Patents

Literature

55results about How to "Short flow path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

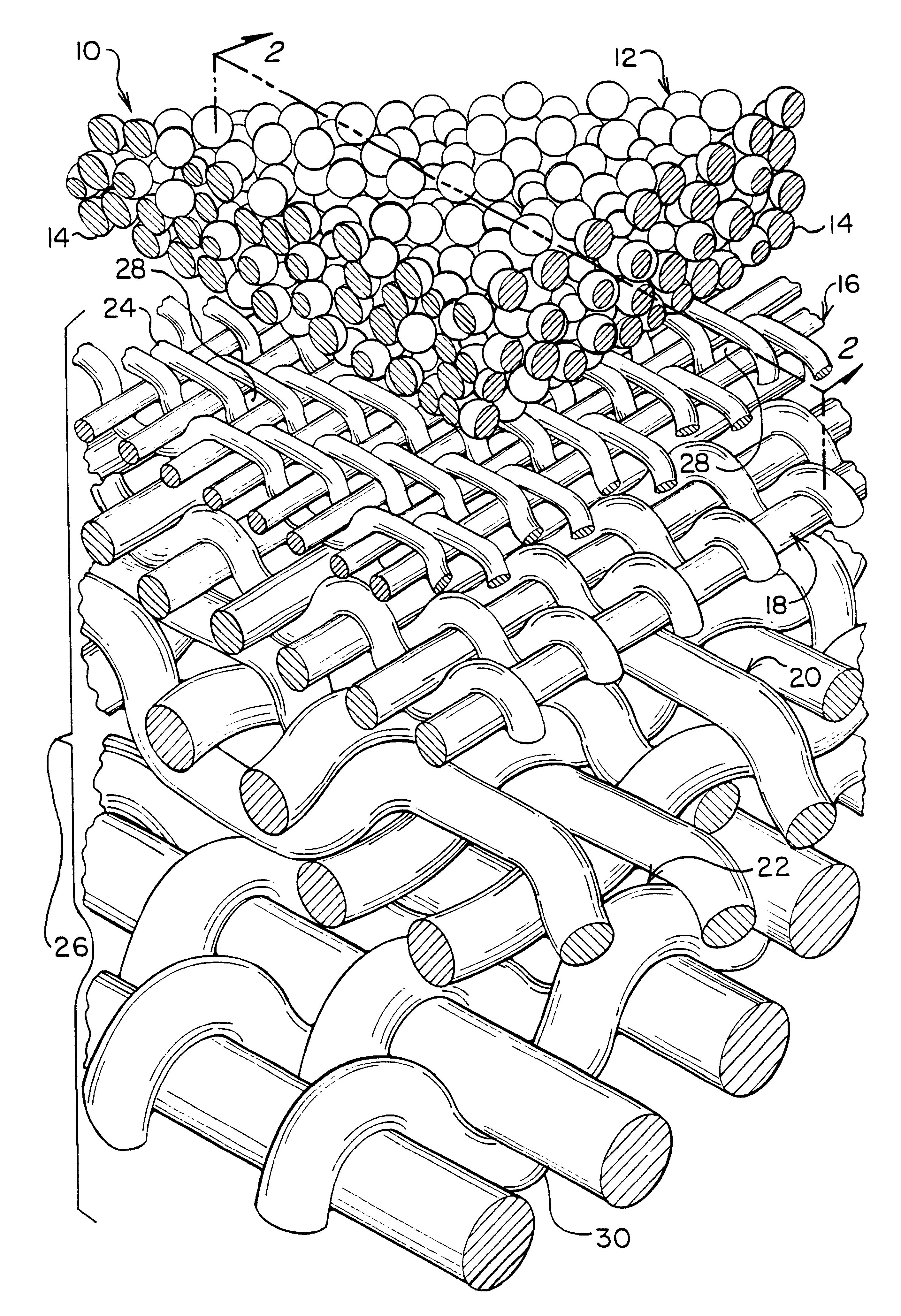

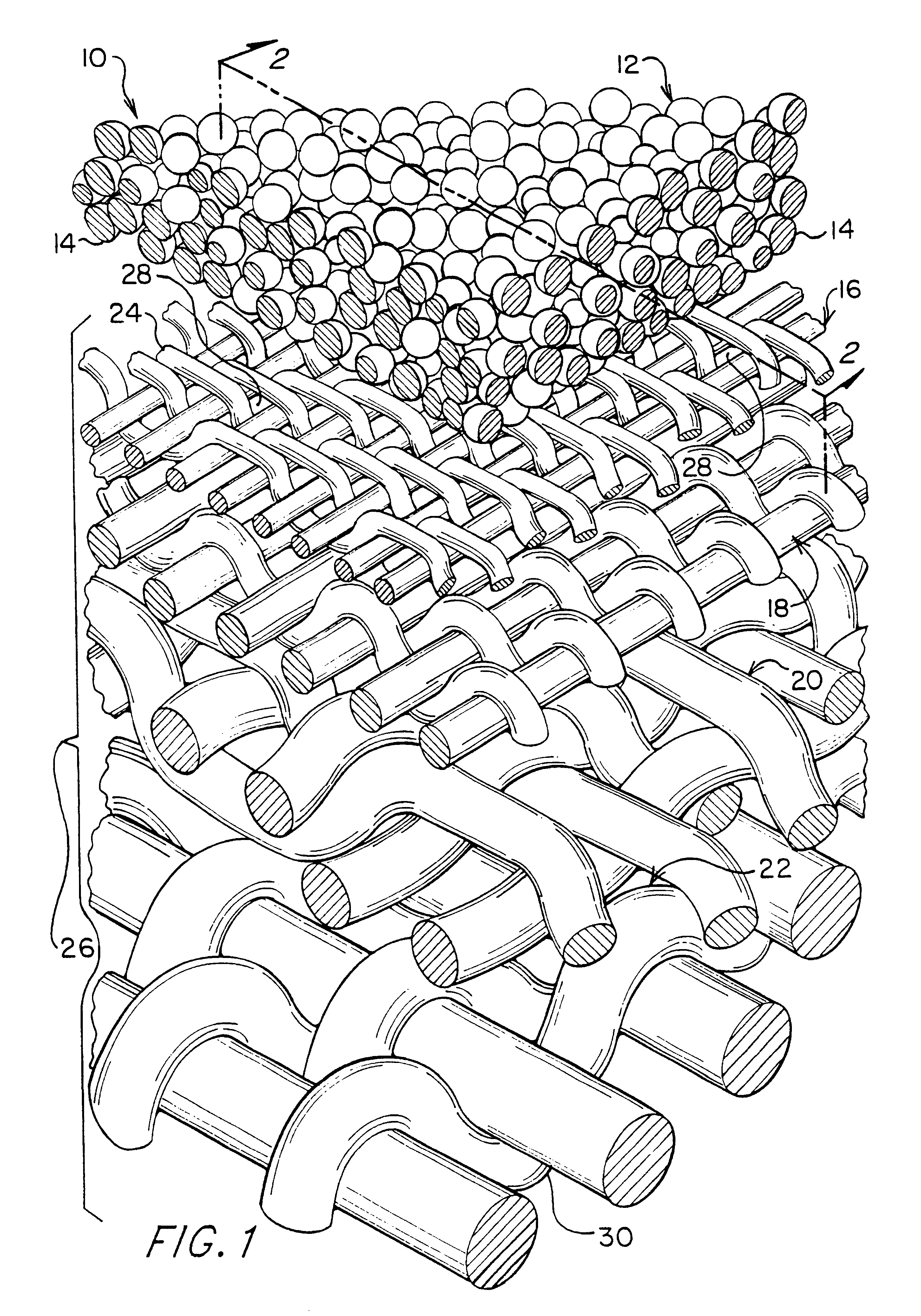

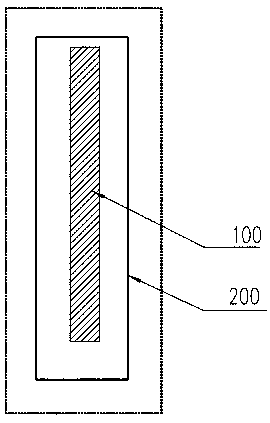

Micro and ultrafilters with controlled pore sizes and pore size distribution and methods for making

InactiveUS6309546B1High permeabilityMinimal pressure dropSemi-permeable membranesMembranesMicrometerPore diameter

A micro / ultrafiltering element (10) and method for making a filter element are provided. The filtering element comprises a multi-level support (26) having a filtering membrane layer (12) formed thereon comprising sintered particles (14) of uniform diameter. The filtering membrane preferably has an average pore size of from about 0.005-10 micrometers. The filter element is capable of being formed in a variety of geometrical shapes based on the shape of the porous support,

