Patents

Literature

60results about How to "Achieve complete combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

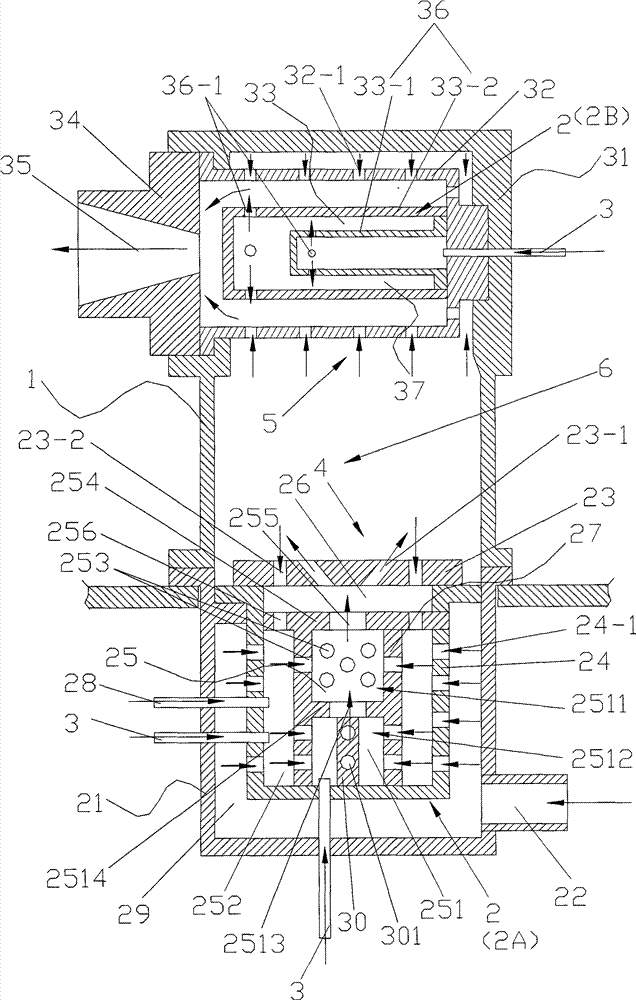

Vertical low-carbon and energy-saving counter burning furnace

InactiveCN102705800ASimple structureImprove performanceSteam generation heating methodsSolid fuel combustionCombustionEngineering

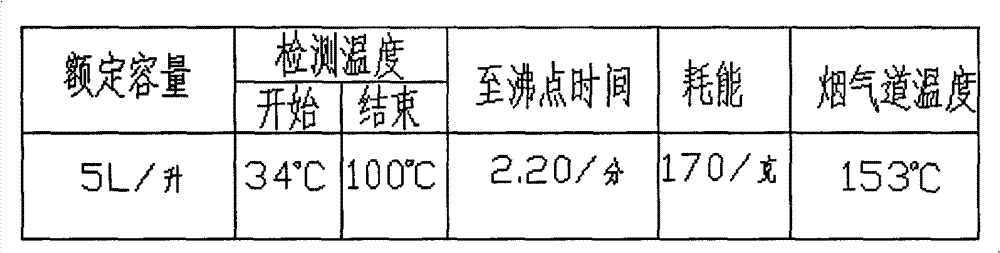

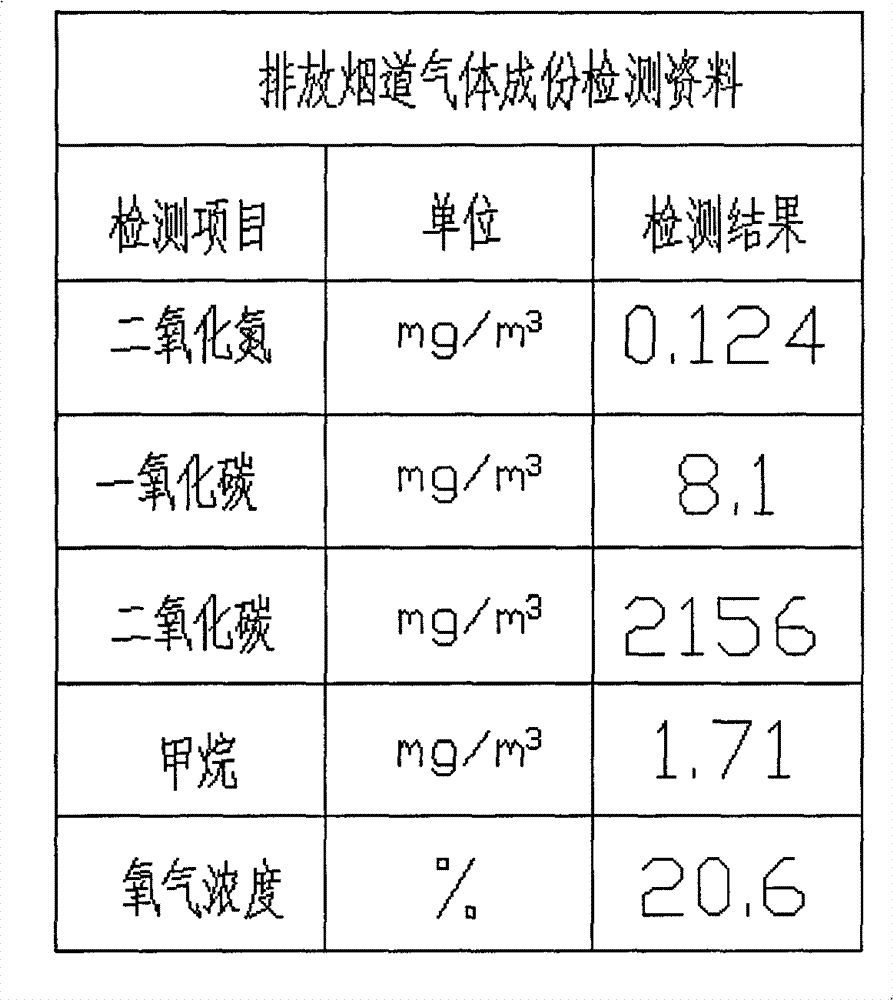

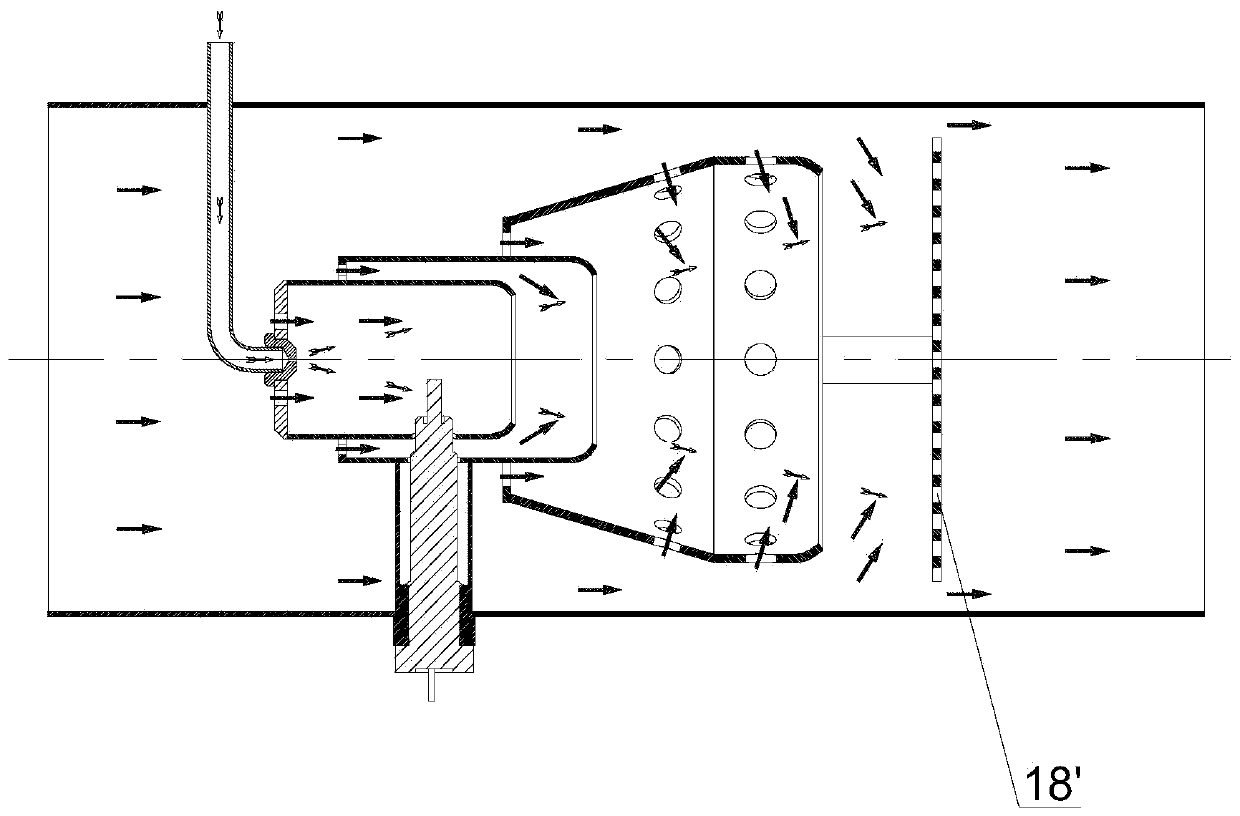

The invention discloses a vertical low-carbon and energy-saving counter burning furnace, which comprises a vertical counter burning furnace pipe and a large horizontal furnace pipe. The vertical counter burning furnace pipe is arranged on the middle lower part in a counter burning furnace body, the vertical section of the vertical counter burning furnace pipe is inverted-'T'-shaped, the large horizontal furnace pipe is arranged on the middle upper part in the counter burning furnace body, the two furnace pipes are communicated with each other by a plurality of straight fire tubes surrounding the upper part of the vertical counter burning furnace pipe, a flue is arranged on the top of the horizontal furnace pipe and penetrates through the top of the counter burning furnace body to form an afterheat flue outlet, a smoke back-combustion type afterheat apparatus is arranged on one side of the counter burning furnace body and consists of a body and a container, an afterheat flue inlet is formed in the top of the smoke back-combustion type afterheat apparatus and is communicated with the afterheat flue outlet via a flue connecting tube, inverted-fan-shaped water tubes are transversely placed in the vertical counter burning furnace pipe, and horn-shaped water tubes are vertically placed in the horizontal furnace pipe. The invention has the advantages that vertical low-carbon and energy-saving counter burning furnace is compact in structure, high in thermal efficiency, stable in performance and easy to popularize and use, and gasification and combustion are performed directly, the height of the furnace body is selectable, secondary pollution is avoided during dust removal, smoke discharge meets requirements on environment friendliness, and the like.

Owner:卢瑞琳

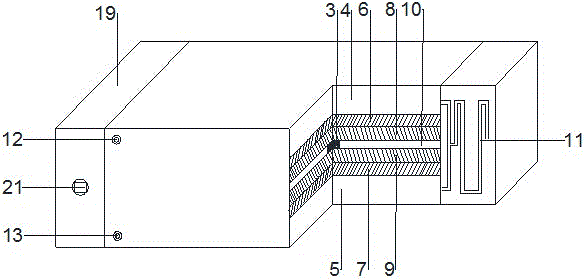

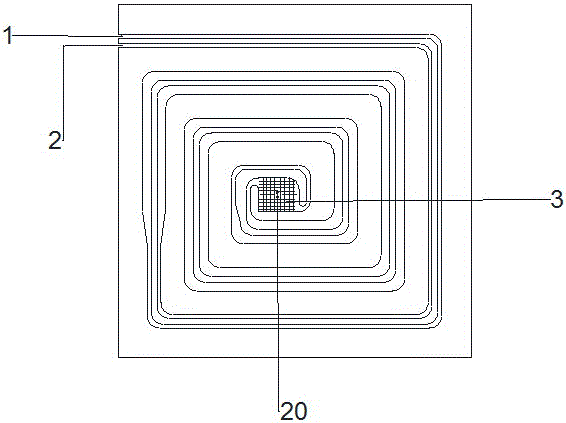

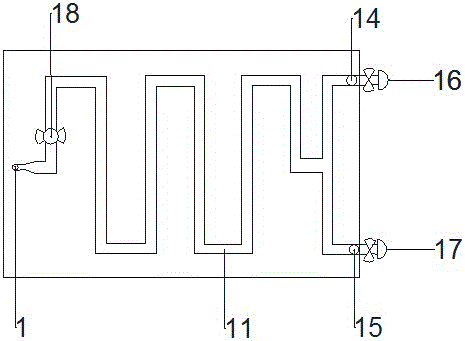

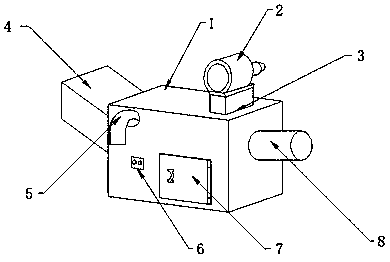

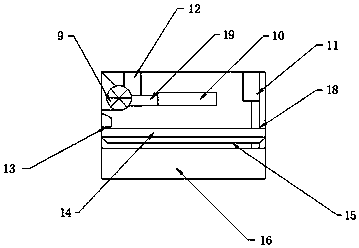

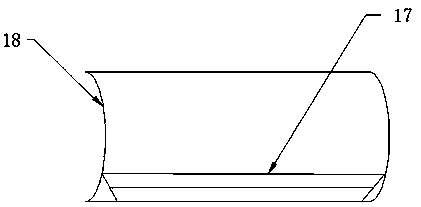

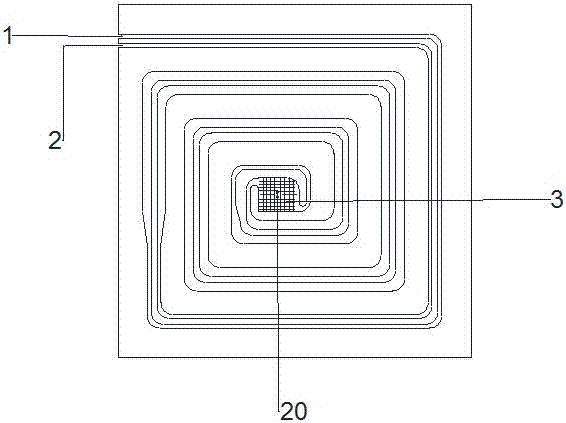

Micro-combustion thermoelectric generator based on porous medium micro-combustion

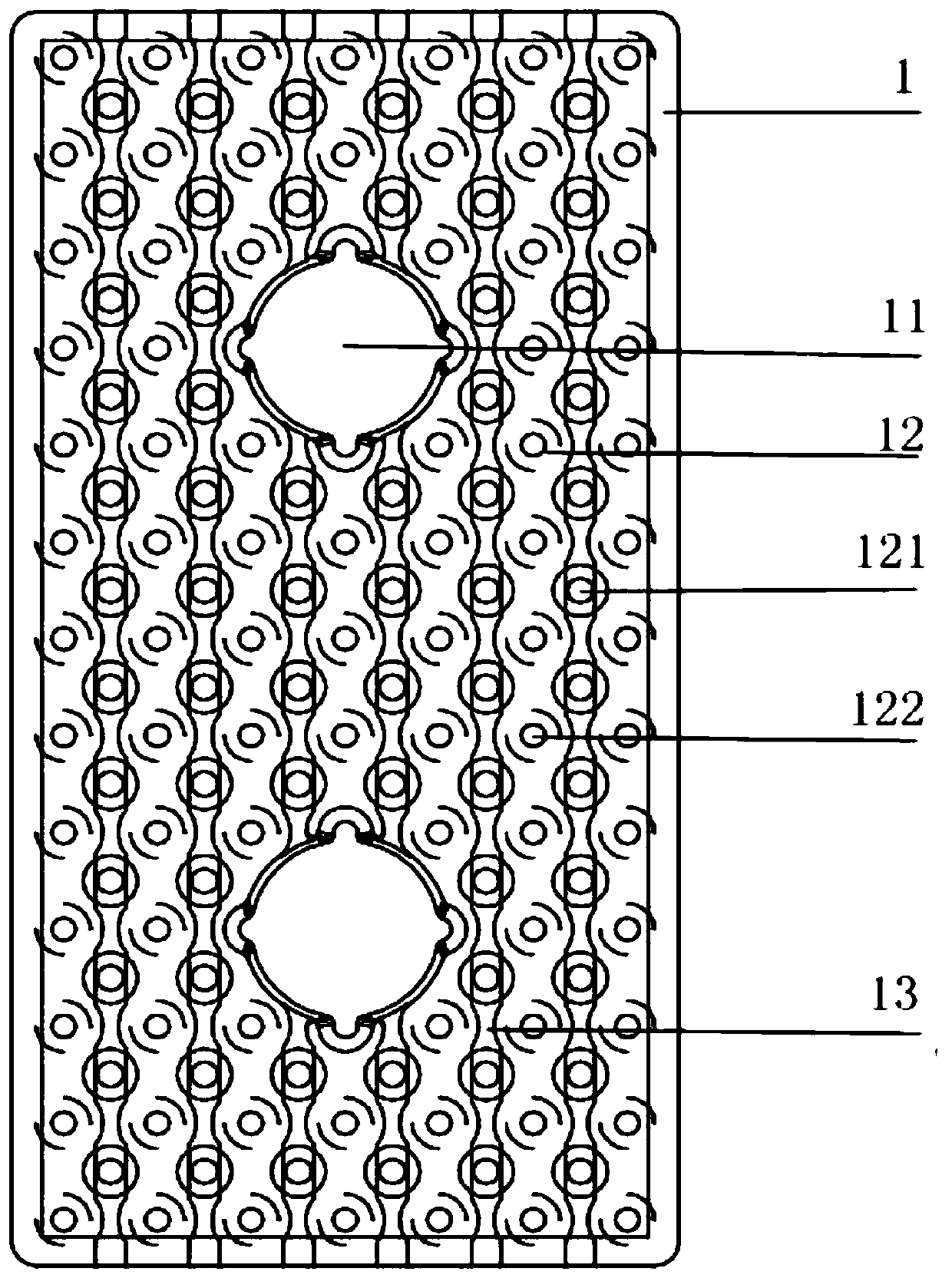

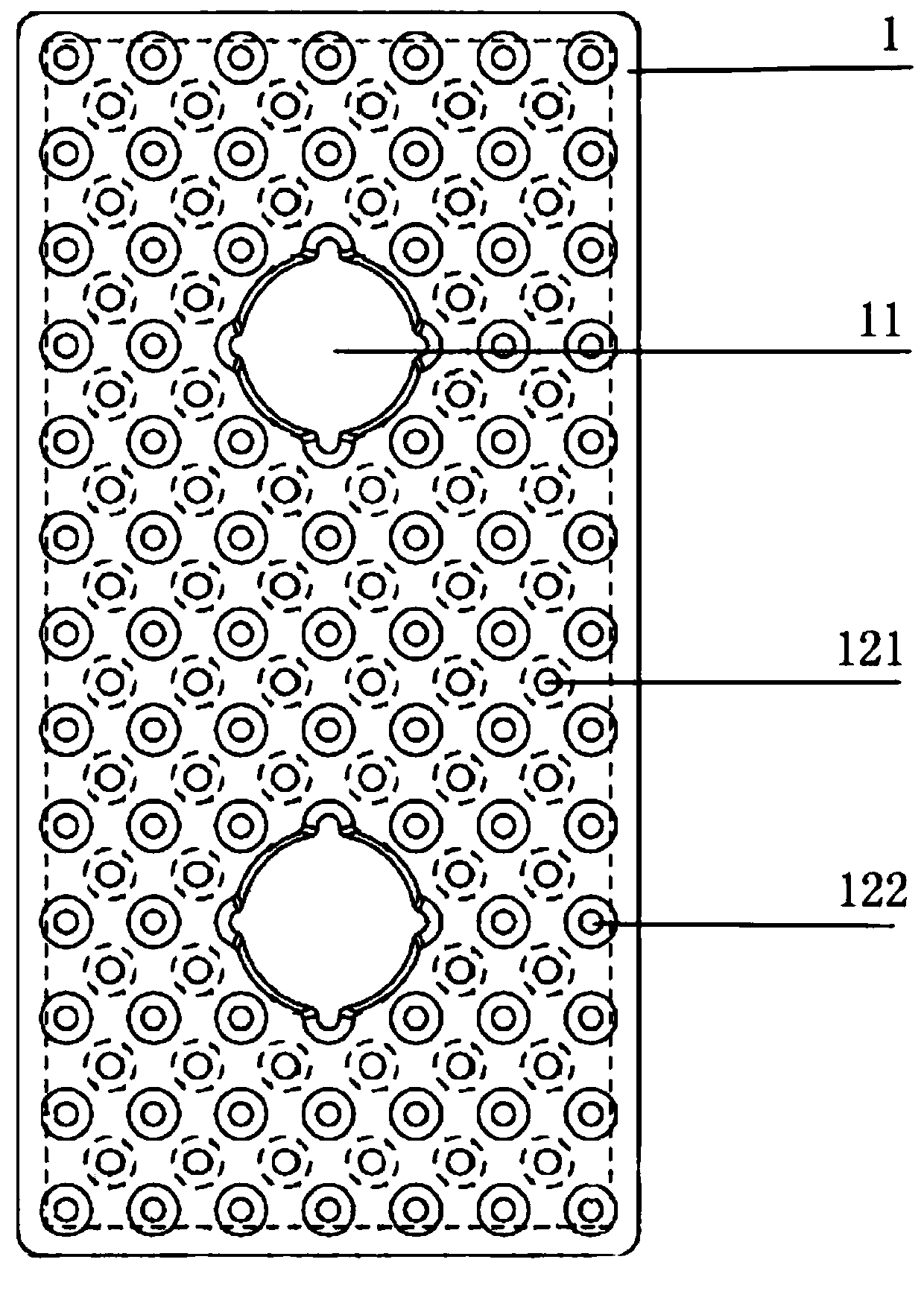

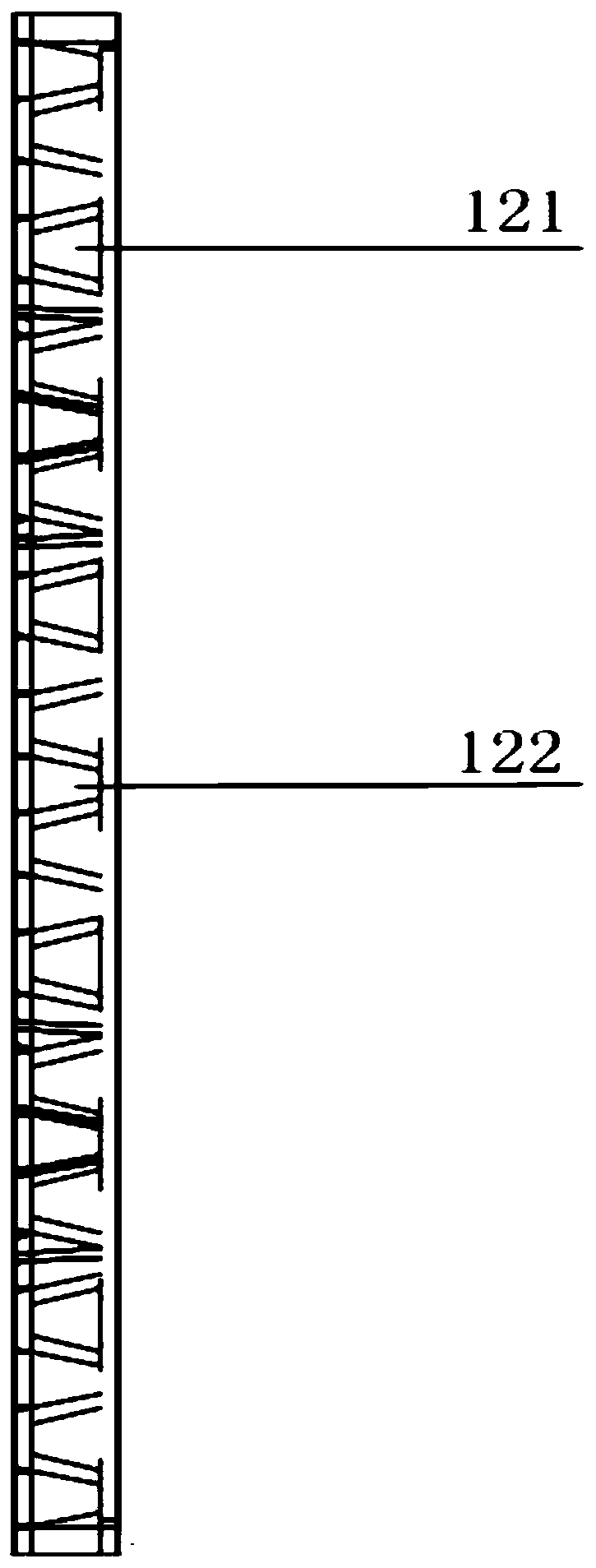

ActiveCN105827152AReduce volumeFix ignition problemsIndirect carbon-dioxide mitigationGenerators/motorsCombustion chamberPorous medium

