Manganese dioxide sulfur-carbon positive electrode and preparation method

A technology of manganese dioxide sulfur carbon and manganese dioxide, which is applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of restricting large-scale application, unfavorable industrial production, and cumbersome steps, so as to inhibit the shuttle effect and improve the utilization rate , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Choose elemental sulfur S 8 React with carbon nanotube powder CNT, sieve sulfur powder 100-200 mesh to obtain sulfur powder, mix with carbon nanotube CNT at a weight ratio of 7:3, put it in a reaction kettle, and react at a high temperature of 155°C for 6 Hour, take out after natural cooling, obtain sulfur-carbon composite material, stand-by;

[0031] 2) With nitrogen methylpyrrolidone NMP as a solvent, the solvent and dry powder are sulfur-carbon composite materials, fine sulfur powder, manganese dioxide, and binder (6% in this embodiment) in a weight ratio of 60:10:20:10 Polyvinylidene fluoride PVDF emulsion) mixing, proportioning slurry, and homogeneous;

[0032] 3) Coating the aluminum foil of the positive electrode current collector with a thickness of 150 microns, and drying in a furnace at 80°C-130°C to obtain a lithium-sulfur battery positive electrode with a manganese dioxide sulfur carbon core-shell structure Pole piece;

[0033] 4) Sublimating the posit...

Embodiment 2

[0036] The preparation method of Example 2 is the same as that of Example 1, except that the weight ratio of the sulfur-carbon composite material, sulfur powder, manganese dioxide, and binder in step 2) is 40:10:40:10.

