Patents

Literature

58results about How to "Best burning state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

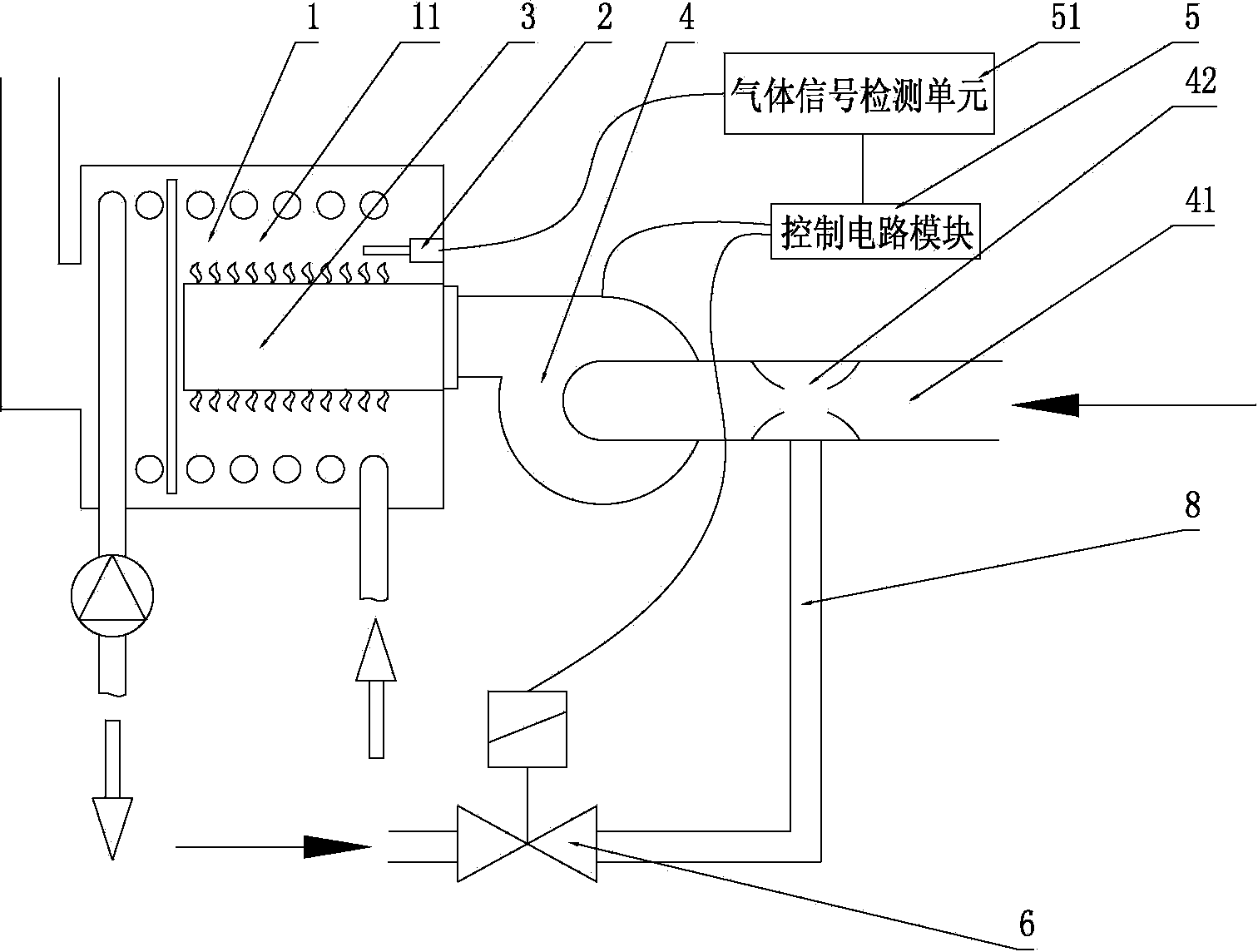

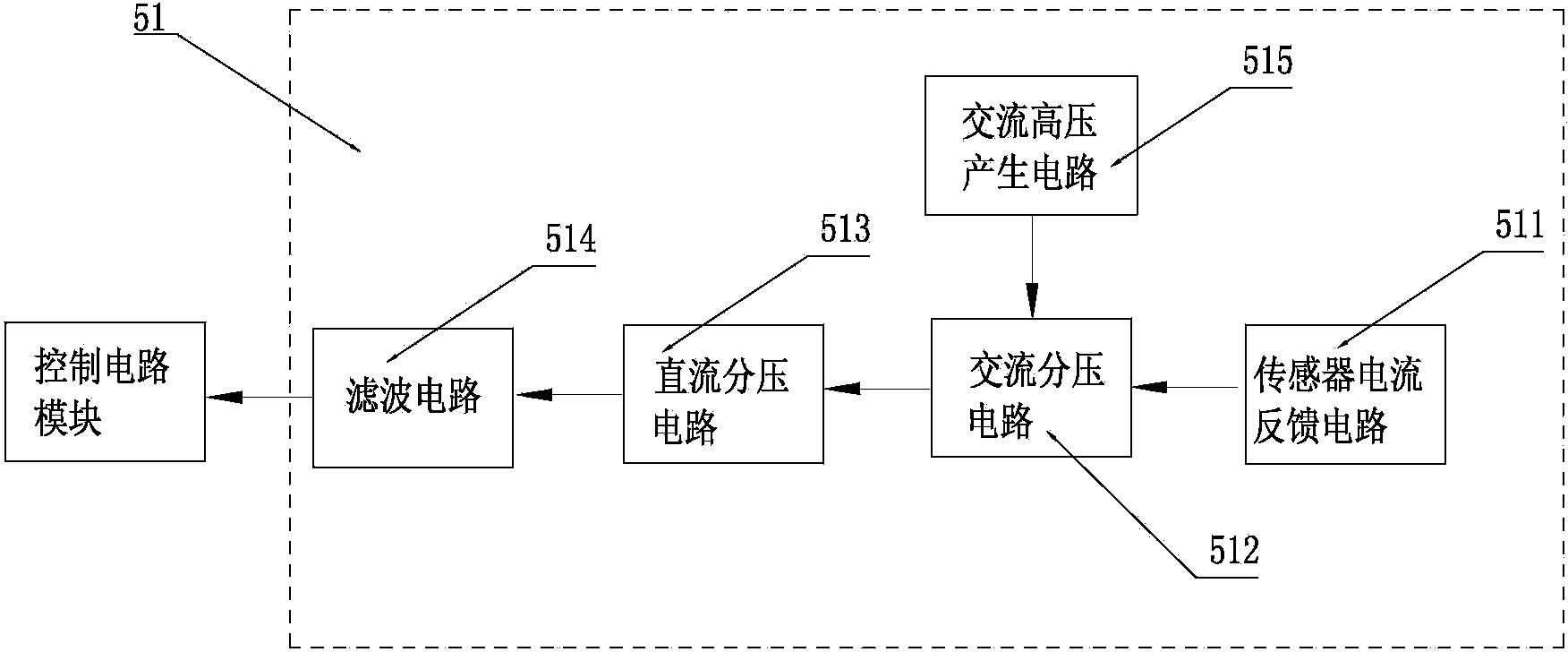

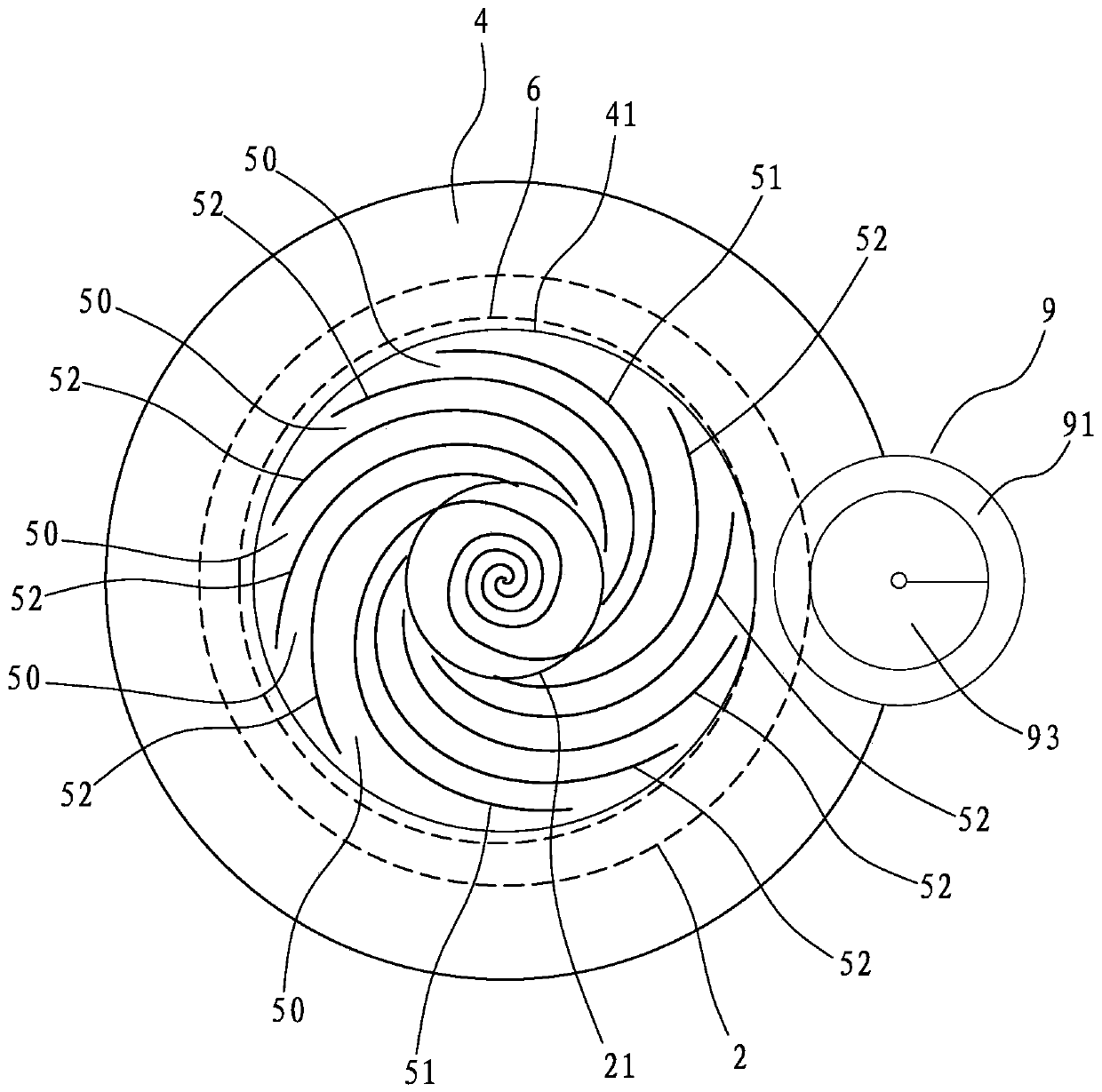

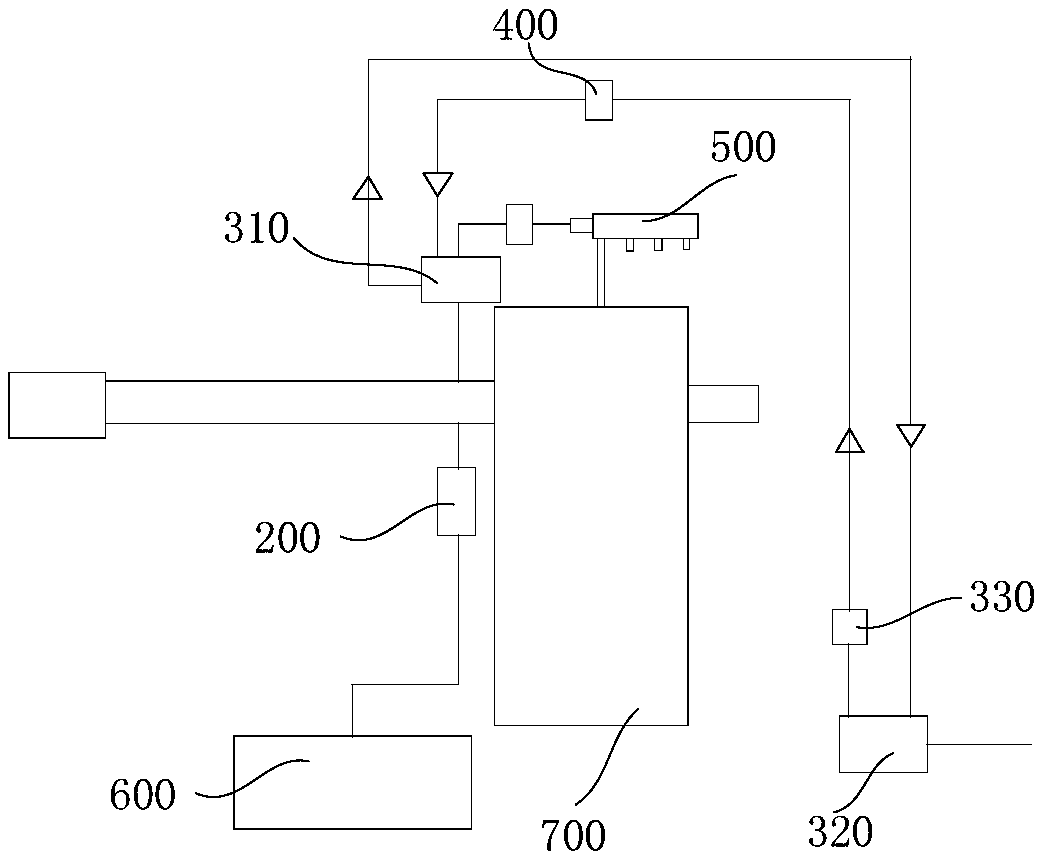

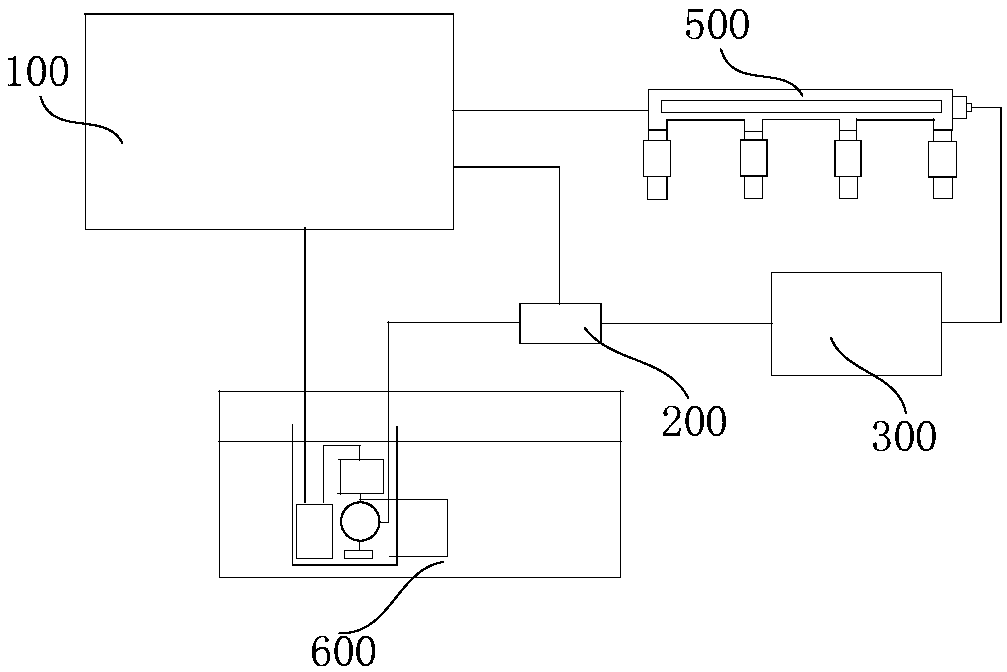

Gas water heating device capable of realizing self-adaptive fully-premixed combustion

ActiveCN104296392AAchieve complete combustionBest burning stateFluid heatersCombustion chamberGas composition

A gas water heating device capable of realizing self-adaptive fully-premixed combustion comprises a heat exchanger, a combustor, a fan, a gas adjusting valve, a gas pipe, a gas sensor, a gas signal detection unit and a control circuit module. An inner cavity of the heat exchanger forms a closed combustion chamber, the combustor and the gas sensor are arranged in the closed combustion chamber, the fan and the gas pipe are communicated with the combustor respectively, the gas adjusting valve is serially connected on the gas pipe, and the gas adjusting valve, the fan, the gas signal detection unit and the gas sensor are electrically connected with the control circuit module respectively. The gas sensor is adopted to detect content of specific gas in smoke after gas combustion, so that a ratio between gas and air can be effectively adjusted to be a new air-gas ratio when gas composition changes to achieve the object of complete combustion of gas.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

