Energy-saving oil-combustion hot-air furnace

A technology of hot air stove and fuel oil, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc. It can solve the problems of non-energy saving, insufficient fuel combustion, low thermal efficiency, etc., and achieves convenient manufacture, simple structure and high thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

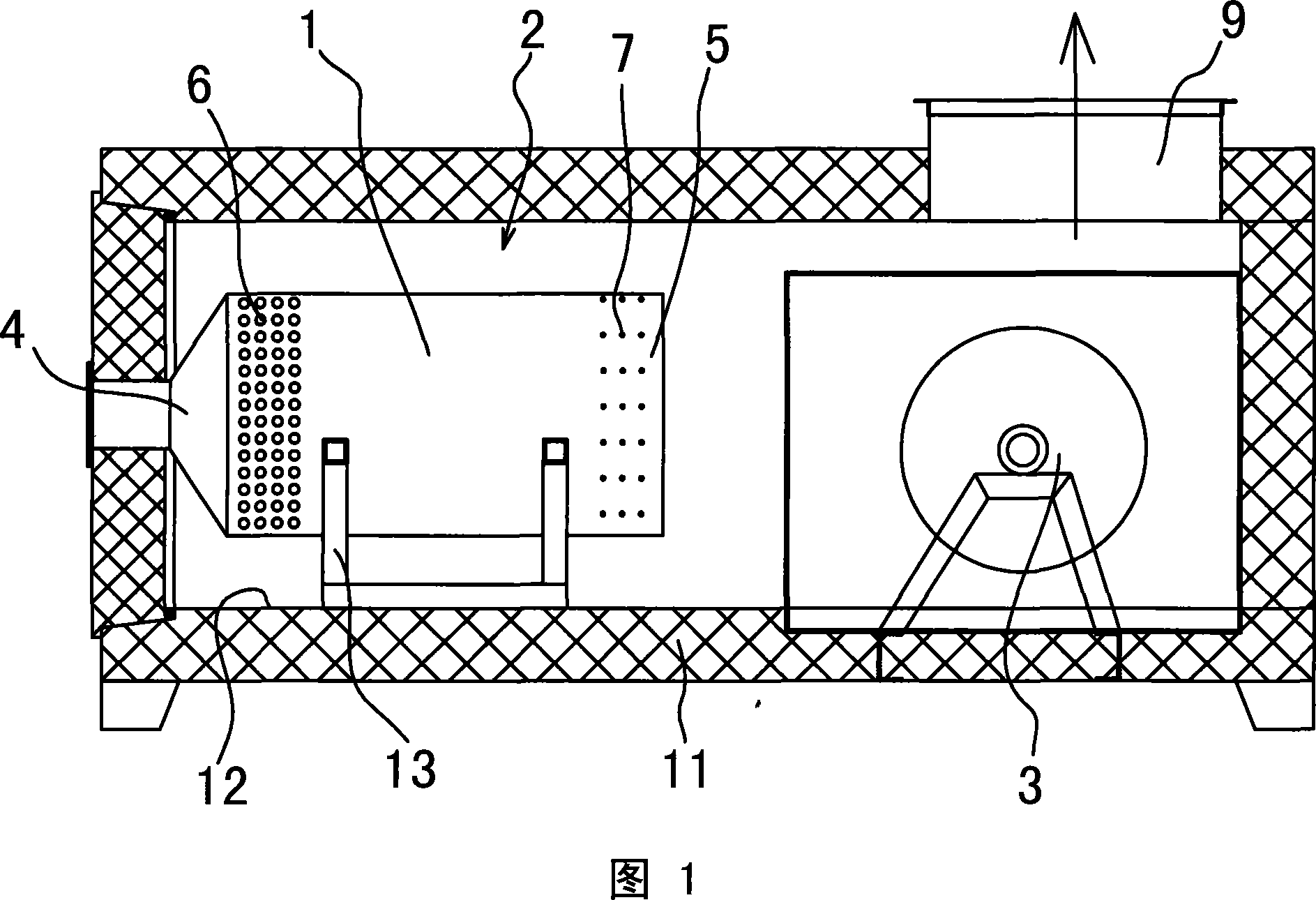