The invention discloses a micro-combustion thermoelectric generator based on porous medium micro-combustion. The structure of the micro-combustion thermoelectric generator is displayed in a flake-shape, and is successively formed from top to bottom by a fuel storage layer, an upper thermoelectric generation sheet, an upper thermal insulation layer, a combustion module, a lower thermal insulation layer, a lower thermoelectric generation sheet, and an oxidant storage layer, wherein a combustion chamber is arranged at a hot end of each thermoelectric generation sheet; a gas preheating layer is arranged at a cold end of each thermoelectric generation sheet; the combustion module comprises an inlet channel, an outlet channel and a combustion chamber; the inlet channel is a square double helix parallel structure; the center combustion chamber is filled with porous mediums; and the upper and lower thermal insulation layers are filled by mixture of conduction oil and trace inert gas. The micro-combustion thermoelectric generator based on porous medium micro-combustion has the advantages of being high in energy, being small in volume, being light in weight, having no noise, being continuously stable and being low in discharge, and mainly aims at the mini electronic equipment field, and is suitable for the field and for power supply of mini precision portable equipment of the military and aerospace field.

Owner:HANGZHOU DIANZI UNIV

Method for preparing water soluble vanadium-inhibiting agent

InactiveCN101265422AAchieve complete combustionNot easy to break emulsionLiquid carbonaceous fuelsFuel additivesSolubilityWater baths

The invention relates to a method for preparing a water-soluble vanadium inhibitor. Firstly, a nonionic surface active agent is added into MgO powder, and is uniformly ground; diethylene glycol or glycerin and alcohol and ethyl acetate and other diluents are used to prepare water-soluble organic solution with a certain concentration, and stand for a while after being mixed; the processed MgO powder is added into the organic solution to be sealed, sonic oscillation is performed, the MgO powder in the product is adequately separated and segregated, the prepared vanadium inhibitor suspending liquid is heated and stands for a while in an aqueous thermostat, and then the vanadium inhibitor with good dispersilbility and water solubility can be obtained. The method of the invention is simple, and the prepared vanadium inhibitor has the advantages that the magensium content is high, the stability is good, the clinker after being burnt is loose and is easy to be cleaned, and the output recovery is good.

Owner:SHANGHAI JIAO TONG UNIV

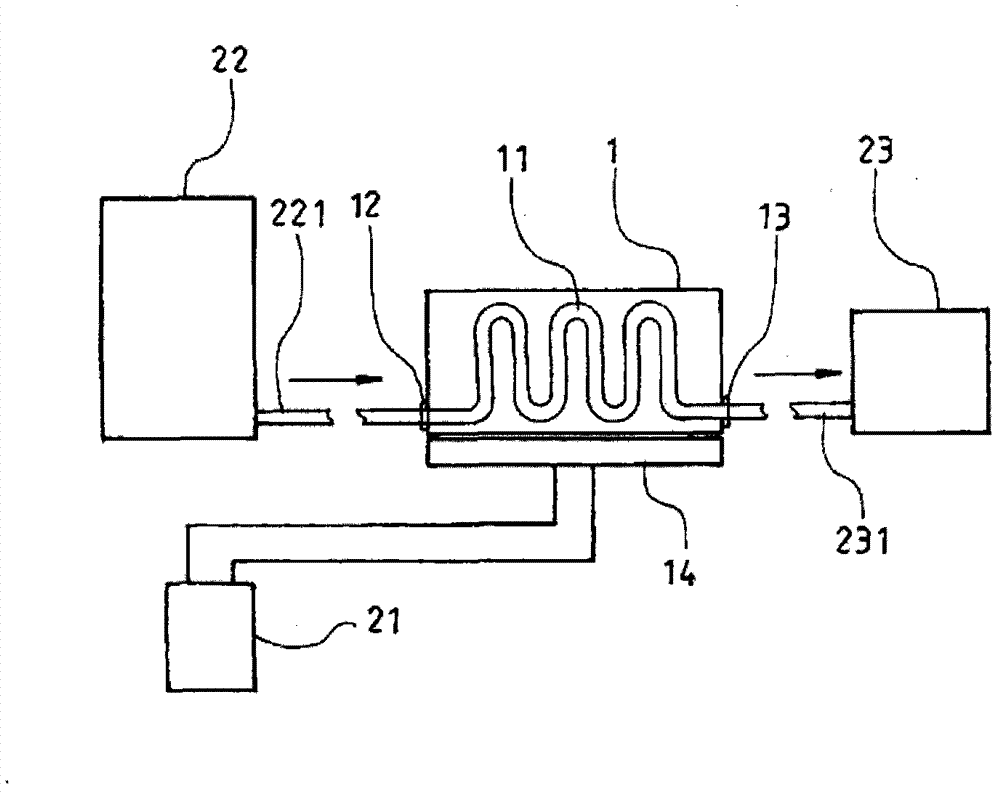

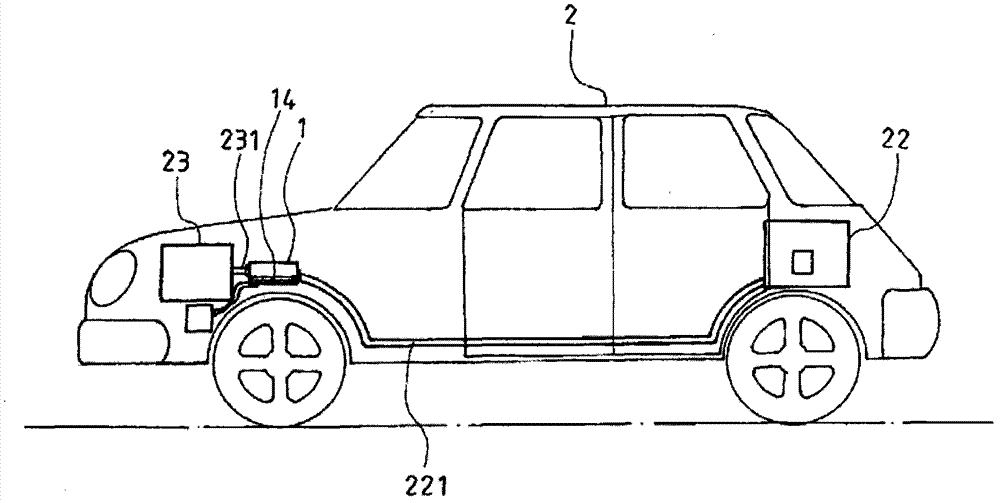

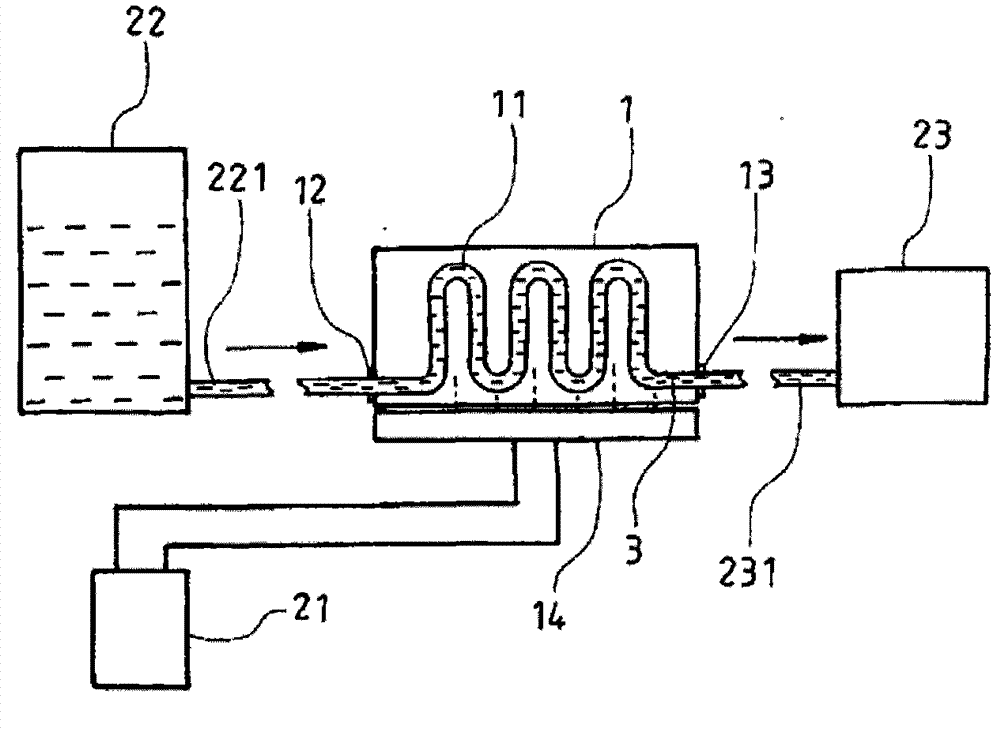

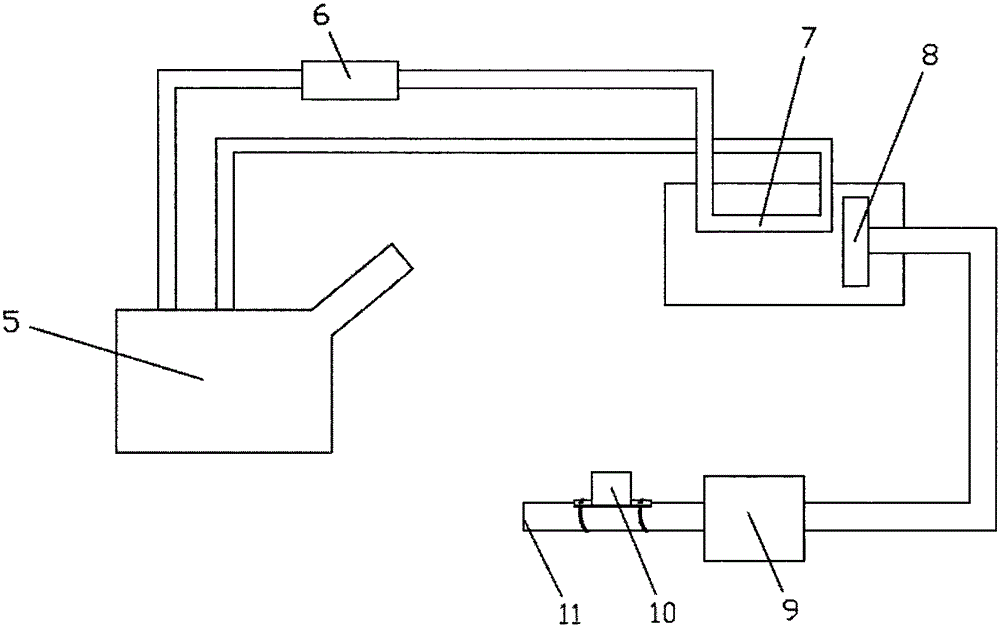

Fuel-saving and carbon-reducing method for fuel use of transportation tool

InactiveCN102817751AVaporization fastAchieve complete combustionInternal combustion piston enginesThermal treatment of fuelCombustionFuel tank

The invention discloses a fuel-saving and carbon-reducing method for fuel use of a transportation tool. According to the method, a heat treatment unit is arranged, a circuitous through pipe is arranged in the heat treatment unit, an input portion and an output portion are arranged at two ends of the through pipe respectively, and an electrical heating element is arranged at the bottom of the heat treatment unit or the through pipe is circled at an exhaust pipe (or an intrinsic heat source) of the transportation tool. The electrical heating element can be connected to an accumulator or a generator of the transportation tool, a fuel tank of the transportation tool is connected to the input portion of the heat treatment unit through a pipe, and the output portion is connected to an engine of the transportation tool through another pipe. Fuel oil in the fuel tank is heated by heat of the electrical heating element or the exhaust pipe (or the intrinsic heat source) when flowing through the heat treatment unit, so that the fuel oil is heated for atomization before sprayed to the engine, volatilization and vaporization of the fuel oil are rapider, complete combustion is achieved, and further fuel-saving and carbon-reducing effects are achieved.

Owner:吴文镇

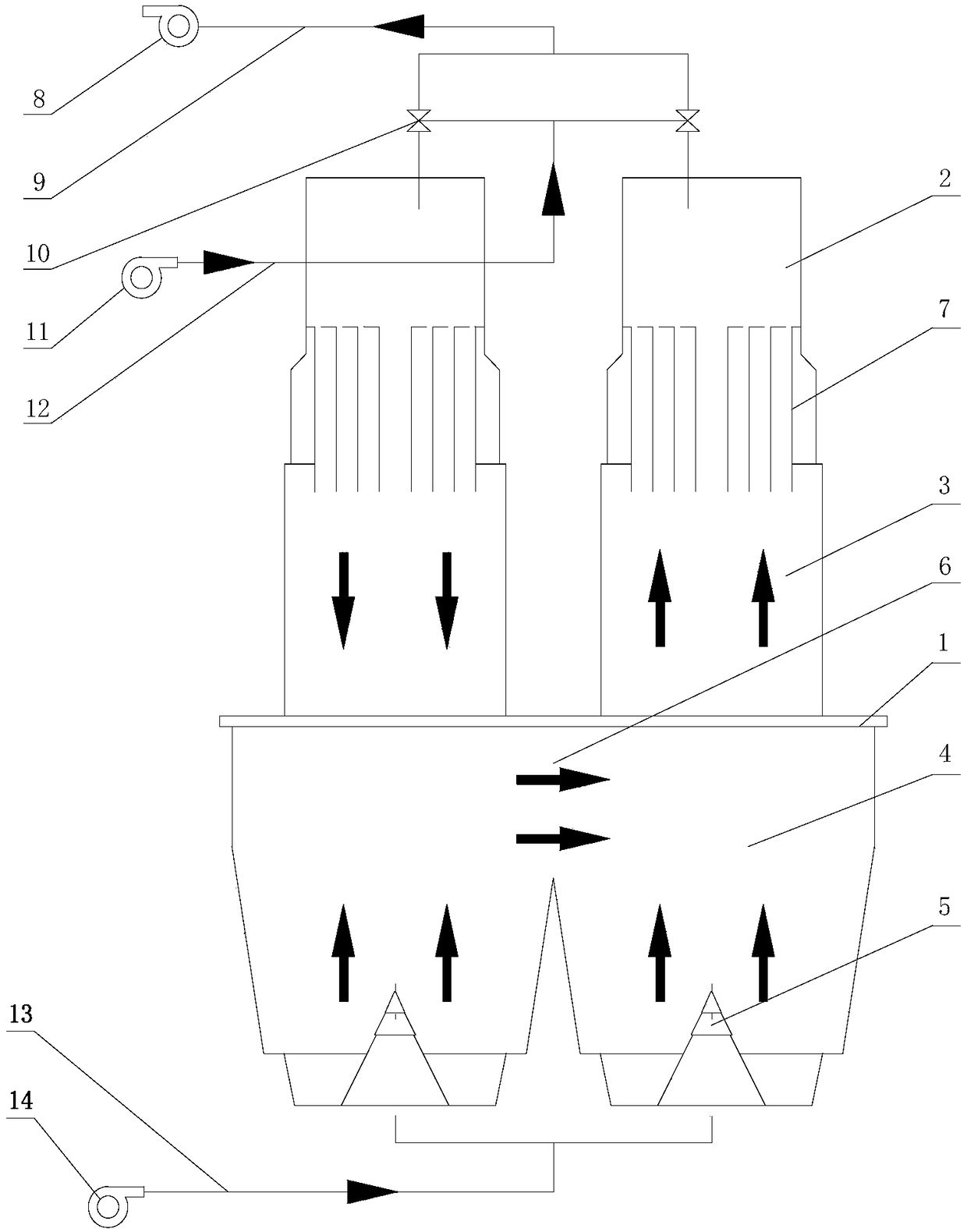

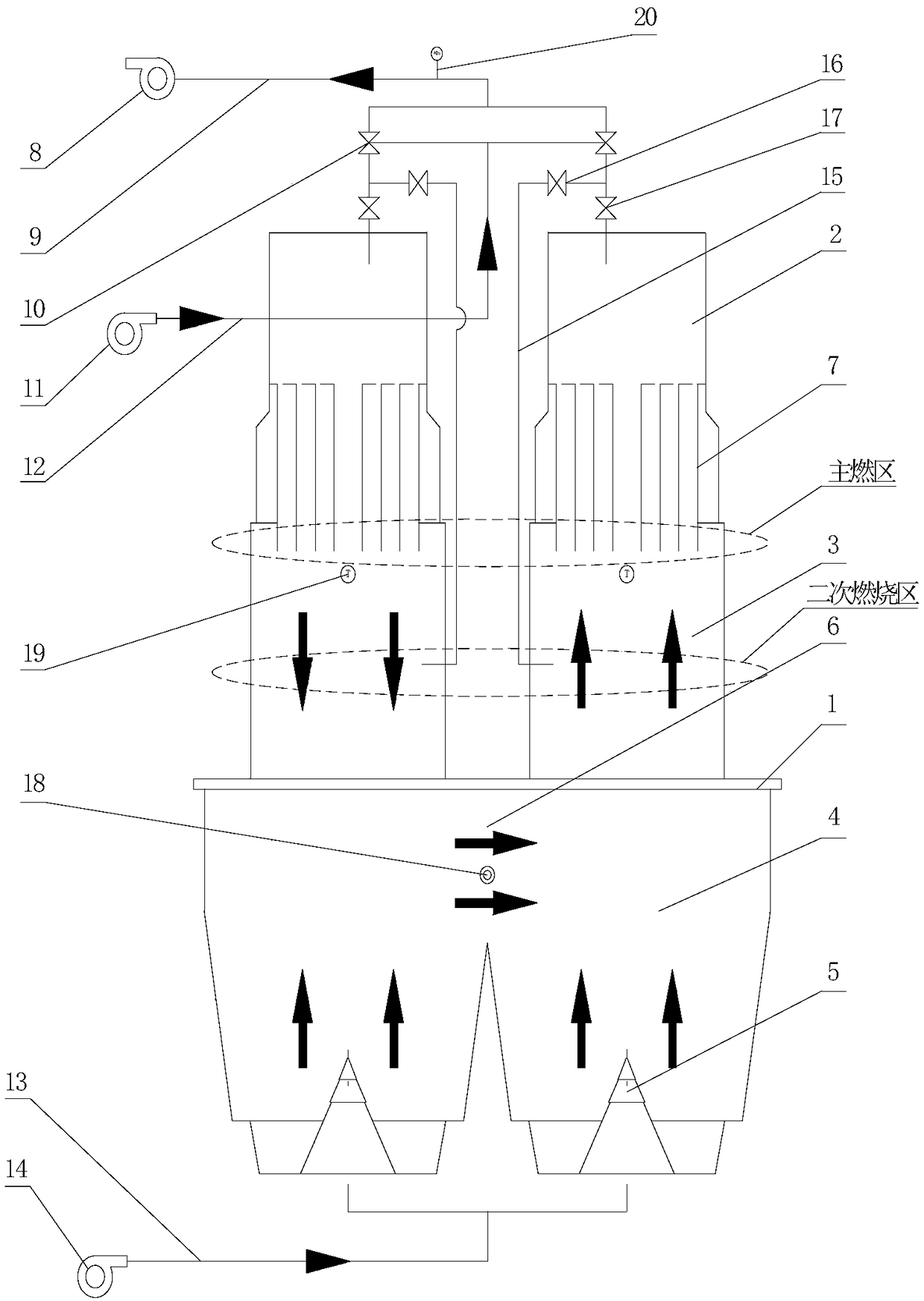

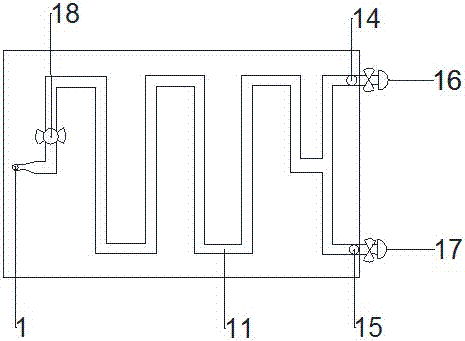

Automatic-switching heat accumulation type gas burner

InactiveCN102563653AFull heat exchangeBurn completelyIndirect carbon-dioxide mitigationGaseous fuel burnerInlet temperatureGas burner

