Heat exchanger

A heat exchanger and distributor technology, applied in the field of parallel flow evaporators, can solve problems such as uneven distribution, and achieve the effects of uniform distribution and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

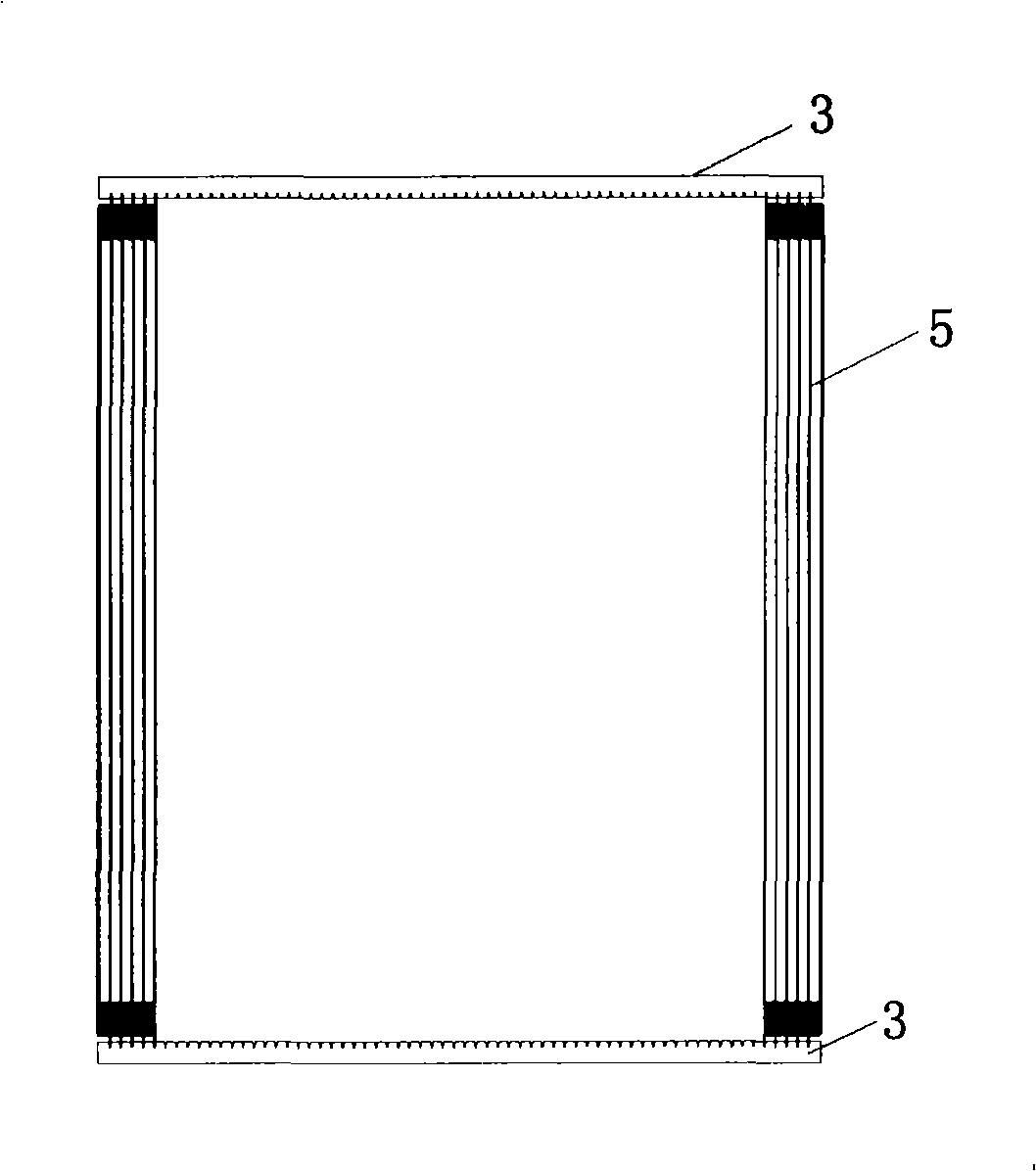

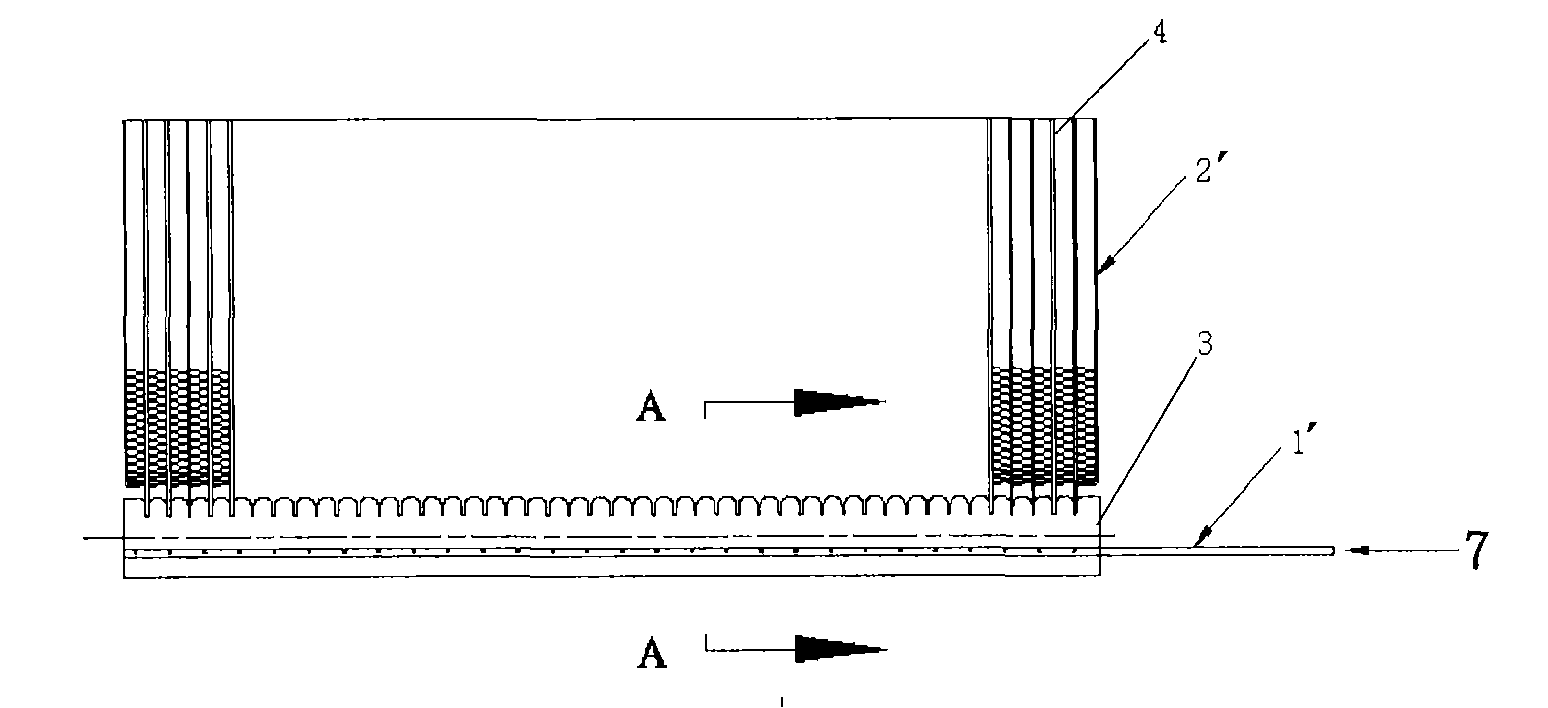

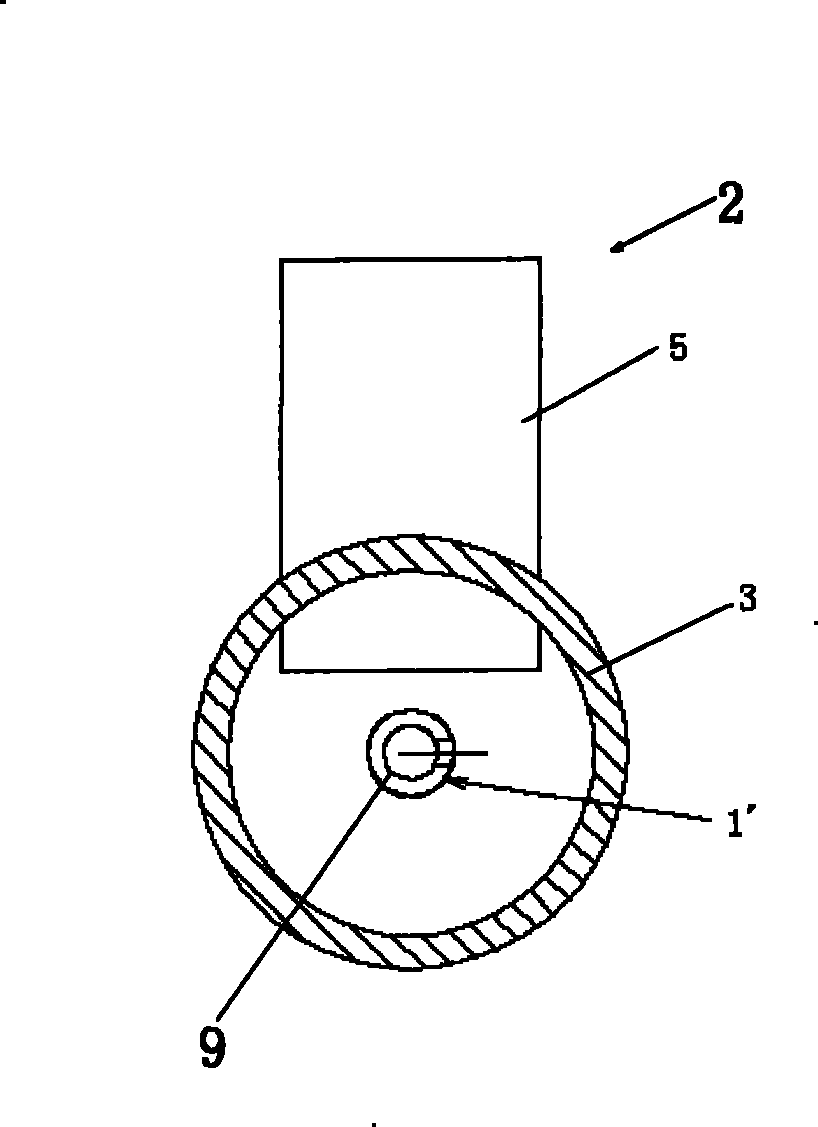

[0029] Figure 4 A schematic diagram showing a partial structure of the parallel flow evaporator 2 according to Embodiment 1 of the present invention. The parallel flow evaporator includes flat tubes 5 as an example of a plurality of fluid channels for heat exchange. The flat tube 5 has a fluid inlet 10 and an outlet. The parallel flow evaporator also includes a header 3 arranged at the end of the flat tube 5 , and the fluid inlet 10 of the flat tube 5 communicates with the header 3 . The parallel flow evaporator also includes a distributor, the distributor includes a distribution pipe 9, the distribution pipe 9 is arranged in the header pipe 3, and the distribution pipe 9 is located far away from the central line of the header pipe 3. One side of the fluid inlet 10 of the flat tube 5.

