Release agent storage tank

A storage tank and release agent technology, which is applied in the directions of containers, packaging, transportation and packaging, can solve the problems of simple structure of the storage tank and single protection effect of the release agent, and achieves firm structure, good internal sealing effect, and reduced impact. The effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred implementation of the release agent storage tank of the present invention will be described in detail below with reference to the accompanying drawings.

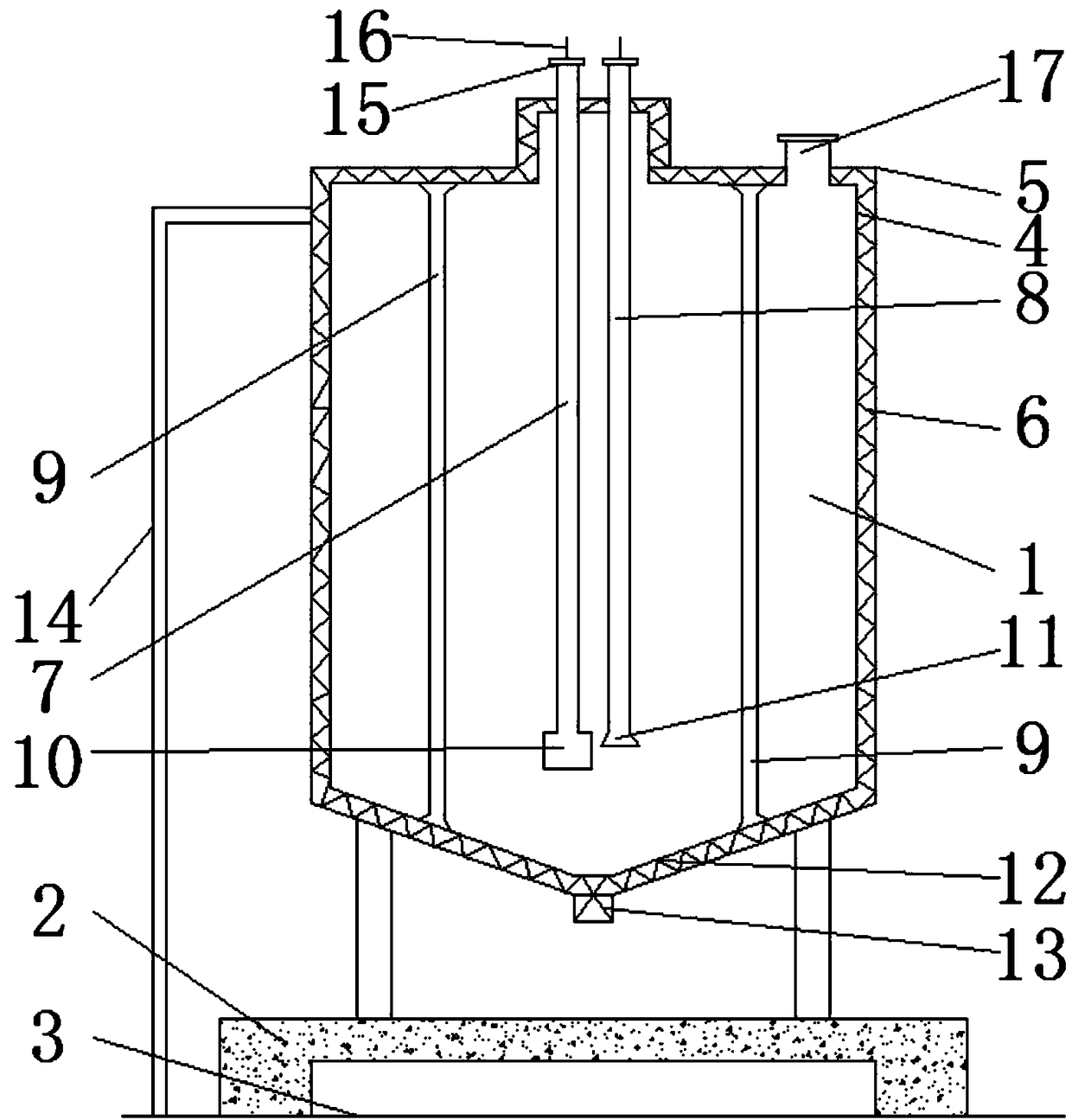

[0014] figure 1 Show the specific embodiment of the release agent storage tank of the present invention: a release agent storage tank, including asphalt sand cushion 2, the oil tank body 1 fixed above the asphalt sand cushion 2 by brackets and inlaid on the asphalt A sandstone cushion 3 in the sand cushion 2 and having a diameter equal to the diameter of the oil tank body 1, the oil tank body 1 includes an inner tank 4 and an outer tank 5, and the inner tank 4 and the outer tank 5 are provided with There is a support body 6 with a wavy cross-section. The upper end of the inner tank 4 is also provided with a protective gas inlet 17 communicating with the inner tank 4. The protective gas inlet 17 is provided with a sealing valve. The oil tank body 1 is also provided with a The oil inlet pipe 7, the oil ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com