The invention provides an automatic-switching heat accumulation type gas burner, wherein two single gas burners with the same structure are arranged at two sides of a furnace body; when one burner burns, the other burner accumulates heat; the automatic reversing of the burner is achieved by an external switching valve; the switching of a low-temperature operating mode and a high-temperature operating mode, the low-temperature high-speed burning and the high-temperature oxygen-lacking burning and smoke reflux technology are adopted, so that the heat exchange is full, the inlet temperature of the combustion-supporting air is improved greatly, the temperature of the exhausted smoke is reduced, the complete burning is achieved, and the low NOx emission, automatic switching of high and low temperature operating modes, high-efficient and energy-saving self heat accumulation function are achieved.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

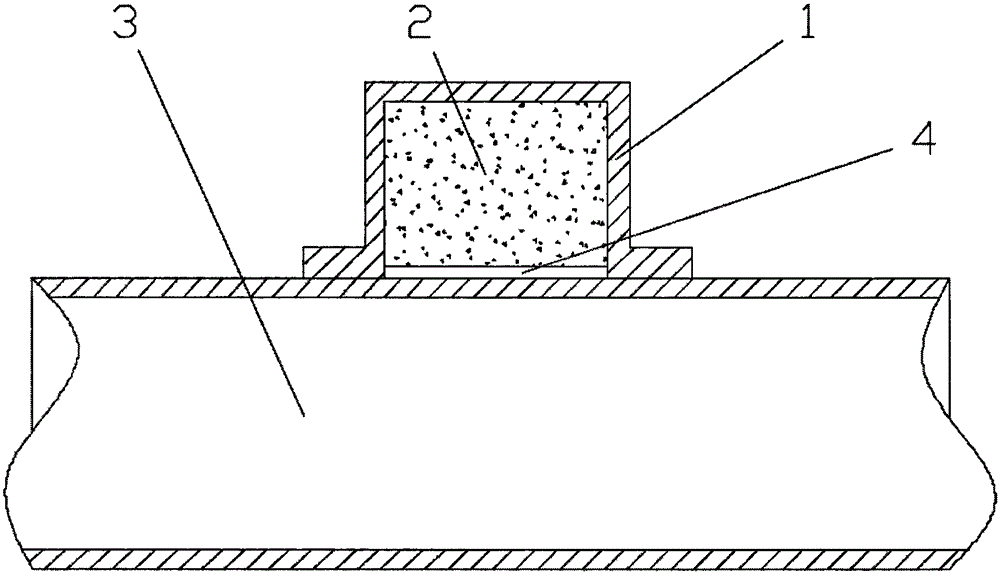

Auxiliary device for enhancing engine performance

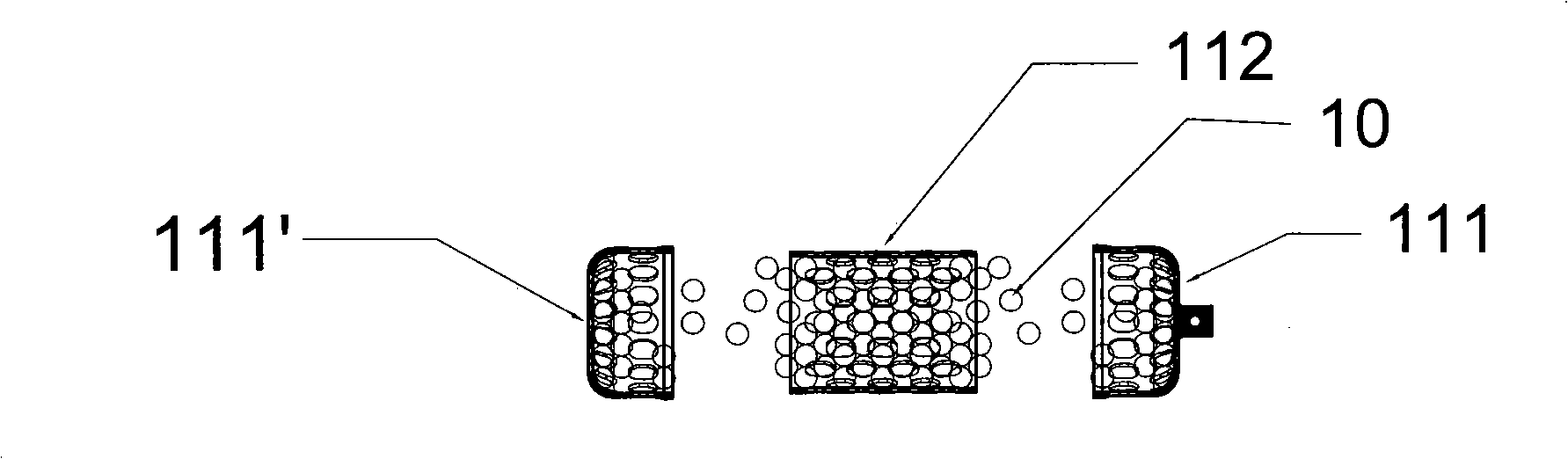

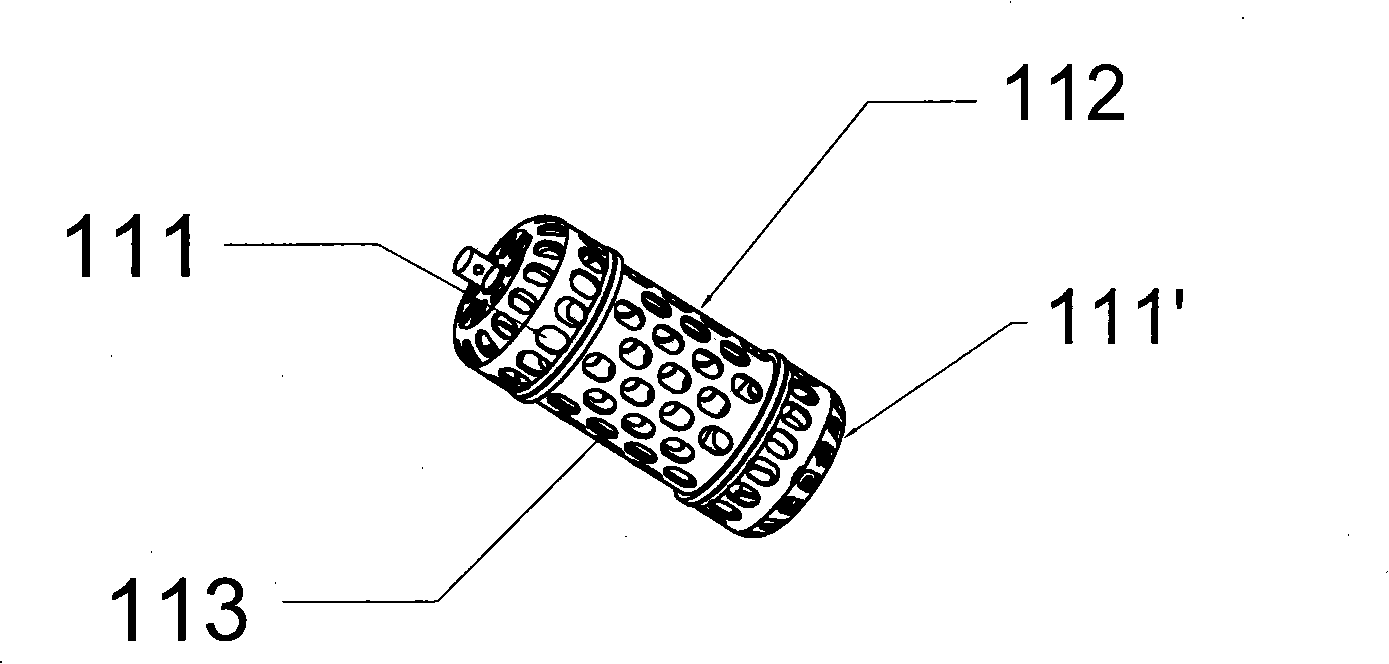

InactiveCN101493056ALower flash pointAchieve complete combustionInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustion chamberComposite ceramic

The invention relates to a device capable of improving engine performance, in particular to a combustion facilitating and energy-saving and discharge-reducing device which can activate fuel oil molecule, lower fuel oil burning point, and improve a cooling device and an air device. The assisting device capable of improving engine performance comprises an oil activating component, an oil stimulating component, a cooling water activating component, and an anion generating and air eddy pressurizing component; wherein, the oil activating component, the oil stimulating component and the cooling water activating component are mainly composed of mineral composite ceramic balls, which can generate far infrared rays, and a hollow package body; the anion generating and air eddy pressurizing component is mainly prepared by minerals, which can generate far infrared rays, and tourmaline. The device, on one hand, uses the energy of far infrared rays to scatter molecular group of fuel oil and cause the scattered oil molecule group to be effectively mixed with oxygen to achieve the aim of complete combustion, and on the other hand, uses the energy of far infrared rays to scatter molecular group of cooling water to enhance cooling effect of a combustion chamber of a cylinder and improve the working efficiency of the engine.

Owner:董立民

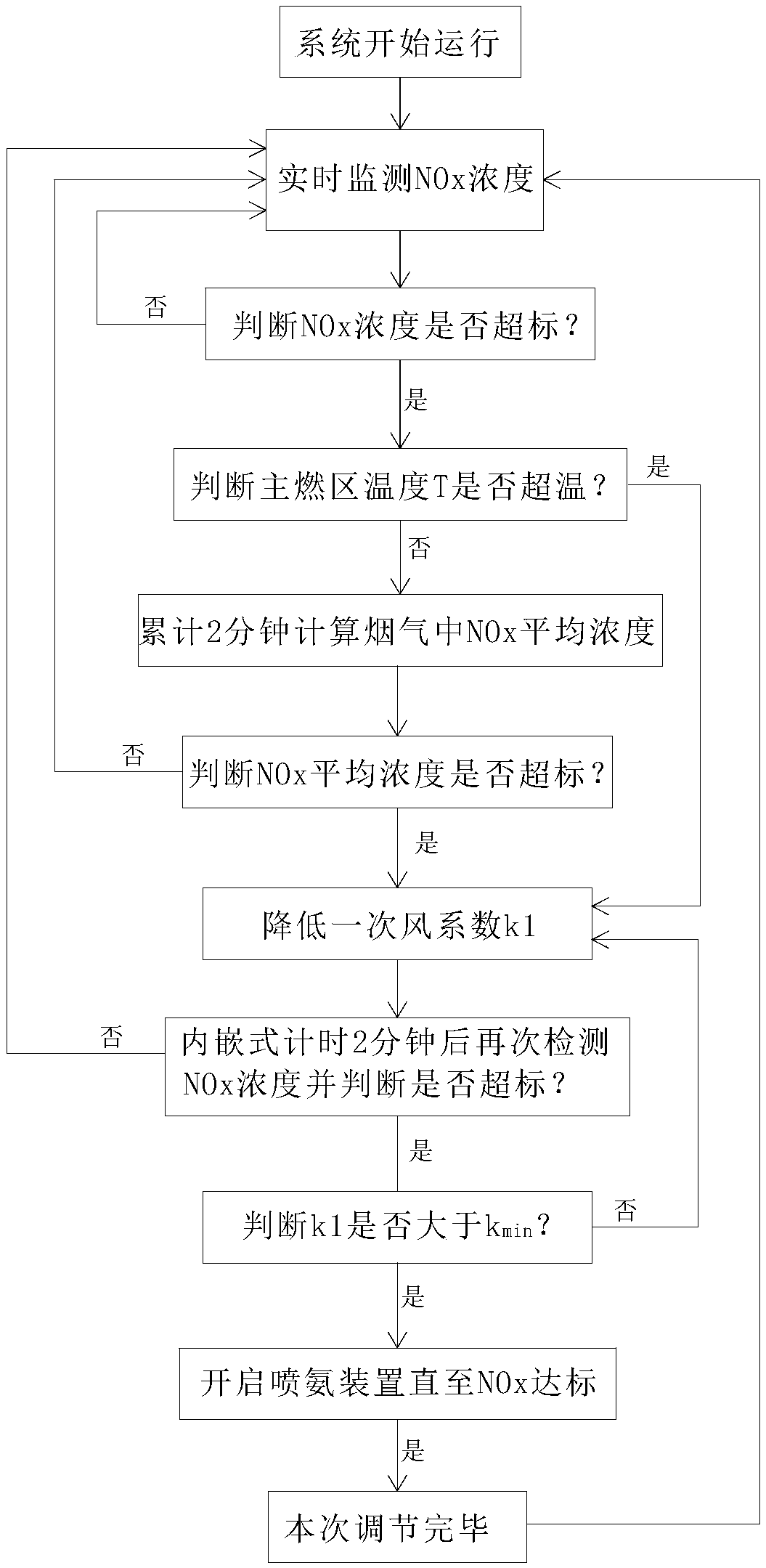

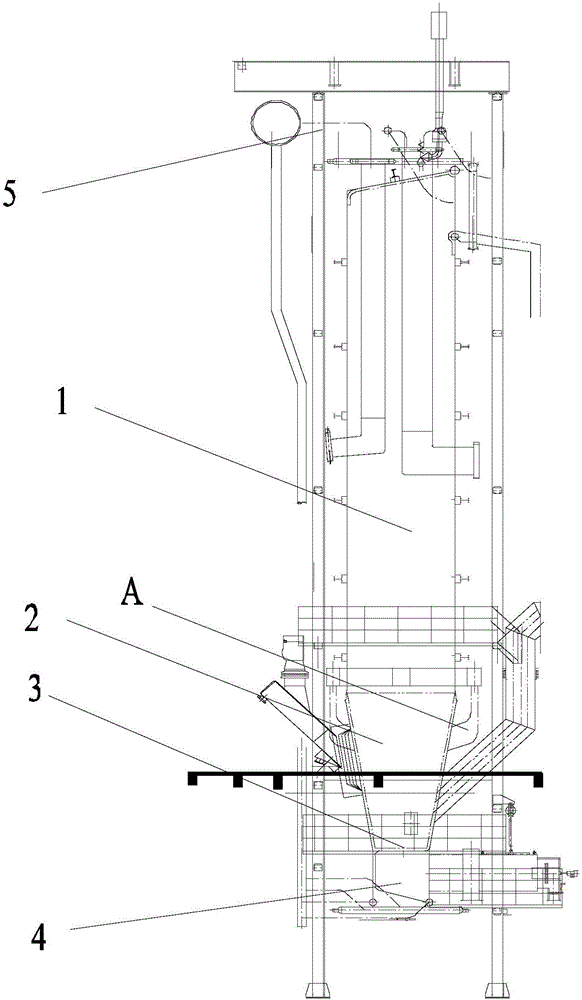

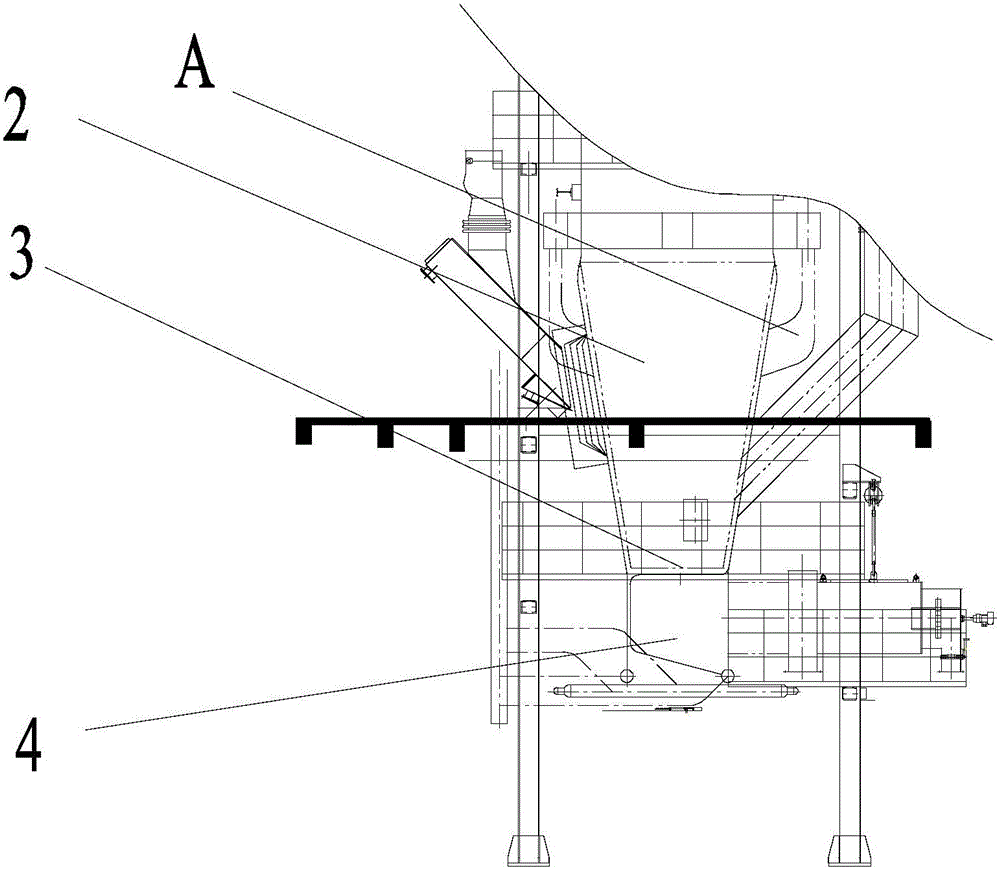

Low NOx clean combustion type lime production method and device as well as control method of low NOx clean combustion type lime production device

InactiveCN109111132ASolve the problem of excessive emissionsReduce contentMaintainance of heating chambersCharge treatment typeEngineeringAir–fuel ratio

The invention discloses a low NOx clean combustion type lime production method and a device as well as a control method of the low NOx clean combustion type lime production device. The production method comprises the following steps that combustion-supporting wind required for calcining quicklime is divided into primary air and over fire air, and the primary air is input from the upstream of a fuel input portion to enable a region, corresponding to the fuel input portion, to form a main combustion region for calcining the quicklime; and the over fire air is input from the downstream of the fuel input portion to form a secondary combustion region for calcining the quicklime at the downstream of the main combustion region. For the lime production method and device as well as the control method, through deviation of air-fuel ratio equivalence, combination process control from NOx production sources can be performed to lower the content of NOx, and the problem of too high NOx emission in the lime production process and various disadvantages caused by adopting a subsequent denitration technology are solved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

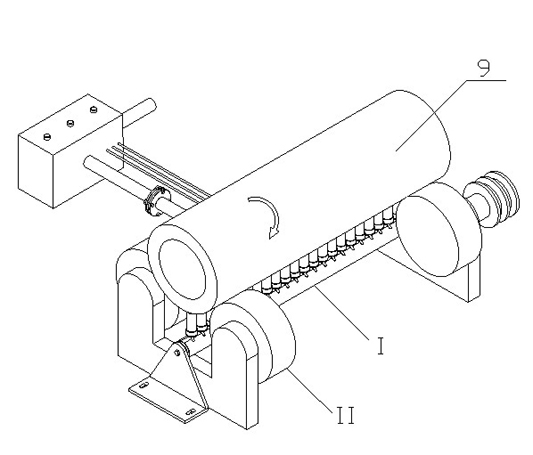

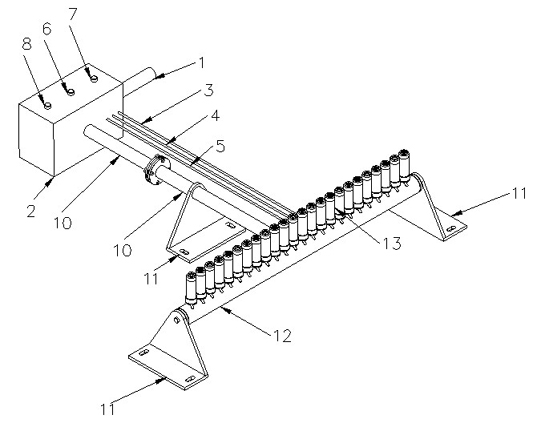

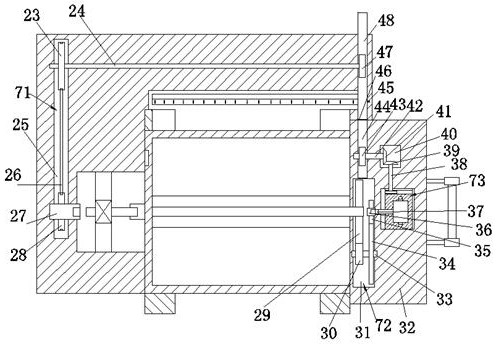

Intelligent heating system for centrifugally casting ultra-long thin-walled slim tubes

The invention discloses an auxiliary intelligent heating system which uses clean energy such as natural gas or liquefied petroleum gas and the like on the traditional centrifugal casting equipment. The system comprises a control box, a gas inlet pipe, a fuel gas output pipe, a gas mixing pipe, an ignition system, a fixing seat and riser burners, wherein the two ends of the gas mixing pipe are fixed to the fixing seat; a plurality of riser burners are uniformly distributed on the gas mixing pipe; the gas mixing pipe is connected with the control box by the fuel gas output pipe; the control box is connected with the gas inlet pipe; and the ignition system, an ignition switch, a fuel gas switch and an electric control switch are arranged on the control box. The heating system has the advantages of low heat loss and uniform heating and ensures that the temperature of molten steel maintains constant during centrifugal casting; and by adopting intelligent control, the temperature of the molten steel is prevented from dropping too fast, the requirement of a process molten steel temperature during the centrifugal casting is met, a heat insulating paint, a heat insulating agent and the like are not needed, the efficiency of the centrifugal casting and the quality of products are improved, and the bottleneck problem of process temperature control in the process of casting ultra-long thin-walled slim tubes in domestic industries is radically solved.

