Carbon fiber reinforced thermoplastic composite material and preparation method thereof

A technology of reinforced thermoplastic and composite materials, applied in the field of new energy vehicle materials, can solve the problems of low impact resistance and damage resistance, high fracture toughness, elongation at fracture, poor thermal conductivity, etc., and achieve superior electrical properties and flame retardancy The effect of improving the mechanical properties of materials and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the above-mentioned carbon fiber reinforced thermoplastic composite material adopts the following steps:

[0021] 1) The raw material thermoplastic resin, carbon fiber and inorganic filler are fully dried by a dryer, and the drying time is 4-5 hours, so that the water content of the dried material is less than 0.02wt%.

[0022] 2) Chromium trioxide and boron nitride are mixed and reacted for subsequent use;

[0023] 3) Mixing the thermoplastic resin and the mixed boron nitride, and heating with a heater, the heating time is 1-1.5 hours, and the temperature is 250°C-280°C;

[0024] 4) mixing the thermoplastic resin mixed in step 3 with inorganic fillers, coupling agents, antioxidants, lubricants, and flame retardants in a mixer at high speed, and then adding the mixed materials into the twin-screw extruder hopper, The carbon fiber is added through the fiberizing port of the extruder, extruded and granulated, and the carbon fiber reinforced ther...

