Anti-fouling heat dissipation composite board and preparation method thereof

A technology of composite board and composite slab, which is applied in the direction of chemical instruments and methods, manufacturing tools, flat products, etc., to achieve the effect of excellent porous performance and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

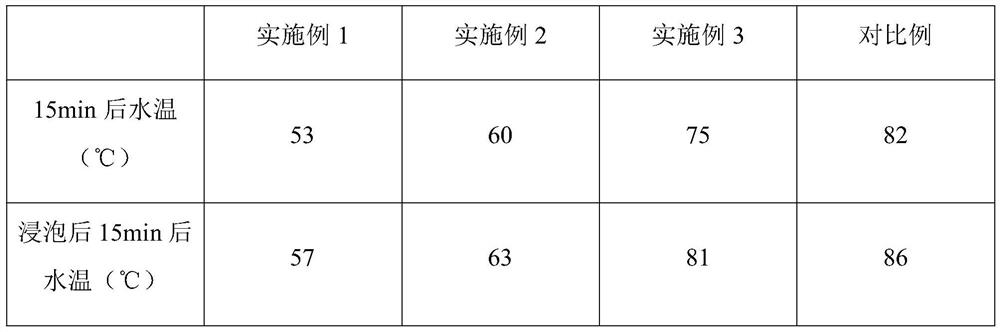

Examples

Embodiment 1

[0034] An anti-fouling and heat-dissipating composite board mainly includes, by weight, 70 parts of modified straw, 6 parts of polypropylene microporous membrane, 60 parts of carbon dioxide, 50 parts of copper ion solution, 25 parts of dopamine and 40 parts of isocyanate glue.

[0035] A method for preparing an antifouling and heat dissipation composite board, the preparation method of the antifouling and heat dissipation composite board mainly includes the following preparation steps:

[0036] (1) Mix the pretreated straw and water in a beaker at a mass ratio of 1:10, and add emulsifier OP-10 with 0.1 times the weight of the pretreated straw and glycidyl methacrylate with 6 times the weight of the pretreated straw into the beaker Esters and benzoyl peroxide of 0.15 times the mass of the pretreated straw were stirred and reacted for 1.5 h at a temperature of 65° C. and a rotating speed of 450 r / min, and then filtered to obtain a pre-modified straw blank. The pre-modified straw ...

Embodiment 2

[0045] An anti-fouling and heat-dissipating composite board mainly includes, by weight, 70 parts of modified straw, 6 parts of polypropylene microporous film, 60 parts of carbon dioxide, 25 parts of dopamine and 40 parts of isocyanate glue.

[0046] A method for preparing an antifouling and heat dissipation composite board, the preparation method of the antifouling and heat dissipation composite board mainly includes the following preparation steps:

[0047] (1) Mix the pretreated straw and water in a beaker at a mass ratio of 1:10, and add emulsifier OP-10 with 0.1 times the weight of the pretreated straw and glycidyl methacrylate with 6 times the weight of the pretreated straw into the beaker Esters and benzoyl peroxide of 0.15 times the mass of the pretreated straw were stirred and reacted for 1.5 h at a temperature of 65° C. and a rotating speed of 450 r / min, and then filtered to obtain a pre-modified straw blank. The pre-modified straw blank Dry at a temperature of 65°C f...

Embodiment 3

[0056] An anti-fouling and heat-dissipating composite board mainly includes, by weight, 70 parts of pretreated straw, 6 parts of polypropylene microporous film, 60 parts of carbon dioxide, 50 parts of copper ion solution, 25 parts of dopamine and 40 parts of isocyanate glue.

[0057] A method for preparing an antifouling and heat dissipation composite board, the preparation method of the antifouling and heat dissipation composite board mainly includes the following preparation steps:

[0058] (1) Mix the pretreated straw with a copper nitrate solution with a mass fraction of 10% at a mass ratio of 1:12, let stand at room temperature for 4 hours, and filter to obtain a mixed modified straw billet, mix the modified straw billet with The organic solvent is mixed in the flask at a mass ratio of 1:10, and carbon dioxide is passed into the flask at a rate of 50mL / min, and after continuous feeding for 40min, it is filtered to obtain mixed modified straw;

[0059] (2) Mix the mixed mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com