Method for rapidly separating calcium and sulfur from industrial by-product gypsum

An industrial by-product gypsum, fast technology, applied in the preparation/purification of sulfur, chemical instruments and methods, sulfur compounds, etc., can solve the problems of loss of titanium gypsum, pollution of the environment, land occupation of titanium gypsum, etc., and achieve the effect of increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific examples.

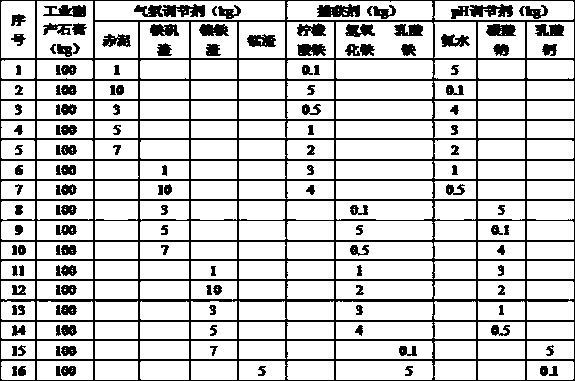

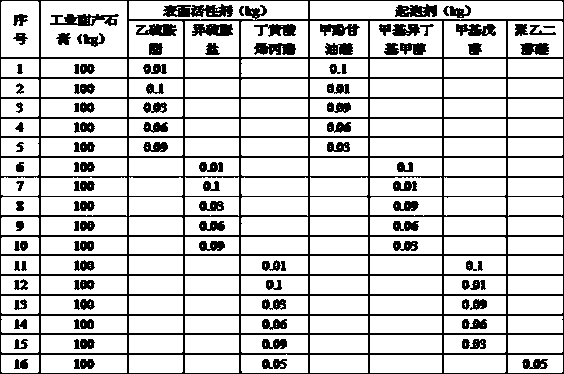

[0024] A method for quick separation of calcium and sulfur from industrial by-product gypsum, which is characterized in that it comprises the following steps in sequence: adding an atmosphere conditioner to the dry industrial by-product gypsum, mixing evenly, adding it to a rapid decomposer for decomposition, and obtaining sulfur dioxide flue gas and solid product; the solid product is magnetically separated and re-selected to obtain an atmosphere regulator, calcium oxide and calcium sulfide; water is added to calcium sulfide, hydrolyzed to obtain calcium hydroxide precipitation and calcium hydrosulfide solution, and solid-liquid separation; Carbon dioxide gas is passed into the calcium hydride solution to obtain calcium carbonate precipitation and hydrogen sulfide gas; a capture agent and a pH regulator are added to the scrubber to absorb hydrogen sulfide gas to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com