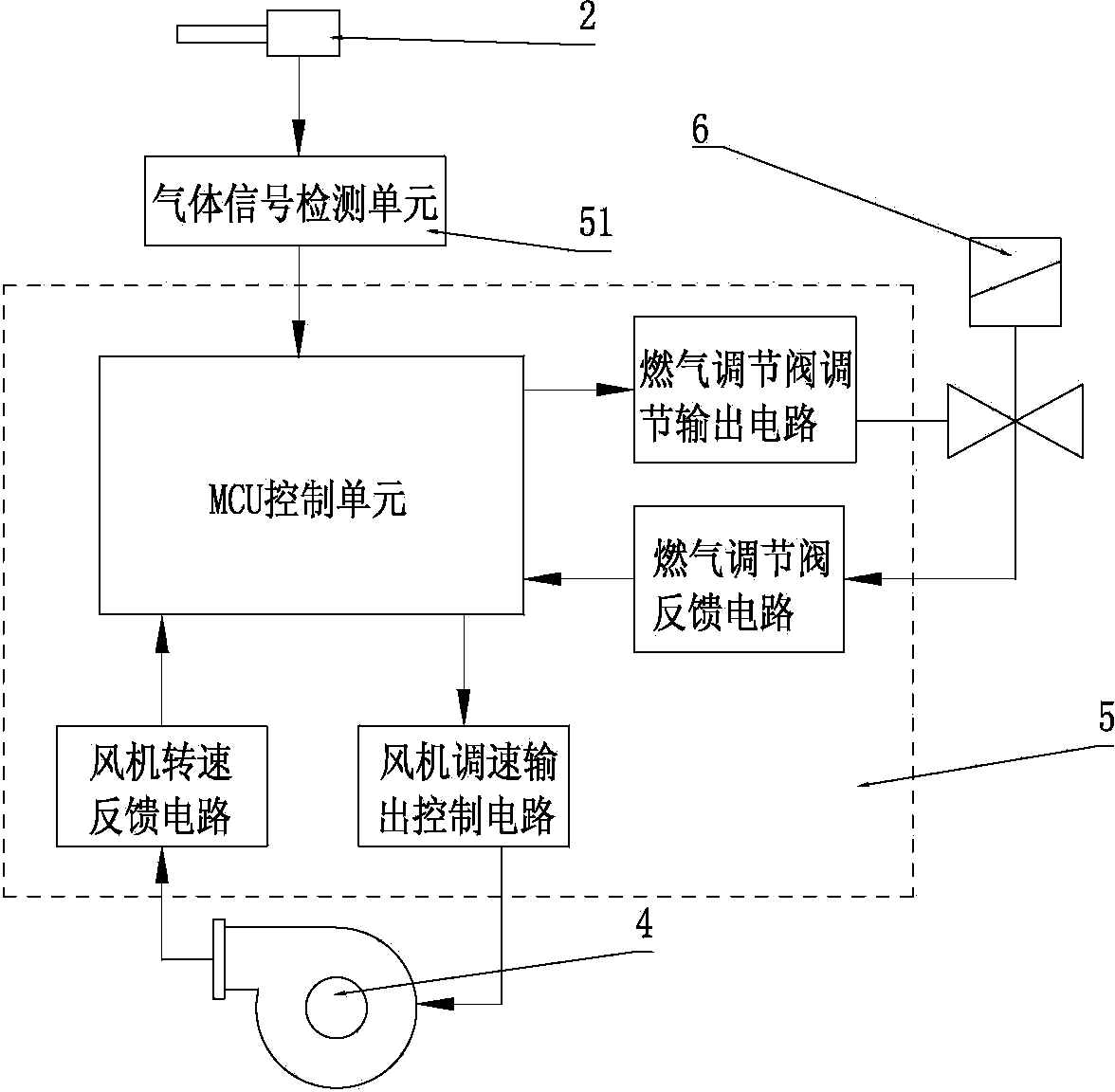

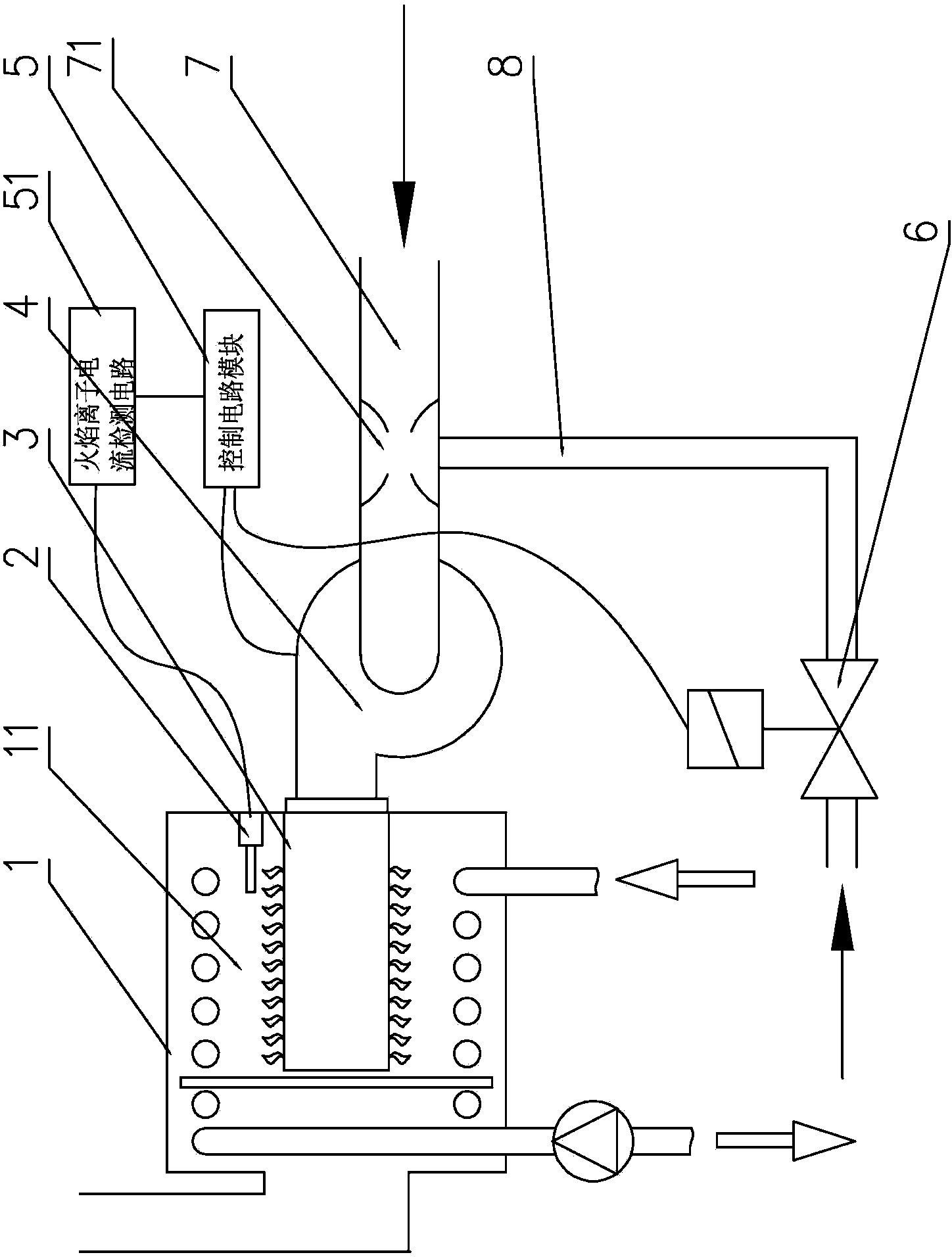

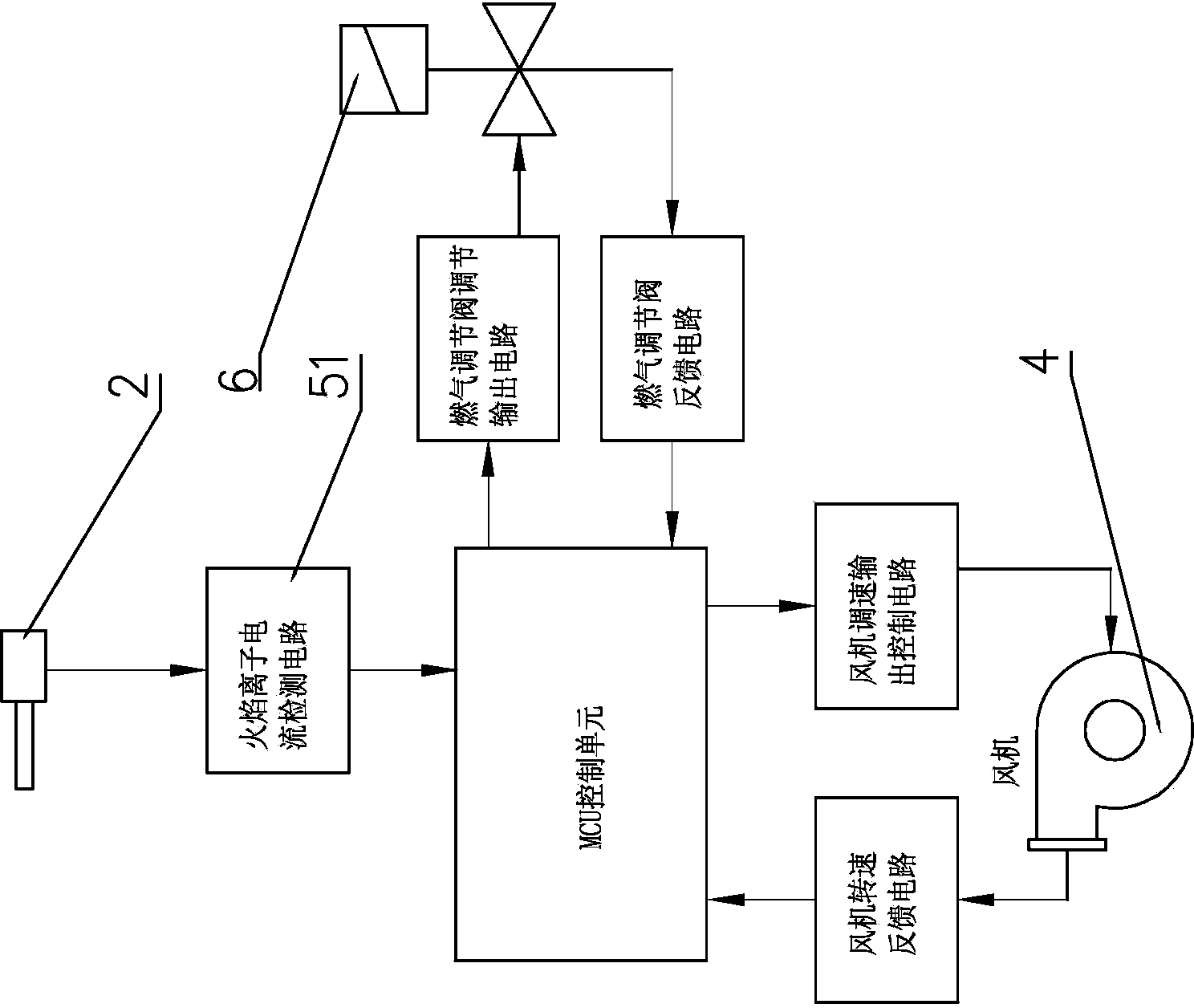

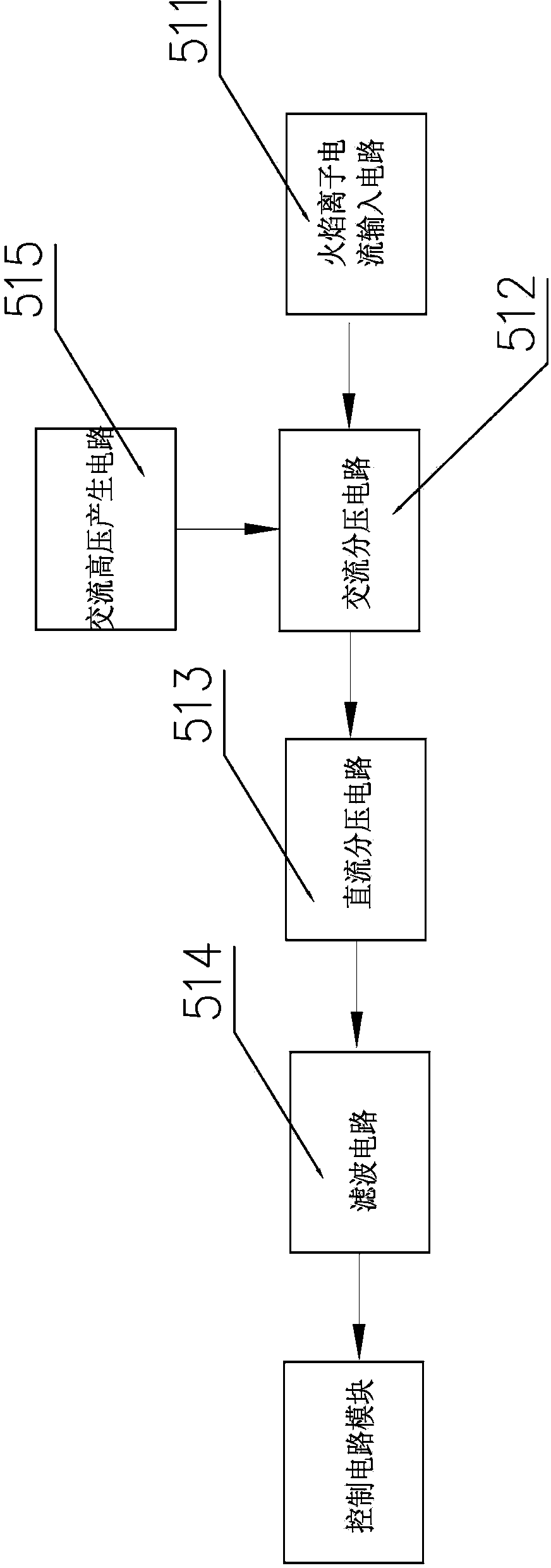

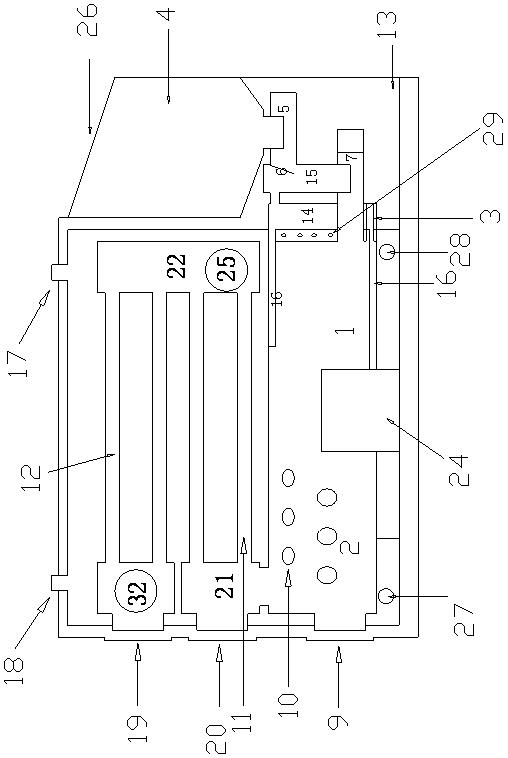

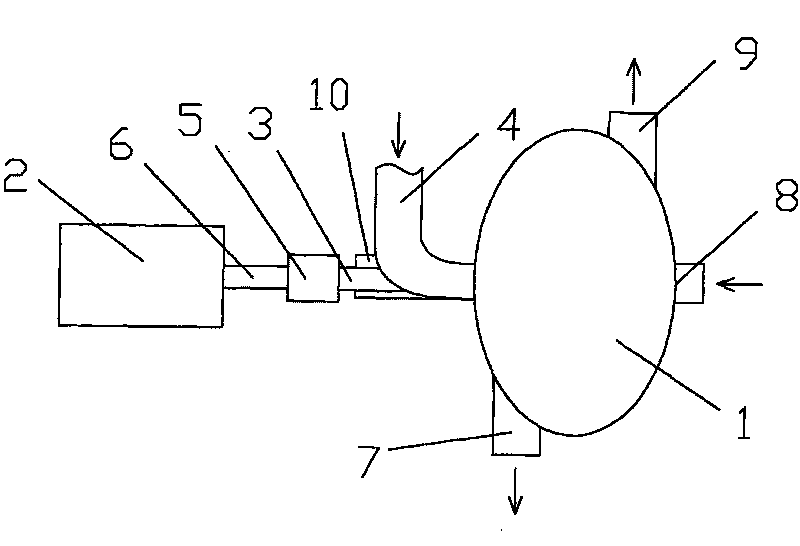

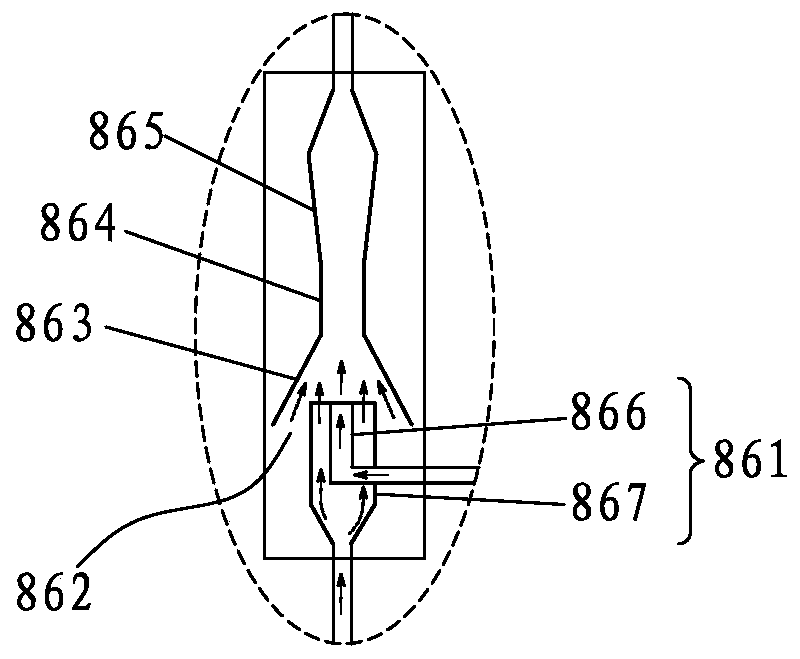

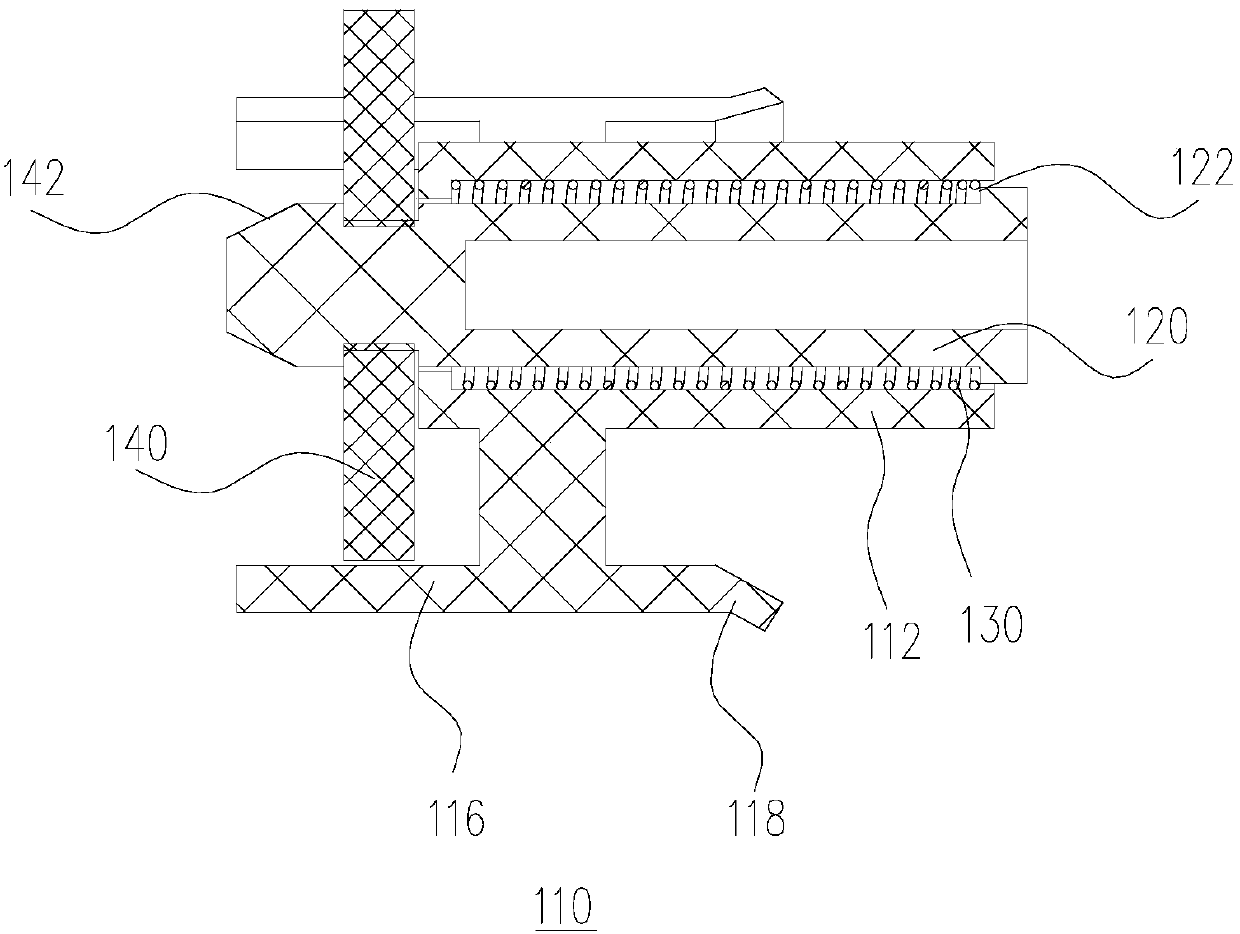

Fully premixed combustion gas heating water heater

InactiveCN103615798ABurn completelyBest burning stateWater heatersGaseous fuel burnerCombustion chamberEngineering

A fully premixed combustion gas heating water heater comprises a heat exchanger, a combustor, a fan, a gas regulating valve, a gas pipe and an air pipe. A closed combustion chamber is formed in an inner cavity of the heat exchanger, the combustor is arranged in the closed combustion chamber, an air outlet of the fan is communicated with an air inlet of the combustor, the gas pipe and the air pipe are communicated with an air inlet of the fan, the gas regulating valve is connected to the gas pipe in series, and the gas regulating valve and the fan are electrically connected with a control circuit module. The fully premixed combustion gas heating water heater further comprises an ionic current feedback pin and a flame ionic current detecting unit. The ionic current feedback pin is installed inside the closed combustion chamber, and the flame ionic current detecting unit is electrically connected with the ionic current feedback pin and the control circuit module. When gas component changes, the fully premixed combustion gas heating water heater enables the proportion of gas and air to be adjusted to a new air-fuel ratio, and therefore the purpose of enabling gas to be combusted fully is achieved.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

