Preparation method for microporous polyphenylene sulfide hollow fiber membrane

A technology of polyphenylene sulfide and fiber membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of uneven pores and low flux, slow down the crystallization speed, and reduce the phase separation temperature , the effect of enhancing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method (abbreviation method) of microporous polyphenylene sulfide hollow fiber membrane, it is characterized in that the method comprises the steps:

[0024] 1) The diluent is ground into powder at room temperature, and then the diluent accounting for 20-60% of the total mass, the porogen accounting for 0-2% of the total mass, the inorganic nanoparticles accounting for 0-2% of the total mass and The polyphenylene sulfide accounting for 40-80% of the total mass is uniformly mixed in a stirrer to obtain a homogeneous polyphenylene sulfide casting solution; the sum of the four mass is 100%;

[0025] The diluent is a benign diluent and an auxiliary diluent; the benign diluent is caprolactam (CPL), benzophenone (BP), diphenyl ether (DPE), benzoin (BZ) or diphenylsulfone (DPS) at least one of; the auxiliary diluent is dibutyl sebacate (DBS), dibutyl phthalate (DBP), dioctyl phthalate (DOP) or dioctyl isophthalate fat (DOTP);

[0...

Embodiment 1

[0038] (1) Batching (PPS: BP: BZ = 80%: 10%: 10%), the pulverizer is pulverized and mixed evenly, and the heating temperature of each segment of the screw section is set (240°C, 282°C, 294°C, 290°C, 290°C ℃, 292 ℃), spinneret temperature and metering pump temperature (264 ℃, 264 ℃), after the temperature is stable, adjust the main engine speed, feeding speed and metering pump speed.

[0039] (2) Adopt the method of passing nitrogen gas to make it hollow, and adjust the nitrogen flow rate of the nozzle to 0.1NI / min.

[0040] (3) During the spinning process, the mixed liquid composed of water and ethylene glycol at a weight ratio of 1:1 was used as a coagulation bath, and its temperature was adjusted to 60°C, and the receiving distance of the coagulation bath was 12cm.

