Nano-cellulose/polydopamine/polyethylene glycol composite material and preparation method thereof

A technology of nanocellulose and polyethylene glycol, applied in the field of nanocomposite materials, can solve the problems of ineffective dispersion and limited wide application, and achieve the effects of preventing irreversible aggregation, good dispersion and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

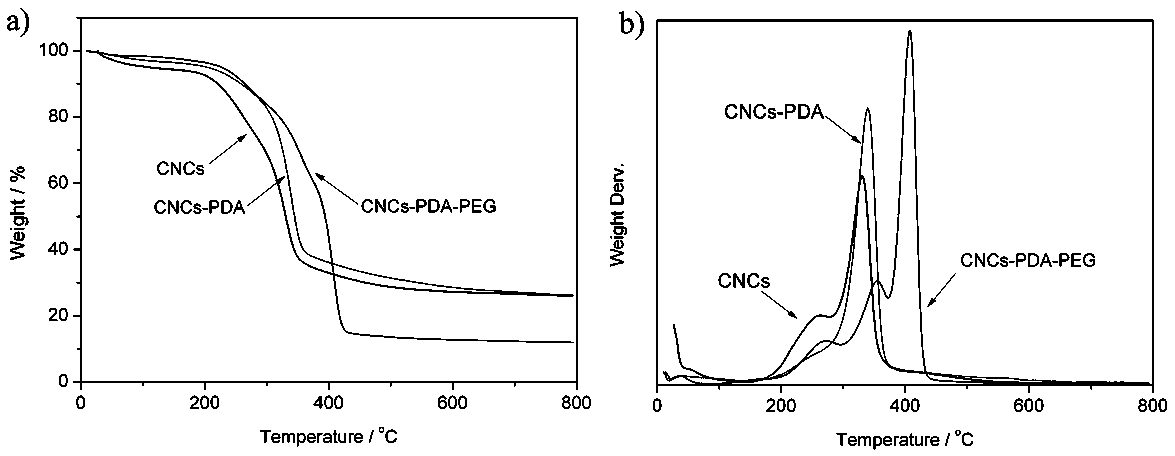

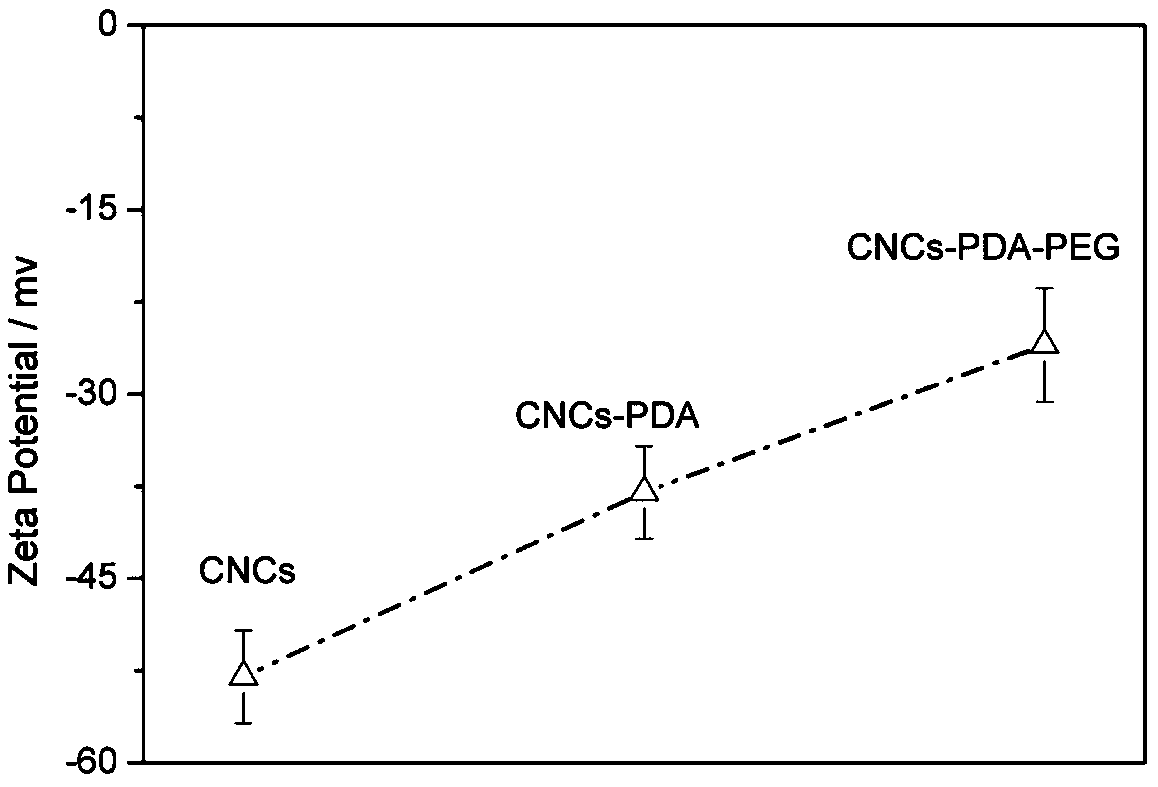

[0023] A nanocellulose / polydopamine / polyethylene glycol composite material, which is modified by polydopamine on the surface of nanocellulose, and then grafted with polyethylene glycol, the polyethylene glycol is amino or mercapto-modified and Methoxy-terminated polyethylene glycol, the mass ratio of nanocellulose, polydopamine, and polyethylene glycol is 5.5:1:2, and the molecular weight of polyethylene glycol is 2000.

[0024] The method for preparing nanocellulose / polydopamine / polyethylene glycol composite material comprises the following steps:

[0025] 1) At 25°C, under non-airtight conditions (that is, the reaction vessel is not corked or opened, so that the subsequent reaction liquid surface is always in contact with the air, so that oxygen can enter the reaction system), the stirring speed is 600 r / min , add 0.2g three ( Mix hydroxymethyl)aminomethane and 0.6g dopamine hydrochloride, react for 24 hours, centrifuge at a centrifugal speed of 10,000r / min for 10 minutes, ...

Embodiment 2

[0028] A nanocellulose / polydopamine / polyethylene glycol composite material, which is modified by polydopamine on the surface of nanocellulose, and then grafted with polyethylene glycol, the polyethylene glycol is amino or mercapto-modified and Methoxy-terminated polyethylene glycol, the mass ratio of nanocellulose, polydopamine, and polyethylene glycol is 5.5:1:3.2; the molecular weight of polyethylene glycol is 5000.

