Polymer expanding material used in permeation or seepage waterish environment and preparation process of polymer expanding material

An expansion material and preparation process technology, applied in the field of polymer expanded foam materials, can solve the problems of low density and compressive strength, inability to meet water impermeability, loss of density and strength, etc., and achieve good adhesion, high compressive strength, The effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

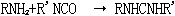

Method used

Image

Examples

Embodiment 1

[0033]A kind of polymer swelling material in the permeable or percolating watery environment of this embodiment includes: rosin polyester polyol (produced by the Institute of Forest Products Chemical Industry, Chinese Academy of Forestry, brand: JC-380) 25 grams, poly Methyl polyphenylisocyanate (produced by Wanhua Chemical Group Co., Ltd., brand: WANNATE 2208) 6 grams, diphenylmethane diisocyanate (produced by Wanhua Chemical Group Co., Ltd., brand: MDI100) 25 grams, reactive type Flame retardant (produced by Jiangsu Yake Technology Co., Ltd., brand: PhireGuard MB-512) 35 grams, physical blowing agent (1,1-dichloro-1-fluoroethane) 7 grams, surfactant (EMALEX SPO -100) 1 g, benzoyl chloride (chemically pure) 0.01 g, catalyst (4,4'-(di-2,1-ethylidene oxide) bismorpholine (HUNTSMAN)) 0.99 g.

[0034] The preparation process of the present embodiment is as follows:

[0035] 1. Add rosin polyester polyol, isocyanate, PhireGuard MB-512, and EMALEX SPO-100 into the reaction kettle ...

Embodiment 2

[0040] A kind of polymer expansion material in the permeable or percolating watery environment of this embodiment includes: rosin polyester polyol (produced by the Institute of Forestry Chemical Industry, Chinese Academy of Forestry, brand name: JC-380) 20 grams, diphenyl Methyl methane diisocyanate (produced by Wanhua Chemical Group Co., Ltd., brand: MDI100) 50 grams, reactive flame retardant (produced by Jiangsu Yake Technology Co., Ltd., brand: PhireGuard MB-512) 20 grams, physical foaming agent (1,1-dichloro-1-fluoroethane) 8.8 g, surfactant EMALEX SPO-100 1 g, benzoyl chloride (chemically pure) 0.01 g, catalyst (4,4'-(di-2 oxide ,1-ethylidene) bismorpholine (HUNTSMAN)) 0.19 g.

[0041] The preparation process of the present embodiment is as follows:

[0042] 1. Measure rosin polyester polyol, isocyanate, PhireGuard MB-512 and EMALEX SPO-100 as above

[0043] Add to the reaction kettle, stir evenly;

[0044] 2. Pass nitrogen into the reactor to replace the air in the re...

Embodiment 3

[0048] A kind of polymer expansion material in the permeable or percolating watery environment of this embodiment includes: rosin polyester polyol (produced by the Institute of Forestry Chemical Industry, Chinese Academy of Forestry, brand name: JC-380) 30 grams, poly Methyl polyphenyl isocyanate (produced by Wanhua Chemical Group Co., Ltd., brand: WANNATE 2208) 15.6 grams, toluene diisocyanate (produced by Wanhua Chemical Group Co., Ltd.) 20 grams, reactive flame retardant (Jiangsu Yake Technology Co., Ltd. Co., Ltd., brand: PhireGuard MB-512) 22 grams, physical foaming agent (1,1-dichloro-1-fluoroethane) 10 grams, surfactant EMALEXSPO-100 2 grams, benzoyl chloride (chemical Pure) 0.01 g, catalyst (4,4'-(oxydi-2,1-ethylidene) bismorpholine (HUNTSMAN)) 0.39 g.

[0049] The preparation process of the present embodiment is as follows:

[0050] 1. Measure rosin polyester polyol, isocyanate, PhireGuard MB-512 and EMALEX SPO-100 as above

[0051] Add to the reaction kettle, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com