Method for directly synthesizing dialkyl dialkoxy silicane by one-step process

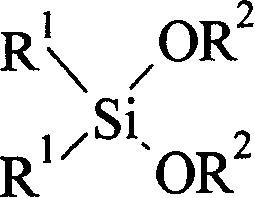

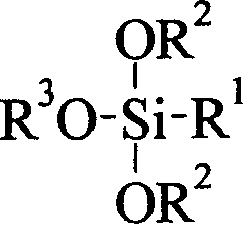

The technology of dialkyl dialkoxy silane and tetraalkoxy silane is applied in the field of synthesis of dialkyl dialkoxy silane and can solve the problem of raw material damage loss, low reaction efficiency and solvent circulation of tetraalkoxy silane. Difficulty in use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

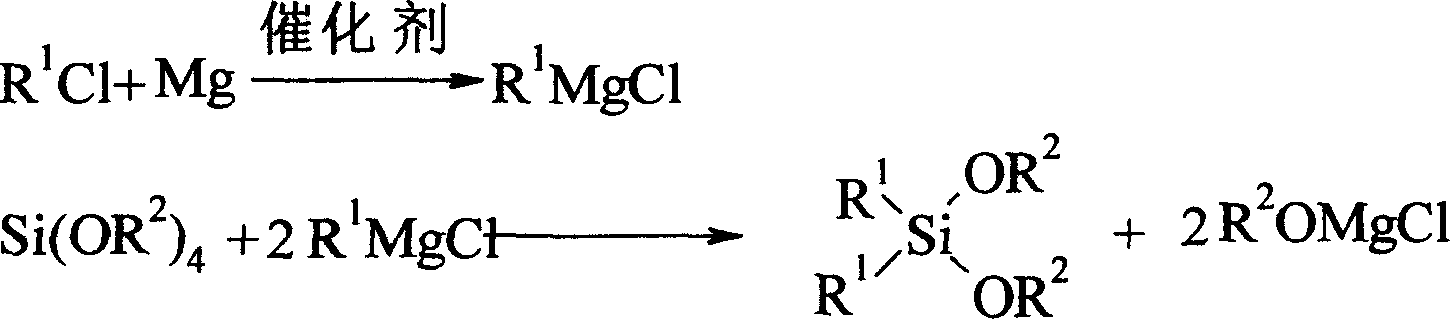

Method used

Image

Examples

example 1

[0048] Example 1. Preparation of dicyclopentyldimethoxysilane

[0049] Replace air with nitrogen in a 2000ml four-necked flask equipped with electric stirrer, thermometer, reflux condenser, and constant pressure dropping funnel, and drop 60.4g (purity 99%, 2.46mole) particle size less than 150 purpose magnesium powder, 40g (purity 99%, 0.38mole) chlorocyclopentane, 180g (purity 99%, 1.17mole) tetramethoxysilane, add 224g (purity 99%, 2.12 mole) the mixed solution of chlorocyclopentane and 400ml methyl-tert-butyl ether. Nitrogen was passed through the reaction system again, two grains of iodine were added to the reactant in the reaction bottle, and then heated to about 55°C, the reaction was violently initiated, and a large amount of reaction heat was released. When the exothermic reaction is initiated for 2 to 3 minutes, add the mixture in the dropping funnel to the reaction bottle dropwise within 20 to 30 minutes, keep the reactants under a relatively vigorous reflux, and th...

example 2

[0051] Example 2. Preparation of diisopropyldimethoxysilane

[0052] Replace the air with nitrogen in a 500ml four-necked flask equipped with an electric stirrer, a thermometer, a reflux condenser, and a constant pressure dropping funnel, and drop 15g (purity 99%, 0.61mole) into the reaction bottle under a nitrogen atmosphere, and the particle size is less than 150 Purpose magnesium powder, 11.9g (purity 99%, 0.096mole) bromoisopropane, 44.5g (purity 99%, 0.29mole) tetramethoxysilane, in constant pressure dropping funnel, add 64.8g (purity 99%, 0.52mole) a mixture of bromoisopropane and 100ml methyl-tert-butyl ether. Nitrogen was passed through the reaction system again, a grain of iodine was added to the reactant in the reaction bottle, and then heated to raise the temperature, the reaction was violently triggered, and a large amount of reaction heat was released. When the exothermic reaction is initiated for 2-3 minutes, add the mixture in the dropping funnel dropwise to th...

example 3

[0054] Example 3. Preparation of diisobutyldimethoxysilane

[0055] The preparation process is the same as that of Example 2, except that isopropane bromide is replaced by equimolar chloroisobutane to obtain 54.2 g of diisobutyldimethoxysilane with a purity of 99.5% and a yield of 91.2% (according to tetramethoxy Silane), 85.5% (based on chloroisobutane).

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com