Fuel-saving and carbon-reducing method for fuel use of transportation tool

A technology for means of transportation and fuel, which is applied to fuel heat treatment devices, combustion engines, internal combustion piston engines, etc., and can solve the problems of complete combustion of fuel, waste of energy, and incombustibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

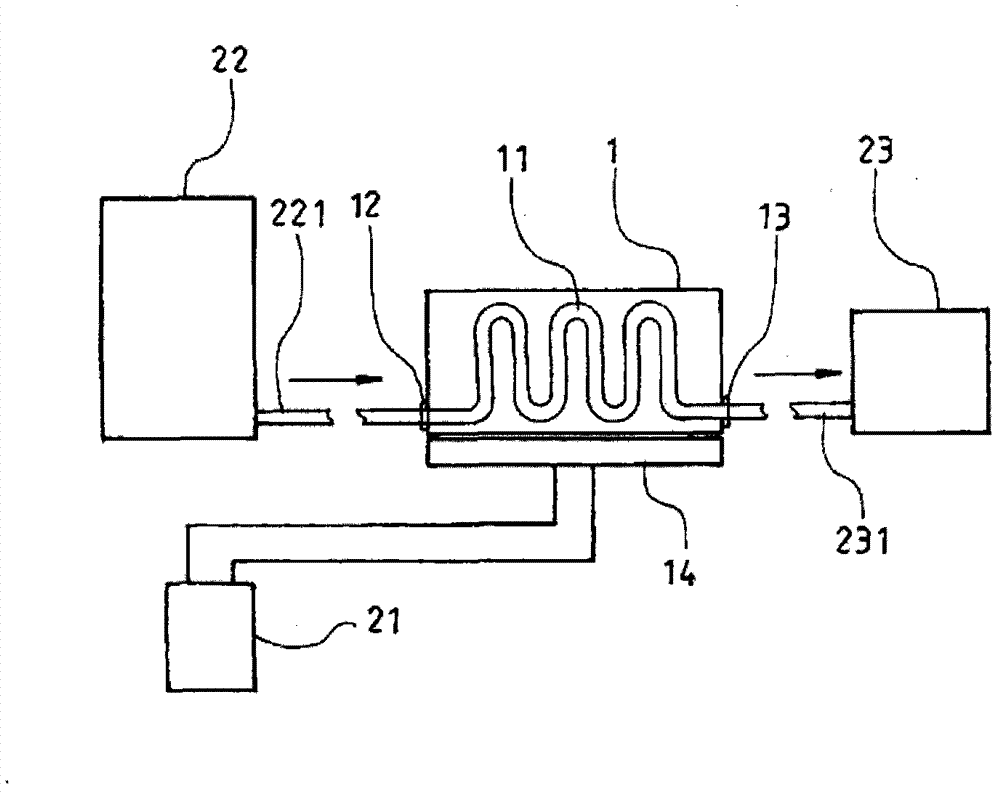

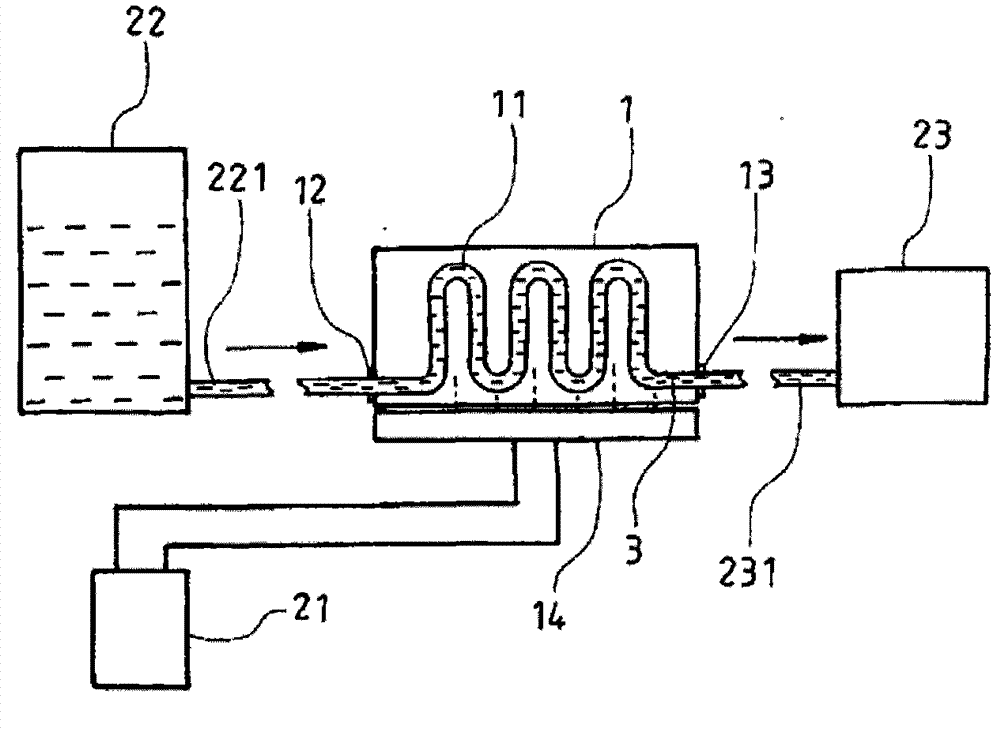

[0022] see figure 1 , is a structural diagram of the present invention. As shown in the figure, the present invention is provided with a heat treatment unit 1. In this embodiment, the heat treatment unit 1 can be a box body or a box body. The heat treatment unit 1 is provided with a circuitously bent through