Preparation method of sludge straw biomass fuel

A biomass fuel, straw technology, applied in the direction of biofuel, waste fuel, fuel, etc., to achieve high calorific value and flammability, improve efficiency, reduce the effect of compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

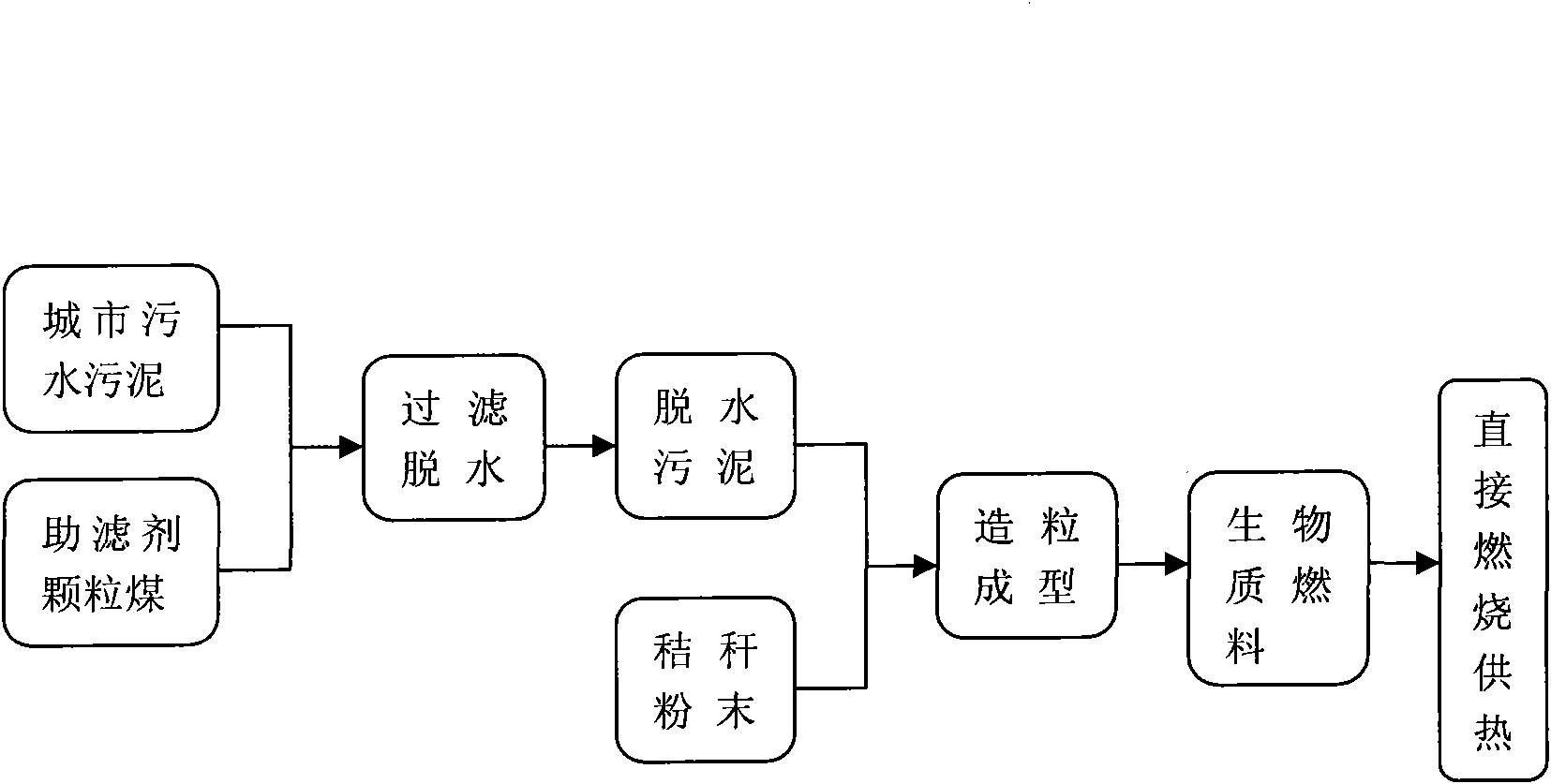

[0020] The preparation method steps are as follows:

[0021] a, carry out filtration and dehydration, first mix the residual sludge of urban sewage treatment plants with a water content above 96% and granular coal (filter aid) with a particle size of 0.15 to 0.18mm, and the mass ratio of sludge to granular coal is 1: 1-2, and then dewatered by existing vacuum filtration and press filtration technology to obtain dewatered sludge (ie sludge filter cake) with a moisture content of 40-60%. The above-mentioned granular coal can be coal for gasification furnace produced by Inner Mongolia Baotou Shenfu Dongsheng Coal Industry Co., Ltd., and the granular coal obtained after crushing and screening.

[0022] b. Stir and mix the dewatered sludge obtained in step a with the straw powder, the mass ratio of the dewatered sludge to the straw powder is 1:99, and after being granulated by a granulator, the sludge straw biomass fuel is obtained.

[0023] The fuel can be directly burned as a su...

Embodiment 2

[0024] Embodiment two: basically the same as embodiment one, the difference is:

[0025] The mass ratio of dewatered sludge to straw powder in step b is 5:95.

Embodiment 3

[0026] Embodiment three: basically the same as embodiment one, the difference is:

[0027] The mass ratio of dewatered sludge to straw powder in step b is 10:90.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com