Patents

Literature

31results about How to "Add room for mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

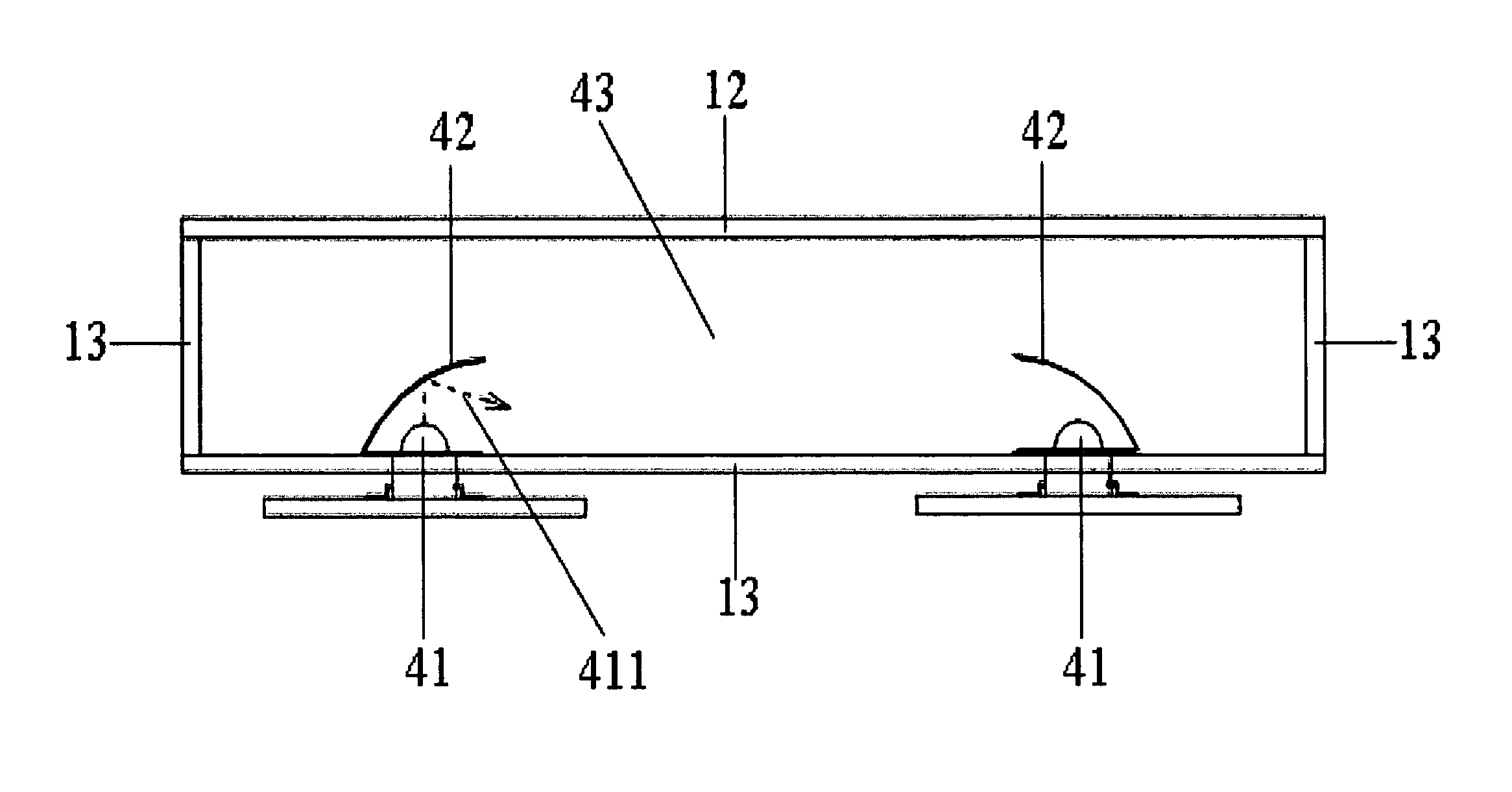

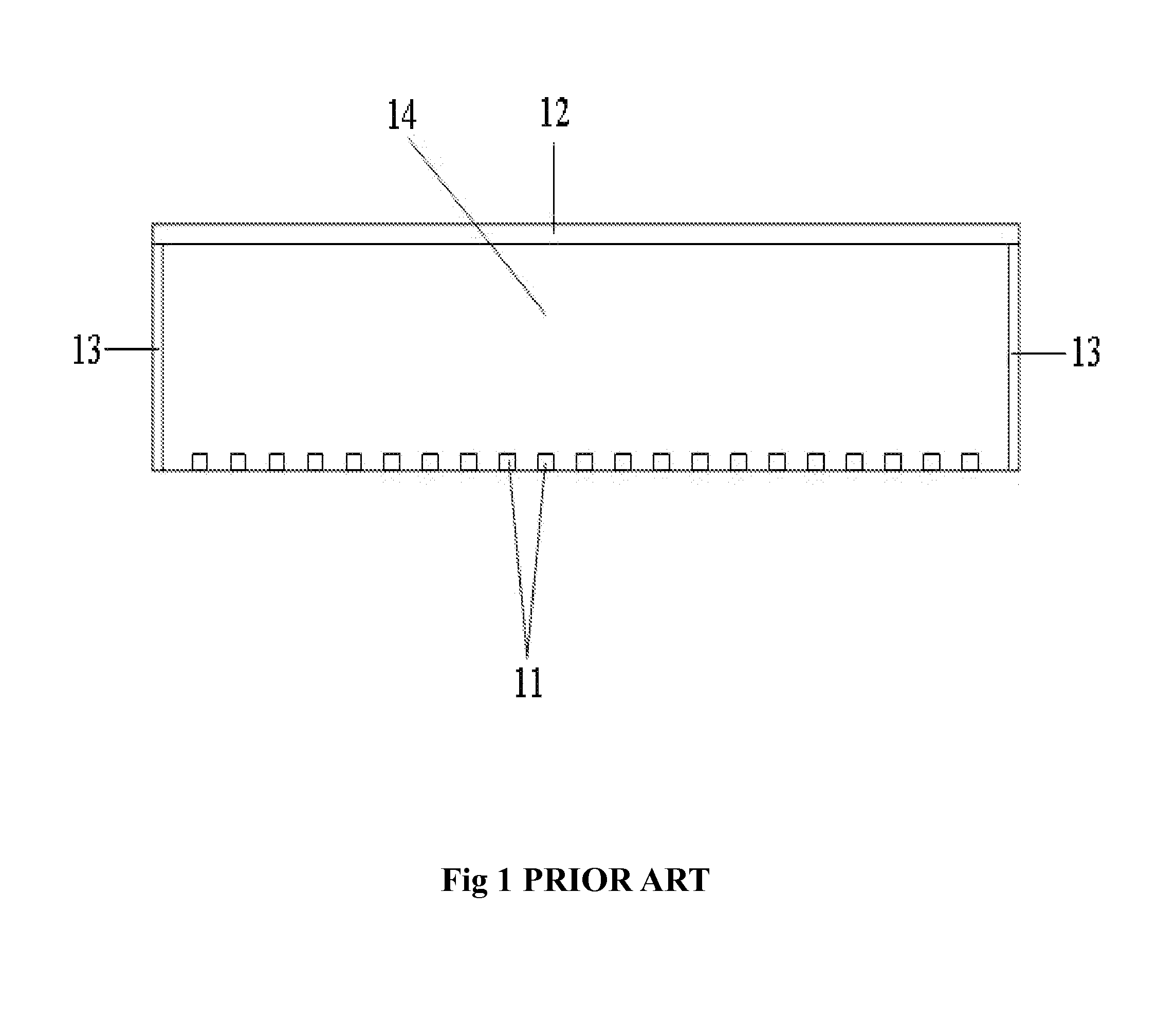

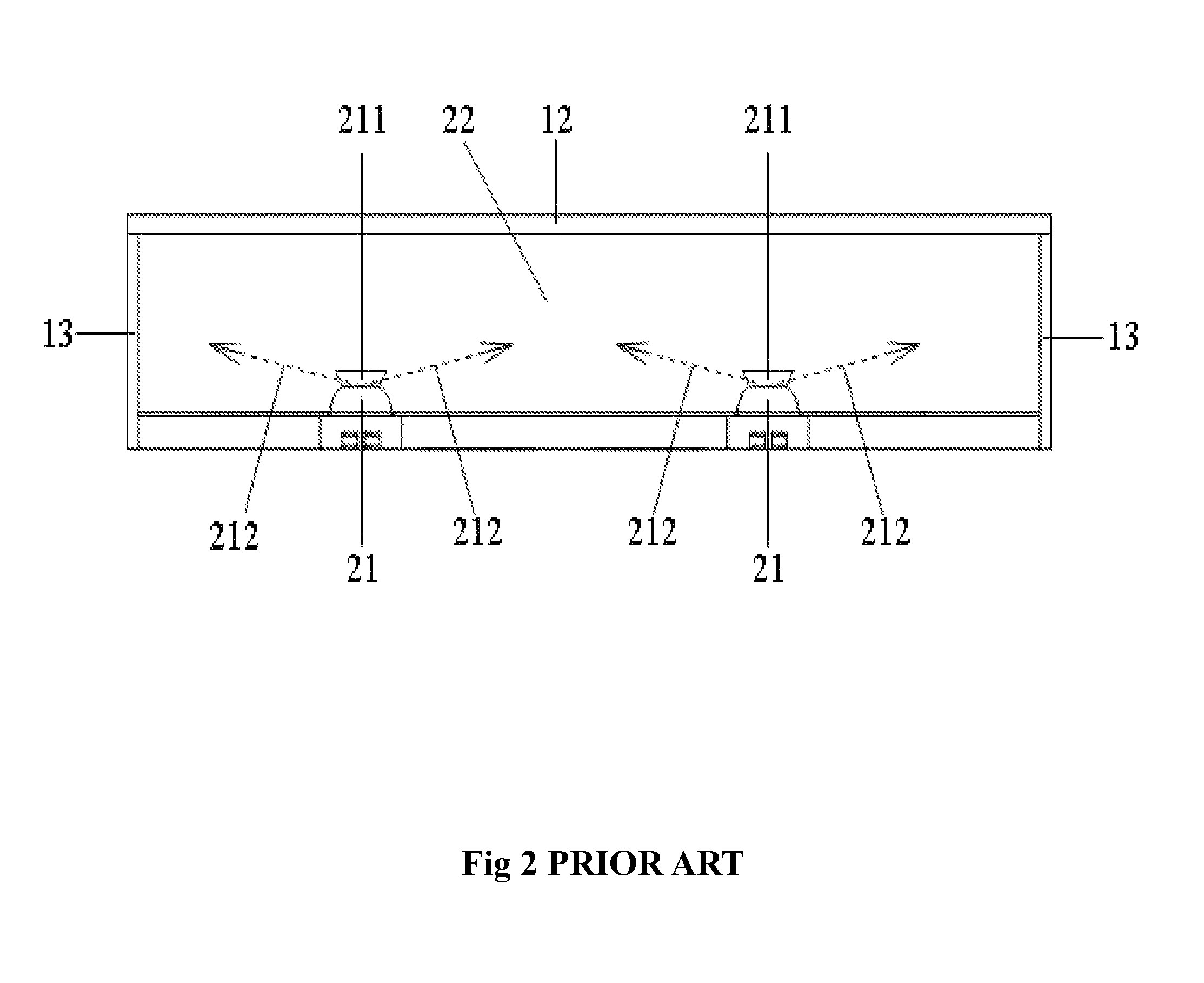

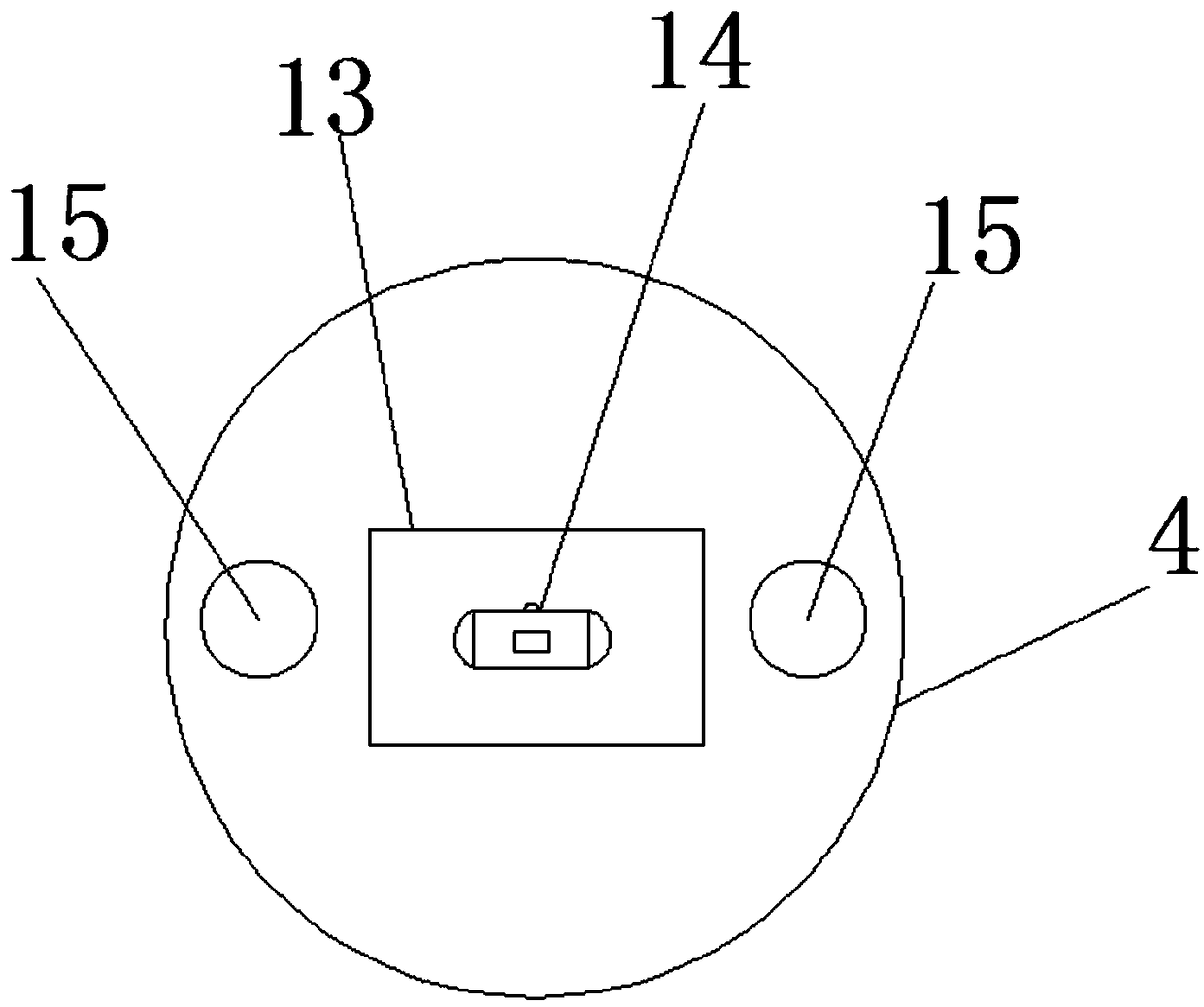

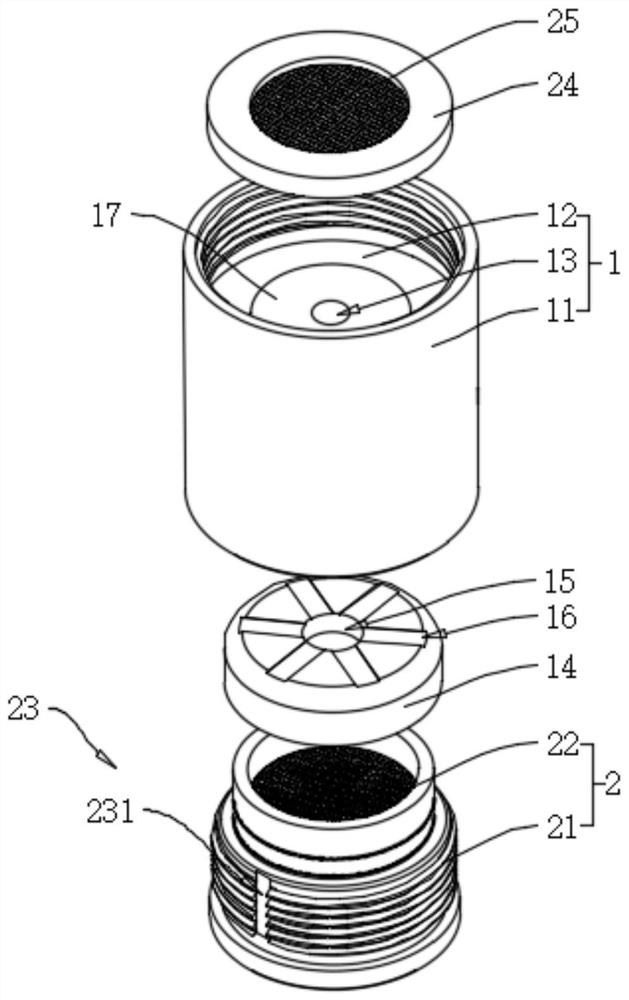

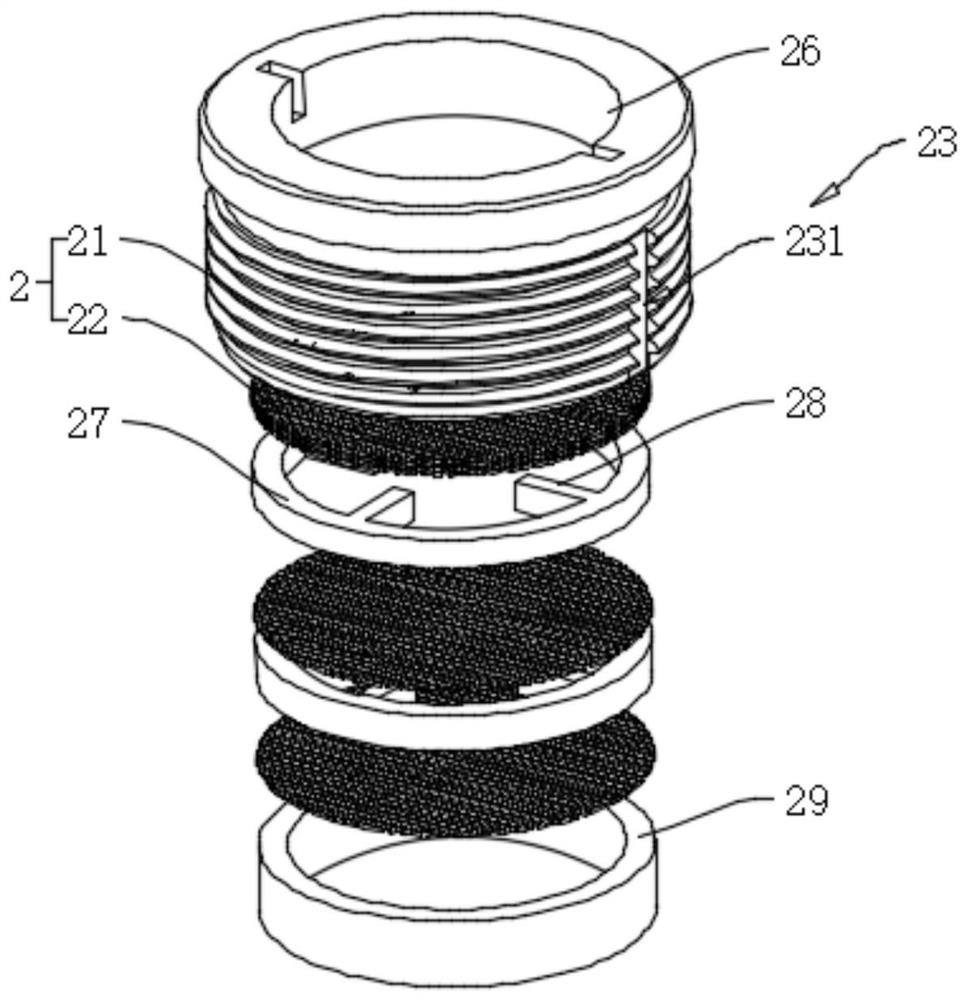

Direct-type backlight unit structure

ActiveUS7229194B2The solution is well mixedAdd room for mixingNon-electric lightingPoint-like light sourceOptoelectronicsUnit structure