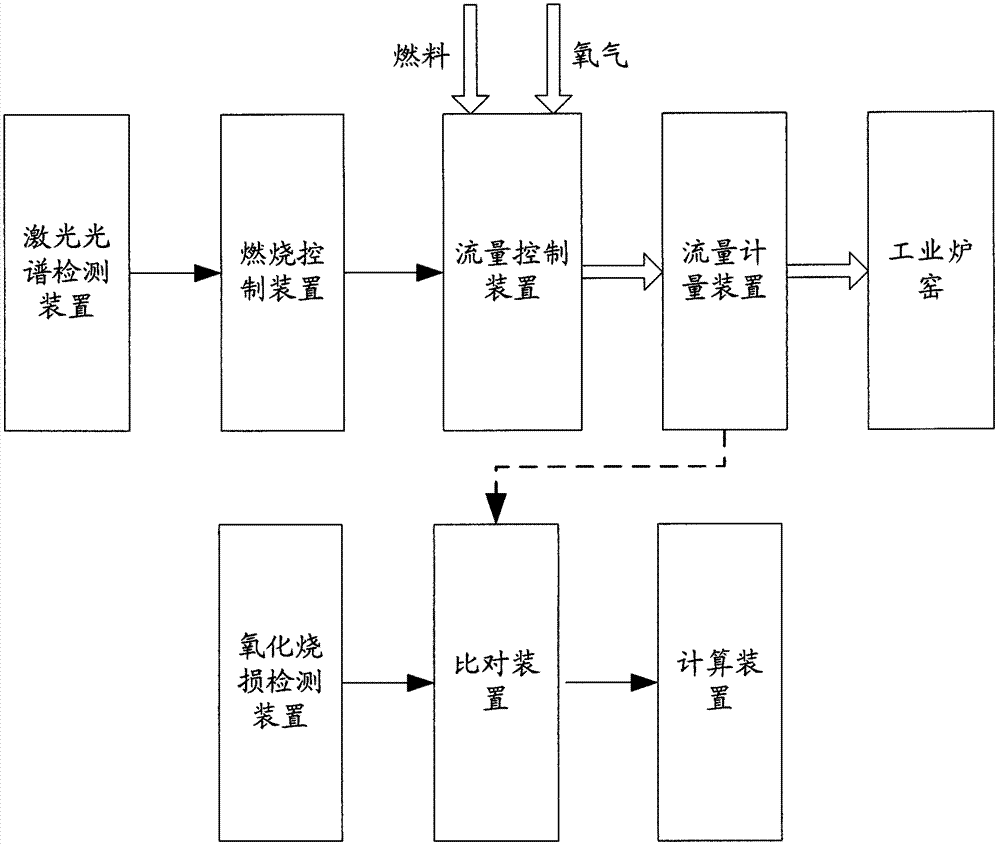

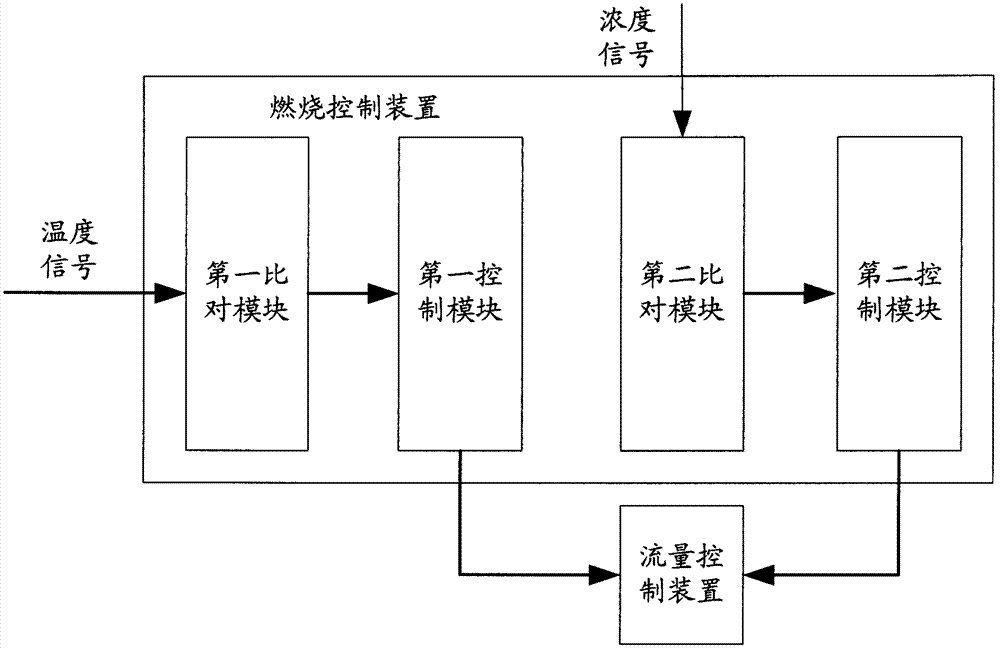

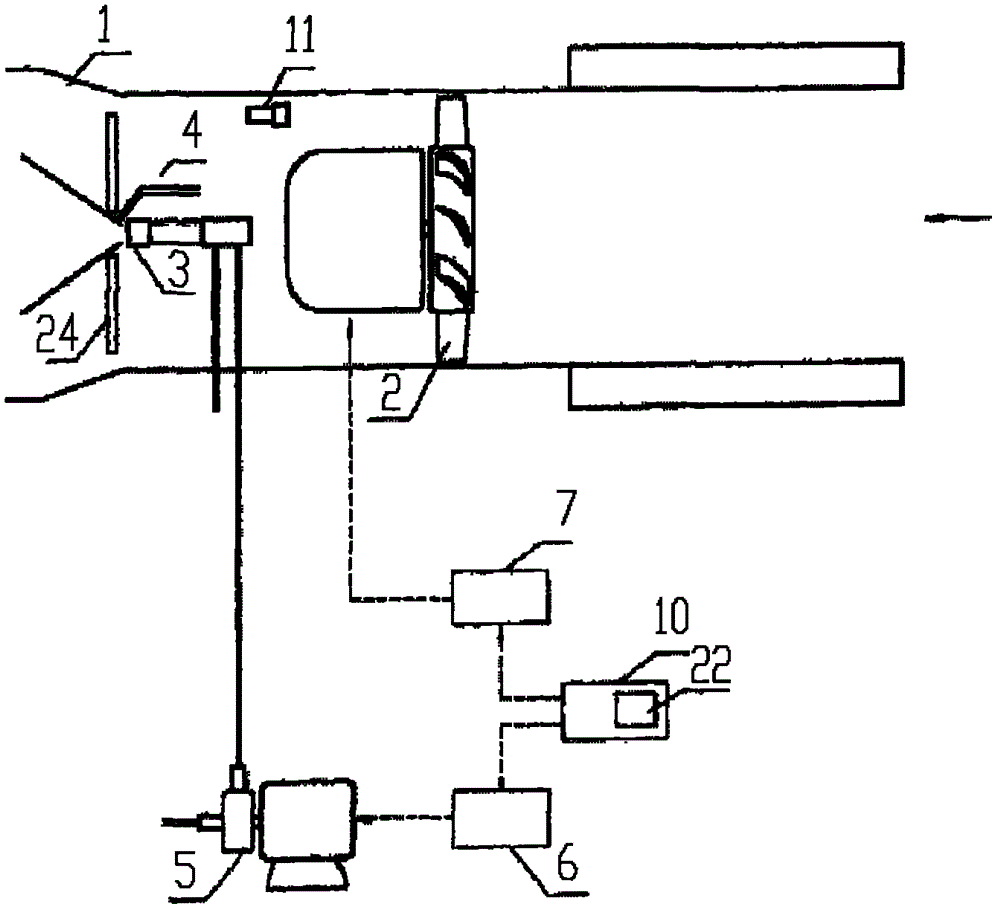

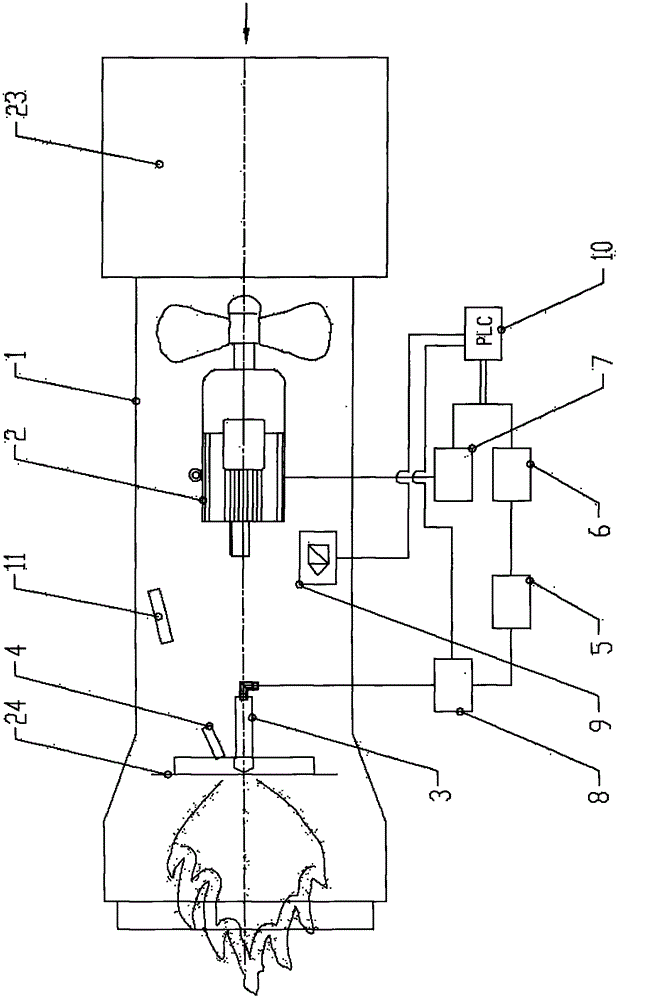

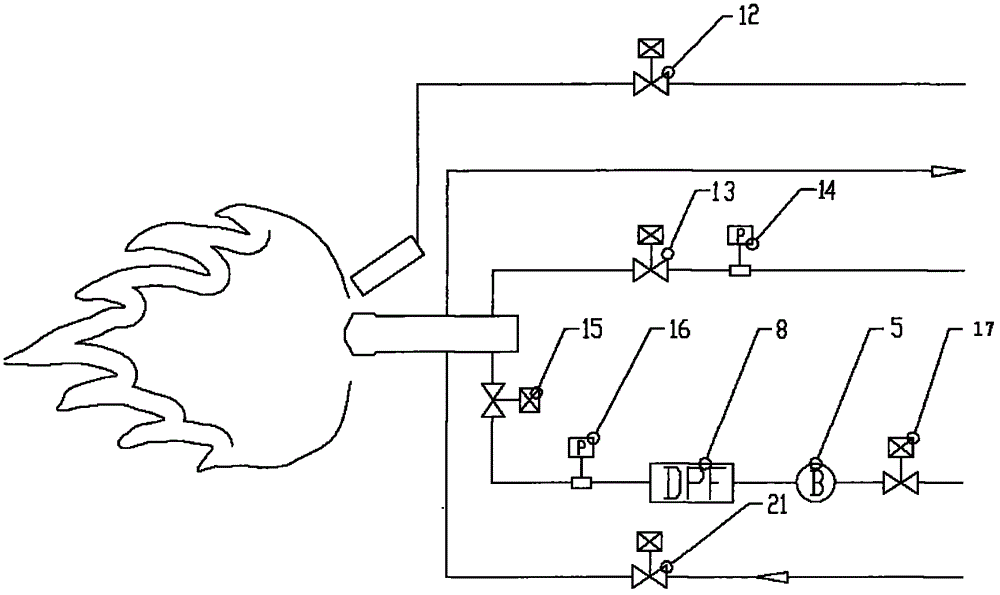

Combustion control system and method of industrial furnace

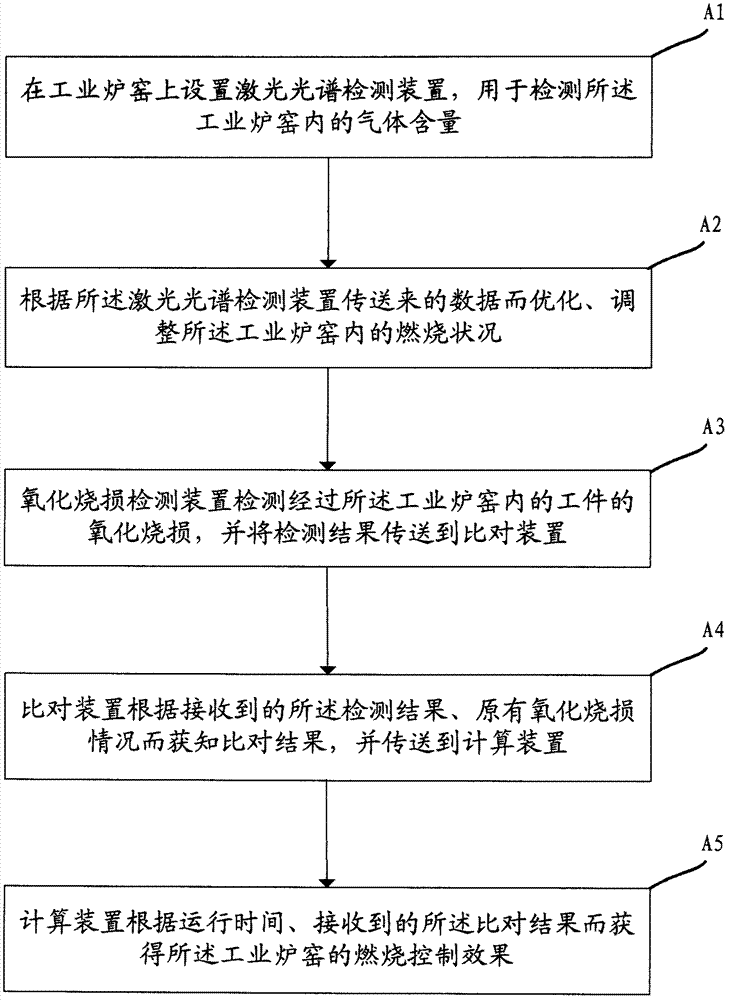

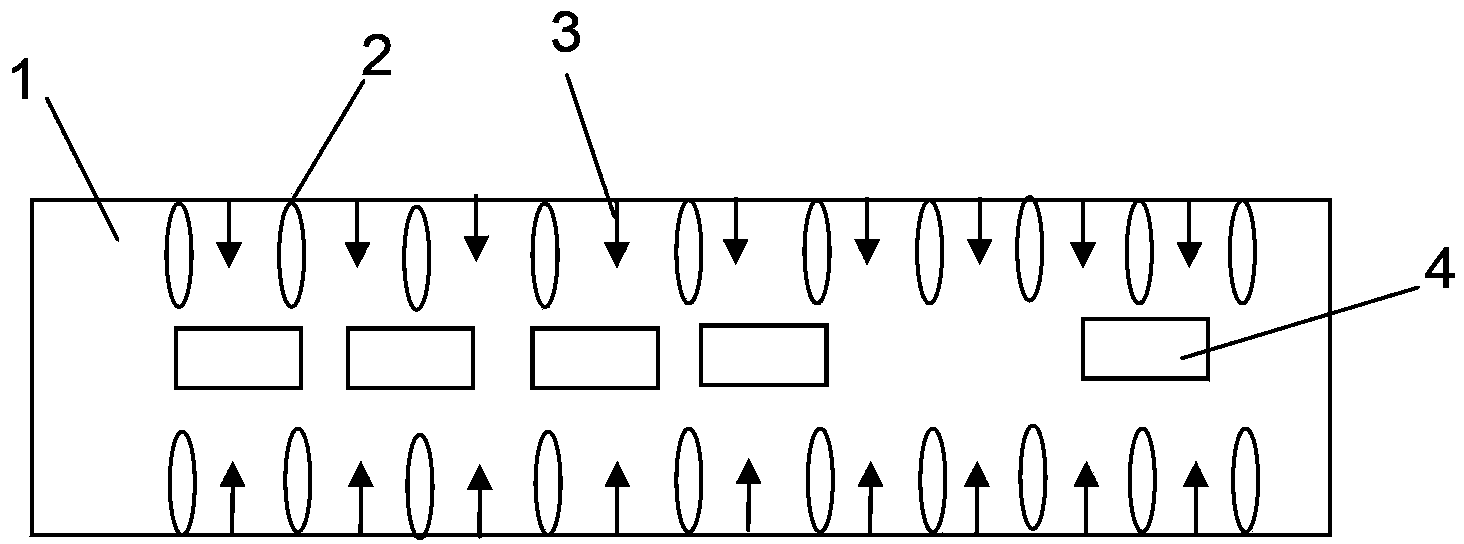

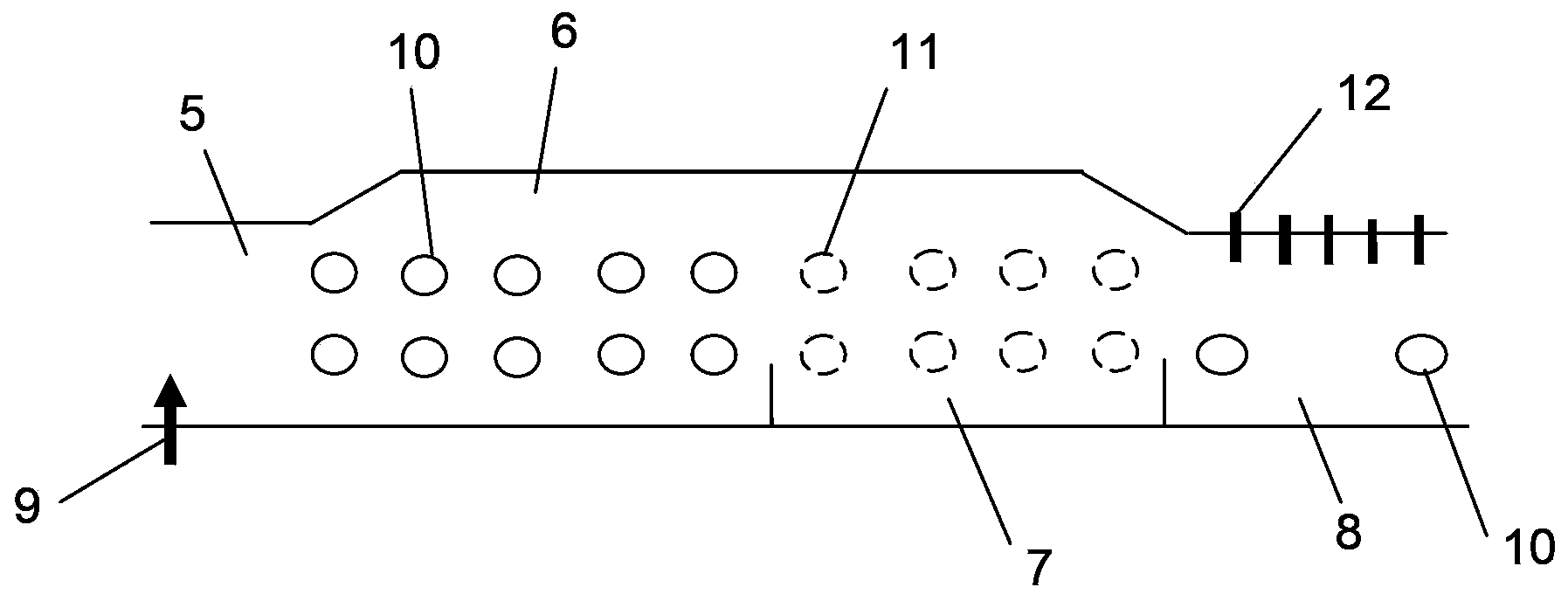

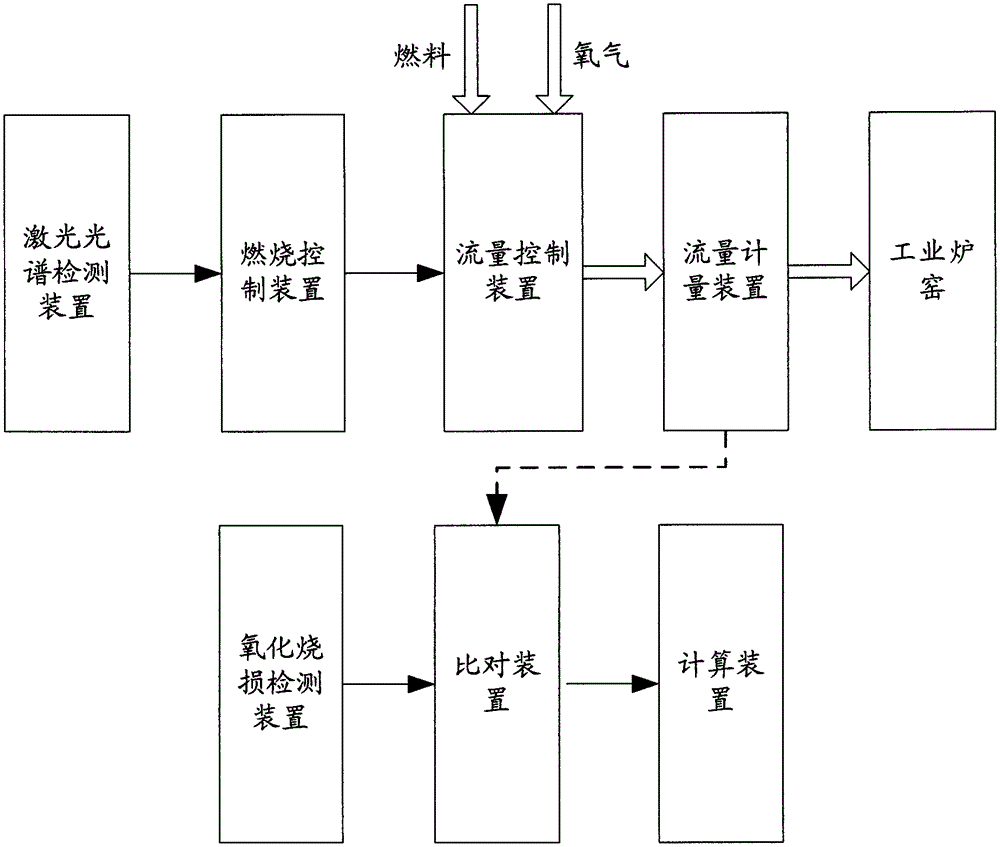

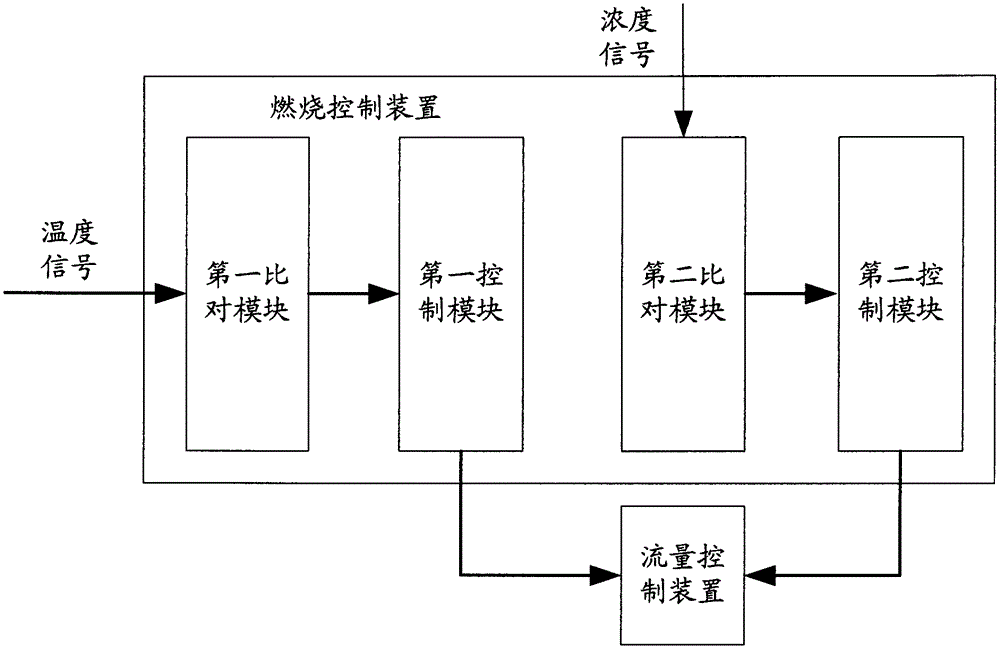

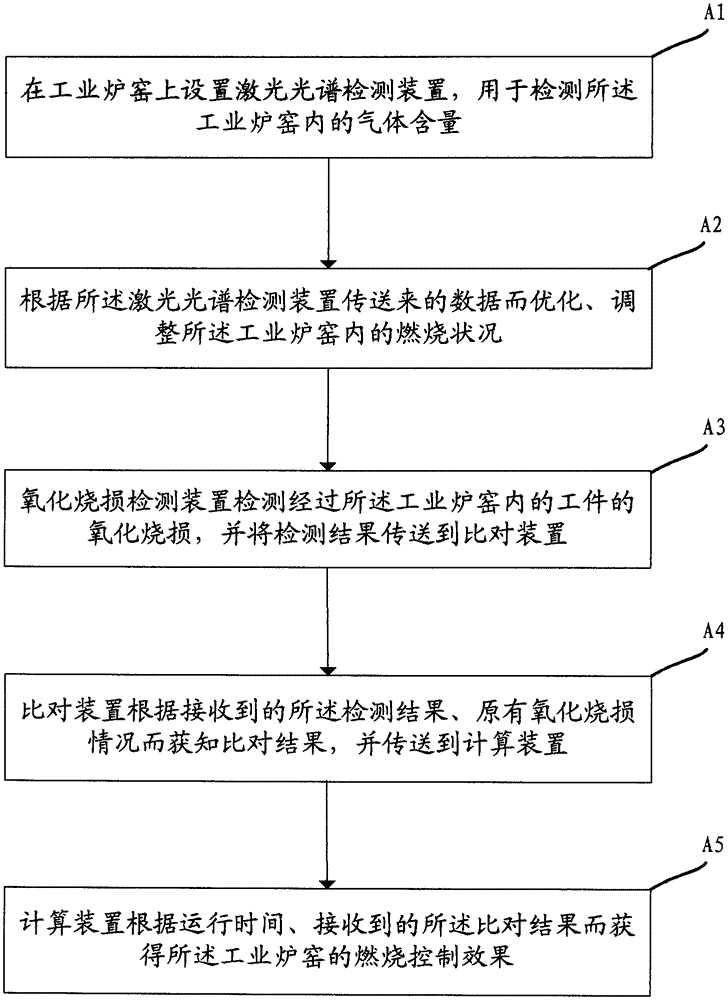

ActiveCN103672948AGood energy saving effectSave fuelFuel supply regulationProduct gasIndustrial furnace

The invention provides a combustion control system and method of an industrial furnace. The combustion control system of the industrial furnace comprises a laser spectrum detection device, a combustion control device, an oxidation burning loss detection device, a comparison device and a computing device, wherein the laser spectrum detection device is used for detecting the content of gas in the industrial furnace, the laser spectrum detection device comprises a laser, a detector and an analysis module, the combustion control device is used for optimizing and adjusting the combustion conditions in the industrial furnace according to data transmitted by the laser spectrum detection device, the oxidation burning loss detection device is used for detecting oxidation burning loss of workpieces which pass through the industrial furnace, and transmitting the detection result to the comparison device, the comparison device is used for obtaining the comparison result according to the received detection result and the original oxidation burning loss conditions, and transmitting the comparison result to the computing device, and the computing device is used for obtaining the combustion control result of the industrial furnace according to the received comparison result. The combustion control system and method of the industrial furnace have the advantages that detection accuracy is high, the detection speed is high, the cost is low, and energy is saved.

Owner:FOCUSED PHOTONICS

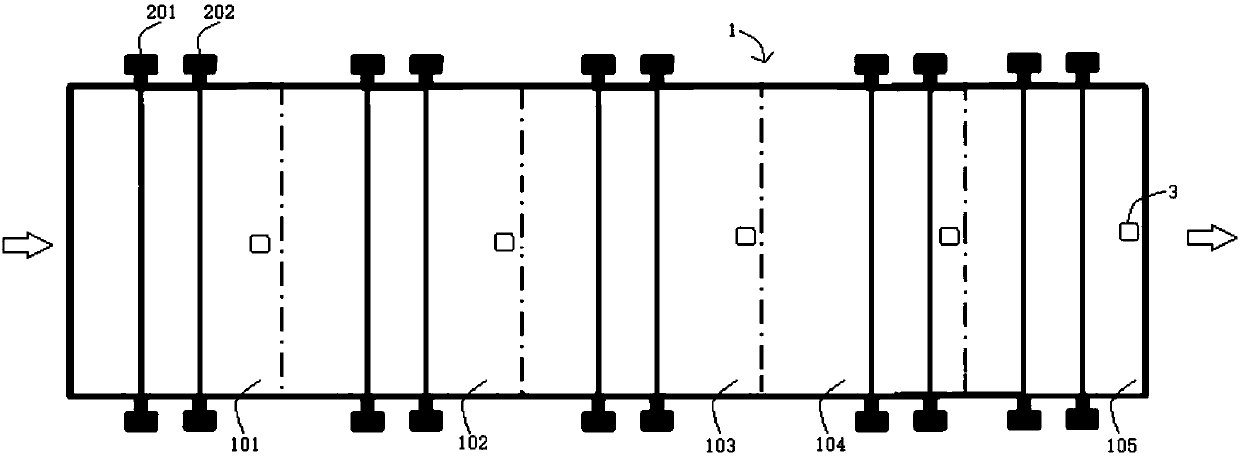

Hot rolling heating furnace and local strengthening heating control method thereof

ActiveCN103388071ABest burning stateTo achieve the purpose of local strengthening heatingFurnace typesMetal rolling arrangementsCombustionProcess engineering

The invention discloses a hot rolling heating furnace; and the hot rolling heating furnace is designed by comprising a furnace tail section, a preheating section, a heating section and a heat average section. The invention also discloses a local strengthening heating control method of the hot rolling heating furnace; an impulse burner is arranged at the preheating section, a constant combustion mode is adopted, the input amount of the impulse burner can be controlled according to the heat demand of the preheating section to make the burner to maintain an optimal combustion state, and the purpose of local strengthening heating can be achieved, so that temperature uniformity of the furnace width direction can be improved, the heating quality can be ensured and the energy saving purpose can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

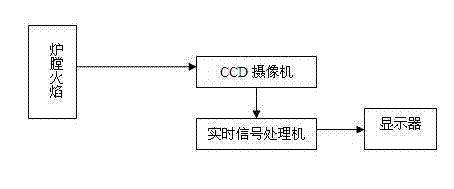

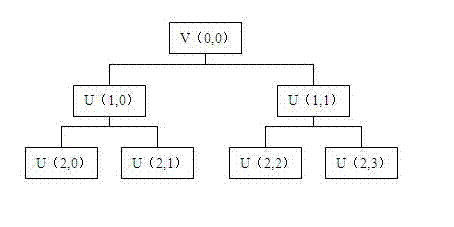

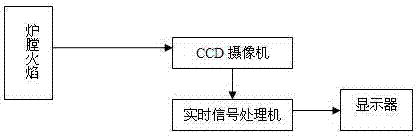

Furnace hearth flame detecting method based on intelligent-control computer vision technology

ActiveCN102506444ABest burning stateGuaranteed uptimeChamber safety arrangementVisual technologyInformation analysis

The invention discloses a furnace hearth flame detecting method based on an intelligent-control computer vision technology. The furnace hearth flame detecting method comprises the following steps of: using a CCD (Charge Coupled Device) camera to take a picture for furnace hearth flame by an optical fibre image sensor, and transmitting the taken image information signal to a real-time signal processor; using a wavelet packet arithmetic to perform de-noising processing to the signal of the image information in the real-time signal processor; and using a BP (Back Propagation) neural network module to detect and distinguish the de-noised image information. The computer vision technology based on the wavelet packet and the BP neural network is applied to the image information analysis and treatment of the power plant furnace hearth flame, so that the intelligent treatment of the power plant furnace hearth flame information can be achieved, and the signal noises in background flame can be effectively removed to acquire a more real and accurate signal; the combustion condition of each combustor can be relatively grasped in a quantitative manner to keep the best combustion condition of a boiler, so that the safe and high-efficient operation of the device is achieved.

Owner:GUODIAN NANJING AUTOMATION

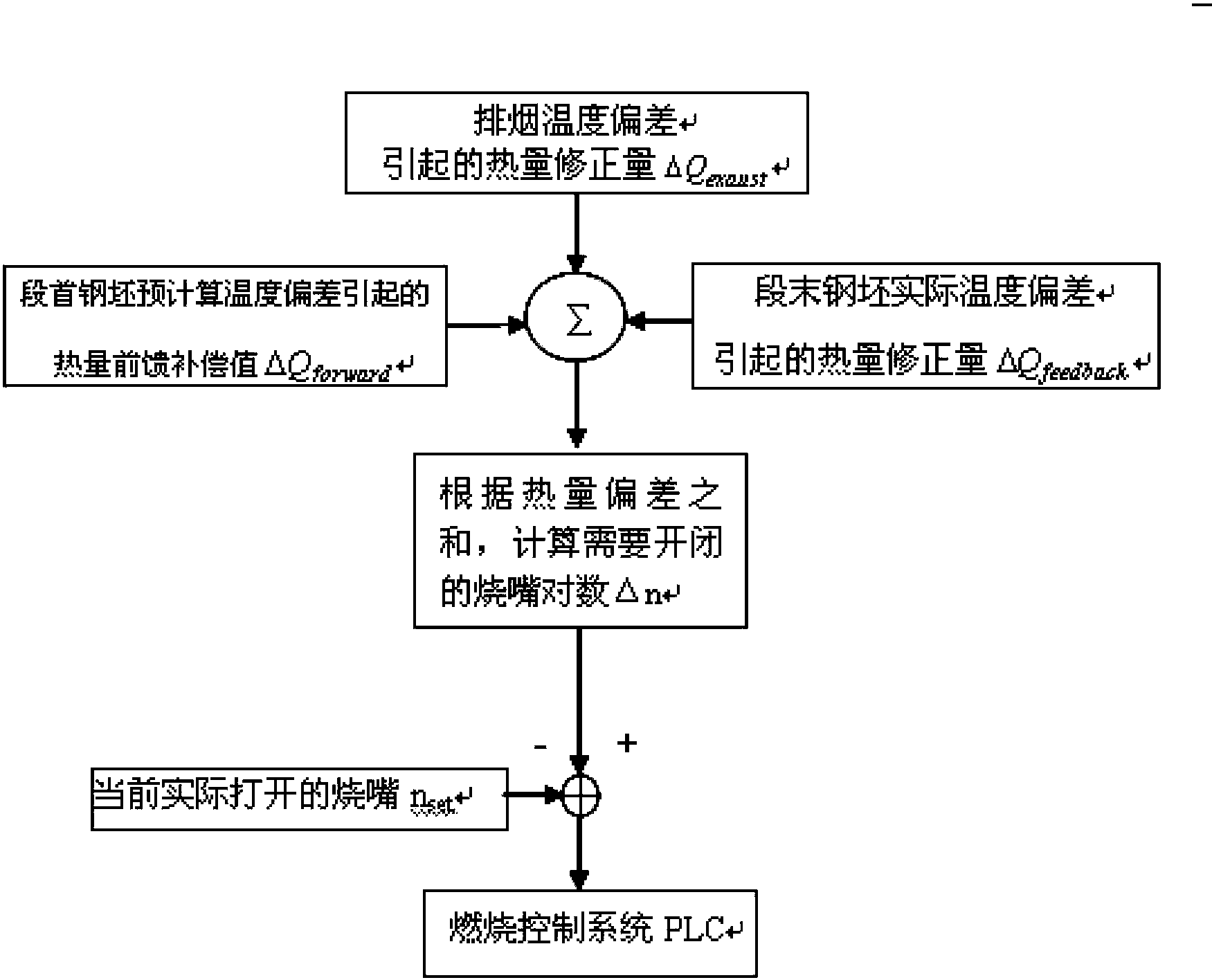

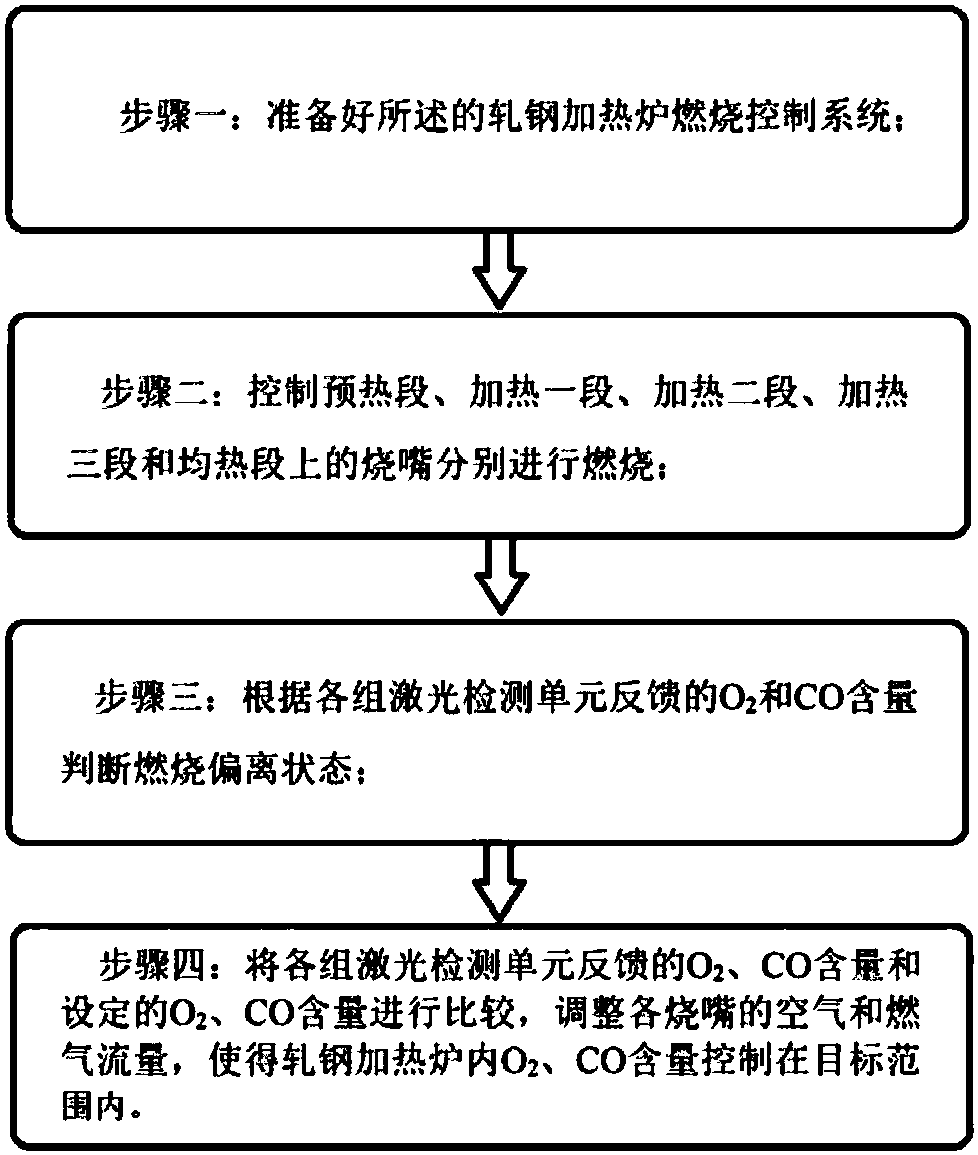

Control system and control method for combustion of steel rolling heating furnace

PendingCN107764076AAir excess factor optimizationBest burning stateControl devices for furnacesControl systemFlue gas

The invention discloses a control system and a control method for combustion of a steel rolling heating furnace and belongs to the field of heating furnace combustion control. The control system comprises the steel rolling heating furnace, a laser detection mechanism and a temperature detector, wherein the laser detecting mechanism is used for detecting components of smoke in the steel rolling heating furnace, and the temperature detector is used for directly measuring the surface temperature of a steel billet. The control method comprises the following steps that firstly, the control system is prepared; secondly, nozzles of all sections are controlled to carry out combustion; thirdly, the content of O2 and the content of CO are fed back; and fourthly, according to feedback, the air and gas flow of all the nozzles is adjusted to control the content of O2 and the content of CO in the steel rolling heating furnace within a target range. The control system and the control method for combustion of the steel rolling heating furnace are provided to overcome the defect that in existing steel rolling working procedures, the oxidation burning loss amount is relatively high, and the oxidation burning loss amount of the steel billet in the steel rolling heating furnace is effectively reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

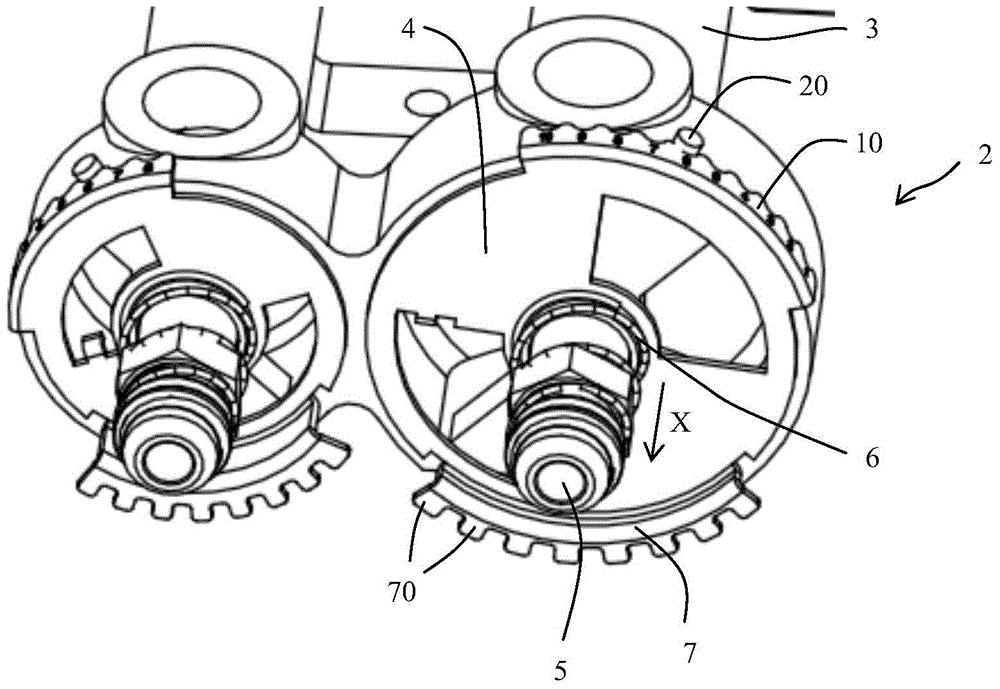

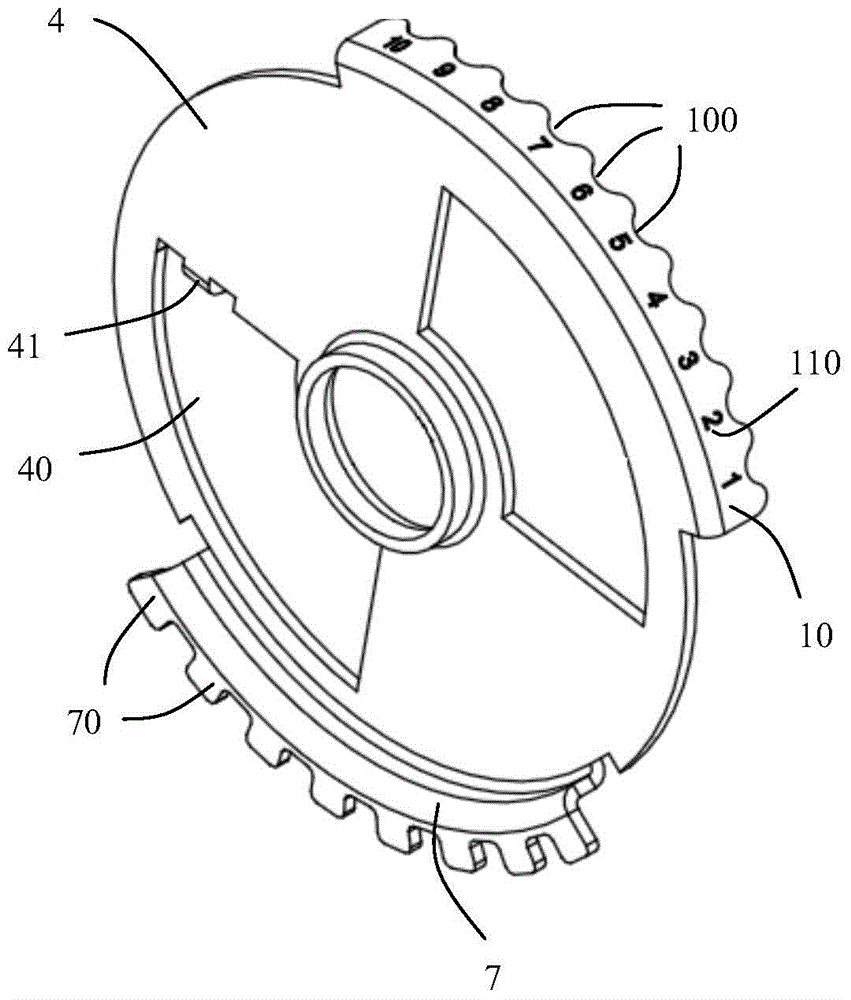

Air valve adjustment device of gas cooker, and gas cooker

ActiveCN104456639APrevent rotationBest burning stateDomestic stoves or rangesLighting and heating apparatusEngineeringFuel gas

