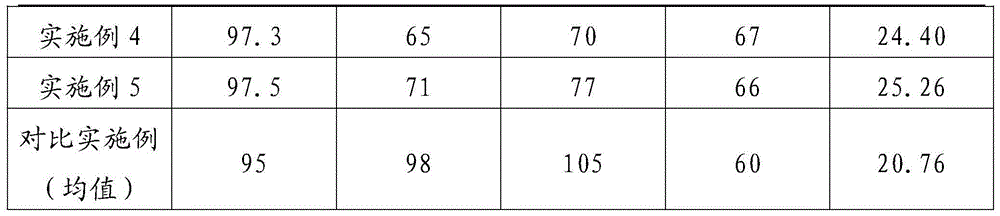

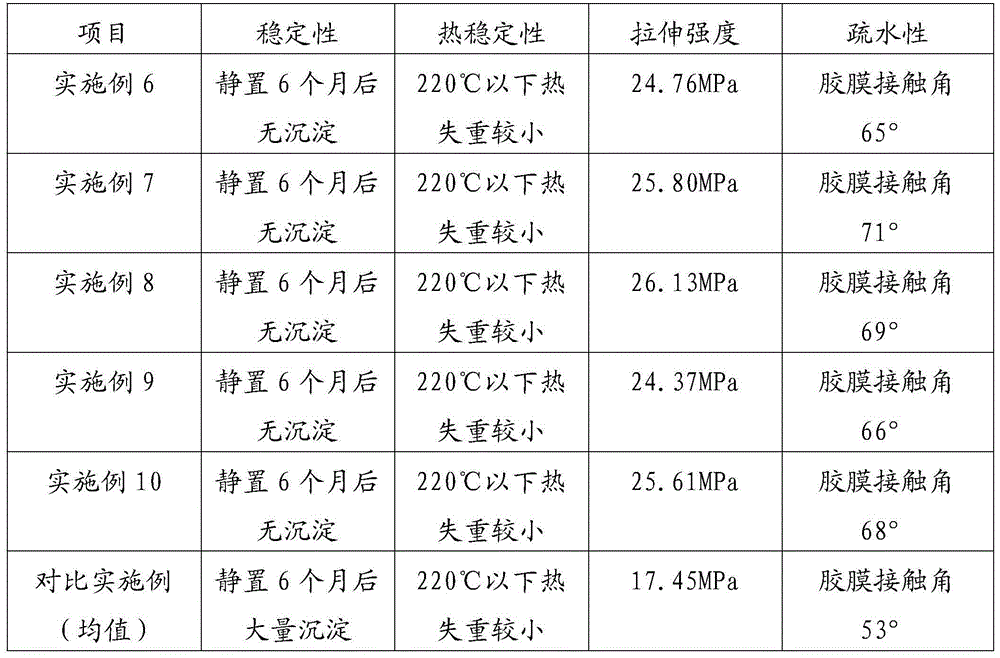

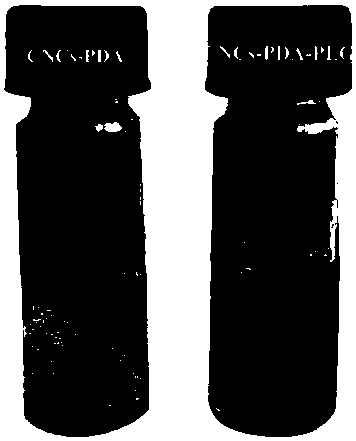

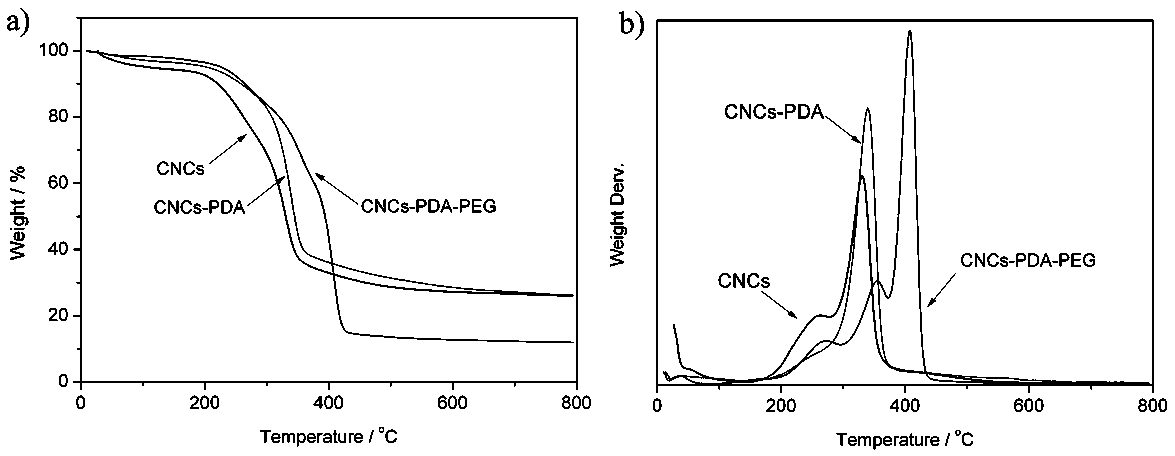

