Gas mixing structure, process chamber and semiconductor processing equipment

A gas mixing and gas technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of blocked pipelines, easy to generate deposits, short gas mixing pipelines, etc., to reduce the length, gas, etc. well-mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

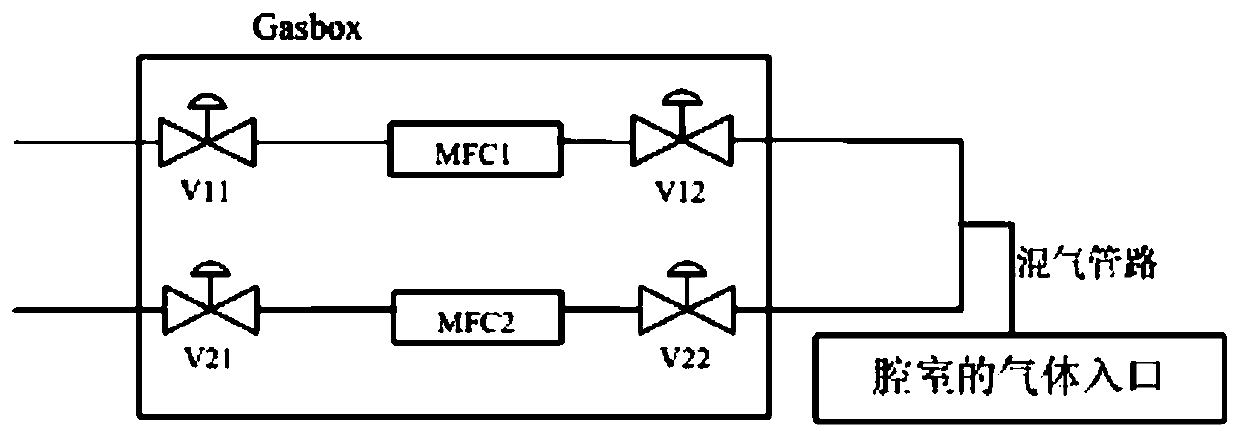

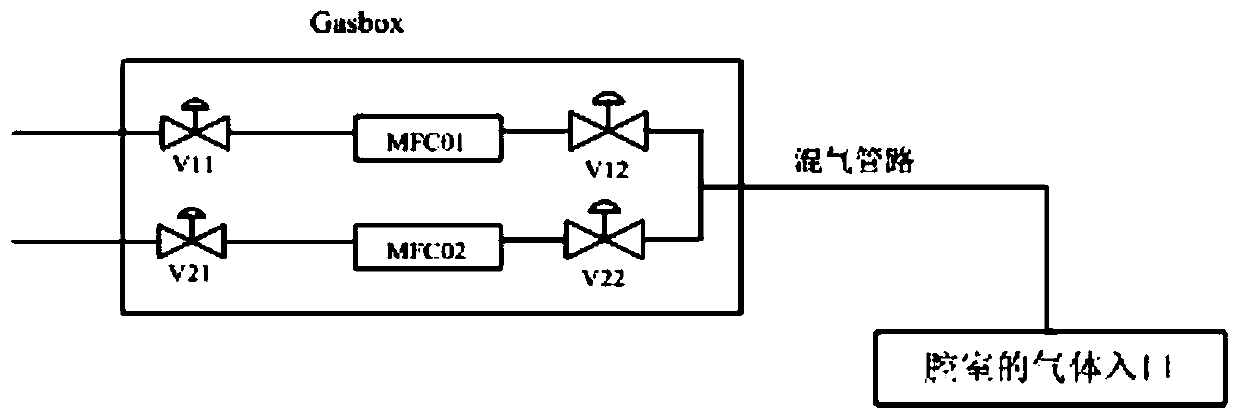

Problems solved by technology

Method used

Image

Examples

Embodiment 1

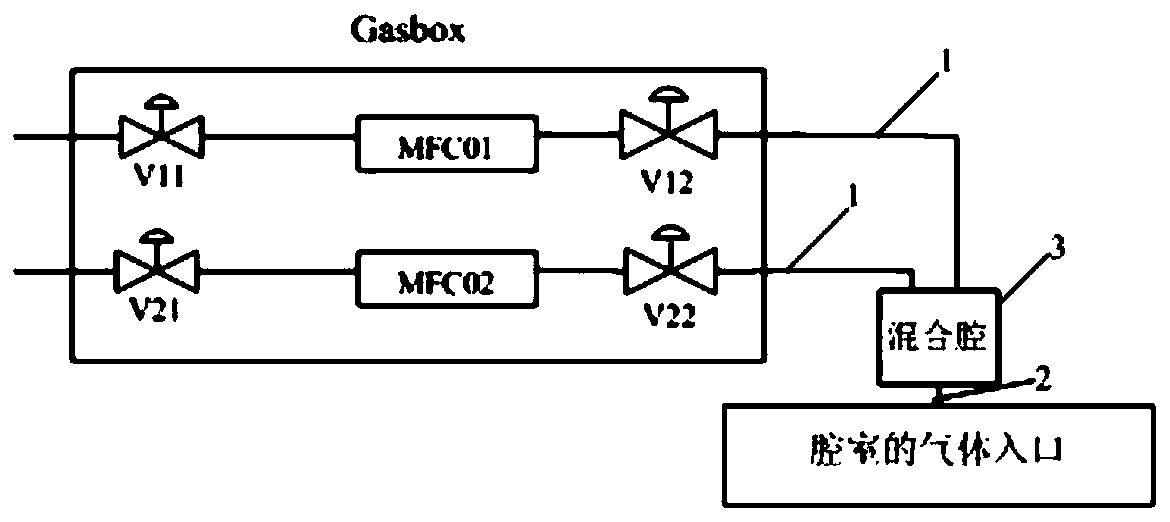

[0044] image 3 This is a schematic structural diagram of a gas mixing structure provided by an embodiment of the present invention; please refer to image 3 , The gas mixing structure provided by the embodiment of the present invention is used to provide gas to the chamber, and includes a multi-channel gas inlet pipe 1 and at least one gas outlet pipe 2. The multi-channel gas inlet pipe 1 is connected to multiple gas sources one by one, The gas outlet pipe 2 is connected to the gas inlet of the chamber. The gas mixing structure further includes a mixing chamber 3, which has a gas mixing space, and the mixing chamber 3 is respectively connected with the gas inlet pipe 1 and the gas outlet pipe 2 for mixing the gases from multiple gas sources in the gas mixing space Then it is output to the gas inlet of the chamber through the gas outlet pipe 2.

[0045] Wherein, the number of air intake pipes 1 included in the air mixing structure can be set as required. For example, the air mixi...

Embodiment 2

[0059] The embodiment of the present invention provides a process chamber including a gas mixing structure for mixing different gases before entering the chamber. The gas mixing structure adopts the gas mixing structure in Embodiment 1.

[0060] The process chamber provided by the embodiment of the present invention adopts the gas mixing structure in Example 1, so the process chamber can not only make the gas mixed more evenly, but also does not block the pipeline, thereby improving the process of the process chamber. The quality and stability and reliability of the chamber.

Embodiment 3

[0062] The embodiment of the present invention provides a semiconductor processing equipment including a process chamber, and the process chamber adopts the process chamber in the above-mentioned embodiment 2.

[0063] The semiconductor processing equipment provided by the embodiments of the present invention adopts the process chamber provided in the above-mentioned embodiment 2 of the present invention, and therefore, the process quality, stability and reliability of the semiconductor processing equipment can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com