Self-sinking polyurethane foam plastic as well as preparation method and application thereof

A technology of foamed plastics and polyurethane, applied in the field of foamed plastics, can solve the problems of rough equipment, cumbersome operation, low opening rate and air permeability of foamed plastics, and achieve the effect of thorough mixing reaction, guarantee of cleanliness, and prevention of quality damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

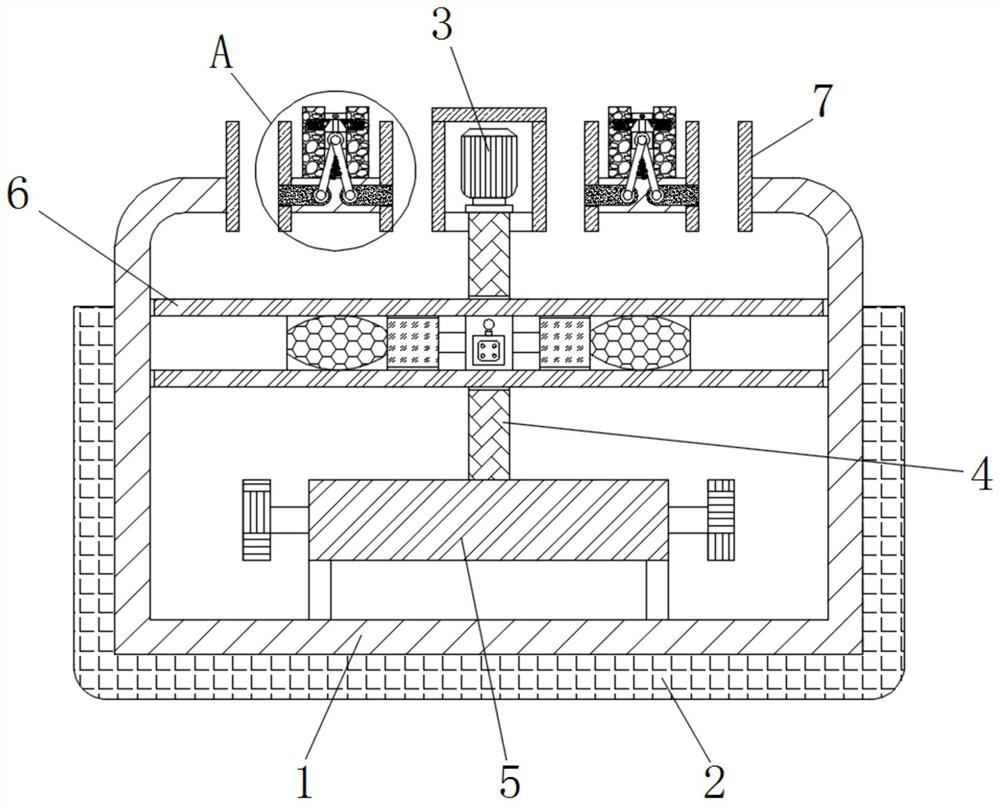

[0033] A spontaneously submersible polyurethane foam and a preparation method thereof, comprising the following method steps:

[0034] S1. Material preparation: polyether polyol A: 50-75 parts, polyether polyol B: 15-25 parts, catalyst 0.1-0.5 parts, foaming agent 1-3 parts, foam stabilizer 0.5-1.5 parts, pro 2 to 8 parts of water materials;