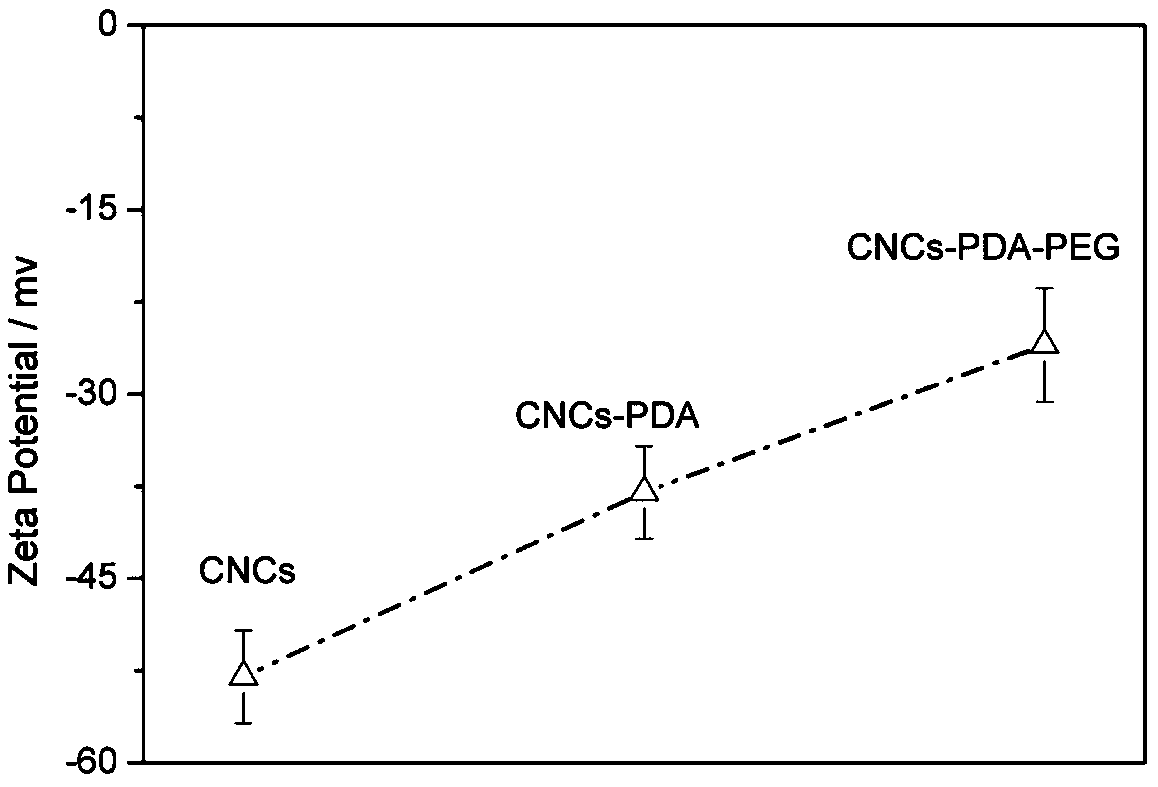

Nano-cellulose/polydopamine/polyethylene glycol composite material and preparation method thereof