Owner:ELLIPSIS CORP

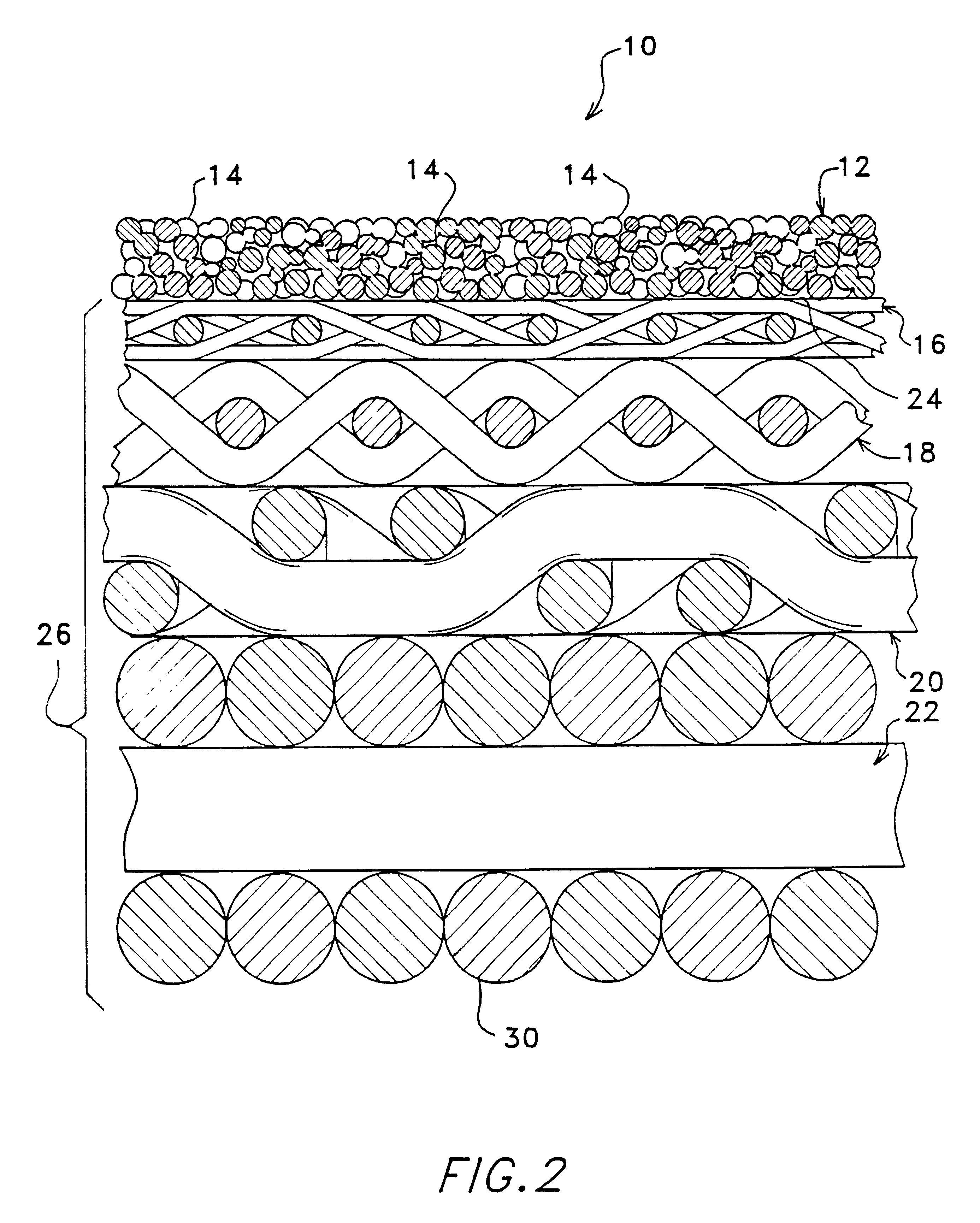

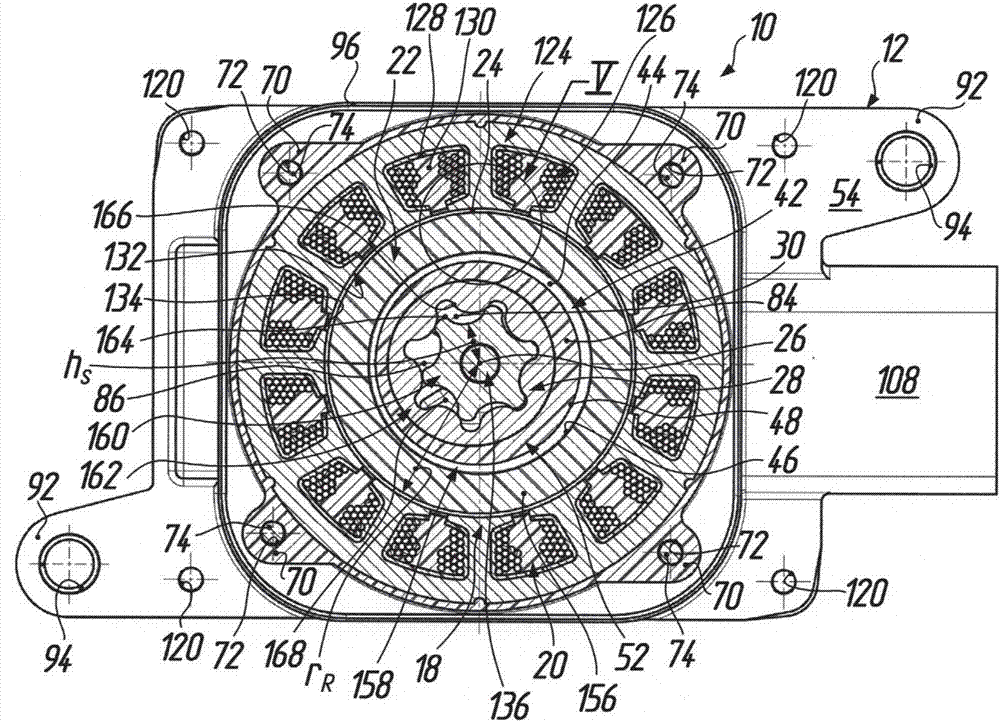

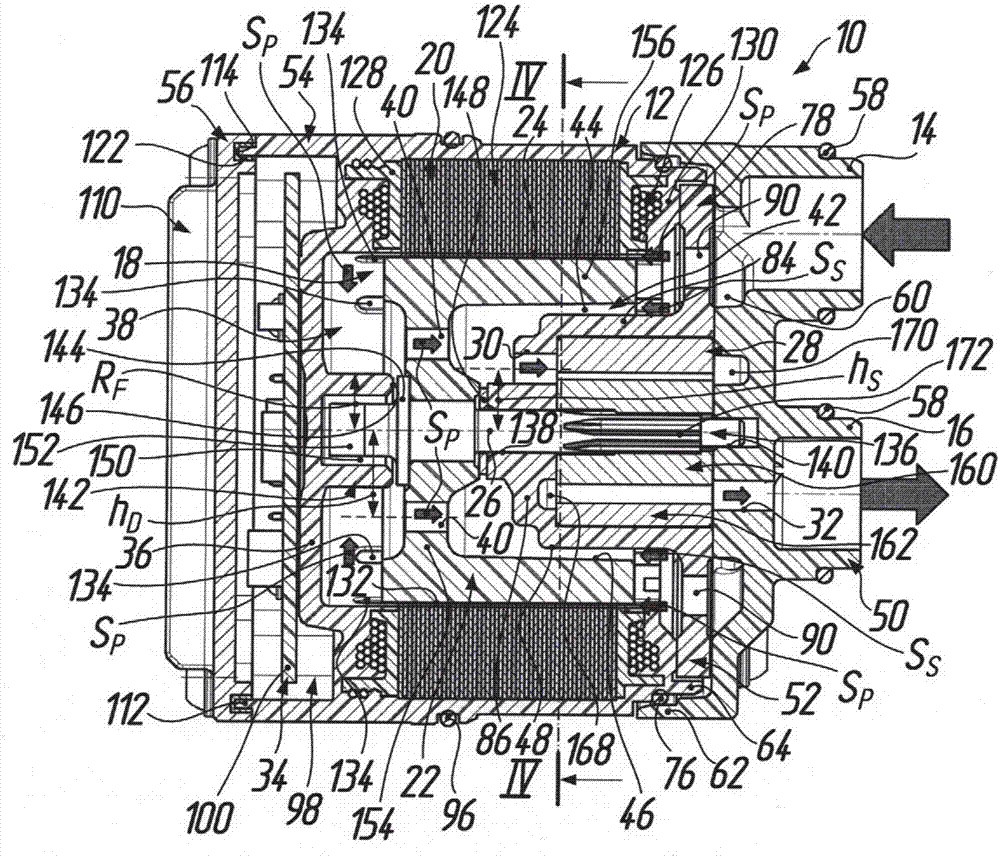

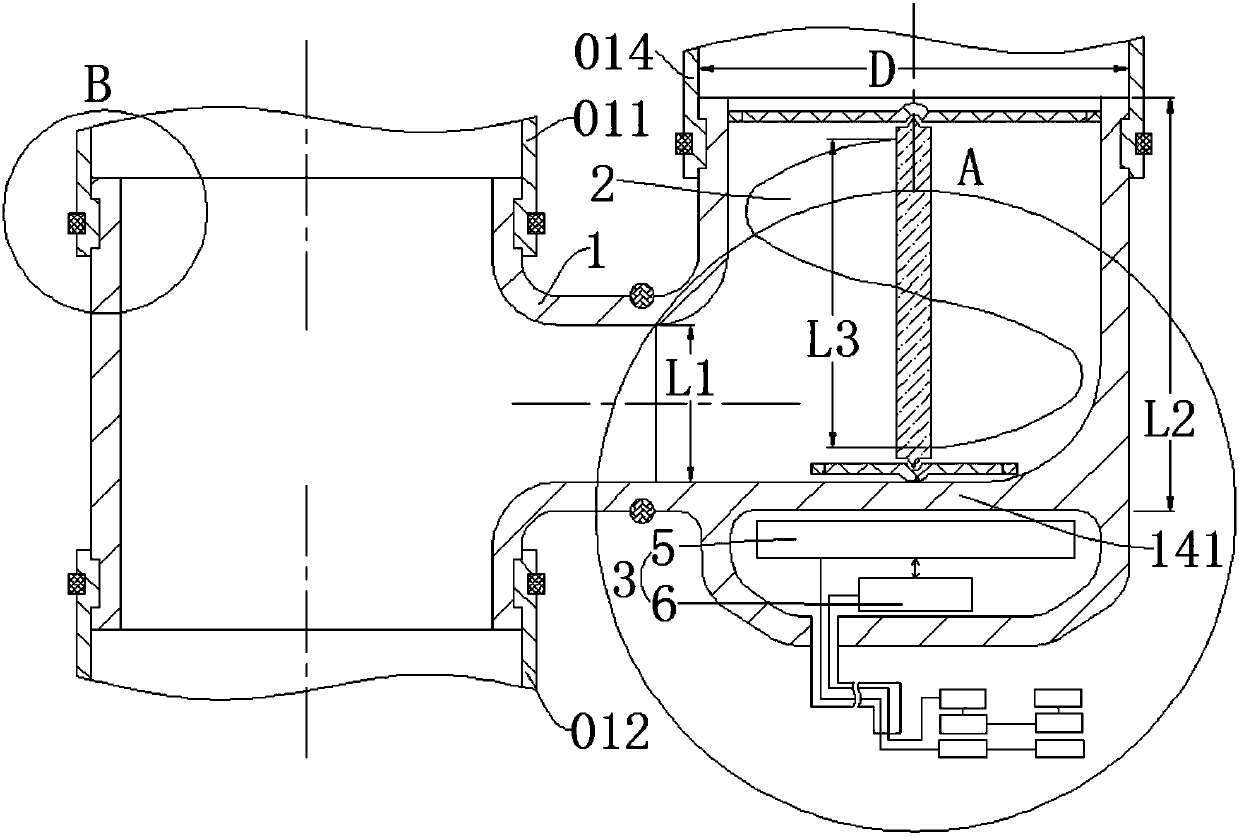

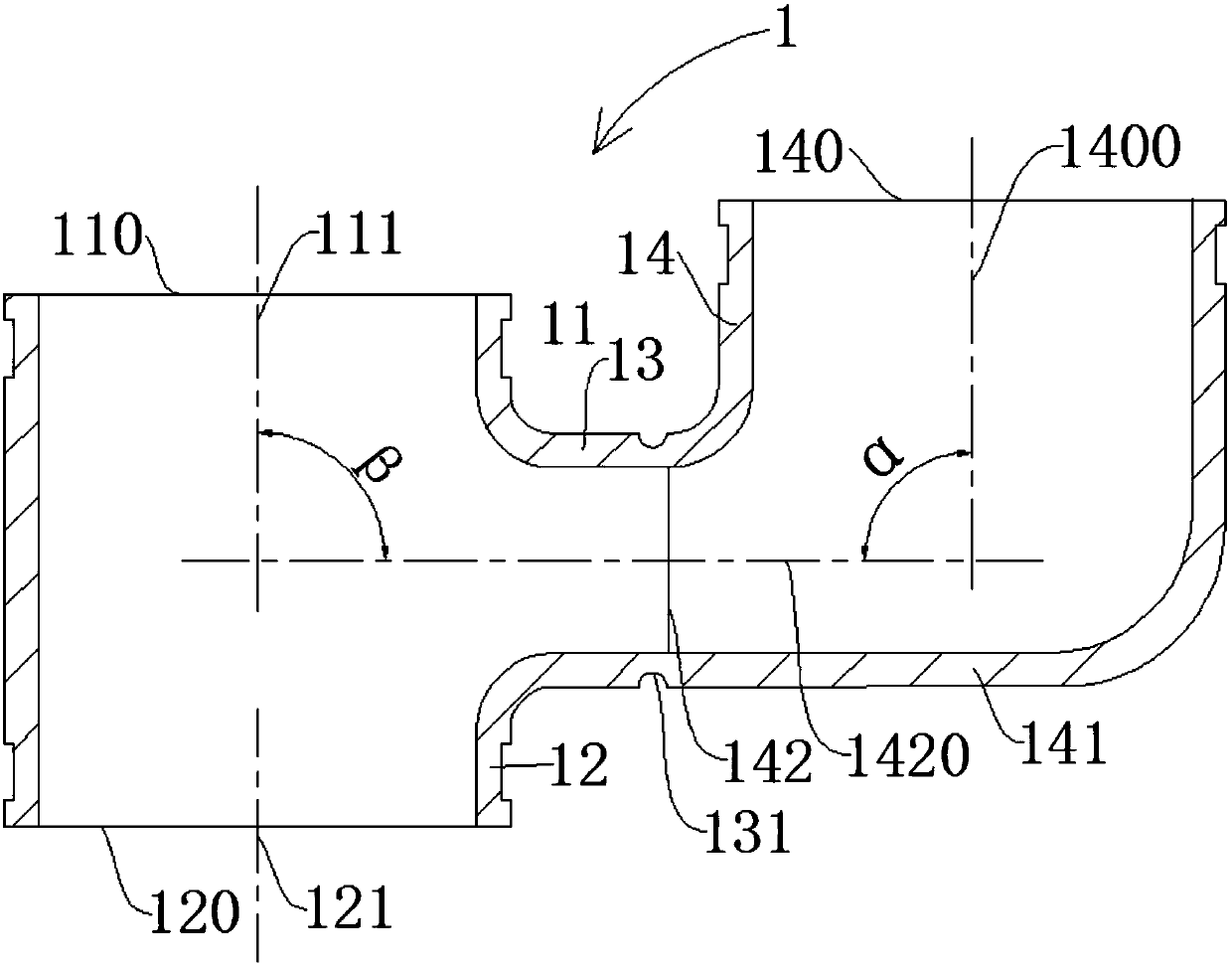

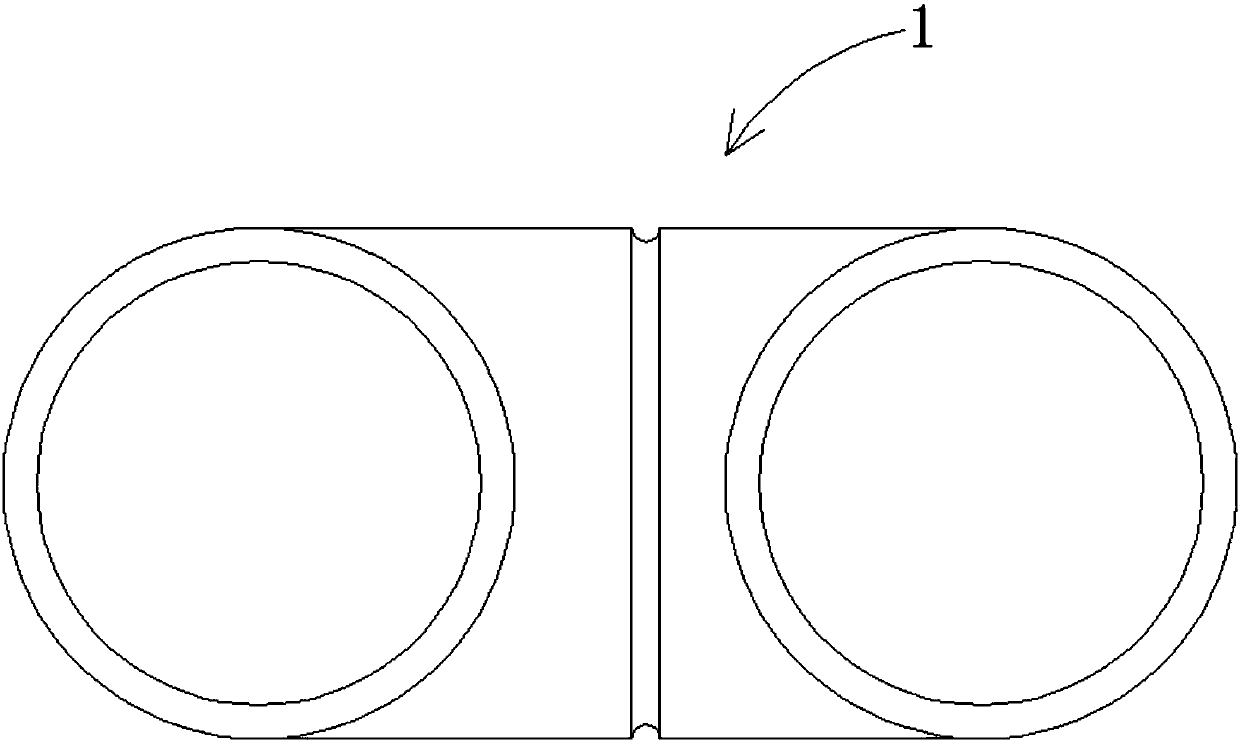

Electric-motor-driven liquid pump

ActiveCN106855051AReduce weightImprove heat transfer performanceWorking fluid for enginesRotary piston pumpsEngineeringPower unit

A liquid pump (10) includes a housing (12), an electric motor (18), a conveying device (28), and an electronic power unit (34). The housing has a suction connection (14) and a pressure connection (16). A stator (20) and a rotor (22) are provided in the electric motor, and the conveying device (28) rotationally driven by the rotor has a suction inlet (30) and pressure outlet (32) which communicate with the suction connection and the pressure connection respectively. The electronic power unit (34) is for the electric motor located on the rear side of a partition wall (36) of the housing, the partition wall being adjacent to the rotor and extending transversely to the axis (26) of rotation of the rotor. For a compact structure and optimized cooling, the suction inlet is arranged at a height (hS) from the axis of rotation smaller than an inner radius (rR) of an annular gap (24) between the stator and rotor, whereas the rotor (22) has a passage (40) extending preferably at a constant height (hD) from the axis of rotation, so that a liquid inducted by way of the suction connection (14) is constrainedly guided in part via the annular gap (24) and undergoes a deflection at the partition wall, while cooling the latter before passing through the passage of the rotor to the suction inlet.