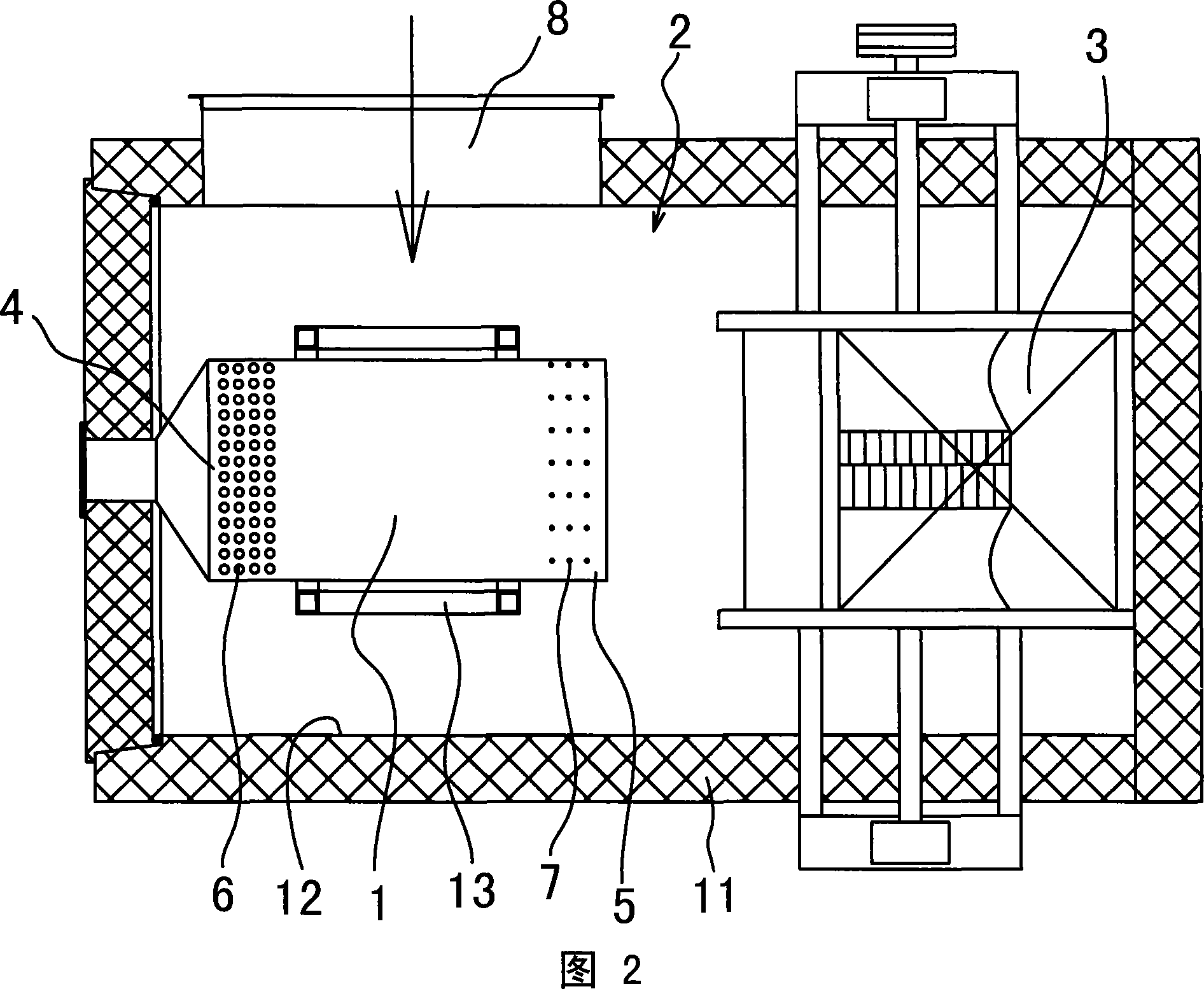

[0021] Embodiment: See accompanying drawings 1 and 2, an energy-saving fuel-fired hot blast stove, mainly composed of a combustion cylinder 1, a heating chamber 2 and a fan 3, the heating chamber 1 is a gas heating passage, and an air inlet is provided at one end of the passage 8, an air outlet 9 is established on the other end.