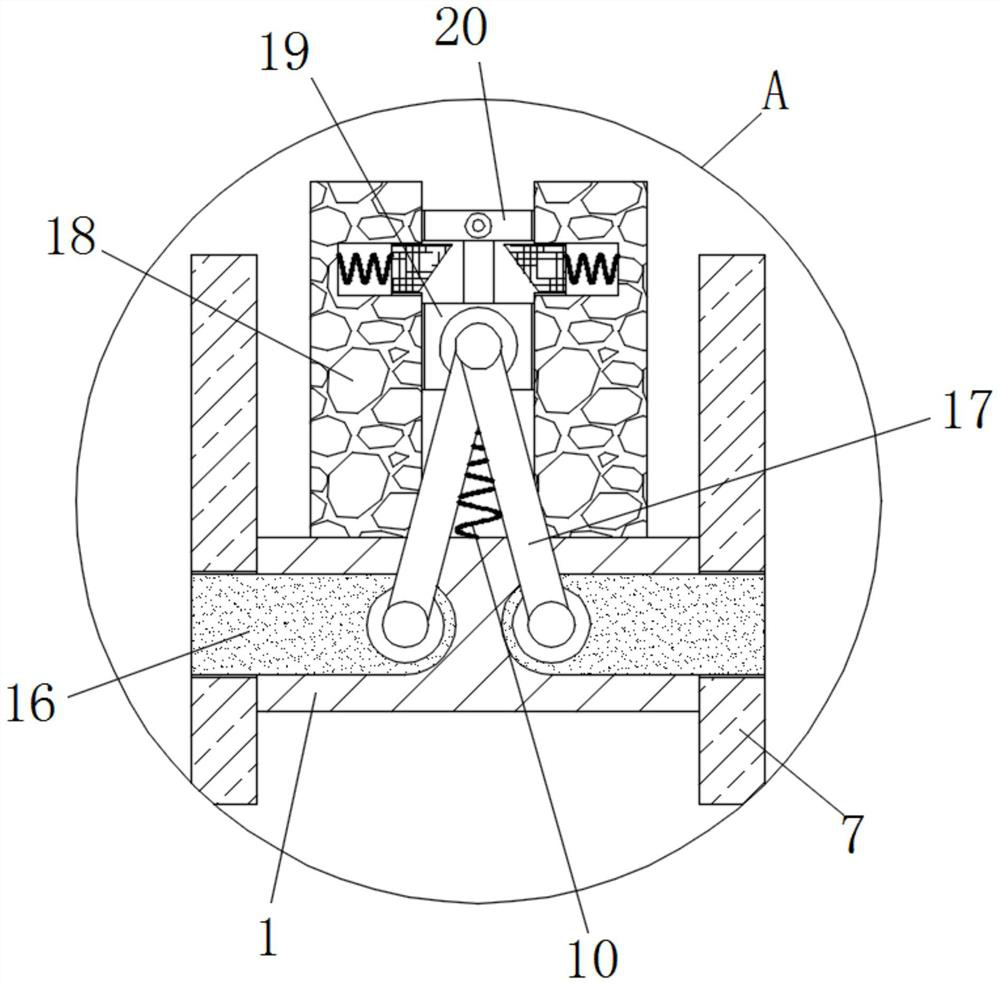

[0035] S2. Equipment preparation: wash the equipment used for mixing and stirring materials with clean water for later use, and prepare a mold covered with polyethylene film;

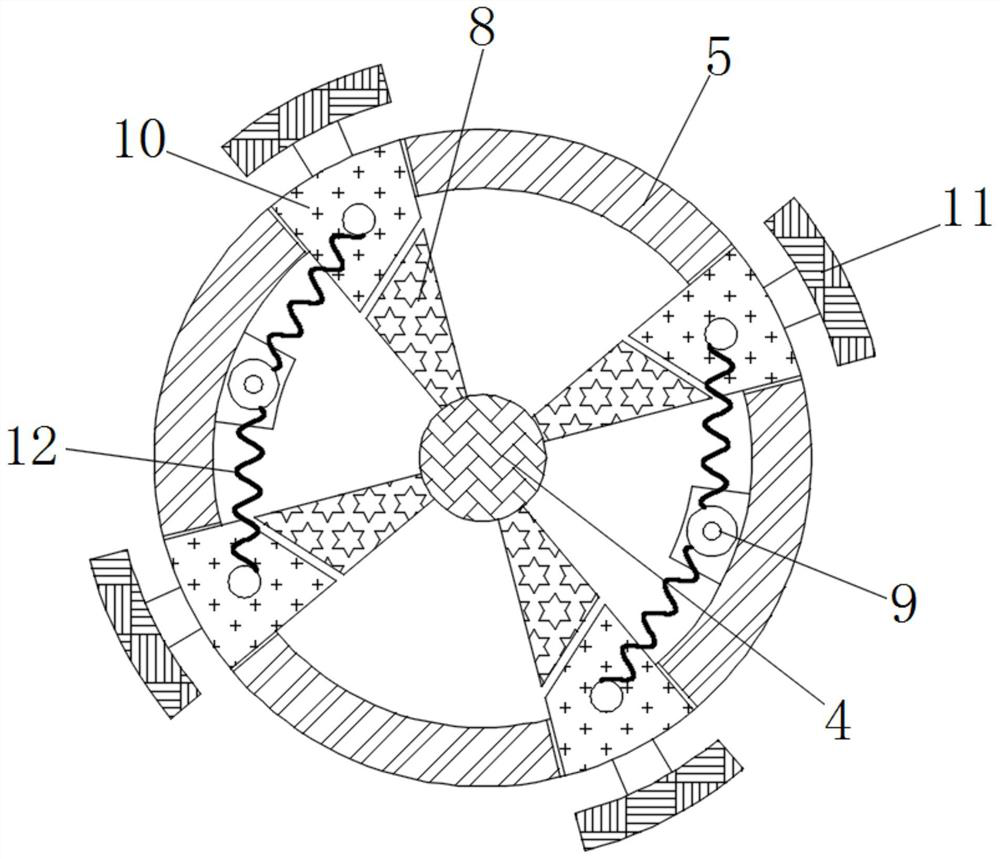

[0036] S3. Mixing and stirring: Pour the prepared materials into the equipment in turn to mix and stir, and introduce the two materials with strong reactions into the equipment from different inlets;

[0037] S4. Temperature control: control the temperature in the equipment during the mixing and stirring process to be between 20° and 24°;

[0038] S5. Pour out and let stand: Pour the stirred and mixed mixture onto a mold covered with a polyethylene film and let ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com