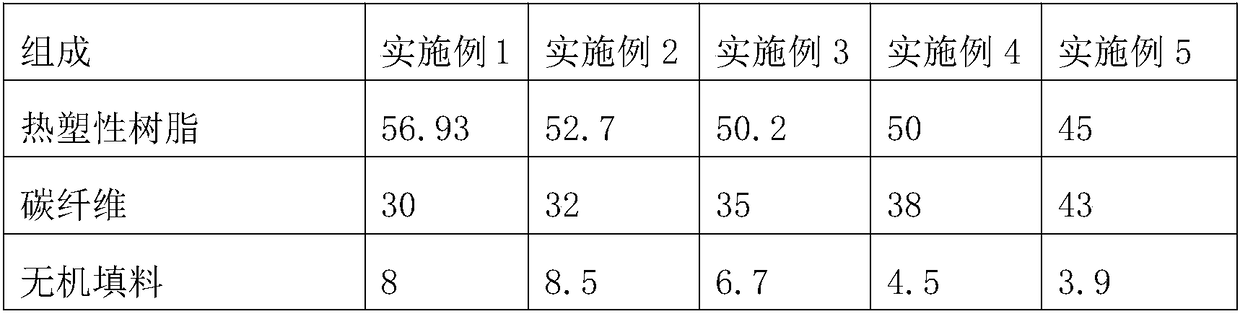

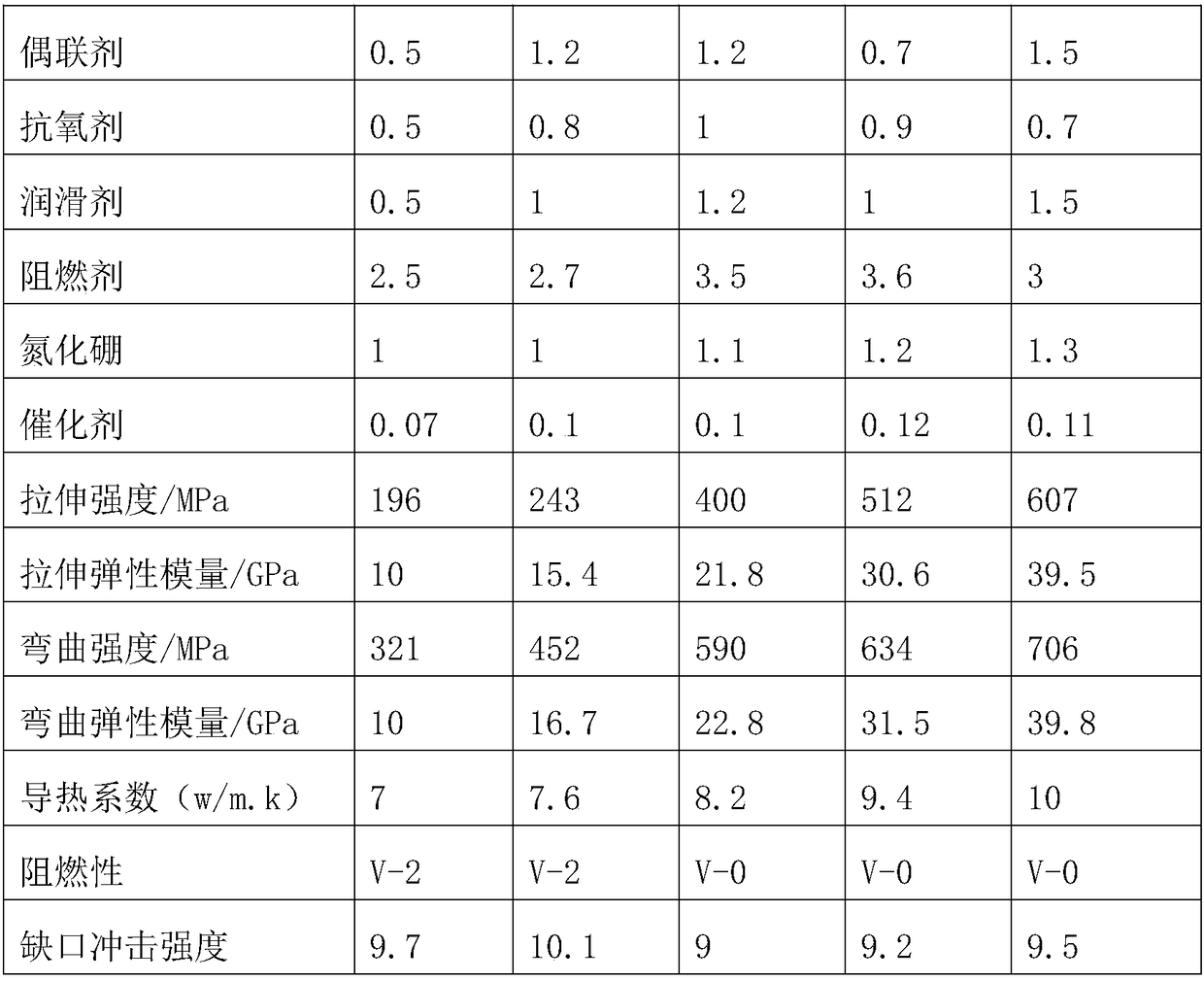

Embodiment 1

[0025] Embodiment 1: The thermoplastic resin 56.93, carbon fiber 30 and inorganic filler 8 are fully dried by a dryer, and the drying time is 4 hours, so that the water content of the dried material is less than 0.02wt%, and dichromium trioxide 0.07 and nitriding Boron 1 mixed reaction for standby; mix thermoplastic resin and mixed boron nitride, and heat through heater, heating time is 1 hour, temperature is 250°C; thermoplastic resin mixed in step 3 and inorganic filler 8 , coupling agent 0.5, antioxidant 0.5, lubricant 0.5, and flame retardant 2.5 are mixed at high speed in the mixer, stirred repeatedly for 3 times, each time for 30 minutes, and then the mixed material is added to the hopper of the twin-screw extruder , and carbon fiber 30 is added through the fiber port of the extruder, extruded and granulated, and the carbon fiber reinforced thermoplastic resin composite material is obtained. 180°C, 220°C, 230°C, 240°C, 250°C, 240°C, and the speed of the host is 240-600 r...

Embodiment 2

[0026] Embodiment 2: The thermoplastic resin 52.7, the carbon fiber 32 and the inorganic filler 8.5 are fully dried by a drier, and the drying time is 4 hours, so that the water content of the dried material is less than 0.02wt%, and dichromium trioxide 0.1 is mixed with nitriding Boron 1 mixing reaction for standby; mix thermoplastic resin and mixed boron nitride, and heat through a heater for 1-1.5 hours at a temperature of 260°C; mix thermoplastic resin mixed in step 3 with inorganic Filler 8.5, coupling agent 1.2, antioxidant 0.8, lubricant 1, and flame retardant 2.7 are mixed at high speed in the mixer, and stirred repeatedly for 3 times for 30 minutes each time, and then the mixed material is added to twin-screw extrusion The hopper of the extruder, and carbon fiber 32 is added through the fiber port of the extruder, extruded and granulated, and the carbon fiber reinforced thermoplastic resin composite material is obtained. The settings are 180°C, 220°C, 230°C, 240°C, 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com