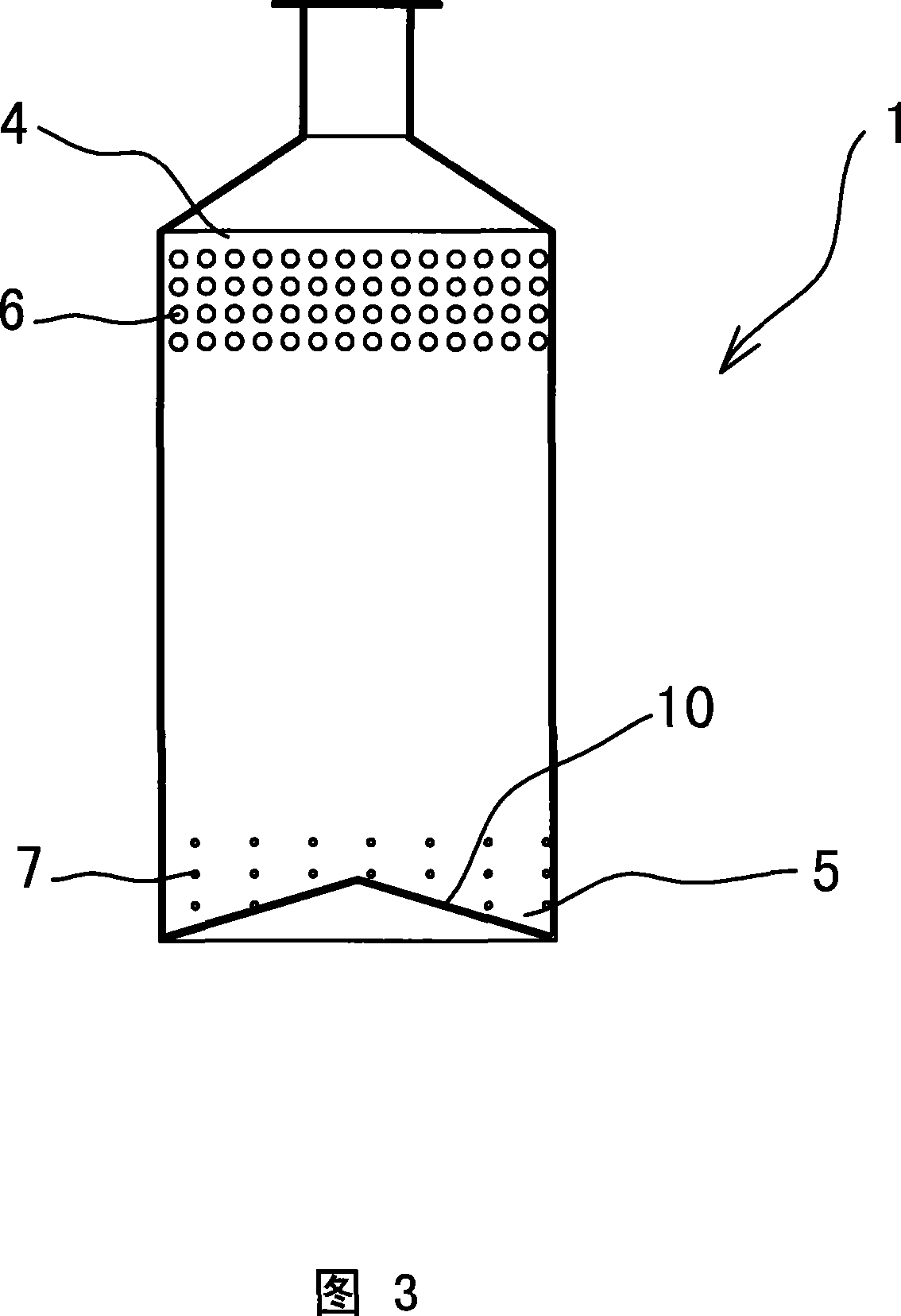

[0022] Referring to the accompanying drawings 1, 2, and 3, the combustion tube 1 is horizontally arranged at the end of the heating chamber 2 near the air inlet 8, and there is an air circulation space between the radial outer circumference of the combustion tube 1 and the wall of the heating chamber 2; Combustion tube 1 is a cylindrical combustion chamber (specifically, it is preferably cylindrical), and one end thereof is an ignition end 4, and the ignition end 4 extends outwards with a constricted portion, which passes through the combustion chamber wall and the The external oil burner is connected, and the other end of the combustion tube 1 is cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com