[0029] The method for preparing nanocellulose / polydopamine / polyethylene glycol composite material comprises the following steps:

[0030] 1) At 25°C, under non-airtight conditions (that is, the reaction vessel is not corked or opened, so that the subsequent reaction liquid surface is always in contact with the air, so that oxygen can enter the reaction system), the stirring speed is 600 r / min , to 150g of nanocellulose aqueous suspension with a concentration of 0.75wt% (diameter of nanocellulose: 5-20 nm, length: 200-800 nm, surface carboxyl content 1.2 mmol / g)...

Embodiment 3

[0033] A nanocellulose / polydopamine / polyethylene glycol composite material, which is modified by polydopamine on the surface of nanocellulose, and then grafted with polyethylene glycol, the polyethylene glycol is amino or mercapto-modified and Methoxy-terminated polyethylene glycol, the mass ratio of nanocellulose, polydopamine, and polyethylene glycol is 10:1:4; the molecular weight of polyethylene glycol is 5000.

[0034]The method for preparing nanocellulose / polydopamine / polyethylene glycol composite material comprises the following steps:

[0035] 1) At 25°C, under non-airtight conditions (that is, the reaction vessel is not corked or opened, so that the subsequent reaction liquid surface is always in contact with the air, so that oxygen can enter the reaction system), the stirring speed is 600 r / min , to 140g concentration of 1.0wt% nanocellulose aqueous suspension (diameter of nanocellulose: 5 ~ 20 nm, length: 200 ~ 800 nm, surface carboxyl content 1.2 mmol / g) sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com