Field type material fine crushing and high-quality and high-efficiency uniform mixing equipment and method

A material and fine crushing technology, applied in chemical instruments and methods, mixers, grain processing, etc., can solve problems such as unsatisfactory sintering, cold agglomeration, limited application of wheel mill mixer, long natural drying process, etc., to reduce overall cost , to achieve the integration of crushing and mixing, to achieve the effect of integration of fine crushing and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The solution of the present invention will be further described in detail below through specific examples.

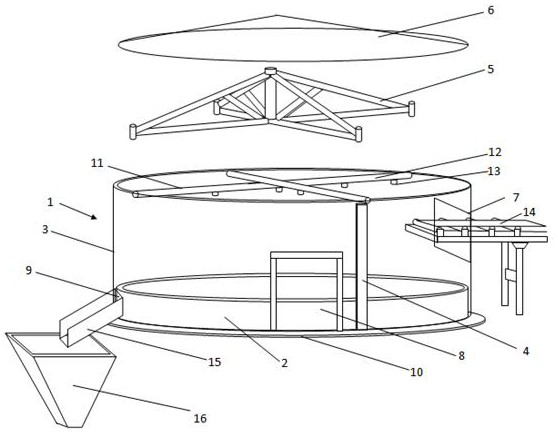

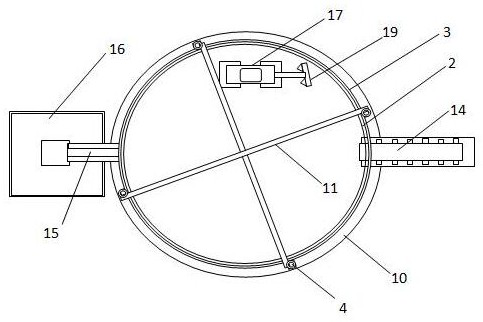

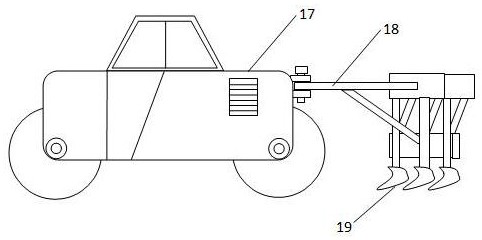

[0031] Such as Figure 1-3 As shown, a site-type material fine crushing and high-quality and efficient mixing equipment includes a grinding chamber 1 and a rolling machine 17, wherein:

[0032] The milling chamber 1 is enclosed by a cylindrical wall, and the wall includes a low wall 2 at the lower part, and a transparent plexiglass wall 3 is arranged on the outside of the low wall 2 . A column 4 is also arranged outside the plexiglass enclosure 3, and a roof frame 5 is fixed on the top of the column 4, and a ceiling 6 is fixed on the roof frame 5. One side of the grinding and mixing chamber 1 is provided with a feed window 7, one side is provided with a vehicle entry and exit door 8, and the other side is provided with a discharge port 9; the bottom ground 10 of the grinding and mixing chamber 1 is made of steel plates. A rubber layer is provided; the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com