The invention relates to an air valve adjustment device of a gas cooker, and the gas cooker. The air valve adjustment device comprises an ejection pipe, an air valve sheet, a gas nozzle, an elastic element and a driving part, and further comprises a first positioning part and a second positioning part, wherein the first positioning part is arranged one of the air valve sheet and the ejection pipe and comprises at least two limiting grooves; the second positioning part is arranged at the other one, of the air valve sheet and the ejection pipe, on that the first positioning part is not positioned; the second positioning part is suitably positioned in the limiting groove; and when the driving part drives the air valve sheet to move around the gas nozzle, the second positioning part can move out from one limiting groove to move into the adjacent limiting groove. The air valve adjustment device disclosed by the invention not only is convenient to adjust but also can prevent the incidental rotation of the air valve sheet, so that the stability of the gas cooker during use is improved.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

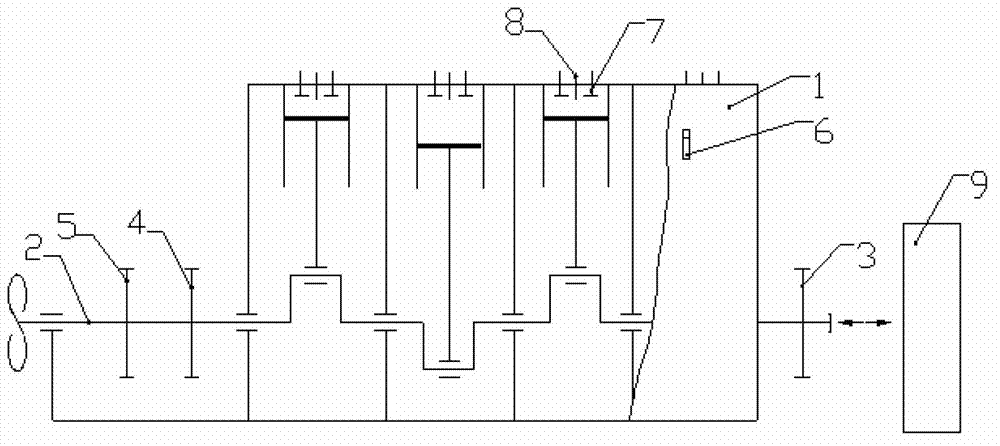

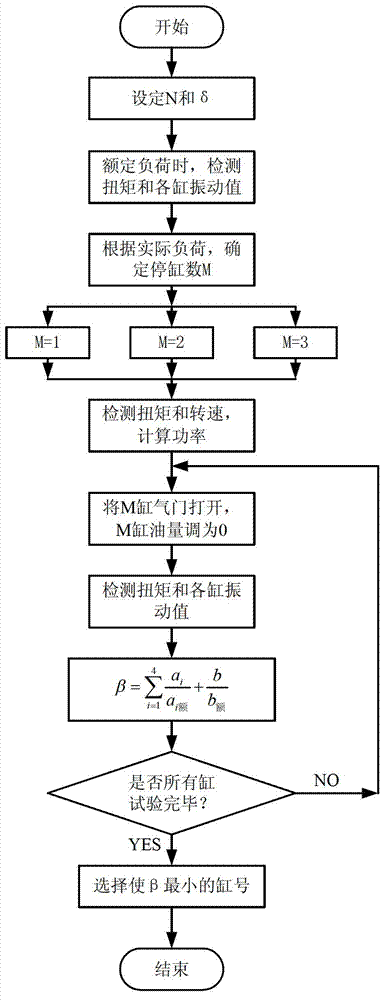

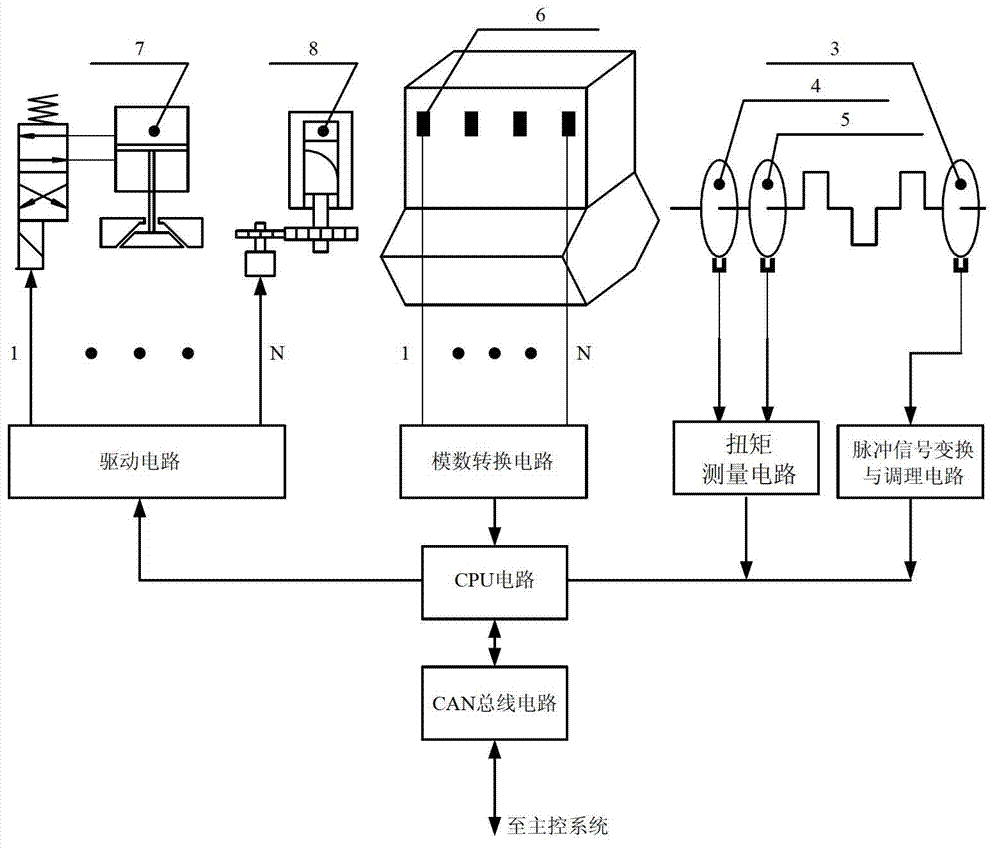

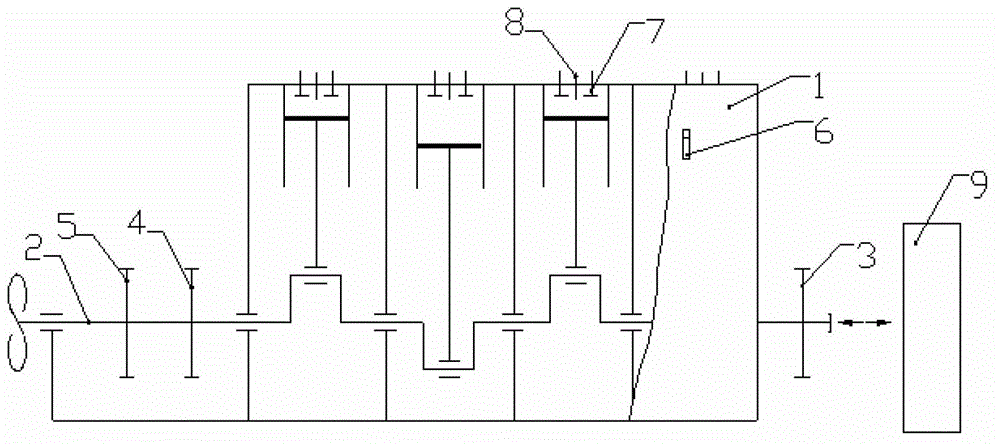

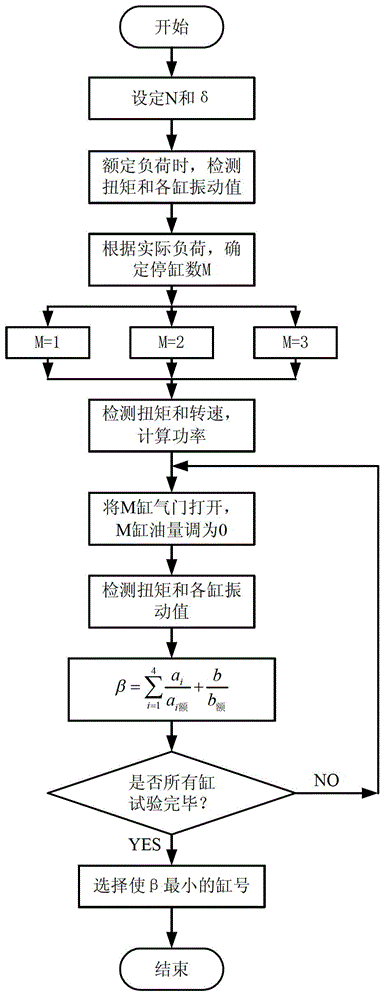

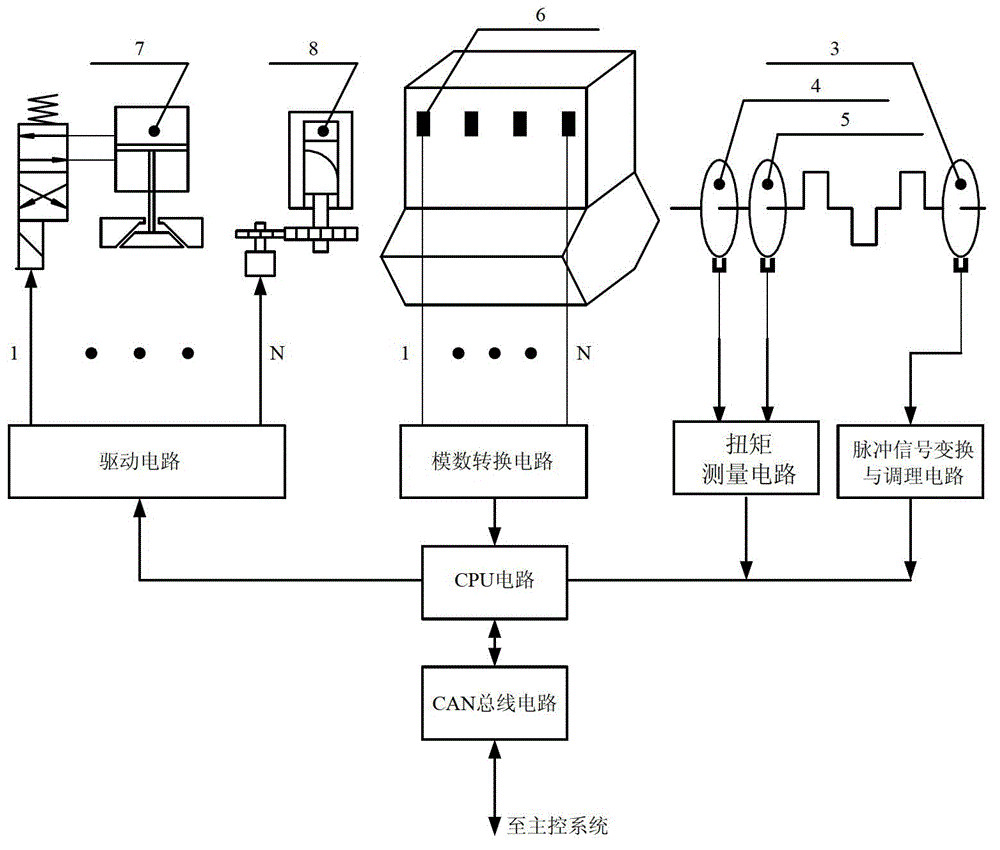

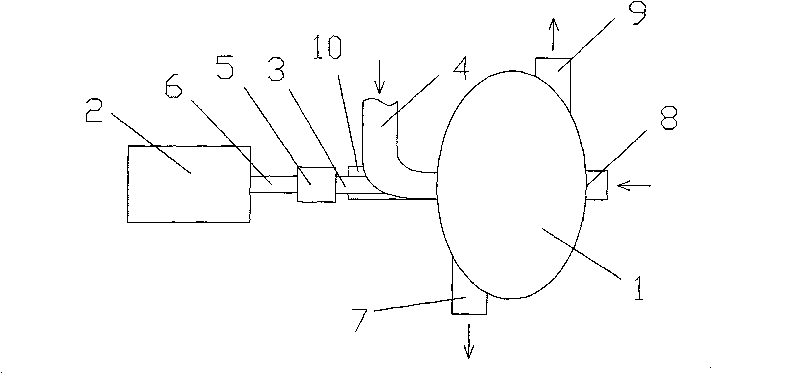

Load control method for reducing cylinders of diesel engine

ActiveCN102817722AImprove operating economyCost-effectiveElectrical controlOutput powerLow loadDiesel engine

The invention relates to a load control method for reducing cylinders of a diesel engine, which comprises the following steps of: arranging a speed-measuring photoelectric encoder at a free end of the diesel engine, arranging a pair of torsion vibration photoelectric encoders at a load end of the diesel engine, arranging a two-way acceleration transducer nearby an air cylinder blasting pressure generating point of a diesel engine body, stopping the cylinders one by one, recoding torsion vibration data and vibration data, and ensuring a cylinder stopping number under some load according to the principle that the sum between the torsion vibration specific value and the vibration specific value is the minimum, and taking the cylinder stopping number as the basis of cylinders reducing control load when the diesel engine runs. The load control method controls the power output of the diesel engine by a cylinder reducing method, the work cylinder can be kept at the optimum burning status, and the oil consumption of the whole diesel engine is near to the minimum oil consumption, so that the running economical efficiency under the medium and low load can be improved.

Owner:海宁鼎丞智能设备有限公司

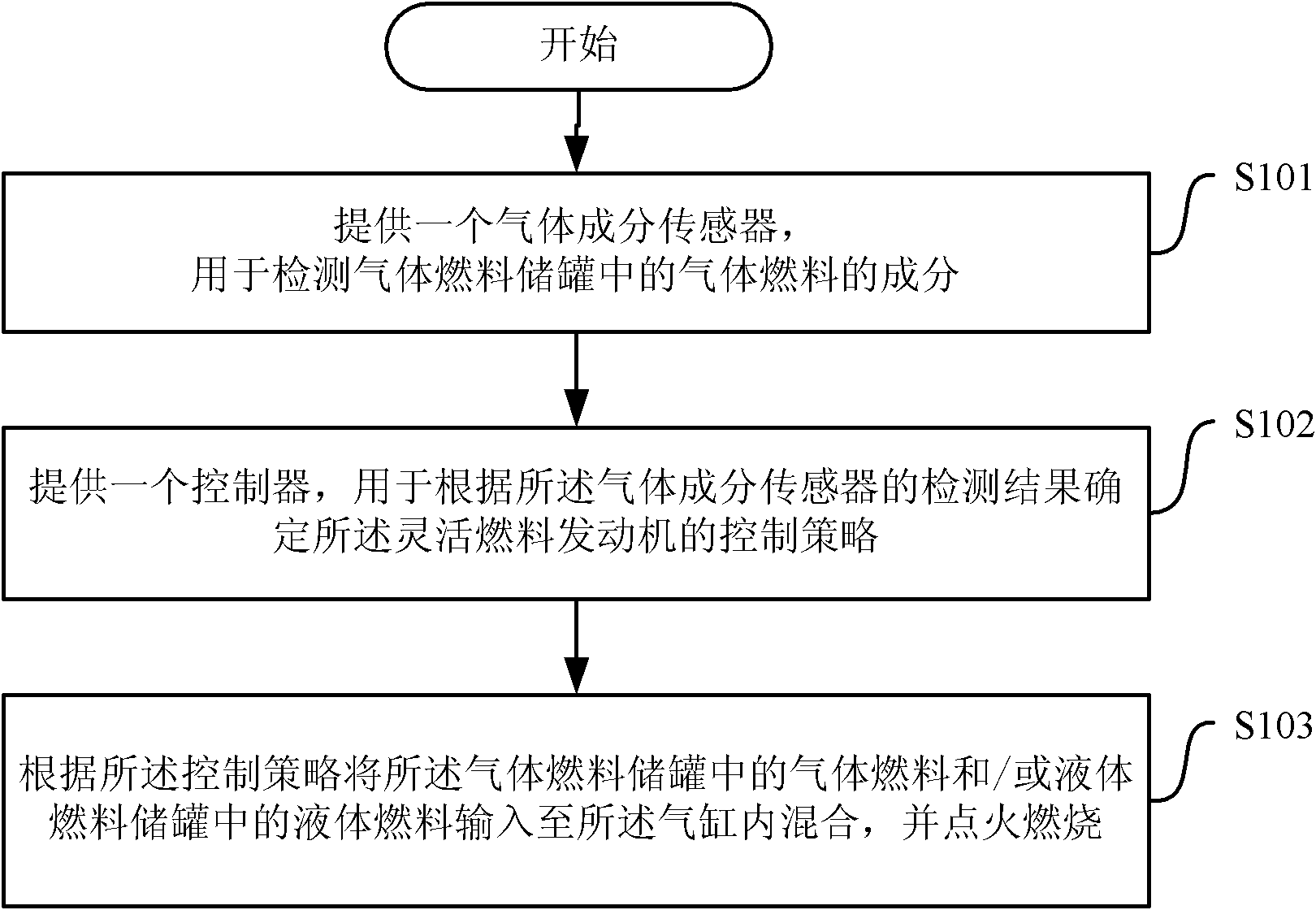

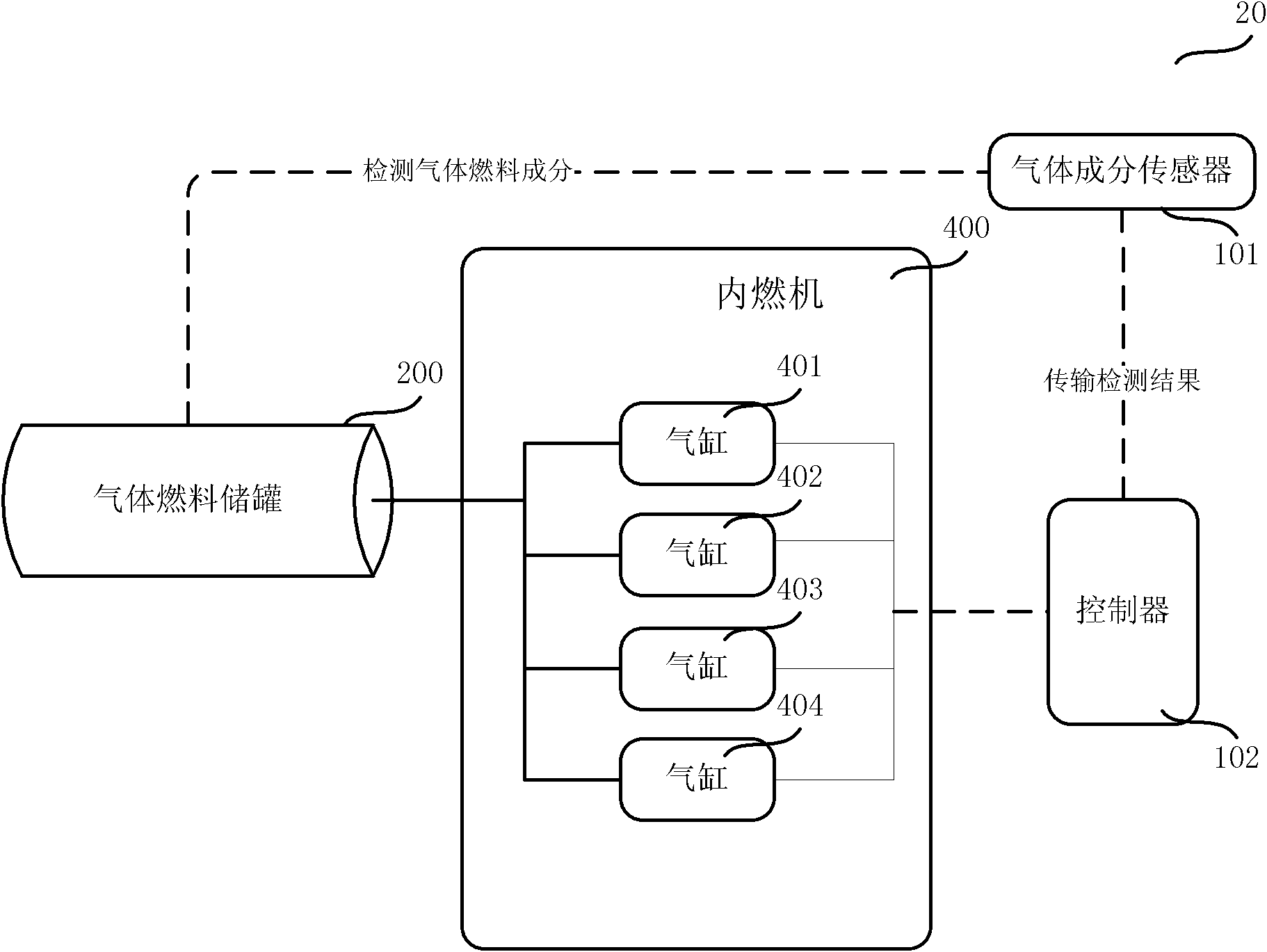

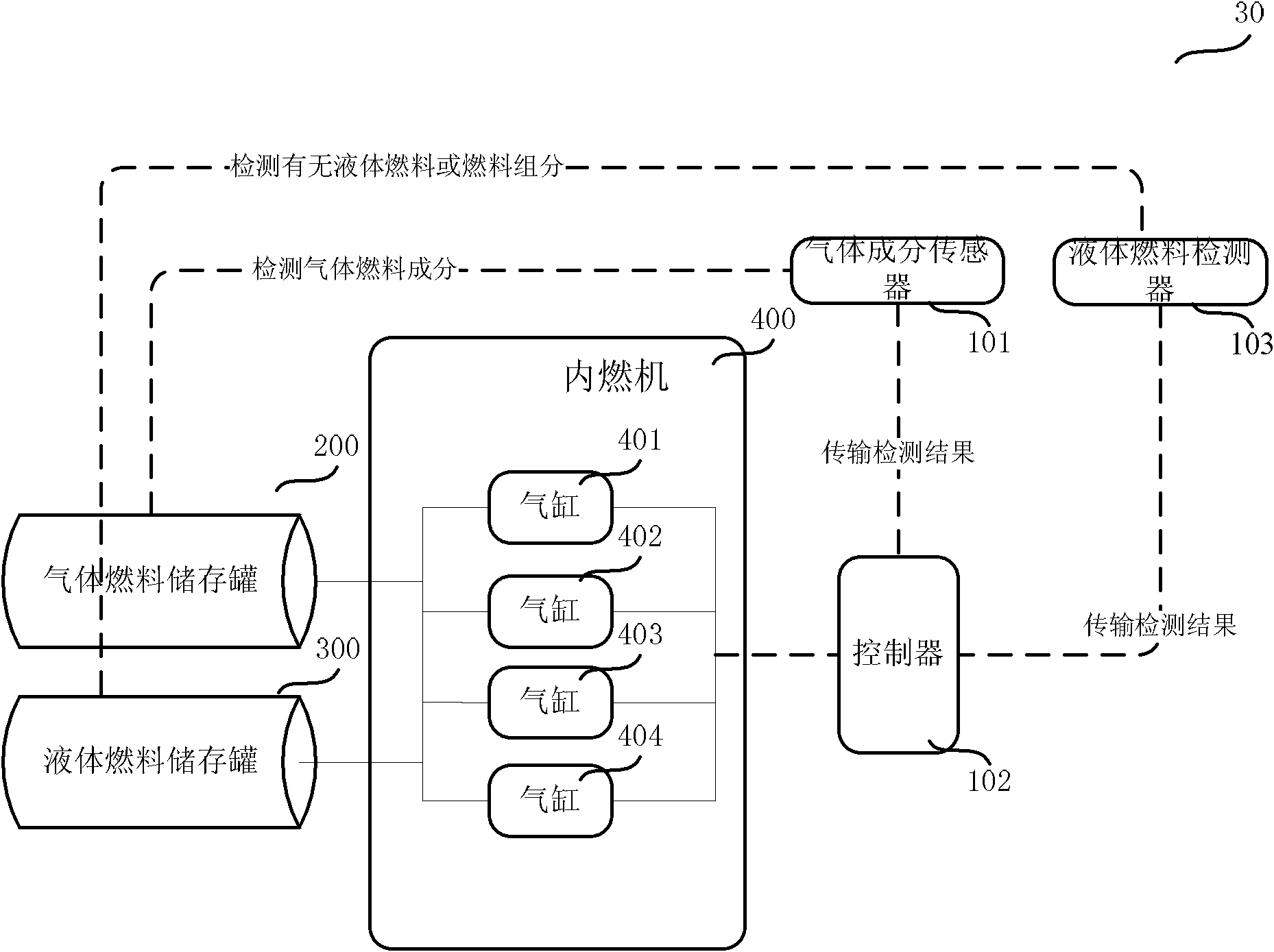

Flexible fuel engine and control method thereof

InactiveCN102418616AFlexible operationImprove efficiencyElectrical controlMachines/enginesLiquid fuelIgnition timing

The invention provides a control method of a flexible fuel engine. The control method comprises the following steps: detecting the components of a gas fuel in a gas fuel storage tank; determining the control strategy of the flexible fuel engine according to the detection result, wherein the control strategy is selected from any one or a combination of a gas fuel and / or liquid fuel proportioning strategy, a gas fuel gas spray timing strategy, a gas fuel gas spray quantity strategy, a liquid fuel oil spray quantity strategy and an ignition timing strategy; and transmitting the gas fuel in the gas fuel storage tank and a liquid fuel in a liquid fuel storage tank into an air cylinder of the flexible fuel engine according to the control strategy, mixing the gas fuel with the liquid fuel and carrying out ignition burning. Correspondingly, the invention also provides a flexible fuel engine system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

