Preparation method of calcium alginate gel balls

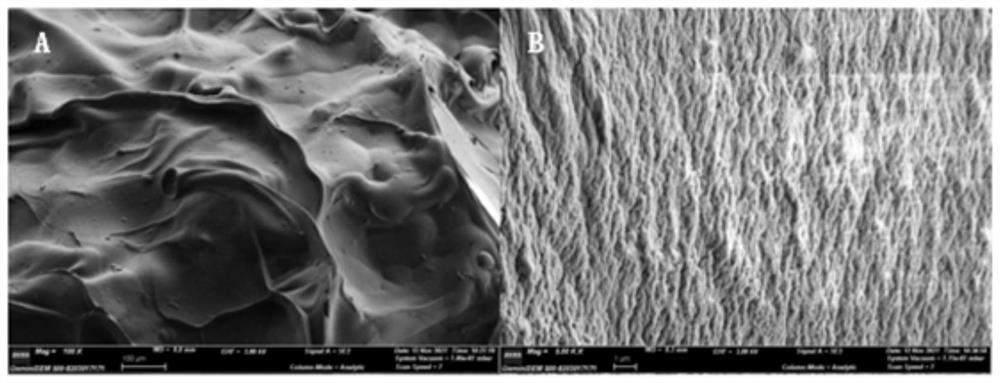

A technology of calcium alginate gel balls and sodium alginate, which is applied in the field of preparation of calcium alginate gel balls, can solve the problems of slow preparation efficiency and poor effect, and achieves low cost, increased specific surface area, and enlarged pores. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method for calcium alginate gel balls, comprising the following steps:

[0035] S1: Prepare sodium alginate solution and calcium chloride solution respectively; Specifically, in this step, take a certain amount of sodium alginate and calcium chloride respectively, and put them into water for dissolving to obtain sodium alginate solution and calcium chloride solution; in order to avoid introducing impurities in the dissolving process, adopt distilled water to carry out the preparation of sodium alginate solution and calcium chloride solution respectively, improve the purity of solution preparation; set the concentration of the sodium alginate solution prepared simultaneously to be 1%~3% ( w / v), to avoid tailing phenomenon when the concentration of sodium alginate solution is too high, resulting in irregular gel shape and inconsistent size; Calcium chloride is reacted to obtain calcium alginate gel balls. The concentration of calcium chloride solution is 3%...

Embodiment 1

[0041] A preparation method for calcium alginate gel balls, comprising the following steps:

[0042] S1: Take 1g of sodium alginate in 100ml of distilled water, soak it for 1 hour, and dissolve it by ultrasonic to obtain a sodium alginate solution with a concentration of 1%. Dissolve 3g of calcium chloride in 100ml of distilled water to obtain a calcium chloride solution with a concentration of 3%. ;

