Method and special device for synthesizing liquid chromatogram stationary phase by catalysis of gas-solid phase

A technology of chromatographic stationary phase and special device, which is applied in the field of synthetic liquid chromatographic stationary phase, can solve the problems of uneven distribution and agglomeration, reduce the bonding density of stationary phase, reduce the reproducibility of bonding reaction, etc., and achieve Good heat transfer performance, reducing high boiling point impurities to participate in the reaction, and solving the effect of uneven mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

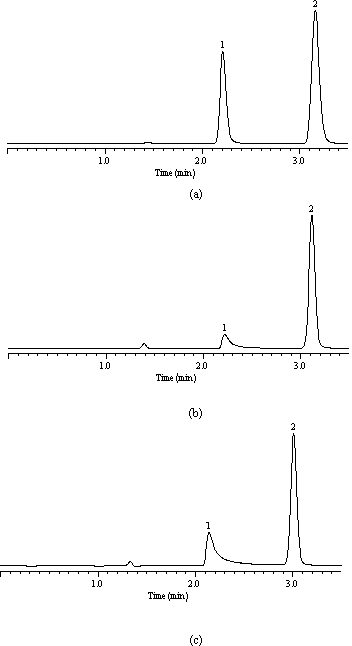

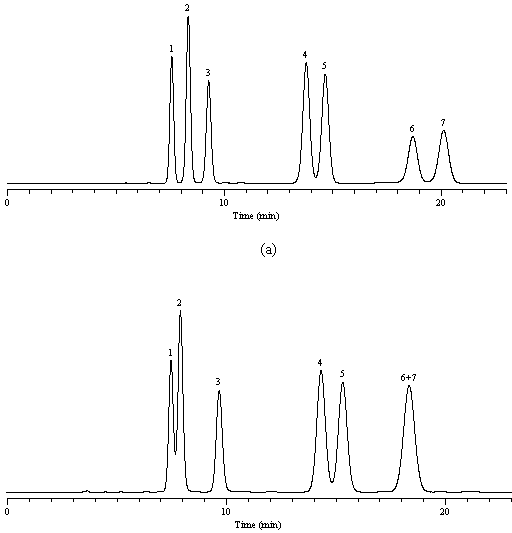

[0039] Example 1 Preparation of C18 chromatographic stationary phase by gas-solid catalytic method

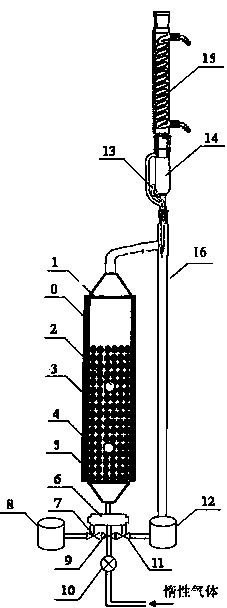

[0040] 100 g of silica gel (3) (AGC Si-Tech Co. Ltd., 5 mm, 100 ?, 440 m 2 / g) into the reactor (0), open the valve B (9), dry nitrogen into the reactor (0) through the flow meter (10) and preheater (6), silica gel (3) through the heater (4) Heat to 170 0 C dry for 24 hours. Add 600 grams of octadecyldimethylchlorosilane into the silane vaporizer (12) and heat it to boiling. The vaporized silane enters the preheater (6) through the valve C (11), and passes into the reactor after further heating In (0), ammonia gas is passed through the catalyst vaporizer (8), valve A (7) and preheater (6) into the reactor (0) to react with the silica gel (3) at the same time. Maintain reaction temperature at 340 with heater (4) o C or so. After the unreacted octadecyldimethylchlorosilane is condensed by the condenser (15), it returns to the Soxhlet extractor (14), and then returns to the s...

Embodiment 2

[0041] Example 2 Preparation of C8 chromatographic stationary phase by gas-solid catalytic method

[0042] 100 g of silica gel (3) (AGC Si-Tech Co. Ltd., 5 mm, 100 ?, 440 m 2 / g) is filled into the reactor (0), and the silica gel (3) is heated to 170 0 C dry for 24 hours, add 150-200 ml of pyridine into the catalyst vaporizer (8), and heat to boiling, the vaporized catalyst enters the preheater (6) through valve A (7), and after further heating, enters the reactor (0). At the same time, 500 milliliters of C8dimethylmethoxysilane is added to the silane vaporizer (12), and heated to boiling, the vaporized silane enters the preheater (6) through valve C (11), and after further heating, enters React with silica gel (3) in reactor (0), maintain reaction temperature at 200 with heating system (4) 0 C or so. After the unreacted eight-carbon dimethylmethoxysilane is condensed by the condenser (15), it returns to the Soxhlet extractor (14), and then returns to the silane vaporizer ...

Embodiment 3

[0043] Example 3 Preparation of C18 stationary phase by liquid phase bonding (for comparison)

[0044] Add 10 g of spherical silica gel (AGC Si-Tech Co. Ltd., 5 mm, 100 ?, 440 m 2 / g), at 170 0 C for 24 hours. After the silica gel was cooled under an argon atmosphere, xylene (100 ml), octadecyldimethylchlorosilane (18 g) and pyridine (5 ml) were added, mechanically stirred and heated to reflux under argon, reaction 16 Hour. Stop the reaction, vacuum filter, wash with toluene, dichloromethane, tetrahydrofuran, acetone, methanol-water (1:1, v / v), methanol, 80 0 C dry for 24 hours. Bonded silica gel was put into a reactor, xylene (100 ml) and hexamethyldisilazane (10 ml) were added, stirred mechanically and heated to reflux under an argon atmosphere, and reacted for 16 hours. Stop the reaction, vacuum filter, wash with toluene, dichloromethane, tetrahydrofuran, acetone, methanol-water (1:1, v / v), methanol, 80 0 C dried for 24 hours to obtain the stationary phase.

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com