Engine cylinder without carbon accumulation

A technology for internal combustion engines and cylinders, applied to engine components, machines/engines, cylinders, etc., can solve problems such as insufficient lubrication of components, increased fuel consumption, and reduced engine power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

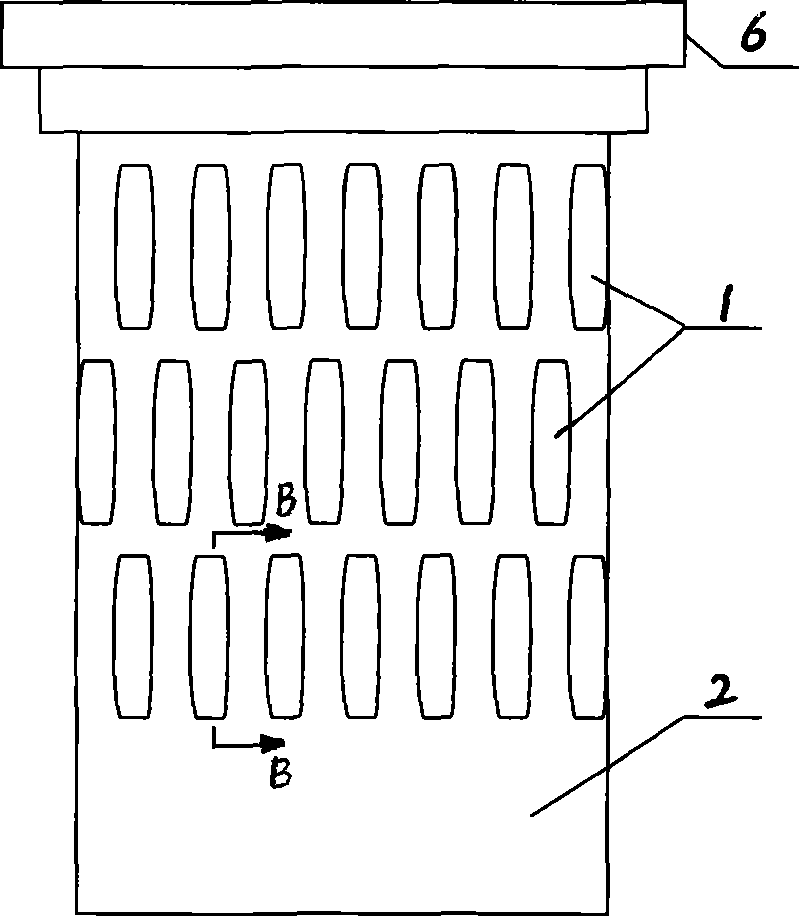

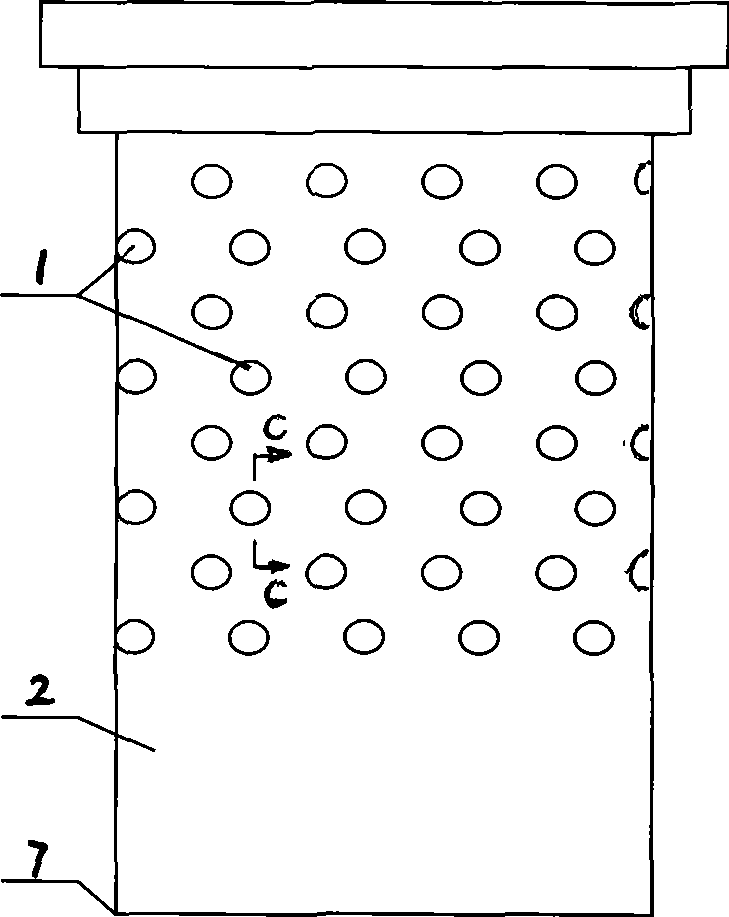

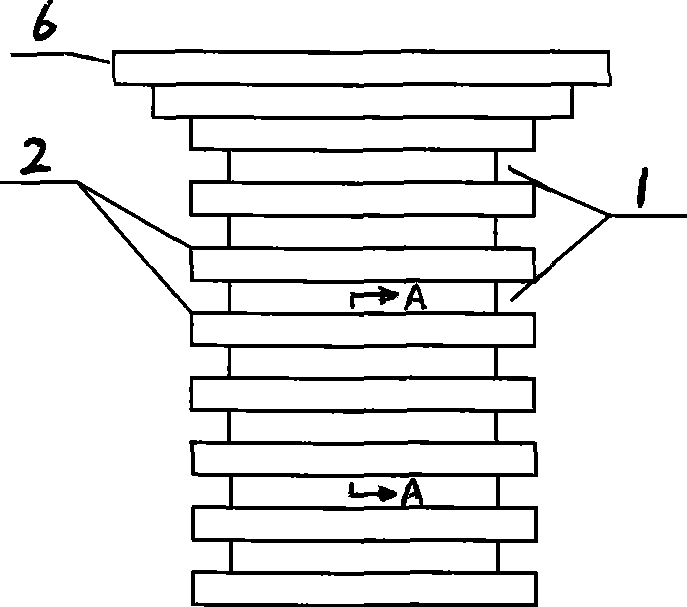

[0012] exist figure 1 , 2 3. In the embodiment shown in 3: on the outer wall (3) of the engine cylinder block (2) contacting with the cooling water or on the cylinder block (2) outer wall (3) of the piston stroke section, grooves or holes (1 ), the distribution arrangement of grooves or holes (1) is set according to the geometric shape according to the actual needs, and the length and width dimensions or diameters of grooves or holes (1) are determined according to the cylinder block (2 ) and actual needs can be set arbitrarily, between the bottom end of the groove or hole (1) and the inner wall of the cylinder (4) according to actual needs, there is a cylinder wall (5) with a thickness of 1 to 40 mm. The distance between the groove or hole (1) and the groove or hole (1) can be set arbitrarily according to actual needs, and the number of grooves or holes (1) can be set arbitrarily according to actual needs ; The cylinder block (2) increases the contact surface with the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com