pipe 11 inside. The through pipe 11 Input part 12 and output part 13 are respectively provided at both ends of the heat treatment unit 1, and an electric heating element 14 is provided at the bottom of the heat treatment unit 1. In this embodiment, the electric heating element 14 can be an electric heating wire, a ceramic electric heating plate, etc.;

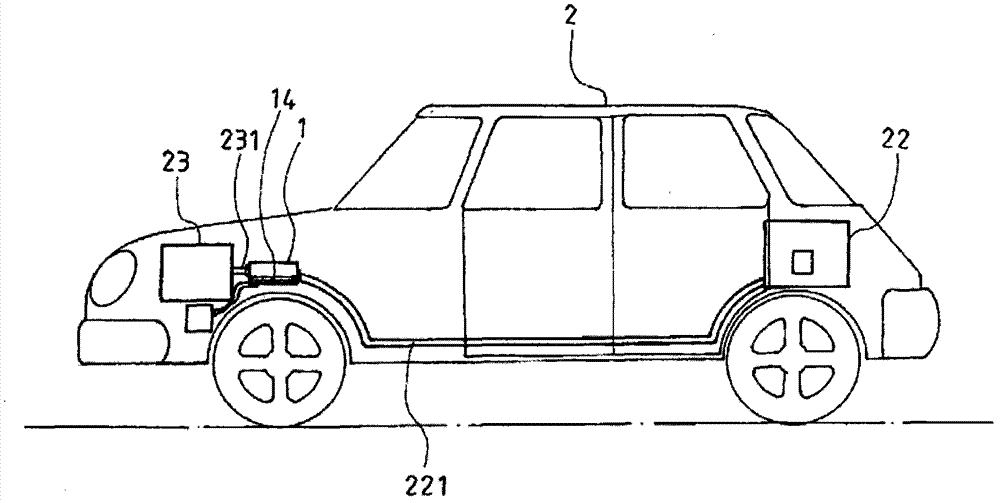

[0023] This heat treatment unit 1 is to connect the electric heating element 14 therein to the accumulator (or generator) 21 of transportation tools such as automobiles, ships, aircrafts, and the fuel tank 22 of the transportation tool is connected to the heat treatment unit 1 with a pipe body 221. The input part 12 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com