Non-aqueous electrolyte battery

A non-aqueous electrolyte and battery technology, applied in the direction of non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of difficult discharge performance and achieve the effect of reducing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

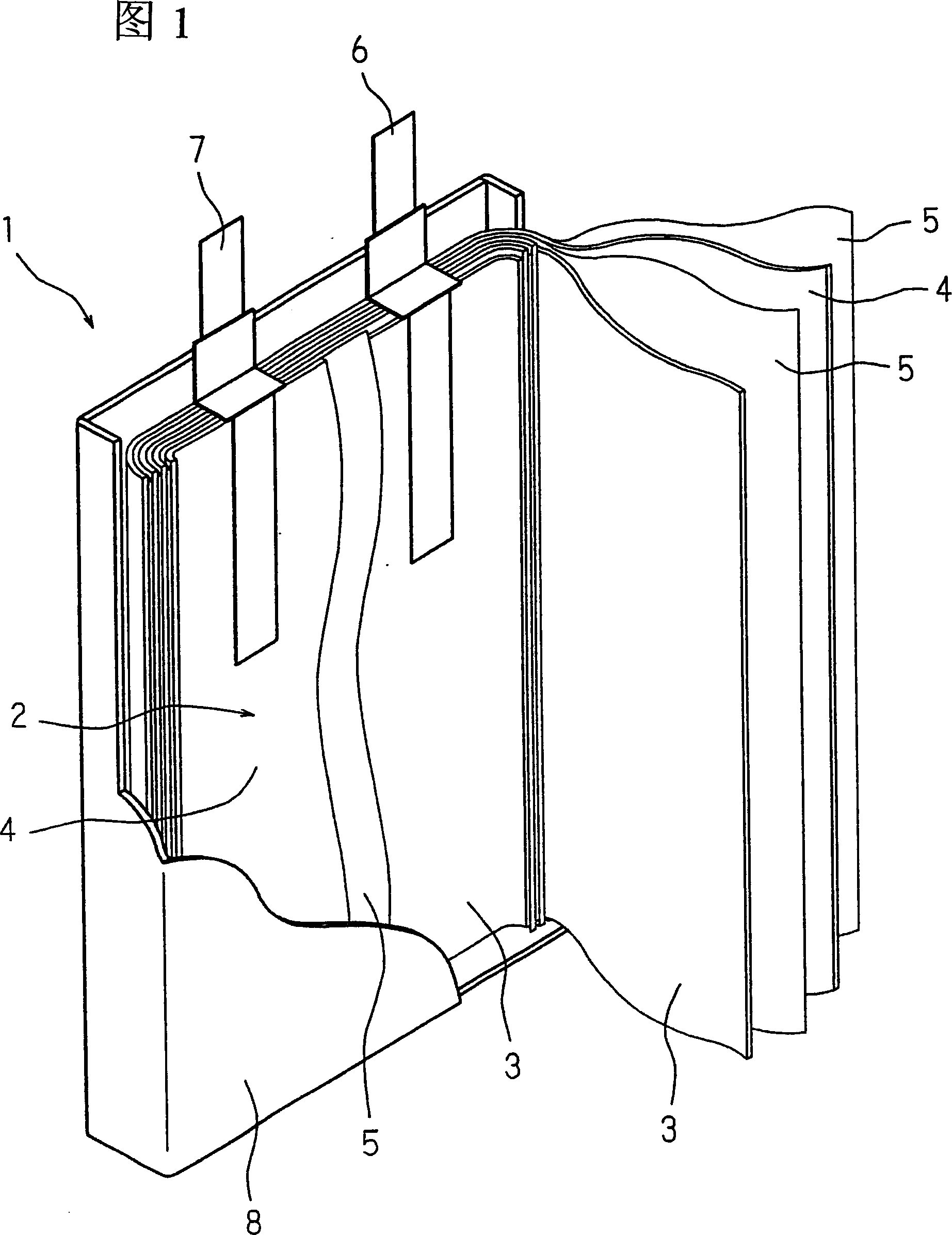

[0021] Fig. 1 shows an exploded perspective view of an example of a nonaqueous electrolyte battery according to the present invention. In Fig. 1, reference numeral 1 is a nonaqueous electrolyte battery (hereinafter referred to as a battery), reference numeral 2 is a generating element (generating element), reference numeral 3 is a positive plate, and reference numeral 4 is a negative plate. Reference numeral 5 is a separator, reference numeral 6 is a positive terminal, reference numeral 7 is a negative terminal, and reference numeral 8 is a battery casing.