The invention discloses a nano-cellulose / polydopamine / polyethylene glycol composite material. The nano-cellulose / polydopamine / polyethylene glycol composite material is prepared by modifying the surface of nano-cellulose through polydopamine and is grafted with polyethylene glycol; the polyethylene glycol is the polyethylene glycol which is subjected to amination or sulfhydrylation modification orterminated by methoxyl. Meanwhile, the invention provides a corresponding preparation method. The nano-cellulose / polydopamine / polyethylene glycol composite material disclosed by the invention can be dispersed in polar solvents, such as water, N',N-dimethylformamide, dimethyl sulfoxide or ethyl alcohol, again; the dispersibility is high; a settlement phenomenon is avoided; the thermal stability ishigh; moreover, the composite material is only limited to modify the surface of the nano-cellulose (CNCs); the structures of nano-crystals of the CNCs are not influenced.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

Polycaprolactone/nano-hydroxyapatite composite material and method for preparing same

The invention relates to a polycaprolactone / nano-hydroxyapatite composite material and a method for preparing the same. The method includes steps of (1), weighing dried nano-hydroxyapatite and monomers epsilon-caprolactone according to certain mass ratios, and uniformly dispersing and mixing the nano-hydroxyapatite and the monomers epsilon-caprolactone with one another in ultrasound to form mixedsuspension; (2), carrying out ring-opening polymerization reaction on the mixed suspension and initiators according to certain ratios; (3), repeatedly washing and precipitating products by deionized water, carrying out vacuum filter on the products and drying the products to obtain the polycaprolactone / nano-hydroxyapatite composite material. The polycaprolactone / nano-hydroxyapatite composite material and the method have the advantages that in-situ bulk polymerization is adopted, the nano-hydroxyapatite is uniformly dispersed in polycaprolactone materials, accordingly, the products are high inpurity, and toxic solvents are omitted in polymerization and after-treatment procedures; hydroxy acid is used as an initiator and a catalyst, accordingly, the method includes simple processes, and thepolycaprolactone / nano-hydroxyapatite composite material prepared by the aid of the method can be applied to bone repair materials.

Owner:DALIAN UNIV

Method for preparing anion template flocculant TPAS (Tissue Plasmogen Activator)

InactiveCN107759731ATargetedImprove chemical reaction efficiencyWater/sewage treatment by flocculation/precipitationChemistryPolypropylene

The invention discloses a method for preparing an anion template flocculant TPAS (Tissue Plasmogen Activator). The method comprises the following steps: with ultrasonic waves as an initialization mode, and by taking acrylamide and sodium p-styrenesulfonate as main raw materials, and polypropylene ammonium chloride PAAC (Polyallyl Acetate) as a template agent, preparing a water solution, adjustingthe pH value by using sodium hydroxide or hydrochloric acid, introducing a sufficient amount of nitrogen, initializing a polymerization reaction in an ultrasonic reactor, after the reaction is completed, performing aging treatment in a water bath pot, taking out a polymer obtained through synthesis, cleaning with alcohol, drying, and powdering, thereby obtaining the anion template flocculant TPAS.The method is simple in process procedure, short in reaction cycle, free of damage to instrument equipment, safe and environmental-friendly, free of toxic or side effect, low in cost, excellent in product property, and good in flocculation effect in treating hematite wastewater.

Owner:CHONGQING UNIV

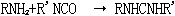

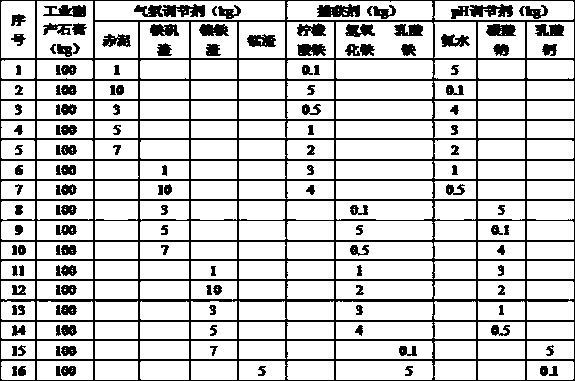

Polymer expanding material used in permeation or seepage waterish environment and preparation process of polymer expanding material

The invention relates to a polymer expanding material used in a permeation or seepage waterish environment and a preparation process of the polymer expanding material and belongs to the technical field of polymer expanding foam materials. The material is prepared from raw materials in parts by weight as follows: 20-30 parts of rosin polyester polyol, 20-50 parts of isocyanate, 20-40 parts of PhireGuard MB-512, 5-10 parts of 1,1-dichloro-1-fluoroethane, 1-2 parts of a surfactant, 0.01-1 part of a catalyst and 0.01 parts of benzoyl chloride. The material has high sand stabilization strength, high curing speed, good elastoplasticity, good pouring property, permeability and expansibility, is applicable to the permeation or seepage waterish environment, particularly to construction of water conservancy projects and following operation processes and is used for solving problems of dam permeation, piping and the like.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD +1

