Oxygen enriched combustion system

A technology of oxygen-enriched combustion and oxygen supply system, which is applied to burners, combustion methods, combustion types, etc., can solve problems such as difficulty in collection, and achieve the effects of facilitating capture, avoiding pulverized coal deflagration, and improving combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described with reference to the accompanying drawings. In the drawings of the specification, elements or devices with similar structures or functions will be denoted by the same reference numerals. The drawings are only for the convenience of illustrating various embodiments of the present invention, and are not intended to describe the present invention exhaustively, nor limit the scope of the present invention.

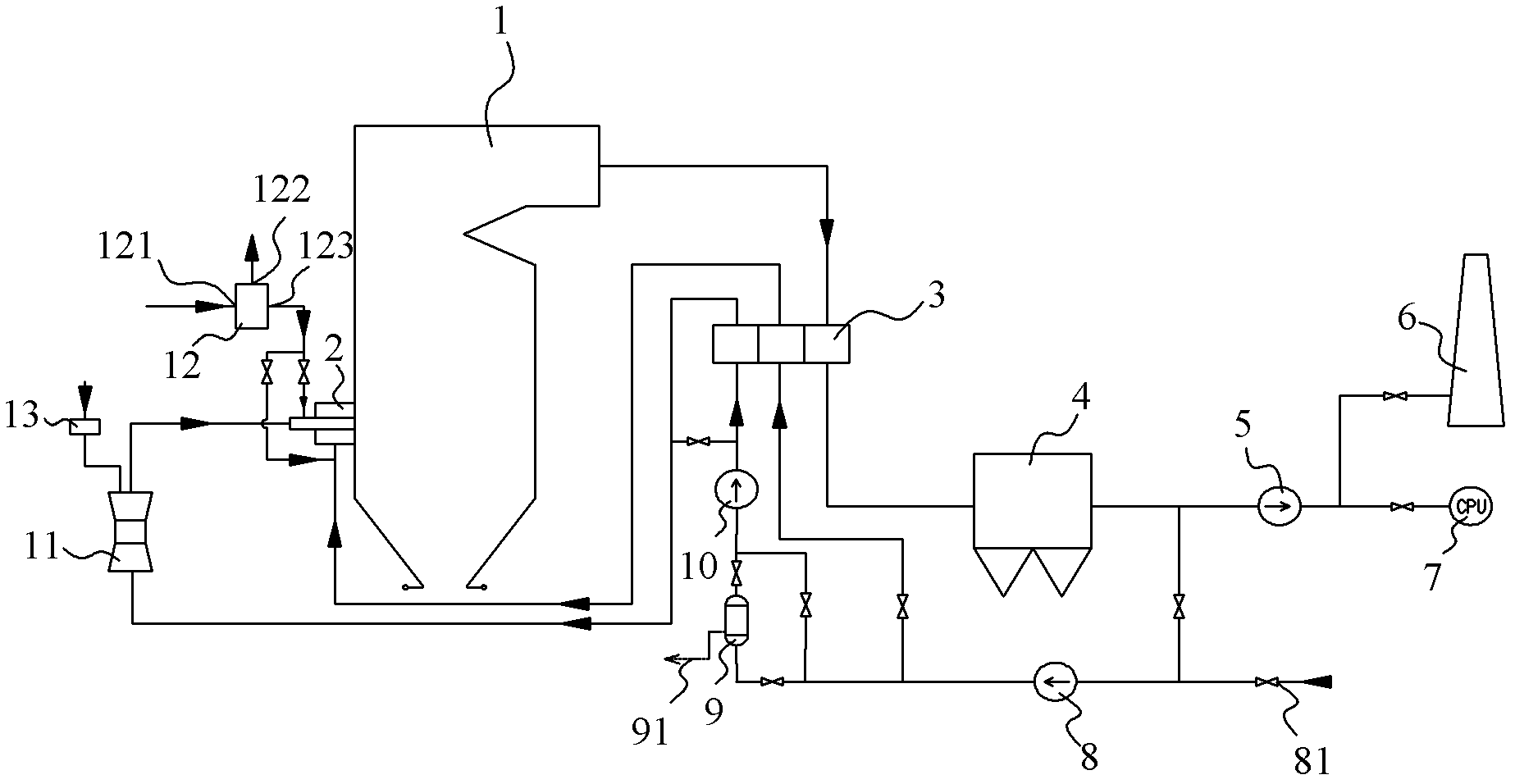

[0036] figure 1 A schematic structural diagram of an oxygen-enriched combustion system according to an embodiment of the present invention is shown. In this embodiment, the oxygen-enriched combustion system includes: a boiler body 1 , a swirl burner 2 arranged on the boiler body 1 , and the swirl burner 2 includes a primary air duct and a secondary air duct. A flue gas heat exchanger 3 and a dust collector 4 are installed in the exhaust pipe of the boiler body 1, and the dust collector 4 is connected to the induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com