Owner:周士友

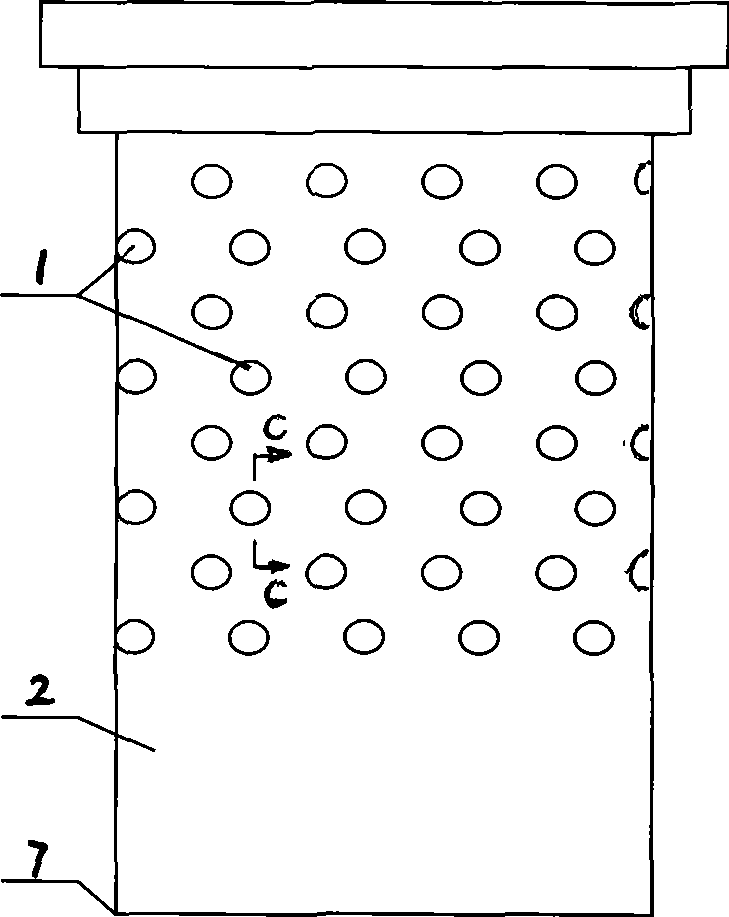

Fire grate of boiler

The invention relates to a first grate of a boiler, wherein the first grate is arranged at the bottom of the boiler and is used for slagging. The fire grate is formed by arranging a plurality of independent grate sheets in parallel, and each grate sheet is provided with a plurality of air vents. Each grate sheet comprises the following components in percentage by weight: 8-11 percent of aluminum, 9.5-10.5 percent of silicon, 2-6 percent of chromium, 15-35 percent of carbon steel and the balance of pig iron. Because the first grate is formed by arranging the plurality of independent grate sheets on a burner beam of the boiler in parallel, the single grate sheet is damaged, the damaged sheet needs to be replaced only, so that convenience is brought for maintenance and use. By changing a structure and materials of the fire grate, the ventilation effect in the boiler is good so as to be beneficial to sufficient combustion in the boiler, and the effect of complete combustion can be achieved. The fire grate disclosed by the invention has the advantages of energy saving, boiler body protection property, high temperature resistance, no smelting after the temperature reaches 1200 DEG C, good smoke and dust removal effect and capability of achieving the effects of residual breaking for crushing; and the fire grate has not special requirements on coals and can ensures good combustion even fault coals are fed.

Owner:宽甸满族自治县新兴锅炉机械厂

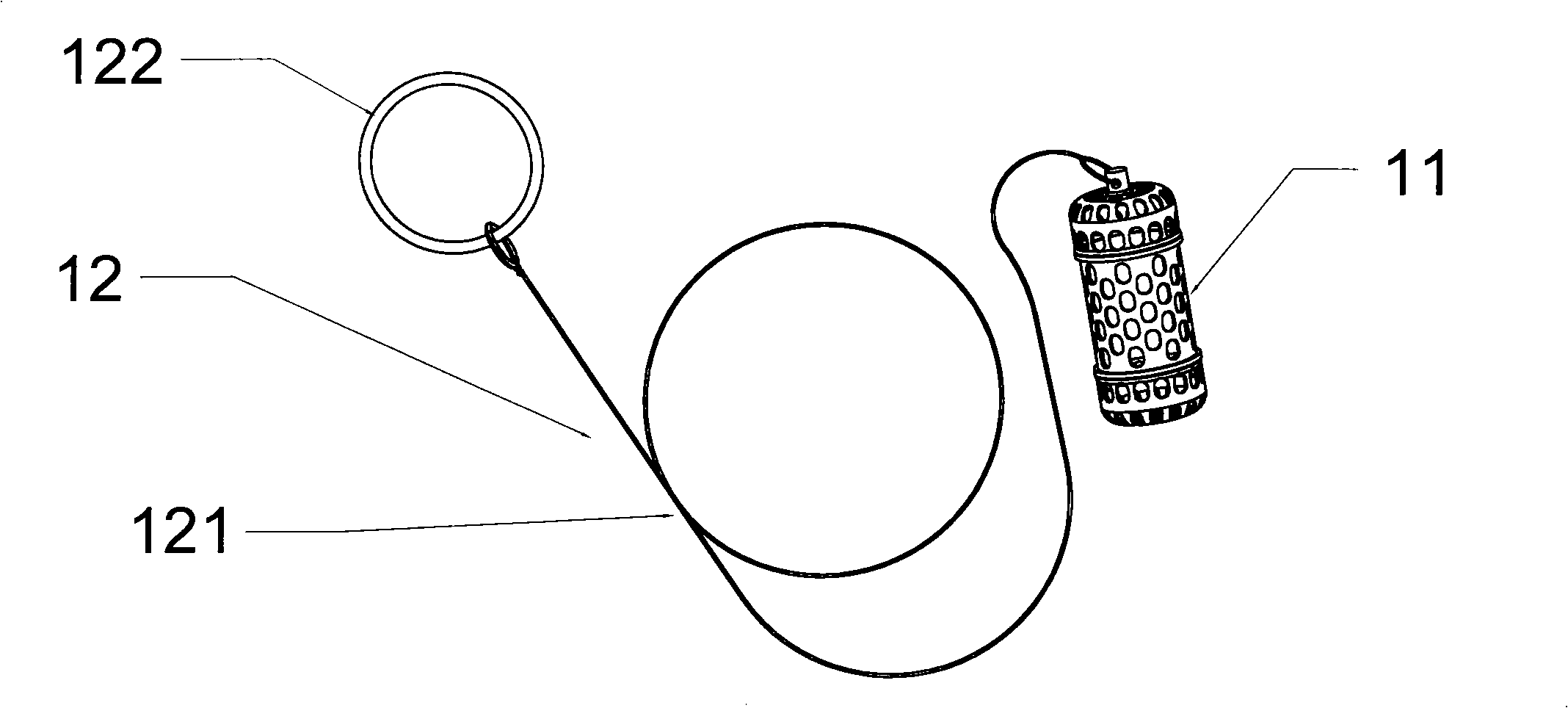

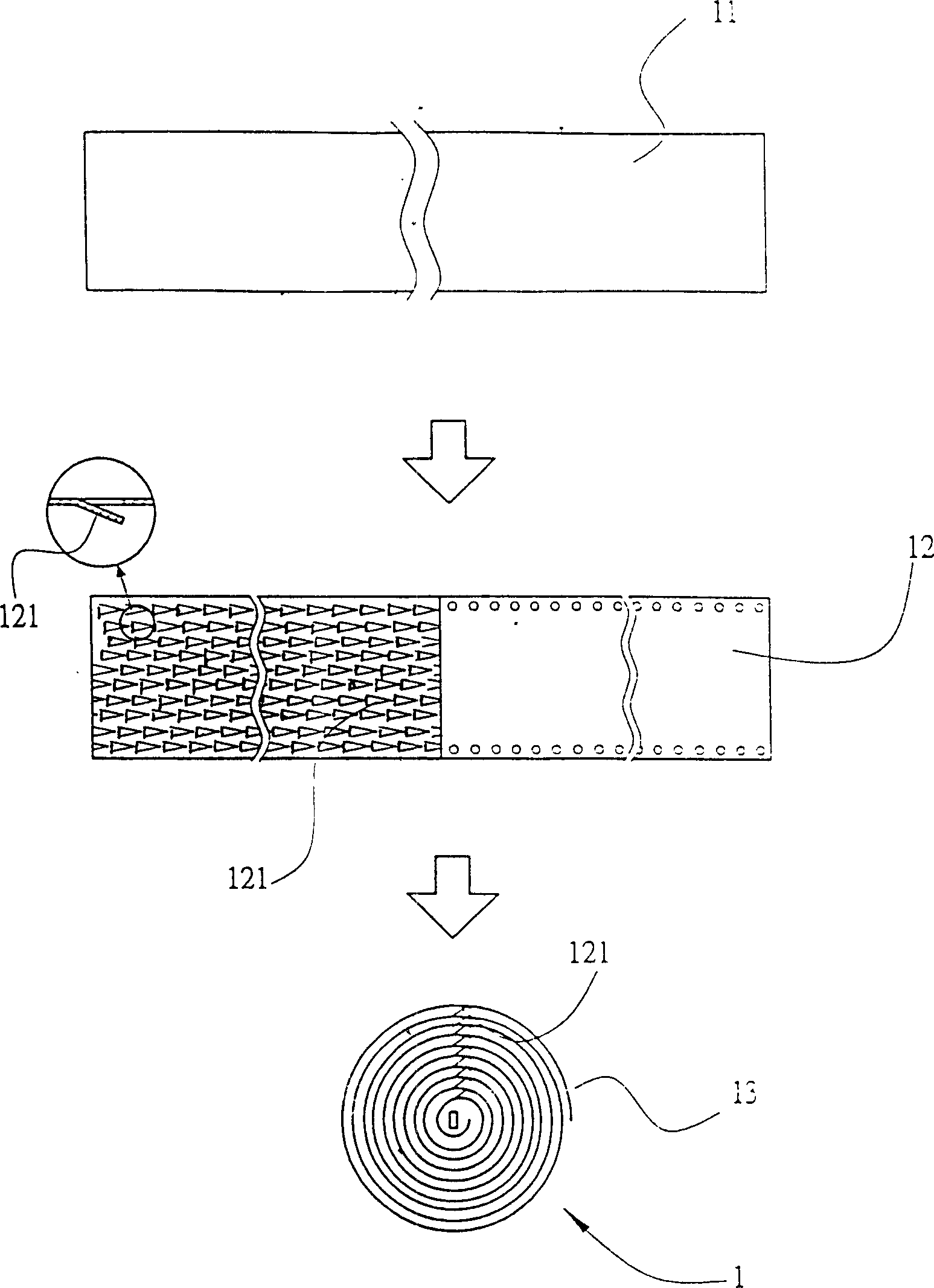

Method for manufacturing energy induction type complete combustion device

InactiveCN1704578AAchieve complete combustionIncrease powerInternal combustion piston enginesCombustion-air/fuel-air treatmentIgnition coilEngineering

This invention relates to a device to make the fuel in combustion engine or external combustion engine completely burn and its preparation method, which comprises air converter, fuel converter and circuit rectifier. Wherein, the air converter is located in air filter or its back air feeder, fuel converter is located on the fuel pipe on the front of fuel feeder or adhered to the fuel case and the circuit rectifier is clamped to lead wire on back of spark coil and electric-distributing plate as well as at front end spark plug, or is directly made muffle covering the plug to completely burn the air and fuel, hereby improving its horsepower.

Owner:林益煌

Oxygen enriching and magnetizing device of air duct of internal combustion engine

InactiveCN105065145AIncrease motivationChange in oxygen concentrationInternal combustion piston enginesCombustion-air/fuel-air treatmentExternal combustion engineTurbocharger

The invention relates to an oxygen enriching and magnetizing device of an air duct of an internal combustion engine. The device comprises a permanent magnet material and a magnetism isolation cover. The permanent magnet material is wrapped in the magnetism isolation cover. The magnetism isolation cover is provided with a magnetic action face formed by gaps. The device is arranged at any position from the front end of a gasoline air intake inlet to a throttle valve of the internal combustion engine passing through a gasoline air cleaner and a turbocharger. The device is arranged at any position from a diesel air intake inlet to a diesel air intake manifold passing through a diesel air cleaner and the turbocharger. According to the oxygen enriching and magnetizing device, the oxygen in the air is enriched, so that the combustion rate of the internal combustion engine is improved, the utilization rate of thermal efficiency of the internal combustion engine is increased, the effective power of the internal combustion engine is improved, exhaust gas emission is lowered, the work noise of the internal combustion engine is lowered, energy consumption is lowered, accumulated carbon in a combustion chamber is cleared to protect the internal combustion engine, and the service life of the internal combustion chamber is prolonged.