Owner:AU OPTRONICS CORP

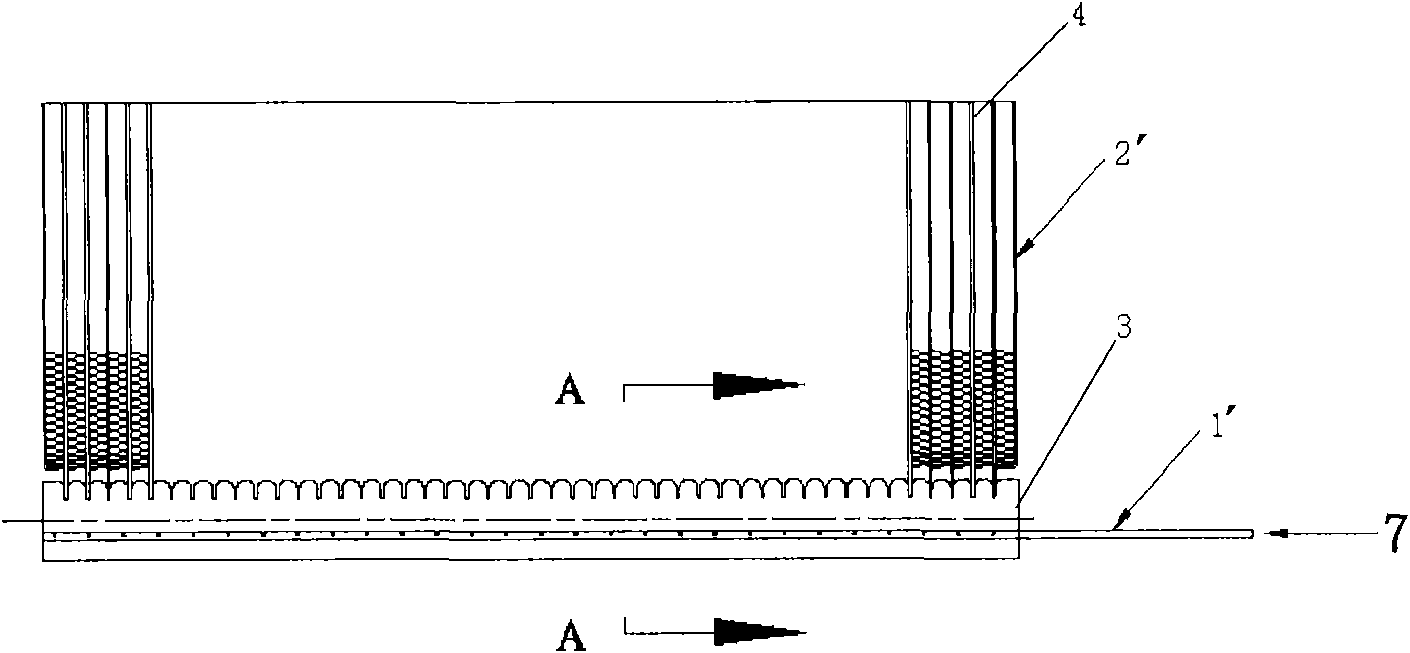

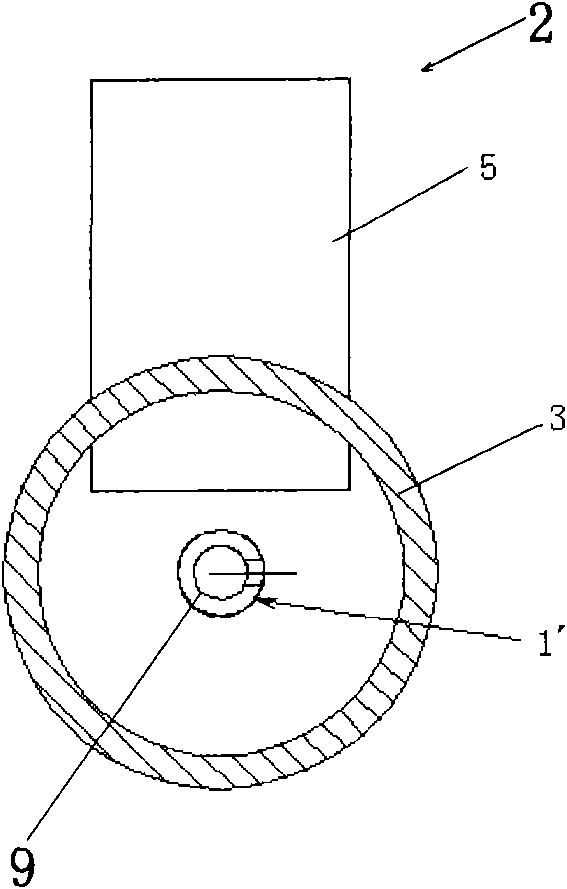

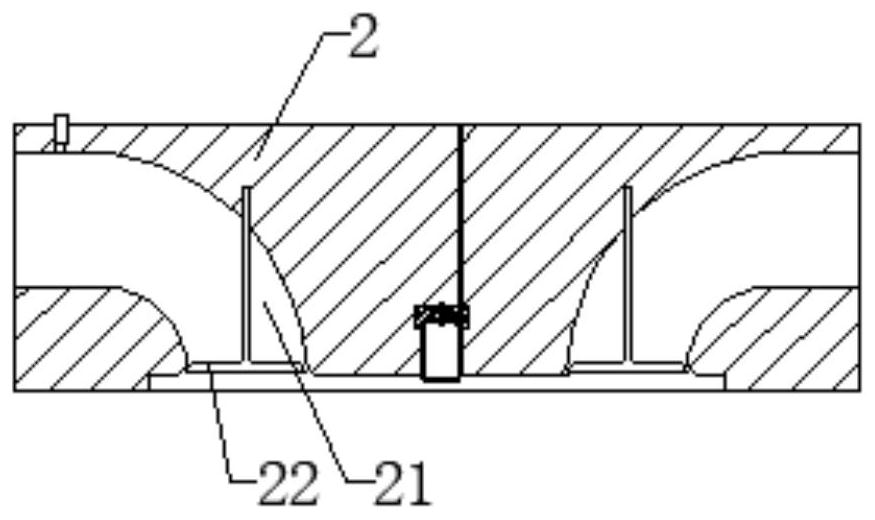

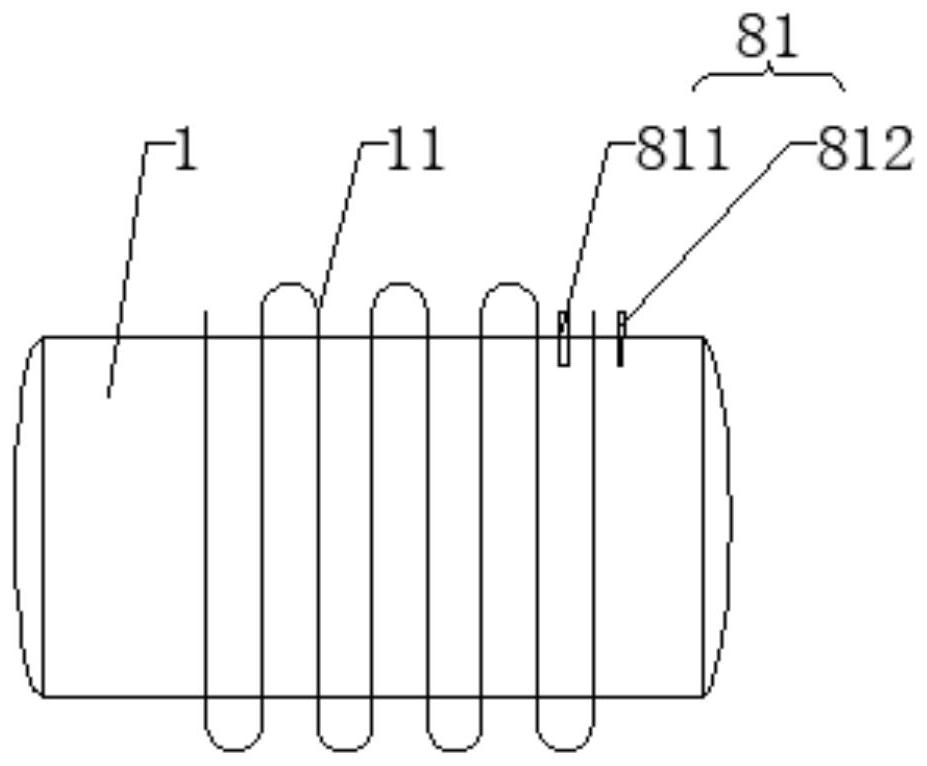

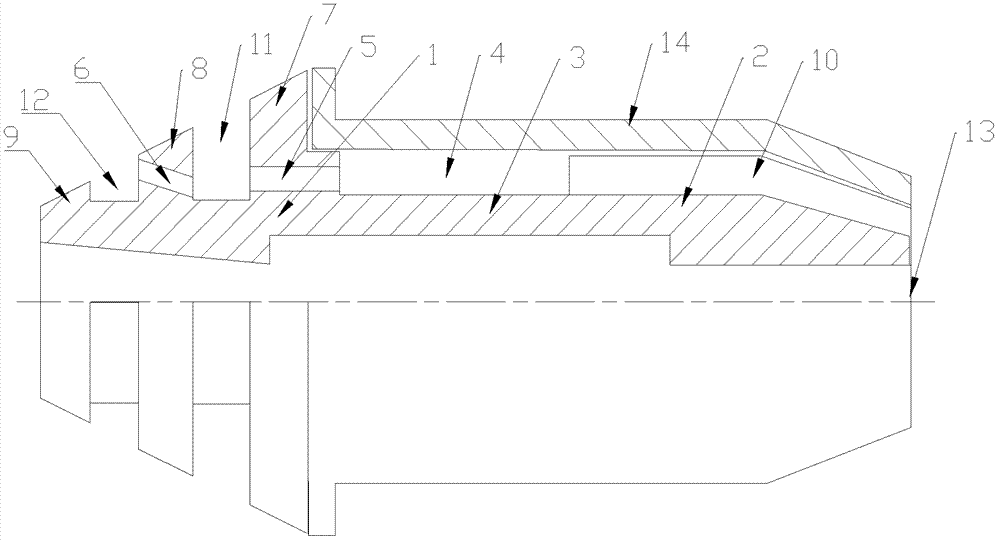

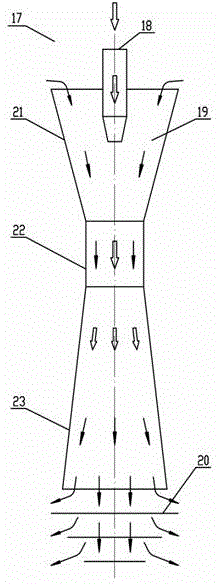

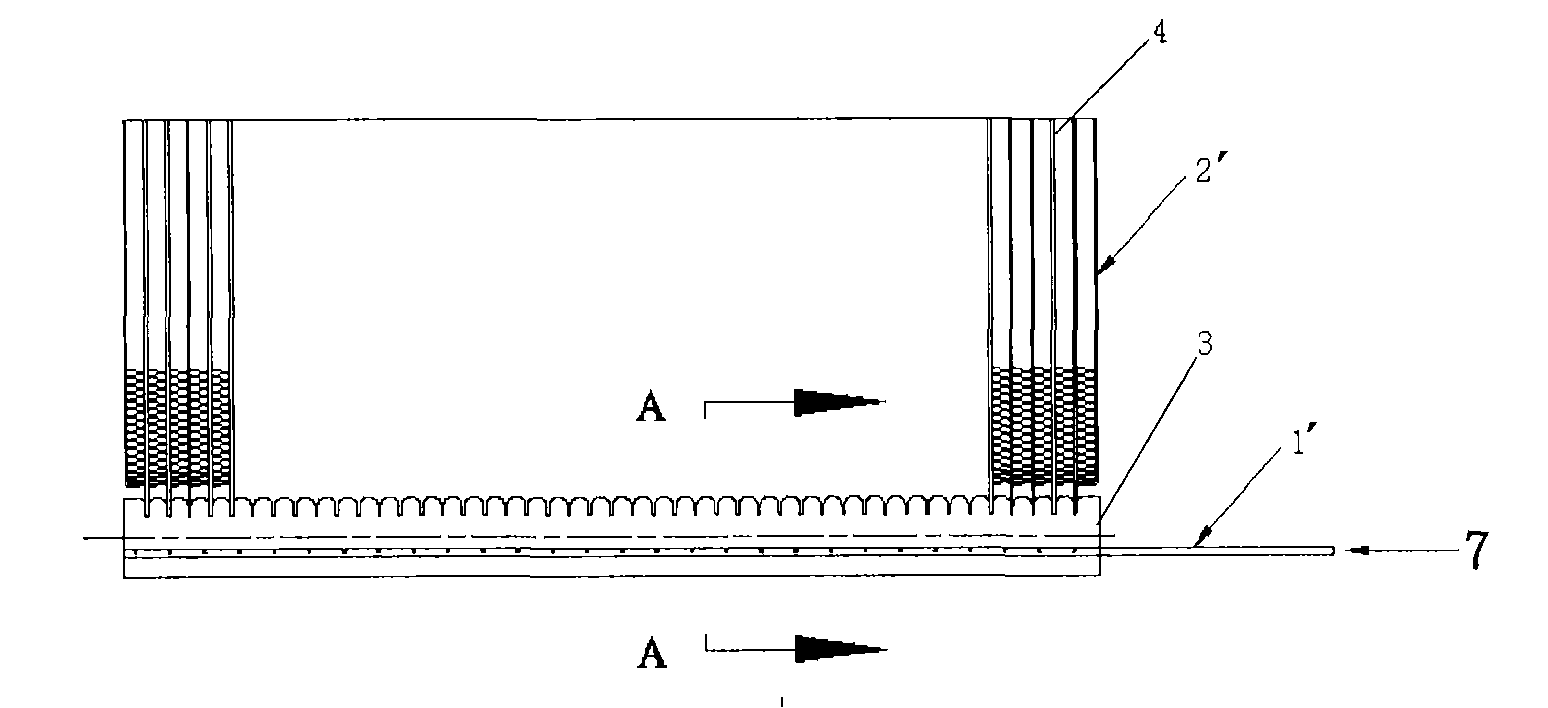

Heat exchanger

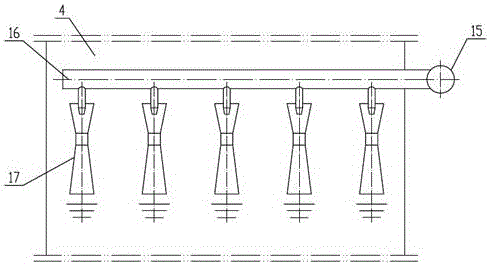

ActiveCN101788235AEvenly distributedAdd room for mixingEvaporators/condensersStationary conduit assembliesVapor liquidRefrigerant distribution

The invention provides a heat exchanger, which comprises a plurality of fluid channels for heat exchange, header pipes arranged at end parts of the plurality of fluid channels and a distributor, wherein each fluid channel is provided with a fluid inlet; the fluid inlets of the plurality of fluid channels are communicated with the header pipes, and the header pipes are provided with center lines; and the distributor comprises distributing pipes, the distributing pipes are arranged in the header pipes, and the distributing pipes are positioned on one side, far away from the fluid inlets of the plurality of fluid channels, of the center lines. By adopting the structure, the mixed space of vapor-liquid two-phase refrigerant outflowing from an outlet hole is enlarged, so that the mixing is relatively uniform and the distribution of the refrigerant is uniform.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER +1

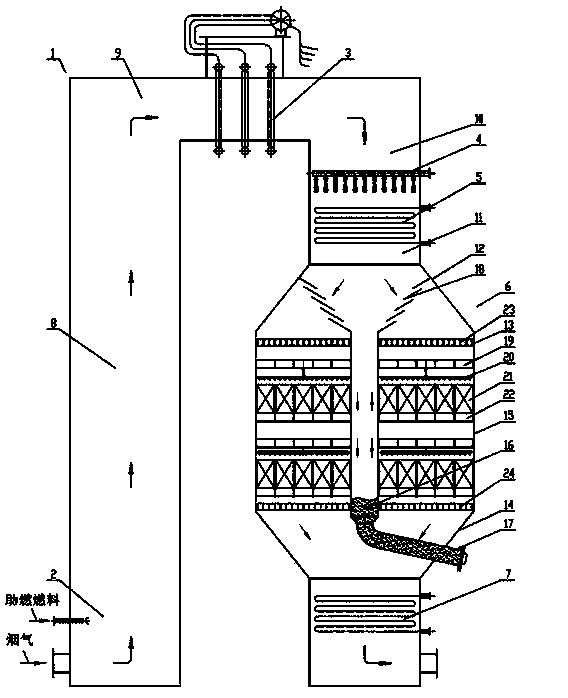

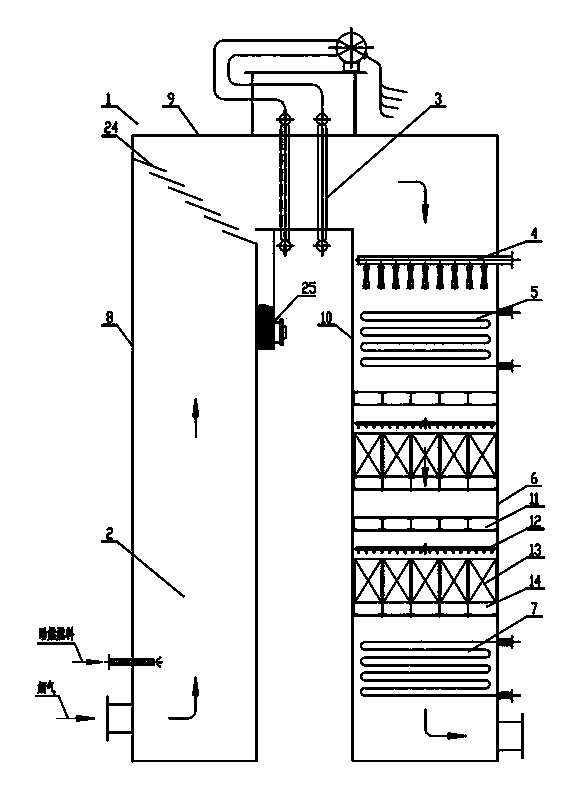

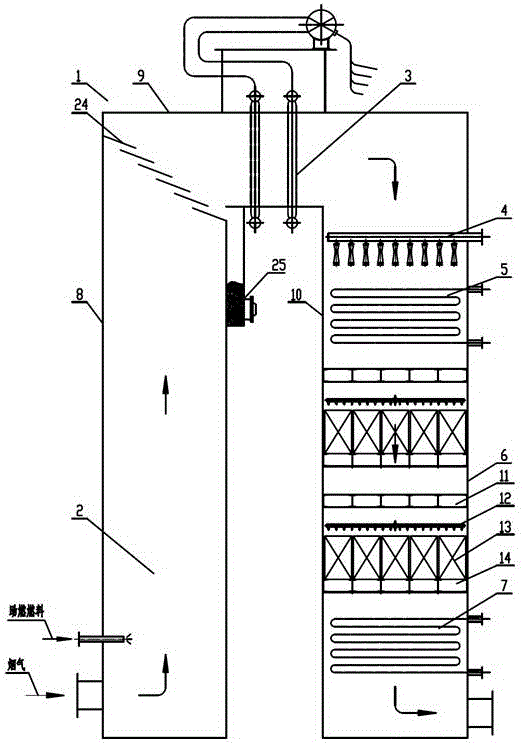

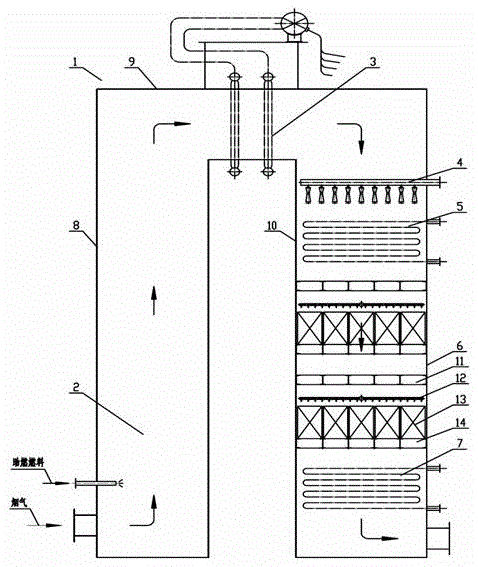

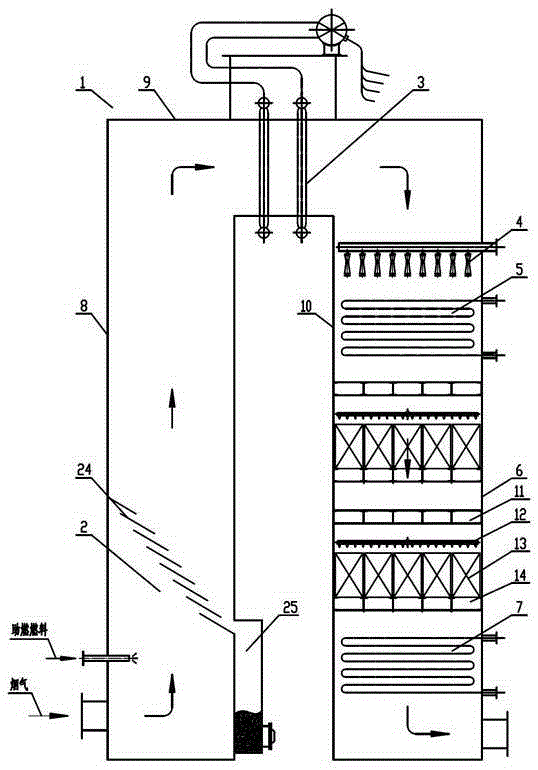

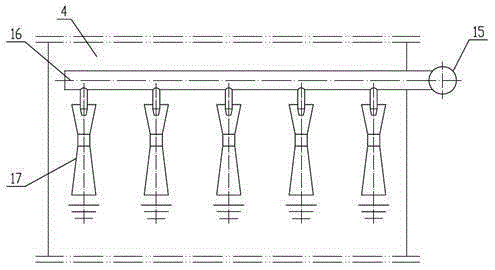

CO boiler having dustproof function and denitration function

ActiveCN103776042AImprove utilization efficiencyEfficient use ofCombination devicesLighting and heating apparatusFlueCoal

The invention relates to a CO boiler having the dustproof function and the denitration function. The CO boiler having the dustproof function and the denitration function comprises a flue, a combustion chamber, steam drums, an evaporation section and an economizer section. The CO boiler further comprises an ammonia spraying and mixing mechanism and a dustproof denitration reactor. The ammonia spraying and mixing mechanism is arranged above the evaporation section or between the evaporation section and the denitration reactor. The dustproof denitration reactor is arranged between the evaporation section and the economizer section and comprises a mixed-smoke inlet section, a denitration section and a purified-smoke discharging section, wherein an ash removal section is arranged between the mixed-smoke inlet section and the denitration section, ash baffles are arranged in the ash removal section, an ash bin is arranged in the denitration section, the center line of the ash bin and the center line of the reactor coincide, and the lower end of the ash bin is connected with an ash discharging pipeline. According to the CO boiler having the dustproof function and the denitration function, the denitration reactor is arranged in the CO boiler, so that the utilization rate of smoke heat is increased; due to the fact that the ash removal section is arranged in the reactor, smoke dust of mixed smoke can be removed before the mixed smoke enters denitration units, catalyst hole channels are prevented from being blocked, and the denitration efficiency and the denitration effect are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

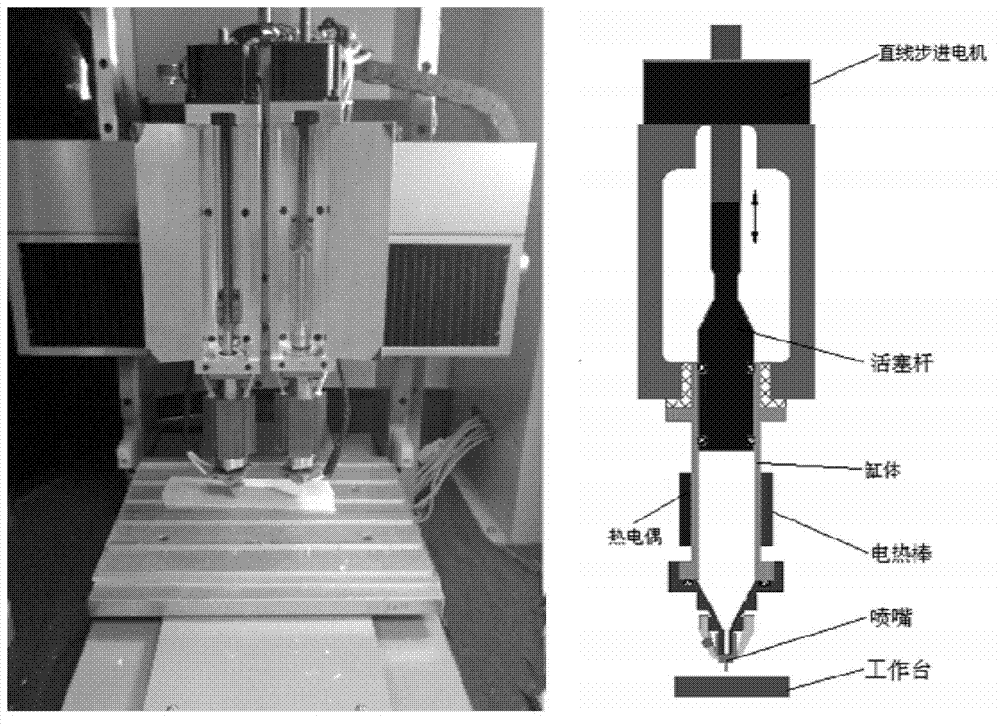

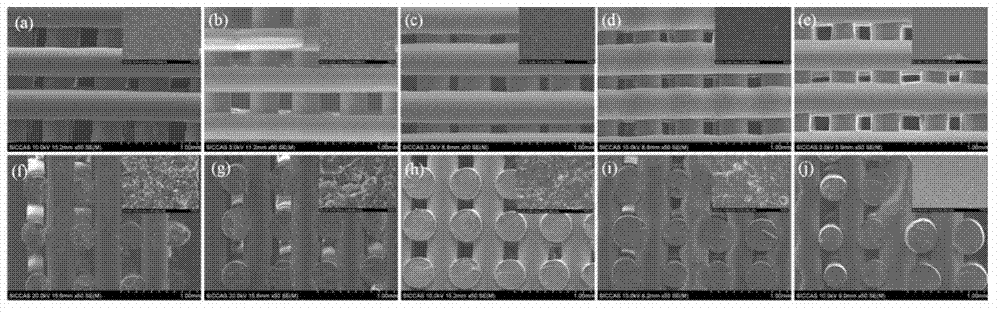

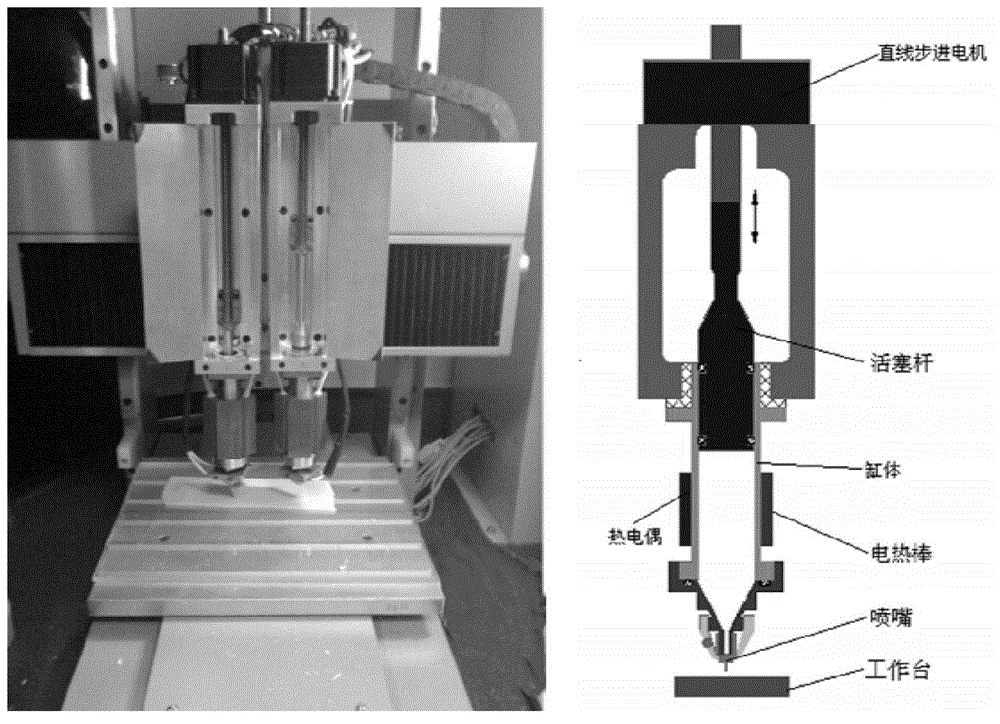

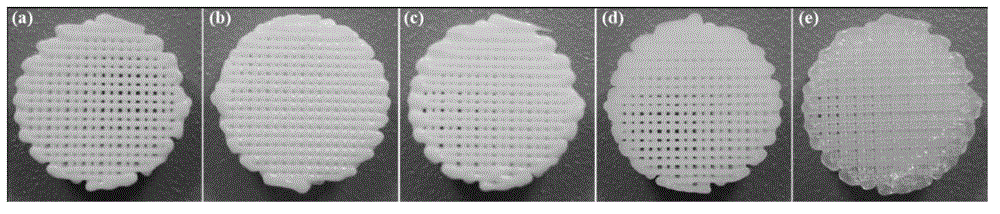

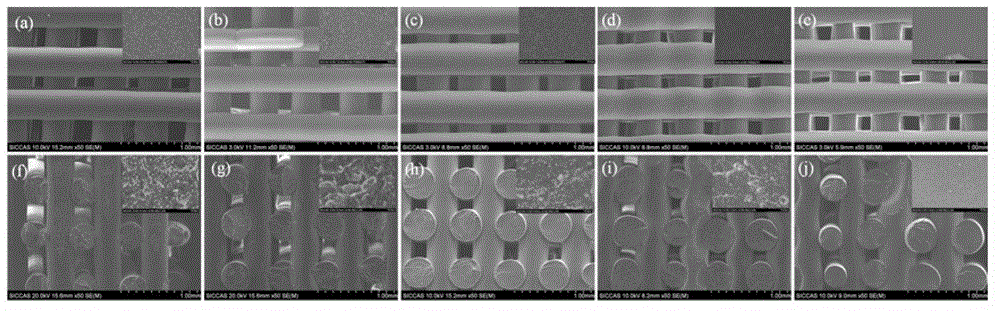

Organic/inorganic composite three-dimensional porous scaffold with drug sustained release function, and preparation method thereof

The invention provides a preparation method of organic / inorganic composite three-dimensional porous scaffold with drug sustained release function. The method comprises the following steps of: (1) preparing organic / inorganic / drug composite material; and (2) putting the organic / inorganic / drug composite material obtained in the step (1) into an extrusion cavity of a motor assisted microsyringe (MAM) free-forming device to form the organic / inorganic composite three-dimensional porous scaffold with drug sustained release function.