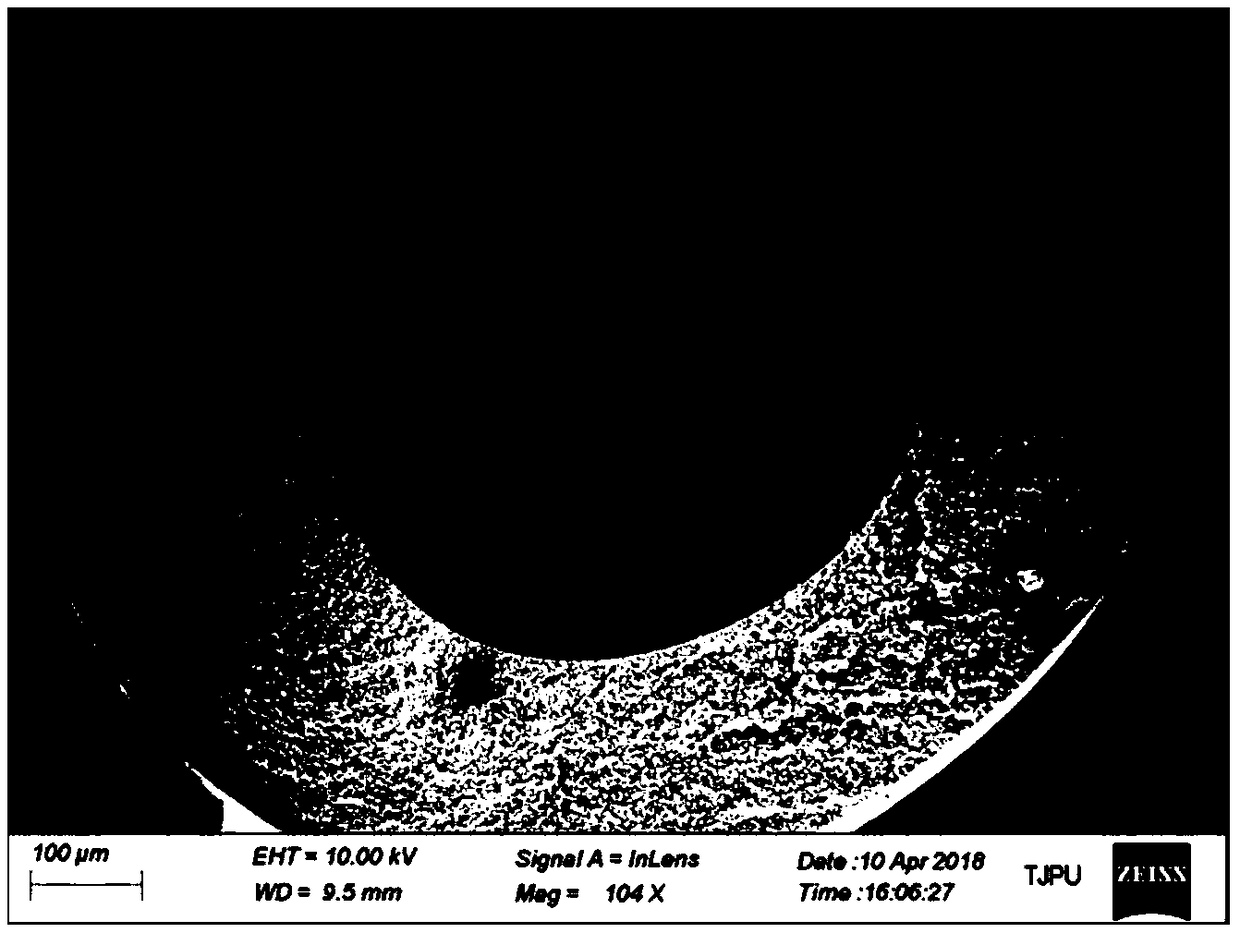

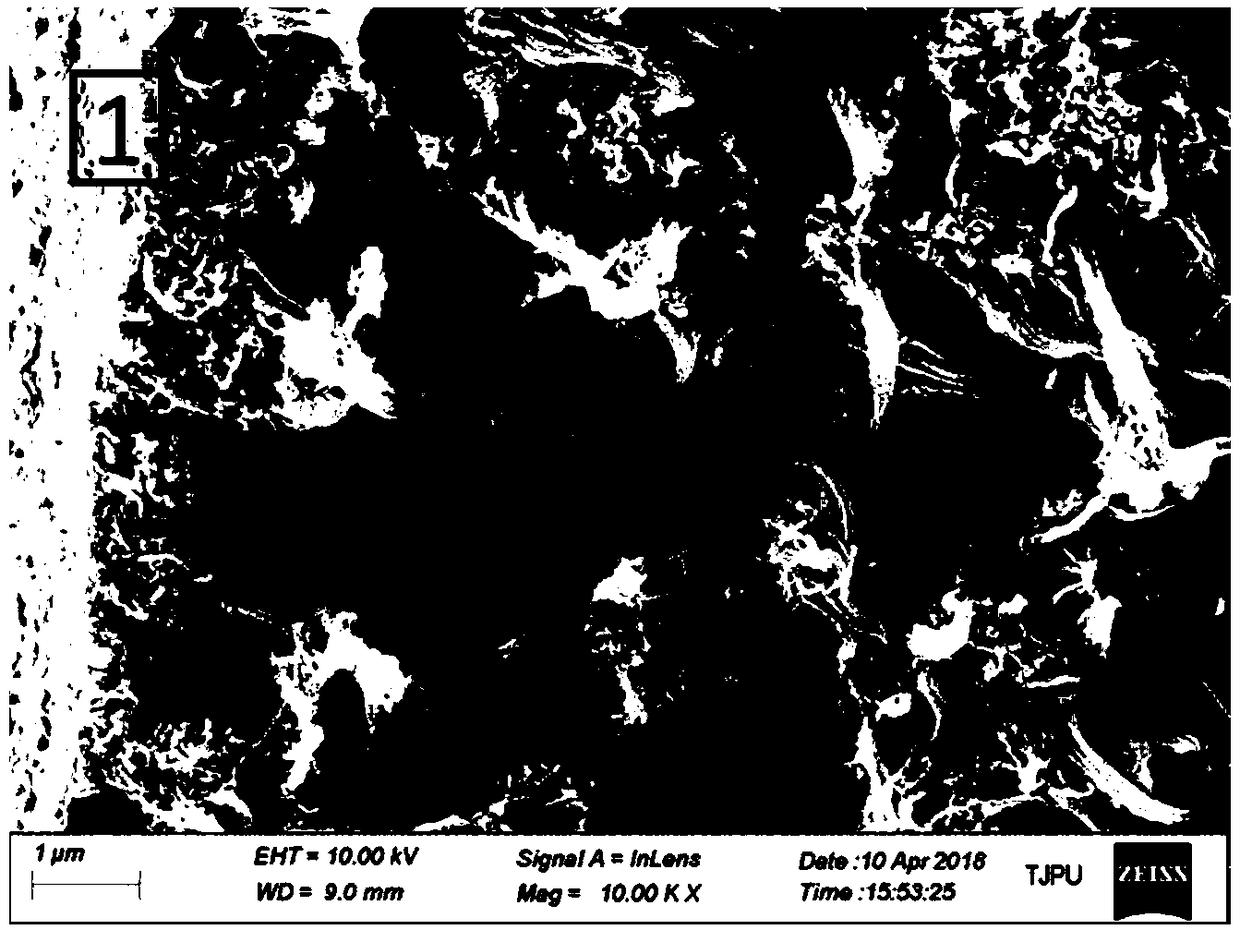

[0041] (4) Soak the membrane filaments in ethanol at 60° C. for 48 hours, then soak them in distilled water for 24 hours, freeze-dry them and store them for later use. Through electron microscope analysis, ther...