Owner:嘉兴市健杰内燃机零件有限公司

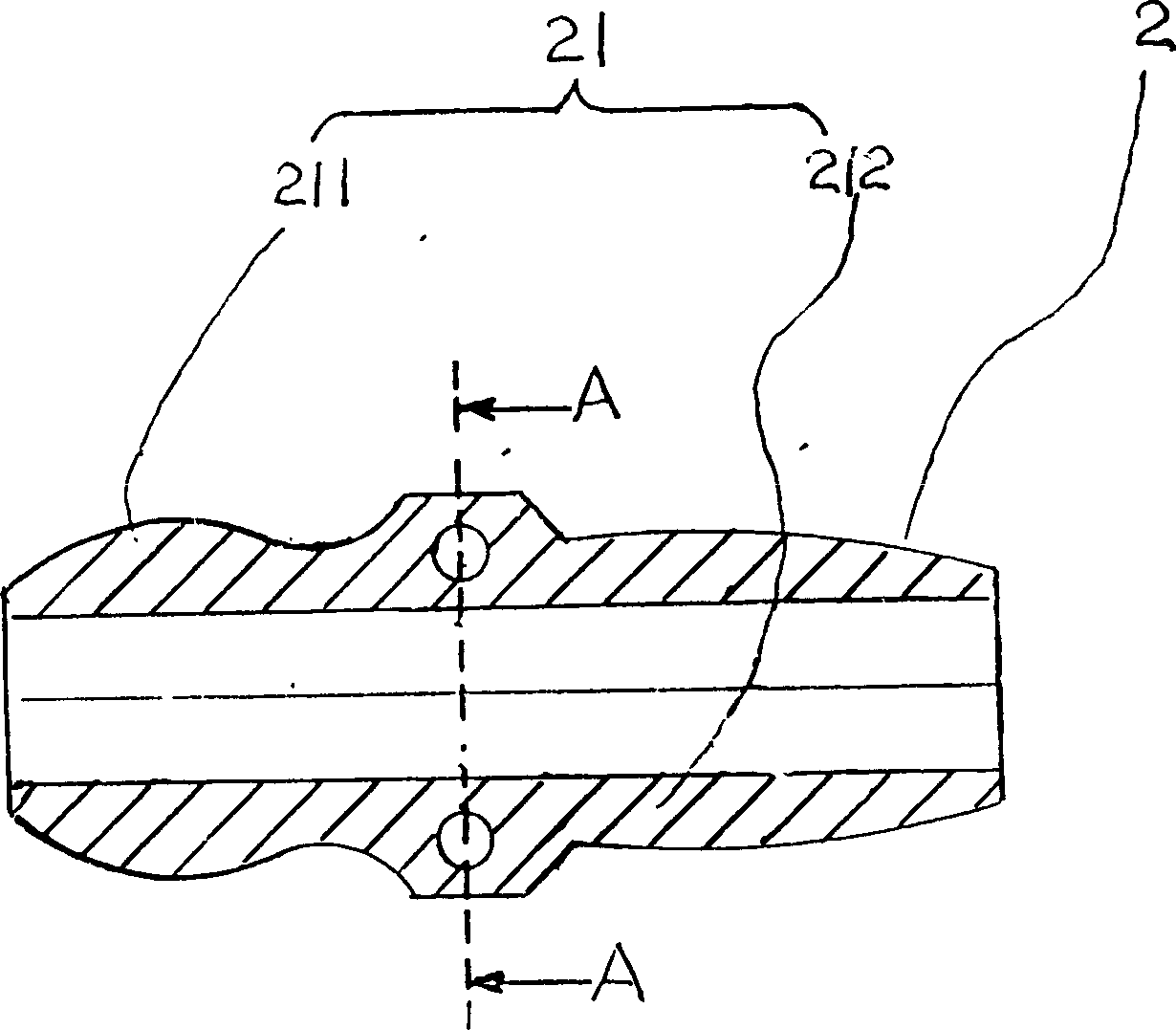

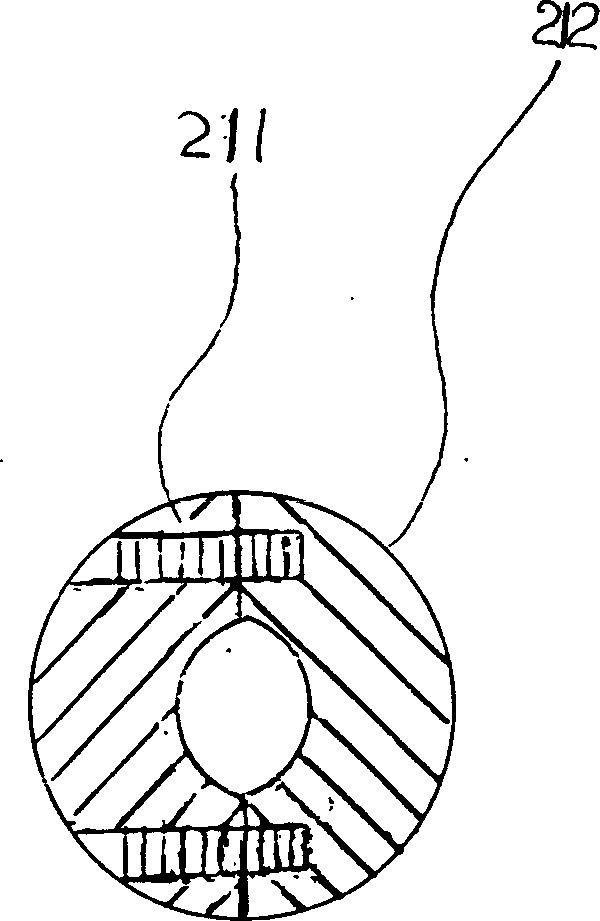

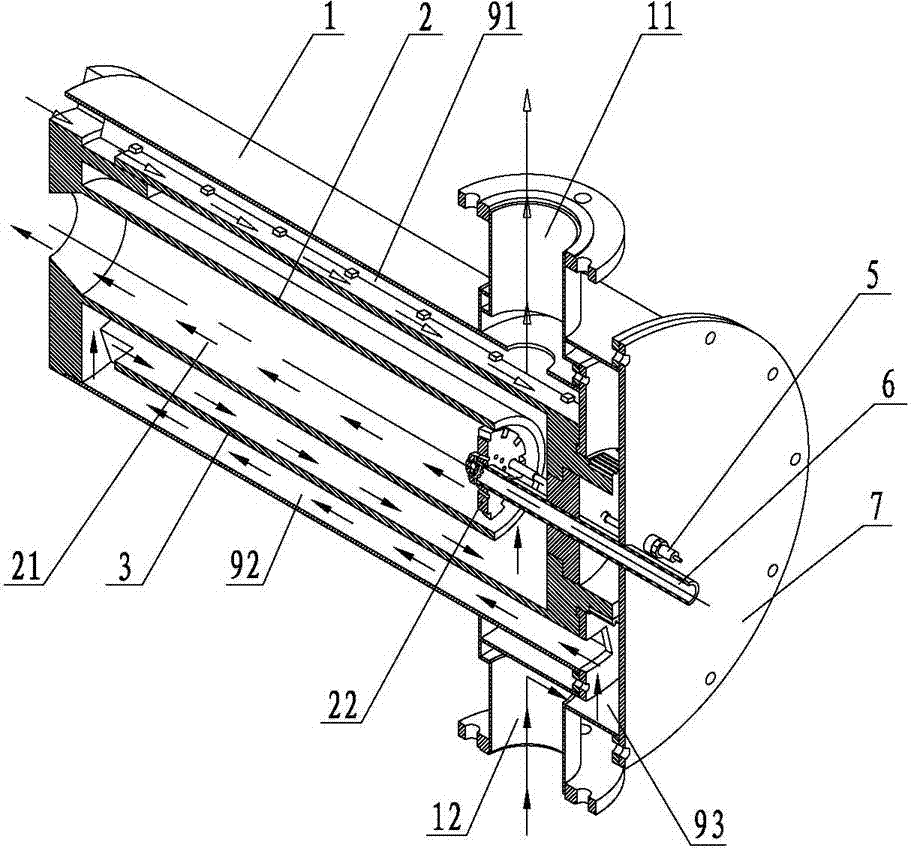

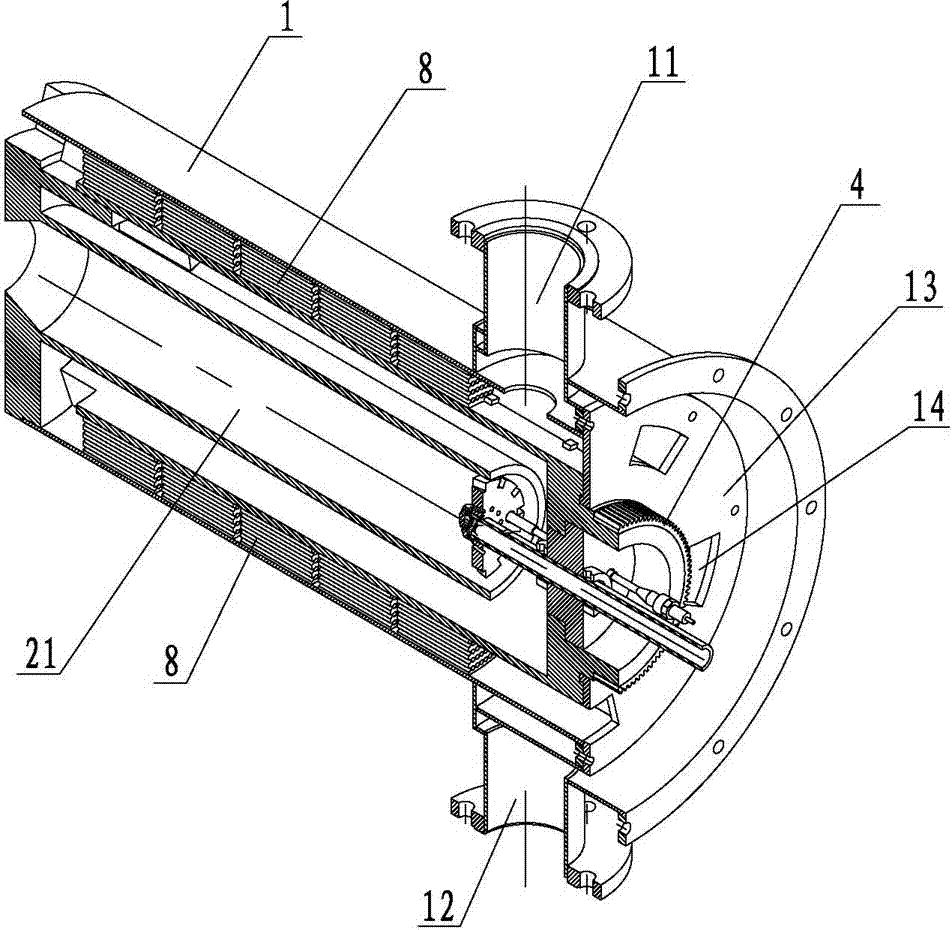

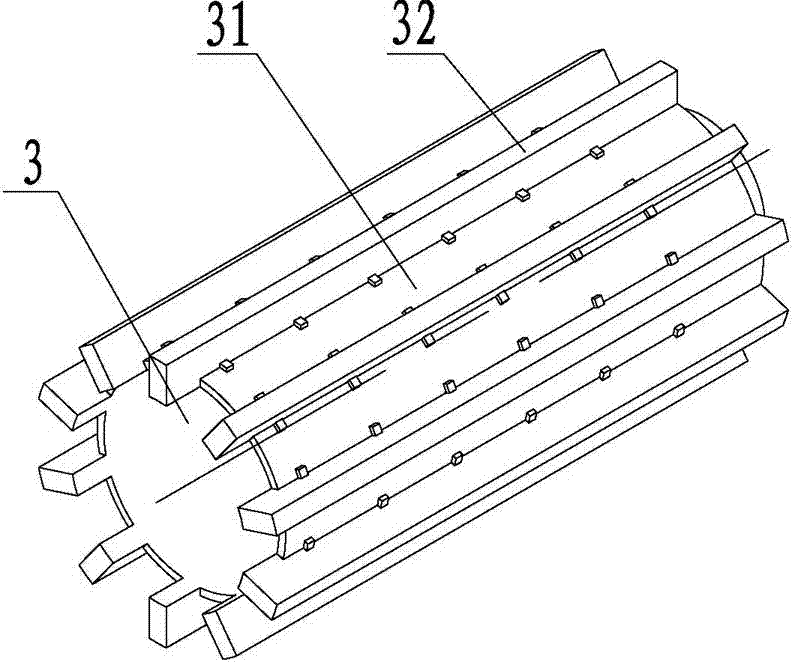

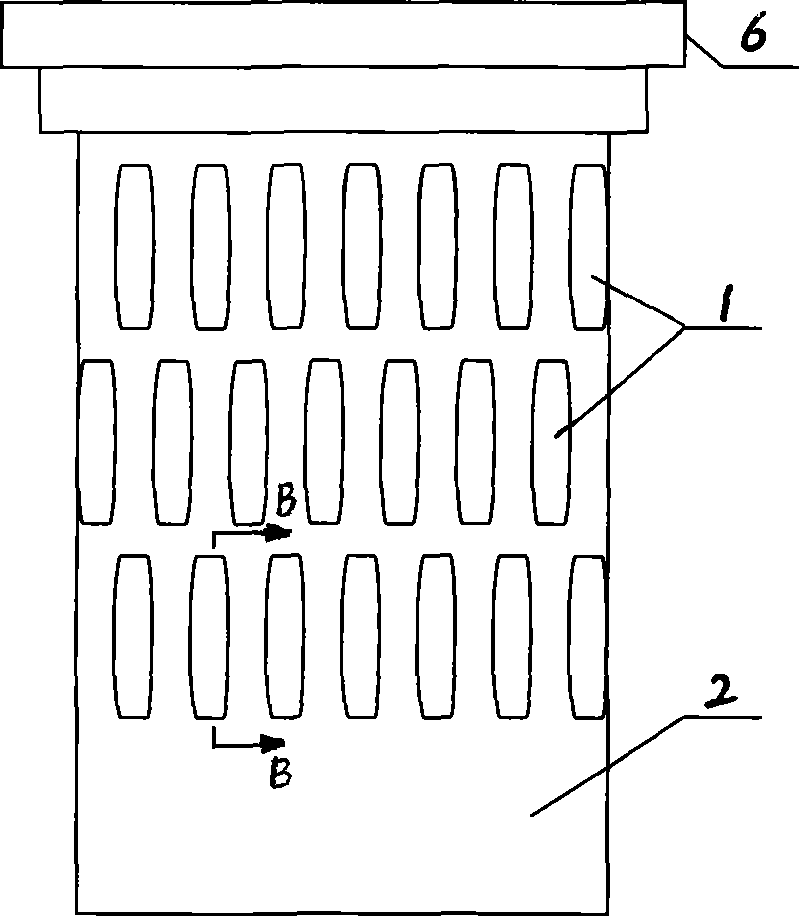

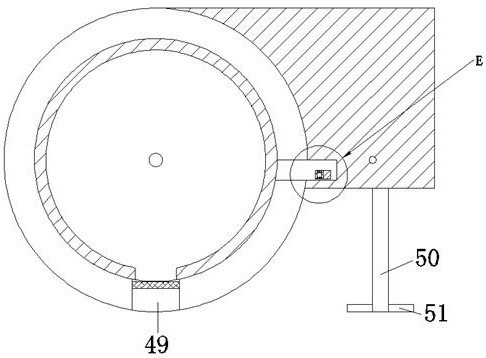

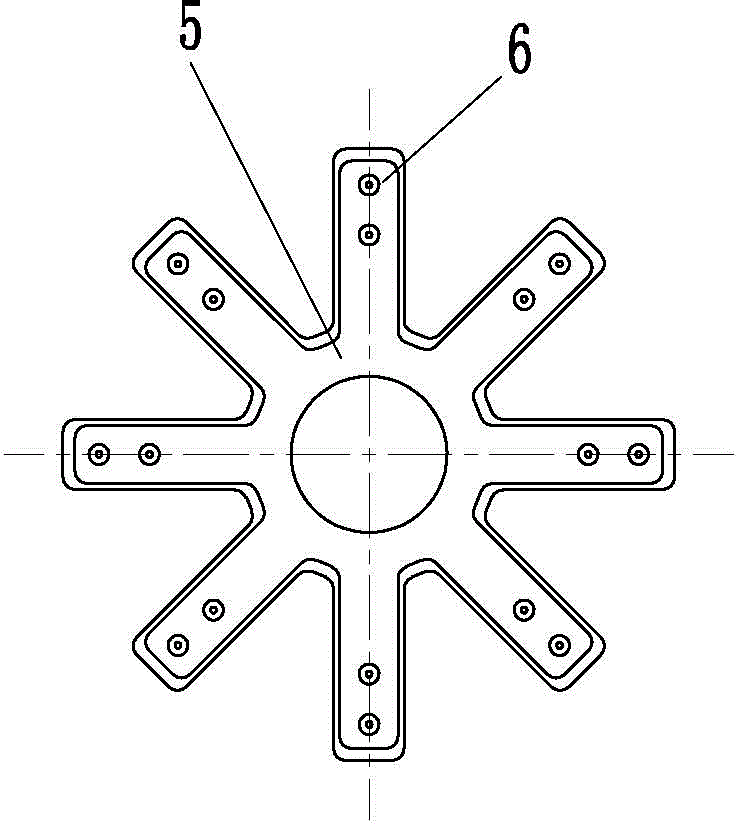

Self-regenerative type burner

ActiveCN103090391ALower discharge temperatureIncrease intake air temperatureIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberEngineering

The invention relates to a self-regenerative type burner. A smoke outlet, an air inlet and a baffle are arranged at the back end of a valve body and a plurality of fan-shaped windows are distributed evenly in the baffle. A burner block is contained in the valve body, a core body is sleeved on the burner block, a plurality of channels are evenly distributed in the core body, and a regenerative body is arranged in each channel. A transmission mechanism is connected with the core body and can drive the core body. A smoke channel and an air channel are formed between the core body and the valve body, wherein the smoke channel is communicated with the smoke outlet. A burning chamber is formed in the middle of the burner block, the burning chamber is communicated with the air channel, and a fire rod and a gas pipe extend into the burning chamber. An end cover is fixedly arranged at the back end of the valve body, and a back end external channel is formed between the end cover and the valve body, the back end external channel is communicated with the air channel through the fan-shaped windows, and the back end external channel is communicated with the air inlet. The self-regenerative type burner heats combustion air by means of smoke so as to greatly improve the air inlet temperature of the combustion air and reduce the smoke exhaust temperature, and therefore heat energy is completely utilized.

Owner:SHAOXING XUEERDE FURNACE IND

Efficient and safe low-calorific-value waste gas burner

PendingCN107543178AReduce lossesWell mixedCasings/liningsIncinerator apparatusCombustorBurn treatment

The invention discloses an efficient and safe low-calorific-value waste gas burner and belongs to the technical field of industrial low-calorific-value waste gas burning treatment waste gas burners. The efficient and safe low-calorific-value waste gas burner is mainly composed of an upper cone, a low-calorific-value burning device, a high-calorific-value burning device, a heat insulation layer, aheat storage layer and a lower cone. The efficient and safe low-calorific-value waste gas burner is characterized in that according to the burner, by arranging the heat insulation layer of a compositestructure and the multi-section turn-back-flow type heat storage layer, the upper cone, the lower cone, the low-calorific-value waste gas burning device and the high-calorific-value gas burning device are separately arranged, and it can be guaranteed that combustible waste gas and air are mixed and in contact with each other repeatedly and are ignited and burn out. The efficient and safe low-calorific-value waste gas burner has the beneficial effects that safe and efficient burning is achieved, and explosion caused by insufficient low-temperature (less than 650 DEG C) burning is avoided. Theefficient and safe low-calorific-value waste gas burner is stable in structure, easy and convenient to operate, efficient and safe.

Owner:阜阳市节能化工工程有限公司

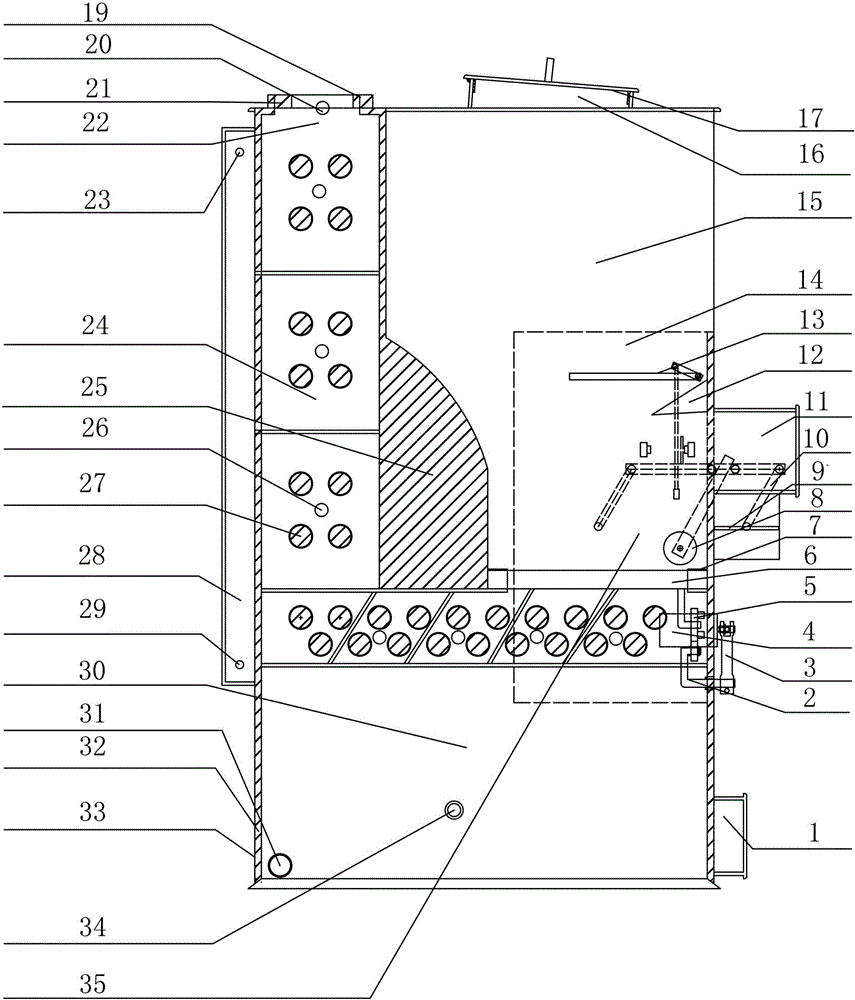

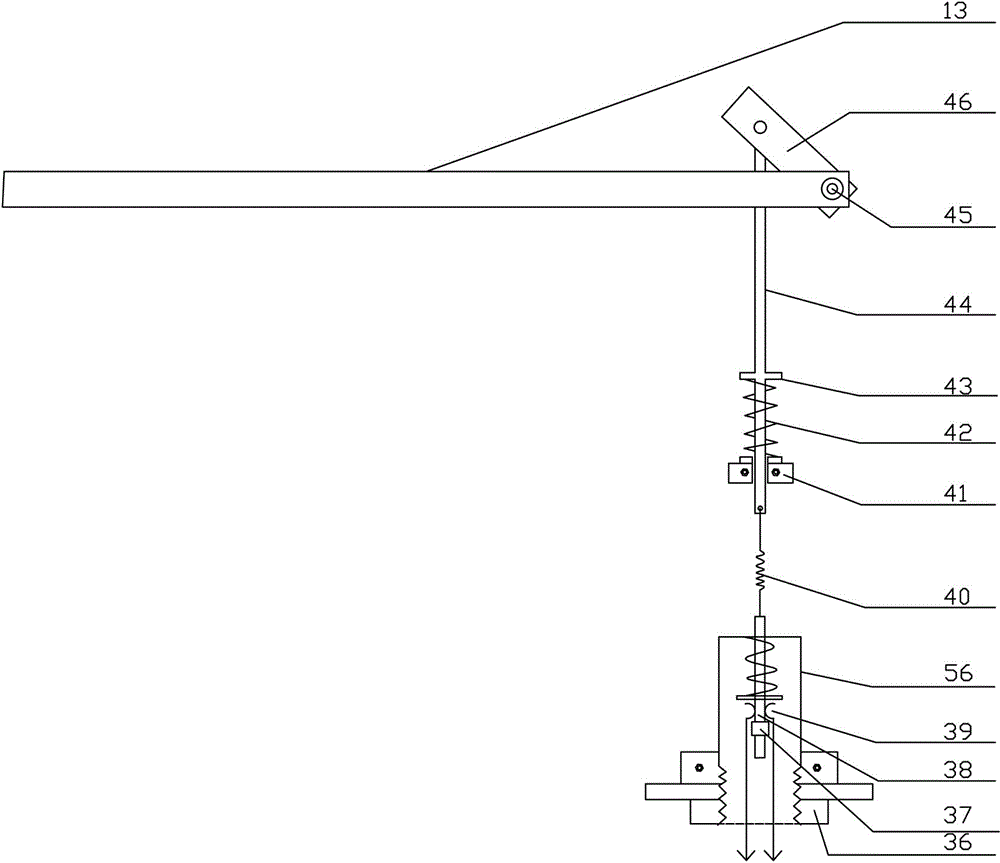

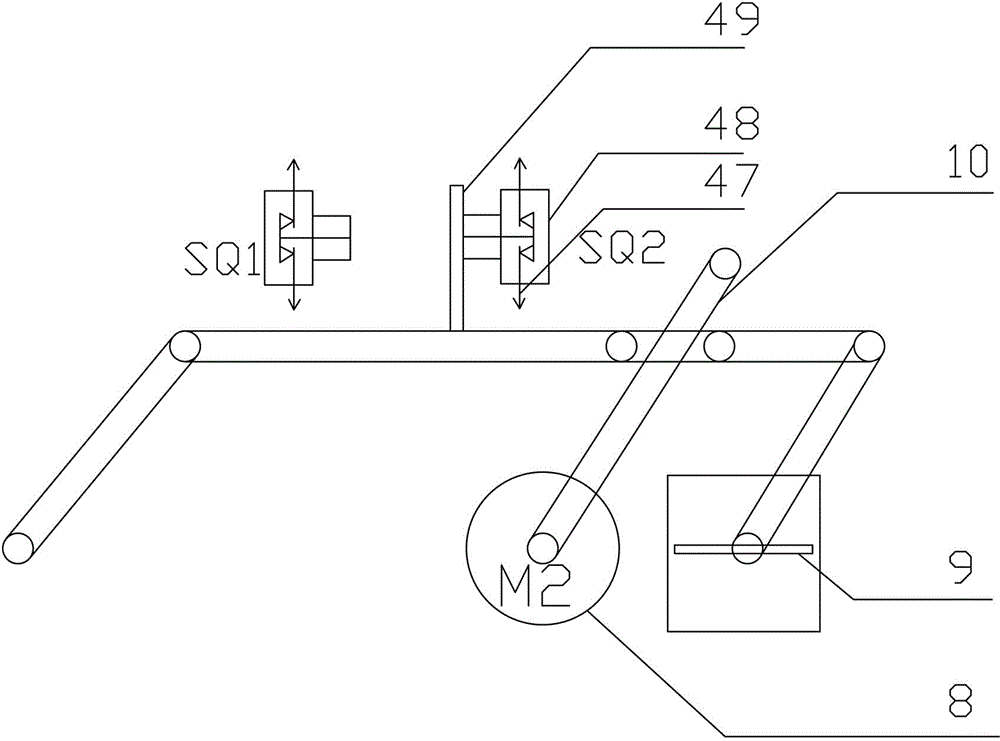

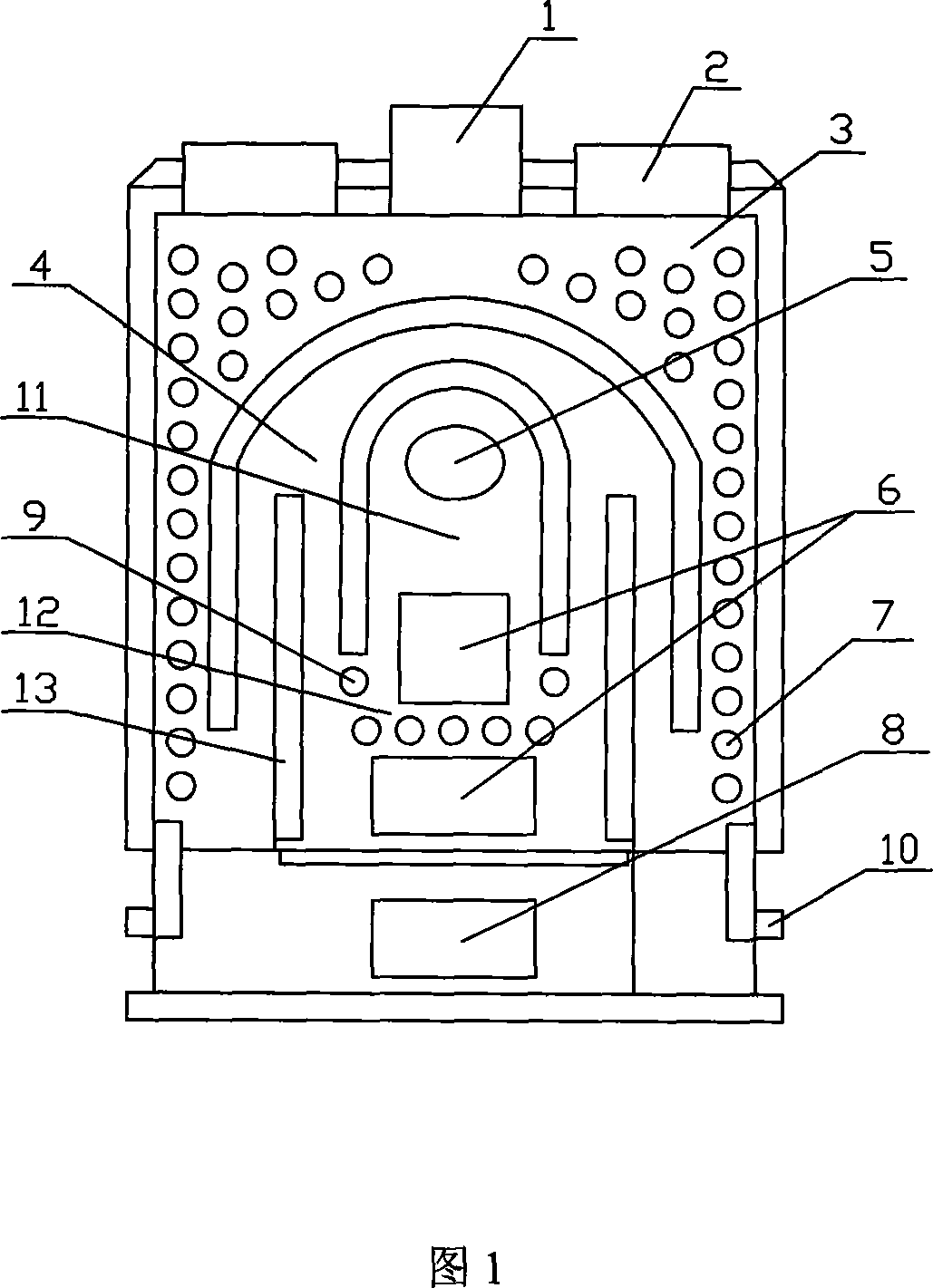

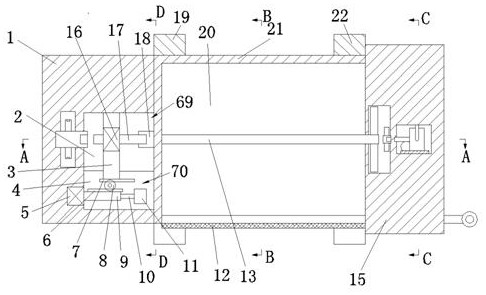

Automatic temperature control lower reverse combustion type coal-fired boiler

The invention discloses an automatic temperature control lower reverse combustion type coal-fired boiler. The automatic temperature control lower reverse combustion type coal-fired boiler comprises a boiler body, a water heating layer, a coal feeding inlet, an ash outlet, a smoke outlet, a waste heat water tank, an electrical appliance protective cover, an observation opening, an automatic reciprocating grate and a linkage arm, wherein the water heating layer is arranged around the boiler body, a heat flow buffer chamber is formed by the water heating layer in the boiler body, the waste heat water tank is arranged outside the water heating layer, and a lower reverse combustion heating pipe is arranged in the boiler body; the automatic reciprocating grate is arranged in the boiler body, an upper combustor is arranged above the automatic reciprocating grate, a lower combustor is arranged below the automatic reciprocating grate, and a temperature sensor is arranged on the boiler body. According to the structure of the automatic temperature control lower reverse combustion type coal-fired boiler, the upper combustor and the lower combustor are formed so as to achieve the purpose of complete combustion, combustion can be conducted for 3-5 days when a coal storage bin is filled with coal, fire banking can be conducted for seven days, the temperature is automatically controlled, the automatic acousto-optical indication is given when coal deficiency exists, ash falls off through the automatic reciprocating grate, drinkable hot water can be obtained for a long time, thermal efficiency is high, the temperature rise is rapid, installation and maintenance are convenient, and the automatic temperature control lower reverse combustion type coal-fired boiler is applicable to civil heating and heating for small enterprises.