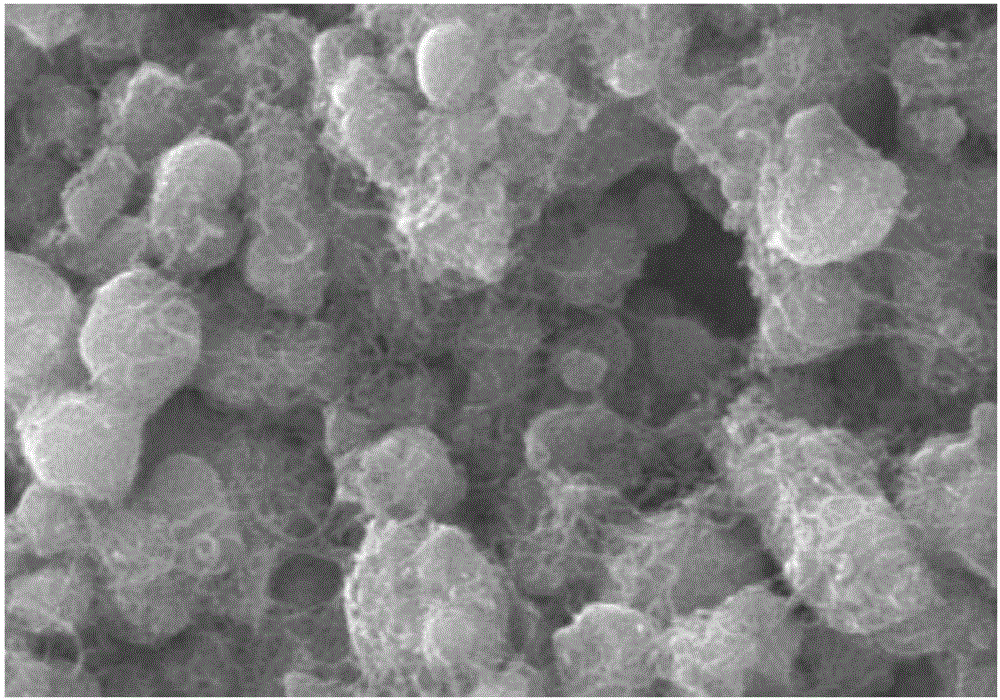

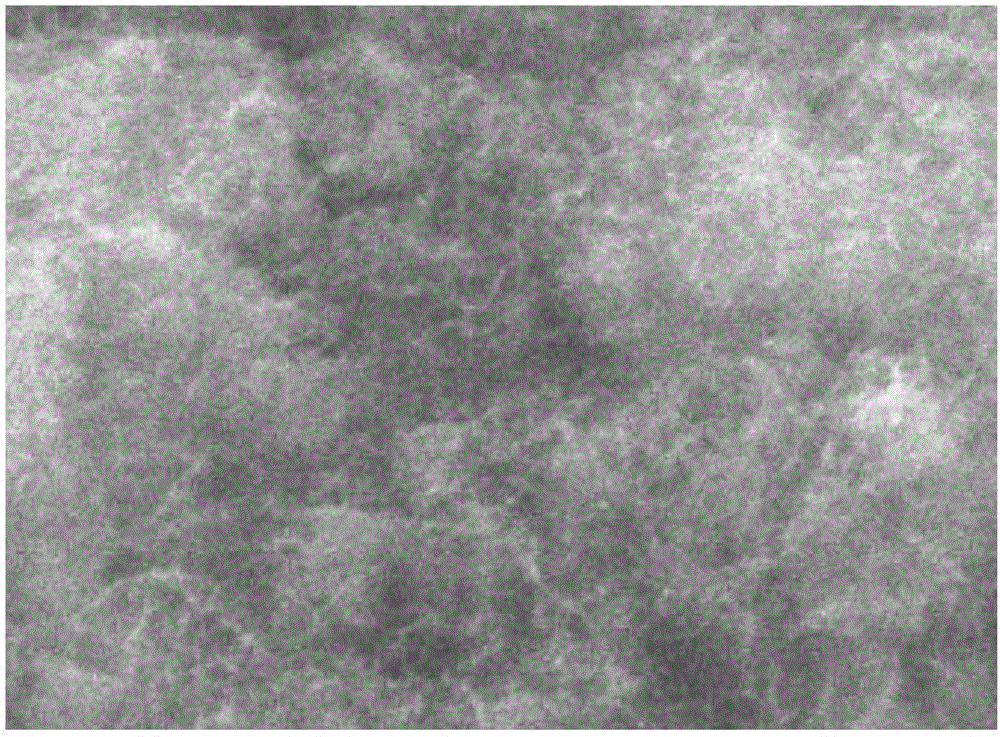

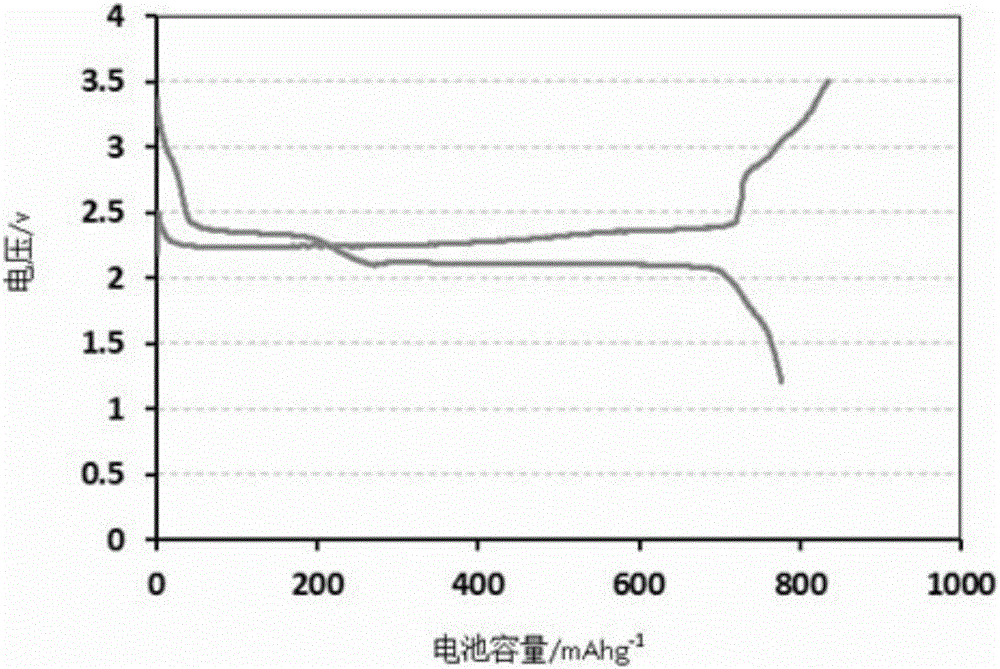

[0037] Figure 4 The scanning electron microscope picture of the lithium-sulfur battery positive electrode sheet with the primary manganese dioxide sulfur carbon core-shell structure prepared in Example 2. Figure 4 It is shown that the sulfur / CNT material is evenly coated on the surface of manganese dioxide, forming a primary manganese dioxide sulfur carbon core-shell structure. Figure 5 The scanning electron microscope picture of the lithium-sulfur battery positive electrode sheet with the secondary manganese dioxide sulfur carbon core-shell structure prepared in Example 2. Depend on Figure 5The microstructure of the lithium-sulfur battery positive electrode sheet is composed of: manganese dioxide is used as a structural support to fix the sulfur-carbon ...

Embodiment 3

[0039] Embodiment 3: the preparation method of embodiment 3 is the same as that of embodiment 1, the only difference is that the ratio of sulfur powder and conductive agent powder graphene in step 1) is: 1:1. The manganese dioxide sulfur carbon core-shell structure composite material button battery prepared by the method has a capacity of up to 220.1 mAh / g, wherein the capacity of the sulfur S8 can reach 680.5 mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com