[0022] For the positive plate 3, by mixing 94% by mass of lithium cobaltate as an active material, 3% by mass of acetylene black as a conductive agent, and 3% by mass of polyvinylidene fluoride as a binder, and then The mixture was dispersed in N-methyl-2-pyrrolidone (NMP) to prepare a slurry. The slurry was uniformly coated on a 15 μm thick aluminum foil collector and dried, and then film-pressed with a roll press to pre...

Embodiment 2

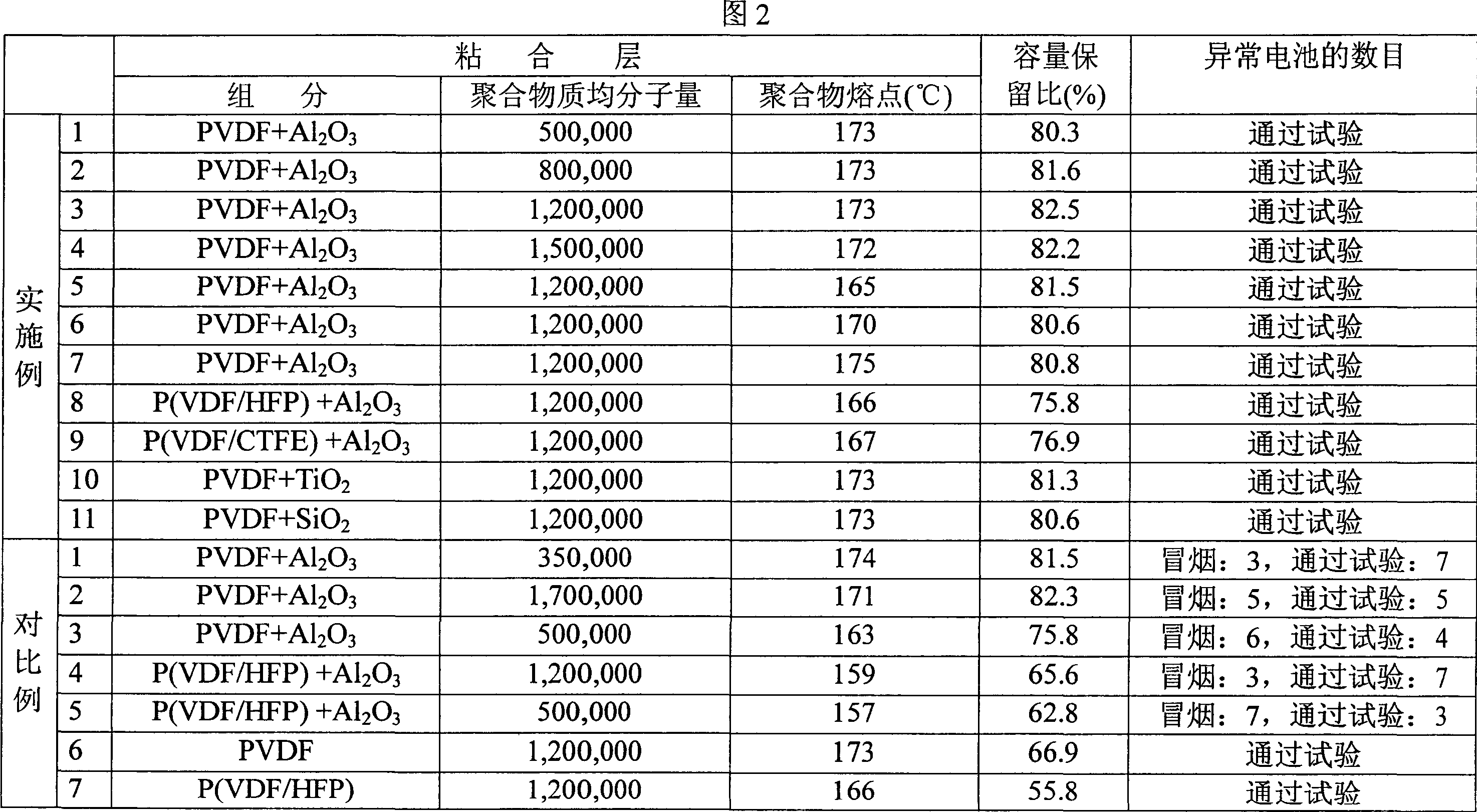

[0027] A battery similar to that of Example 1 was fabricated except that the adhesive layer polymer had a mass average molecular weight of 800,000.

Embodiment 3

[0029] A battery similar to that of Example 1 was fabricated except that the mass average molecular weight of the adhesive layer polymer was 1,200,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com