Owner:姜国庆

Automatic staged methane burner

InactiveCN103256598ASatisfy automatic graded combustionEfficient combustionGaseous fuel burnerCombustorEngineering

The invention belongs to the technical field of tail gas treatment in the methane industry, and provides a burner capable of achieving automatic staged burning of methane at different pressures. The burner can achieve thorough burning and is safe and environment-friendly. The burner adopts the technical scheme that a main burner nozzle is mounted at the upper end of a main blow-down pipe; a main burner nozzle spoiler is mounted at the upper part of the main burner nozzle; a central pipe with an opened upper part and a opened lower part is fixedly mounted at the middle part of the main burner nozzle in a sleeving manner; a methane distribution chamber is mounted on the external circumference surface of the central pipe in a sleeving manner; a plurality of secondary burner nozzles are mounted on the methane distribution chamber; the methane distribution chamber is communicated with the main blow-down pipe by a plurality of distribution pipes; a plurality of primary gravity pressure regulation devices are mounted at communicating openings; a burner air mixer is mounted above the methane distribution chamber; a plurality of venturi air inlets are formed in the burner air mixer; the methane distribution chamber is divided into a plurality of cavities from the top down by partition plates; every two adjacent cavities are mutually communicated; a plurality of gravity pressure regulation devices are mounted at communicating openings; and the secondary burner nozzles are mounted on the cavities.

Owner:SHANXI ALEX ENVIRONMENTAL PROTECTION TECH

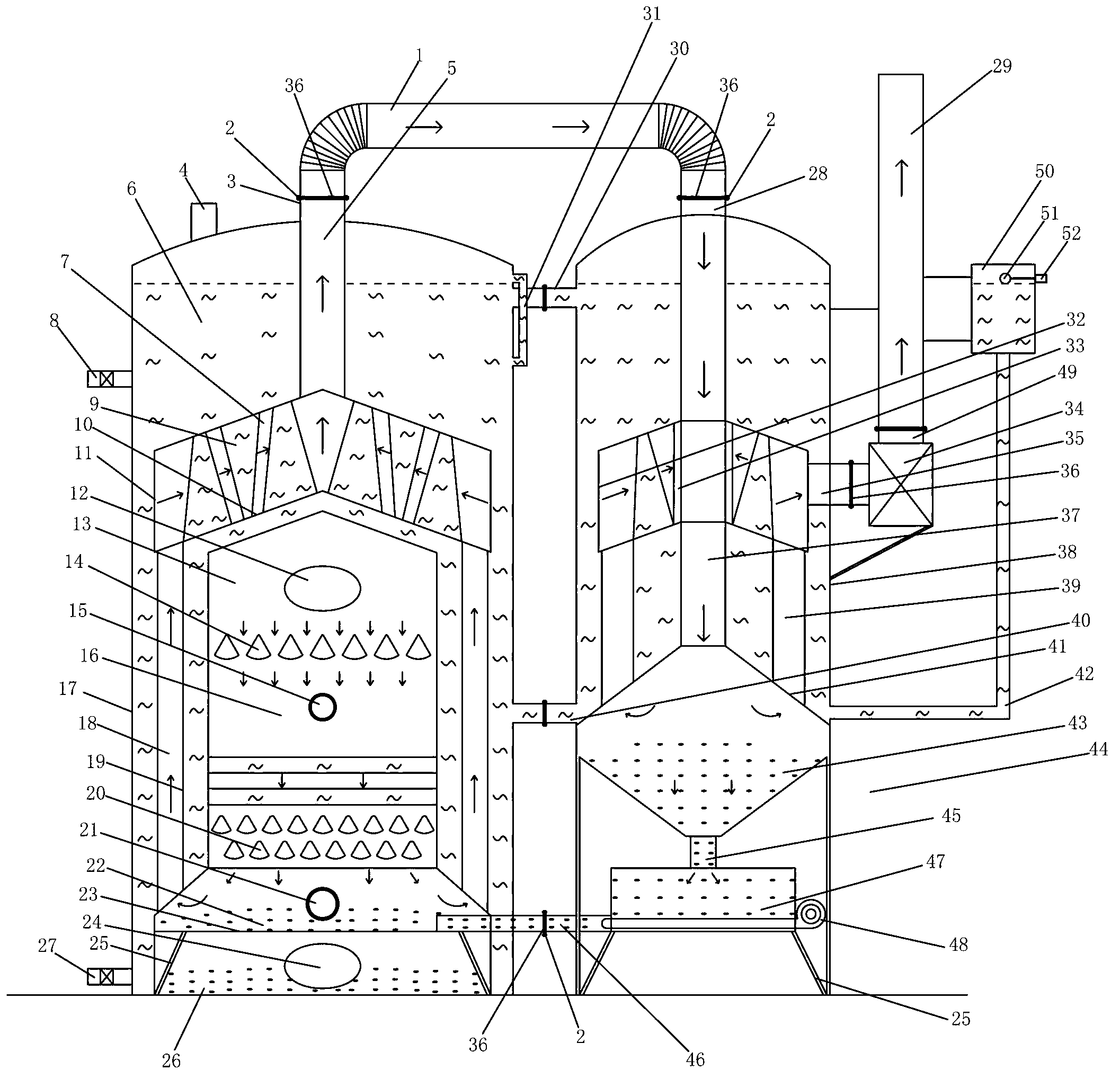

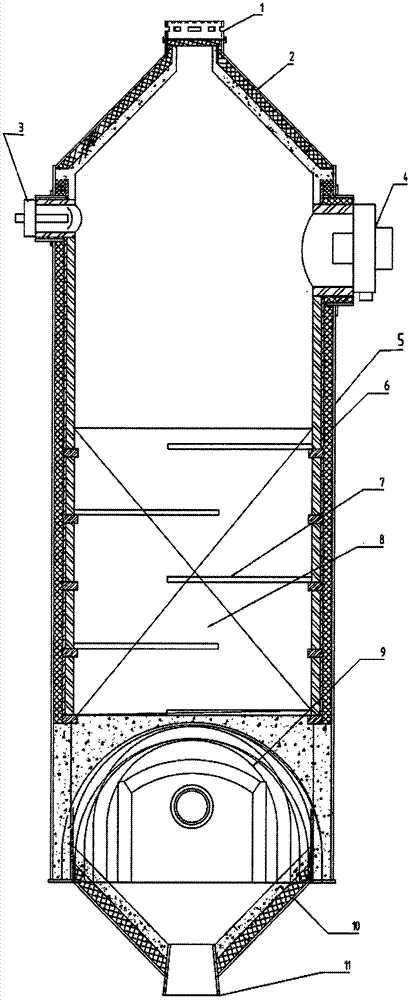

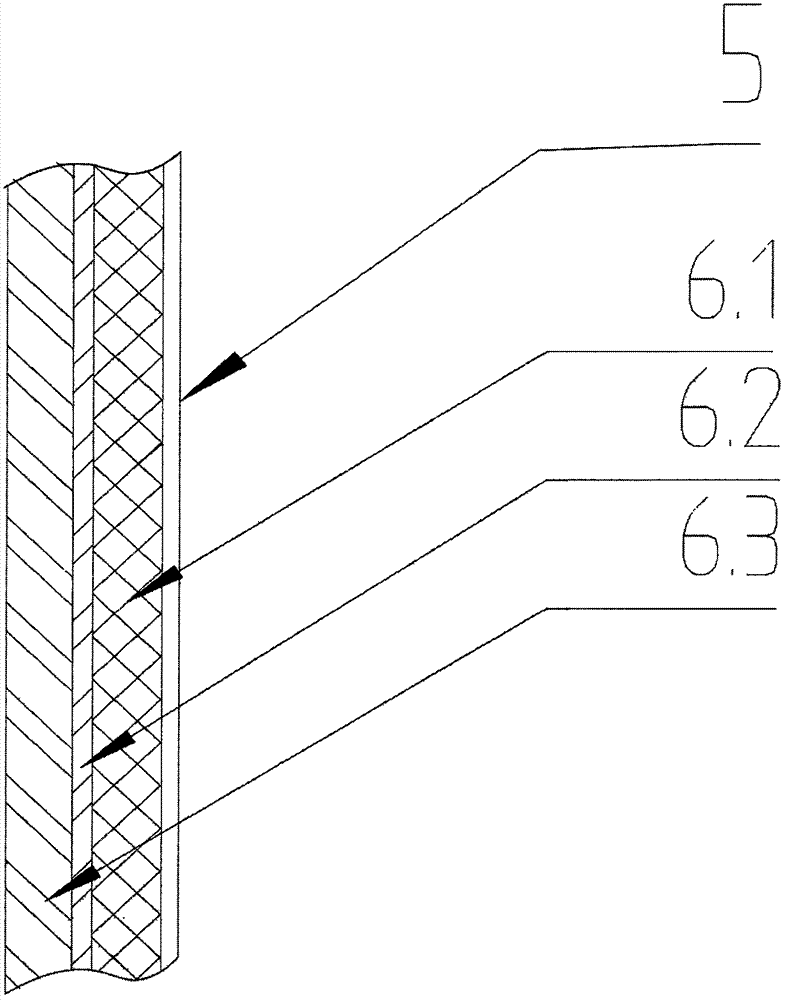

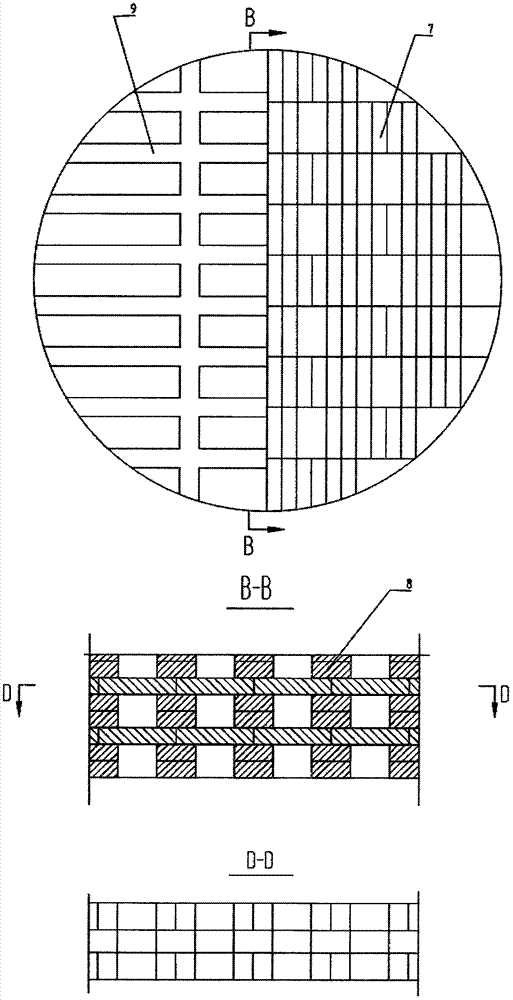

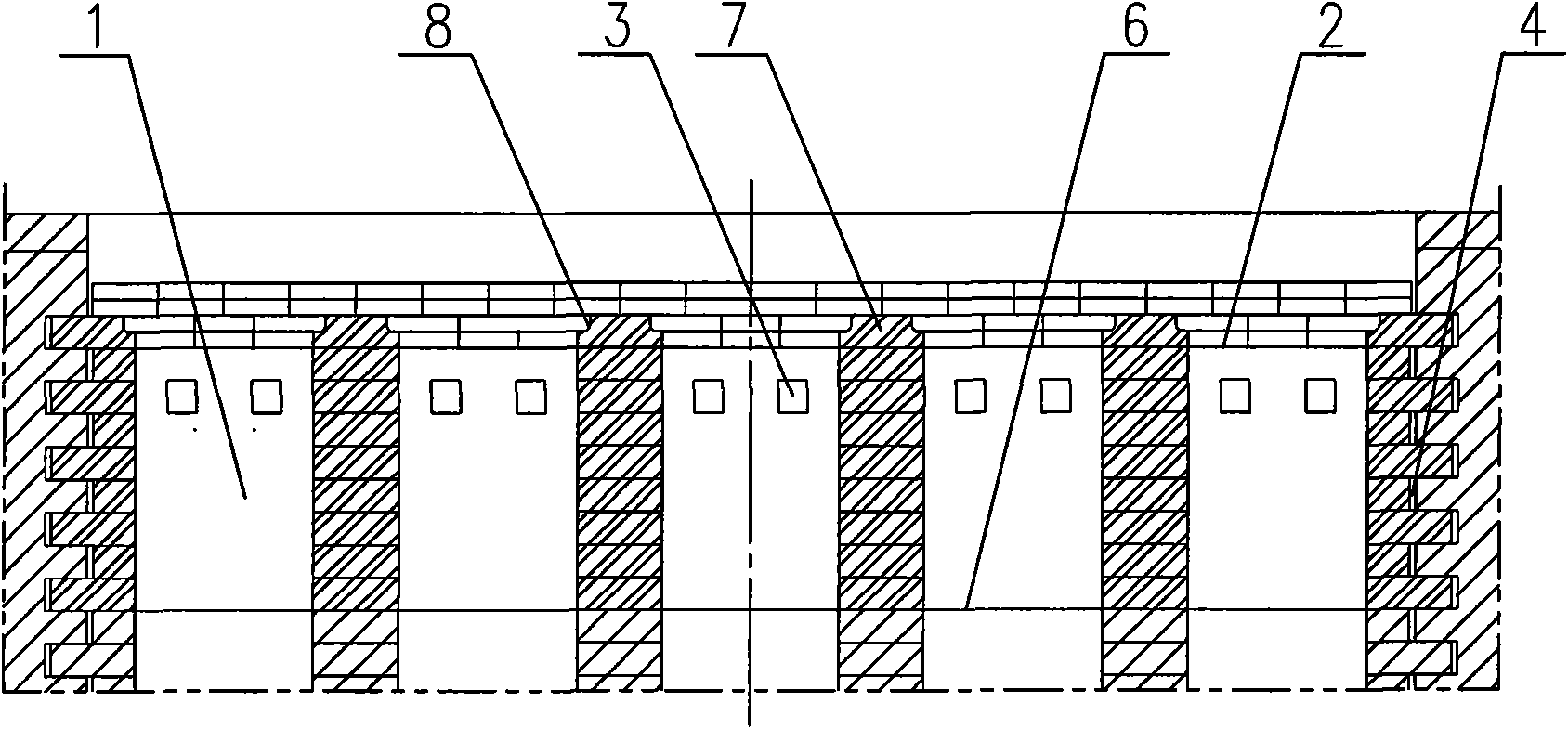

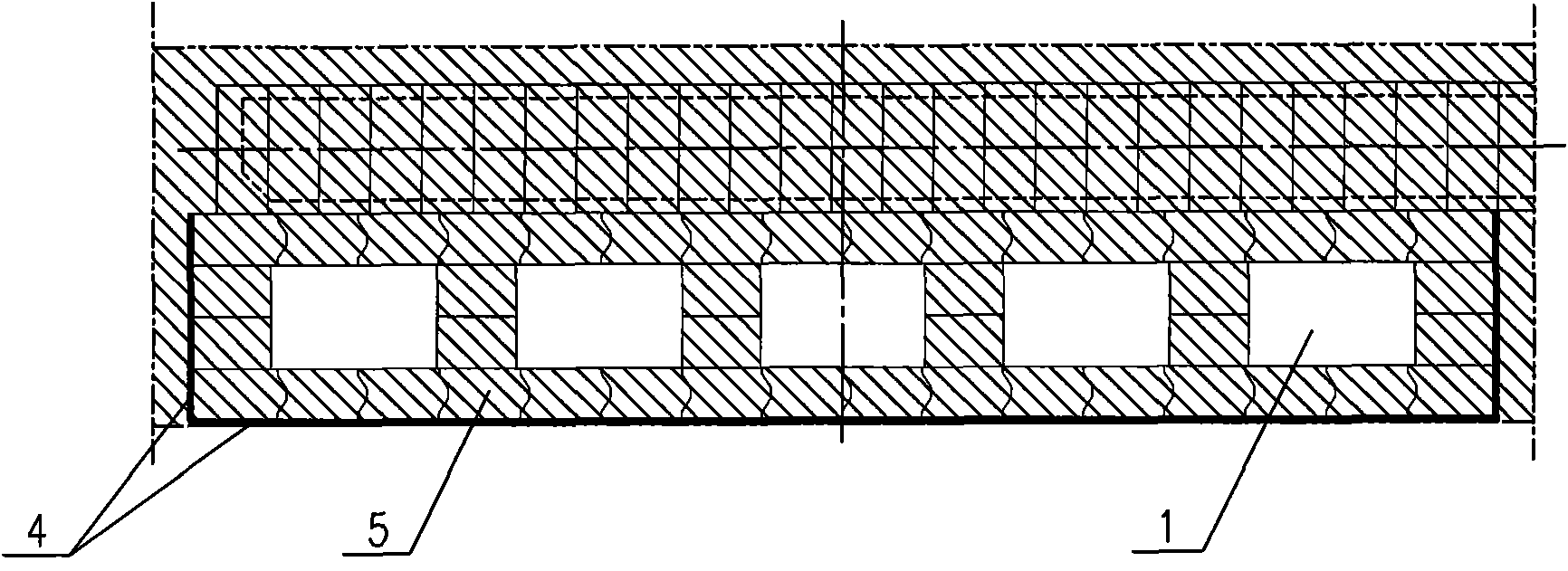

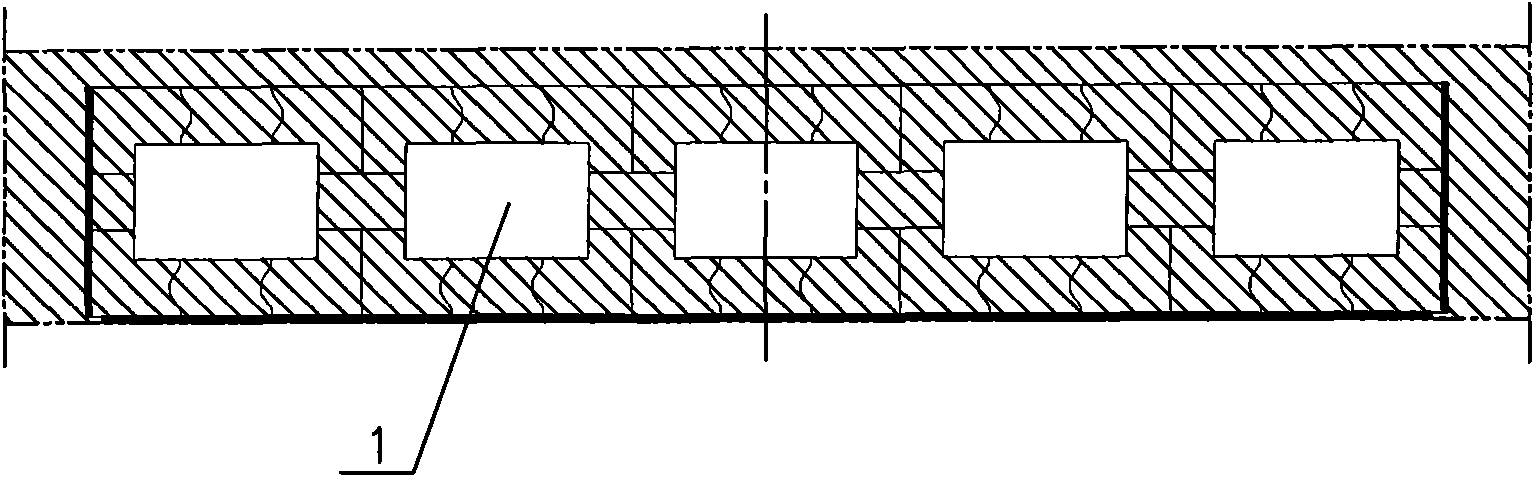

Vertical flashback type coal burning boiler

InactiveCN101093107AIncrease profitAchieve complete combustionWater heatersNuclear engineeringBack-fire

This invention relates to a vertical back-fire coal-burning boiler, in which a body includes a gas generating chamber, a firebox and a burn-off chamber characterizing in applying a back-fire coal-burning mode and a vertical boiler, the upper part of which is set with a chimney and an ash-cleaning door, the lower part is set with a return pipe, the gas generating chamber includes a bunker, a feed mouth, an air inlet and a dregs cleaning port, the feed mouth and the air inlet are set with air duct, fire grates are set in the combustion chamber isolated by several water-jacket clapboards, and gas goes along two symmetrical dual-S, and multiple convection pipes are set in the burn-off chamber, which increases usage of fuel by two symmetrical dual-S paths of fuel and reduces temperature to 130deg.C from 300deg.C and applies natural air without blast or inducing so as to reduce cost greatly.

Owner:徐昌延

Boiler furnace device

PendingCN106813239AImprove combustion efficiencyImprove the quality of dust removalFluidized bed combustionCasings/liningsBoiler furnaceNitrogen oxides

The invention discloses a boiler furnace device which comprises a boiler furnace, wherein the upper part of the boiler furnace is a cuboidal furnace, namely, a dilute phase zone; the bottom of the boiler furnace is a conical furnace, namely, a dense phase zone; a water-cooled air distribution plate is arranged at the bottom of the conical furnace; a plurality of air caps are arranged on the surface of the water-cooled air distribution plate; a primary air compartment is also arranged at the bottom of the water-cooled air distribution plate, and the air caps on the water-cooled air distribution plate are communicated with a primary air inlet pipe; through holes in the air caps are used for introducing primary air from the primary air compartment; the conical furnace is also communicated with a secondary air inlet pipe; a wearproof layer is also arranged at the inner top of the boiler furnace; a membrane water wall is integrally arranged on the outer layer of the boiler furnace. According to the boiler furnace device, complete combustion of a biomass fuel is ensured, the combustion efficiency is improved, production of a large amount of nitrogen oxide is avoided, and the device also has the structural characteristic of the membrane water wall.