Water-soluble capsanthin

The invention discloses water-soluble capsanthin, and belongs to the field of high-color-value and high-extinction-ratio water-soluble capsanthin and a preparation method thereof. The water-soluble capsanthin is used in the field of coloring of the industries such as food, pharmacy and dyeing. The color value is 140-180, and the extinction ratio is greater than 1.0000. The preparation method of the water-soluble capsanthin comprises the following steps: carrying out saponifying and hydrolyzing on fat-soluble capsanthin; after extracting the fat-soluble capsanthin with a solvent, carrying out separation and purification by a column chromatography to obtain eluant of main coloring ingredients, which comprise capsaicin and capsorubin, of the capsanthin, concentrating the eluant, and then emulsifying the emulsify. The water-soluble capsanthin has the advantages of high color value, high extinction ratio, red and bright color, easiness in coloring, and no precipitation or layering after centrifuging.

Owner:河北东之星生物科技股份有限公司

Method for rapidly separating calcium and sulfur from industrial by-product gypsum

ActiveCN110562933AAvoid enteringIncrease the concentration of sulfur dioxideCalcium/strontium/barium carbonatesSulfur preparation/purificationCalcium carbonate precipitationNuclear chemistry

The invention discloses a method for quickly separating calcium and sulfur from industrial byproduct gypsum, and the method comprises the following steps: quickly decomposing the industrial byproductgypsum to obtain sulfur dioxide flue gas and a solid product; sorting the solid product to obtain an atmosphere regulator, calcium oxide and calcium sulfide; hydrolyzing the calcium sulfide to obtaina calcium hydroxide precipitate and a calcium hydrosulfide solution; introducing carbon dioxide gas into the calcium hydrosulfide solution to obtain a calcium carbonate precipitate and hydrogen sulfide gas; and absorbing the hydrogen sulfide gas, and floating to obtain elemental sulfur. Compared with the prior art, the method has the characteristics of low production cost, high production efficiency and good product quality.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Bottom feed type gas method and equipment for preparing gas with no tar products through oxygendeficient fluid bed combustion

InactiveCN100543116CAccelerate modification/decomposition reactionSimple equipment structureBulk chemical productionGranular/pulverulent flues gasificationFluidized bedFixed bed

This invention relates to downdraft gasification method and equipment for preparing tar-free product gas by oxygen-deficient fluidized burning. The equipment comprised a front fluidized bed burner, a downdraft fixed bed gasifier set lower than the burner, a transporting pipe for carbocoal and semi-finished gas connecting the burner and the gasifying furnace, a fuel inlet and an oxidant inlet. The method comprised: (1) adding fuel through the fuel inlet of the fluidized bed burner, and performing oxygen-deficient fluidized burning with oxidant added through the oxidant inlet at the bottom of the fluidized bed burner to obtain carbocoal and semi-finished gas containing tar, and (2) sending the unseparated carbooal and semi-finished gas containing tar to a down-draft fixed bed gasifier at a high temperature to gasify the carbocoal, and modifying and cracking the tar introduced by the semi-finished gas by the catalytic activity of high-temperature carbocoal to obtain the product gas with tar. The equipment has such advantages as simple structure, easy operation and high gasifying efficiency, and is suitable for a wide variety of fuels and can produce product gas without tar.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Medical lactide and preparation method thereof

The invention relates to medical lactide and a preparation method thereof, and the preparation method comprises the following steps: dehydrating lactic acid to obtain dehydrated lactic acid; adding acatalyst into the obtained dehydrated lactic acid, and carrying out a polycondensation reaction to generate a lactic acid oligomer; sequentially carrying out thermal cracking treatment on the generated lactic acid oligomer in batches, and then carrying out vacuum reduced pressure distillation to obtain a lactide crude product; and recrystallizing and purifying the obtained lactide crude product toobtain the medical lactide. The preparation method of the medical lactide has the advantages that the yield and the purity are improved, and the problems that a system is easy to block, the fluidityand the heat transfer effect of the system are reduced, and a reaction system changes color due to high-temperature carbonization can be effectively solved.