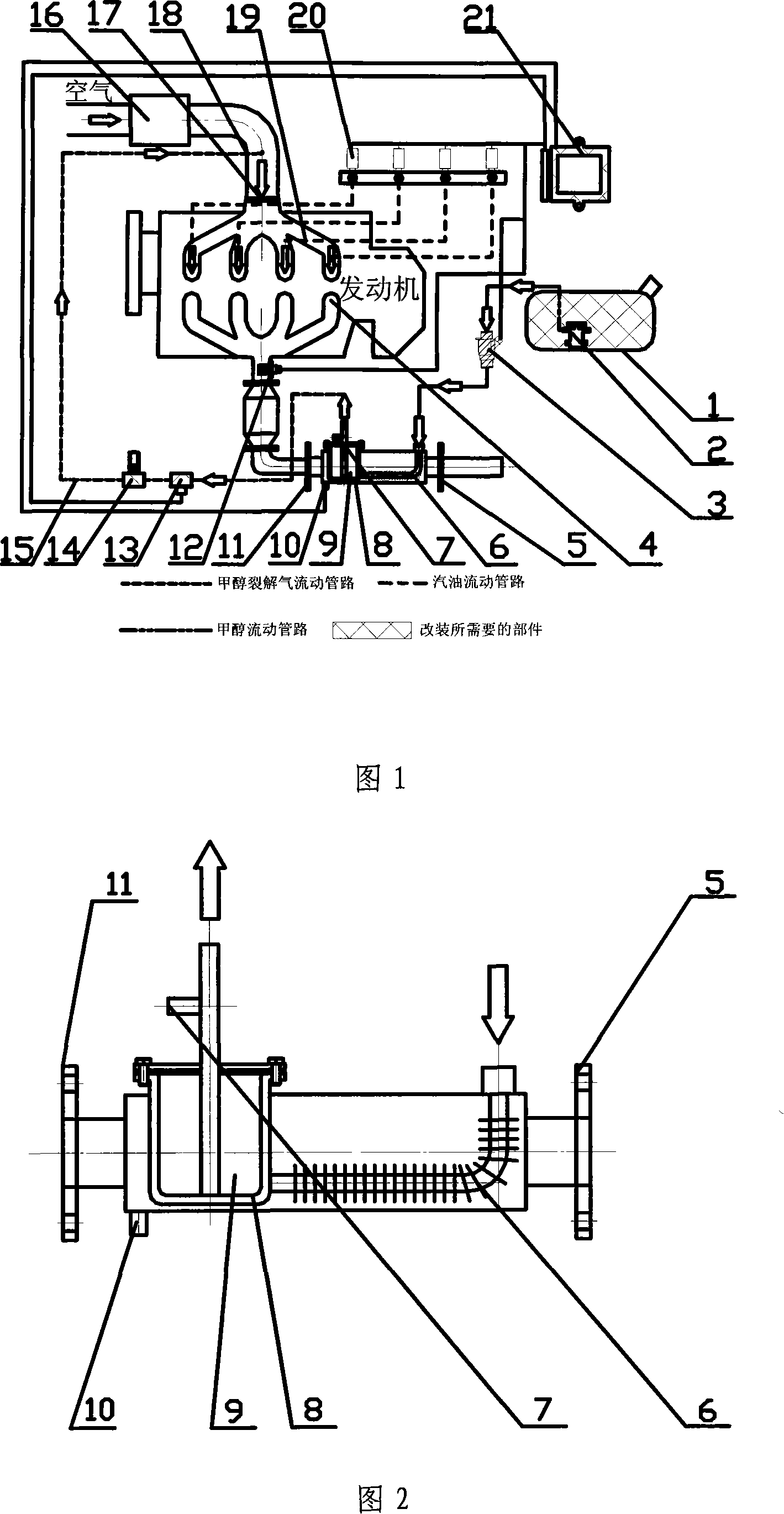

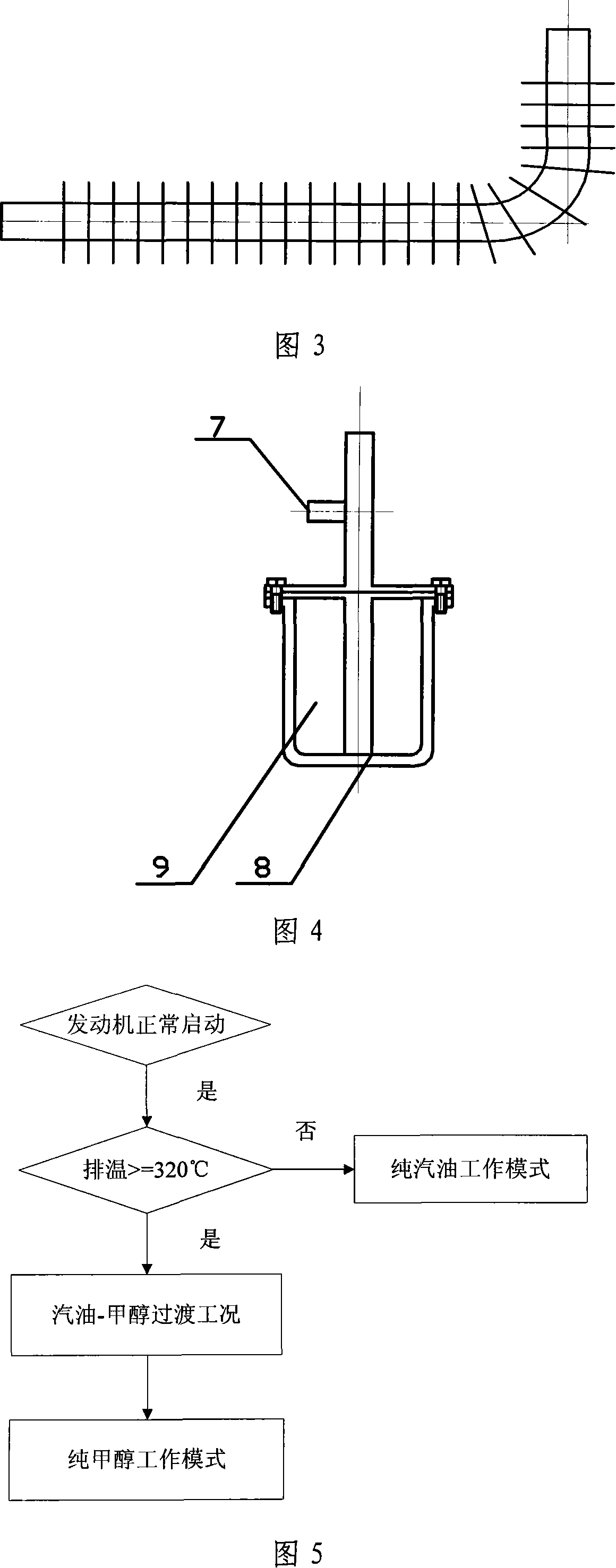

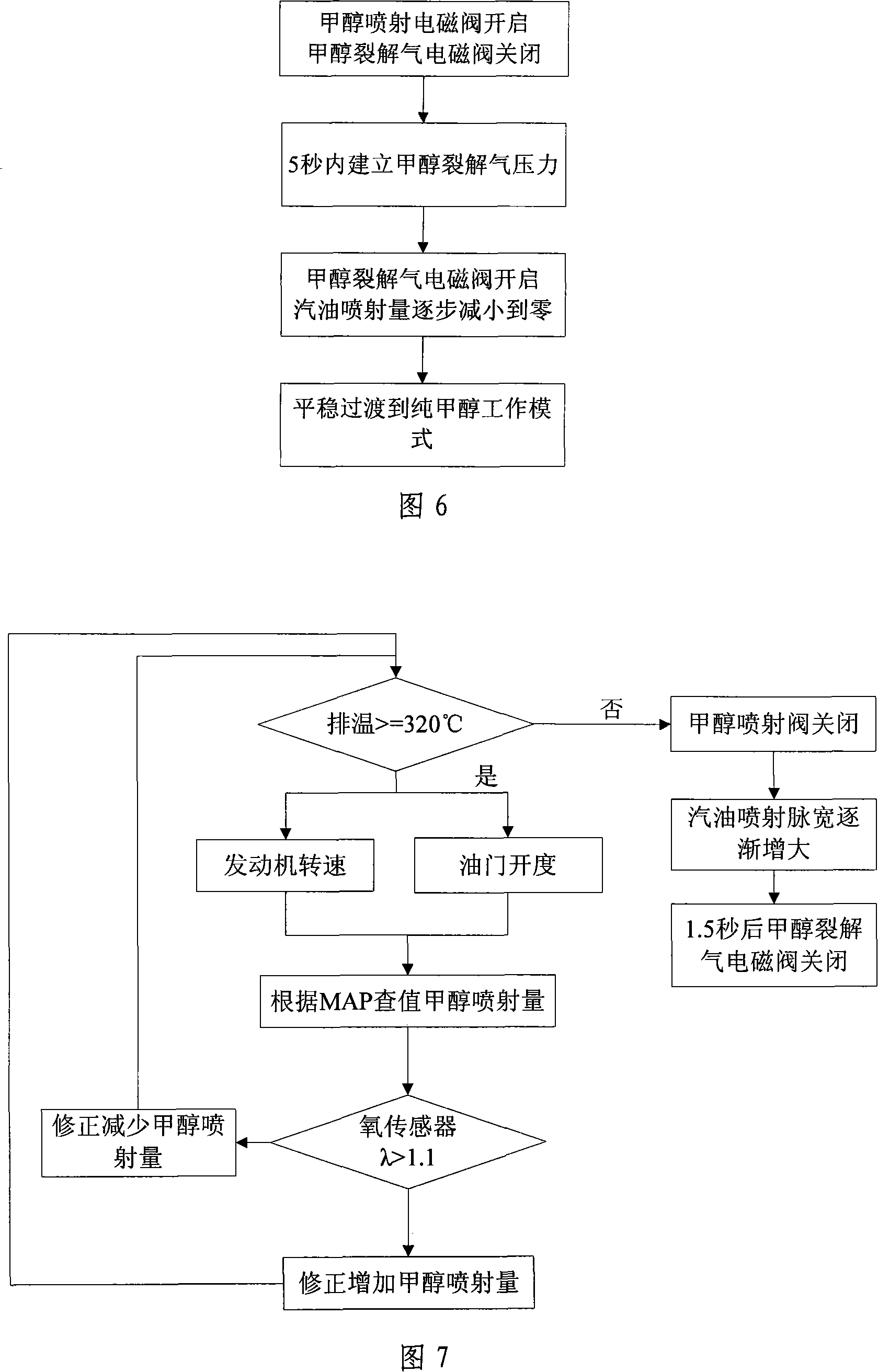

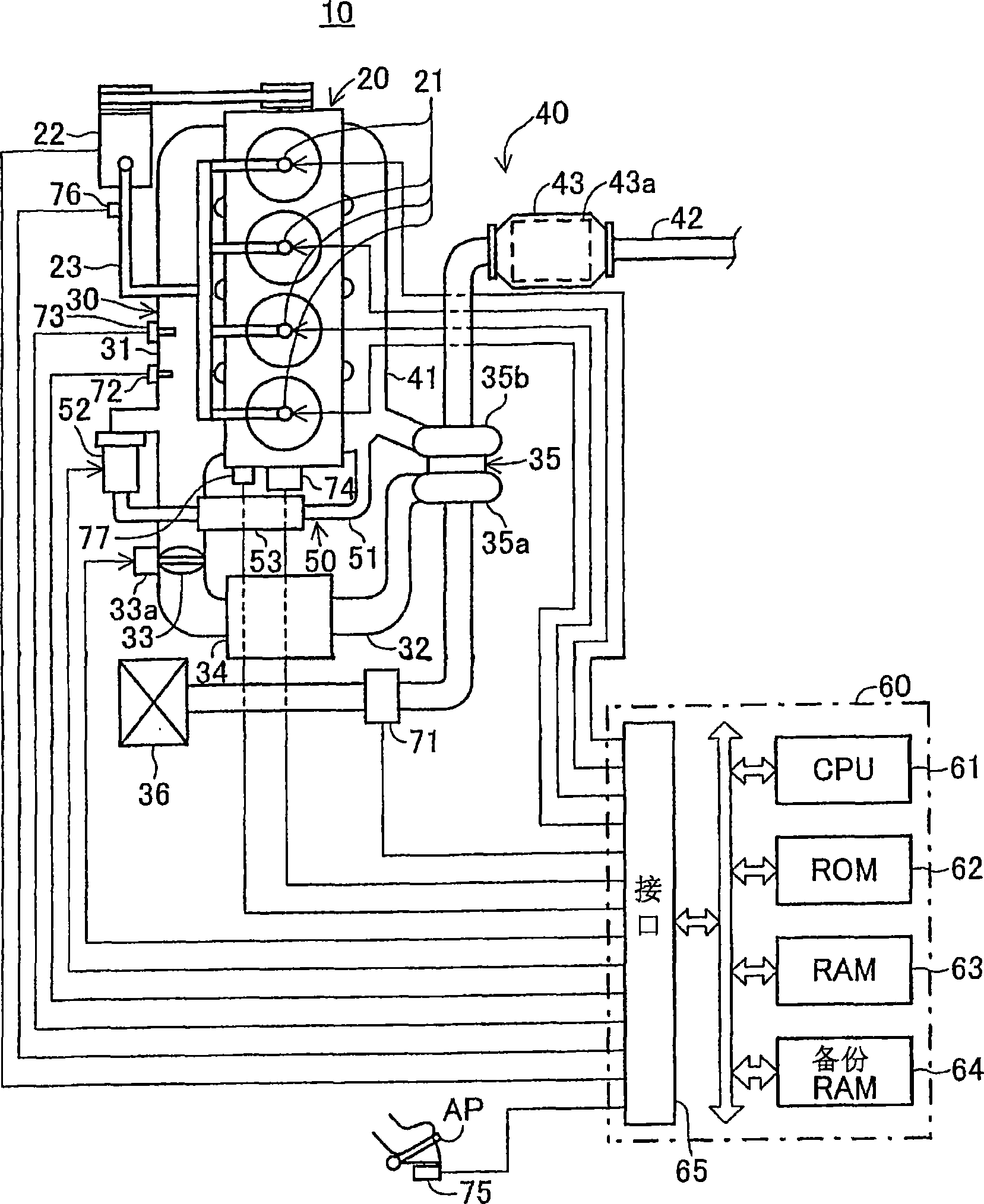

Ignition type engine directly burning methanol cracking product and control method thereof

InactiveCN101135273AHigh thermal efficiencyEliminate emissionsInternal combustion piston enginesEngine controllersSolenoid valveFuel tank

The present invention relates to one kind of ignition type engine burning methane cracking product directly and its control method. The engine includes one gasoline engine system, one methane cracking set, one methane fuel tank, one cracked gas conveying pipe with one normally closed solenoid valve, and one electrical control unit connected to the methane cracking set. The control process of the engine includes the following steps: 1. starting the engine in gasoline work mode; 2. detecting the exhaust temperature; 3. continuing the gasoline work mode when the exhaust temperature is lower than 320 deg.c; and 4. entering to the transition gasoline-methane work mode when the exhaust temperature is not lower than 320 deg.c, and further entering to the methane work mode. The present invention has the advantages of over 20 % raised heat efficiency, capacity of eliminating the aldehyde exhaust caused by burning methane fuel, etc.

Owner:TIANJIN UNIV

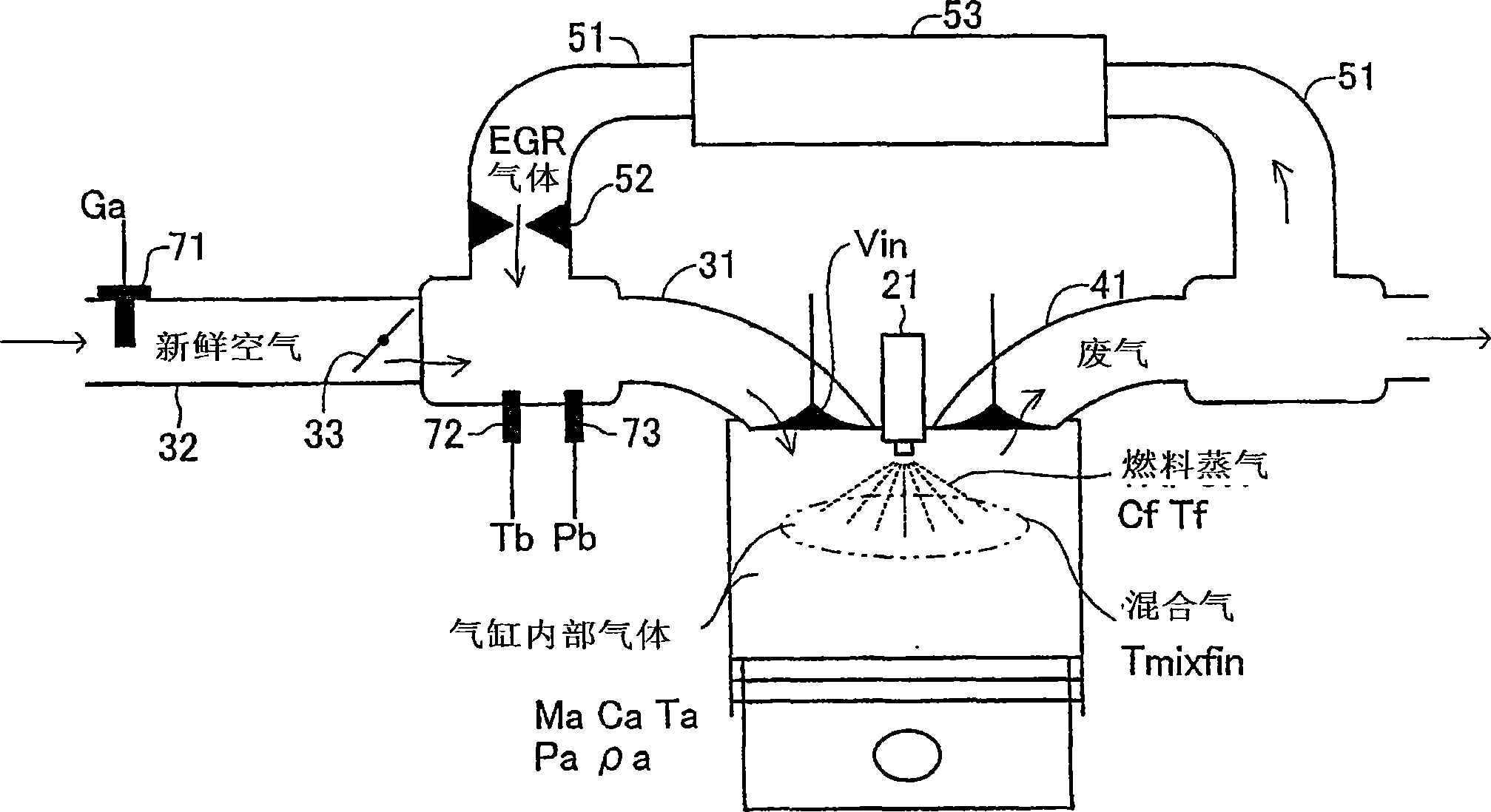

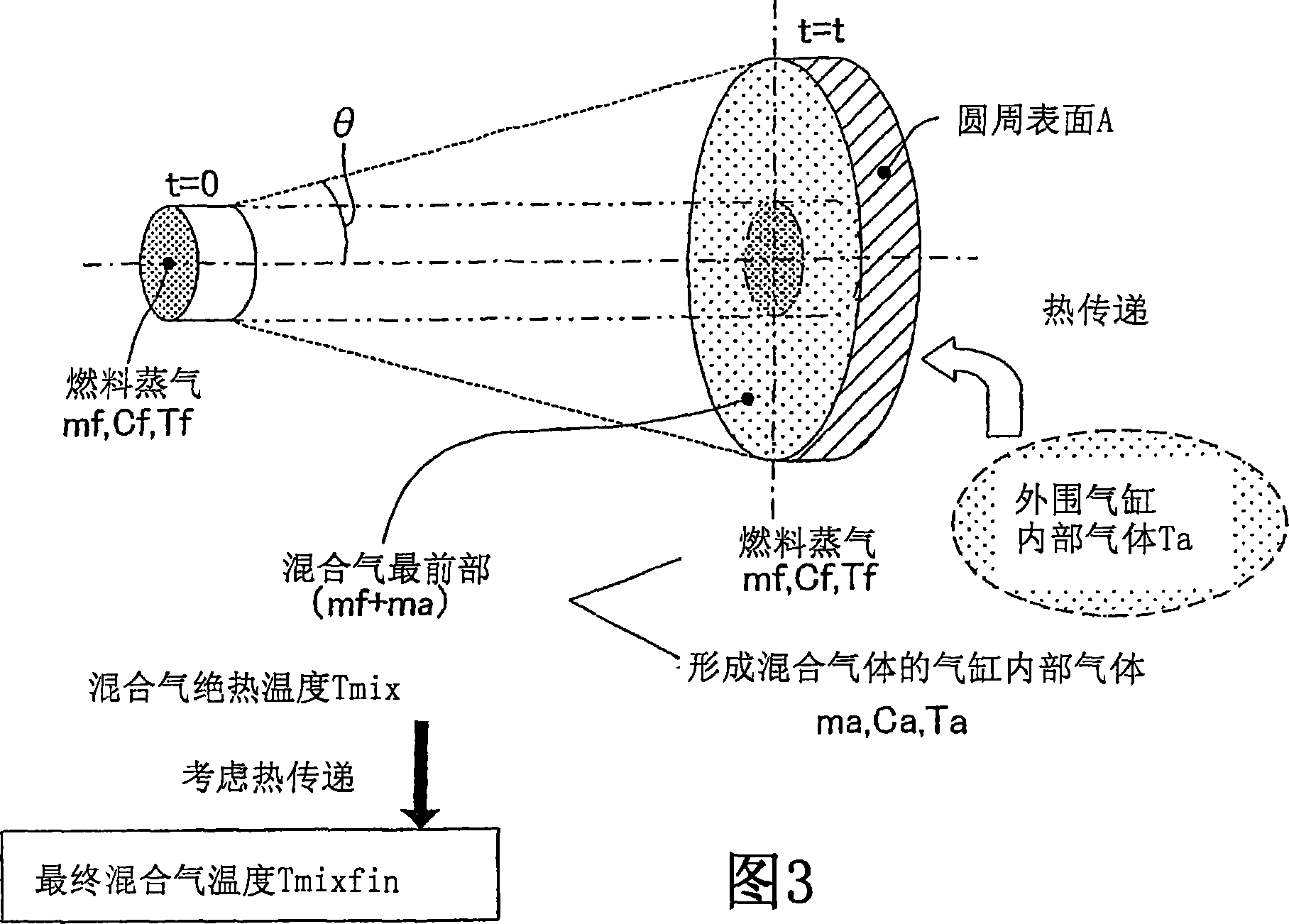

Method of estimating state quantity or temperature of gas mixture for internal combustion engine

InactiveCN1853037ABest burning stateElectrical controlMachines/enginesMass ratioExternal combustion engine

The present apparatus calculates a mass ma (mass ratio ma / mf) of mixing-gas-forming cylinder interior gas, which is a portion of cylinder interior gas to be mixed with a forefront portion of injected fuel vapor having a mass of mf, on the basis of a predetermined empirical formula. Subsequently, under the assumption that heat exchange with the outside does not occur, the apparatus calculates an adiabatic gas mixture temperature Tmix of the gas mixture forefront portion on the basis of the heat quantity of the fuel vapor having a mass of mf and the heat quantity of the mixing-gas-forming cylinder interior gas having a mass of ma. Subsequently, in consideration of an amount of heat that the gas mixture forefront portion receives from peripheral cylinder interior gas mainly via a circumferential surface thereof, the apparatus estimates a final gas mixture temperature Tmixfin of the gas mixture forefront portion (i.e., the temperature of the gas mixture) in accordance with the equation Tmixfin=Tmix (1-Kex) + Ta Kex, where Ta represents cylinder interior gas temperature, and Kex represents a heat exchange coefficient (0 < Kex < 1).

Owner:TOYOTA JIDOSHA KK

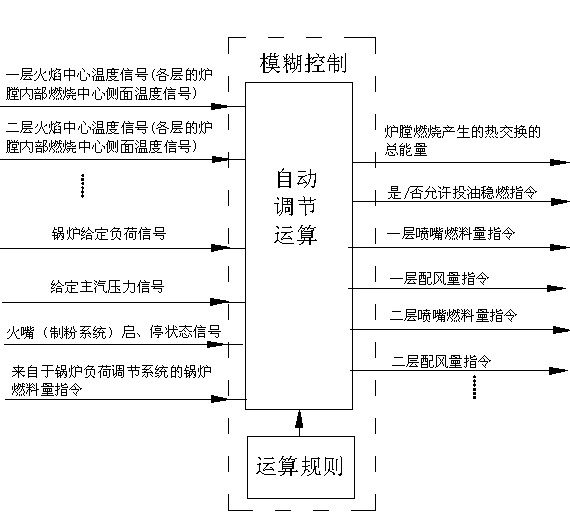

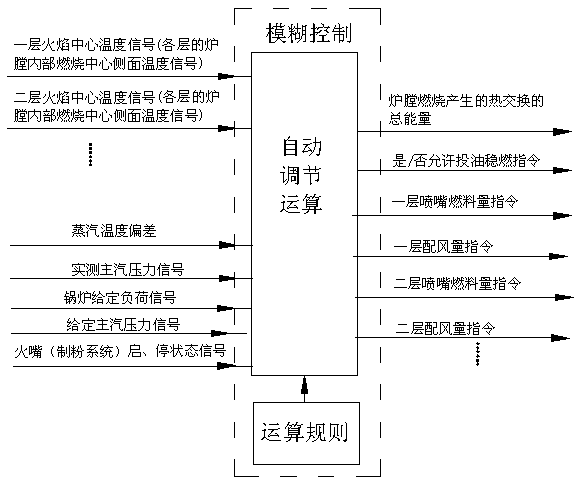

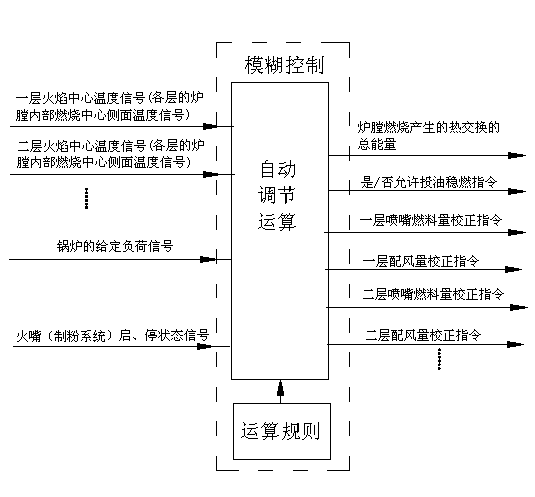

Automatic control method for preventing extinguishment and realizing ideal combustion for hearth

ActiveCN103047678AAutomatically adjust coal consumptionPrevent deflagrationCombustion regulationAutomatic controlCombustion

The invention discloses an automatic control method for preventing extinguishment and realizing ideal combustion for a hearth. The automatic control method is implemented by the aid of a full hearth control unit, signals inputted into the full hearth control unit at least include center temperature signals of various flame layers, given load signals of a boiler and starting and stopping state signals of various nozzles or pulverizing systems, automatic control operation is carried out inside the full hearth control unit, and signals outputted after automatic control operation at least include one type of fuel quantity instructions or fuel quantity correcting instructions of the various layers, air distribution quantity instructions or air distribution quantity correcting instructions of the various layers, oil feed combustion stabilizing instructions and total heat exchange energy signals generated during combustion of the hearth. The automatic control method has the advantages that the fuel coal quantity of the boiler and air quantities of the combustion nozzles can be adjusted automatically, excessively high temperature of the inside of the hearth is prevented, the boiler keeps in a stable combustion state, the extinguishment condition is stopped, the automatic control method is safe and convenient, and accordingly purposes of preventing extinguishment and realizing ideal low-nitrogen combustion are achieved for the hearth.