Owner:SUZHOU DISEN BIOLOGICAL ENERGY +1

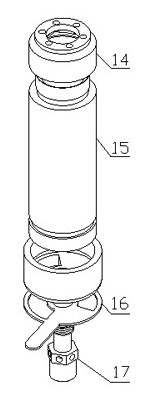

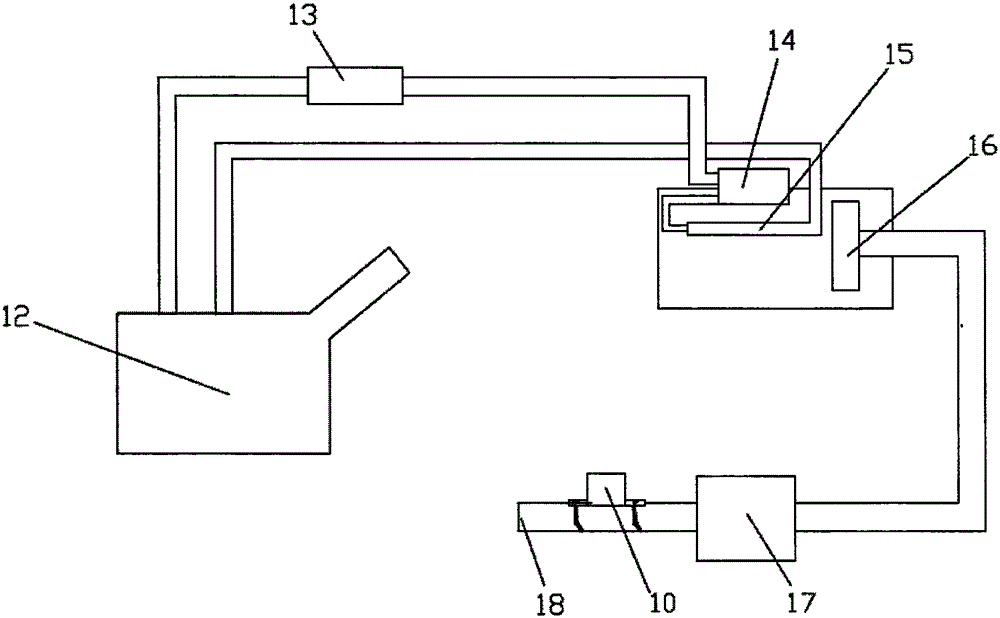

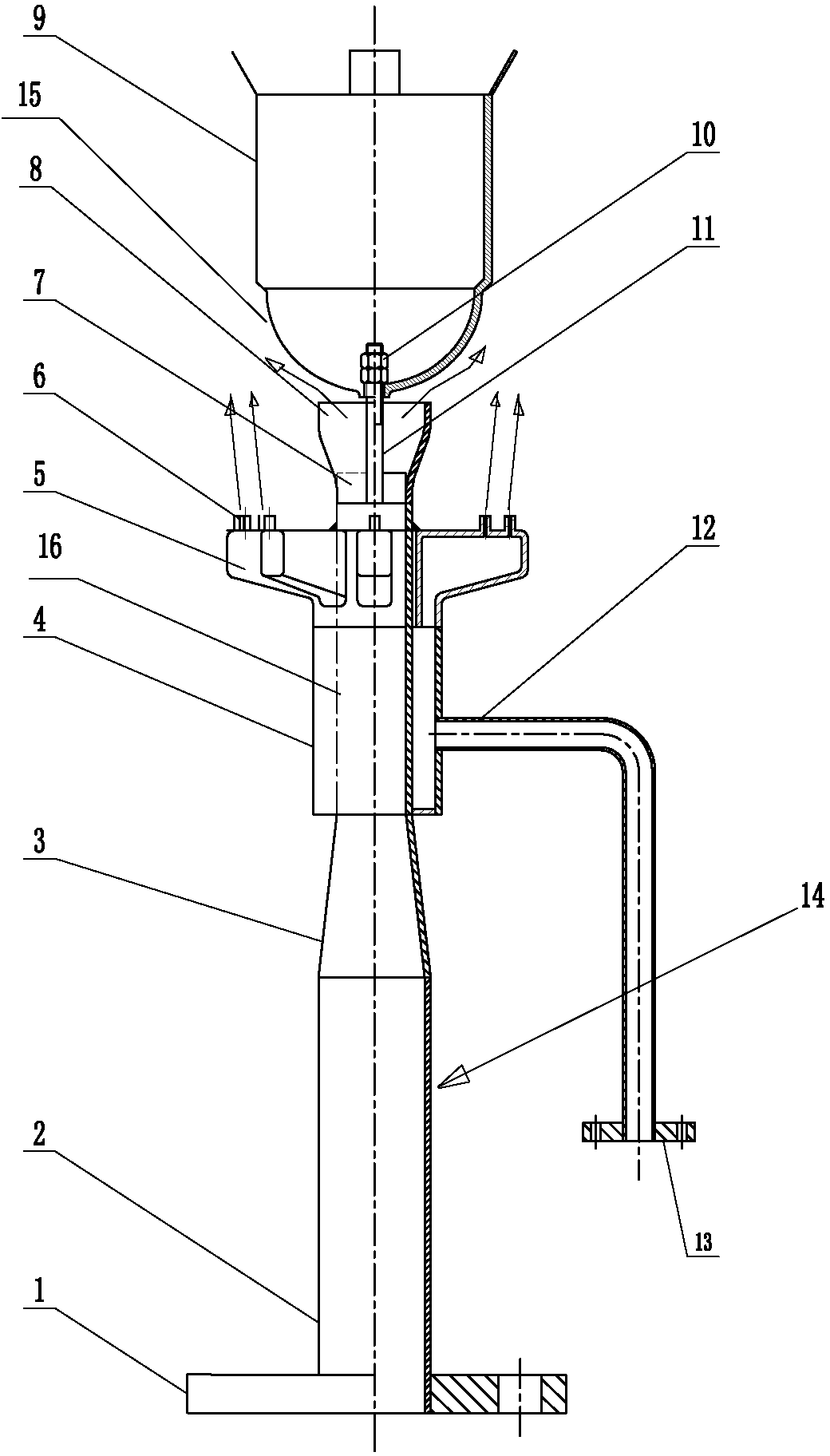

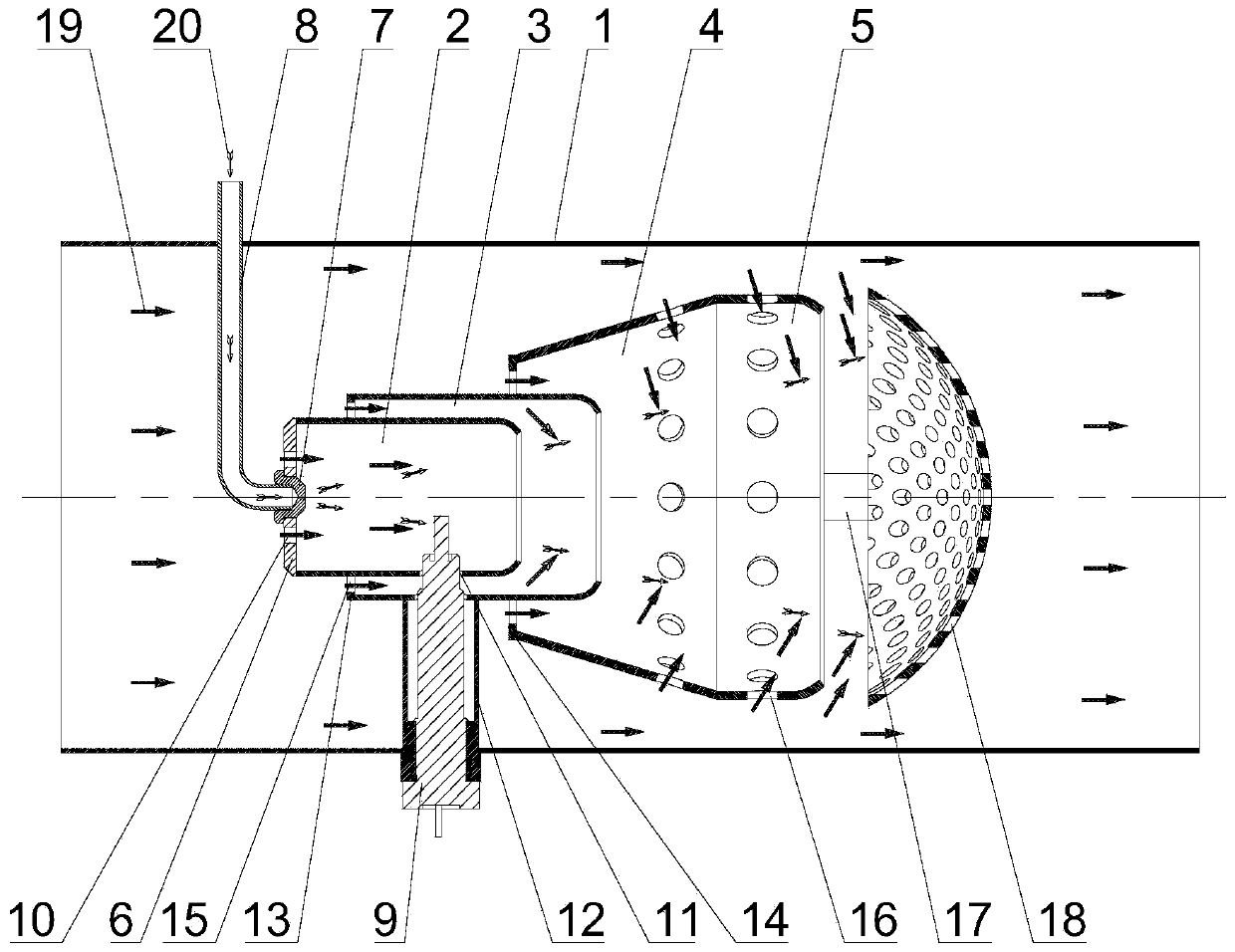

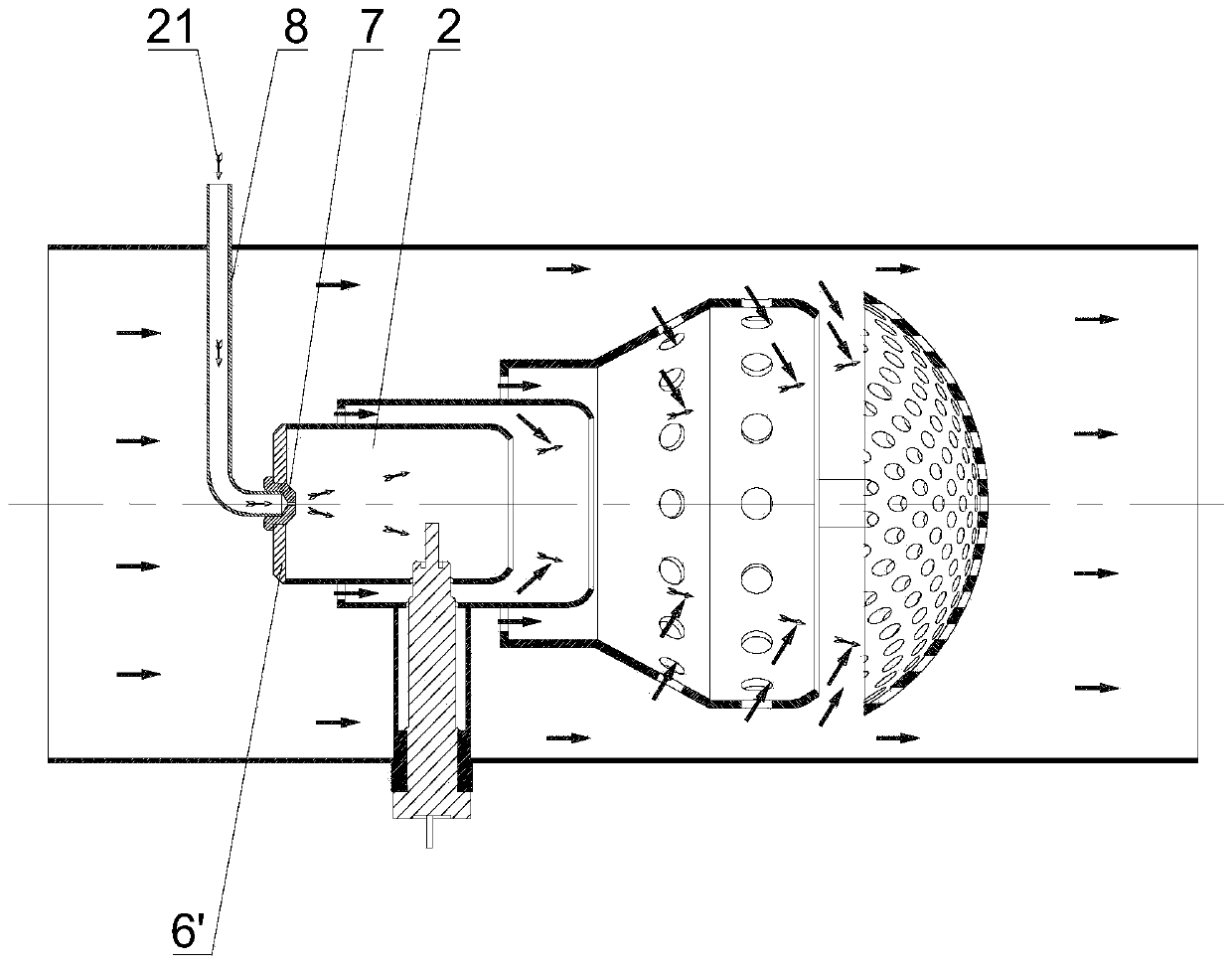

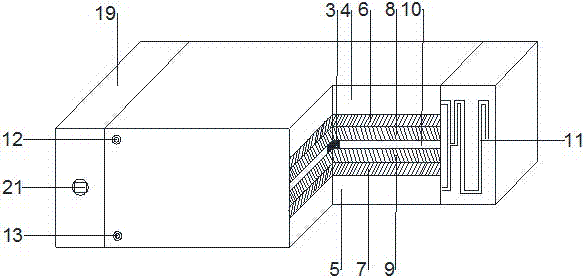

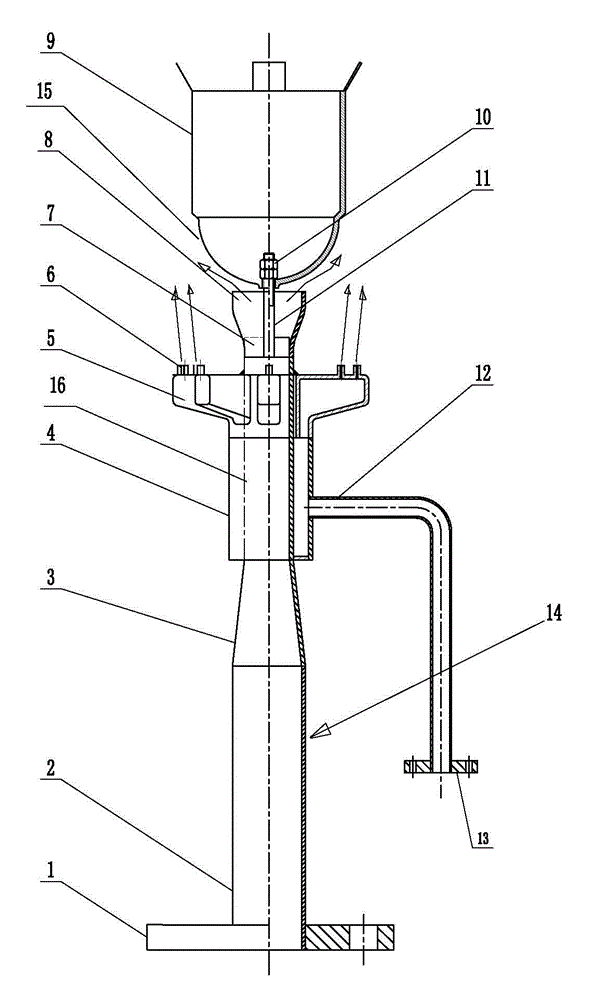

Ultra-low pressure flare gas burning device

An ultra-low pressure flare gas burning device comprises a boiler cylinder (9), a burner (8) and a flare gas inlet pipe (14). The burner (8) is connected with one end of the flare gas inlet pipe (14). The ultra-low pressure flare gas burning device is characterized in that a rib plate (7) is arranged in the burner (8), a boiler bottom (15) of the boiler cylinder (9) is located on the upper portion of the burner (8) through a connecting bolt (11) connected with the rib plate (7) and a nut (10). A cone body (5) is sleeved on the flare gas inlet pipe (14) on the lower portion of the burner (8). A nozzle (6) communicated with an inner cavity of the cone body (5) is arranged on the upper end closed end face of the cone body (5). The lower end of the cone body (5) is communicated with one end of a casing pipe (4) which is sleeved on the flare gas inlet pipe (14) as well. The lower end of the casing pipe (4) is in a closed state. The casing pipe (4) is connected with a branch pipe (12) used for supplying steam or air or gas. According to the ultra-low pressure flare gas burning device, pressure required for combustion is low, auxiliary steam using amount is small, and meanwhile full combustion of the flare gas can be guaranteed. The ultra-low pressure flare gas burning device is particularly suitable for disposal with the ultra-low pressure flare gas.

Owner:JIANGSU SUNPOWER TECH

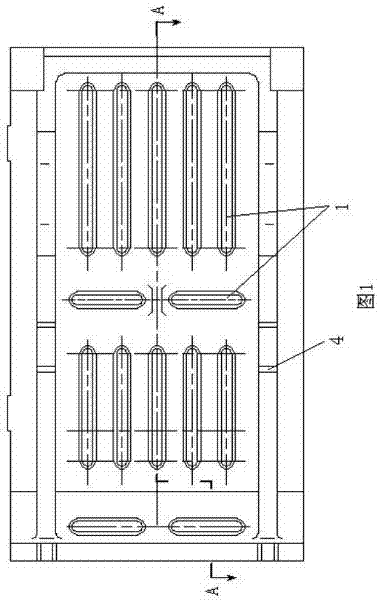

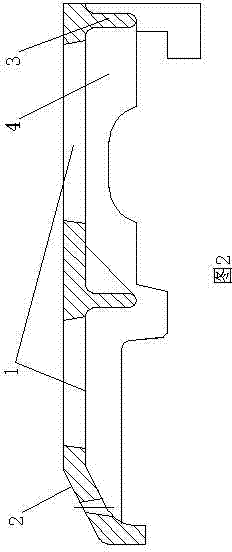

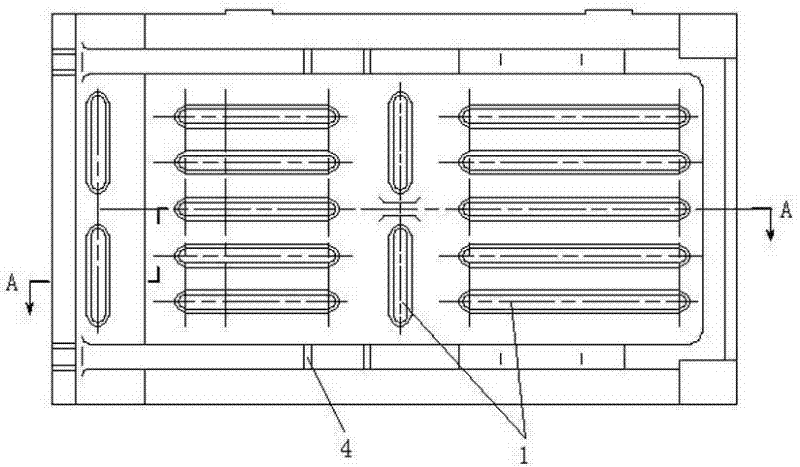

Burner capable of producing multiple burning working condition characteristics

InactiveCN103075726AAchieve complete combustionNon-existent processingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

The present invention discloses a burner capable of producing multiple burning working condition characteristics. A purpose of the present invention is to provide a burner capable of completely burning a fuel so as to avoid discharge of a large amount of harmful gas during fuel burning. The burner comprises a housing (1), wherein the housing (1) is provided with two or more burners (2), each burner (2) is provided with at least a fuel inlet (3), and a burning port (4) of the one burner (2) is an air inlet (5) of the other burner (4). The burner has characteristics of simple structure, high fuel burning efficiency, and efficient energy-saving and environmental protection performance.

Owner:伍镜清

Gas well structure for electrode roasting furnace

InactiveCN101571353AOverall goodGood absorption of expansion stress performanceFurnace componentsFurnace temperatureGraphite electrode

The invention discloses an electrode roasting furnace in the field of graphite electrode production, in particular to a gas well structure for an electrode roasting furnace. The gas well structure is characterized in that a gas well building body is built by gas well shaped bricks, a gas well mouth is arranged at the top of the gas well and a combustion-supporting air inlet opening is arranged at the upper part of the gas well. The gas well has good integrity; because a plurality of dilatation joint structures are arranged in the gas well building body, the gas well building body has good swelling stress absorption property; the gas well ensures the reliable deformation resistance when being taken as the combustion space and sufficient combustion-supporting air enters during the fuel combustion to achieve the purpose of complete combustion and improves the utilization ratio of fuel and reduces the energy consumption; the gas well keeps the cross section basically unchanged, is favorable for keeping the reasonable distribution of the negative pressure in the flame system and the smooth smoke flowing and effectively ensures the compliance between the furnace temperature distribution and the baking curve and the quality of the baked products; and the gas well can effectively ensure the capability of the main smoke extraction system to provide the negative pressure to the electrode roasting furnace.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Engine cylinder without carbon accumulation

InactiveCN101545413AIncrease powerReduce functional lossCylinder headsCylindersExhaust gasLubrication

The present invention relates to an engine cylinder without carbon accumulation. The aim of the invention is to overcome the defects of no enough lubrication degree, power reduction, oil consumption increase, component seizure which normally occurs commonly, etc. caused by the high-temperature carbon accumulation at the inner part of cylinder. The technical plan for settling the problem is strengthening the heat dissipation of cylinder block, greatly reducing the high temperature in the cylinder for causing that the temperature for sintered carbon accumulation in the cylinder is not obtained and therefore the carbon accumulation does not occur. Simultaneously the flexibilities of piston, connecting rod and crankshaft in the cylinder are increased. The function loss of engine is reduced for causing the complete combustion of fuel oil. The experiment for one year approves that the technical plan not only does not reduce the strength of cylinder, but also simultaneously settles the problem of high-temperature sintered carbon accumulation. The lubricity of cylinder is increased. The inner wall of cylinder is lubricated and smoothed as a mirror. The flexibility and service lifetime of components of cylinder, piston, connecting rod, crankshaft, etc. are increased. The engine cylinder further has the advantages of relatively saved fuel oil, increased power of engine and reduced pollution of exhaust gas.