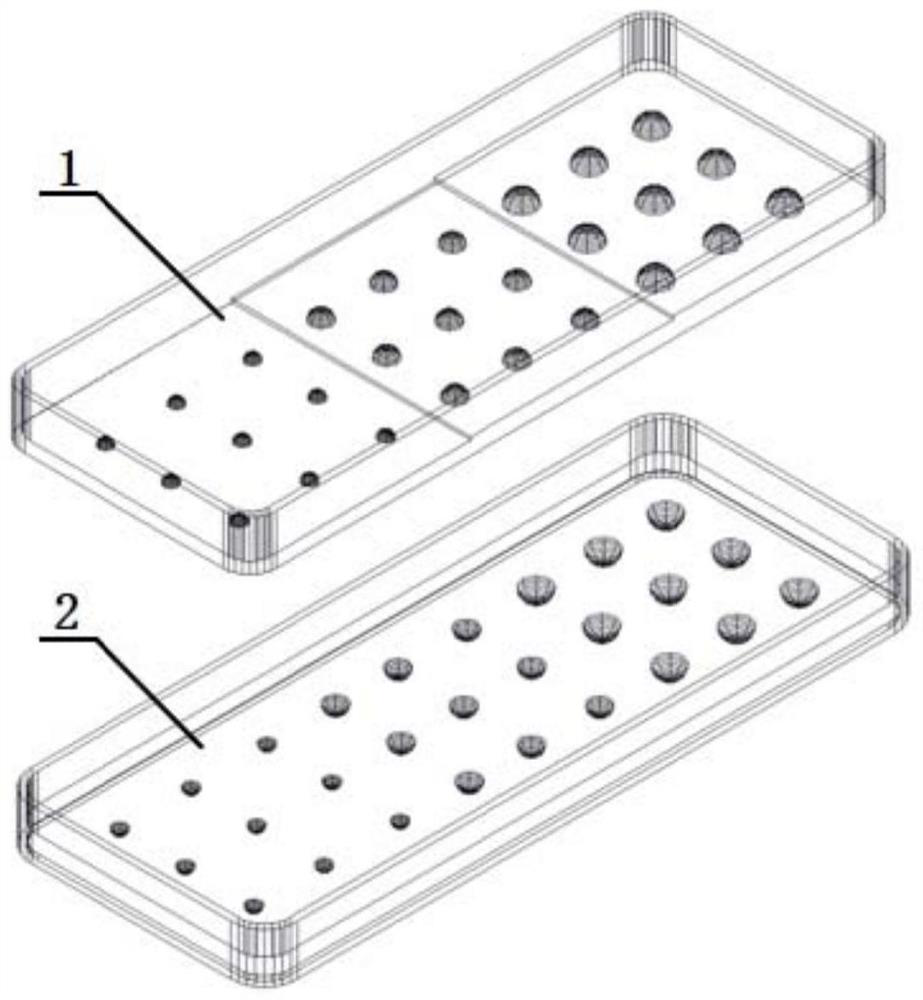

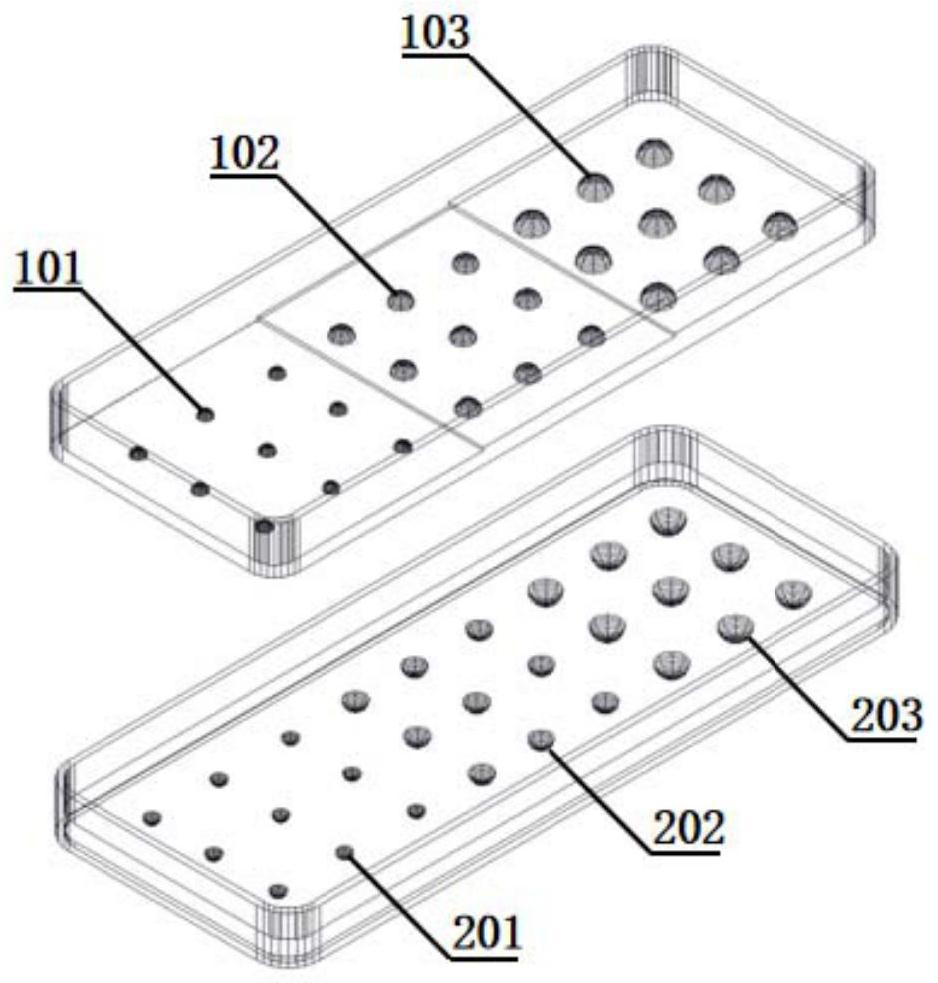

[0043] S2: Pour the prepared sodium alginate solution into the mold lower cover 2, then seal it with the upper cover 1, drain the excess sodium alginate solution through the drain hole on the upper cover 1, and put it in a -40°C refrigerator to freeze Take it out after 10 minutes, thaw at 24°C for 5 minutes, and then get sodium alginate ice balls;

[0044] S3: Soak the sodium alginate ice balls in a 3% calcium chloride solution for immersion and stirring. After reacting for 4 hours, take them out and wash them with distilled water for 3 times to obtain calcium alginate gel ball...

Embodiment 2

[0047] A preparation method for calcium alginate gel balls, comprising the following steps:

[0048] S1: Take 3g of sodium alginate in 100ml of distilled water, soak for 1 hour, and ultrasonically dissolve to obtain a sodium alginate solution with a concentration of 3%; dissolve 4g of calcium chloride in 100ml of distilled water to obtain a calcium chloride solution with a concentration of 4%. ;

[0049] S2: Pour the prepared sodium alginate solution into the mold lower cover 2, then seal it with the upper cover 1, drain the excess sodium alginate solution through the drain hole on the upper cover 1, and put it in a -30°C refrigerator to freeze Take it out after 20 minutes, thaw at 20°C for 10 minutes, and then get sodium alginate ice balls;

[0050] S3: Soak the sodium alginate ice balls in a 4% calcium chloride solution for immersion and stirring. After reacting for 2 hours, take them out and wash them with distilled water for 3 times to obtain calcium alginate gel balls. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com