A coal mine wet spraying system and wet spraying method with high strength and low energy consumption

A low-energy, high-strength technology, applied in chemical instruments and methods, injection devices, mining equipment, etc., can solve the problems of large dust in the working environment, low initial strength of concrete, and large rebound rate, etc., to achieve fast injection speed, The effect of excellent raw material quality and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

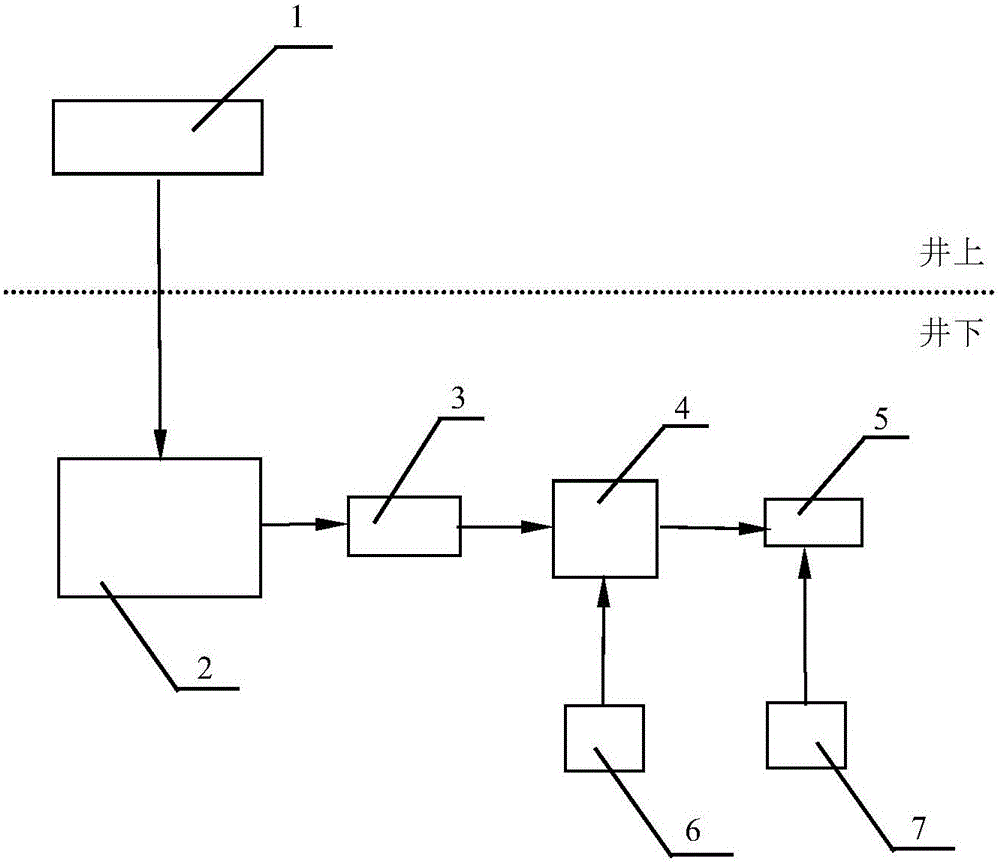

[0040] like figure 1 As shown, a coal mine wet spraying system with high strength and low energy consumption includes a batching machine 1, a mixer 2, a spiral quantitative water distribution vehicle 3 and a wet spraying machine arranged in sequence, and the mixer 2 is set on the batching machine Downstream of 1, the spiral quantitative water distribution vehicle 3 is set at the outlet end of the mixer 2, and the wet spray machine is set at the discharge port end of the spiral quantitative water distribution vehicle 3.

Embodiment 2

[0042] like figure 1 As shown, a coal mine wet spraying system with high strength and low energy consumption includes a batching machine 1, a mixer 2, a spiral quantitative water distribution vehicle 3 and a wet spraying machine arranged in sequence, and the mixer 2 is set on the batching machine Downstream of 1, the spiral quantitative water distribution vehicle 3 is set at the outlet end of the mixer 2, and the wet spray machine is set at the discharge port end of the spiral quantitative water distribution vehicle 3.

[0043] The batching machine 1 is arranged on the ground, and the mixer 2, the screw type quantitative water distribution vehicle 3 and the wet spraying machine are arranged in the underground, and the discharge port of the batching machine 1 passes through the feeding device and the mixer 2. The mouth end is connected; the batching machine 1 includes a filter device and a weighing device, the transport device is a mine transport vehicle including a closed tran...

Embodiment 3

[0053] A method of wet spraying carried out by using the high-strength and low-energy coal mine wet spraying system of the present invention, comprising the steps of:

[0054] Step 1. Put the raw material in the batching machine 1, the weighing device in the batching machine 1 accurately weighs each component of the raw material, and the filter device filters the tailings to make the particle size less than or equal to 10mm, and stir Mix evenly to obtain mixed dry material I; the raw material is composed of the following materials in weight percentage: 63% of ordinary cement clinker; 28% of tailings; 2.6% of gypsum; 0.45% of Glauber's salt; Sodium 1.5%, formaldehyde 1.8%;

[0055]Step 2, put the mixed dry material I into a closed transport box, transport it to the underground by a mine transport vehicle, unload the mixed dry material I into the mixer 2, add the mixed dry material I quality 2% high-efficiency water reducer, fully mixed and stirred to obtain mixed dry material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com