Owner:郑光升

Inserting type multi-level mixing DPF combustor

PendingCN111520216AAdd room for mixingProlong the time of mixed combustionExhaust apparatusSilencing apparatusCombustion chamberCombustor

The invention discloses an inserting type multi-level mixing DPF combustor. A combustor outer barrel and a multi-level combustion chamber are included. The multi-level combustion chamber comprises aninner combustion chamber and a rear combustion chamber which are sequentially arranged in the combustor outer barrel in the exhaust flowing direction. The inner combustion chamber is provided with a first end cover. The first end cover is provided with a nozzle. The barrel wall of the combustor outer barrel is provided with a material spraying pipe stretching into the interior from the exterior and an igniter. The material spraying pipe is connected with the nozzle so as to spray fuel into the inner combustion chamber. An ignition head of the igniter stretches into the inner combustion chamber. A fire stop net is arranged at the tail end of the rear combustion chamber. According to the inserting type multi-level mixing DPF combustor, the rest of oxygen in diesel engine exhaust gas is utilized for being mixed with fuel for combustion, an air blower is eliminated, multi-time mixing of exhaust gas and fuel is formed through the multi-level combustion chamber, the mixing space of the exhaust gas and the fuel is increased, the mixing and combusting time is prolonged, the fuel and the rest of oxygen in the exhaust gas are sufficiently mixed, the combustion efficiency is improved, complete combustion is achieved, and the exhaust temperature is effectively increased.

Owner:KAILONG HIGH TECH

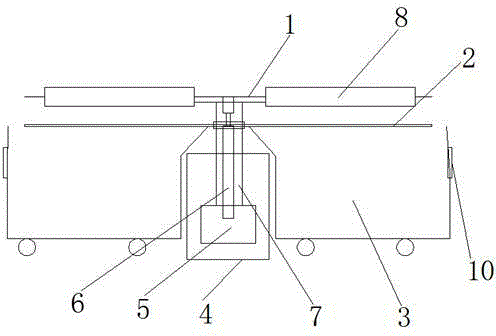

Multifunctional internal combustion engine power environment-friendly energy-saving device and materials for preparing device

PendingCN110094283AIncrease motivationEnhanced Momentum ExchangeMachines/enginesAir intakes for fuelFiberCarbon fibers

The invention discloses a multifunctional internal combustion engine power environment-friendly energy-saving device and materials for preparing the device. The multifunctional internal combustion engine power environment-friendly energy-saving device comprises an air inlet pipeline, wherein an air turbulent flow baffle is arranged on the air inlet pipeline, two large air inlet holes are symmetrically formed in the two sides of the transverse central axis of the air turbulent flow baffle, and a plurality of small air inlet holes are formed beside each of the two large air inlets. The materialsare composed of rubber, carbon black, graphene, nanoscale carbon fibers, rare earth materials and the like. According to the multifunctional internal combustion engine power environment-friendly energy-saving device and the materials for preparing the device, air is enabled to form a turbulent flow at an outlet of the air inlet pipeline, so that combustible gas makes full contact with the air, the mixing time is shortened, the combustion efficiency of the combustible gas is improved, the reaction flame is relatively shortened, the power of an internal combustion engine is improved, carbon deposit water and fuel separation are not generated, and the effect of complete combustion of the fuel is achieved.

Owner:梁有敏

Waste incineration cylinder with rolling cleaning function

InactiveCN111765476AImprove cleaning efficiencyReduce processingHollow article cleaningIncinerator apparatusElectric machineWater rinsing

The invention discloses a waste incineration cylinder with a rolling cleaning function. The waste incineration cylinder with the rolling cleaning function comprises an incineration cylinder body, a power cavity is formed in the incineration cylinder body, and an energy supply device with a power supply function is arranged in the middle of the power cavity. The energy supply device comprises a sliding plate which is in contact with the upper end wall of the power cavity and can slide, the center of the sliding plate is fixedly connected with a power motor, a switching cavity with an upward opening is formed in the lower side of the power cavity, and the switching cavity is internally provided with a switching device switching the working state for the power motor. According to the waste incineration cylinder with the rolling cleaning function, waste can roll in the cylinder to achieve the purpose of complete combustion during waste incineration, after the combustion is complete, a scraping plate can extend into the cylinder to be in contact with the inner wall, then through the way of water washing, ash removal and cleaning can be completed simultaneously when the cylinder rotates,and finally, sewage after cleaning is discharged from a sewage outlet on the lower side and is not piled up into the cylinder.

Owner:SANMEN DUODA ENVIRONMENTAL PROTECTION EQUIP CO LTD

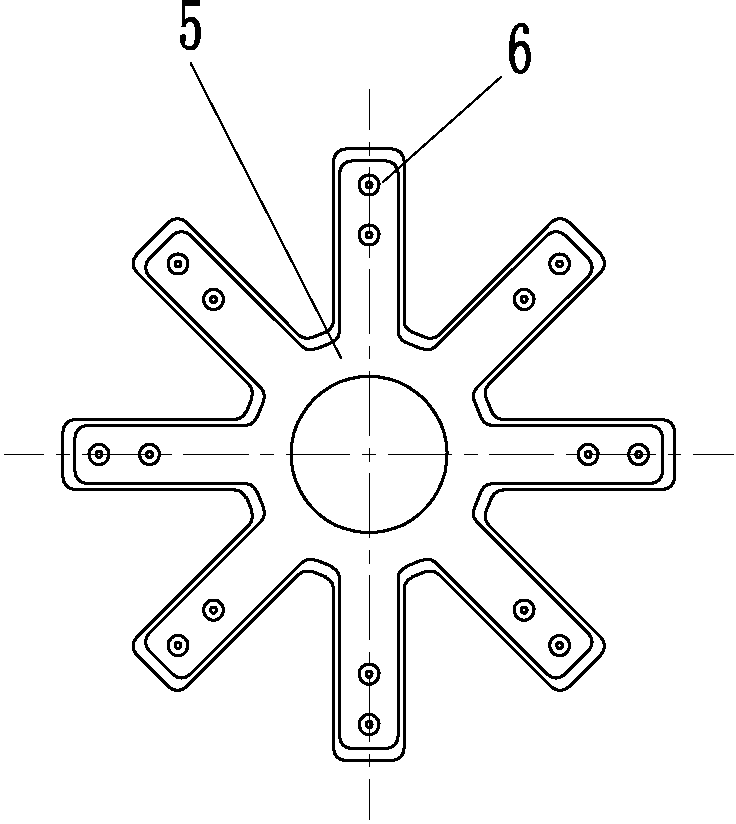

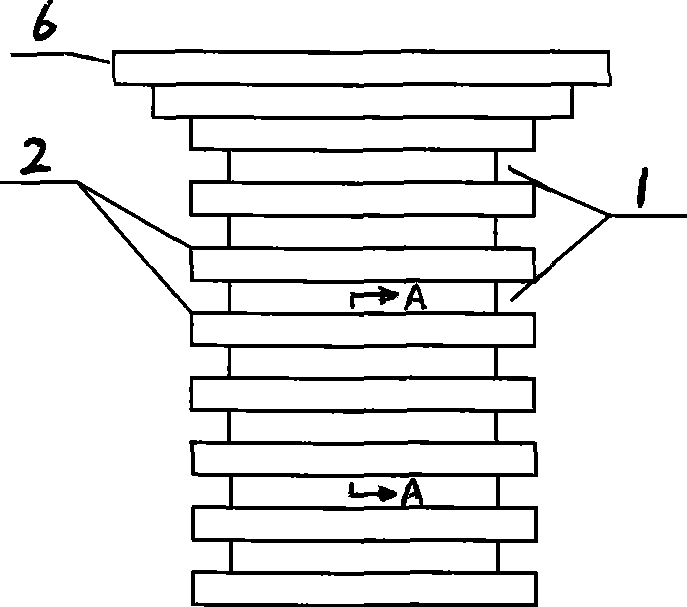

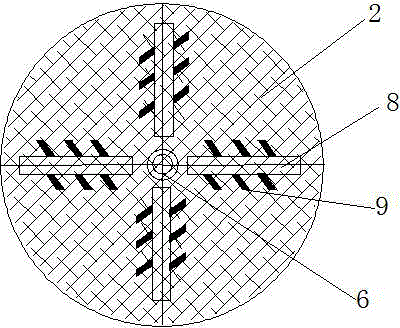

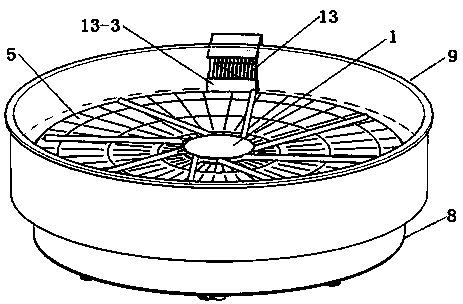

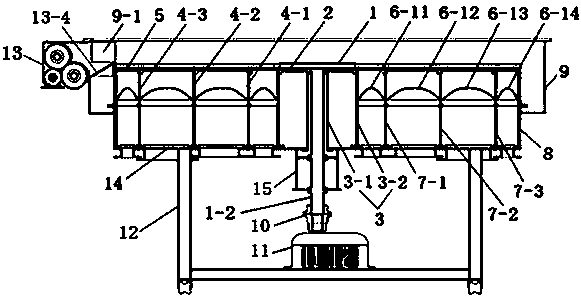

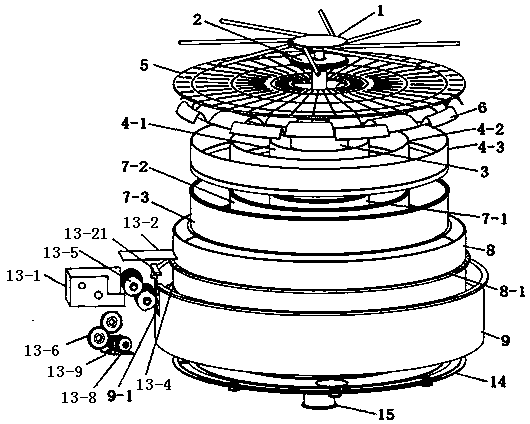

Boiler grate

InactiveCN105783002AImprove ventilationImprove combustion performanceRevolving grateRocking grateBoiler furnaceSlag

The invention discloses a boiler grate. The boiler grate comprises a grate, a fire bar, a slag discharge car and a support disc, wherein the fire bar is positioned under the grate, and the slag discharge car and the support disc are positioned under the fire bar; a motor is fixed to the interior of the support disc, a rotating shaft is arranged on the motor, the rotating shaft passes through the center of the grate and the fire bar and is fixedly connected with the grate, the rotating shaft is in gear connection with the fire bar, an insulation sleeve sleeves the periphery of the rotating shaft, the grate is composed of four grate segments, and strip-shaped irons are uniformly fixed to the surfaces of the grate segments. According to the boiler grate, both the grate and the fire bar can rotate around the rotating shaft, so that coal can fully burn in a burning process; the strip-shaped irons are arranged on the grate segments, so that large coal can be stirred into pieces by the strip-shaped irons in a rotating process, and the coal fully burns; slags generated by burning can fall into the slag discharge car, so that the pollution is effectively reduced, and the ventilation effect is good; the insulation sleeve fixedly sleeves the outer layer of the rotating shaft of the motor, so that the motor can be effectively protected.

Owner:TIANJIN CITY BAODI DISTRICT KUNYU CORNCOB CO LTD

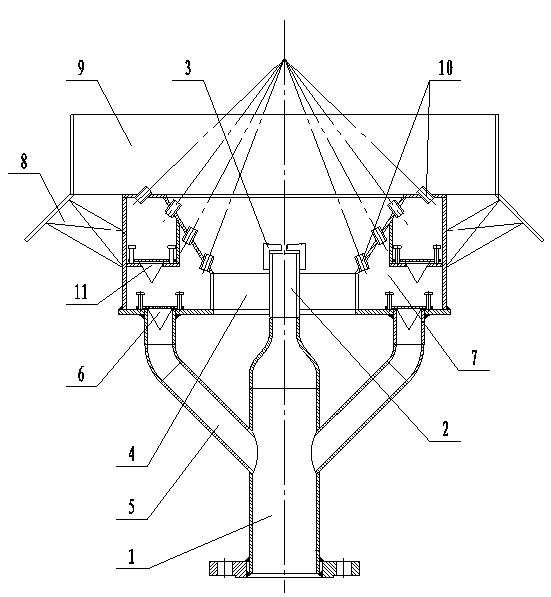

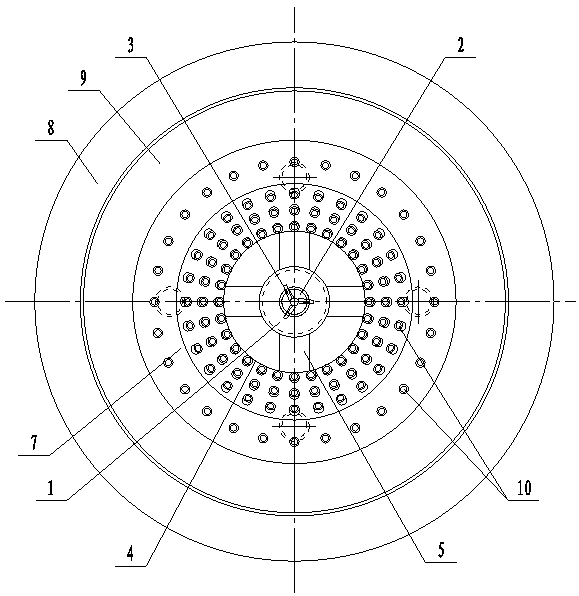

Biomass burner and use method

PendingCN108488781AImprove abilitiesIncrease output powerSolid fuel combustionAir/fuel supply for combustionProcess engineeringEngineering

The invention relates to a biomass burner and a use method. The biomass burner is arranged inside a boiler cavity, biomass fuel is scattered at the center of a stirring disc, a motor I drives the stirring disc to rotate, a plurality of stirring rods of the stirring disc lay the biomass fuel on the surface of a burning disc, meanwhile, an air supplying motor conveys high-pressure air to an air cavity tray, the concentrated bunch high-pressure air is turned into high-pressure spiral air by air uniforming protective blocks to be conveyed to a burning space inside a boiler, oxygen filling aid-combustion is performed on the biomass fuel, the burned biomass fuel is circled and blocked by an ash block when entering the burning disc step by step to perform tail burning namely the carbon burning stage, the multiple stirring rods of the stirring disc stir residue after tail burning into an ash discharging box again, and the biomass fuel residue is smashed and discharged by two residue breaking devices. The biomass burner and the use method have the beneficial effects that the problem perplexing straw fuel burning for a long time of coking, slagging and being unable to be popularized and applied is solved, the purpose of innocuous treatment is realized, and discharged flue gas reaches the standard of clean energy.

Owner:天津市星拓科技发展有限公司

Hot-blast stove used for grain drying

InactiveCN109282628APrevent spontaneous combustionAchieve complete combustionDrying gas arrangementsSeed preservation by dryingAgricultural engineeringAir blower

The invention discloses a hot-blast stove used for grain drying. The hot-blast stove includes a wind furnace box; the top of the wind furnace box is provided with a cylindrical air blower; the bottomof the air blower is provided with a fixing plate; the fixing plate covers the outer side face of the air blower and fixedly connected to the air blower through screws; one side on the outer surface of the air blower is provided with a dust discharging port; the dust discharging port passes through the internal of the wind furnace box and is welded with the wind furnace box; the bottom of the dustdischarging port is provided with a control panel; the side face of the control panel is provided with a stove door; the end part of the stove door is provided with a cylindrical discharge port; theend part of the wind furnace box is provided with a feeding port; and the feeding port is embedded in the wind furnace box. Through the arrangement of a drying machine in the wind furnace box and theincreasing of a heat absorbing plate at the bottom, the hot-blast stove can rapidly absorb heat to provide high temperature for the drying machine so that the drying speed can be accelerated.

Owner:周如彬

Waste burning recycling system

InactiveCN103868074AImprove utilization efficiencyAchieve complete combustionIncinerator apparatusHeat energyHeat pipe heat exchanger

The invention discloses a waste burning recycling system. The waste burning recycling system sequentially comprises a waste burning system, a heat exchanging system, a heat energy recycling system and a smoke purifying system, and the waste burning recycling system is characterized in that the waste burning system comprises a hot blast stove and a cracking furnace; the heat exchanging system is a heat-pipe heat exchanger; the heat energy recycling system is an energy storage device; the smoke purifying system comprises a purifying groove, a fan and a smoke exhaust pipe. By adopting the waste burning treatment system, organic waste gas enters the annular cracking furnace through the waste gas fan, the waste gas is enabled to be adequately burned in a high-temperature flame area after entering the burning furnace, so that an effect of toxic-free and harmless complete burning can be realized, and safety, reliability and accuracy in control can be realized; the heat energy is stored by the heat storage device, so that the utilization rate of the energy is improved, and more environmental friendliness is realized; moreover, a temperature control system and an automatic timing system in heat storage device are almost automatically completed, so that the automation degree is improved, and the manpower and material resource can be saved.

Owner:JIANGSU SUNRISE CHEM ENG TECH

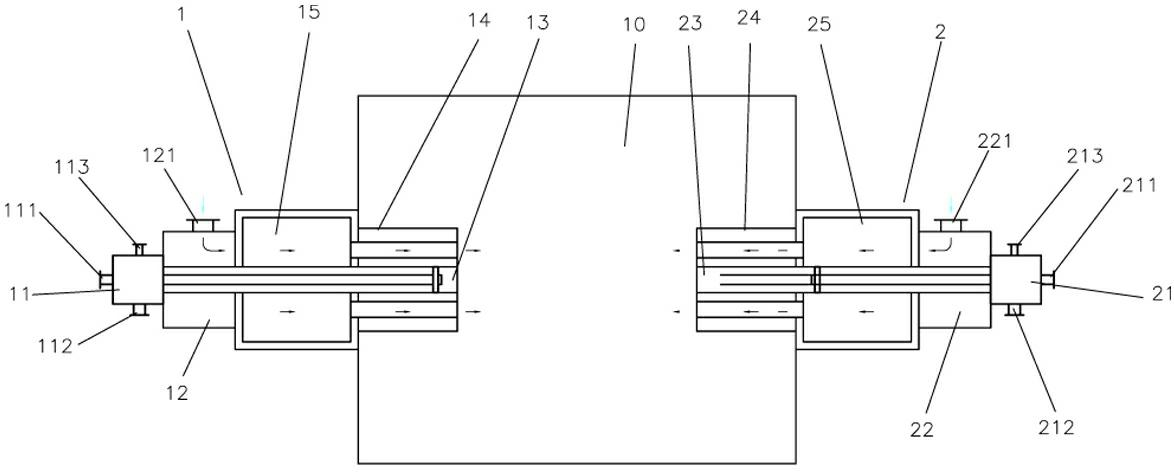

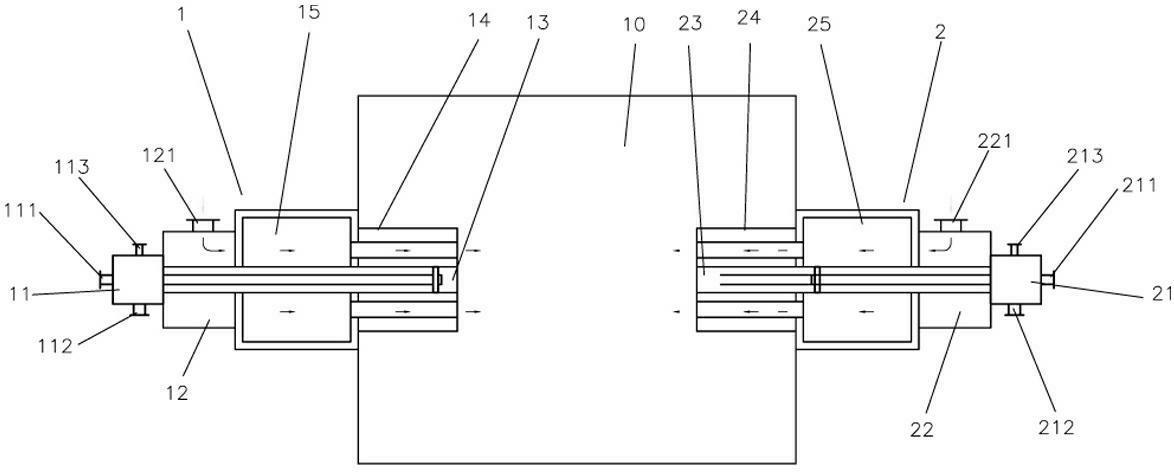

Micro-combustion thermoelectric generator based on stable combustion in porous media

ActiveCN105827152BReduce lossesGuaranteed smooth passageIndirect carbon-dioxide mitigationGenerators/motorsCombustion chamberThermal insulation

The invention discloses a micro-combustion thermoelectric generator based on porous medium micro-combustion. The structure of the micro-combustion thermoelectric generator is displayed in a flake-shape, and is successively formed from top to bottom by a fuel storage layer, an upper thermoelectric generation sheet, an upper thermal insulation layer, a combustion module, a lower thermal insulation layer, a lower thermoelectric generation sheet, and an oxidant storage layer, wherein a combustion chamber is arranged at a hot end of each thermoelectric generation sheet; a gas preheating layer is arranged at a cold end of each thermoelectric generation sheet; the combustion module comprises an inlet channel, an outlet channel and a combustion chamber; the inlet channel is a square double helix parallel structure; the center combustion chamber is filled with porous mediums; and the upper and lower thermal insulation layers are filled by mixture of conduction oil and trace inert gas. The micro-combustion thermoelectric generator based on porous medium micro-combustion has the advantages of being high in energy, being small in volume, being light in weight, having no noise, being continuously stable and being low in discharge, and mainly aims at the mini electronic equipment field, and is suitable for the field and for power supply of mini precision portable equipment of the military and aerospace field.

Owner:HANGZHOU DIANZI UNIV

Ultra-low pressure flare gas burning device

An ultra-low pressure flare gas burning device comprises a boiler cylinder (9), a burner (8) and a flare gas inlet pipe (14). The burner (8) is connected with one end of the flare gas inlet pipe (14). The ultra-low pressure flare gas burning device is characterized in that a rib plate (7) is arranged in the burner (8), a boiler bottom (15) of the boiler cylinder (9) is located on the upper portion of the burner (8) through a connecting bolt (11) connected with the rib plate (7) and a nut (10). A cone body (5) is sleeved on the flare gas inlet pipe (14) on the lower portion of the burner (8). A nozzle (6) communicated with an inner cavity of the cone body (5) is arranged on the upper end closed end face of the cone body (5). The lower end of the cone body (5) is communicated with one end of a casing pipe (4) which is sleeved on the flare gas inlet pipe (14) as well. The lower end of the casing pipe (4) is in a closed state. The casing pipe (4) is connected with a branch pipe (12) used for supplying steam or air or gas. According to the ultra-low pressure flare gas burning device, pressure required for combustion is low, auxiliary steam using amount is small, and meanwhile full combustion of the flare gas can be guaranteed. The ultra-low pressure flare gas burning device is particularly suitable for disposal with the ultra-low pressure flare gas.

Owner:JIANGSU SUNPOWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com