Owner:广州雄俊智能科技有限公司

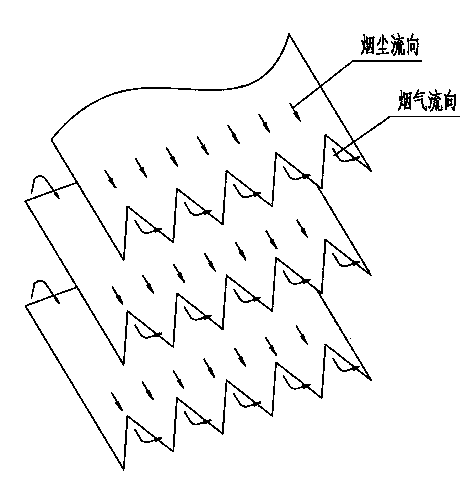

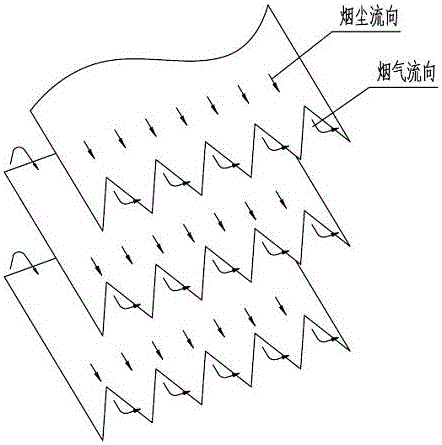

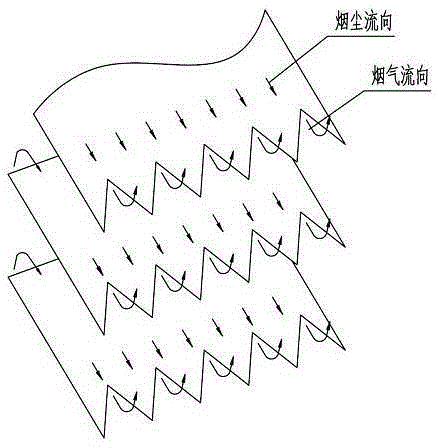

CO boiler having ash removal function

ActiveCN103776014AImprove heat transfer efficiencyReduce the frequency of soot blowingDispersed particle separationSteam boilersFlueEngineering

The invention discloses a CO boiler having the ash removal function. The CO boiler having the ash removal function comprises a first vertical flue, a horizontal flue and a second vertical flue, wherein ash baffles are arranged at the connection position between the first vertical flue and the horizontal flue, an ash storage bin is arranged at the position, flush with the lower edge of the lowest ash baffle, of the inner side of the first vertical flue, the ash baffles are of the structure that multiple layers of baffles are arranged in a staggered mode, each ash baffle is arranged in an inclined mode, and the outer end of each ash baffle is higher than the inner end of the ash baffle. According to the CO boiler having the ash removal function, the ash baffles arranged in the CO boiler can remove most of smoke dust contained in smoke and also play a role in rectifying the smoke, so that the smoke is rectified into the stable horizontal laminar flow state, the smoke evenly passes through steam drums, and the heat exchange efficiency of the boiler is high. The CO boiler having the ash removal function can solve the problem of equipment wear and abrasion caused by the smoke dust to the maximum extent, optimize the smoke processing technology, reduce energy consumption and reduce investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

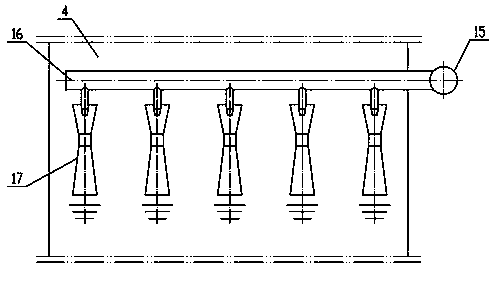

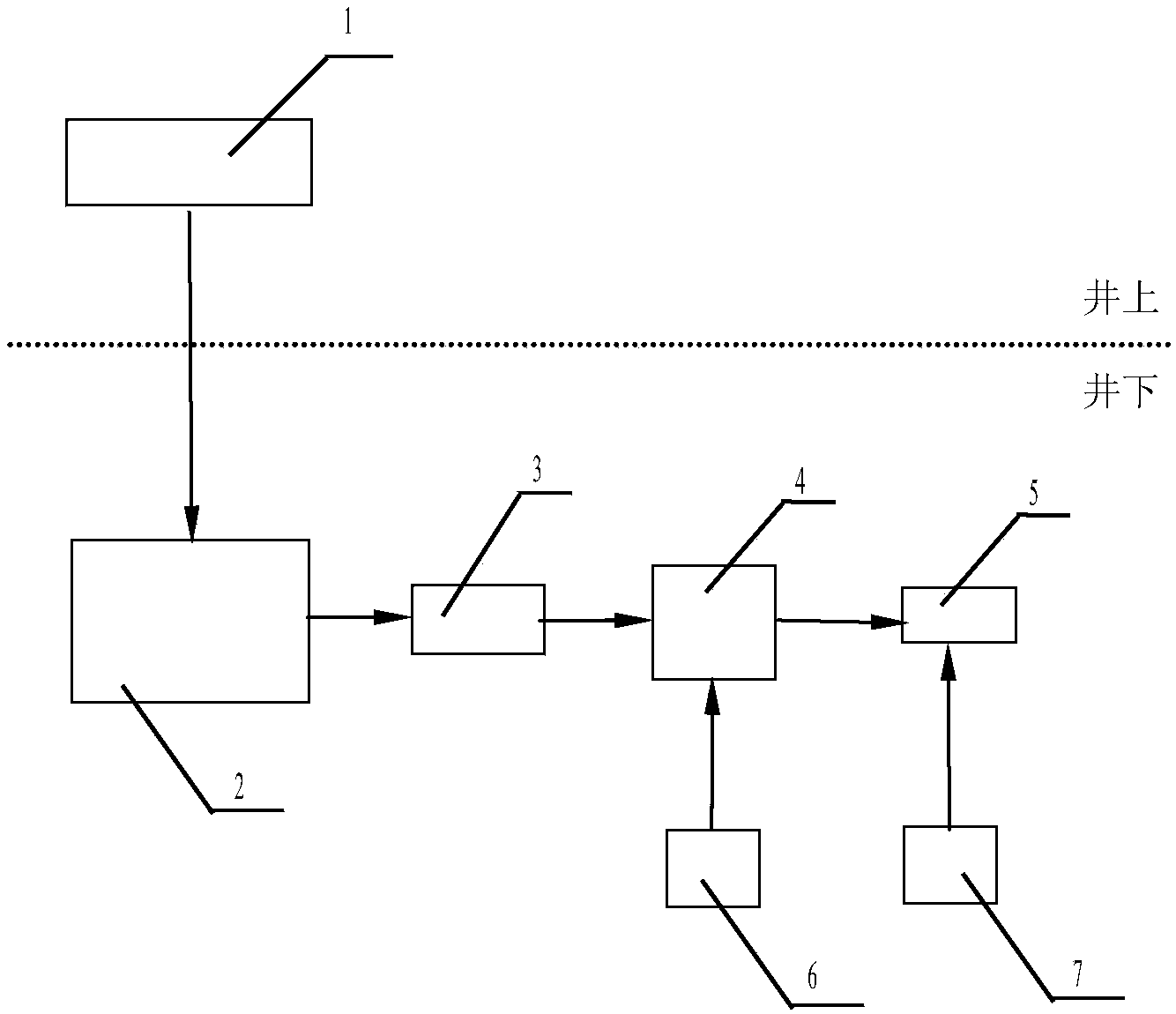

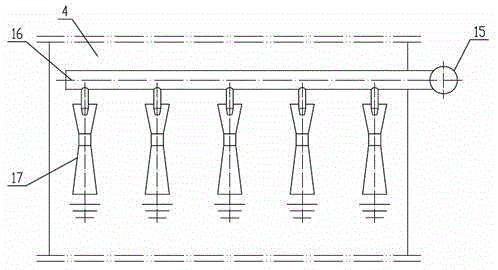

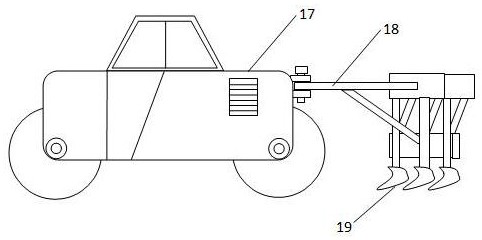

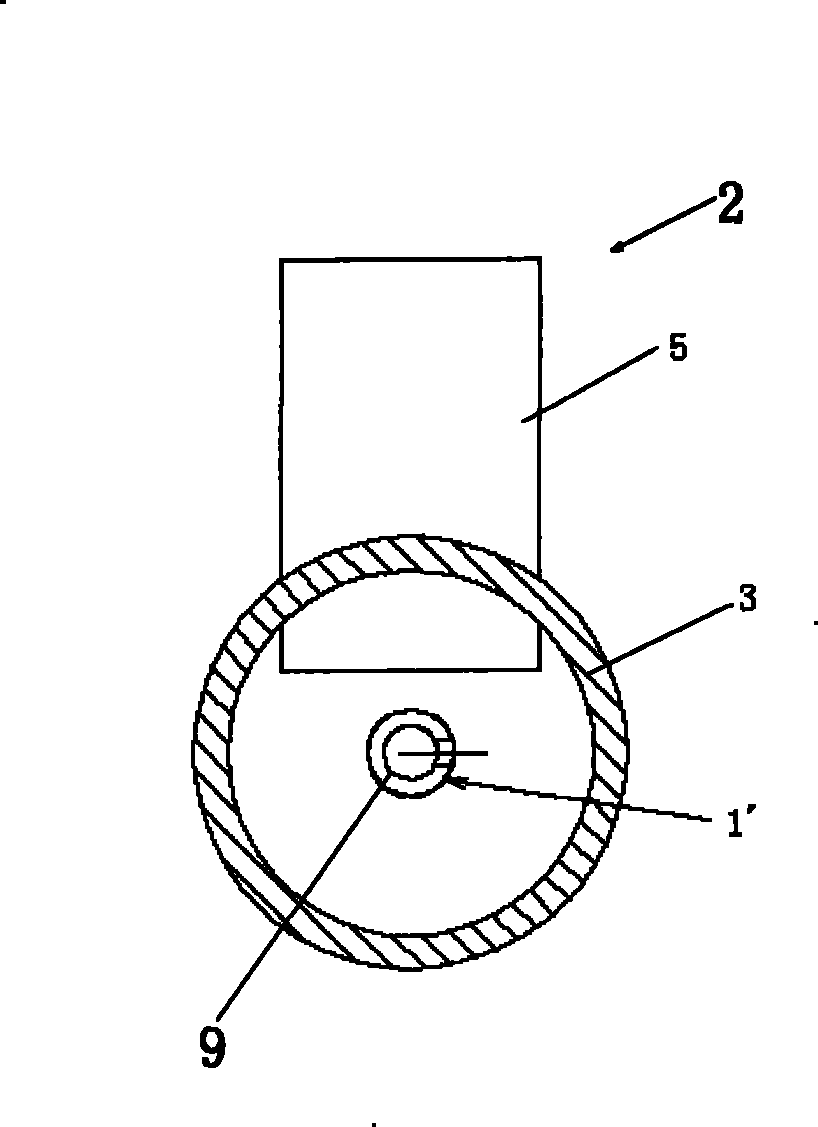

High-strength and low-energy-consumption coal mine wet spraying system and method

InactiveCN103643969AHigh strengthImprove energy consumptionUnderground chambersMixing operation control apparatusBatch machineUltimate tensile strength

The invention discloses a high-strength and low-energy-consumption coal mine wet spraying system. The wet spraying system comprises a batching machine (1), a blender (2), a spiral quantitative water distribution and transport vehicle (3) and a wet spraying machine which are arranged sequentially, wherein the blender (2) is arranged on the downstream of the batching machine (1); the spiral quantitative water distribution and transport vehicle (3) is arranged at a discharge port of the blender (2); and the wet spraying machine is arranged at a discharge port of the spiral quantitative water distribution and transport vehicle (3). According to the high-strength and low-energy-consumption coal mine wet spraying system, mechanized quantitative control of water, cement, sand, stone and various additives is realized, the working strength of a worker is reduced, and the stability of concrete performance is guaranteed.

