Anti-burst-burning gas water-heater

A gas water heater and gas technology, applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve the problems of cumbersome operation, inability to adjust the size of combustion gas, and inability to automatically adjust the amount of gas, so as to avoid the effect of deflagration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

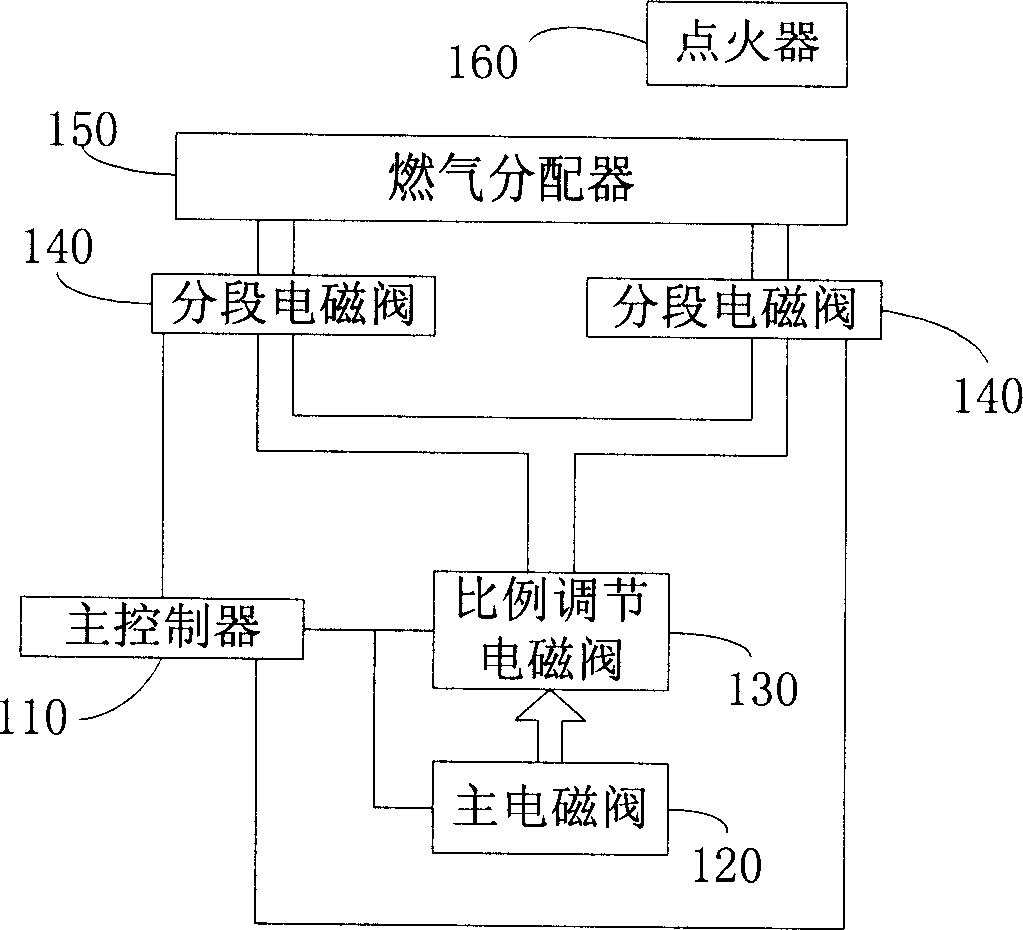

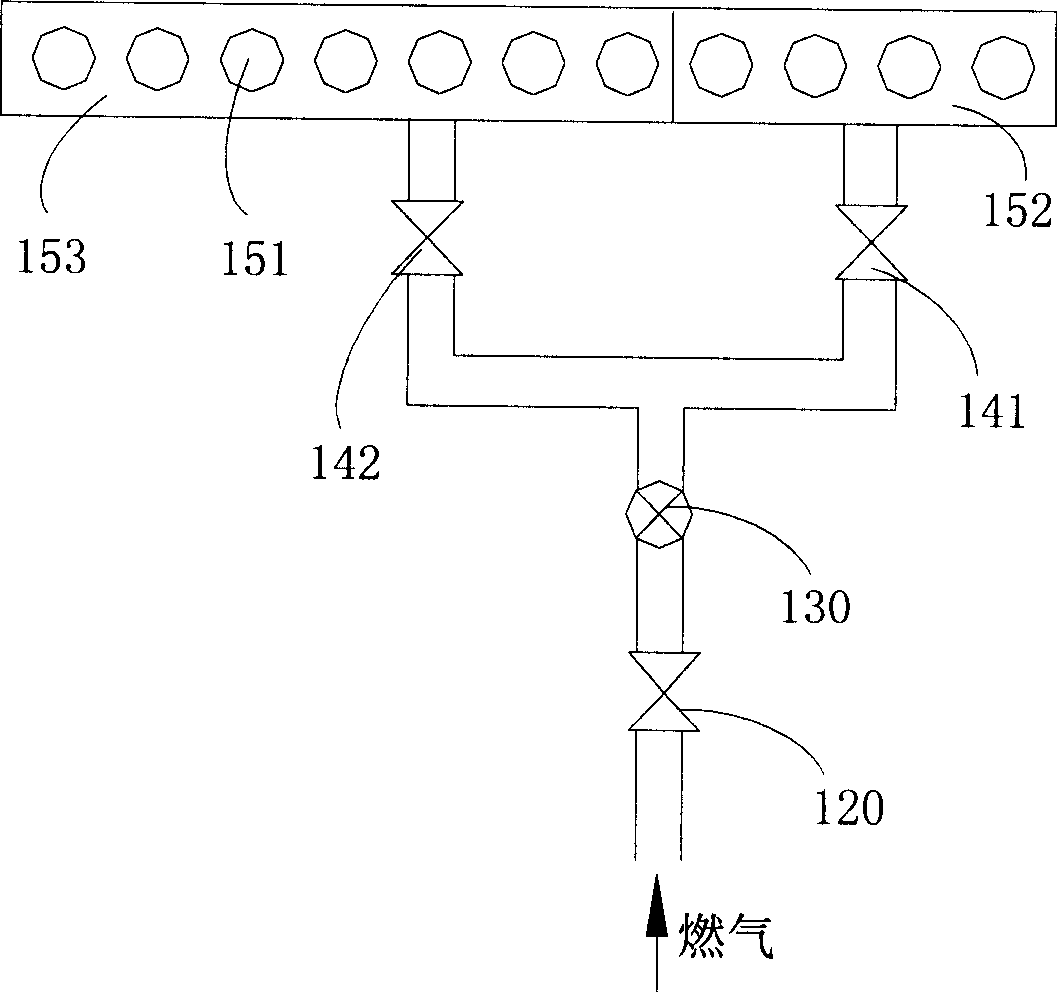

[0029] see figure 2 , is the principle block diagram of the explosion-proof gas water heater of the present invention. The water heater includes a main controller 110, a main solenoid valve 120, a proportional regulating solenoid valve 130, several segmented solenoid valves 140, a gas distributor 150 with several air inlet holes, and an igniter 160 matched with an ignition needle.

[0030] Wherein, the main controller 110 is electrically connected to the main solenoid valve 120, the proportional regulating solenoid valve 130 and several section solenoid valves 140, and controls and coordinates the switch states of the solenoid valves.

[0031] The main solenoid valve 120 is installed on the gas passage (not marked), and is the master switch of the entire gas passage. It can operate by receiving instructions from the main controller 110 to control the opening and disconnection of the gas passage.

[0032] The proportional regulating solenoid valve 130 is installed on the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com