co boiler with ash removal function

A boiler and functional technology, applied in the field of CO boilers, can solve the problems of reduced heat extraction section efficiency, high smoke and dust content, equipment corrosion, etc., to reduce the frequency of soot blowing, simplify the dust removal system, and save investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

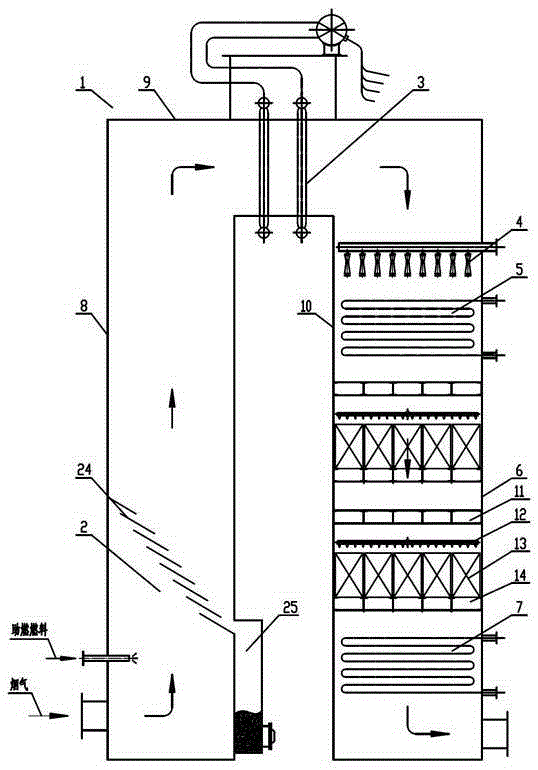

[0028] The specific scheme and usage of the denitration reactor of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, the CO boiler with ash removal function of the present invention includes a flue 1, a combustion chamber 2, a steam drum 3, an evaporation section 5, an economizer section 7 and an ash baffle 24, and the flue includes a first vertical A flue 8, a horizontal flue 9 and a second vertical flue 10, the two ends of the horizontal flue 9 communicate with the upper parts of the first vertical flue 8 and the second vertical flue 10 respectively, and the combustion chamber 2 is set In the first vertical flue 8 , the steam drum 3 is arranged in the horizontal flue 9 , and the evaporation section 5 and the economizer section 7 are arranged in the second vertical flue 10 . In the combustion chamber 2 of the first vertical flue 8, an ash baffle 24 is arranged, and an external ash storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com