Owner:ANHUI UNIV OF SCI & TECH

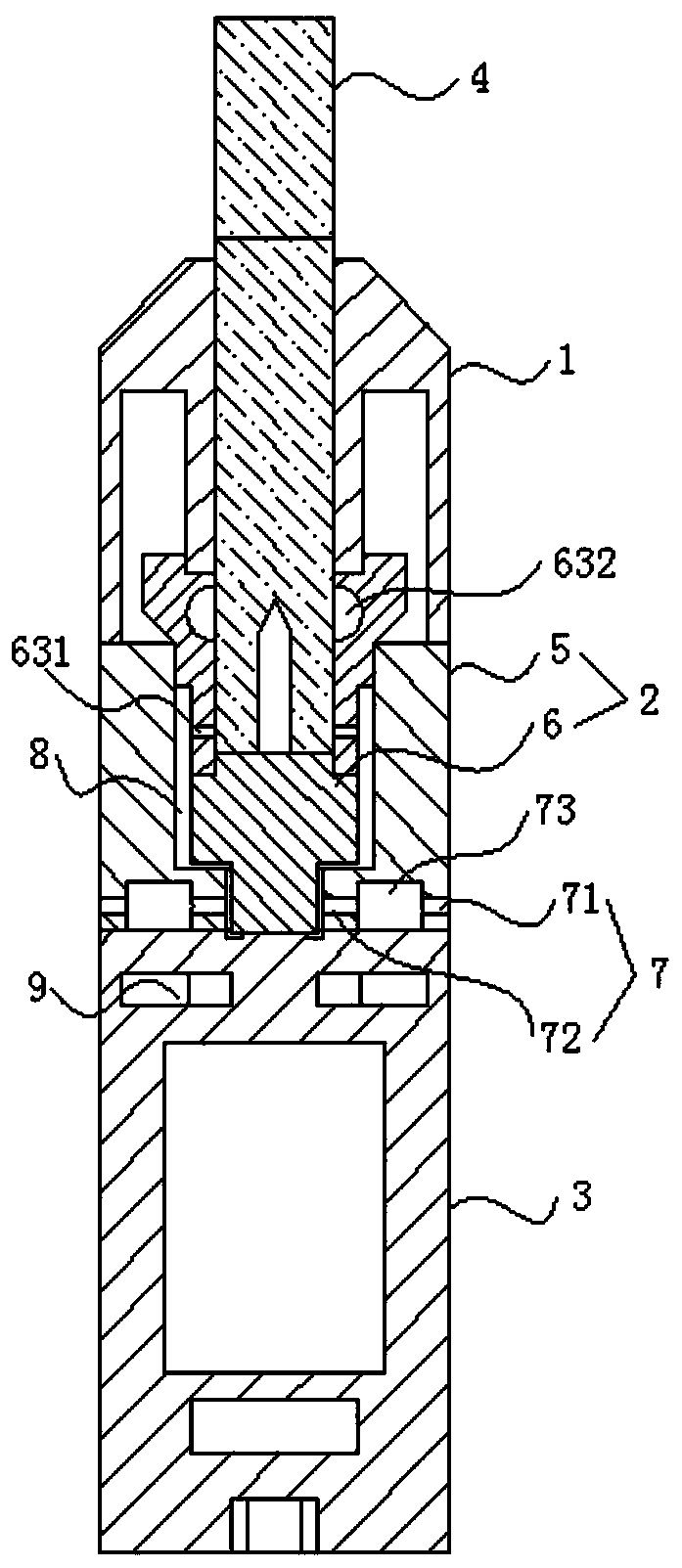

Cigarette heating device

Owner:CHINA TOBACCO GUANGDONG IND

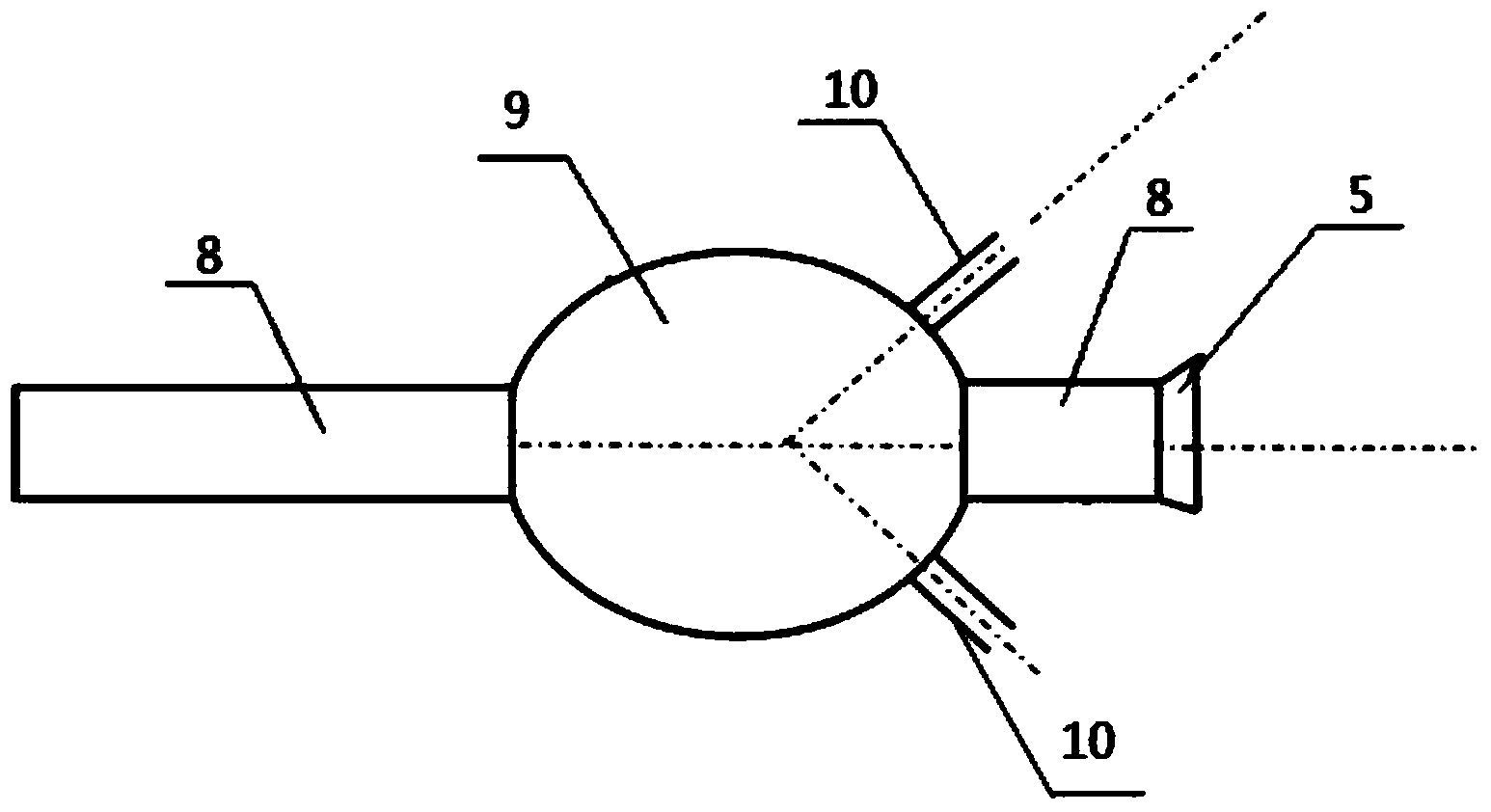

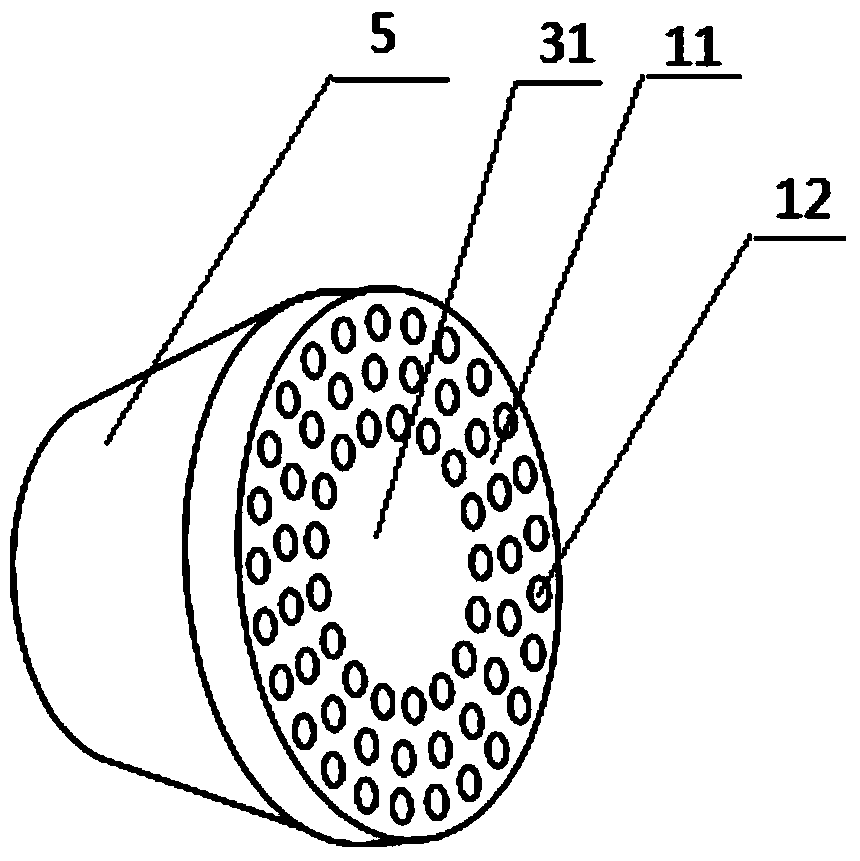

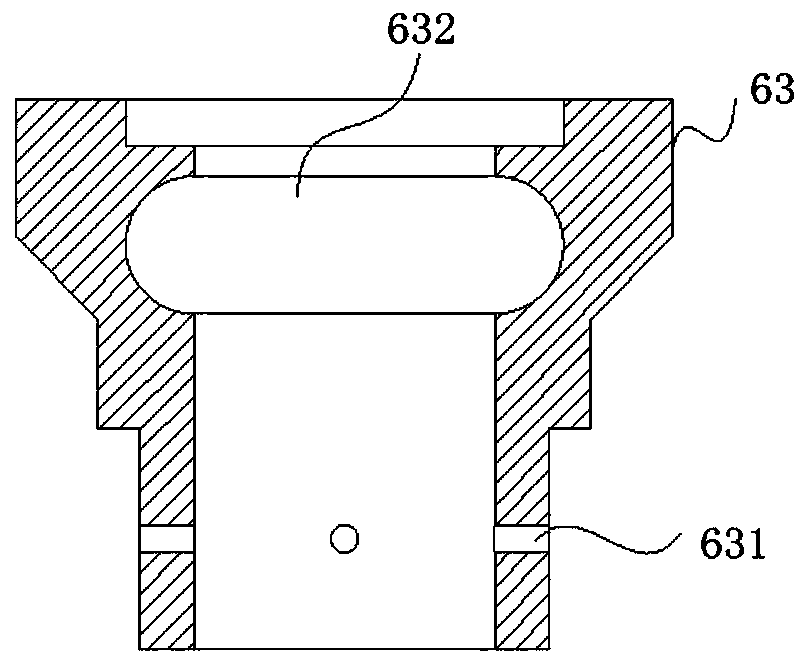

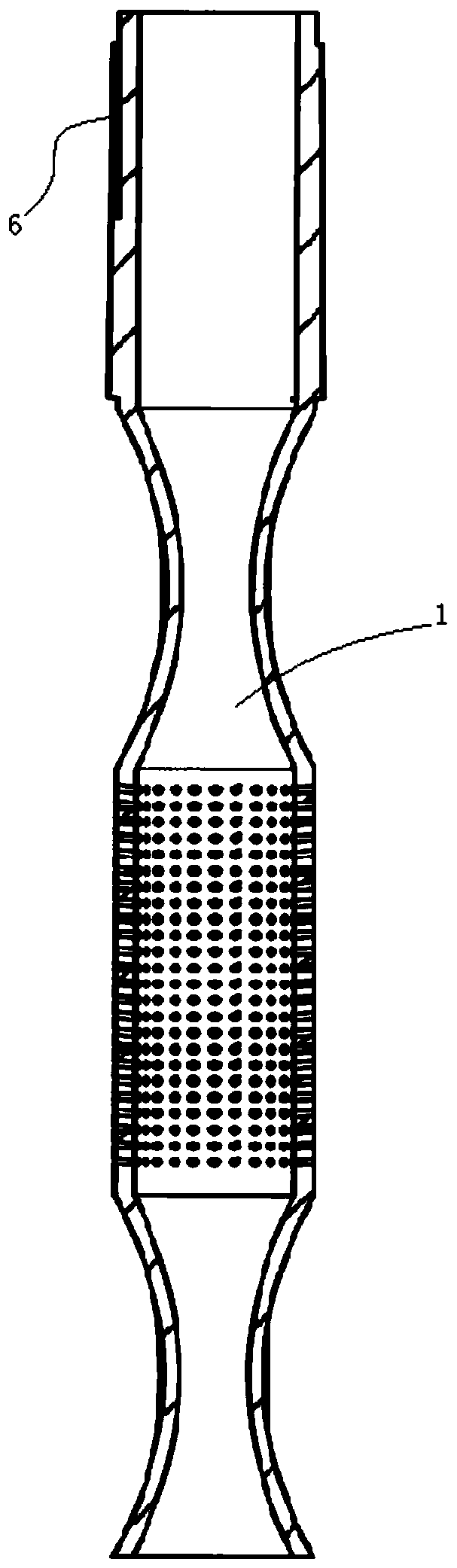

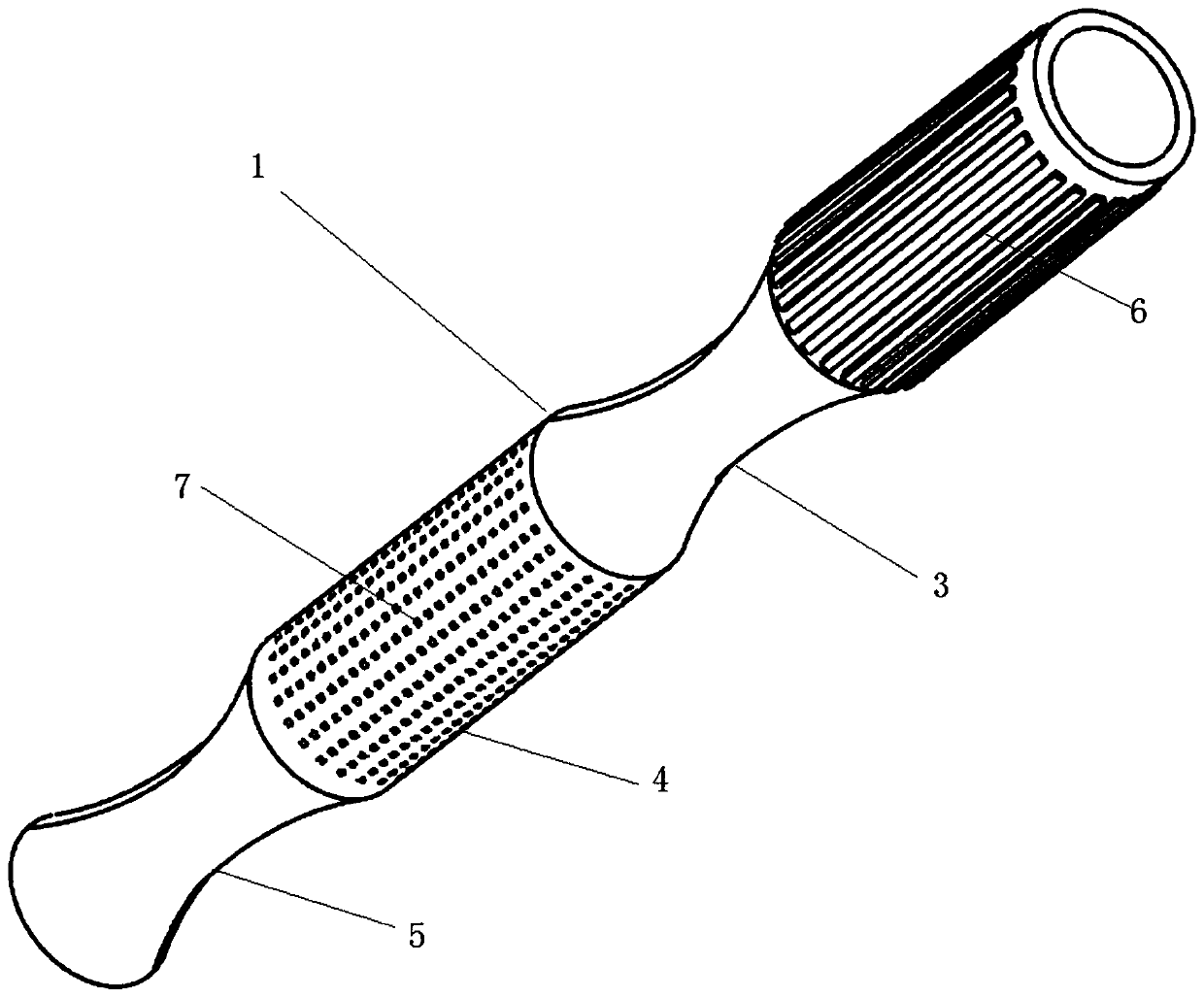

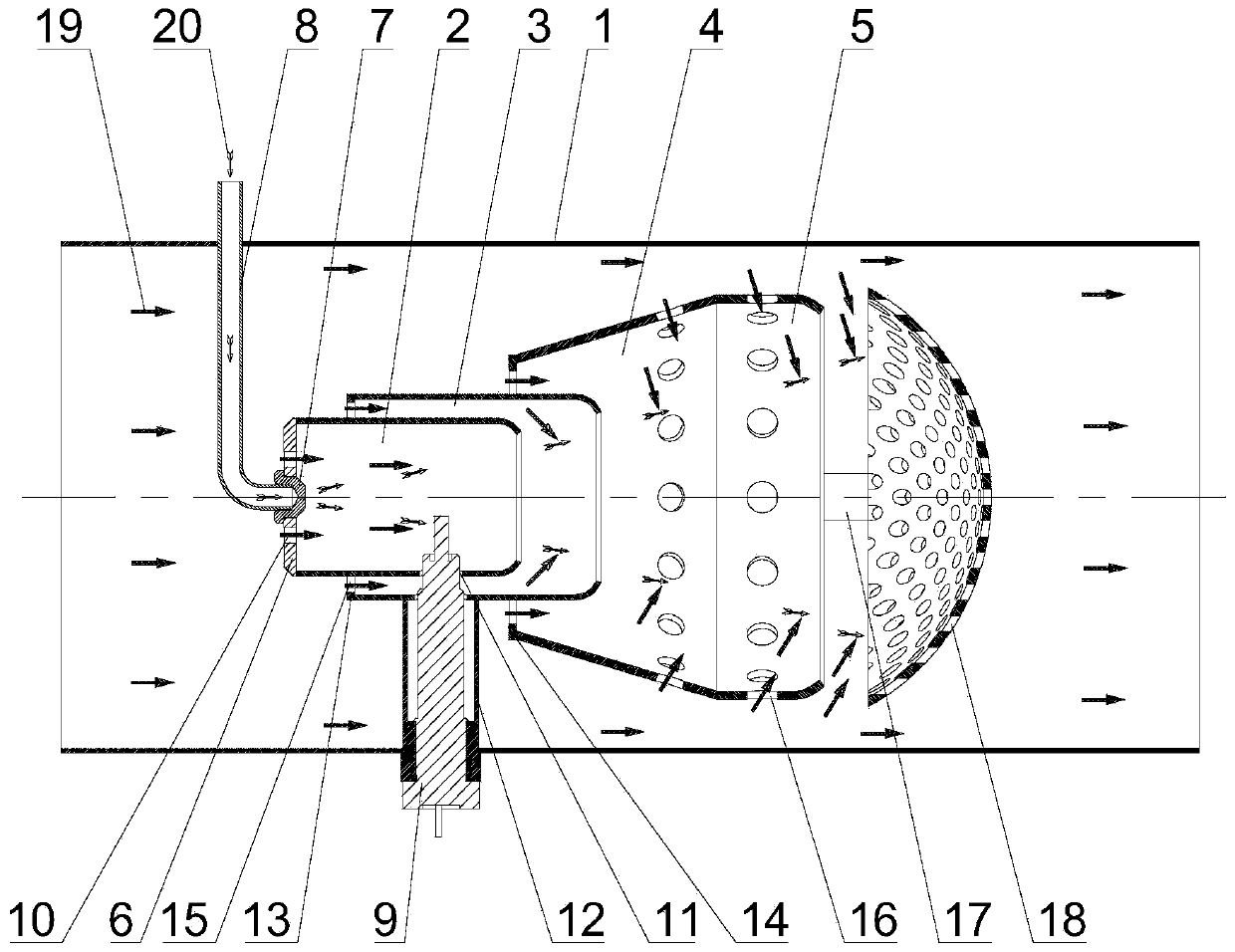

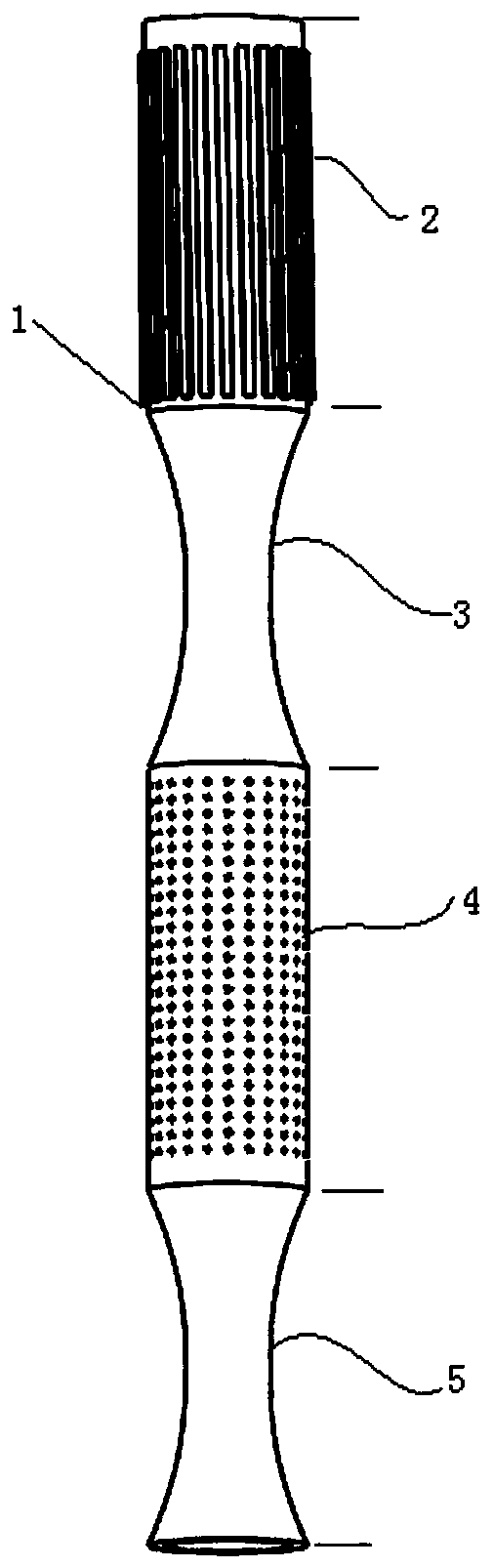

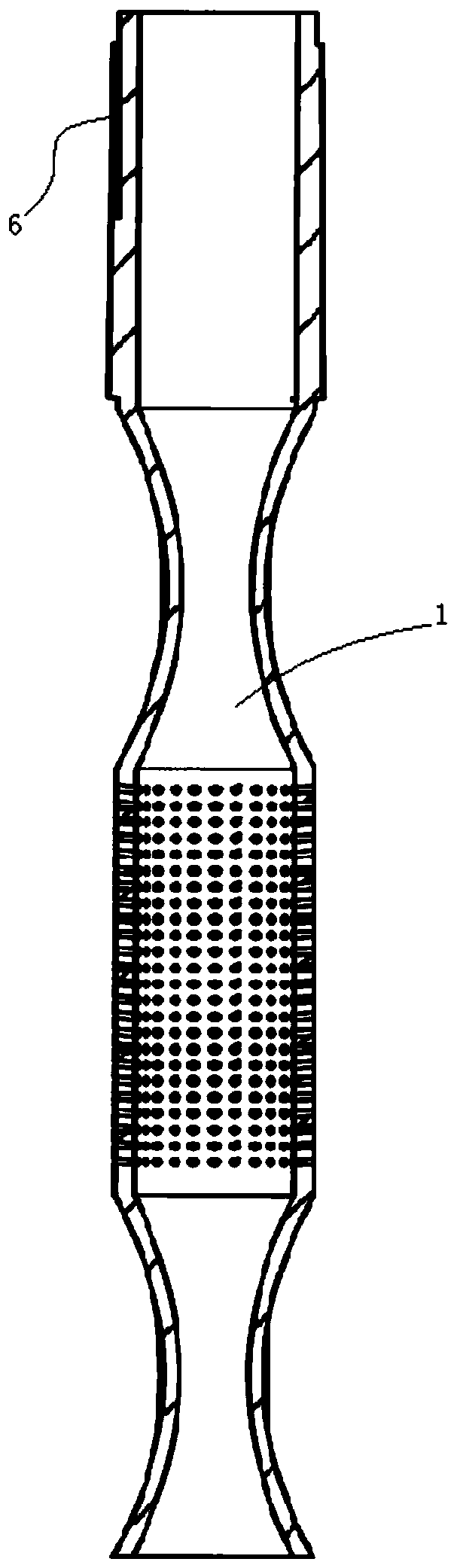

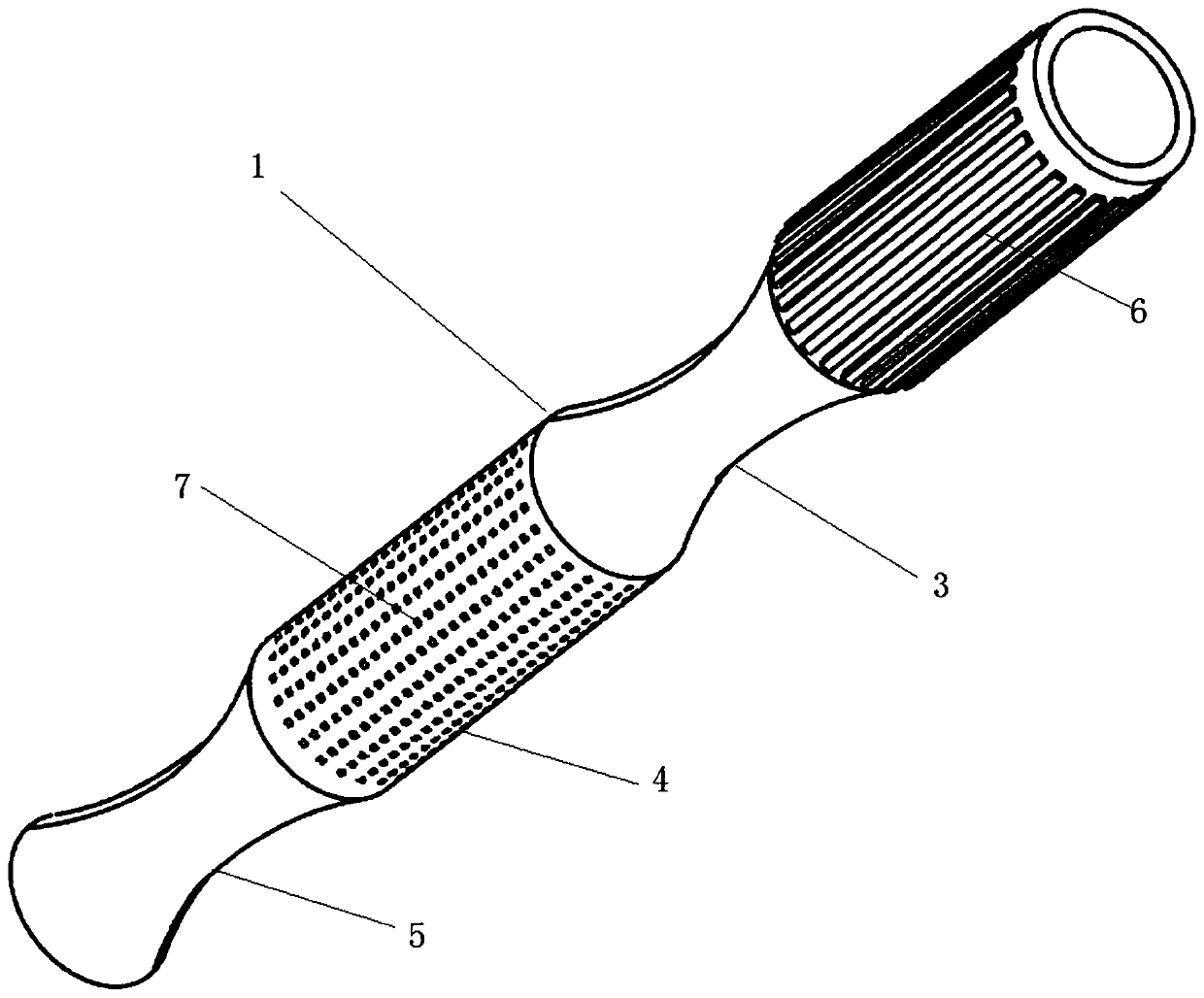

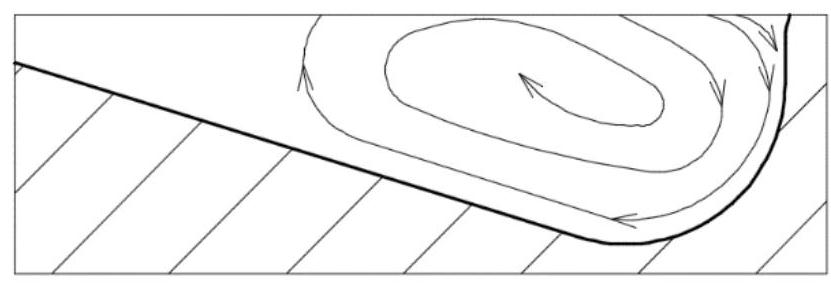

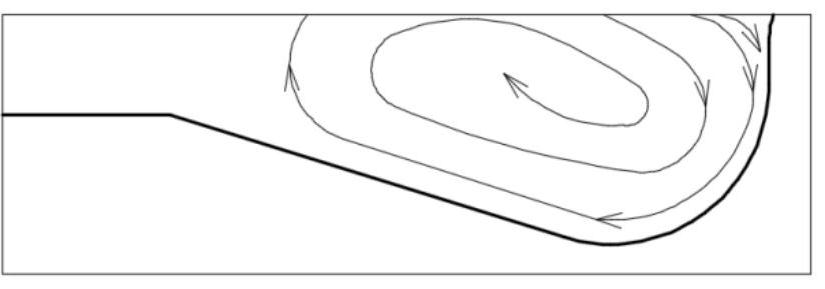

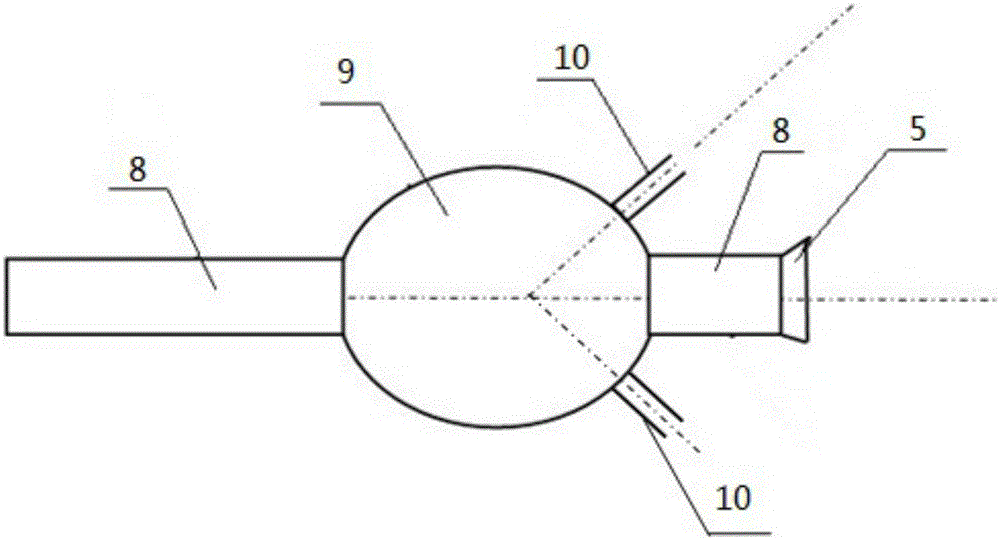

Evaporating pipe structure for engine combustion chamber and engine combustion chamber structure

ActiveCN110375331AAdd room for mixingImprove heat transfer effectContinuous combustion chamberCombustion chamberJet flow

The invention discloses an evaporating pipe structure for an engine combustion chamber and an engine combustion chamber structure. An internal concave curved surface section composed of at least two cambered surfaces is utilized, two column cambered surfaces arranged symmetrically are adopted in each cambered surface, the internal concave curved surface section adopts a gradual contracting and gradual stretching structure, mixed gas flows through an evaporating pipe, a backflow area is formed in the internal concave curved surface section, the speed is reduced, the mixed space of fuel oil andair is increased, stay time in the evaporating pipe is prolonged, the contact area of the mixed gas and the wall face of the evaporating pipe is increased, and gas heat exchange is enhanced. By meansof the gradual contracting and gradual stretching curved wall face, the strong shearing effect brought by the gas enables the fuel oil and the air to be mixed more fully. Fins are arranged on the outer surface of a first cylinder section, heat exchange between high-temperature airflow in a flame cylinder and the evaporating pipe is enhanced, and the temperature in the evaporating pipe is increased. Mixing holes form oblique holes to jet flow to enable air to directly impact oil fog, atomizing evaporation of the fuel oil is promoted, the atomizing and evaporating effect of the fuel oil in the evaporating pipe is enhanced, the fuel oil is combusted fully, and emission of pollutants is reduced while the combustion efficiency is improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