Owner:刘建松

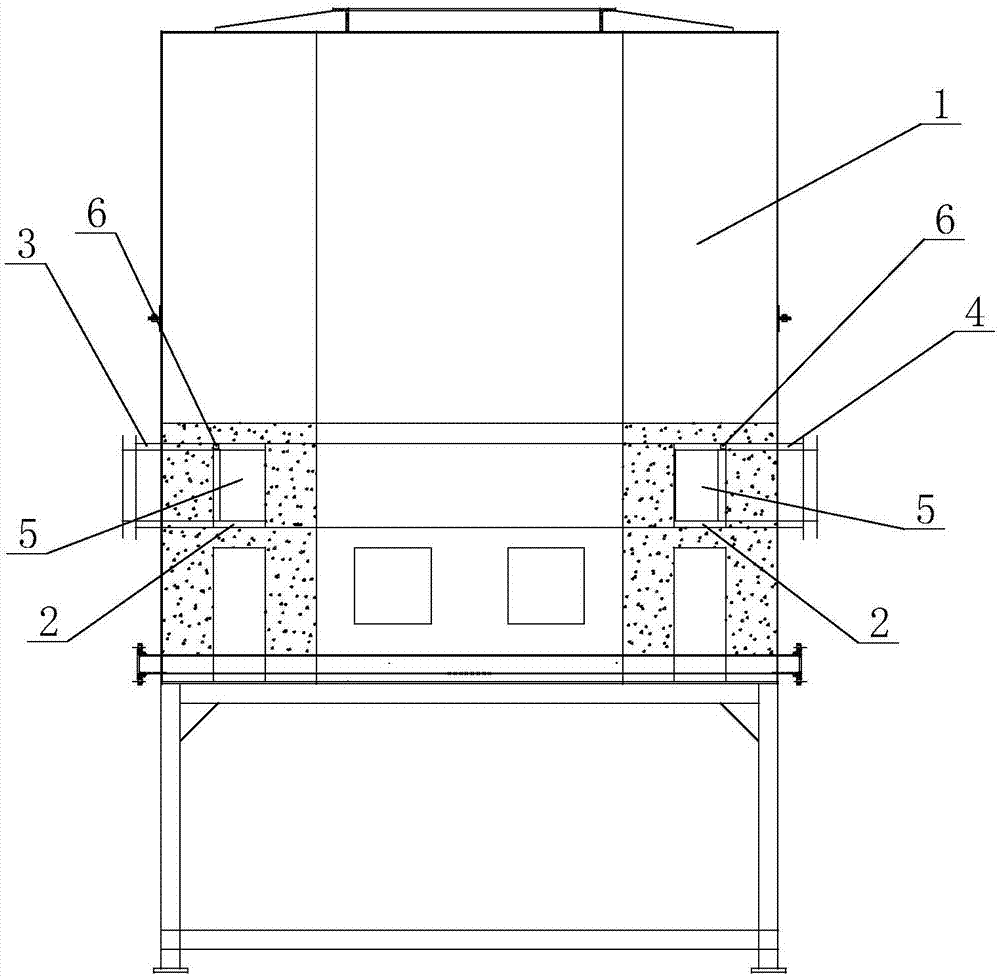

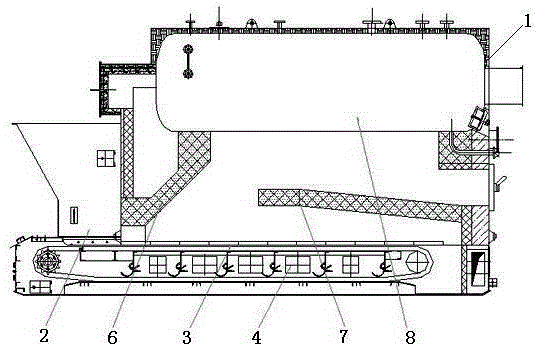

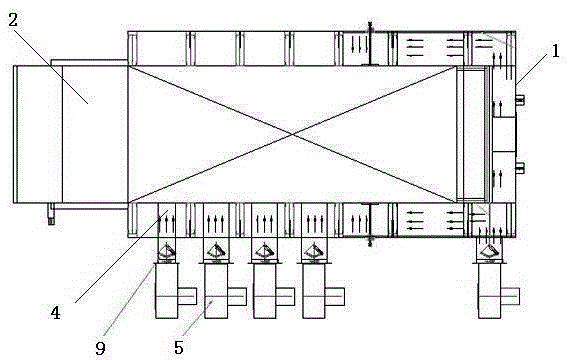

Biomass horizontal type cyclone burning boiler

ActiveCN103307593AGuaranteed combustion effectBest burning stateSolid fuel combustionCombustion technology mitigationCycloneCombustion chamber

The technology provides a biomass horizontal type cyclone burning boiler, which can allow fuels to burn sufficiently, prevent the fuels from coking and stack, and is convenient and comfortable to use and maintain. The boiler comprises horizontal type cyclone air pipes and a horizontal type combustor, wherein a plurality of the semi-cylindrical cyclone air pipes are evenly arranged on the inner wall at the back end of the combustor; front ends, positioned inside the combustor, of the cyclone air pipes are sealed, and the back ends of the cyclone air pipes are communicated with an airing and air distributing chamber; the front end of the combustor is communicated with a heat transfer smoke pipe, and the back end of the combustor is separated by a combustor back plate and the airing and air distributing chamber; a slag box is arranged at the lower part of connecting parts of the front ends of the cyclone air pipes and the combustor; a heat transferring medium chamber is arranged on the periphery of the combustor and the heat exchange smoke pipe; a first feeding packing auger is arranged in a first fuel feeding channel; a blower nozzle is arranged on the first fuel feeding channel; air outlets are formed in pipe walls of the cyclone air pipes, axial directions of the air outlets and the radial direction of the combustor form acute angles to allow airs entering into the combustor from the air outlets to form an eddy rotating in a same direction; and the airing and air distributing chamber is communicated with an outlet of the combustor.

Owner:胡光

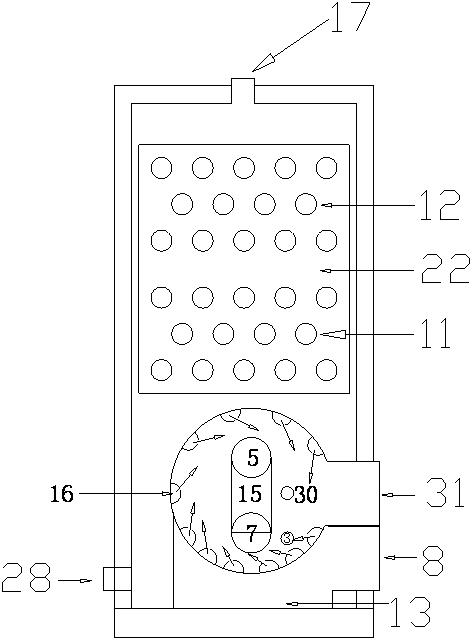

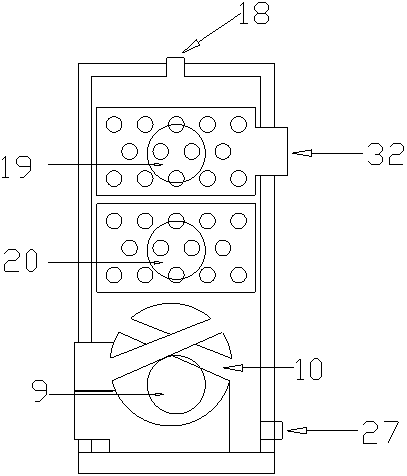

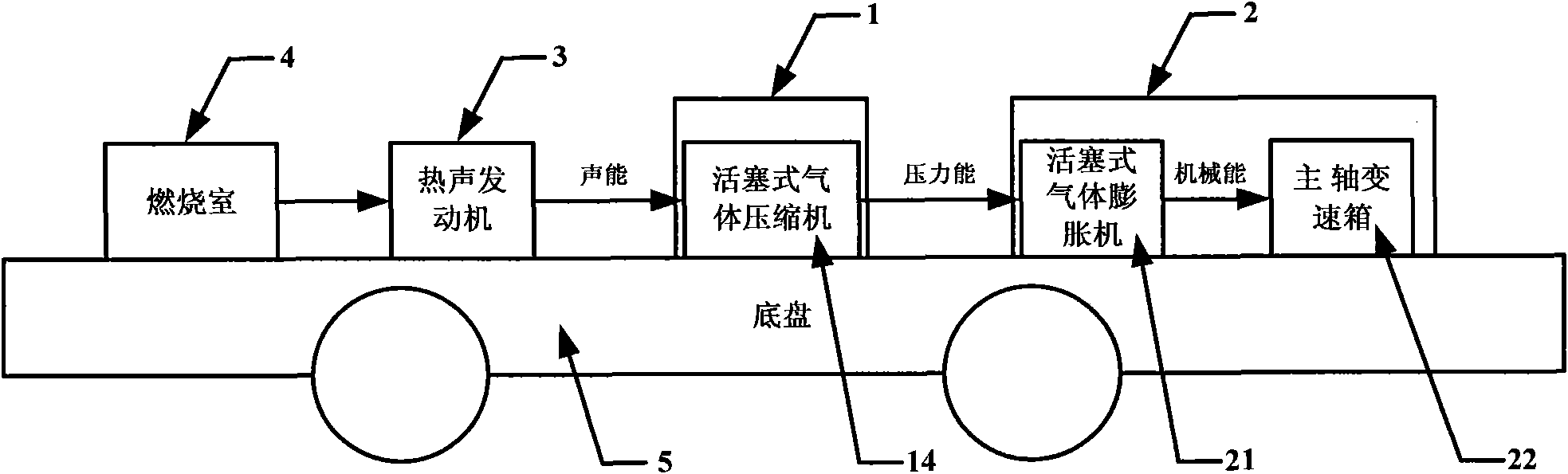

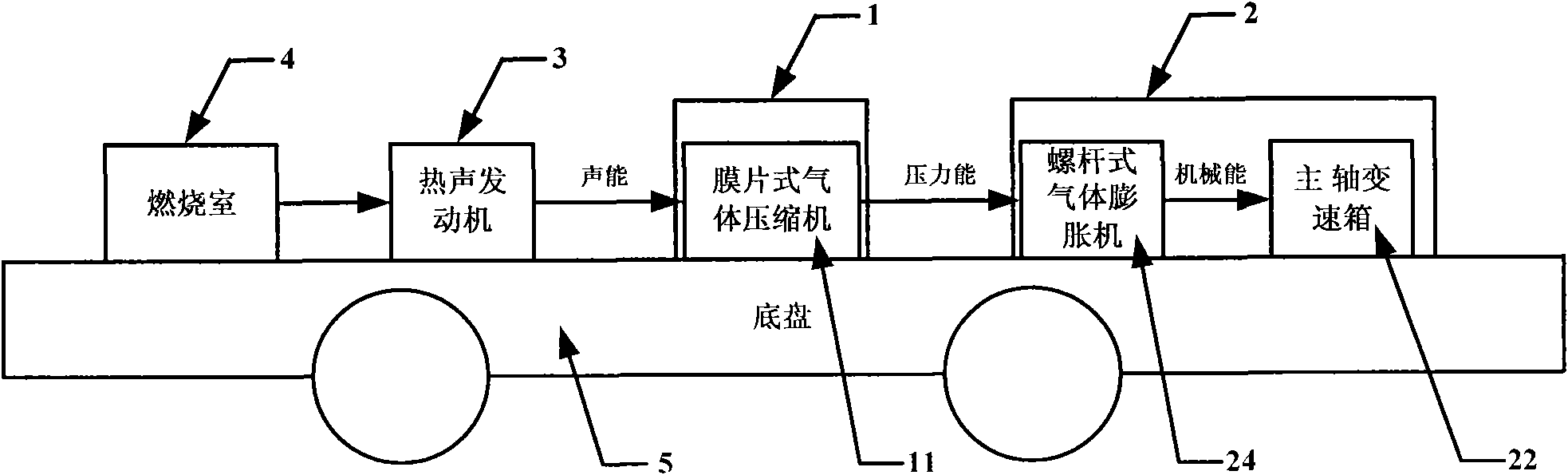

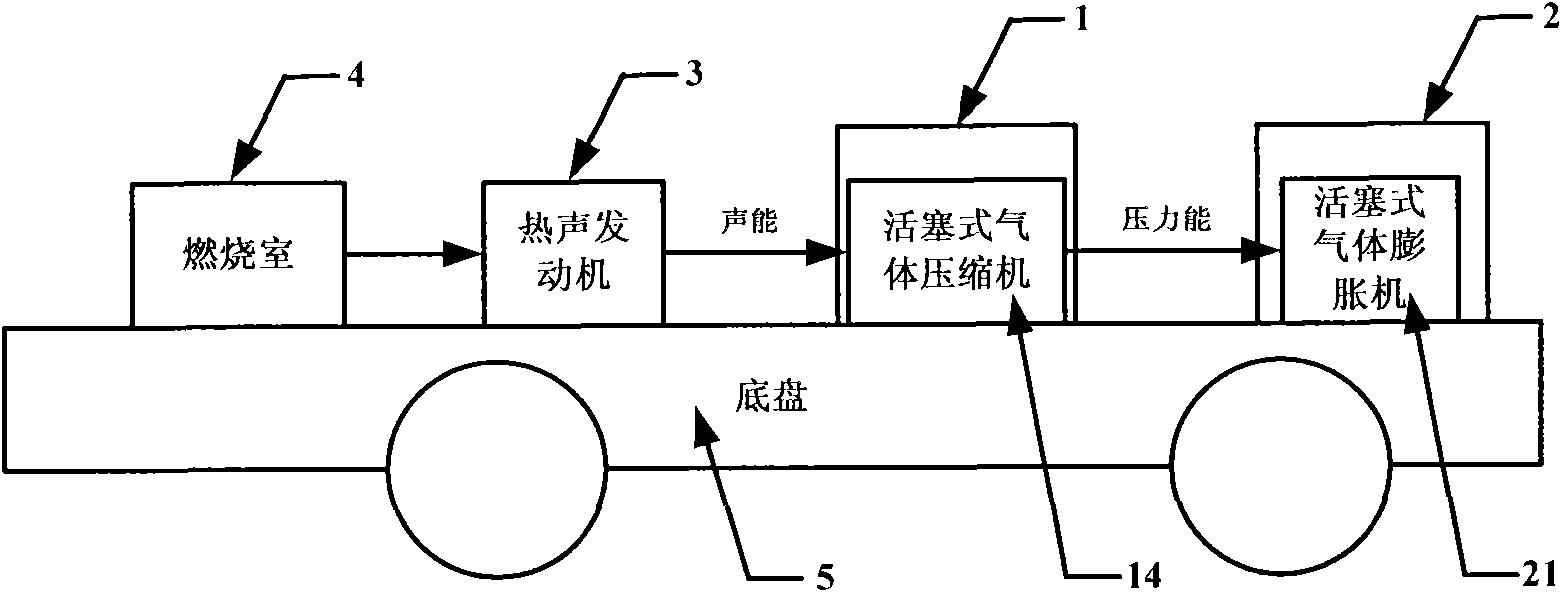

Automobile driven by thermoacoustic engine

InactiveCN101941374AEnsure balanced drivingReduce consumptionElectric propulsion mountingMachines/enginesElectric energyCombustion chamber

The invention provides an automobile driven by a thermoacoustic engine. The automobile comprises a thermoacoustic engine and a chassis; in addition, the automobile comprises a combustion room, a sound energy conversion system, an automobile transmission system and an energy storage system; the automobile converts the heat energy generated by the combustion room into the sound energy(pressure oscillation) by the thermoacoustic engine and then converts the sound energy into the pressure energy, mechanical energy or electric energy by the sound energy converter; and the pressure energy drives the automobile by a pneumatic motor, and the electric energy drives the automobile by an electric motor. The automobile has the advantages that: 1, the endurance problem existing in the pure pneumatic or pure electric automobile is solved; 2, because the thermoacoustic engine adopts external combustion, the requirements on fuel of the automobile are much lower than those of the automobiles adopting internal combustion, and the combustion conditions can be better controlled, so that the consumption of fuel is reduced and the environmental pollution is lowered; and 3, because the thermoacoustic engine does not have moving parts at high temperature, the automobile driven by the thermoacoustic engine is high in reliability and low in cost.

Owner:肖家华

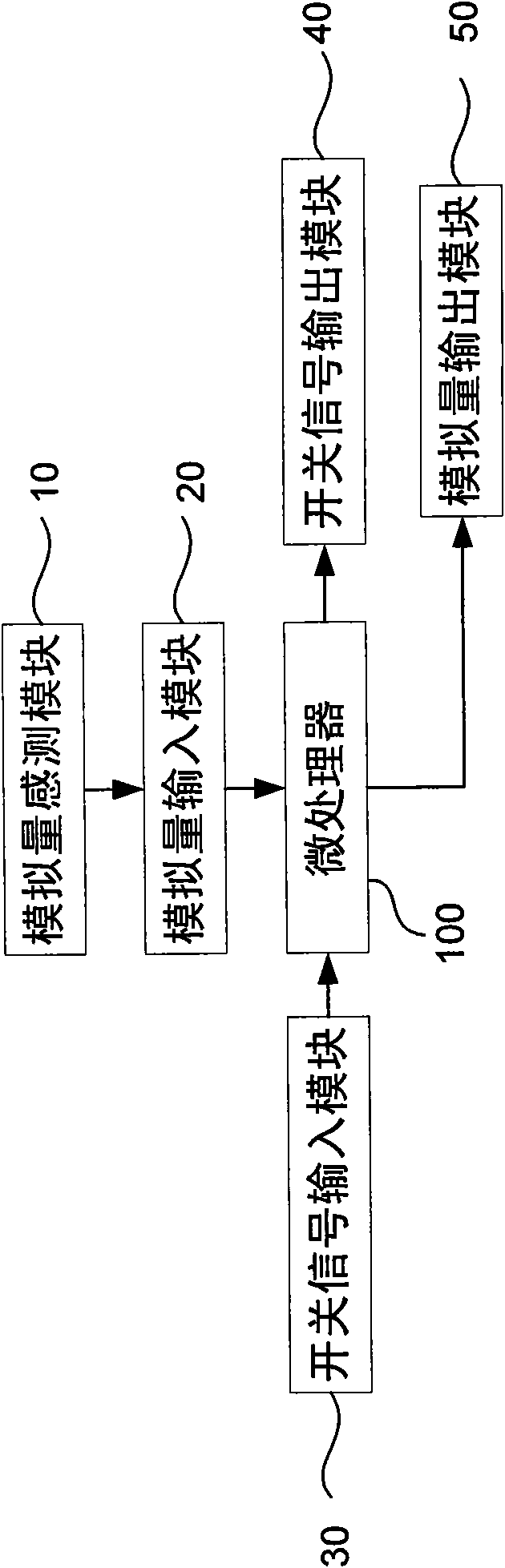

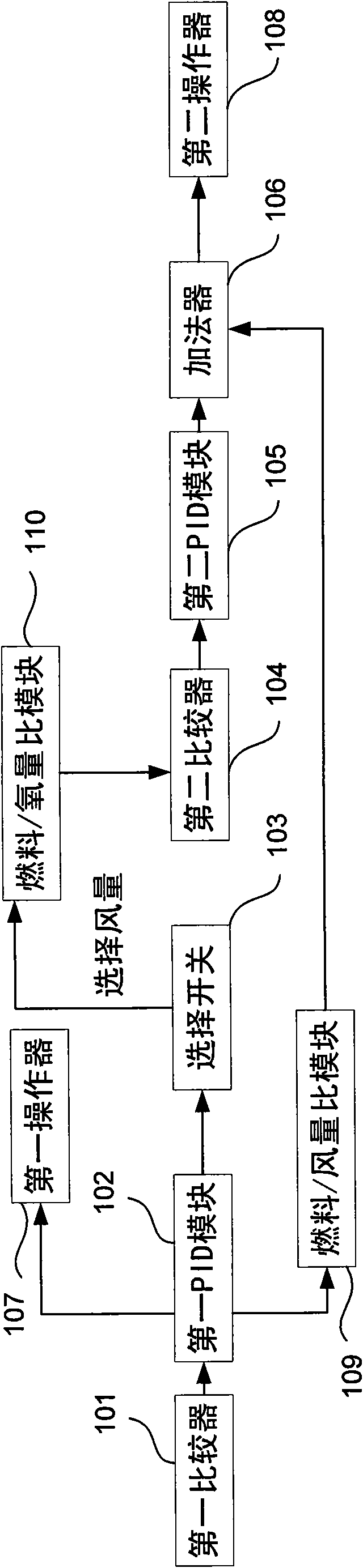

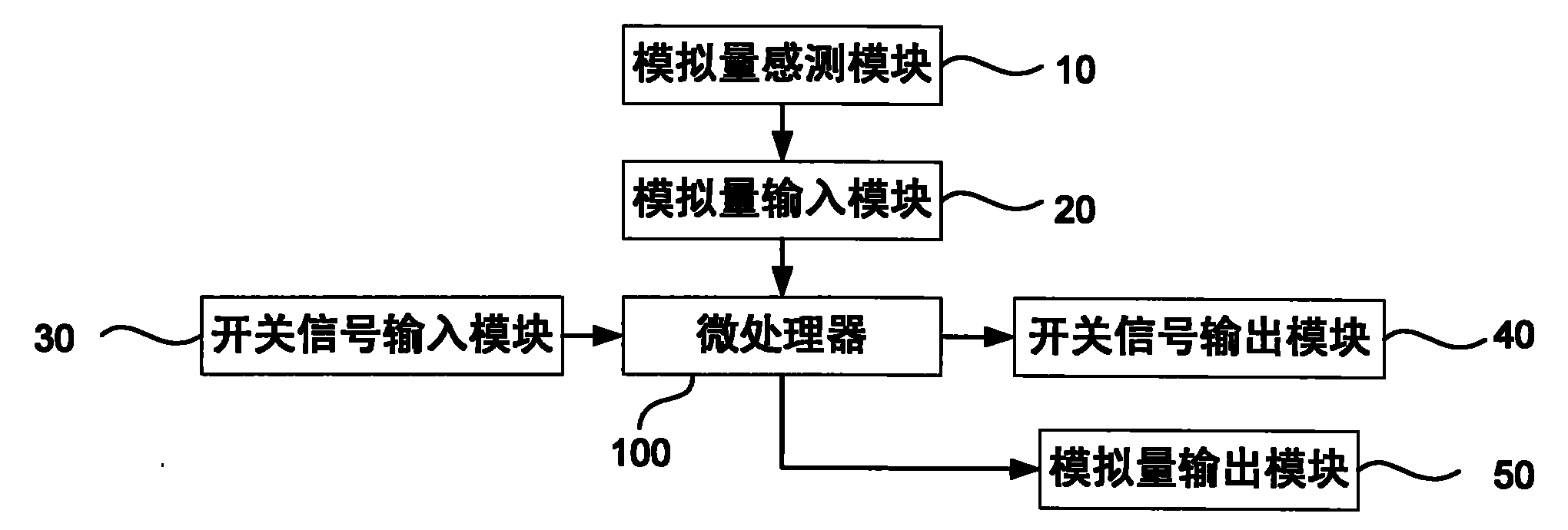

Controlling, adjusting and remote monitoring system for fuel gas-fired boiler

InactiveCN102032588AMeet the requirements of different load operationAdjust combustion in real timeFuel supply regulationVIT signalsRemote patient monitoring

The invention relates to a controlling, adjusting and remote monitoring system for a fuel gas-fired boiler, comprising an analog-quantity sensing module, a switching signal input module, a microprocessor and a switching signal output module, wherein the analog-quantity sensing module acquires a sampling parameter signal of a monitored boiler; the switching signal input module provides a switchingsignal indicating whether the monitored boiler meets safety conditions or not; one signal input end of the microprocessor is connected with the output end of the analog-quantity sensing module, and one control input end of the microprocessor is connected with the output end of the switching signal input module; under the switching signal meeting the safety conditions, the microprocessor is used for generating a control signal according to the sampling parameter signal, and the control signal comprises an opening signal of a fuel or gas-fired regulating solenoid valve and an opening signal of a blast-volume regulating solenoid valve; and the switching signal output module is used for controlling a blast blower of a burner and a main fuel solenoid valve of the burner. The system has a function of monitoring oxygen quantity in real time, thereby accurately meeting the requirements of the boiler to various load operations; the burning of the boiler is adjusted in real time so that the boiler is always in the best burning state and in the best burning efficiency, the high efficiency for burning is really realized.

