Automatic control method for preventing extinguishment and realizing ideal combustion for hearth

An automatic control device and anti-fire technology, which is applied in the field of automatic control of idealized combustion and fire prevention in the furnace, and can solve the problems of changes in the combustion state of the boiler and inconspicuous phenomena, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

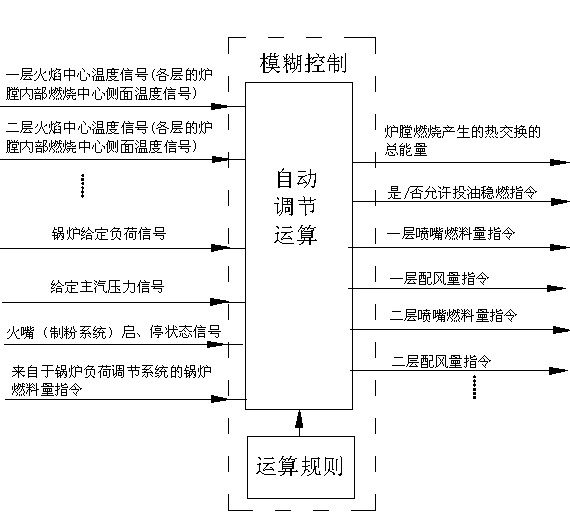

[0136] Directly adjustable and precise full furnace control unit:

[0137] Such as figure 1 Shown: The signals input to the whole furnace control unit are: the temperature signal of the flame center of each layer or the temperature signal of the combustion center side of each layer of the furnace, the given load signal of the boiler, the given main steam pressure signal, each burner (pulverizing) System) start and stop status signals, the boiler fuel quantity command signal output by the boiler load regulation system, the whole furnace control unit first gives the boiler a given load signal, a given main steam pressure signal and the burner (pulverizing system) start and stop The status signal is calculated to calculate the given value of the flame center temperature of each nozzle layer:

[0138] ,

[0139] T nSV The value principle is: T of each layer nSV The value is close, 900℃nSV <1500℃

[0140] The calculated set value of flame center temperature of each nozzle layer and flam...

Embodiment 2

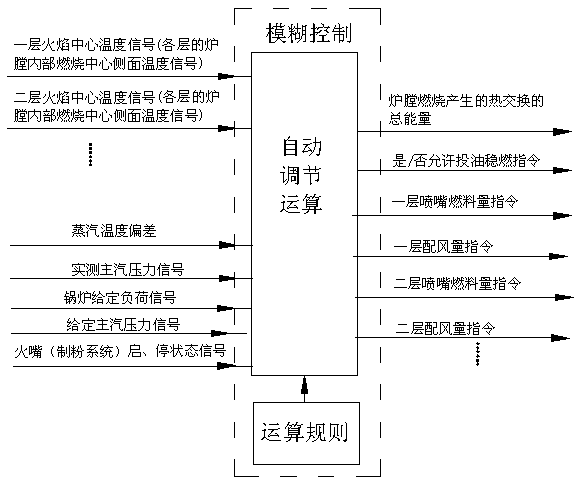

[0142] Directly regulated, accurate, steam temperature deviation correction, load deviation correction full furnace control unit:

[0143] Such as figure 2 Shown: The signals input to the whole furnace control unit are: flame center temperature signal of each layer or side temperature signal of the combustion center inside the furnace of each layer, boiler given load signal, steam temperature deviation signal, given main steam pressure signal, actual measurement The main steam pressure signal, the start and stop status signals of each burner (pulverizing system); the whole furnace control unit first gives the boiler load signal, the main steam pressure signal and the burner (pulverizing system) start and stop status The signal is calculated to calculate the given value of the flame center temperature of each nozzle layer:

[0144] ,

[0145] T nSV The value principle is: T of each layer nSV The value is close, 900℃nSV <1500℃

[0146] The calculated flame center temperature setting ...

Embodiment 3

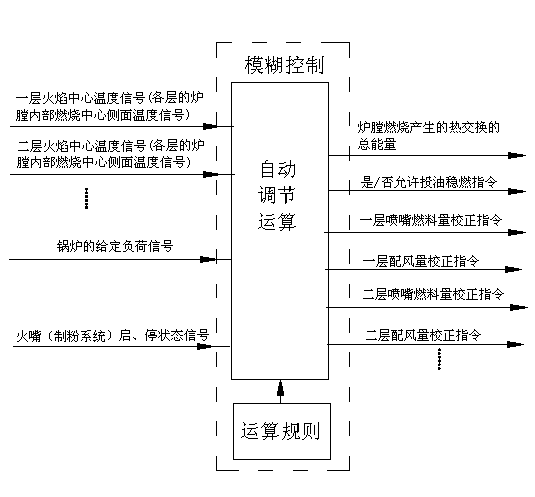

[0148] Full furnace control unit in corrected form:

[0149] Such as image 3 Shown: The signals input to the whole furnace control unit are: the flame center temperature signal of each layer or the side temperature signal of the combustion center inside the furnace of each layer, the given load signal of the boiler, the start and stop status signals of each burner (pulverizing system) ; The whole furnace control unit first calculates the given load signal of the boiler, the given main steam pressure signal and the start and stop status signals of the burner (pulverizing system), and calculates the given value of the flame center temperature of each burner layer:

[0150] ,

[0151] T nSV The value principle is: T of each layer nSV The value is close, 900℃nSV <1500℃

[0152] The calculated flame center temperature setting value of each burner layer and other input signals are automatically controlled and operated. The automatic control unit outputs the fuel volume correction instruct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com