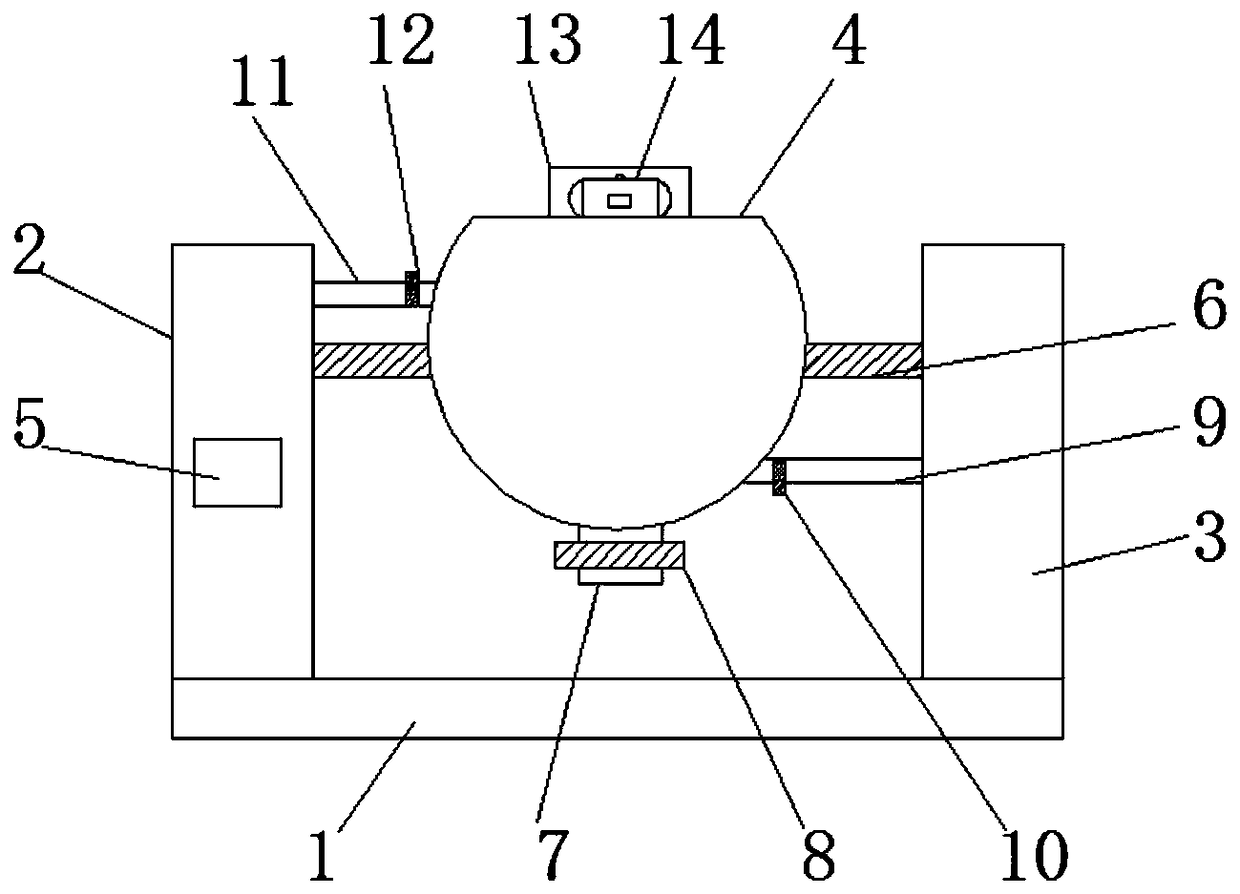

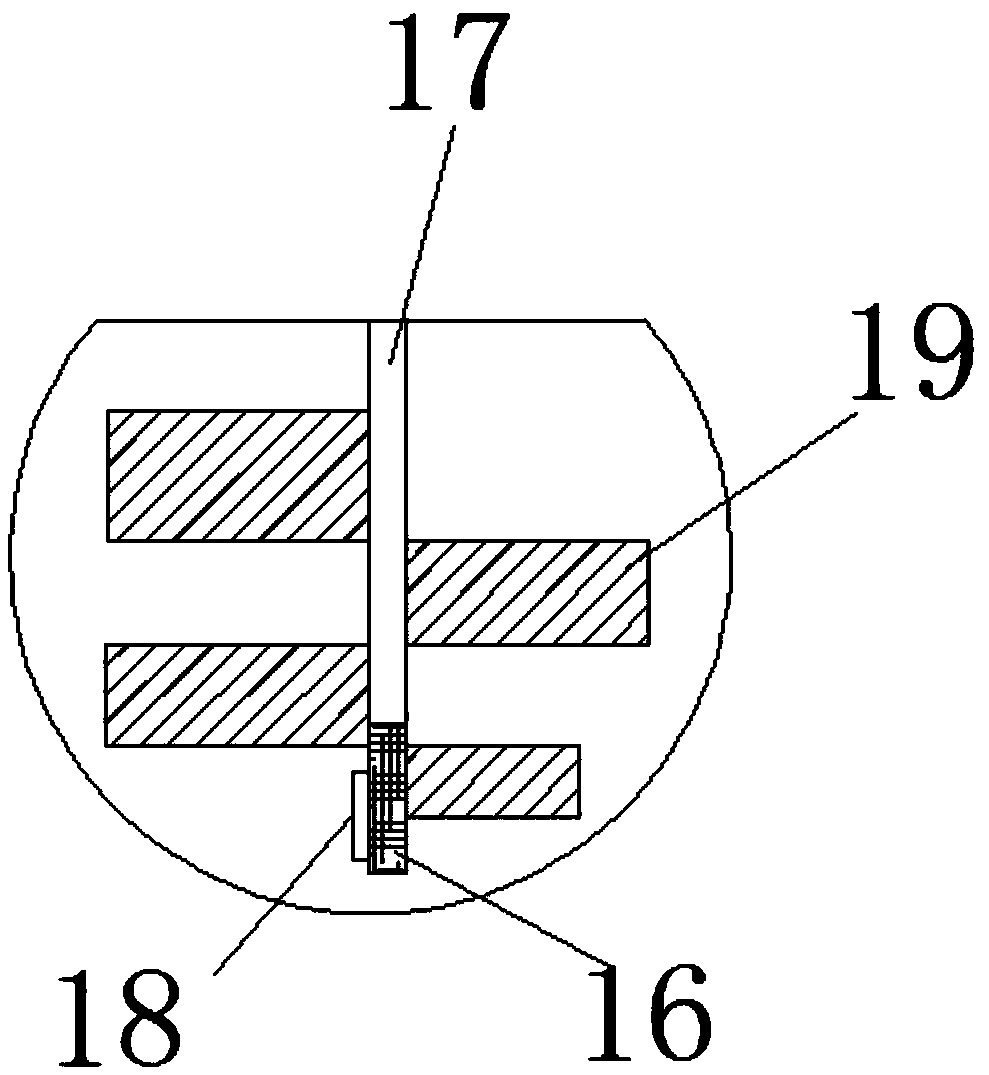

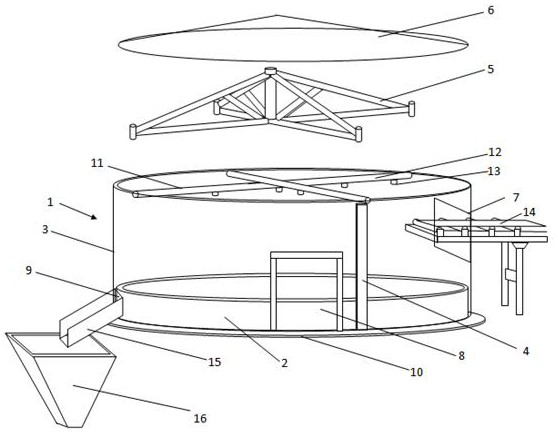

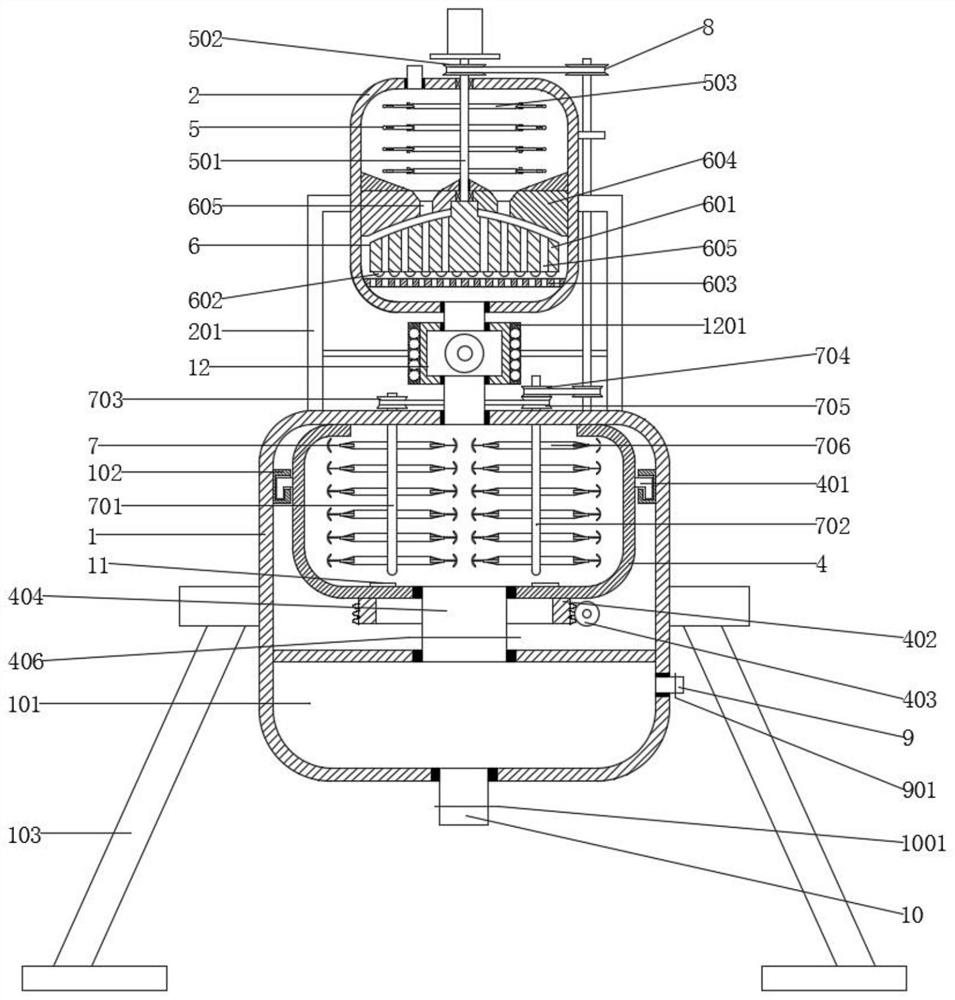

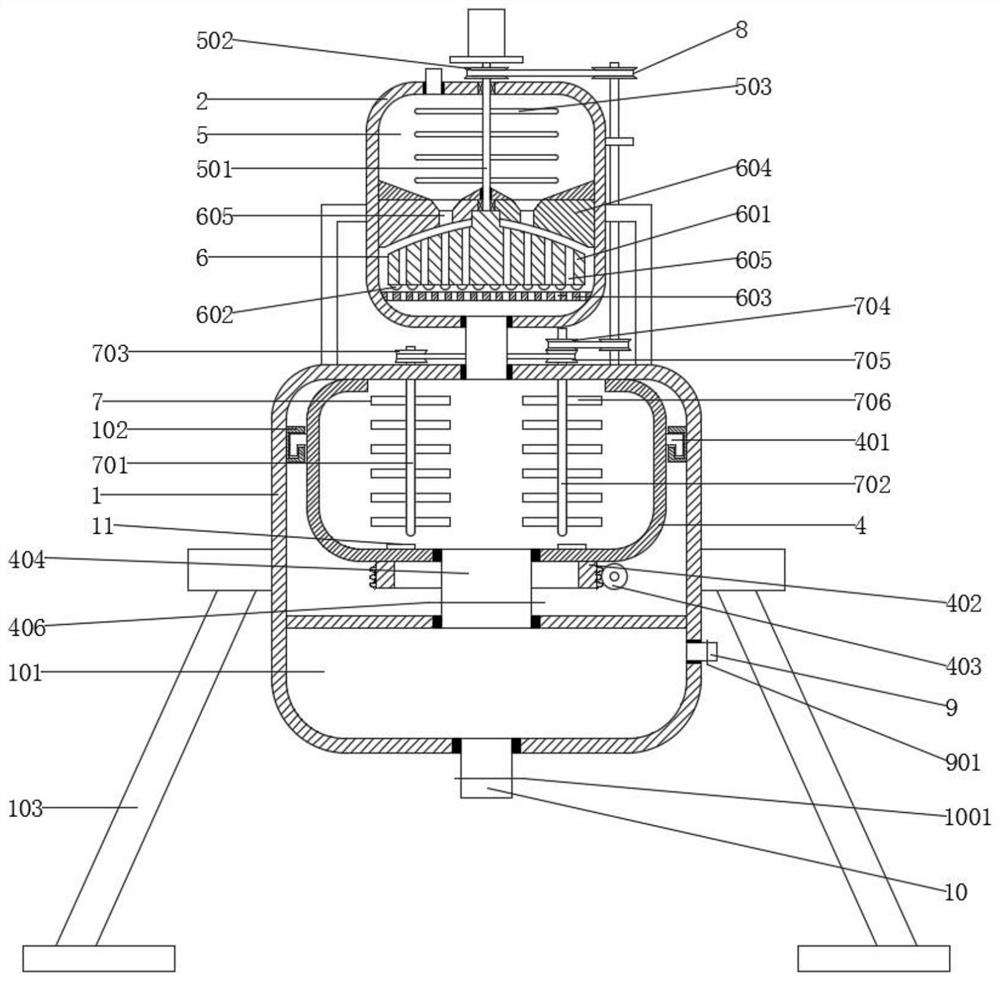

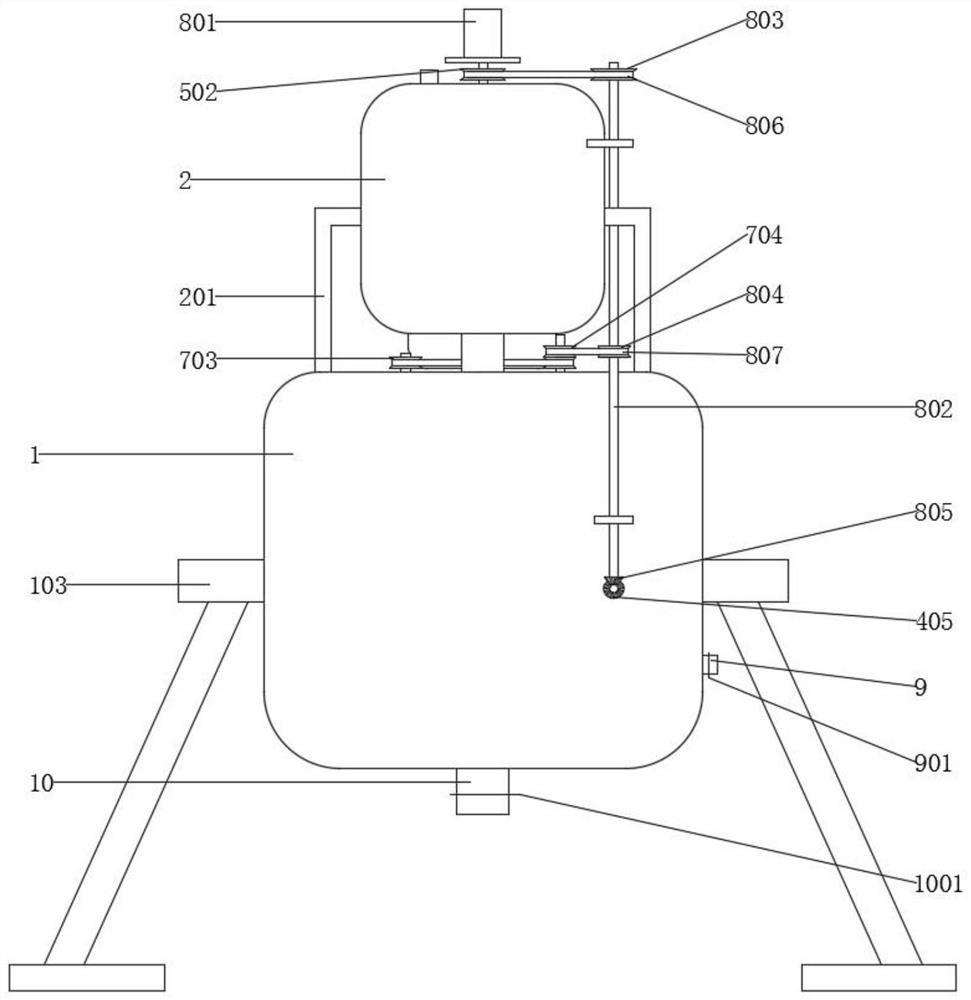

Purification equipment for protein polypeptide in peanut meal

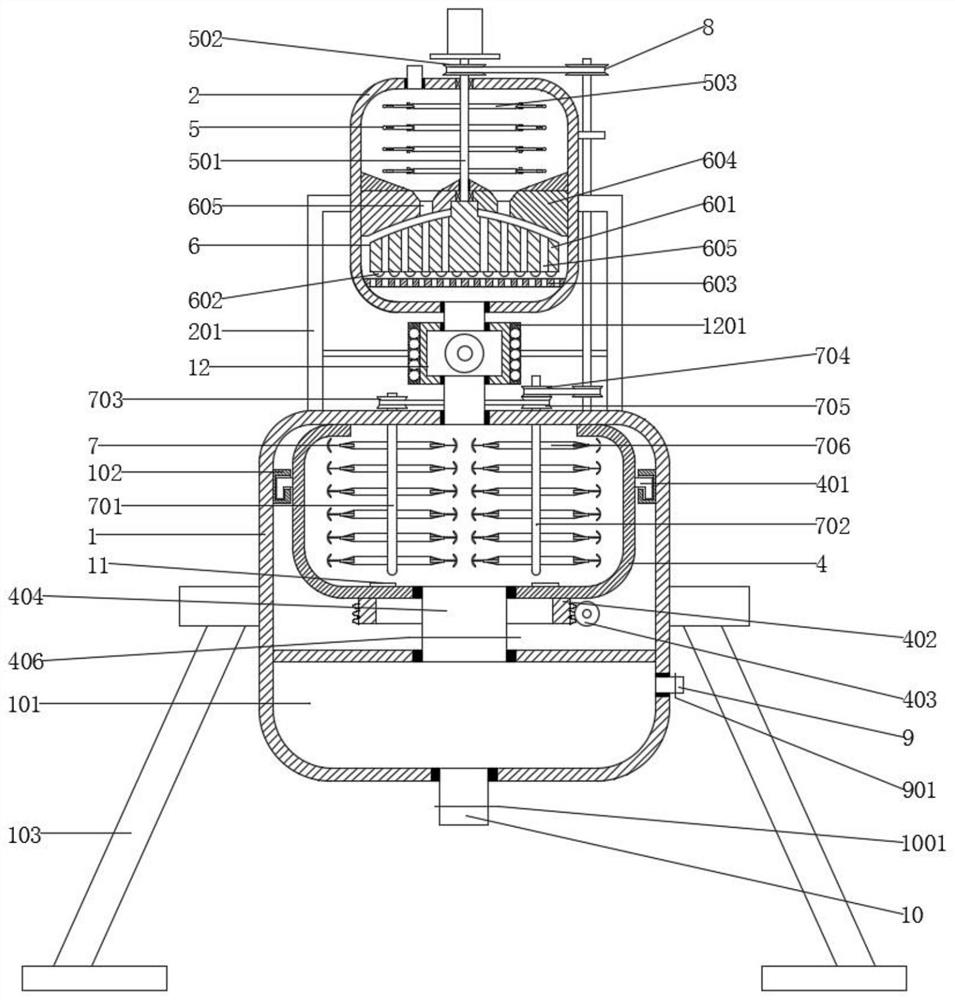

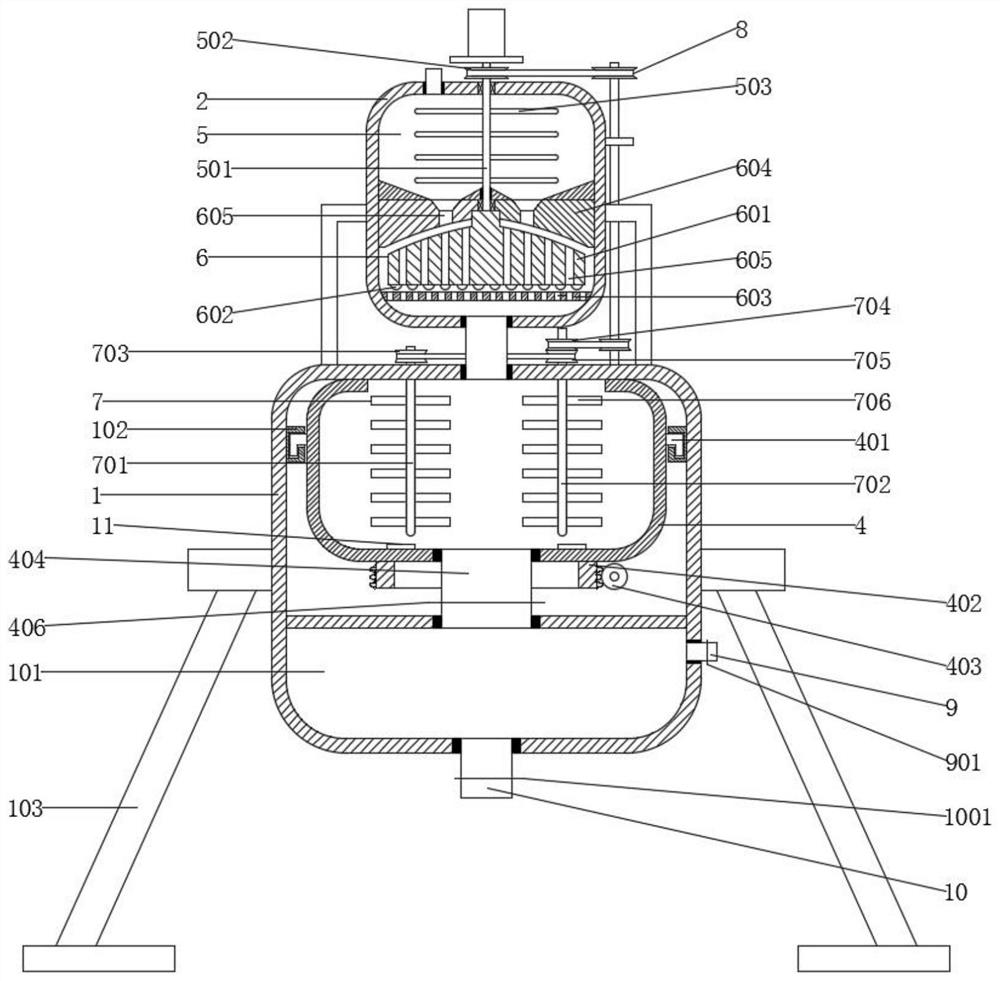

ActiveCN111808163AThe mixed reaction is thoroughGuaranteed ExtractionPeptide preparation methodsEngineeringPeanut meal

The invention relates to the technical field of purification of protein polypeptide in peanut meal, in particular to purification equipment for protein polypeptide in peanut meal. The peanut meal is pretreated through a grinding box, condensed peanut meal is dispersed through a material dispersing mechanism, the peanut meal is ground into fine particles through a grinding mechanism, subsequent peanut meal and a solution are effectively mixed and react thoroughly, the extraction amount of the protein peptide is guaranteed, waste of peanut meal raw material is reduced, and the conversion rate isincreased; a turbine and a worm are matched to drive a reaction box to rotate, the reaction box drives the internal solution and the peanut meal to rotate and mix, and a mixing mechanism continuouslystirs the solution and the peanut meal, so that the mixing speed and the mixing uniformity are improved, the reaction time is shortened, and the mixing efficiency and the processing efficiency are improved; and a premixing box premixes the solution and peanut meal, a preheating layer preliminarily heats the solution and the peanut meal, the reaction speed is increased, the mixing time in the reaction box in the later period is shortened, and a solution box is arranged at the rear end of the grinding box, so that the interior of the premixing box is convenient to clean.