Owner:SHENZHEN CORLIBER SCI

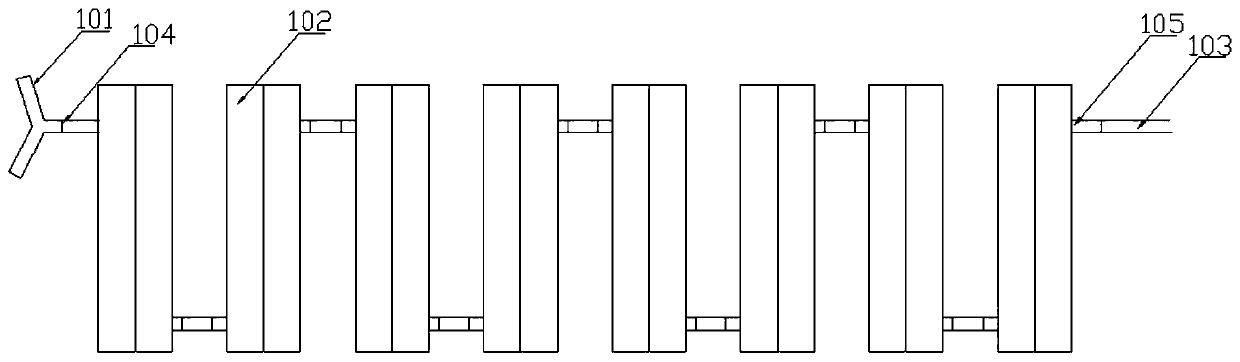

System and method for synthesizing rubber scorch retarder CTP

ActiveCN109876746AAchieve uninterrupted responseIncrease productivityOrganic chemistryChemical/physical/physico-chemical microreactorsSocial benefitsEconomic benefits

The invention belongs to the technical field of fine chemical engineering, and particularly relates to a system and a method for synthesizing rubber scorch retarder CTP. The system provided by the invention comprises a conveying pipeline for cyclohexyl sulfenyl chloride and catalyst mixed liquid, a conveying pipeline for phthalimide sodium salt and catalyst mixed liquid, and a micro-reaction device, wherein the micro-reaction device is respectively connected with the material outlet of the conveying pipeline for cyclohexyl sulfenyl chloride and catalyst mixed liquid and the material outlet ofthe conveying pipeline for phthalimide sodium salt and catalyst mixed liquid; the micro-reaction device is a microchannel reactor, a high-shear reactor or a pipe-type reactor. According to the systemprovided by the invention, liquid and liquid two-phase liquid is used for being in full contact in the micro-reaction device to react to synthesize the rubber scorch retarder CTP, the uninterrupted reaction of the CTP synthesis is realized, and the production efficiency and the reaction yield of the synthesized CTP can be greatly improved. Meanwhile, the purity and the quality stability of the product are improved. the system has a good application prospect and can generate considerable economic benefits and social benefits.

