Double-vortex-flow type urea mixing device

A technology of mixing device and double scroll, applied in muffler device, exhaust device, exhaust gas treatment and other directions, can solve the problems of poor mixing uniformity, slow urea shunting, poor decomposition, etc., to prevent accumulation, promote shunting, improve Effect of airflow uniformity and urea mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described in conjunction with the accompanying drawings in Example:

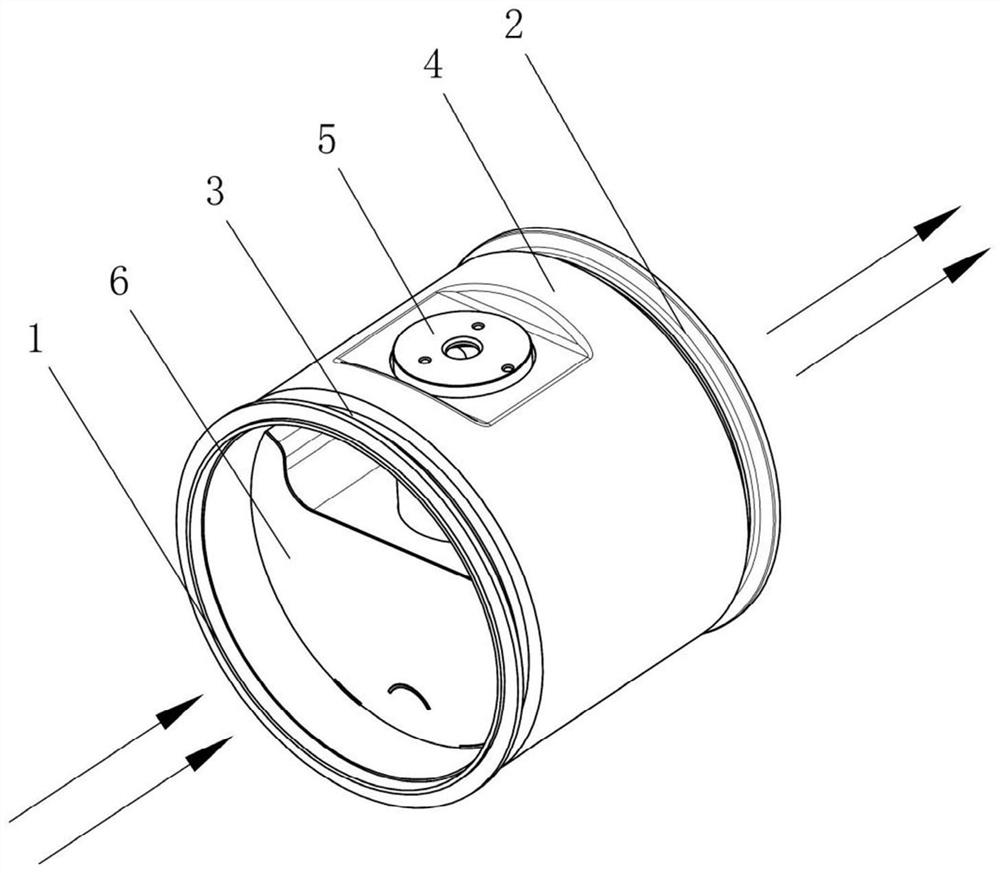

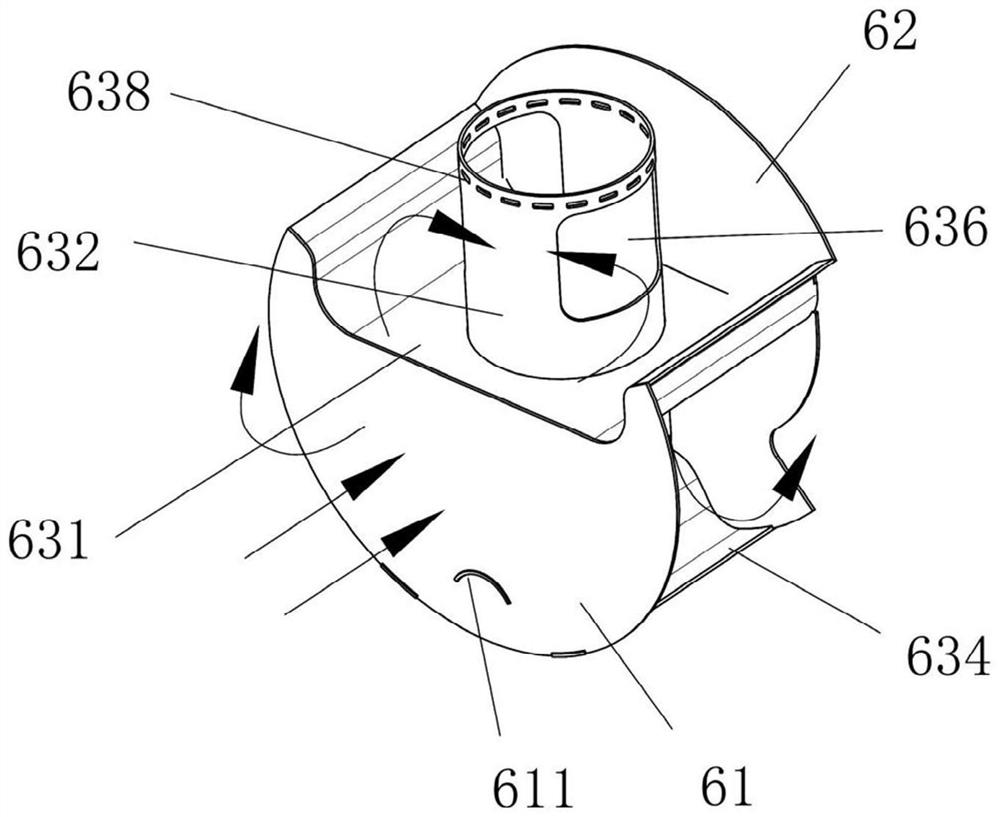

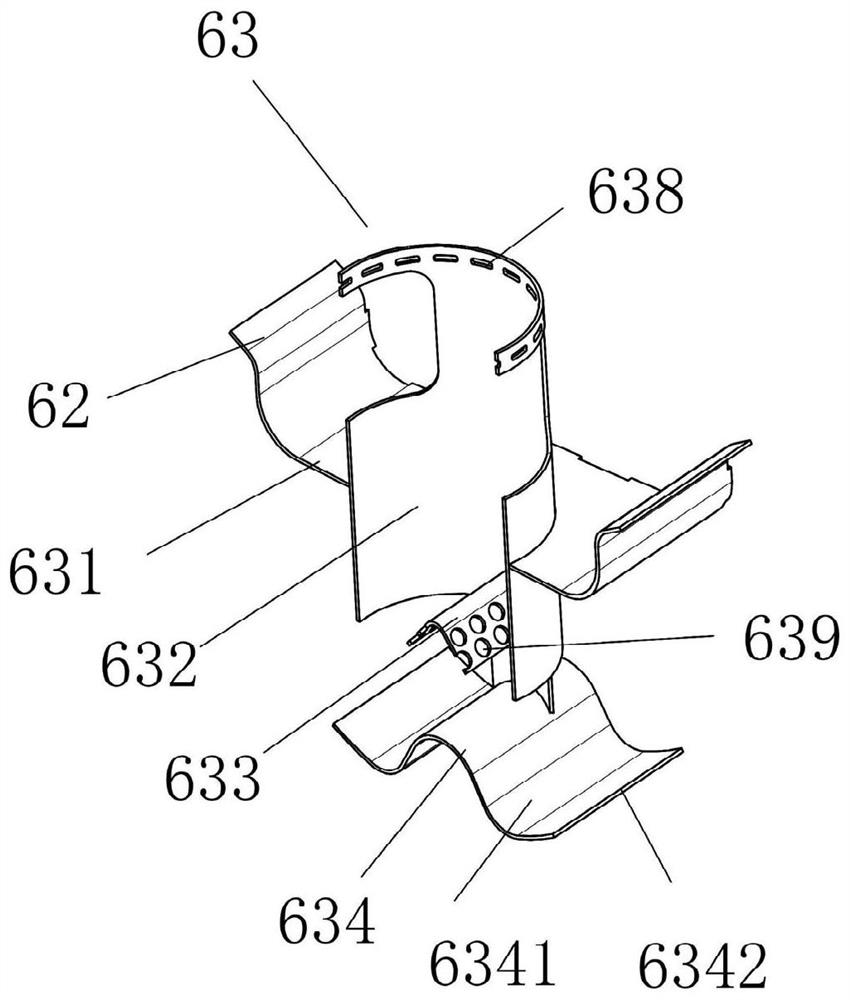

[0030] As illustrated, as figure 1 , figure 2 As shown in a double spiral flow type mixing apparatus of the urea present invention is mainly composed of a front flange, a rear flange 2, 3 Simplified, the heat shield 4, 5 and the nozzle base assembly 6 and other components. Wherein the front flange 1, a rear flange 2 are welded at both ends of the cylindrical body 3, and the SCR catalytic unit used for like structure is connected; 4 welded to a heat shield outer cylinder 3, for thermal insulation, reducing the mixing means heat loss, the temperature of the exhaust gas to enhance the mixing apparatus. The nozzle base 5 is welded to the cylinder hole location for mounting the nozzle of urea, and the urea injection during use. 3 welded to the tube assembly inside the cylinder 6, is connected to the nozzle base 5, for mixing urea, crushing, while forming a double swirl to enhance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com