Owner:江西天禹科技协同创新有限公司

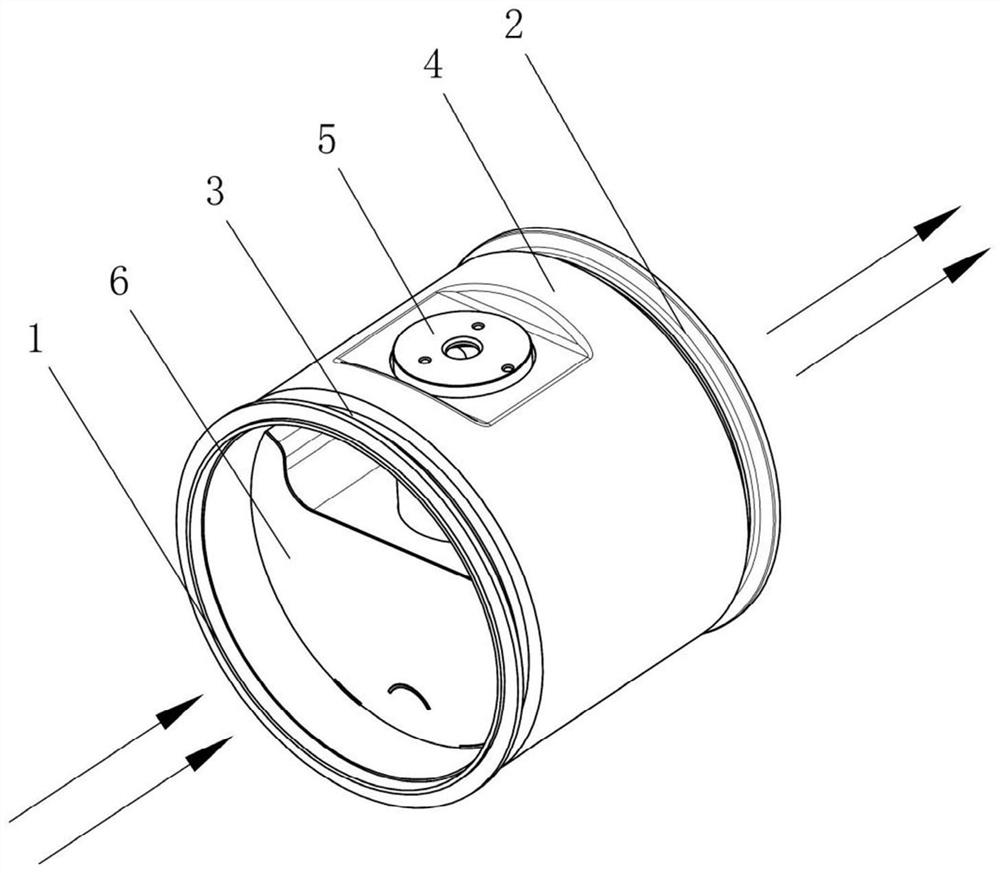

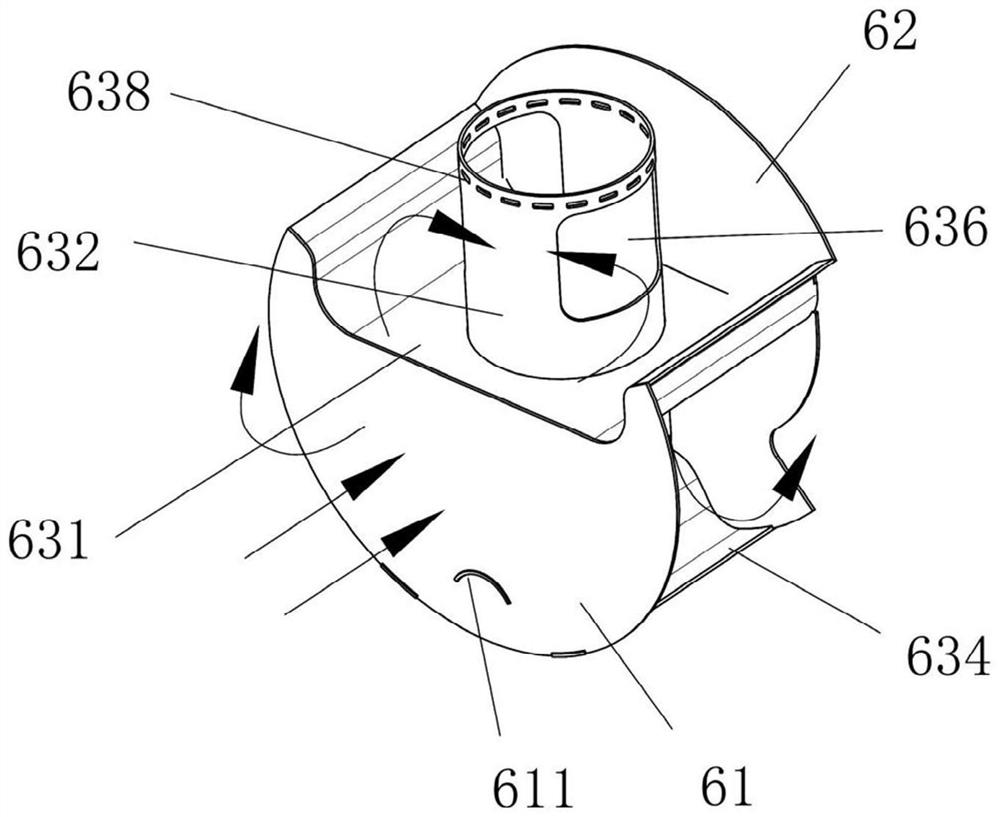

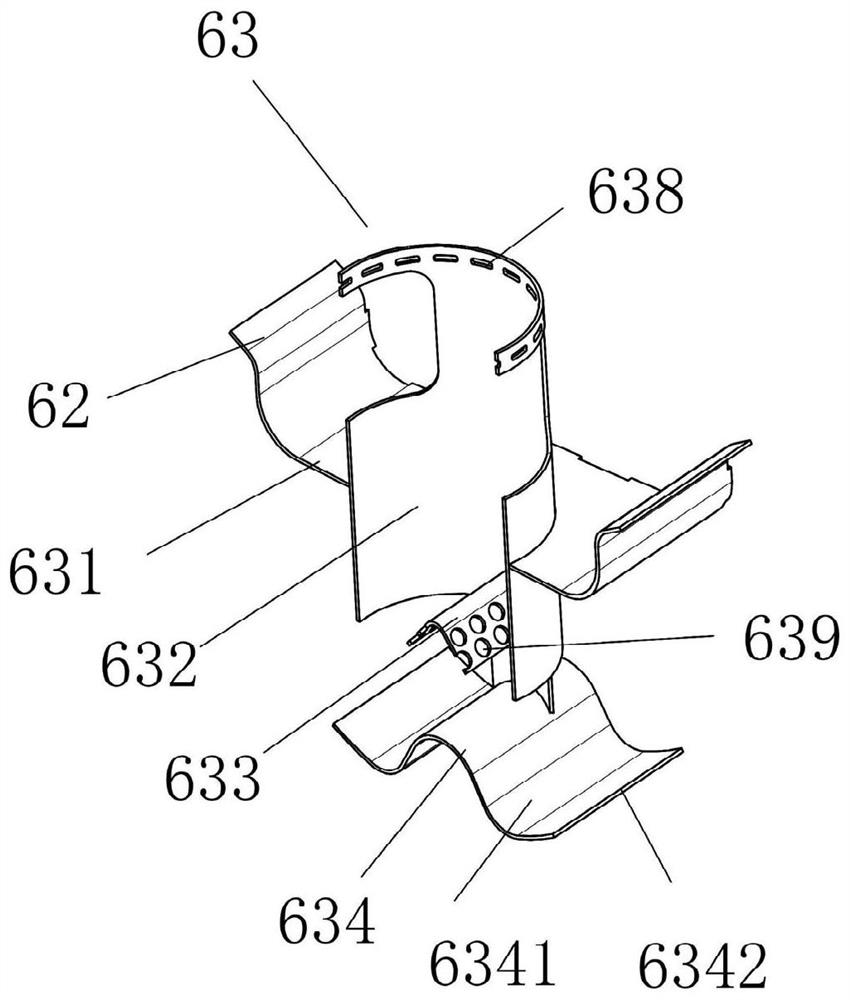

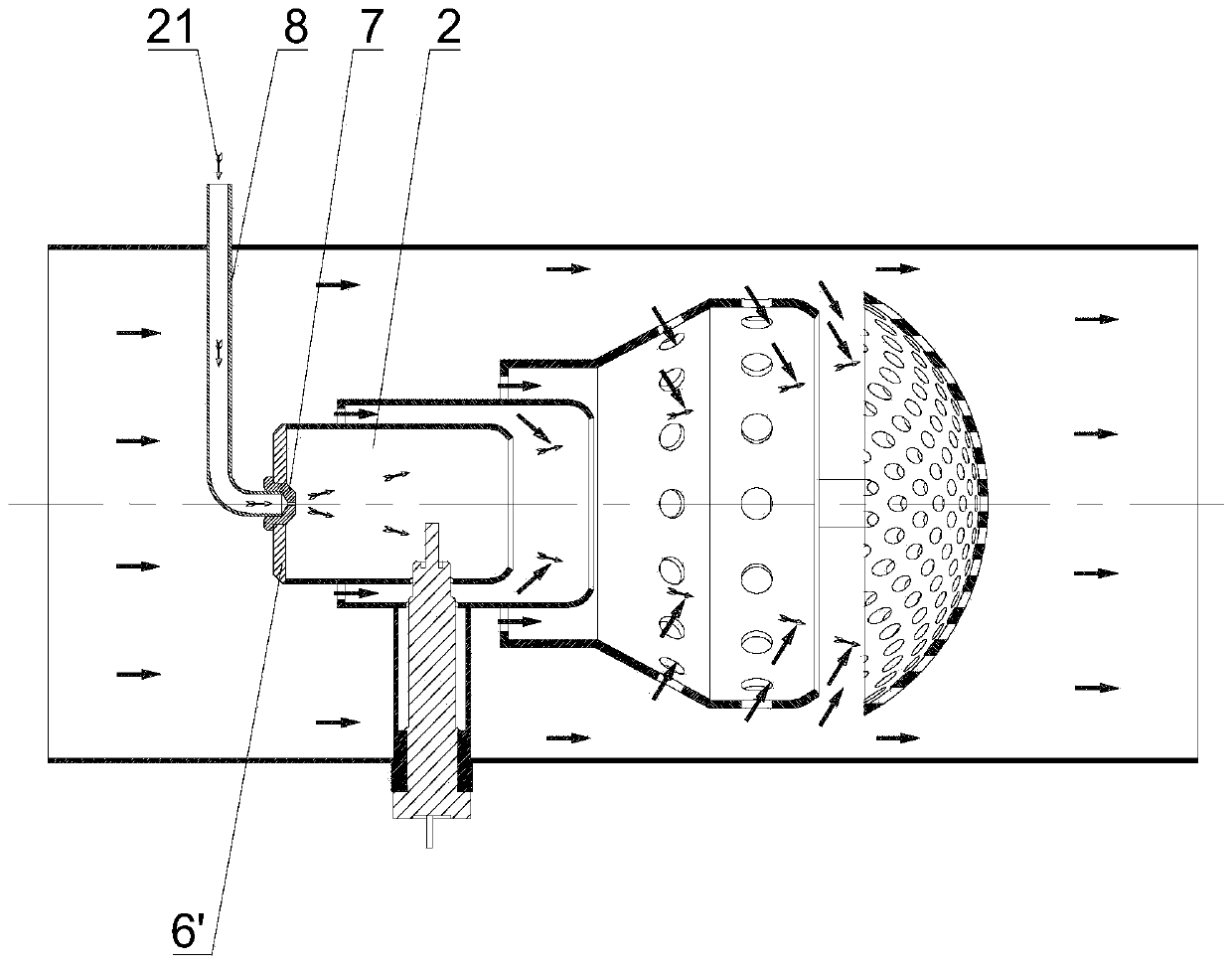

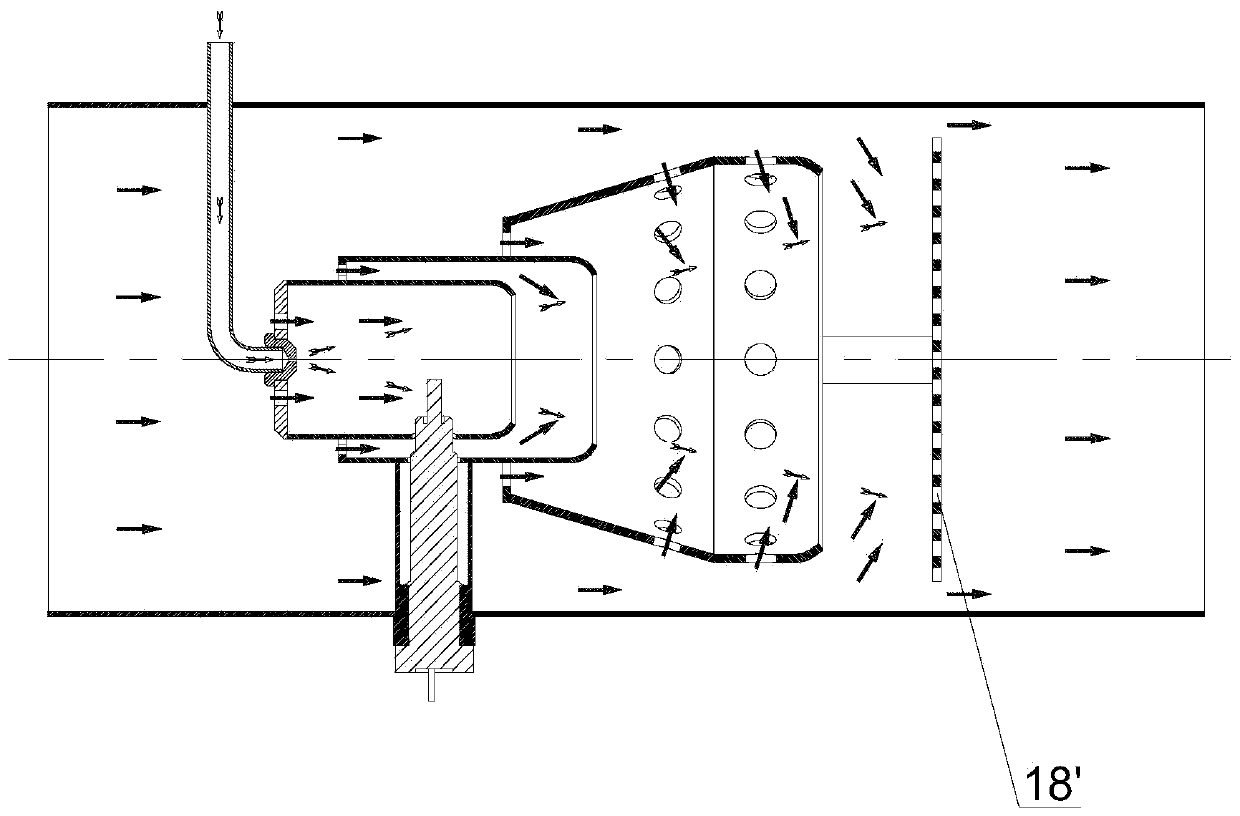

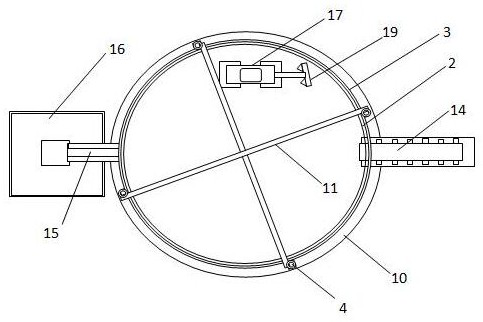

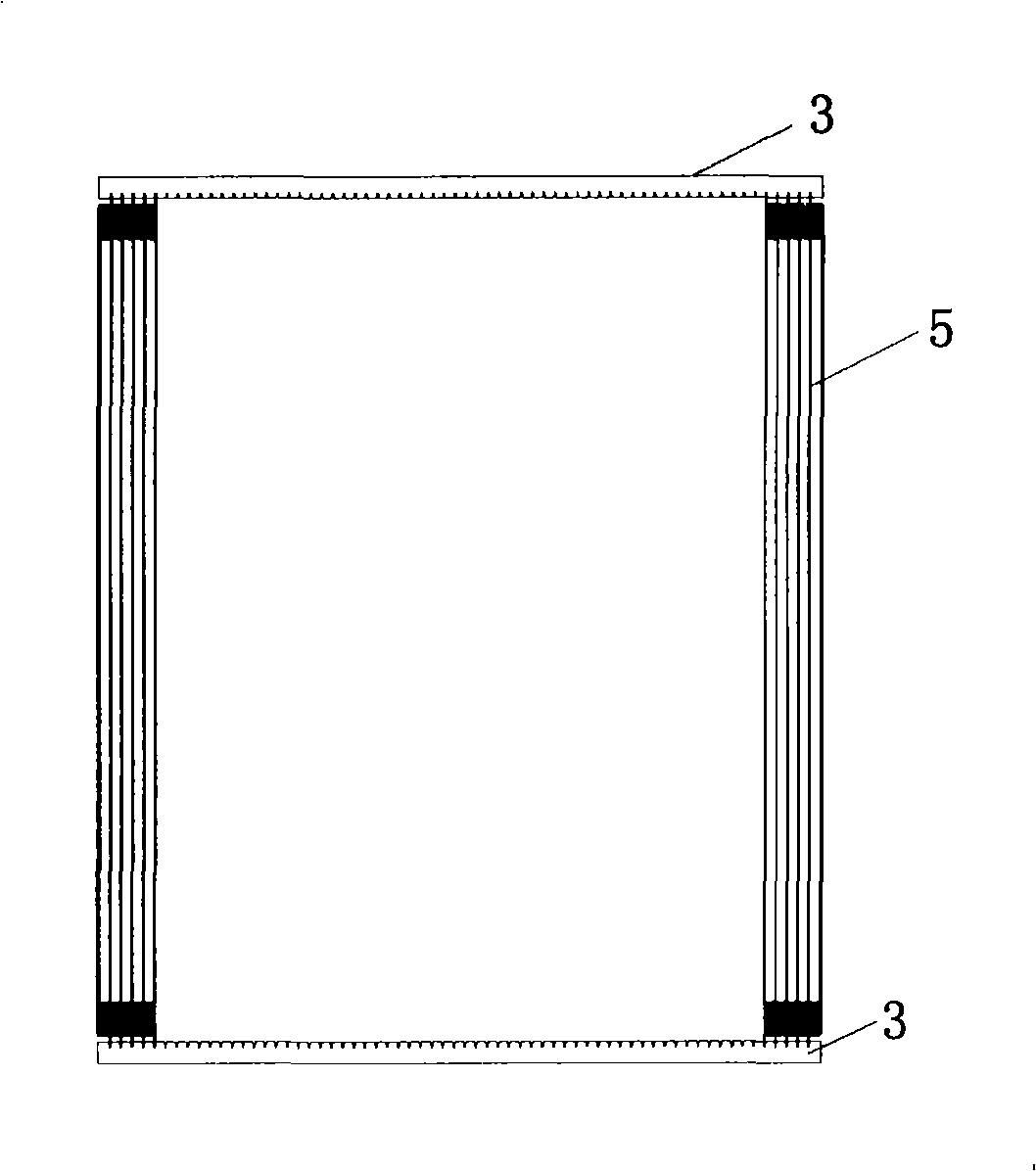

Double-vortex-flow type urea mixing device

ActiveCN113790092AImprove the mixing effectEnsure mixing uniformityInternal combustion piston enginesExhaust apparatusDieselingEngineering

The invention relates to a double-vortex-flow type urea mixing device, and belongs to the field of diesel engine tail gas after-treatment. The double-vortex-flow type urea mixing device comprises a front flange, a rear flange, a cylinder, a heat shield, a nozzle base and an in-cylinder assembly, the front flange and the rear flange are respectively welded at two ends of the cylinder, the heat shield is welded outside the cylinder, the nozzle base is welded on the cylinder, and the in-cylinder assembly is welded in the cylinder and is connected with the nozzle base; and the in-cylinder assembly comprises a front partition plate, a rear partition plate and a flow dividing pipe set, wherein the front partition plate and the rear partition plate are welded to the two sides of the flow dividing pipe set respectively. According to the double-vortex-flow type urea mixing device, a simple pipe and baffle structure is adopted to realize shunting and double-vortex rotation of urea, so that the mixing effect of urea and waste gas is improved, and the mixing uniformity of a SCR catalytic unit is ensured; and a notch in the upper end of the flow dividing pipe is used for guiding airflow to enter the flow dividing pipe from the two sides of the flow dividing pipe, so that urea sprayed from the upper portion is taken away smoothly, and the accumulation of the urea sprayed on the inner wall face of the flow dividing pipe is reduced.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

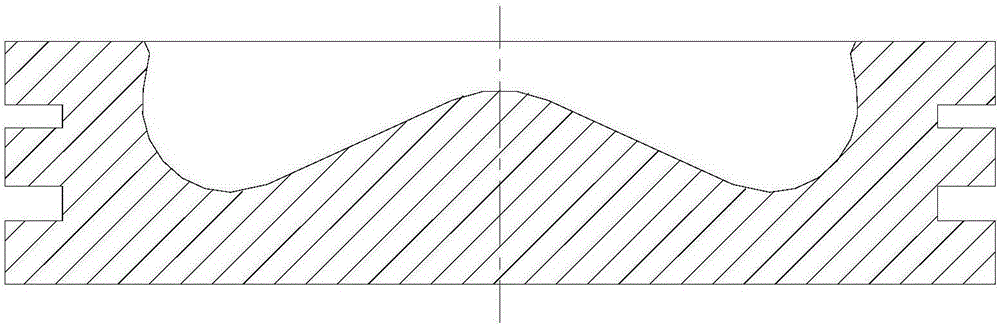

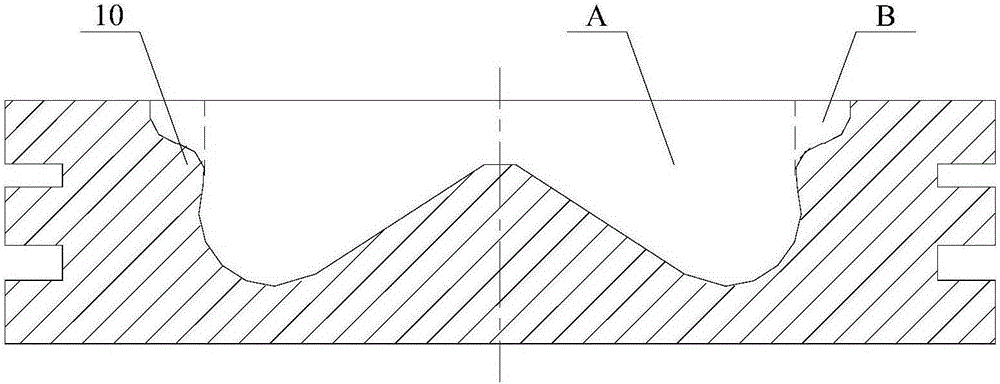

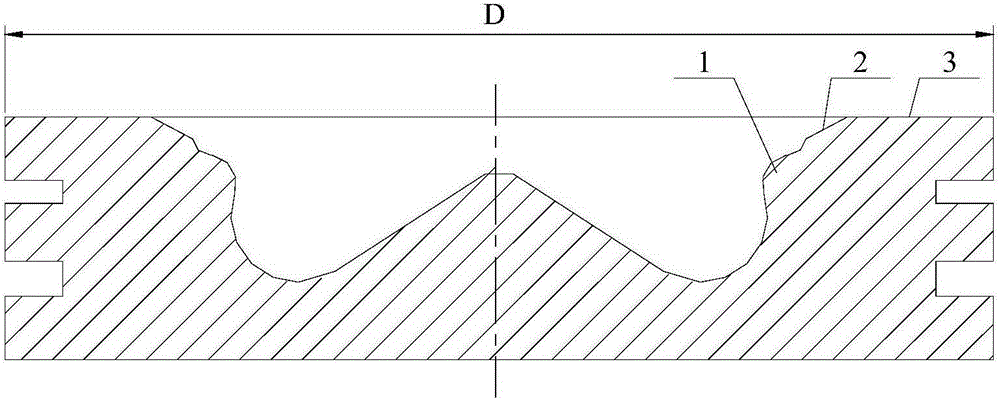

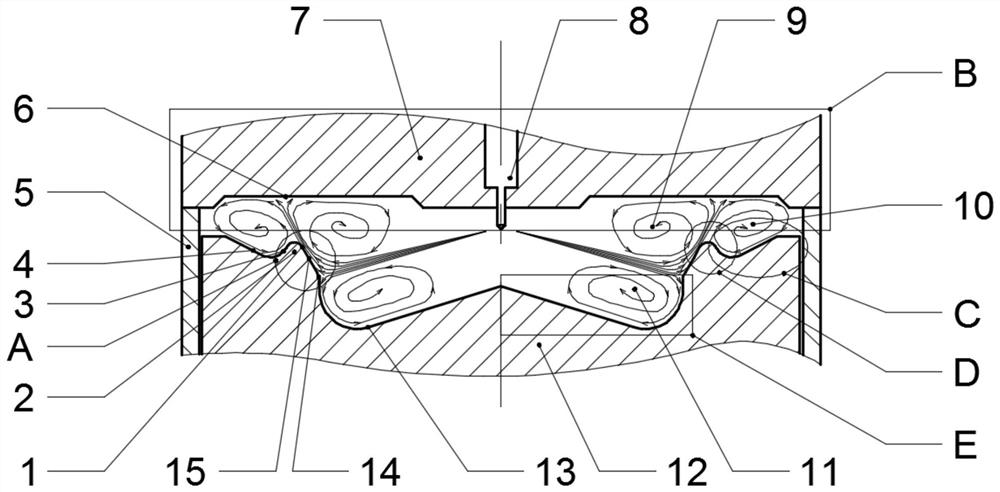

A diesel engine cylinder piston and a diesel engine using the combustion chamber

ActiveCN103696870BAdd room for mixingWell mixedMachines/enginesPistonsCombustion chamberDiesel engine

The invention discloses a cylinder piston of an engine diesel. The top surface of the cylinder piston is provided with a combustion chamber with a W-shaped axial section external profile; the inner wall of the outer side of the combustion chamber is provided with an arc-shaped ridge which is extended into an accommodating cavity, and the combustion chamber is divided into an inside conventional region and a groove region by a tangent line formed by the highest point of radial protrusion of the arc-shaped ridge; the outer edge of the throat opening of the combustion chamber is provided with an end bevel, so as to form a buffer region communicated with the groove region; the external profile of the buffer region is of asymptotic trend change from the groove region to the top surface of the piston. By virtue of the structural optimization of the combustion chamber, the upper vortex trend can be adjusted, and the problem that the thermal load of the bottom surface of a cylinder cover can be effectively avoided on the basis of improving the thermal efficiency and reducing the oil consumption. On the basis, the invention further provides a diesel engine applying the cylinder piston.

Owner:WEICHAI POWER CO LTD

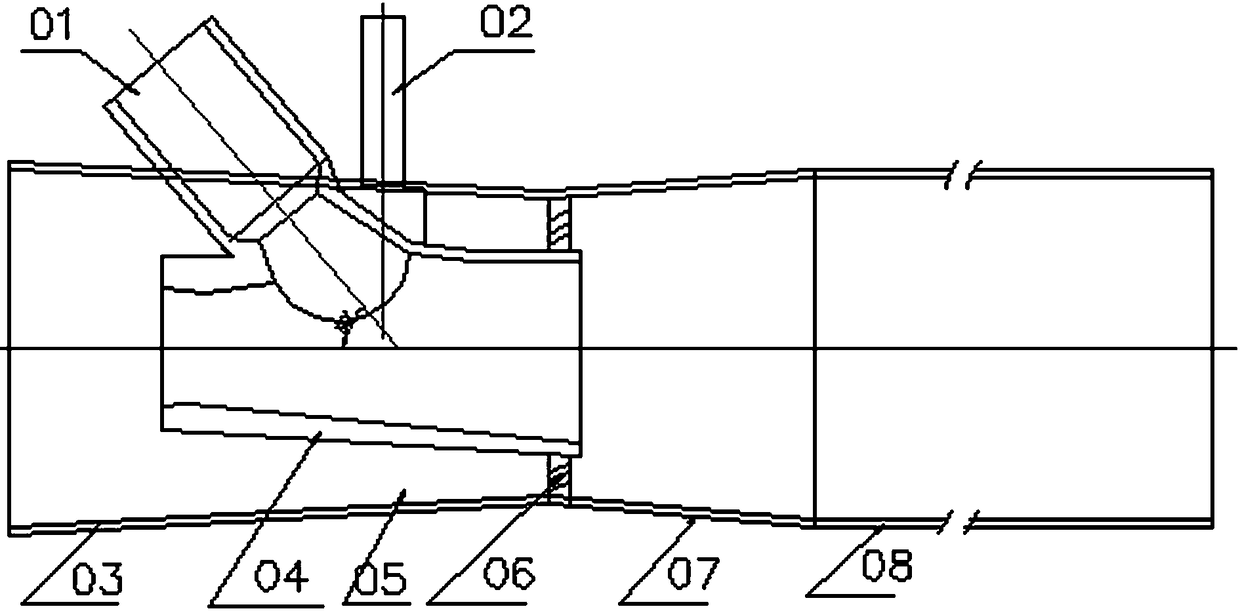

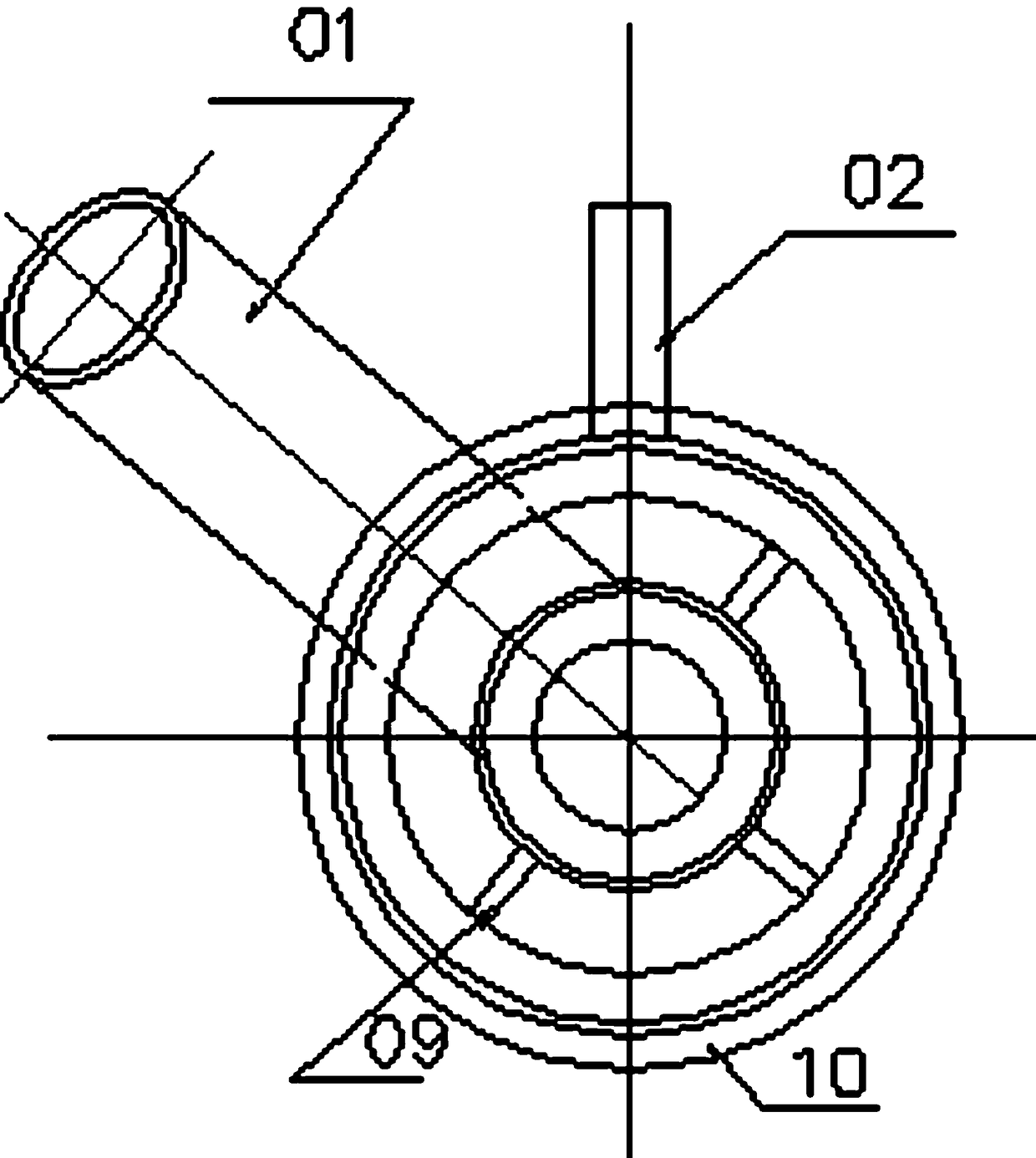

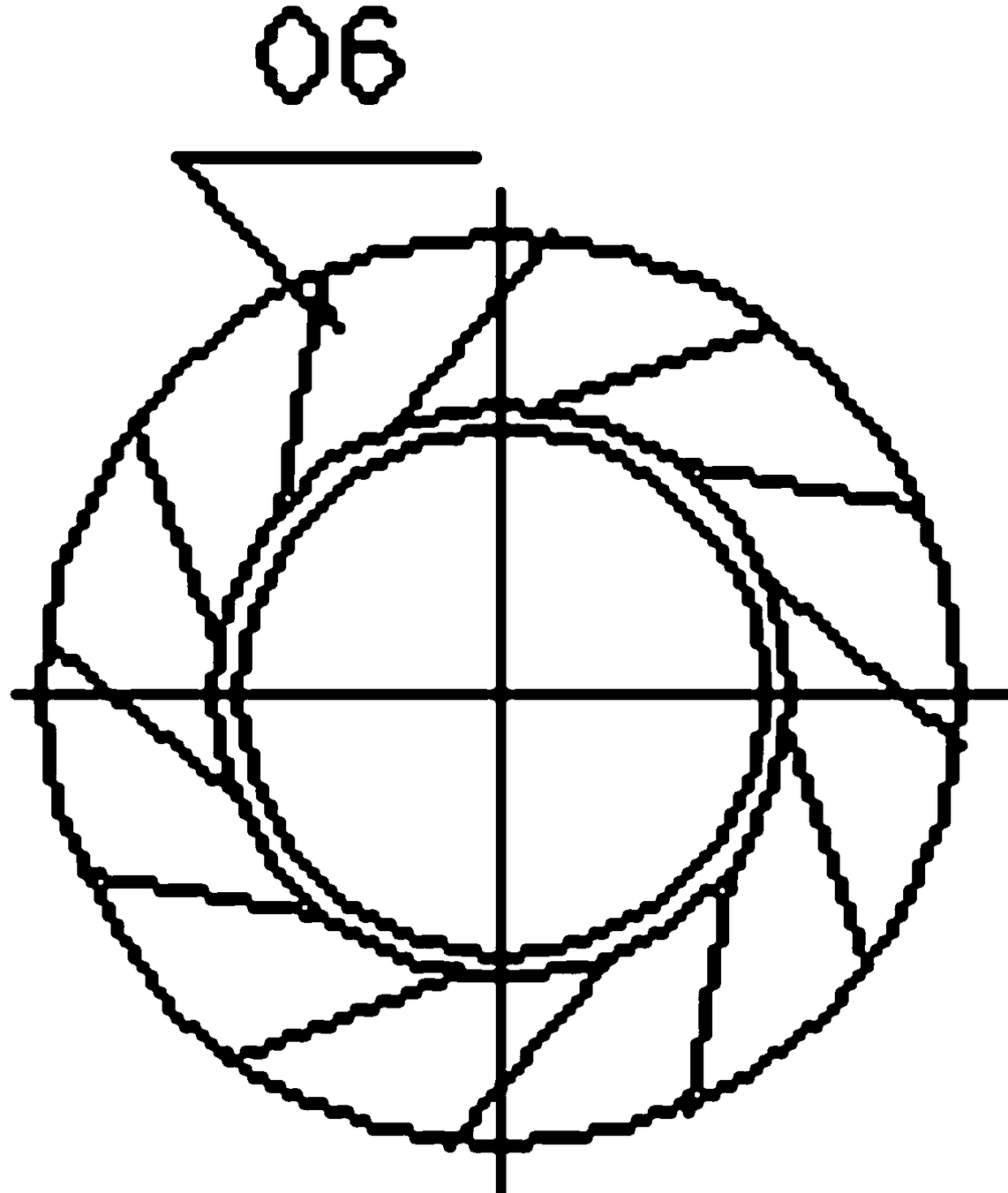

Inserting type multi-level mixing DPF combustor

PendingCN111520216AAdd room for mixingProlong the time of mixed combustionExhaust apparatusSilencing apparatusCombustion chamberCombustor

The invention discloses an inserting type multi-level mixing DPF combustor. A combustor outer barrel and a multi-level combustion chamber are included. The multi-level combustion chamber comprises aninner combustion chamber and a rear combustion chamber which are sequentially arranged in the combustor outer barrel in the exhaust flowing direction. The inner combustion chamber is provided with a first end cover. The first end cover is provided with a nozzle. The barrel wall of the combustor outer barrel is provided with a material spraying pipe stretching into the interior from the exterior and an igniter. The material spraying pipe is connected with the nozzle so as to spray fuel into the inner combustion chamber. An ignition head of the igniter stretches into the inner combustion chamber. A fire stop net is arranged at the tail end of the rear combustion chamber. According to the inserting type multi-level mixing DPF combustor, the rest of oxygen in diesel engine exhaust gas is utilized for being mixed with fuel for combustion, an air blower is eliminated, multi-time mixing of exhaust gas and fuel is formed through the multi-level combustion chamber, the mixing space of the exhaust gas and the fuel is increased, the mixing and combusting time is prolonged, the fuel and the rest of oxygen in the exhaust gas are sufficiently mixed, the combustion efficiency is improved, complete combustion is achieved, and the exhaust temperature is effectively increased.