[0030] Figure 4 In the example in , the parallel flow evaporator is placed upright, and the distribution pipe 9 is arranged in the header 3 on the lower side. At this time, the distributi...

Embodiment 2

[0036] Embodiment 2 is a modification to Embodiment 1, Figure 5a and 5b A schematic diagram showing a partial structure of a parallel flow evaporator 2 according to a second embodiment of the present invention. In this embodiment, on the basis of Embodiment 1, the angle a between the centerline 12 of the outlet hole 8 and the horizontal centerline H satisfies: 5° Figure 5a and 5b shown.

[0037] In the example shown in the figure, for example, Figure 5b Among them, the centerline of the header 3 and the axial centerline 14 of the flat tube 5 are substantially in the same plane. Alternatively, the centerline of the header 3 and the axial centerline of the flat tube 5 may not be in the same plane, for example, they may deviate from each other by a certain distance. For example, the centerline of the header 3 is shifted by a certain distance relative to the axial centerline of the flat tube 5 , thus, the centerline of the header 3 is offset by a certain distance relative to...

Embodiment 3

[0041] Embodiment 3 is a modification to Embodiment 1, Image 6 A schematic diagram showing a partial structure of a parallel flow evaporator 2 according to a third embodiment of the present invention. In this embodiment, on the basis of Embodiment 1, two outlet holes 8 are arranged at substantially the same axial position in the pipe wall of the distribution pipe 9, and the centerlines of the two outlet holes 8 are about the flat tube 5 The axial centerline 14 is substantially symmetrical. The angle b between the centerline 12 of the outlet hole 8 and the axial centerline of the flat tube 5 satisfies the condition: 5°<b<85°.

[0042] In the example shown in the figure, where the parallel flow evaporator is placed upright, the centerlines 12 of the two outlet holes 8 may be symmetrical about the vertical centerline V of the header 3, and the centerlines 12 of the outlet holes 8 The included angle b with the vertical centerline V of the header 3 satisfies the condition: 5° Im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com