Owner:TANGYIN YONGXIN CHEM CO LTD

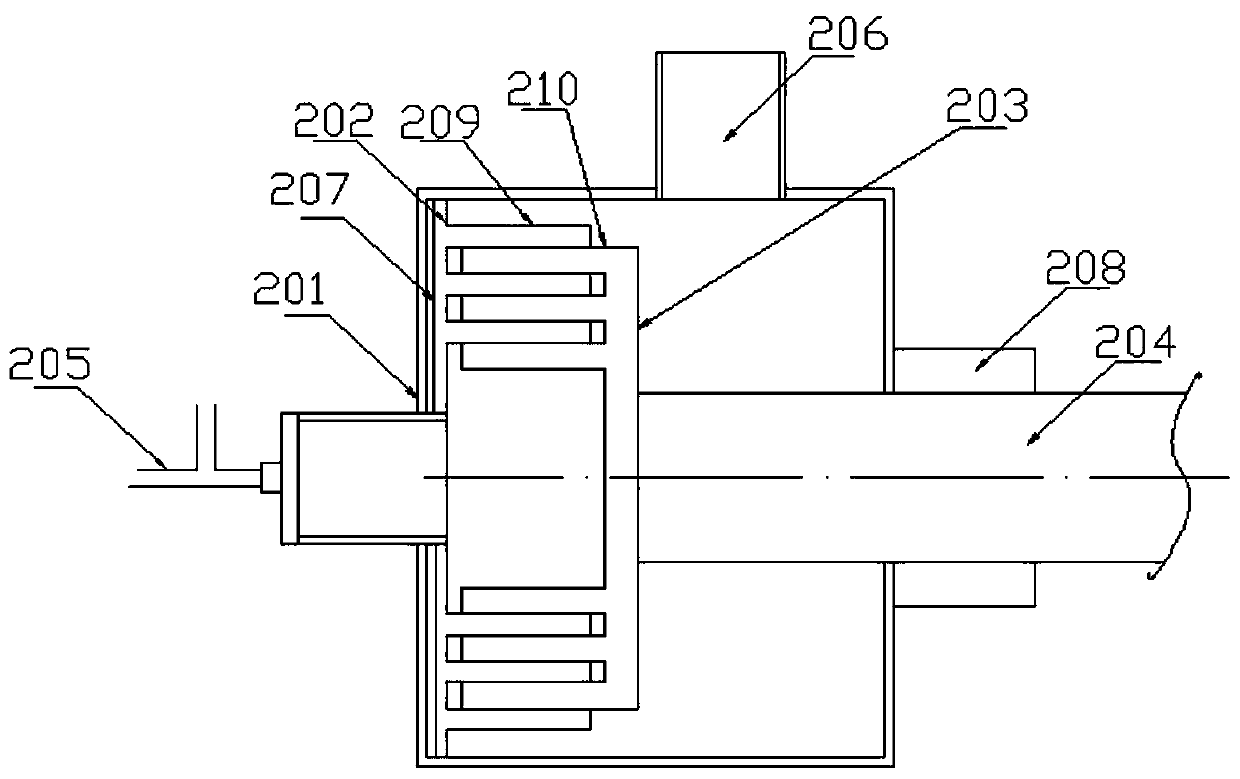

Hydrogen supply system, fuel cell engine and vehicle

InactiveCN112421072AMeet job needsAchieve cycleFuel cell heat exchangeReactant parameters controlExhaust valveProcess engineering

The invention discloses a hydrogen supply system, a fuel cell engine and a vehicle, which relate to the technical field of fuel cell vehicles. The hydrogen supply system comprises a hydrogen supply pipeline, ahydrogen circulating pipeline and an exhaust valve, wherein thehydrogen supply pipeline is provided with a hydrogen heater and an injection ejector, a gas inlet of the hydrogen heater is configured to be communicated with a hydrogen supply source, a gas outlet of the hydrogen heater is communicated with an inlet of the injection ejector, and an outlet of the injection ejector is configured to be communicated with an anode inlet of an electric pile; the inlet end and the outlet end of the hydrogen circulating pipeline are configured to be respectively communicated with the anode outletof the electric pile and the inlet of the injection ejector; one end of the exhaust valve is communicated with the hydrogen circulating pipeline, and the other end of the exhaust valve is communicated with the outside of the hydrogen supply system. When the hydrogen supply system supplies hydrogen to the electric pile, the working requirements of the fuel cell engine under all working conditionscan be met, the power consumption is low, the hydrogen supply quality can be ensured in the long-term use process, and the reaction efficiency of the galvanic pile is ensured.

Owner:FAW JIEFANG AUTOMOTIVE CO

Preparation method of calcium alginate gel balls

ActiveCN113980341ALarge specific surface areaIncrease the gapCoatingsMicroorganismPhysical chemistry

The invention discloses a preparation method of calcium alginate gel balls, and belongs to the field of natural carrier preparation. Aiming at the problems of low preparation efficiency and poor effect of existing calcium alginate gel balls, the invention provides a preparation method of calcium alginate gel balls, wherein the preparation method comprises the following steps: respectively preparing a sodium alginate solution and a calcium chloride solution; pouring the prepared sodium alginate solution into a mold, freezing the mold, and then obtaining sodium alginate ice balls; and putting the sodium alginate ice balls into a calcium chloride solution, soaking and stirring to obtain the calcium alginate gel balls. The sodium alginate solution is frozen, water in the solution can be converted into ice crystals, the specific surface area of the obtained sodium alginate ice balls is increased, gaps are increased, the obtained sodium alginate ice balls and the calcium chloride solution are subjected to a cross-linking reaction to form more pore structures, the specific surface area and pore volume of the calcium alginate gel balls are increased, and the calcium alginate gel balls serve as a microbial immobilization carrier; and the microorganism attachment area is increased, the efficiency is high, and the subsequent effect is strong.