Owner:KAILONG HIGH TECH

A co boiler with ash removal function

ActiveCN103776014BWith ash removal functionImprove heat transfer efficiencyDispersed particle separationSteam boilersEngineeringSteam drum

The invention discloses a CO boiler having the ash removal function. The CO boiler having the ash removal function comprises a first vertical flue, a horizontal flue and a second vertical flue, wherein ash baffles are arranged at the connection position between the first vertical flue and the horizontal flue, an ash storage bin is arranged at the position, flush with the lower edge of the lowest ash baffle, of the inner side of the first vertical flue, the ash baffles are of the structure that multiple layers of baffles are arranged in a staggered mode, each ash baffle is arranged in an inclined mode, and the outer end of each ash baffle is higher than the inner end of the ash baffle. According to the CO boiler having the ash removal function, the ash baffles arranged in the CO boiler can remove most of smoke dust contained in smoke and also play a role in rectifying the smoke, so that the smoke is rectified into the stable horizontal laminar flow state, the smoke evenly passes through steam drums, and the heat exchange efficiency of the boiler is high. The CO boiler having the ash removal function can solve the problem of equipment wear and abrasion caused by the smoke dust to the maximum extent, optimize the smoke processing technology, reduce energy consumption and reduce investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic/inorganic composite three-dimensional porous scaffold with drug sustained release function, and preparation method thereof

The invention provides a preparation method of organic / inorganic composite three-dimensional porous scaffold with drug sustained release function. The method comprises the following steps of: (1) preparing organic / inorganic / drug composite material; and (2) putting the organic / inorganic / drug composite material obtained in the step (1) into an extrusion cavity of a motor assisted microsyringe (MAM) free-forming device to form the organic / inorganic composite three-dimensional porous scaffold with drug sustained release function.

Owner:广州雄俊智能科技有限公司

Ignition and low-load stable combustion burner for fluidized bed boiler

ActiveCN106482094BWell mixedIncrease ingress velocityBurnersFluidized bed combustionCombustion chamberCombustor

The invention discloses a burner for ignition and low-load stable combustion of a fluidized bed boiler, and the burner belongs to fluidized bed boiler ignition and low-load stable combustion technologies. The novel burner has the micro-oil ignition or less-oil ignition and low-load stable combustion functions, and mainly aims to achieve cold-state ignition and low-load stable combustion for the fluidized bed boiler. The burner comprises an oil combustor, an oil gun ignition device, a secondary oil combustor, a fire check device, a swirl flow air channel, swirl vanes, a burner convergent section, a burner divergent section, a cooling air channel and a uniform-temperature mixing section. As for design, the ignition device is used for atomizing fuel through high-pressure air firstly, a small amount of fuel is burnt sufficiently in the oil combustor, an oil gun adopts mechanical atomization or air atomization, then the fuel is completely burnt out in the secondary combustor through primary air, and flames are pushed to spray out of the secondary combustor; the swirl vanes enable the primary air in the swirl flow air channel to rotate and be fully mixed with the flames spraying out of the secondary combustor, and the effect of cooling the secondary combustor is realized; and finally, air temperatures are uniformly mixed at the uniform-temperature section.

Owner:山西泰锐达科技有限公司

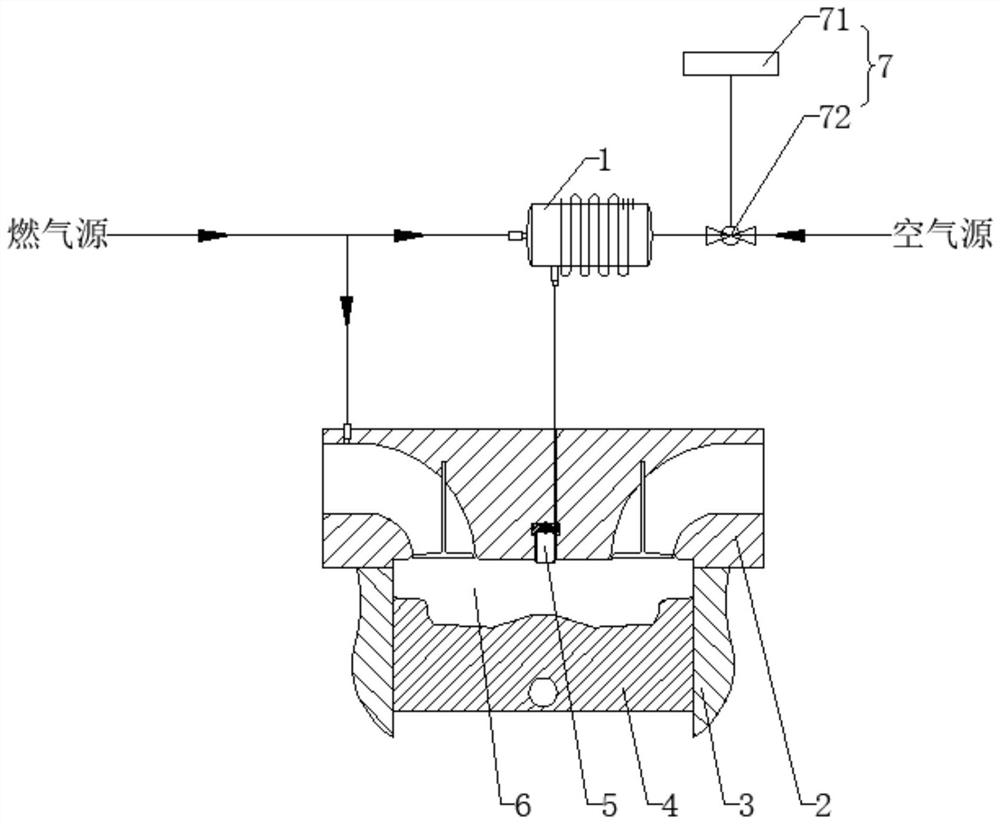

Air inlet device and combustion system

PendingCN114320672AReduce lean burn non-combustible areasWell mixedInternal combustion piston enginesFuel supply apparatusCombustion systemCombustion chamber

The air inlet device comprises a machine body; the piston is mounted in the machine body; the cylinder cover is installed at the opening position of the machine body, and the cylinder cover, the machine body and the piston define a first combustion chamber; the air inlet part comprises a second combustion chamber formed in the cylinder cover and communicated with the first combustion chamber; the air inlet end of the premixing tank is communicated with an air source and a fuel gas source respectively, and the exhaust end of the premixing tank is communicated with the second combustion chamber; wherein the air and the fuel gas are mixed in the premixing tank, and the mixed gas is output into the second combustion chamber. The combustion system comprises an air inlet device; a natural gas storage tank; and a compressed air storage tank; wherein the output end of the natural gas storage tank and the output end of the compressed air storage tank are respectively communicated with the premixing tank.

Owner:TIANJIN UNIV

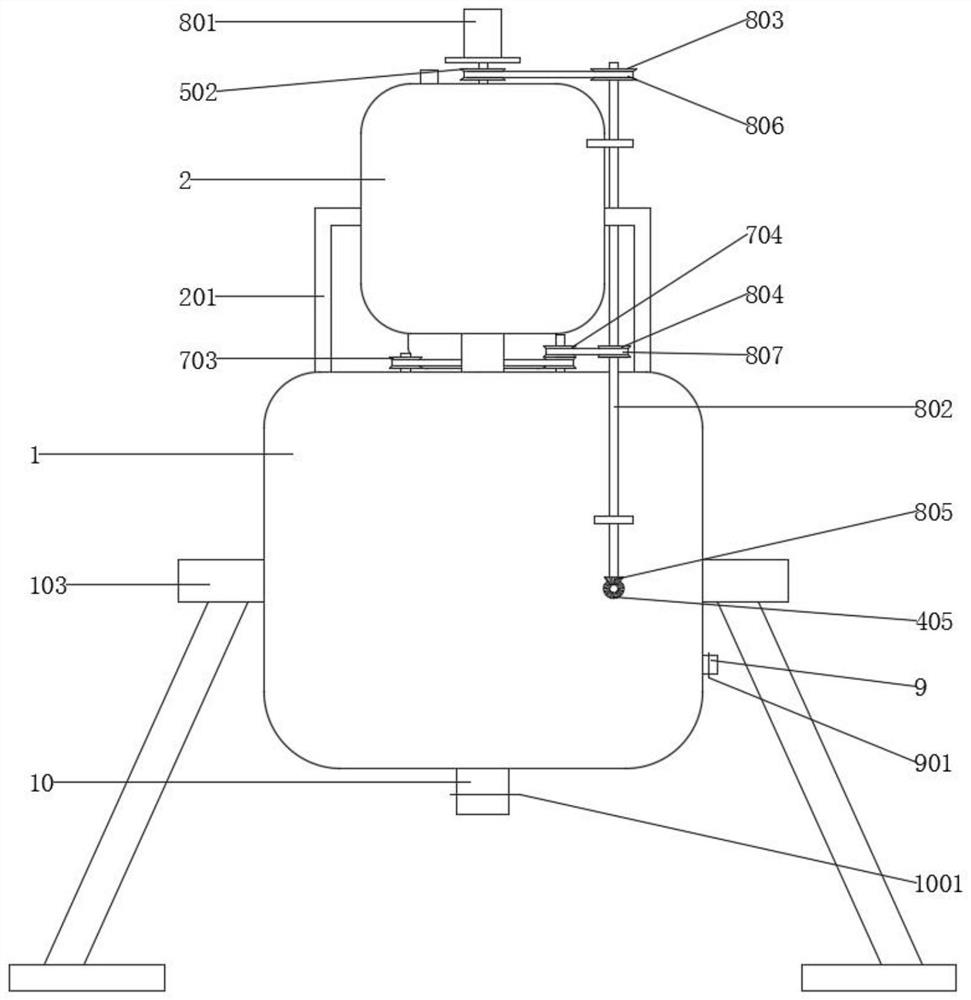

Omeprazole sodium mixing device

InactiveCN108745164AWell mixedEasy Pneumatic MixingTransportation and packagingRotary stirring mixersOmeprazole SodiumEngineering

The invention discloses an omeprazole sodium mixing device. The omeprazole sodium mixing device comprises a base, wherein one side of the top of the base is fixedly connected with a first control box;the other side of the top of the base is fixedly connected with a second control box; a control panel is arranged on the middle part of the outer surface of the first control box; a circuit board isarranged on the inner part of the first control box; a controller is arranged on the inner part of the circuit board; medicine inlets are formed in the two sides of the top of the mixing box; stirringblades are arranged at the two sides of the rotary shaft; one side of the bottom end of the rotary shaft is equipped with a temperature sensor; and an uniformity detector is arranged on the bottom ofthe rotary shaft. The omeprazole sodium mixing device is reasonable in design, is convenient to use, and is very suitable for mixing medicine powder; through a matched operating way of a first air blower, a second air blower, a first air feeding channel and a second air feeding channel, the medicine powder can be pneumatically mixed conveniently, so that the medicine powder is prevented from caking, and the medicine powder is conveniently moved, and therefore, the omeprazole sodium mixing device is simple and convenient, and is suitable for being widely popularized.

Owner:徐艳

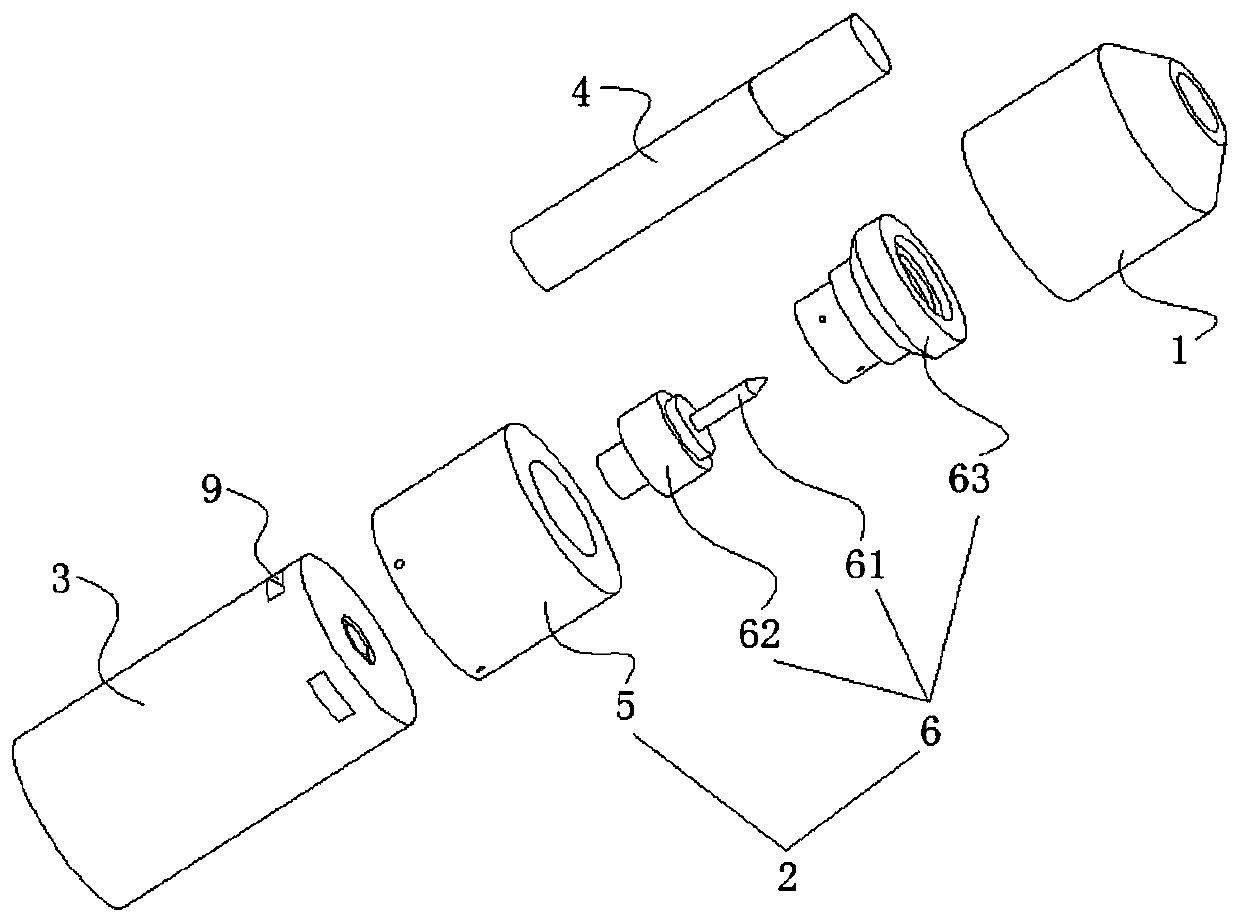

Integral continuous casting cutting nozzle and processing method thereof

The invention discloses an integral continuous casting cutting nozzle and a processing method thereof, which have the advantages that the structure and the processing are simple, the gas is not leaked, the deformation is small, and the process is simple. The cutting nozzle comprises an integral core body, wherein the integral core body consists of a core seat, a core head and a core rod through integral processing, and a pre-mixing chamber is arranged on the core seat of the integral core body. In the processing method, firstly, a gas inlet concave ring groove and a gas mixing concave ring groove are processed on the frustum-shaped core seat, then, an inclined hole is drilled on a corresponding convex ring table in a direction from the gas inlet concave ring groove to the pre-mixing chamber and is made into a fuel gas hole, and a hole is drilled on the corresponding convex ring table in a direction from one side of a mixing chamber to the pre-mixing chamber and is made into a preheating oxygen hole.

Owner:陈寅明

A co boiler with denitrification function

ActiveCN103776043BImprove utilization efficiencyEfficient use ofLighting and heating apparatusDispersed particle separationCombustion chamberEvaporation

The invention relates to a CO boiler having the denitration function. The CO boiler comprises a flue, a combustion chamber, steam drums, an evaporation section and an economizer section. The flue comprise a first vertical flue body, a horizontal flue body and a second vertical flue body, wherein the two ends of the horizontal flue body are communicated with the upper portion of the first vertical flue body and the upper portion of the second vertical flue body respectively, the combustion chamber is arranged in the first vertical flue body, the steam drums are arranged in the horizontal flue body, and the evaporation section and the economizer section are arranged in the second vertical flue body. The CO boiler further comprises an ammonia spraying and mixing mechanism and a denitration reactor. The ammonia spraying and mixing mechanism is arranged in the second vertical flue body and is located above the evaporation section. The denitration reactor is arranged between the evaporation section and the economizer section. The CO boiler having the denitration function can effectively improve the mixing uniformity of smoke and ammonia gas, improve the denitration efficiency and prevent ammonia escape; due to the fact that the denitration reactor is arranged in the CO boiler, an ammonia mixing grid is not needed, the utilization efficiency of smoke heat is improved, and the occupied space of the CO boiler and equipment investment are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Burner for ignition and low-load stable combustion of fluidized bed boiler

ActiveCN106482094AWell mixedIncrease ingress velocityBurnersFluidized bed combustionCombustion chamberCombustor

The invention discloses a burner for ignition and low-load stable combustion of a fluidized bed boiler, and the burner belongs to fluidized bed boiler ignition and low-load stable combustion technologies. The novel burner has the micro-oil ignition or less-oil ignition and low-load stable combustion functions, and mainly aims to achieve cold-state ignition and low-load stable combustion for the fluidized bed boiler. The burner comprises an oil combustor, an oil gun ignition device, a secondary oil combustor, a fire check device, a swirl flow air channel, swirl vanes, a burner convergent section, a burner divergent section, a cooling air channel and a uniform-temperature mixing section. As for design, the ignition device is used for atomizing fuel through high-pressure air firstly, a small amount of fuel is burnt sufficiently in the oil combustor, an oil gun adopts mechanical atomization or air atomization, then the fuel is completely burnt out in the secondary combustor through primary air, and flames are pushed to spray out of the secondary combustor; the swirl vanes enable the primary air in the swirl flow air channel to rotate and be fully mixed with the flames spraying out of the secondary combustor, and the effect of cooling the secondary combustor is realized; and finally, air temperatures are uniformly mixed at the uniform-temperature section.

Owner:山西泰锐达科技有限公司

Field type material fine crushing and high-quality and high-efficiency uniform mixing equipment and method

PendingCN113041944AQuality improvementLow costTransportation and packagingMixer accessoriesBLENDER/MIXERMachine

The invention provides field type material fine crushing and high-quality and high-efficiency uniform mixing equipment and method. The equipment comprises a grinding and mixing chamber and a grinding machine, the grinding and mixing chamber is defined by cylindrical enclosing walls, a feeding window is arranged on one side of the grinding and mixing chamber, a vehicle access door is arranged on a second side of the grinding and mixing chamber, and a discharging opening is formed in a third side of the grinding and mixing chamber; and the rolling machine can be driven in from the vehicle access door and performs annular rolling operation in the rolling and mixing chamber. The tail part of the grinding machine is connected with a plough share through a connecting rod, so that materials can be turned over while rolling and mixing. The grinding and mixing equipment is simple in structure and low in construction cost and operation and maintenance cost; the crushing and uniform mixing effects are equivalent to those of a common wheel rolling stirrer, but the single-batch treatment capacity is large due to field type rolling and mixing; and the grinding machine can realize material rolling and material turning at the same time, and is flexible to operate and low in failure rate.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Evaporation tube structure for engine combustion chamber and engine combustion chamber structure

ActiveCN110375331BAdd room for mixingImprove heat transfer effectContinuous combustion chamberCombustion chamberPollutant emissions

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

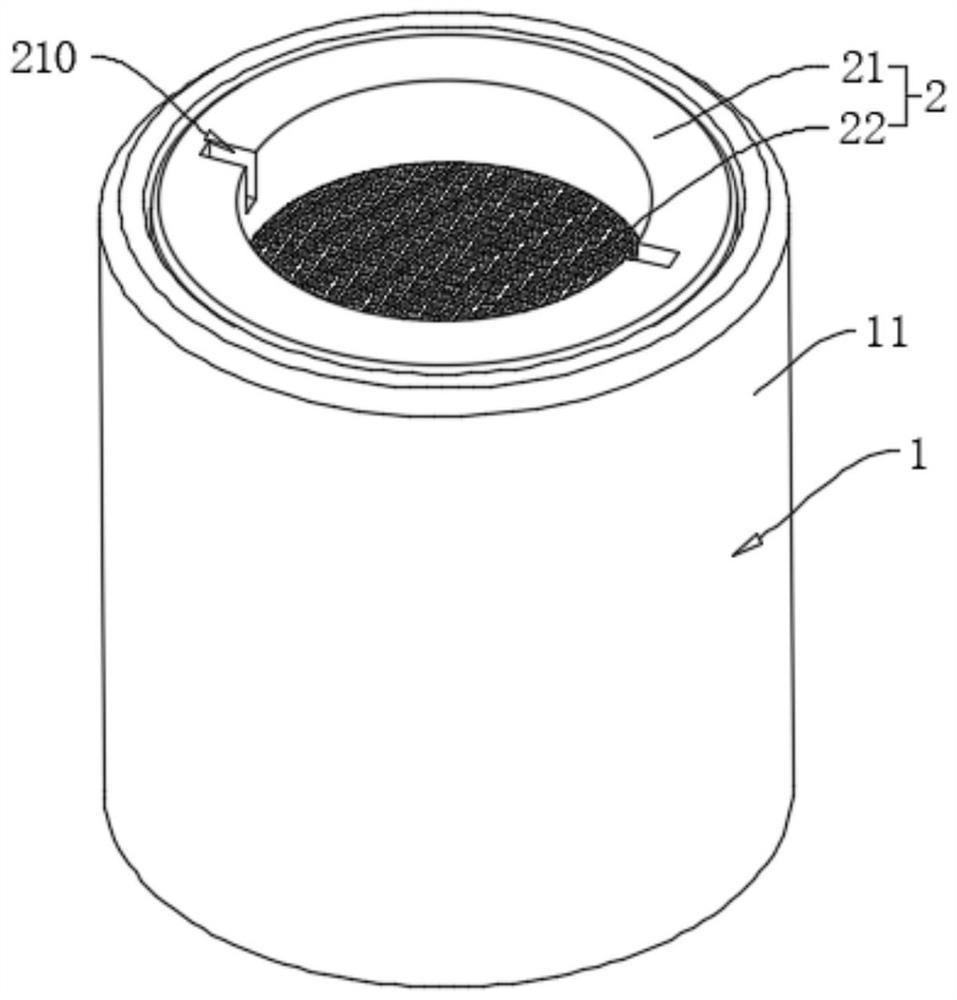

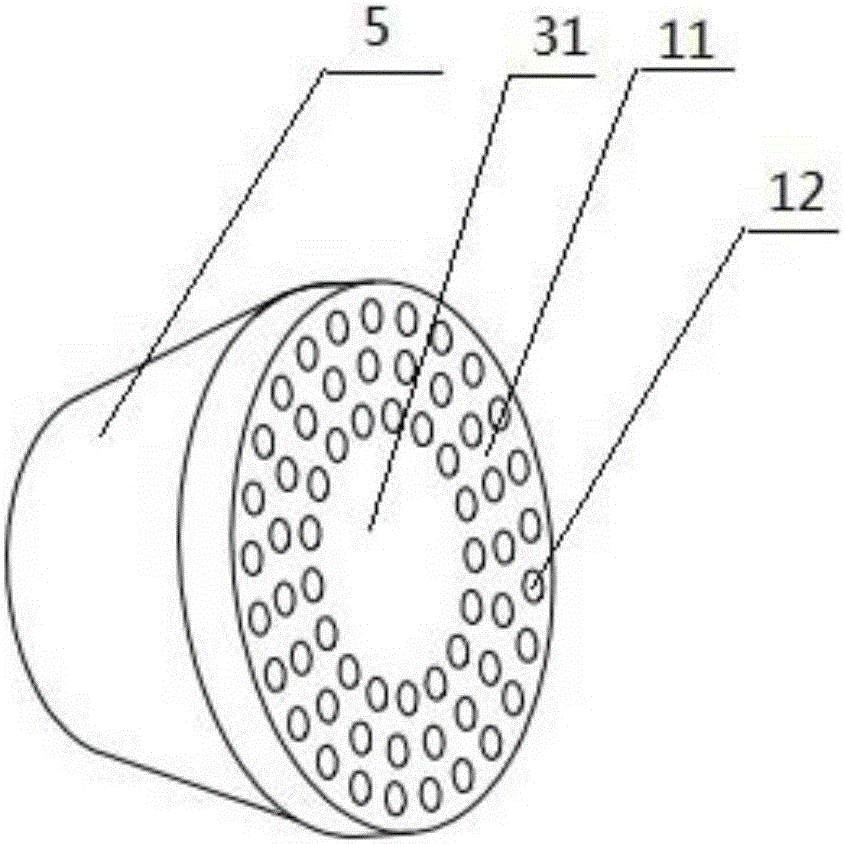

Efficient micro-nano bubble generator

PendingCN113617236ALess prone to cloggingAvoid cloggingFlow mixersMixing methodsMicro nanoEngineering

The invention discloses an efficient micro-nano bubble generator, which comprises a fixing assembly and a bubble cutting assembly, wherein the fixing assembly comprises a barrel, the inner wall of the barrel is fixedly connected with a first pressurizing plate, a first pressurizing hole is formed in the first pressurizing plate, the bubble cutting assembly comprises a cutting barrel, a cutting net is arranged in the cutting barrel, external threads are formed in the outer side wall of the cutting barrel, the cutting barrel is in threaded connection with the inner wall of the barrel, a first air inlet groove is formed in the outer side wall of the cutting barrel, a second pressurizing plate is arranged in the barrel, a second pressurizing hole is formed in the second pressurizing plate, the first pressurizing hole is communicated with the second pressurizing hole, the inner diameter of the second pressurizing hole is larger than that of the first pressurizing hole, a second air inlet groove is formed in the second pressurizing plate and communicates with the second pressurizing hole, and a gap exists between the second pressurizing plate and the inner wall of the barrel. According to the efficient micro-nano bubble generator, the working efficiency of the micro-nano bubble bubbler is improved, and the service life of the micro-nano bubble bubbler is prolonged.