Embodiment 2

[0043] (1) Batching (PPS: BP: BZ = 50%: 50%: 0%), crushed by a pulverizer and mixed evenly, set the heating temperature for each segment (225°C, 264°C, 265°C, 261°C, 260°C, 260°C), spinneret temperature and metering pump temperature (245°C, 245°C), after the temperature stabilizes, adjust the speed of the main engine, feeding speed and metering pump.

[0044] (2) Adopt the method of passing nitrogen gas to make it hollow, and adjust the nitrogen flow rate of the nozzle to 0.1NI / min.

[0045] (3) During the spinning process, the mixed liquid composed of water and ethylene glycol at a weight ratio of 1:1 was used as a coagulation bath, and its temperature was adjusted to 60°C, and the receiving distance of the coagulation bath was 12cm.

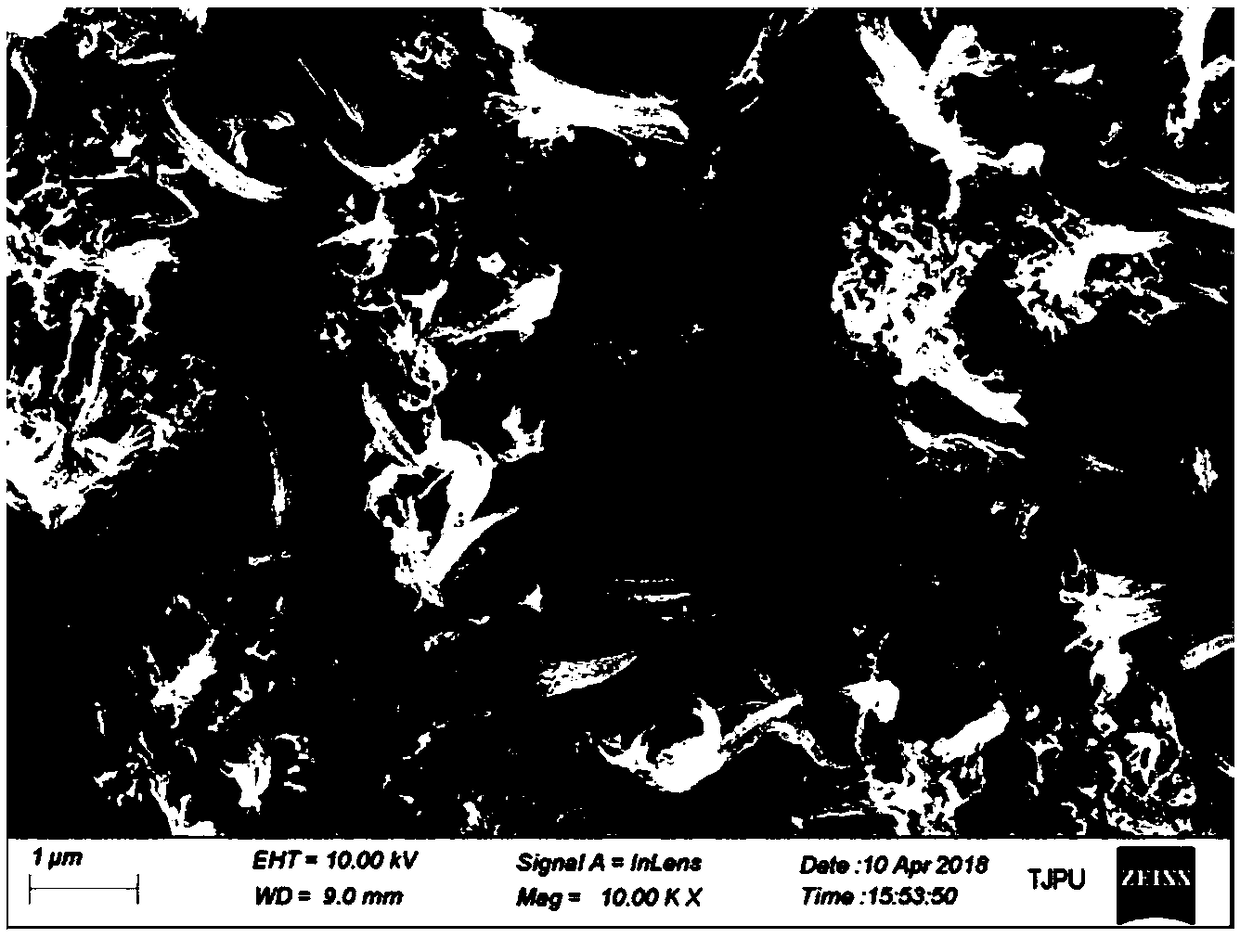

[0046] (4) Soak the membrane filaments in ethanol at 60° C. for 48 hours, then soak them in distilled water for 24 hours, freeze-dry them and store them for later use. Through electron microscope analysis, there are fine crystal particles in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com