Owner:SHANGHAI INST OF TECH

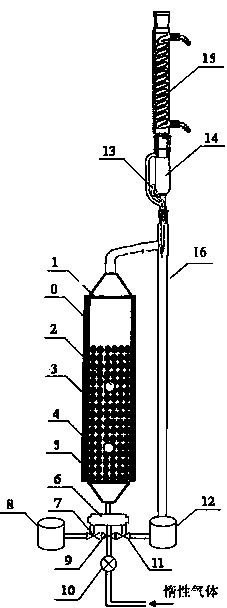

Method and special device for synthesizing liquid chromatogram stationary phase by catalysis of gas-solid phase

InactiveCN103736470AAvoid uneven mixingHomogeneous bonding reactionOther chemical processesChemical/physical processesStationary phaseEndcapping

The invention discloses a method for synthesizing a liquid chromatogram stationary phase. The method comprises the following steps: firstly, performing heating pretreatment on a carrier; then, bonding a gasified catalyst and gasified silane to the carrier; finally, reacting the bonded carrier with a gasified silane capping reagent to obtain the liquid chromatogram stationary phase. A gas-solid phase catalytic fluidized bed synthesis reaction device is established on the basis of a principle that gas molecules have high diffusion speed and facilitate participation in a reaction with solid in each part of particles. The method and the device are easy and convenient to operate and have high reproducibility; the carbon loading amount and the bonding intensity of the chromatographic stationary phase can be greatly improved. A chromatographic filler prepared by the method and the device can be effectively used for the separation and the analysis of acidic, neutral and basic compounds.