Owner:SHANGHAI JIEQIAO NANO TECH CO LTD

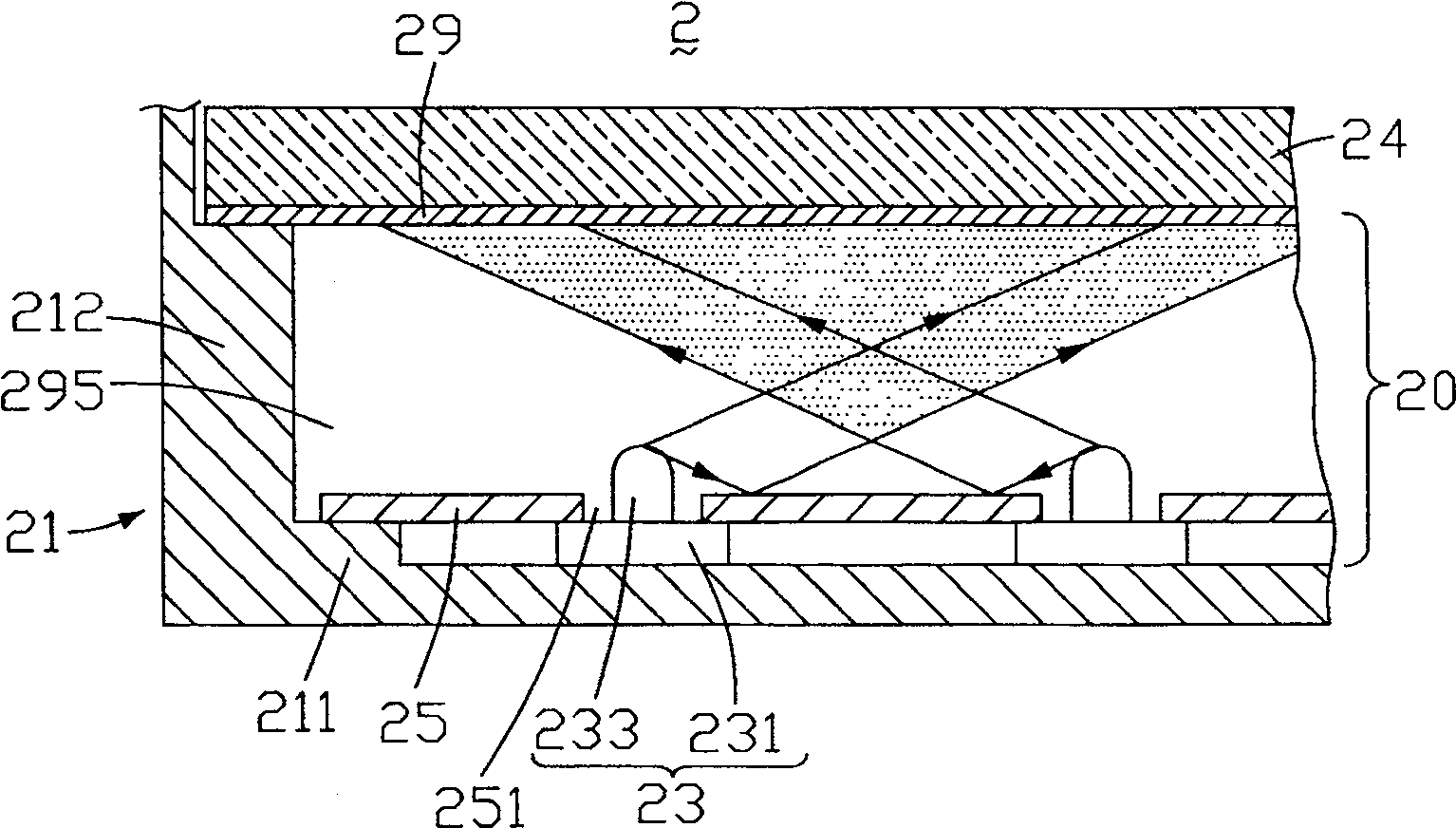

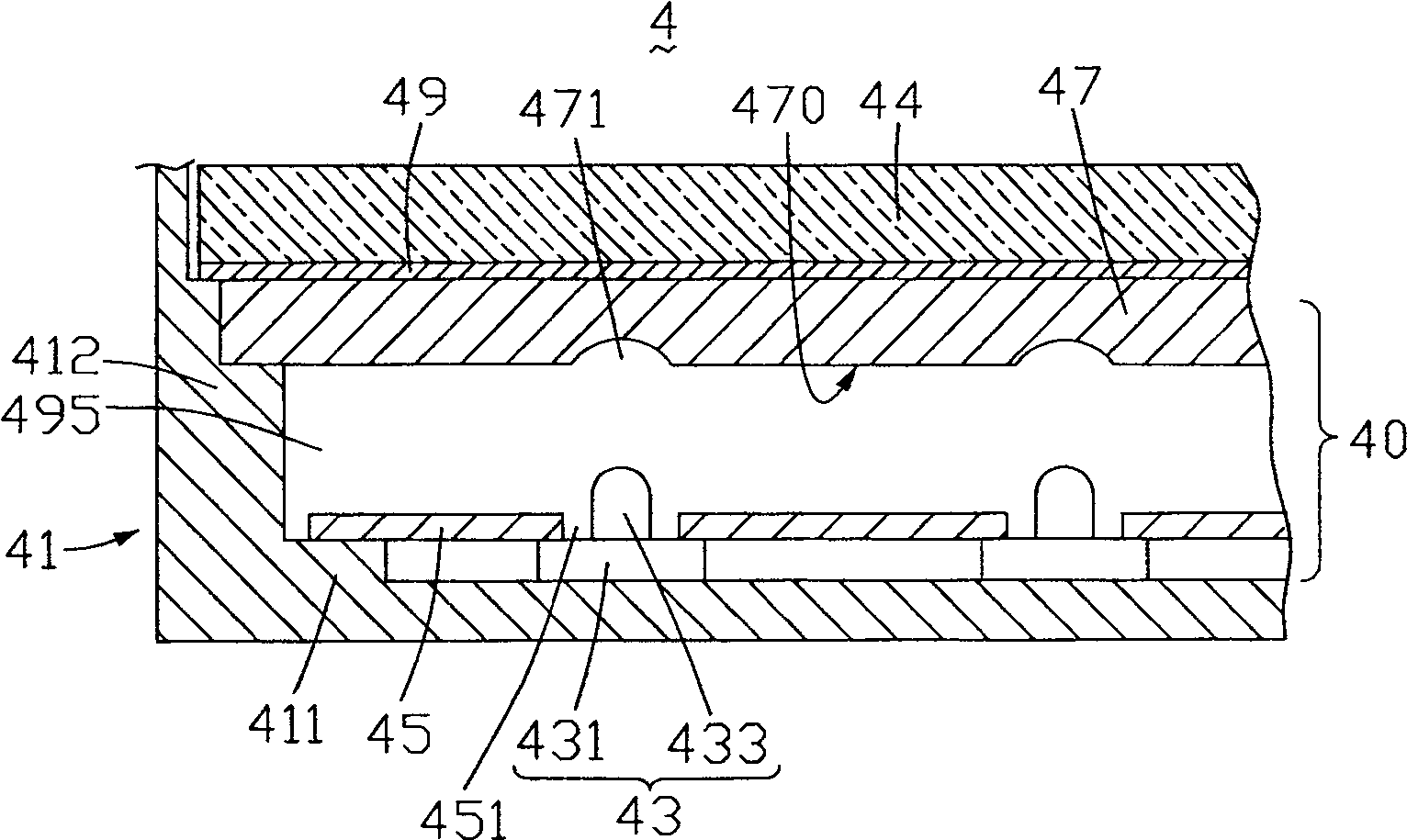

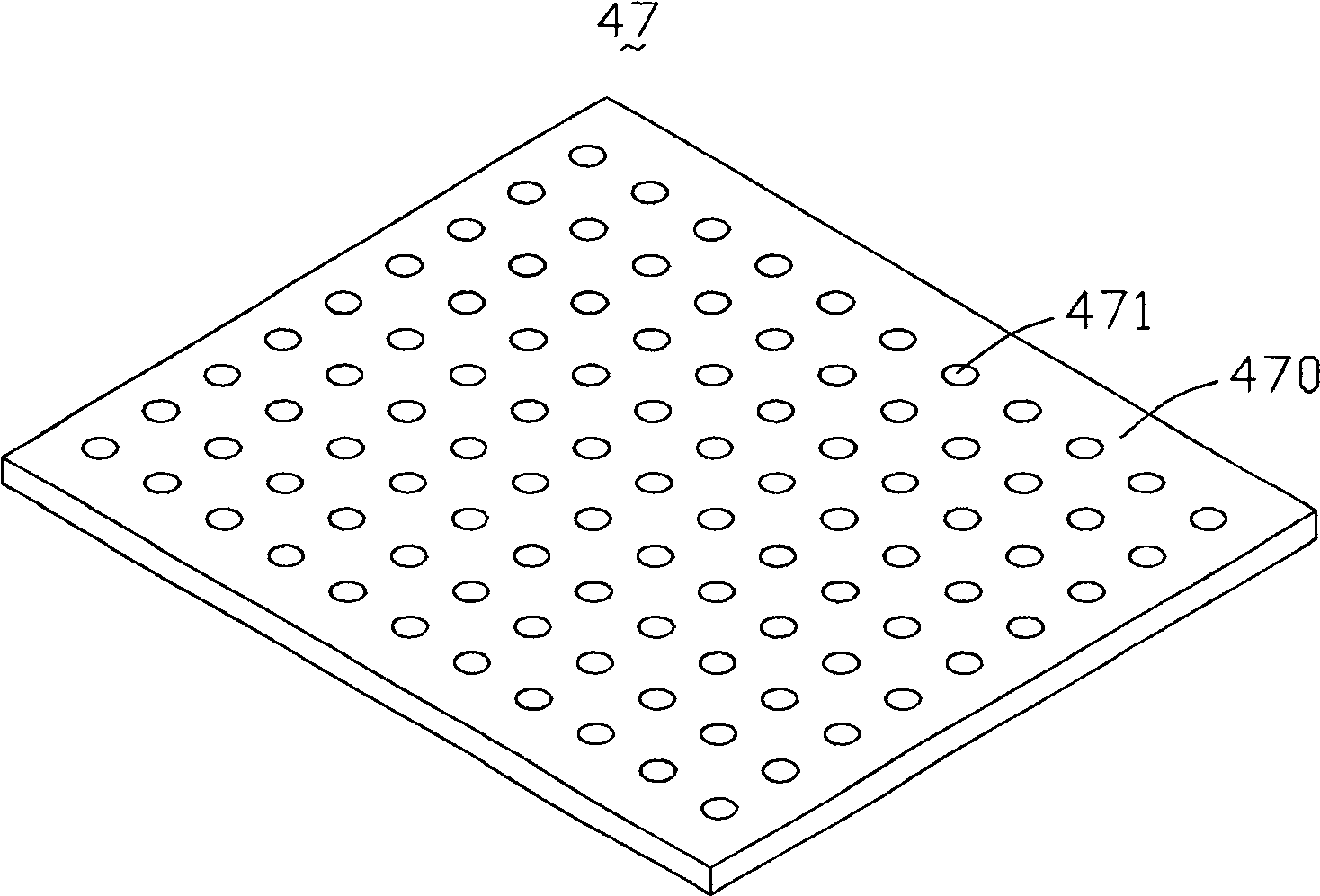

Back light module unit and LCD device

ActiveCN100543552CIncreasing the thicknessAdd room for mixingStatic indicating devicesNon-linear opticsLiquid-crystal displayLight source

The invention relates to a backlight module and a liquid crystal display device using the backlight module. The backlight module includes multiple light sources and a light mixing plate. The plurality of light sources can respectively emit light of different colors. The light mixing plate is adjacent to the plurality of light sources, and has a plurality of groove structures on a side adjacent to the plurality of light sources. The backlight module and the liquid crystal display device using the light mixing plate are thin in thickness and small in volume under the condition of meeting light mixing requirements.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

Purification equipment for protein and polypeptide in peanut meal

ActiveCN111808163BThe mixed reaction is thoroughGuaranteed ExtractionPeptide preparation methodsBiotechnologyPeanut meal

The invention relates to the technical field of purification of protein polypeptides in peanut meal, in particular to purification equipment for protein polypeptide in peanut meal. The present invention pretreats peanut meal through a grinding box, disperses the coagulated peanut meal through a bulk material mechanism, and grinds the peanut meal The meal is ground into fine particles, which effectively makes the subsequent peanut meal and solution mix and react thoroughly, ensures the extraction of protein peptides, reduces the waste of peanut meal raw materials, and improves the conversion rate; the turbine and worm cooperate to drive the reaction box to rotate, and the reaction box drives the internal solution. Rotating and mixing with peanut meal, the mixing mechanism continuously stirs the solution and peanut meal, improves its mixing speed and mixing uniformity, shortens the reaction time, improves mixing efficiency and processing efficiency; the pre-mixing box pre-mixes the solution and peanut meal, and preheats the layer Preliminarily heat it to promote its reaction speed, shorten the mixing time in the reaction box in the later stage, and set the solution box at the back end of the grinding box to facilitate cleaning inside the premixing box.

Owner:江西天禹科技协同创新有限公司

A Lip Jet Combustion System for Direct Injection Diesel Engine

ActiveCN112324556BAdd room for mixingImprove air utilizationInternal combustion piston enginesCylinder headsCombustion systemCombustion chamber

The invention relates to a lip jet combustion system of a direct-injection diesel engine, comprising a fuel injector and a combustion chamber composed of a diesel engine cylinder head, a cylinder liner and a piston; into the combustion chamber. The lip jet combustion system of the direct injection diesel engine of the present invention can not only greatly increase the oil-gas mixing space in the cylinder, but also realize the active guidance of the local fuel flow in the combustion chamber to a specific area by using the lip jet principle and the bottom surface structure of the diesel engine cylinder head, so that In the combustion chamber, the simultaneous combustion process of the inner zone, the middle zone and the outer zone is formed, which realizes the combustion organization concept of dispersing the fuel in the cylinder and then breaking it one by one, and greatly improves the utilization rate of the air in the cylinder. Under the calibrated working conditions, compared with the traditional combustion system, the lip jet combustion system can reduce the fuel consumption by 4% and the soot emission by 80% under the same NOx emission.

Owner:赵伟

Heat exchanger

ActiveCN101788235BEvenly distributedAdd room for mixingEvaporators/condensersStationary conduit assembliesVapor liquidRefrigerant distribution

The invention provides a heat exchanger, which comprises a plurality of fluid channels for heat exchange, header pipes arranged at end parts of the plurality of fluid channels and a distributor, wherein each fluid channel is provided with a fluid inlet; the fluid inlets of the plurality of fluid channels are communicated with the header pipes, and the header pipes are provided with center lines; and the distributor comprises distributing pipes, the distributing pipes are arranged in the header pipes, and the distributing pipes are positioned on one side, far away from the fluid inlets of the plurality of fluid channels, of the center lines. By adopting the structure, the mixed space of vapor-liquid two-phase refrigerant outflowing from an outlet hole is enlarged, so that the mixing is relatively uniform and the distribution of the refrigerant is uniform.

Owner:SANHUA(HANGZHOU) MICRO CHANNEL HEAT EXCHANGER CO LTD +1

A coal mine wet spraying system and wet spraying method with high strength and low energy consumption

InactiveCN103643969BImprove compactnessGuaranteed quantitative additionUnderground chambersMixing operation control apparatusBatch machineHigh intensity

The invention discloses a high-strength and low-energy-consumption coal mine wet spraying system. The wet spraying system comprises a batching machine (1), a blender (2), a spiral quantitative water distribution and transport vehicle (3) and a wet spraying machine which are arranged sequentially, wherein the blender (2) is arranged on the downstream of the batching machine (1); the spiral quantitative water distribution and transport vehicle (3) is arranged at a discharge port of the blender (2); and the wet spraying machine is arranged at a discharge port of the spiral quantitative water distribution and transport vehicle (3). According to the high-strength and low-energy-consumption coal mine wet spraying system, mechanized quantitative control of water, cement, sand, stone and various additives is realized, the working strength of a worker is reduced, and the stability of concrete performance is guaranteed.

Owner:ANHUI UNIV OF SCI & TECH

co boiler with ash removal function

ActiveCN103776013BWith ash removal functionHigh thermal efficiencyDispersed particle separationSteam boilersCombustion chamberFlue gas

The invention discloses a CO boiler with the ash removing function. The CO boiler comprises a first vertical flue, a horizontal flue and a second vertical flue. The first vertical flue is provided with a combustion chamber. The combustion chamber is provided with ash baffles. An externally-hung ash storage bin is arranged on the outer side of the portion, adjacent to the second vertical flue, of the flue wall of the combustion chamber. The first vertical flue is provided with an ash discharge port which is communicated with the ash storage bin. The ash baffles are of the structure that the baffles are arranged in multiple layers in a staggered mode. Each ash baffle is obliquely arranged, wherein the outer end of the ash baffle is higher than the inner end of the ash baffle. According to the CO boiler with the ash removing function, the ash baffles arranged in the CO boiler can remove most of smoke dust contained in flue gas, as a result, the problem of equipment abrasion caused by the smoke dust can be solved to the maximum extent, the flue gas processing technology is optimized, energy consumption is lowered, and investment is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

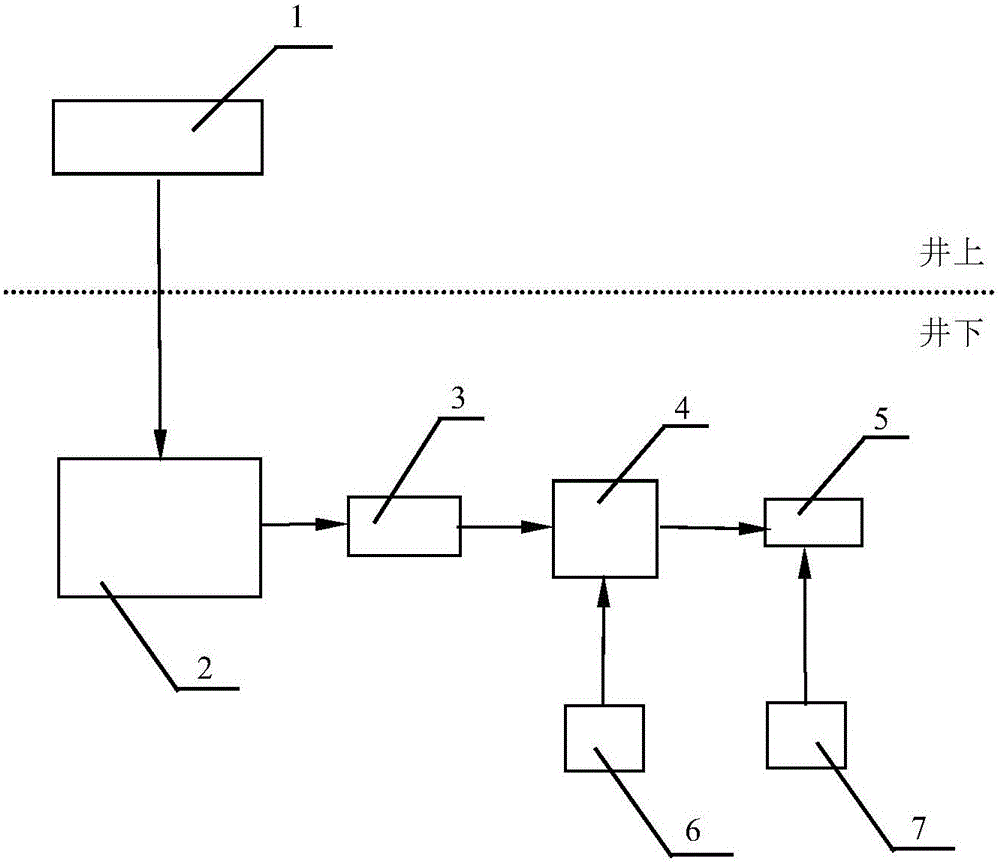

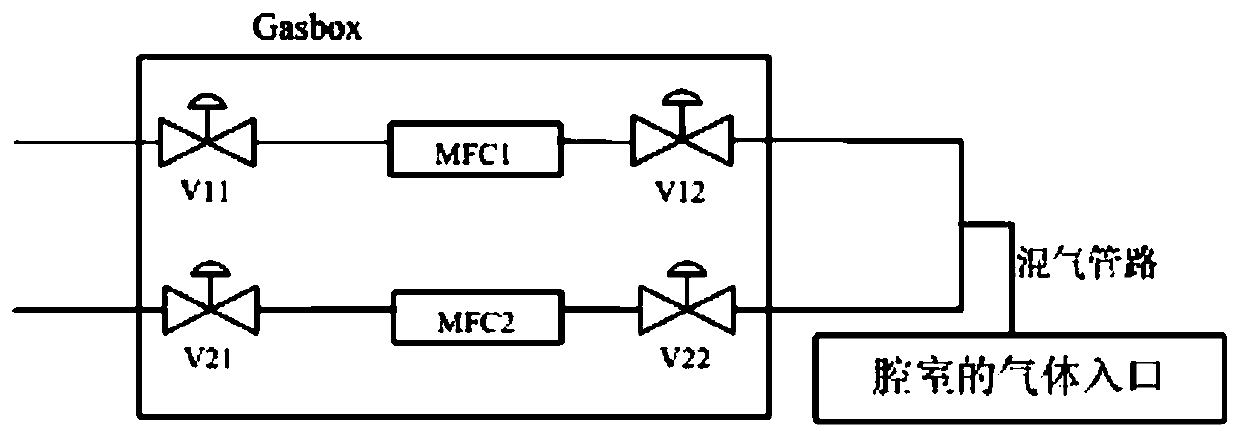

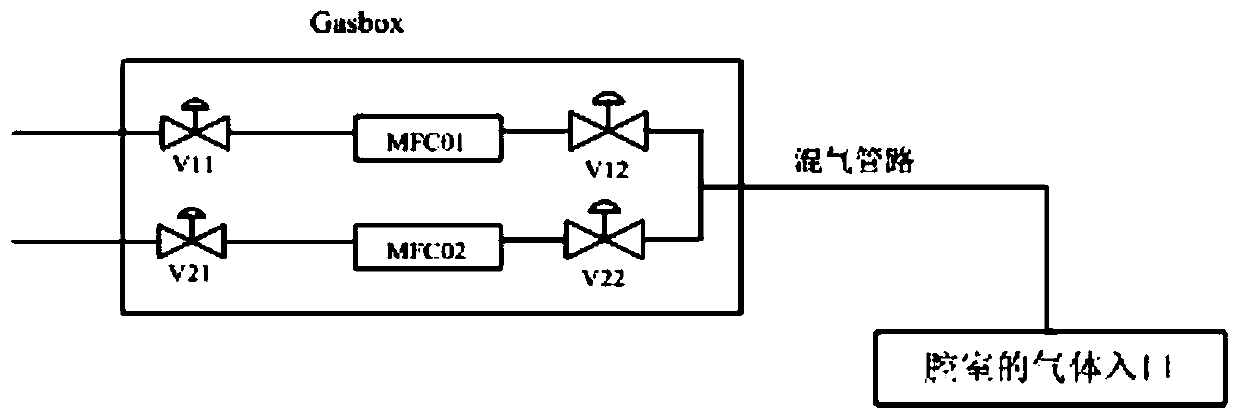

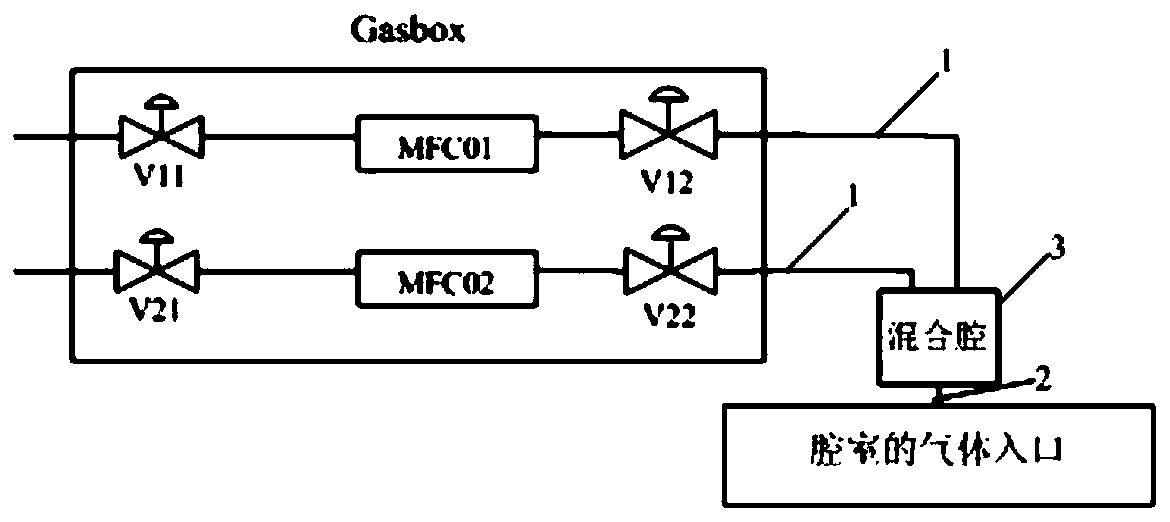

Gas mixing structure, process chamber and semiconductor processing equipment

ActiveCN108728820BWon't clogAdd room for mixingChemical vapor deposition coatingThermodynamicsSemiconductor

The invention provides a gas mixing structure. The gas mixing structure is used for providing gas for a chamber and comprises multiple gas inlet pipelines and at least one gas outlet pipeline. The multiple gas inlet pipelines and multiple gas sources are in one-to-one correspondence connection, and the gas outlet pipeline is connected with a gas inlet of the chamber. A mixing cavity is further included and has a gas mixing space, and the mixing cavity is connected with the gas inlet pipelines and the gas outlet pipeline and is used for enabling gas of the multiple gas sources to be mixed in the gas mixing space and then output to the gas inlet of the chamber through the gas outlet pipeline. The invention further provides the process chamber and a semiconductor processing equipment. According to the gas mixing structure, the process chamber and the semiconductor processing equipment, the gas can be mixed to be uniform, and the pipelines cannot be blocked.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com