Purification equipment for protein and polypeptide in peanut meal

A technology of protein polypeptide and purification equipment, which is applied in the field of purification of protein polypeptide in peanut meal, can solve the problems of affecting the extraction amount of protein peptide, large original particle of peanut meal, incomplete purification reaction, etc., so as to improve mixing efficiency and processing efficiency, Effects of improving conversion rate and shortening mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

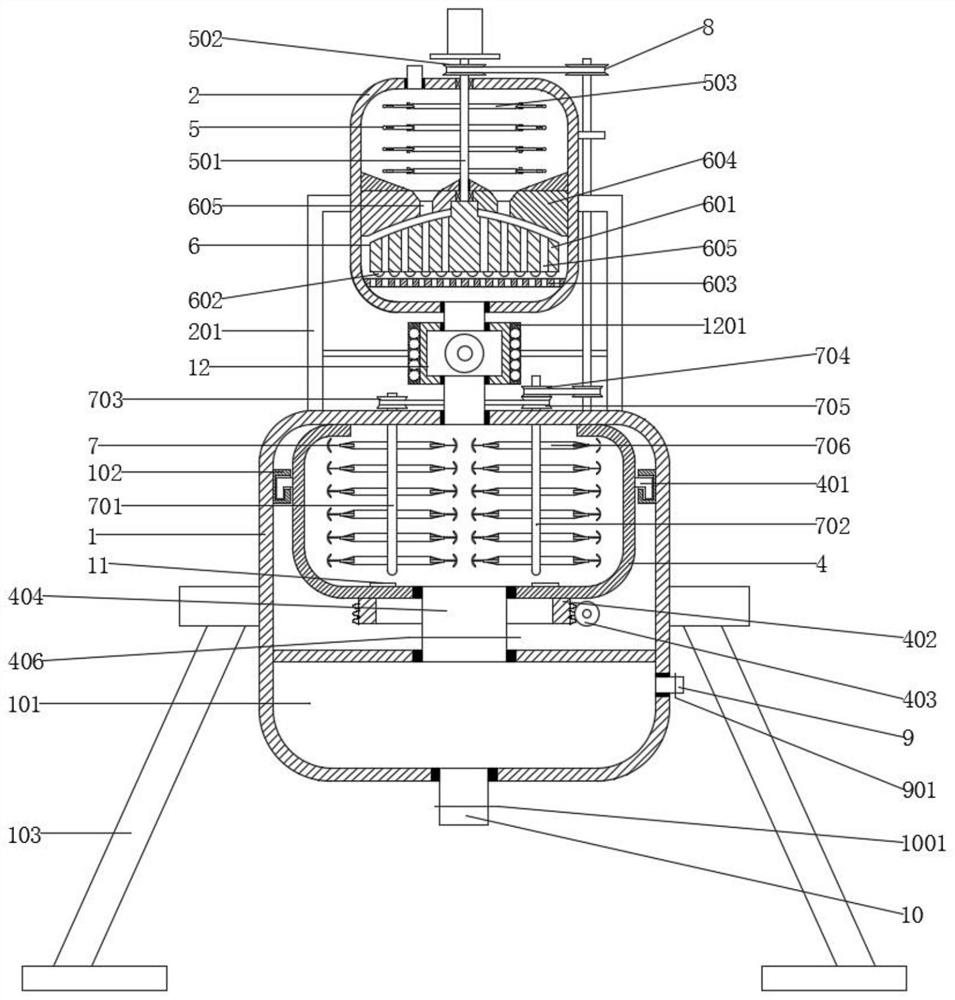

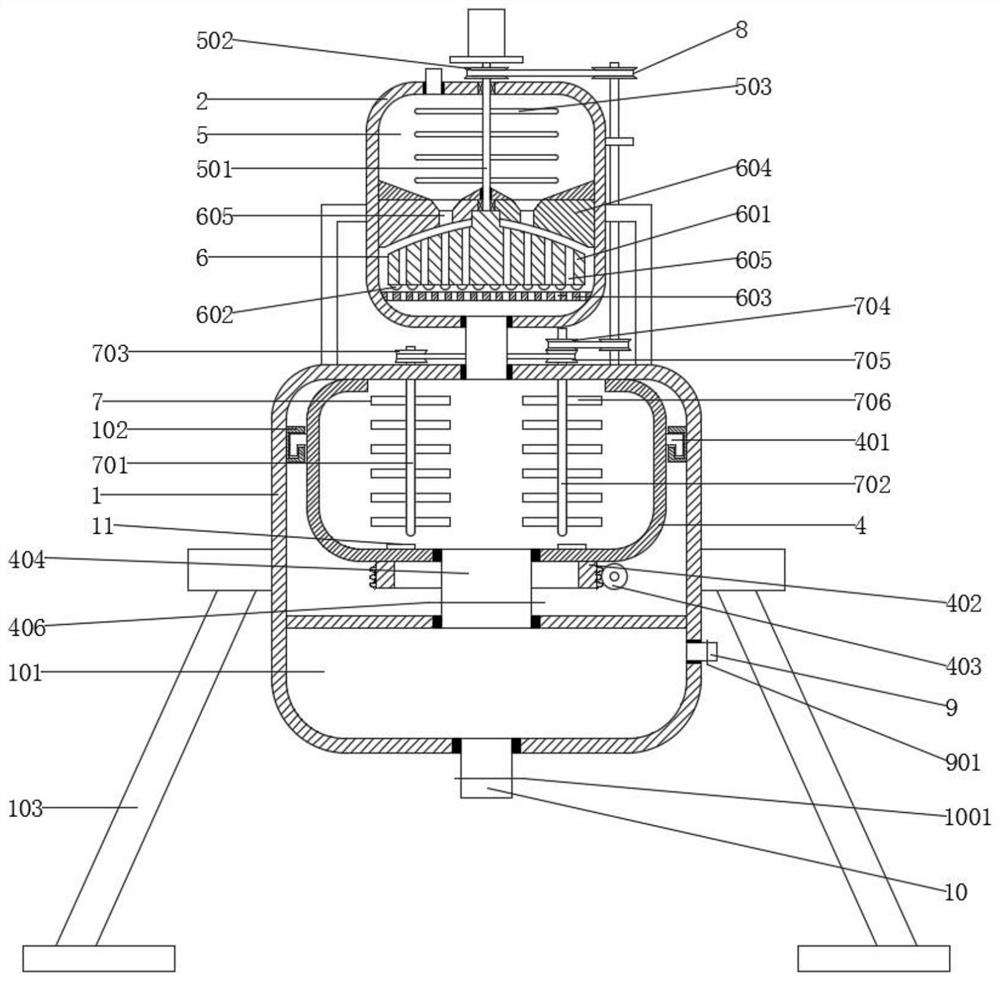

[0057] refer to Figure 1 to Figure 4 The purification equipment for protein and polypeptide in peanut meal of this embodiment includes a purification box 1; a grinding box 2 is arranged on the front side of the upper end of the purification box 1, a solution box 3 is arranged on the rear side of the front end, and a reaction box is arranged on the upper side of the purification box 1. 4. A precipitation chamber 101 is provided on the lower side of the interior, and a bulk material mechanism 5 is provided on the upper side of the grinding box 2. Specifically, the bulk material mechanism 5 includes a bulk material rod 501, a No. 1 transmission wheel 502, and a bulk material tooth 503. The grinding box 2. A bulk material rod 501 is rotatably connected to the upper end of the interior. The upper end of the bulk material rod 501 passes through the grinding box 2 and is fixedly connected with a No. 1 driving wheel 502. The uniformly distributed material teeth 503 are fixedly connect...

Embodiment 2

[0073] Such as Figure 1 to Figure 5 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as Figure 5 As shown, the upper end of the purification box 1 is provided with a premixing box 12, the front side of the upper end of the premixing box 12 is connected with the grinding box 2, the rear side of the upper end is connected with the solution box 3, and the front side of the lower end of the premixing box 12 is connected with the purification box 1 The pre-heating layer 1201 is arranged on the left and right sides of the pre-mixing box 12, and the inside of the pre-mixing box 12 is connected with a conveying rod 1202. , and is connected with a pre-mixing motor 1204.