Owner:SHANGHAI INDAL BOILER RES INST

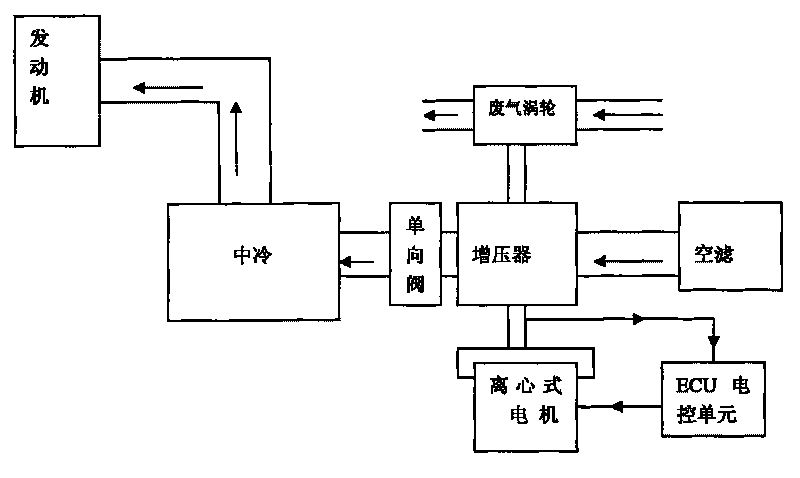

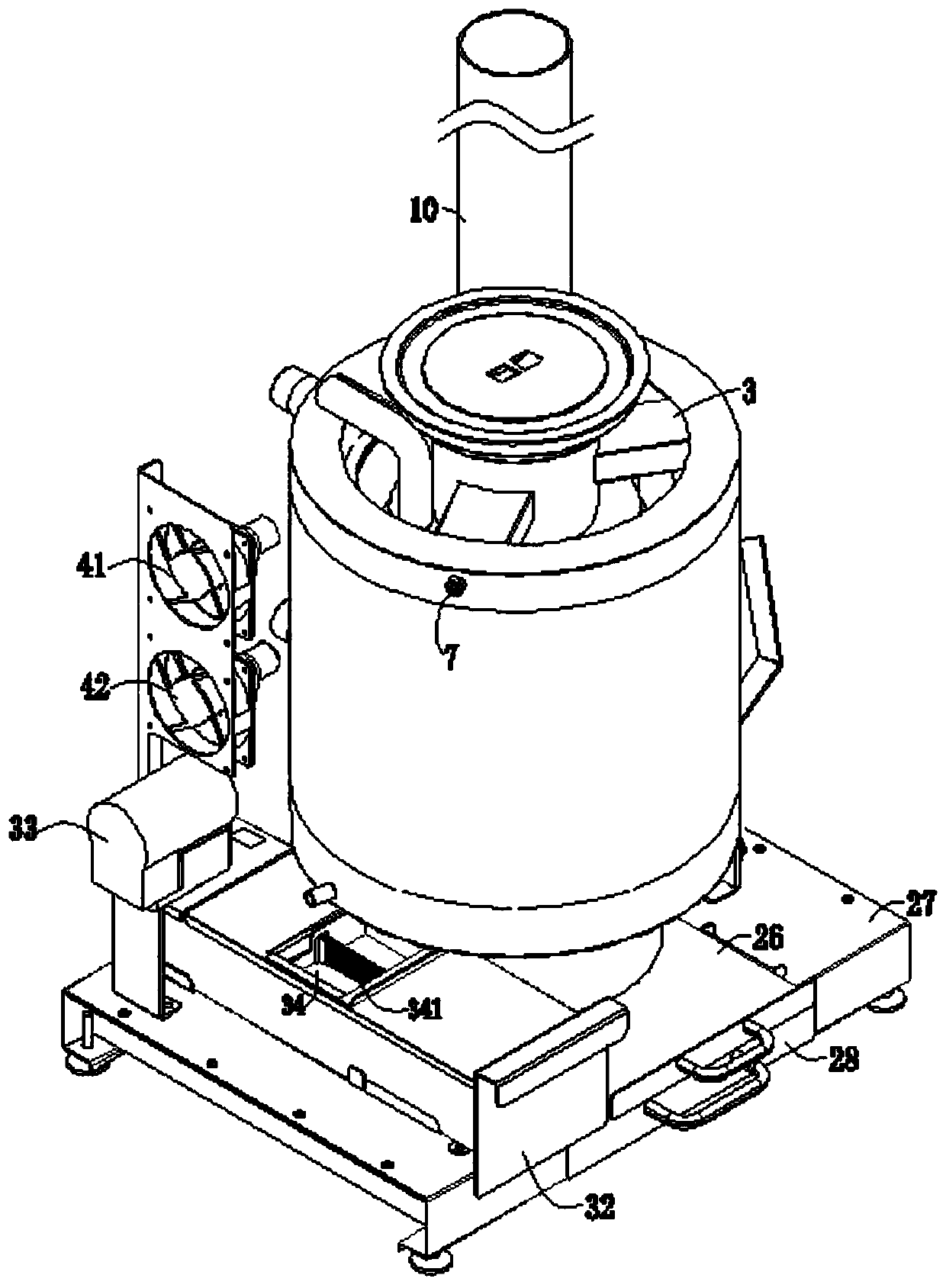

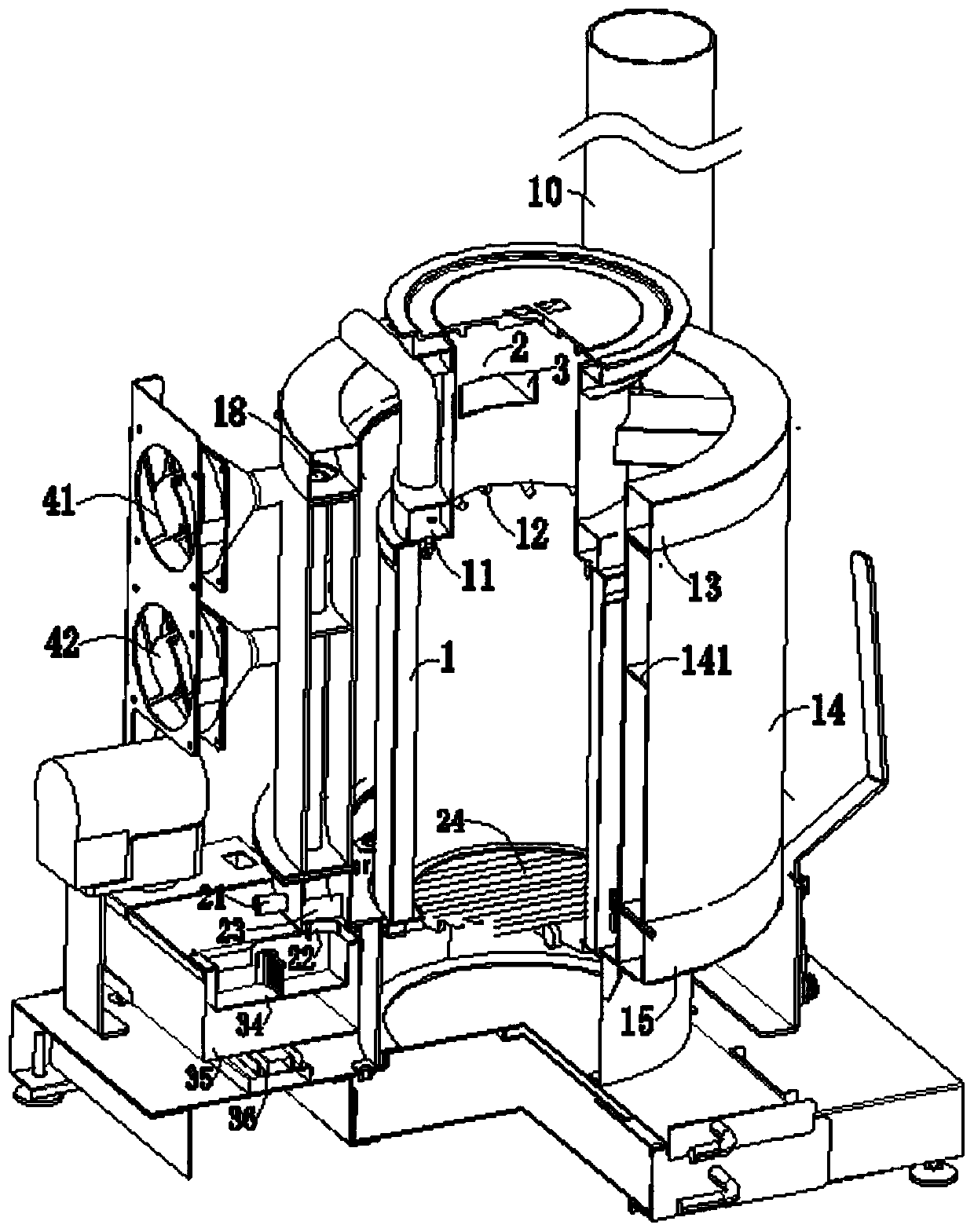

Electric centrifugal-type air supplement device

InactiveCN101737150AWill not affect service lifeLow costInternal combustion piston enginesLow speedCombustion

The invention relates to an electric centrifugal-type air supplement device which comprises an exhaust-gas turbo charger and an intercooling system, wherein the intercooling system is connected with an engine, a check value is arranged on an air outlet end of the exhaust-gas turbo charger, and a main shaft extension end of the exhaust-gas turbo charger is connected with the air supplement device through a clutch shaft. The electric centrifugal-type air supplement device not only can supplement air with high speed in the low-speed state, achieves the optimal combustion state, but also has simple manufacturing process and lower cost and can not influence the service life of a motor.

Owner:常州天大龙成节能环保科技有限公司

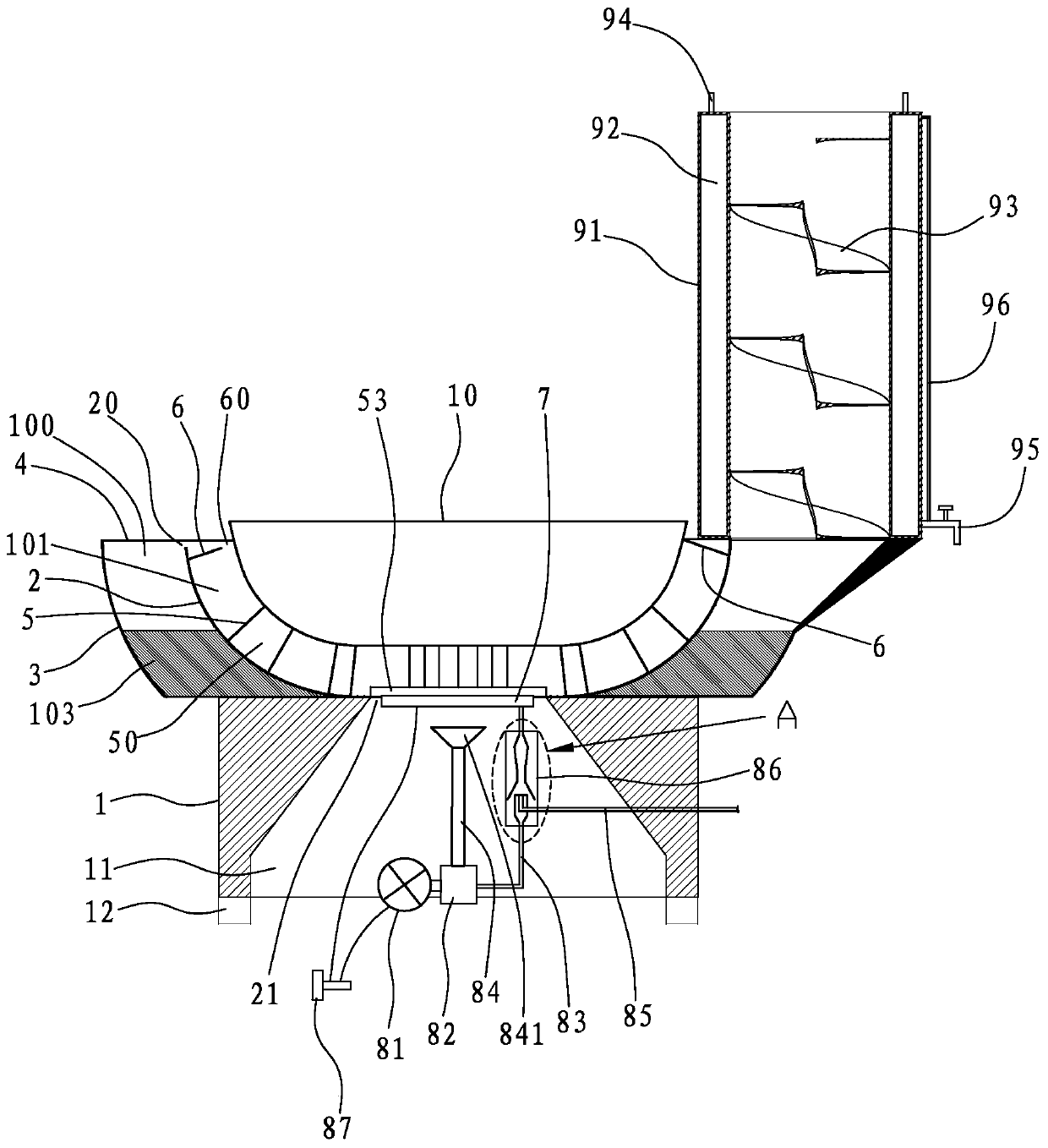

Heating device using solid fuels

PendingCN111396930APrecise adjustment of oxygen contentBest burning stateStoves/ranges with convection heatingLighting and heating apparatusAir volumeProcess engineering

The invention discloses a heating device using solid fuels, and belongs to the field of civil heating furnaces. An air distribution system achieves an upper way and lower way of independent and adjustable air supplying, the furnace temperature is controlled to be within a reasonable interval, the burning efficiency can be significantly improved, the content of oxygen in a hearth can be accuratelyadjusted, thus it is guaranteed that the interior of a furnace is always in an optimal burning state, and the superior burning efficiency and the better emission reduction effect are achieved; and a control system can set different air distribution schemes including the air distribution proportion and the total air volume according to burning properties of the different solid fuels and can furtherreal-timely adjust the air distribution proportion and the total air volume according to CO content and the temperature change fed back by a detection unit, and thus it is guaranteed that the solid fuels are always in an optimal burning state in the burning process, wherein the solid fuels especially refer to coal. Through the scheme of adaptively adjusting the air distribution proportion and thetotal air volume, different combustion-supporting modes are given to the different types of fuel coal so that the optimal burning and optimal emission effects on the fuel coal with different properties can be achieved.

Owner:马鞍山洁之燃信息科技有限公司

Automatic temperature control burner

InactiveCN103062765AImprove combustion efficiencyImprove efficiencyBurnersTemperature controlCombustor

The invention discloses an automatic temperature control burner comprising a machine body, an air feeding device, a fuel oil atomization device, an ignition device, a fuel supplying pump, a first motor rotating speed controller used for controlling the fuel supplying pump, a second motor rotating speed controller used for controlling the air feeding device, a flow sensor or a flow meter used for monitoring flow of fuel, an air pressure sensor used for monitoring quantity of air feeding, and a main controller. The automatic temperature control burner can precisely control the quantity of oil and the quantity of air feeding to obtain precise air-oil ratio and timely adjust the air-oil ratio to an optimal state, enable flame to achieve the best burning state, and is high in burning efficiency. The automatic temperature control burner can monitor actual quantity of oil using, statistics of on-day gross of oil consumption, monthly gross of oil consumption, average oil consumption of each day and the like can be carried out, a user can conveniently judge whether the quality of the oil is good or bad and adjust the quality of the oil, the oil is saved for the user, and energy conservation and emission reduction are really achieved.

Owner:JIANGYIN XINHAI ROAD CONSTR MATERIAL

Activation catalyst for energy conservation, automobile economizer containing catalyst and installation method of automobile economizer

PendingCN109261178AIncrease the calorific value of combustionWell mixedInternal combustion piston enginesHeterogenous catalyst chemical elementsCombustionOxygen

The invention relates to the field of energy conservation and emission reduction devices, and provides an activation catalyst for energy conservation, an automobile economizer containing the catalystand an installation method of the automobile economizer. The catalyst comprises a nano composite negative ion far-infrared material and a carrier. By means of the catalyst, the molecular activity of fuel molecules and oxygen molecules can be improved at the same time, the combustion environment is improved, and the combustion heat value of fuel is improved, so that the power of an engine during combustion of equal amount of fuel is higher, therefore the energy-saving effect is achieved, and the safety performance of an automobile and the service life of the engine are not affected. Besides, the power of the engine is improved by the activation catalyst for the automobile economizer, the energy-saving effect is achieved, and harmful gas in tail gas is also reduced. Meanwhile, oxidation is carried out in the exhausted gas, the harmful gas is decomposed, and the catalyst in the tail gas in a silencer is activated. According to the installation method, the energy-saving and emission-reducing effects of the engine at different rotating speeds can be taken into consideration, so that the optimal energy-saving and emission-reducing effects are achieved in general.

Owner:高洁泉 +2

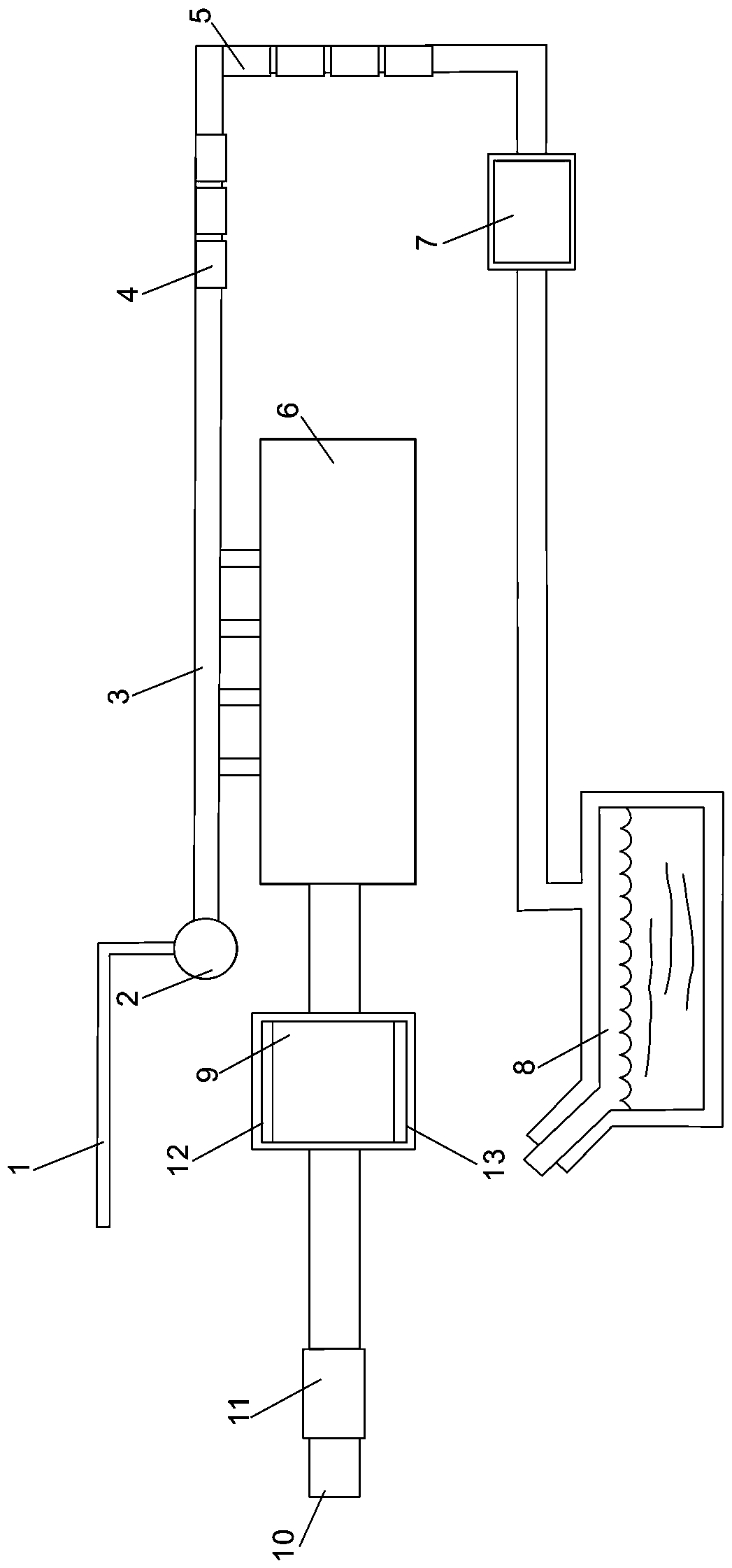

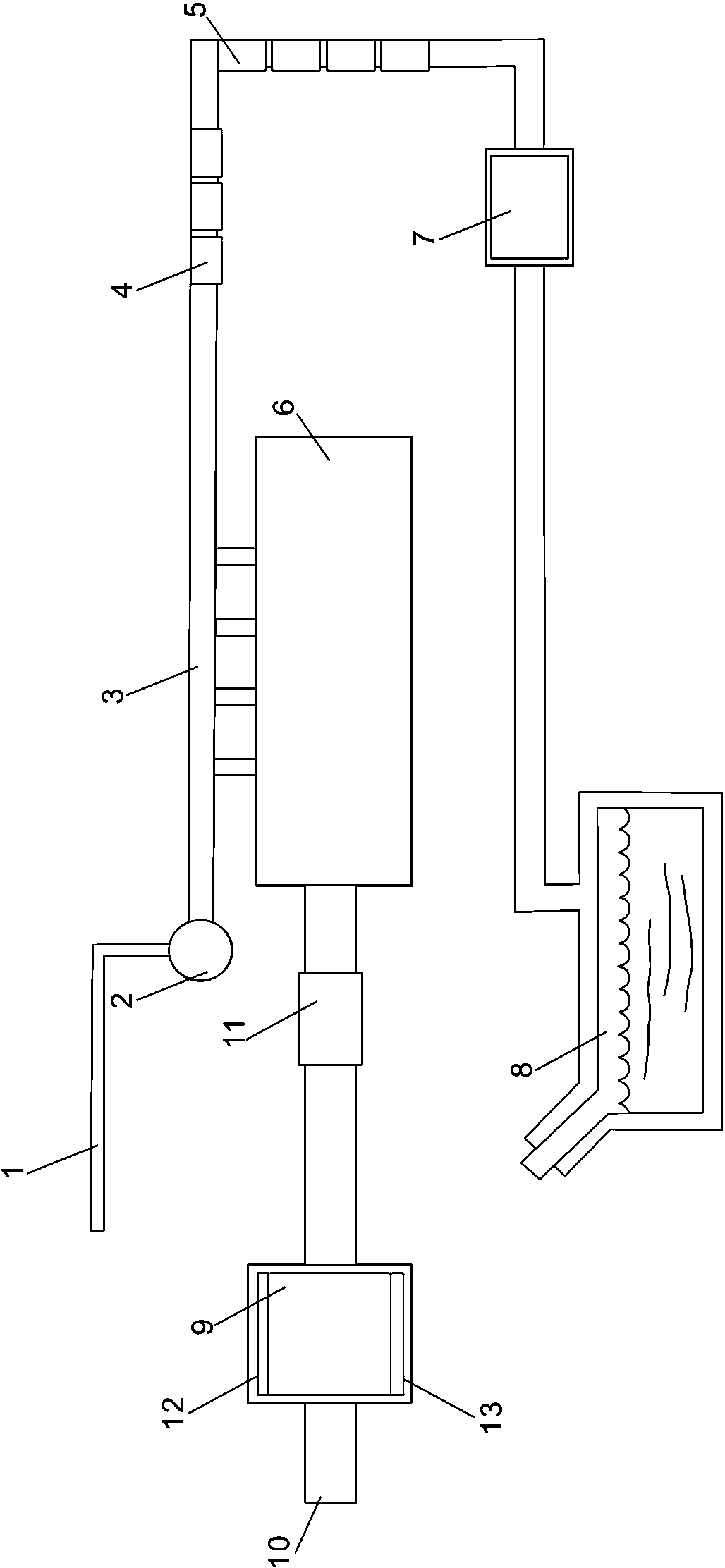

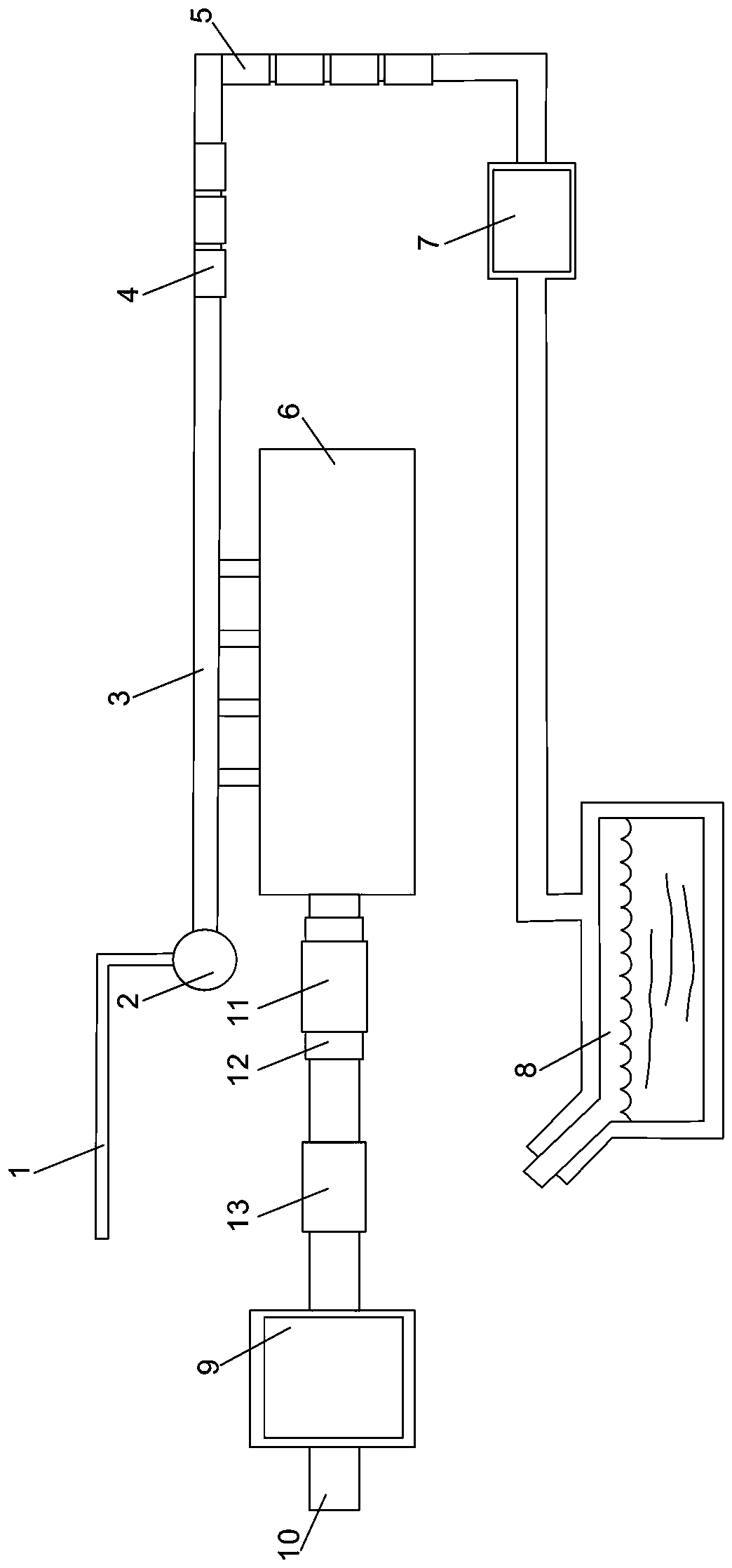

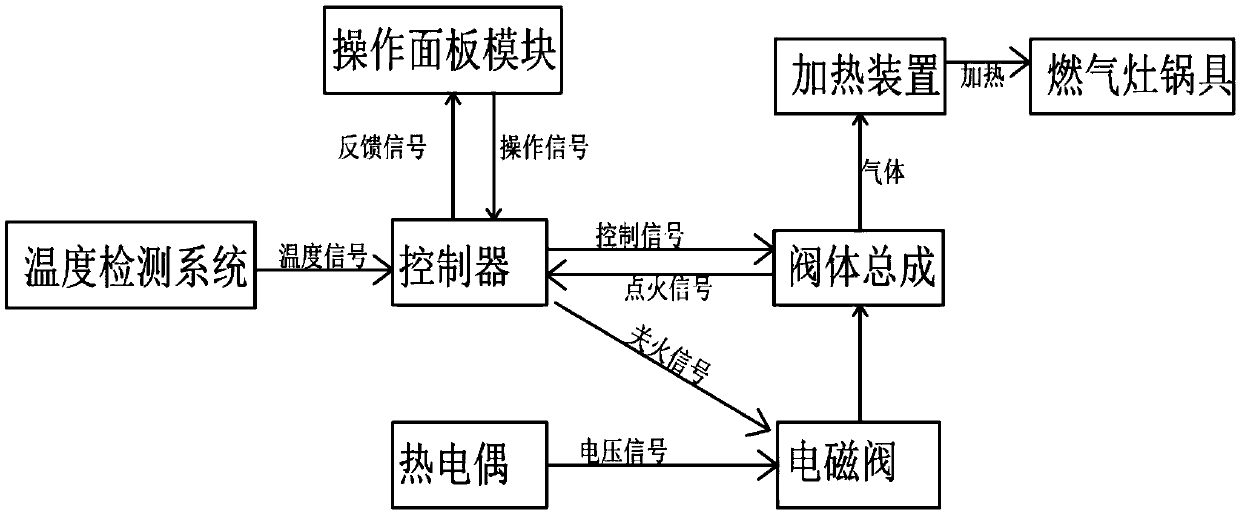

Control method for intelligent gas stove cookware constant-temperature cooking and system thereof

ActiveCN109631098ABest burning stateAchieve heat preservationDomestic stoves or rangesLighting and heating apparatusCombustionGas passing

The invention discloses a control method for intelligent gas stove cookware constant-temperature cooking and a system thereof. The method comprises the following steps: insulation and insulation operation are started; in the insulation operation, a temperature sensor compares an insulation temperature with a detecting temperature to obtain a temperature difference numerical value; when the temperature difference is returned in real time, if the temperature difference is a positive value, a controller controls a corresponding valve body assembly to increase the flow of passing gas; and if the temperature difference is negative, the controller reduces the flow of the passing gas of the corresponding valve body assembly. The system comprises the controller, an operation panel module, a temperature detecting system, the valve body assembly, gas stove cookware and a heating device; in the system, the controller, the operation panel module, the temperature detecting system, the valve body assembly, the gas stove cookware and the heating device are cooperated to achieve a stable insulation temperature effect; and through continuous optimization of the flow value of the gas passing throughthe valve body assembly, an optimal combustion state is found to realize insulation.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