Owner:北京迪马欧泰科技发展中心

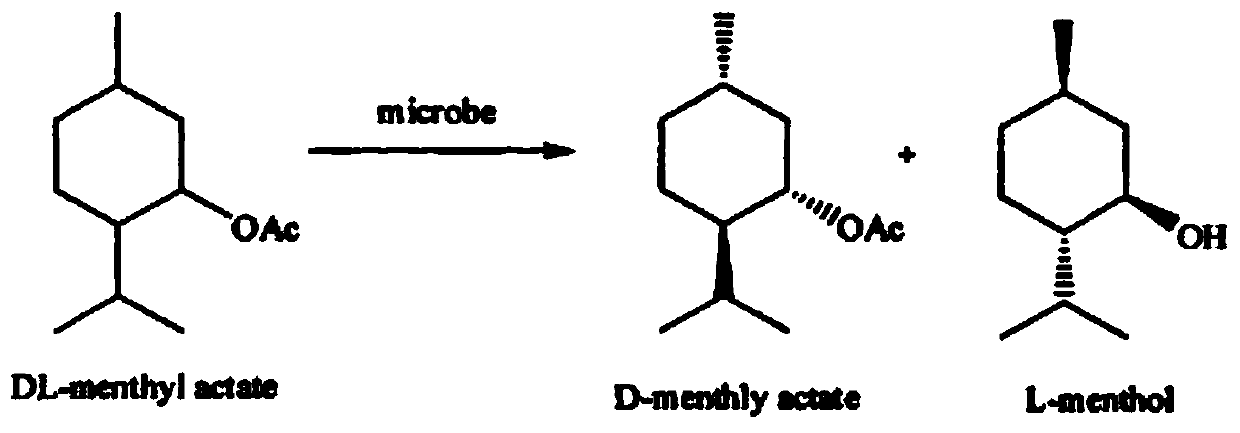

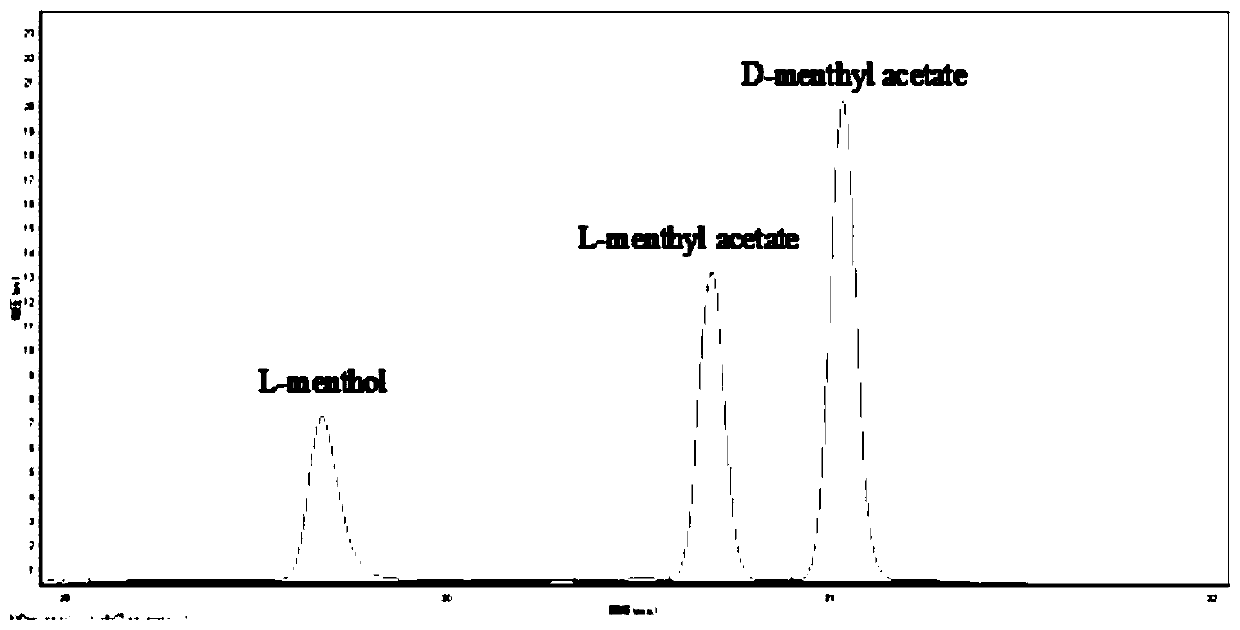

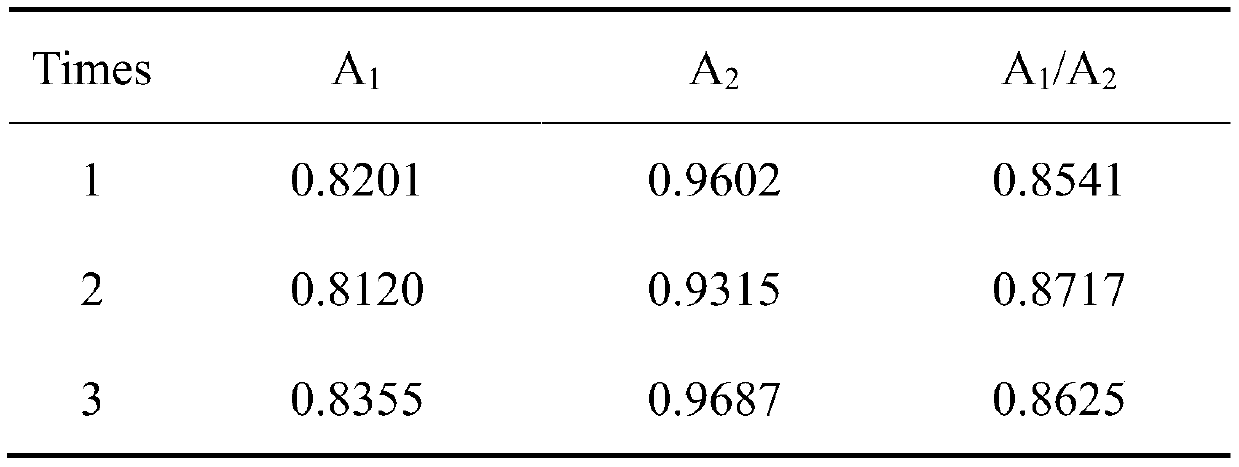

Bacillus subtilis and method of using same to prepare L-menthol

ActiveCN110373366AEasy to recycleImprove solubilityBacteriaMicroorganism based processesMicroorganismL menthol

The invention provides bacillus subtilis IFE122 and a method of using the same to prepare L-menthol. Bacillus subtilis IFE122 is collected at the China General Microbiological Culture Collection Center at 3# Yard One, Beichen West Road, Chaoyang District, Beijing on June 06th, 2019 under the number of CGMCC No.17904. The method is stable in process, ee value during preparation reaches 99.49%, sideeffects like hydrolysis and racemization caused by polar solvent conversion are overcome, and product purifying difficulty is lowered.

Owner:ANHUI FENGLE PERFUME +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com