[0074] The conveying mot...

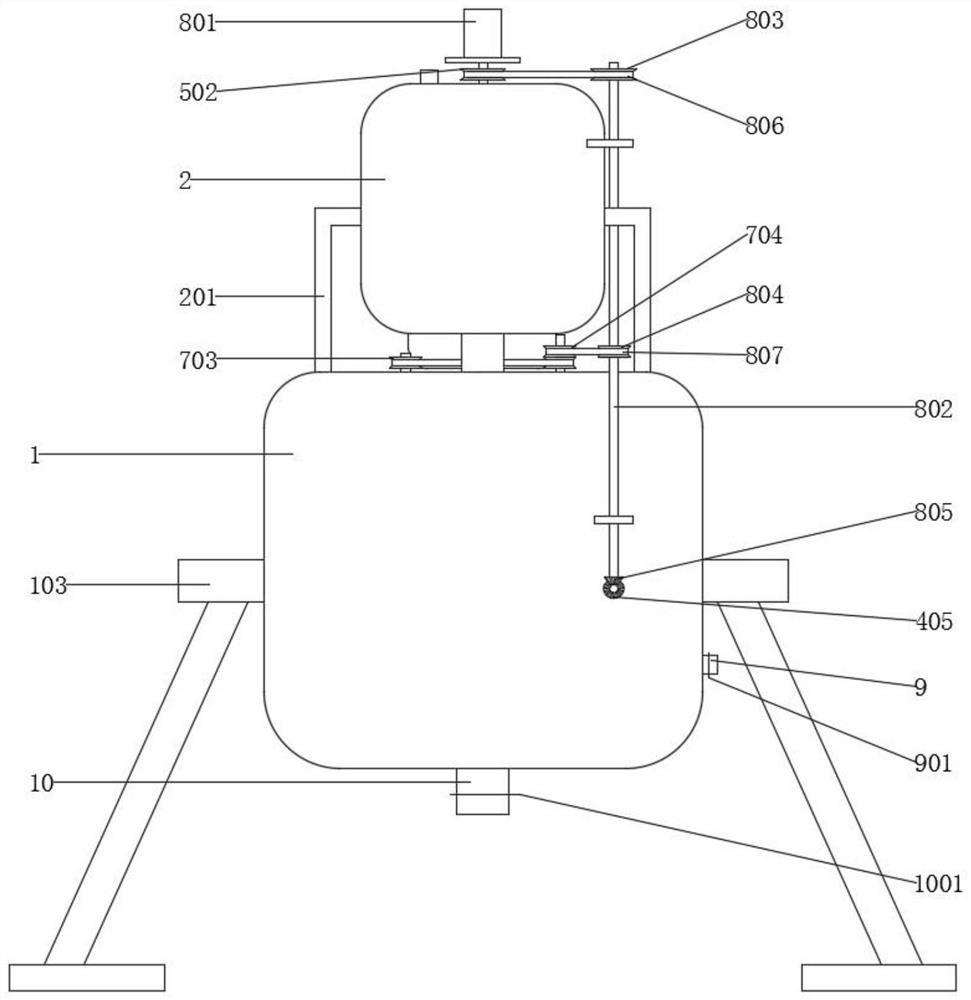

Embodiment 3

[0077] Such as Figure 1 to Figure 6 As shown, the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of brevity, only the differences from the second embodiment will be described below. The difference between the third embodiment and the second embodiment is: as Figure 6 As shown, the right side of the premixing box 12 is provided with a pumping mechanism 13, and the pumping mechanism 13 includes a cam 1301, a rotating support block 1302, a torsion spring, a fixed rod 1303, a piston rod 1304, a piston plate 1305 and a piston chamber 1306, and the delivery rod The rear end of 1202 is fixedly connected with a cam 1301, and the cam 1301 is located at the front side of the premixing motor 1204. The rear end of the purification box 1 is fixedly connected with a fixed plate, and the upper end of the fixed plate is fixedly connected with a fixed rod 1303. The block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com