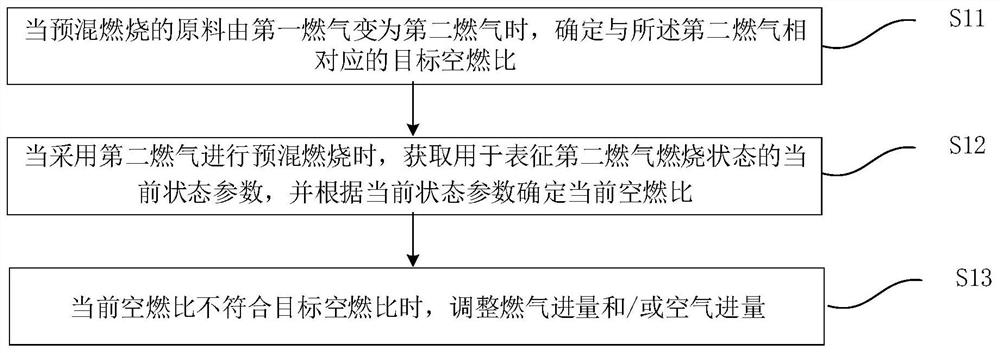

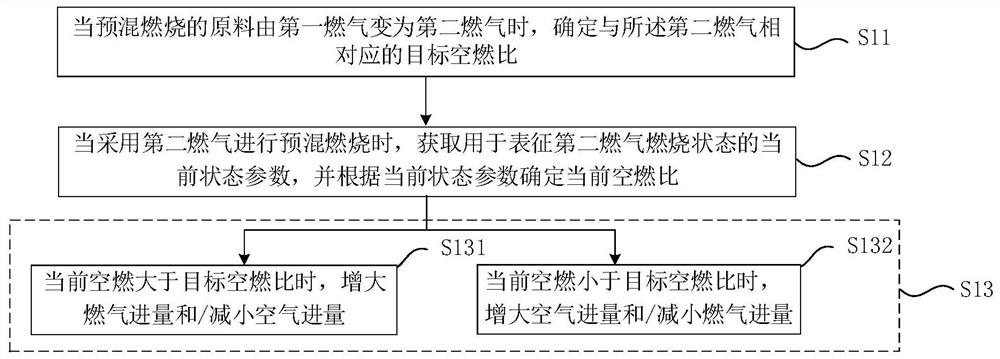

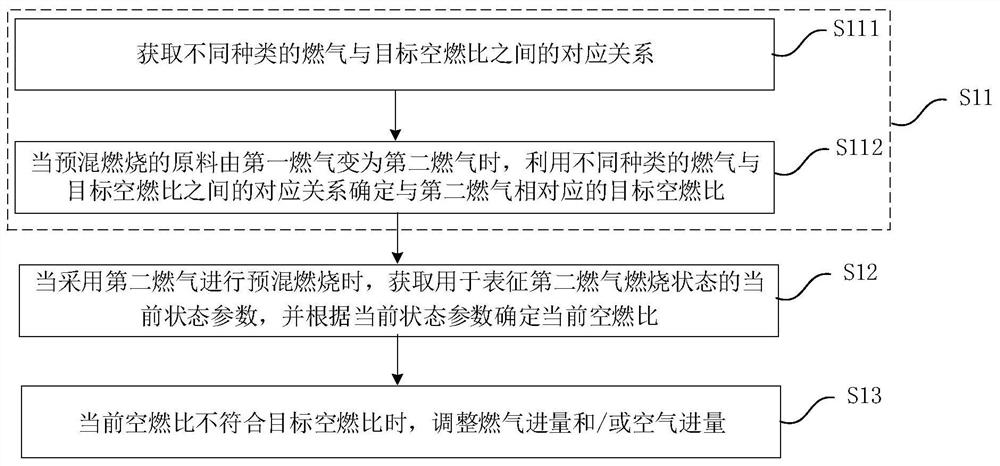

Self-adaptive control method and device for premixed combustion and gas equipment

InactiveCN112146123ABest burning stateAvoid safety hazardsCombustion regulationThermodynamicsProcess engineering

The invention discloses an adaptive control method and device for premixed combustion and gas equipment. The adaptive control method for premixed combustion comprises the following steps of determining a target air-fuel ratio corresponding to second gas when premixed combustion raw materials are changed into the second gas from first gas; when the second fuel gas is adopted for premixed combustion, acquiring current state parameters used for representing the combustion state of the second fuel gas, and determining the current air-fuel ratio according to the current state parameters; and when the current air-fuel ratio does not conform to the target air-fuel ratio, adjusting the gas inlet amount and / or the air inlet amount. Through the implementation of the self-adaptive control method anddevice for premixed combustion and the gas equipment, the air-fuel ratio of the gas equipment can be guaranteed to be adjusted according to different kinds of gas, the optimal combustion state of thegas is guaranteed, and the potential safety hazards caused by abnormal combustion due to the fact that the air-fuel ratio is not suitable are avoided.

Owner:GREE ELECTRIC APPLIANCES INC

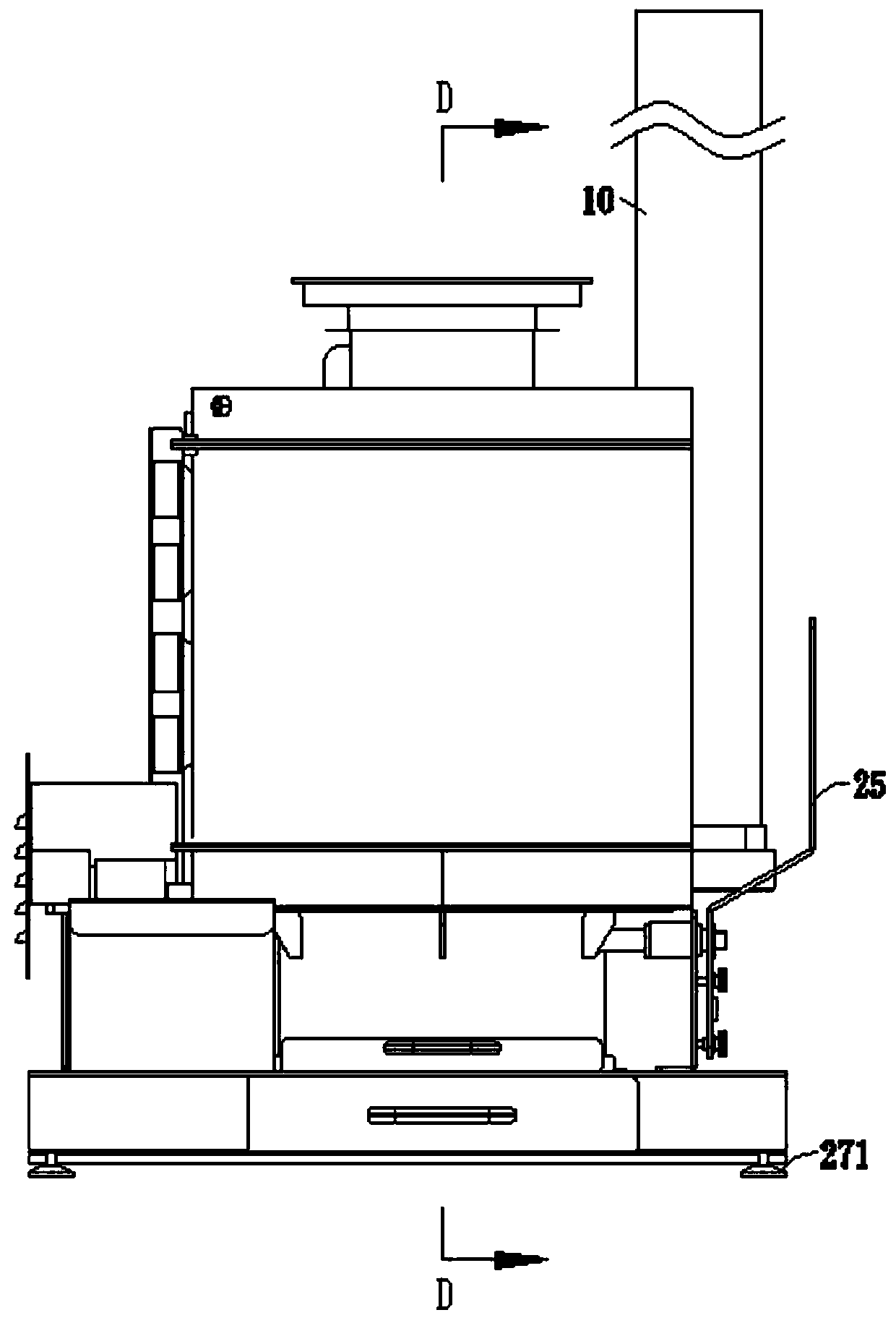

Secondary combustion chamber combustion regulating mechanism used for pyrolysis furnace

The invention discloses a secondary combustion chamber combustion regulating mechanism used for a pyrolysis furnace. The secondary combustion chamber combustion regulating mechanism comprises a pyrolysis furnace body, wherein a secondary combustion chamber is arranged on the pyrolysis furnace body; a first smoke gas inlet and a second smoke gas outlet are formed in the secondary combustion chamber; and a regulating part used for changing the size and the direction of outlet smoke gas is arranged on each of the first smoke gas outlet and the second smoke gas outlet. The secondary combustion chamber combustion regulating mechanism used for the pyrolysis furnace disclosed by the invention can regulate the size and the direction of the smoke gas outlet at one side according to a garbage combustion state of the first smoke gas outlet and the second smoke gas outlet, so that sufficient oxygen gas is supplied to the secondary combustion chamber at the other side, and therefore, domestic garbage is combusted more sufficiently to achieve the optimal combustion state in the pyrolysis furnace. The secondary combustion chamber combustion regulating mechanism greatly reduces working condition instability and equipment loss, caused by insufficient combustion, is safe, efficient, energy-saving, environmentally friendly, and is suitable for large-area development popularization.

Owner:江苏利百川环保科技有限公司

Load control method for reducing cylinders of diesel engine

InactiveCN102817722BControl vibrationImprove operating economyElectrical controlOutput powerLow loadTransducer

The invention relates to a load control method for reducing cylinders of a diesel engine, which comprises the following steps of: arranging a speed-measuring photoelectric encoder at a free end of the diesel engine, arranging a pair of torsion vibration photoelectric encoders at a load end of the diesel engine, arranging a two-way acceleration transducer nearby an air cylinder blasting pressure generating point of a diesel engine body, stopping the cylinders one by one, recoding torsion vibration data and vibration data, and ensuring a cylinder stopping number under some load according to the principle that the sum between the torsion vibration specific value and the vibration specific value is the minimum, and taking the cylinder stopping number as the basis of cylinders reducing control load when the diesel engine runs. The load control method controls the power output of the diesel engine by a cylinder reducing method, the work cylinder can be kept at the optimum burning status, and the oil consumption of the whole diesel engine is near to the minimum oil consumption, so that the running economical efficiency under the medium and low load can be improved.

Owner:海宁鼎丞智能设备有限公司

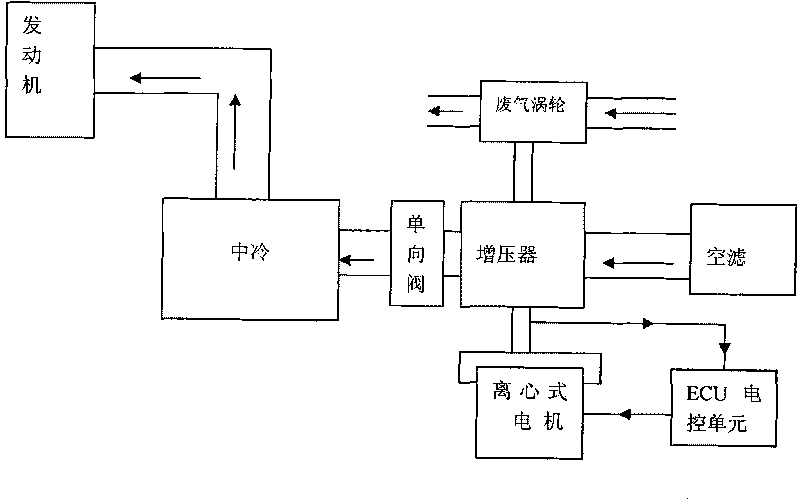

Vehicle turbocharging device

InactiveCN101737149AWill not affect service lifeLow costInternal combustion piston enginesEngine componentsImpellerLow speed

The invention relates to a vehicle turbocharging device. The vehicle turbocharging device comprises an exhaust gas turbocharger as well as an electric device for driving the exhaust gas turbocharger to work normally when the exhaust gas turbocharger can not work normally because the vehicle initially starts and the exhaust gas air capacity is not sufficient. The main shaft of the exhaust gas turbocharger axially extends from a blower impeller end, passes through the bend tube wall of an air inlet pipe of the exhaust gas turbocharger from the inside to the outside and is coupled to the shaft of a drive motor through a clutch. By adopting the invention, the air can be supplemented at high speed at the state of low speed, the optimum combustion state can be achieved, the making process is simple, the service life of the motor is not affected and the cost is lower.

Owner:常州天大龙成节能环保科技有限公司

Boiler with improved air supply manner

InactiveCN105258149ABest burning stateImprove heat transfer efficiencyBlast-producing apparatusFrequency changerAir volume

The invention relates to a boiler, namely a boiler with an improved air supply manner. The boil is characterized in that a plurality of blowers supply air to a plurality of air chambers of an air supply system. The air supply system is provided with independent air chambers and independent blowers, namely each air chamber is provided with one blower, and each air chamber and the corresponding blower are simultaneously regulated by a frequency changer and a ventilation door, so that the air pressure and air flow of each air chamber can be conveniently accurately controlled; semi coke can be guaranteed to be always in the best burning state on a fire grate; the heat exchange efficiency of the boiler is improved, and the burn-off rate of the semi coke is increased. A lot of experiments prove that because the independent air chambers and the independent blowers are used and are respectively controlled by the frequency changers and the ventilation doors, the burn-off rate of the semi coke is increased from about 90% to about 96%, and the heat exchange efficiency of the boiler is improved from 79% to about 84%. The burn-off rate of the semi coke of which the annual yield is over one hundred million tons at present is increased by 6%, so that 6 million tons of the semi coke is saved; with the continuous development of a coal reduction campaign, the utilized range of the semi coke can be continued to be enlarged, and the energy-saving effect can also be continued to be enlarged.

Owner:大连旺佳新能源科技开发股份有限公司

Dragon wind energy-saving stove

PendingCN110793069AReduce convective radiationSlow down crawlingDomestic stoves or rangesCooking fumes removalEngineeringStructural engineering

The invention discloses a dragon wind energy-saving stove which comprises a base. A hearth frame, a shell and a cover plate are arranged on the base, and an inner hearth and an outer hearth are formed. The cover plate is provided with a stove opening which allows a pot to be put into the inner hearth and is matched with the pot bottom. The hearth frame is provided with spiral fire extending wallswhich are spirally ascended along the inner wall of the hearth frame. A diffraction fire extending wall which divides a spiral channel between the two spiral fire extending walls into a plurality of spirally-ascending fire extending channels is arranged between the two adjacent spiral fire extending walls. The spiral fire extending walls and the diffraction fire extending walls form a spiral pot frame which is used for supporting the pot and matched with the pot bottom. A fire plate opening is formed in the bottom of the hearth frame. A fire plate is arranged at the fire plate opening. An annular fire retaining wall is arranged on the outer side of the spiral pot frame. An annular discharge flue is arranged on the upper portion of the outer hearth. An exhaust port is formed in the cover plate and communicates with the discharge flue. An outer passing port and an inner passing port are formed between the hearth frame and the cover plate as well as between the fire retaining wall and thepot bottom respectively, wherein the portions, close to the exhaust port, of the outer passing port and the inner passing port are small, and the portions, away from the exhaust port, of the outer passing port and the inner passing port are big. The dragon wind energy-saving stove has the functions of fire extending and fire evening, and the thermal efficiency is high.

Owner:徐振学

Pulverized coal sulfur fixing, freeze preventing and coarsening agent, preparation method and application method thereof

The invention relates to a pulverized coal sulfur fixing, freeze preventing and coarsening agent, a preparation method and an application method thereof, and aims to solve the problems that the prior art cannot realize pulverized coal sulfur fixing, freeze preventing and coarsening at the same time. The pulverized coal sulfur fixing, freeze preventing and coarsening agent consists of a composite sulfur fixation antifreezing agent and a bonding penetrant which are separately packaged. The preparation method comprises the following steps of: 1, preparing a separate package, i.e. the composite sulfur fixation antifreezing agent; and 2, preparing the separate package, i.e. the bonding penetrant. The application method specifically comprises the following steps of: adding the composite sulfur fixation antifreezing agent at first, dissolving the bonding penetrant into water to prepare bonding penetrant aqueous solution, and then, adding the bonding penetrant aqueous solution to stir uniformly. The methods are mainly used for preparing and applying the pulverized coal sulfur fixing, freeze preventing and coarsening agent.

Owner:赵志文

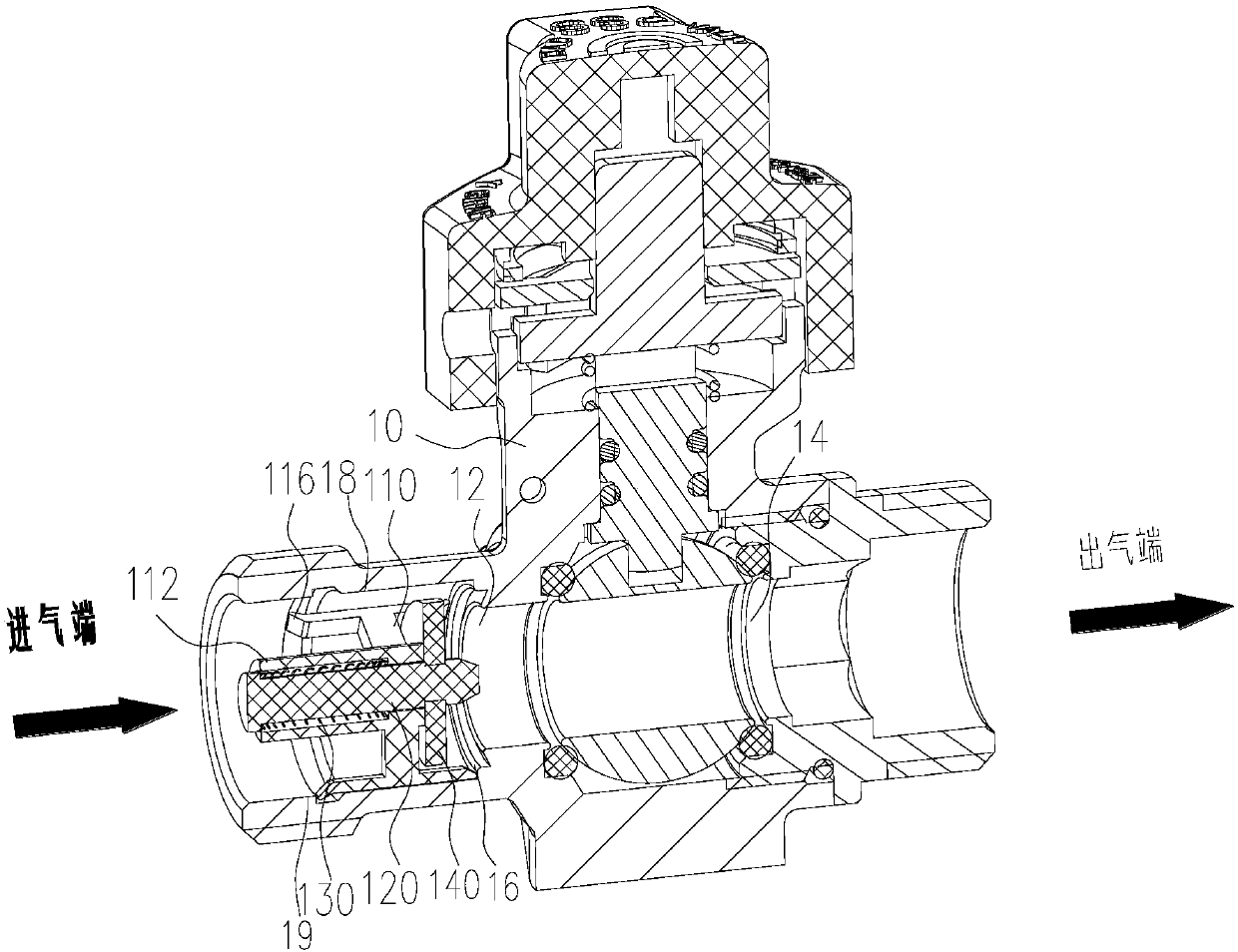

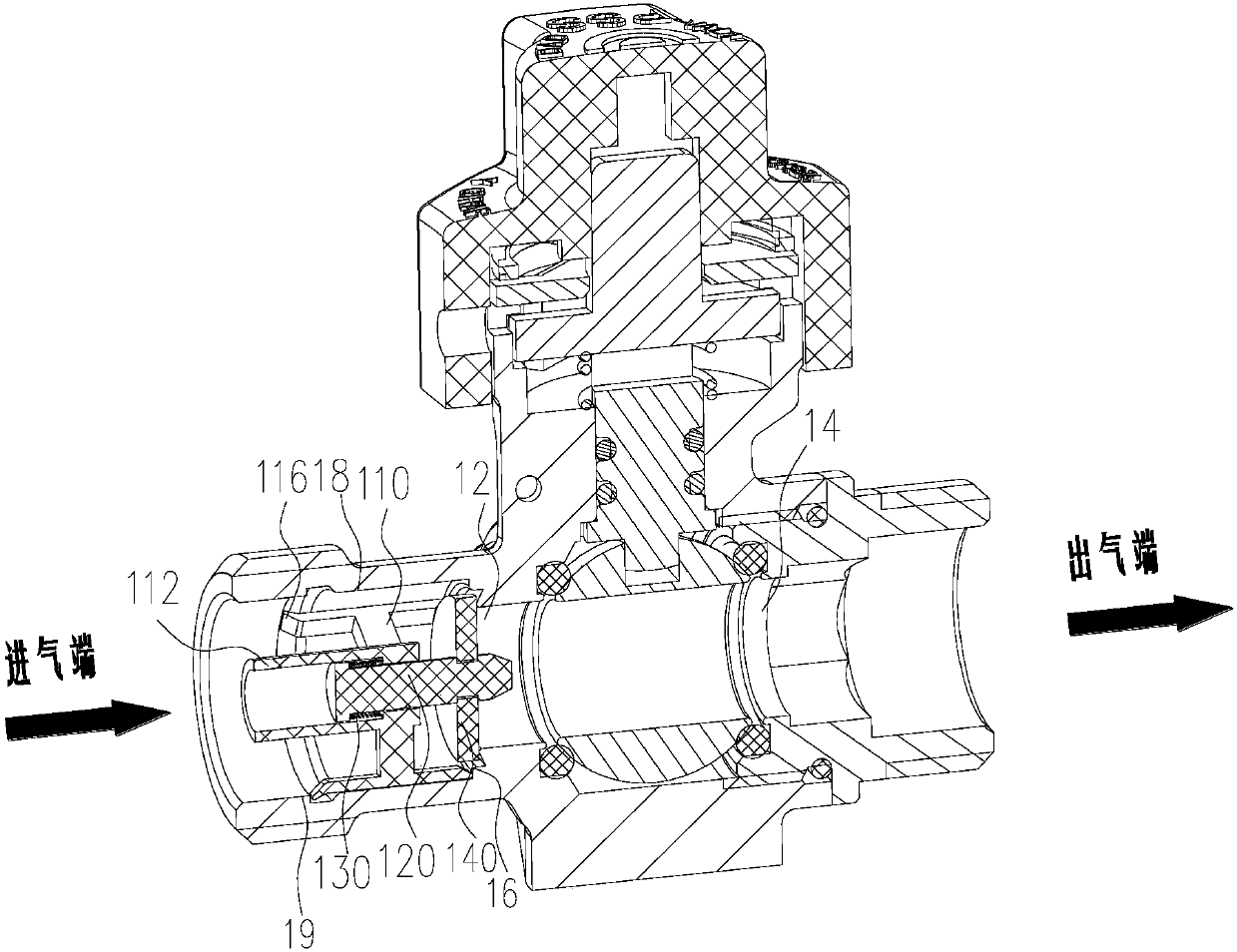

Fuel gas safety valve

PendingCN107606223APrevent leakageGuarantee the safety of usePlug valvesEqualizing valvesAutomatic controlEngineering

The invention discloses a fuel gas safety valve. The fuel gas safety valve comprises a main valve body and an gas flow automatic controlling device arranged in an inner cavity of the main valve body,the gas flow automatic controlling device comprises a supporting base, an adjusting rod, an elastic mechanism and a sealing gasket; and the gas flow automatic controlling device is fixed to the innercavity of the main valve body through the supporting base, one end of the adjusting rod is fixedly connected with the sealing gasket, and the elastic mechanism is arranged between the other end of theadjusting rod and the supporting base, and gas compresses the adjusting rod to drive the sealing gasket to move so as to change the opening degree of the main valve body. According to the fuel gas safety valve, the gas flow automatic controlling device used for adjusting gas flow is arranged in the main valve body, the gas flow automatic controlling device can control the rated gas consumption volume of a burning appliance automatically, so that the fuel gas flow is always constant and the best combustion state is achieved; and not only is the goal for saving the fuel gas achieved, but also gas leakage caused by incomplete combustion is avoided, and using safety of fuel gas is ensured.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +2

Fuel temperature controlling system and fuel temperature controlling method

InactiveCN108678876ASolve the problem of unstable temperature controlBest burning stateMachines/enginesThermal treatment of fuelTemperature controlEngine efficiency

The invention provides a fuel temperature controlling system and a fuel temperature controlling method, and relates to the engine field. The fuel temperature controlling system comprises a vehicle control device, a detection device and an execution device, and controls the fuel temperature such that an actual value of the fuel temperature is maintained within a certain temperature range based on aresult of the vehicle control device comparing an actual parameter to a set parameter. The fuel temperature controlling method comprises a preset step, a detection step, a process step and a fuel temperature control step, and specifically refers to: setting upper and lower limits of the fuel temperature, comparing a detected actual temperature to the upper and lower limits, and regulating an actual temperature value between the upper and lower limits according to a comparison result. The system and the method can alleviate problems such as low engine efficiency, high fuel consumption and severe emission caused by unstable vehicle engine fuel temperature control in the prior art.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

Combustion control system and control method for industrial furnace

ActiveCN103672948BReduce oxidation lossImprove energy savingFuel supply regulationControl systemProduct gas

The invention provides a combustion control system and method of an industrial furnace. The combustion control system of the industrial furnace comprises a laser spectrum detection device, a combustion control device, an oxidation burning loss detection device, a comparison device and a computing device, wherein the laser spectrum detection device is used for detecting the content of gas in the industrial furnace, the laser spectrum detection device comprises a laser, a detector and an analysis module, the combustion control device is used for optimizing and adjusting the combustion conditions in the industrial furnace according to data transmitted by the laser spectrum detection device, the oxidation burning loss detection device is used for detecting oxidation burning loss of workpieces which pass through the industrial furnace, and transmitting the detection result to the comparison device, the comparison device is used for obtaining the comparison result according to the received detection result and the original oxidation burning loss conditions, and transmitting the comparison result to the computing device, and the computing device is used for obtaining the combustion control result of the industrial furnace according to the received comparison result. The combustion control system and method of the industrial furnace have the advantages that detection accuracy is high, the detection speed is high, the cost is low, and energy is saved.

Owner:FOCUSED PHOTONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com