A diesel engine cylinder piston and a diesel engine using the combustion chamber

A cylinder piston and combustion chamber technology, applied in the directions of pistons, machines/engines, mechanical equipment, etc., can solve the problems of increased heat load on the bottom surface of the cylinder head, inability to effectively control fuel consumption, and restrict the rapid mixing of oil and gas, so as to reduce fuel consumption, avoid Higher thermal load and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

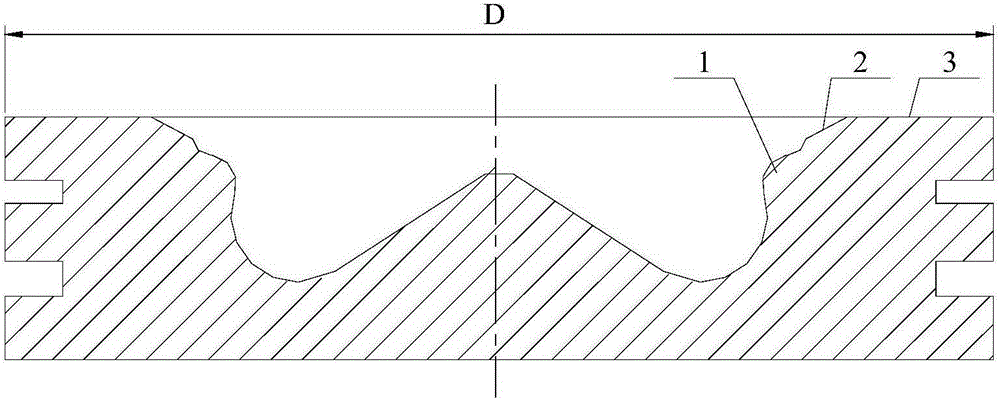

[0027] The core of the invention is to optimize the structure of the combustion chamber of the cylinder piston of the diesel engine. By adjusting the direction of the upper vortex, on the basis of improving thermal efficiency and reducing fuel consumption, the problem of high thermal load on the bottom surface of the cylinder head can be effectively avoided. A detailed description will be given below in conjunction with the accompanying drawings of the description.

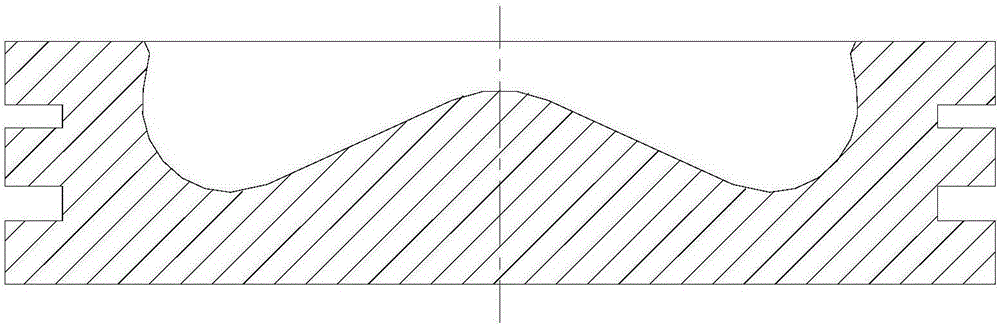

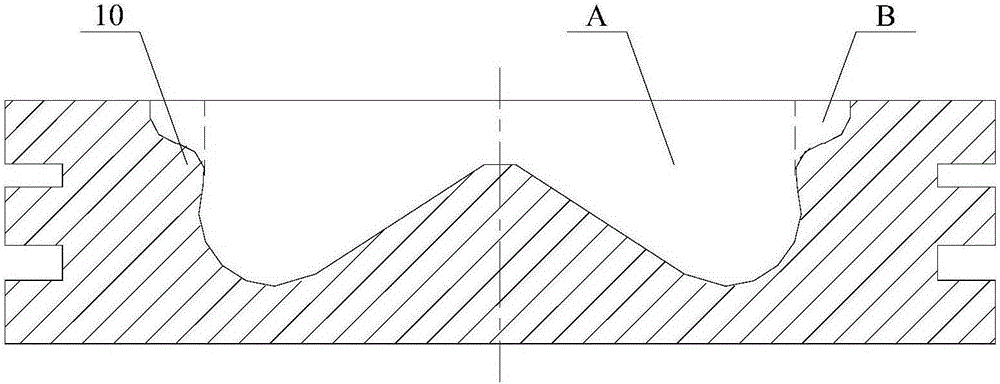

[0028] See image 3 and Figure 4 ,in, image 3 It is a schematic diagram of the axial section of the cylinder piston of the diesel engine described in the first embodiment, Figure 4 for image 3 A partially enlarged schematic view of the combustion chamber shown in .

[0029] The top surface of the cylinder piston of the diesel engine has a combustion chamber whose axial cross-sectional outer profile is "ω"-shaped, and the basic shape of the combustion chamber is roughly the same as that of the prior art. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com