Automatic temperature control lower reverse combustion type coal-fired boiler

An automatic temperature control, coal-fired boiler technology, applied in the field of heating boilers, can solve the problems of decreased heat absorption, excessive smoke scale on the inner wall, and large fuel loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

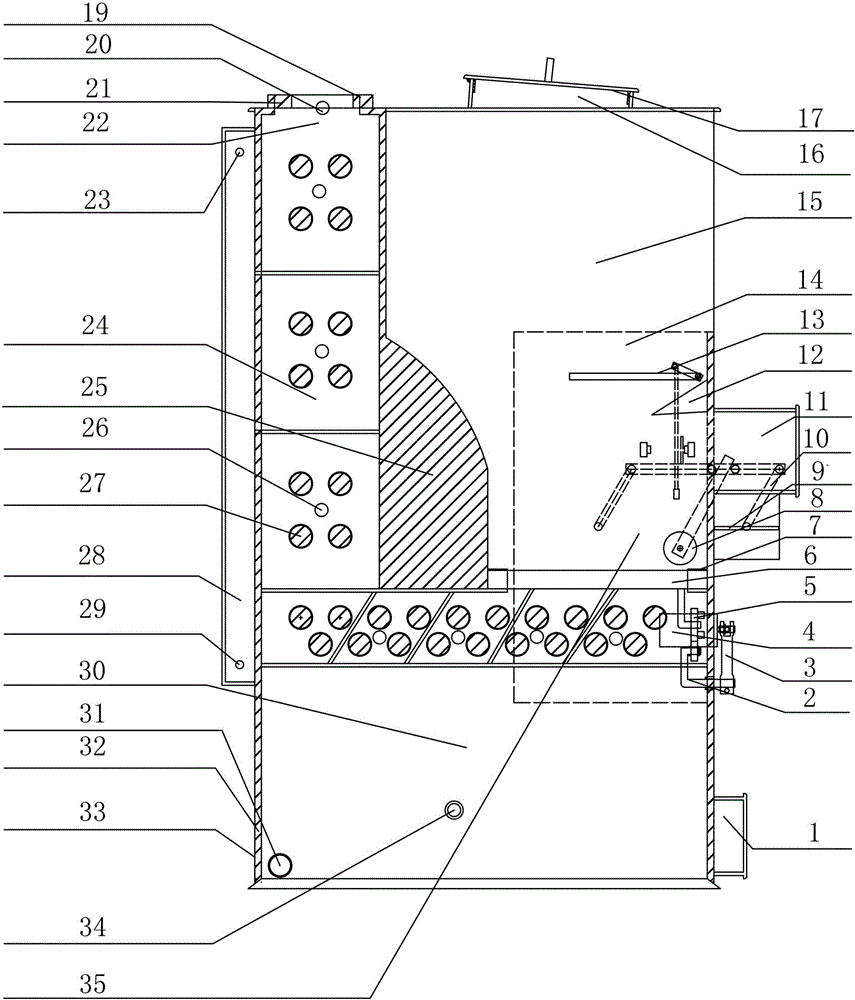

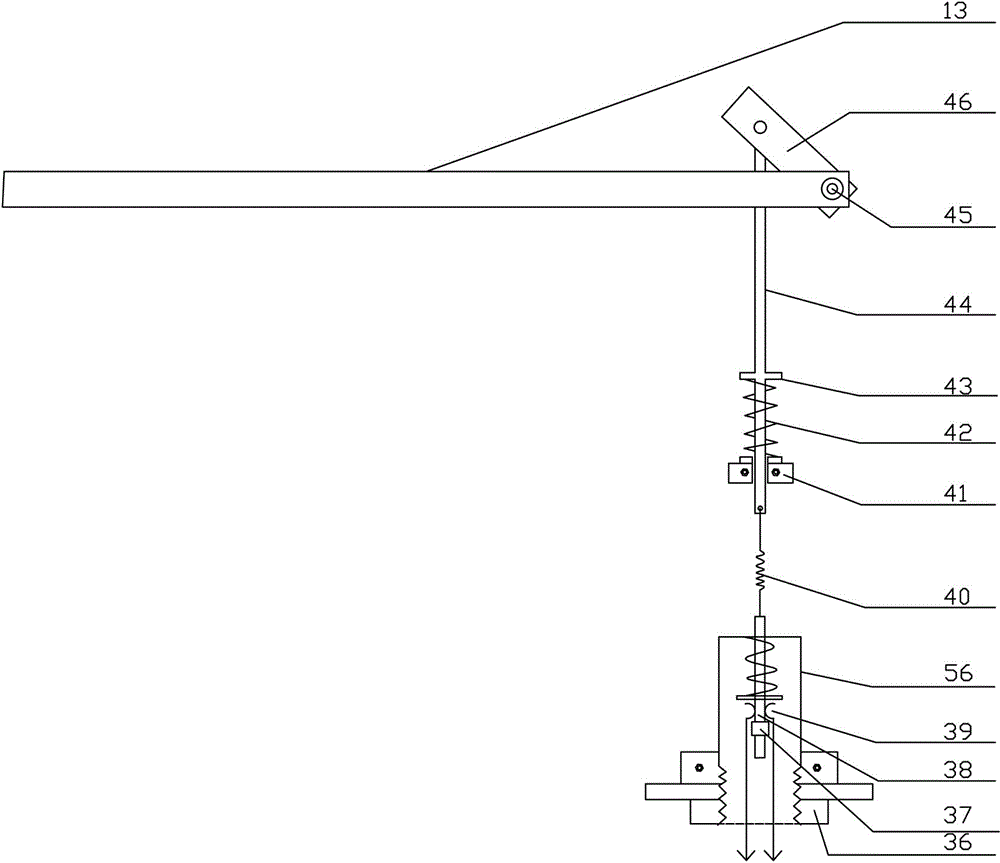

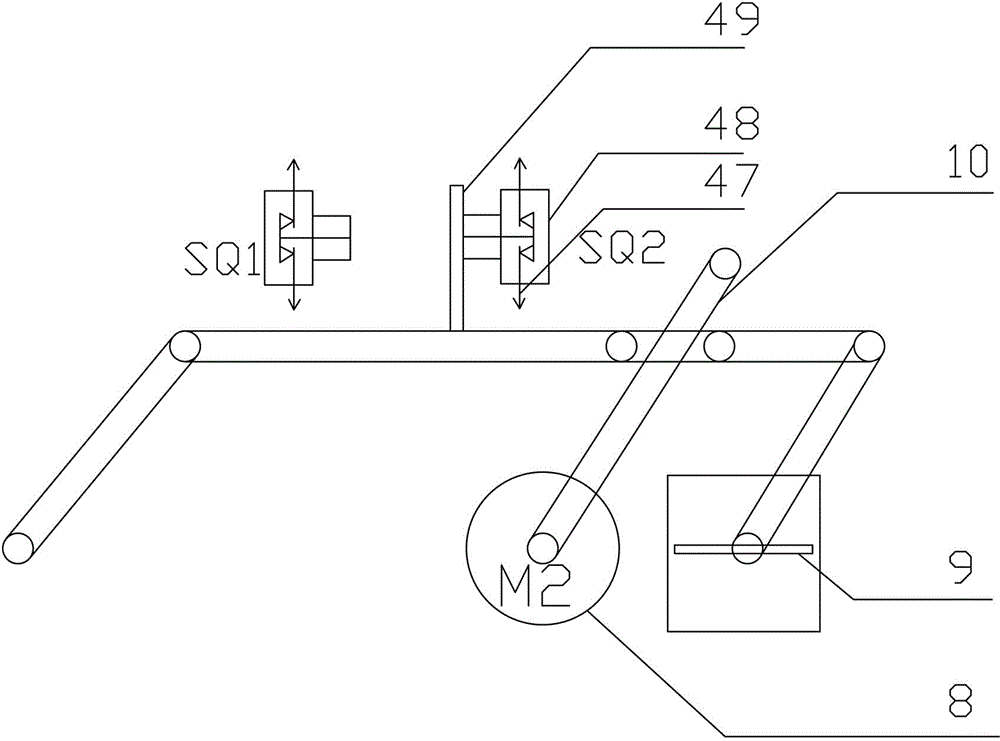

[0021] detailed description The present invention will be further described below in conjunction with accompanying drawing.

[0022] Depend on figure 1 It can be seen that the reverse combustion coal-fired boiler under automatic temperature control consists of a furnace body 33, a heating water layer 32, a coal filling port 16, an ash outlet 1, a smoke exhaust port 22, a waste water tank 28, an electrical protection cover 14, and an observation port 11. , an automatic reciprocating fire grate 6 and a connecting arm 10, a heating water layer 32 is arranged around the furnace body 33, a first water inlet 31 and a first water outlet 21 are arranged on the heating water layer 32, and a safety valve is arranged on the side of the first water outlet 21 19. When the pressure is too high, the safety valve 19 will automatically open, the heating water layer 32 forms a heat flow buffer chamber 25 in the furnace, and the waste water tank 28 is set outside the heating water layer 32, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com