Owner:FTE AUTOMOTIVE GMBH & CO KG

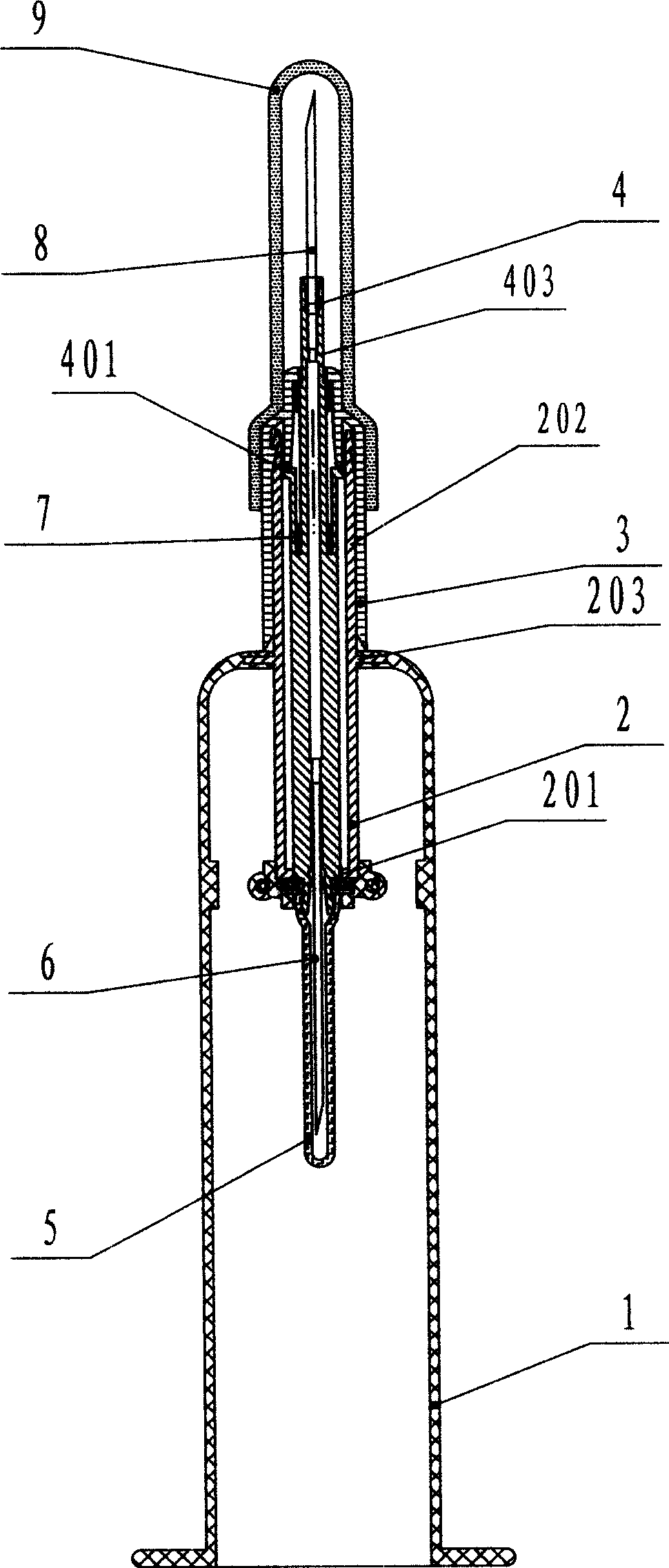

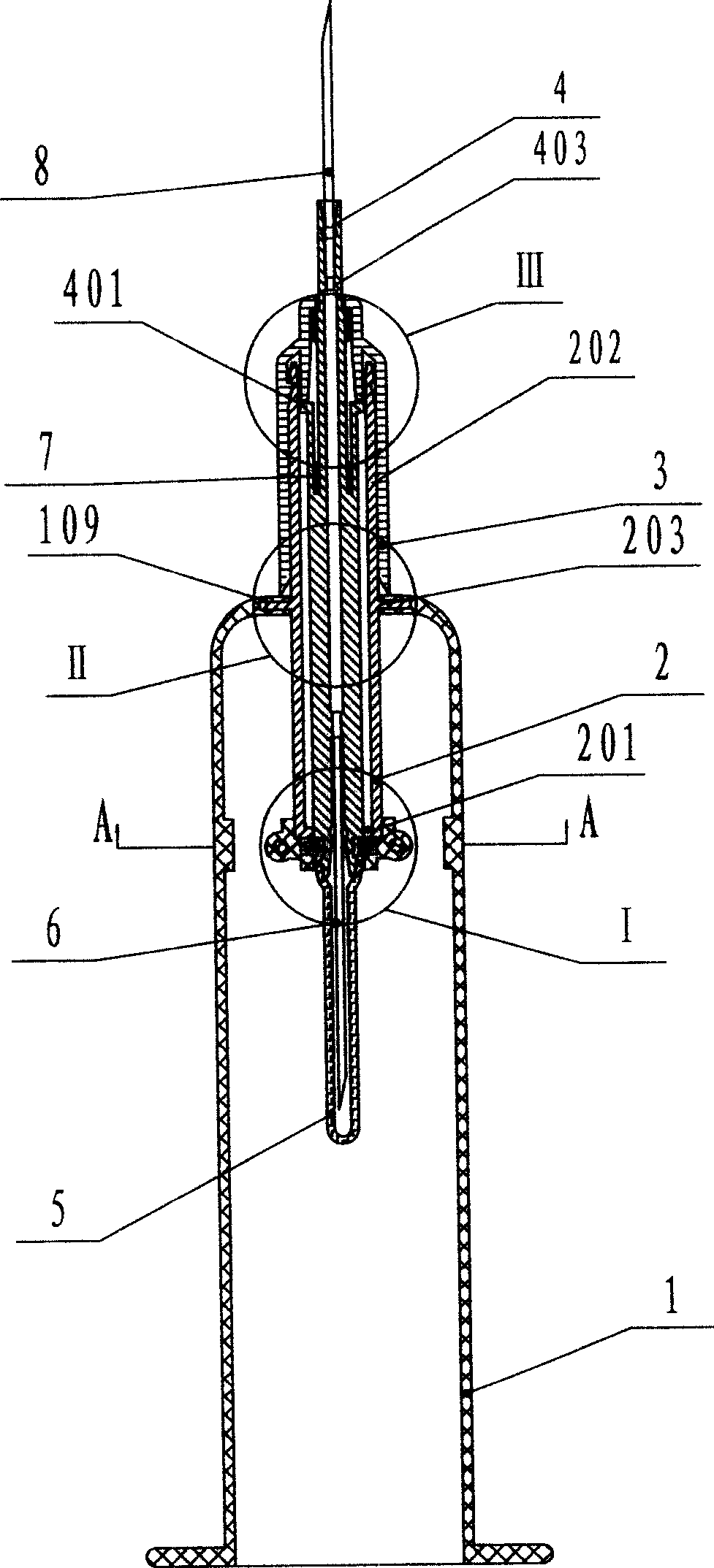

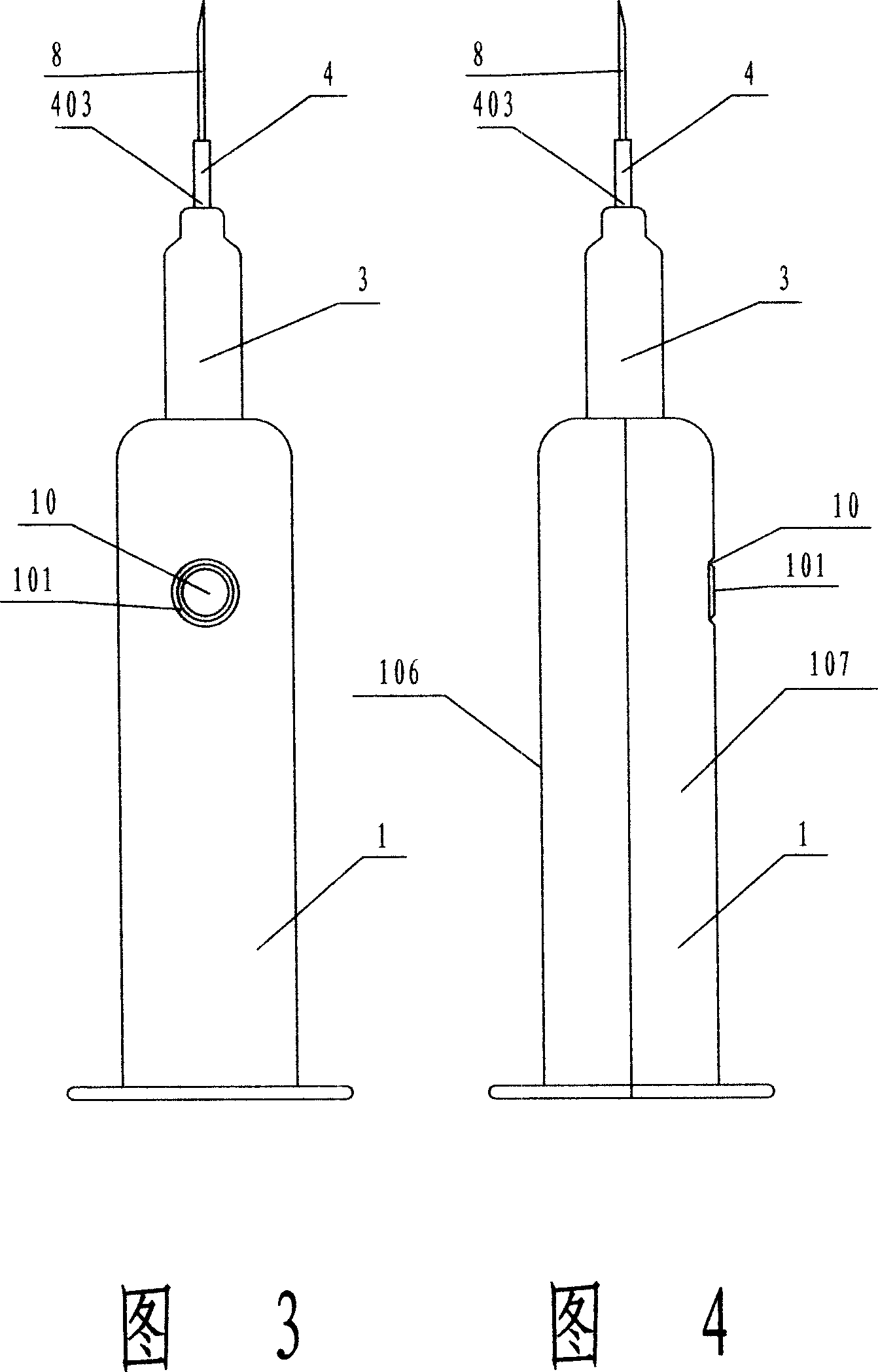

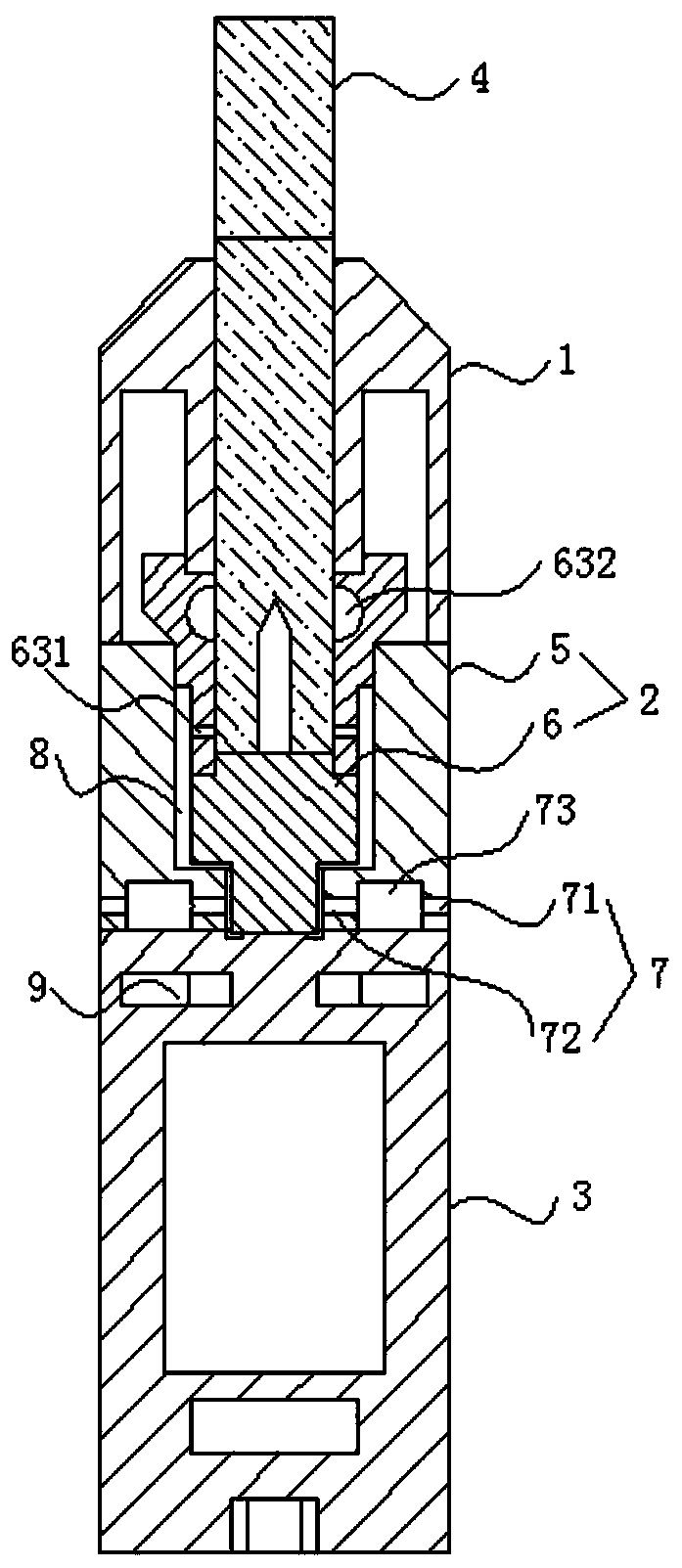

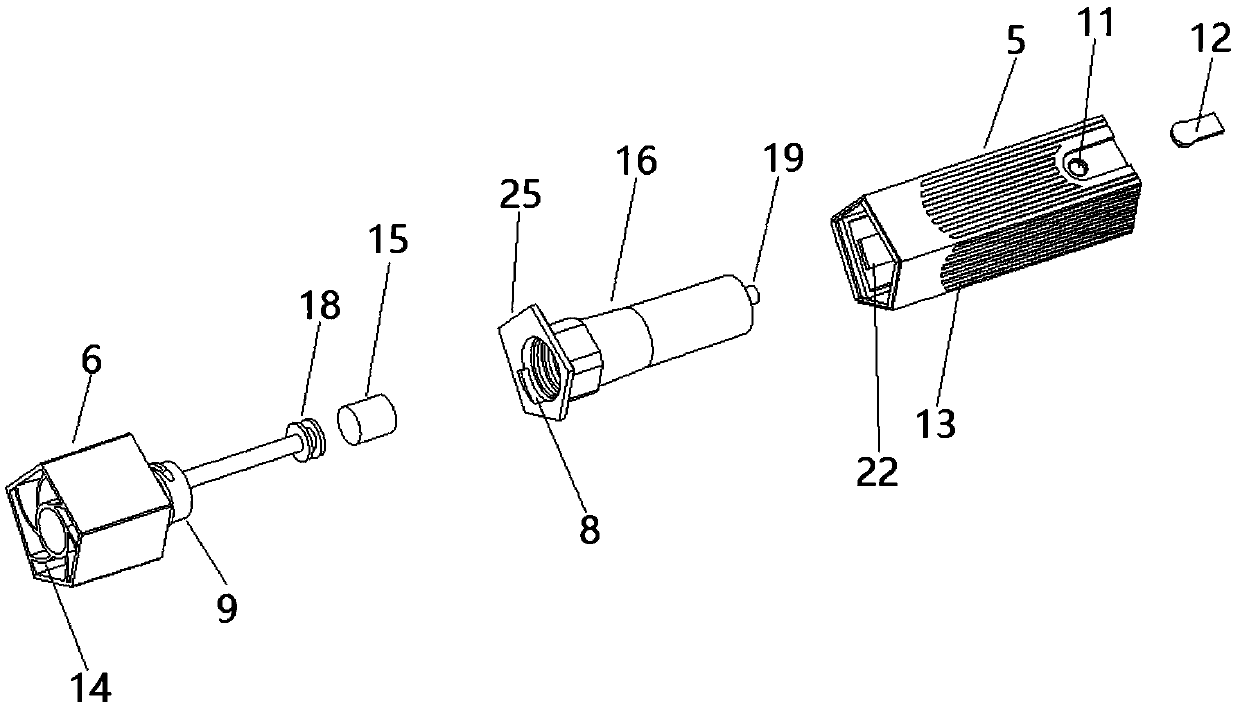

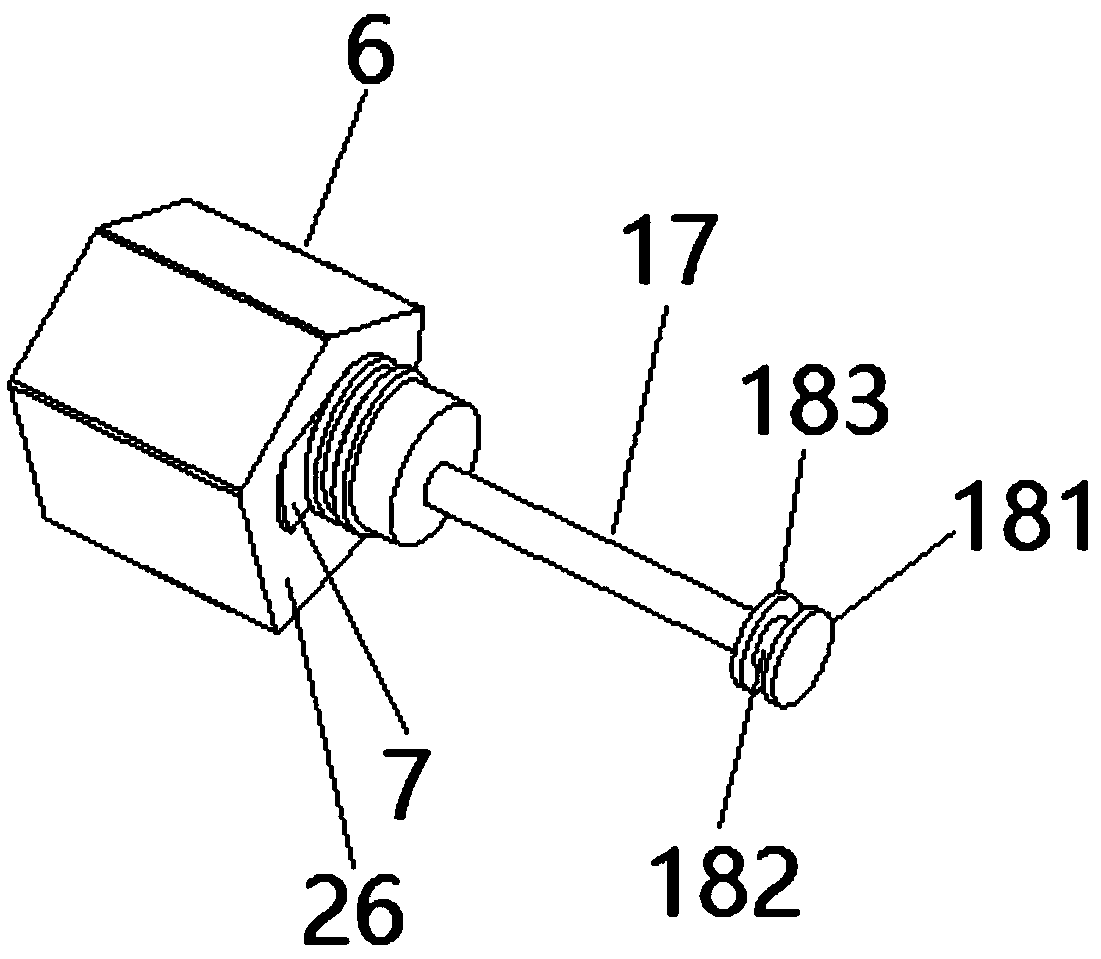

One-time operation safe vacuum blood-sample acquisition needle

InactiveCN101361661ARelieve painShort flow pathDiagnostic recording/measuringSensorsDiseaseWorking environment

The invention discloses a disposable safe vacuum blood sampling needle which relates to the technical field of medical appliances, comprises a blood taking needle (8), a cork puncturing needle (6) and a needle holder (4), and is characterized in that: the disposable safe vacuum blood sampling needle further comprises a main body (1), a needle holder sleeve (2), an embolism (3), a compressed spring (7), a retracted button (10) and a button spring (11), and the retracted button (10) can be pressed so as to lead the blood taking needle (8) to be retracted and hidden after blood sampling is finished. The disposable safe vacuum blood sampling needle has reasonable structure design, convenient assembly and reliable action, the needle holder (4) takes transparent material and is convenient for observing blood backflow, and the blood taking flow path is ultra-short, thus having minimal blood oxidation influence due to tiny amount of air and improving the accuracy of blood examination and analysis results; the blood taking needle (8) is retracted and hidden, thus ensuring that the medical care personnel is prevented from accident damages caused by a polluted needle tip, avoiding the pathophoresis of blood-borne diseases, providing safer working environments and more healthful and safer use for the medical care personnel, and being favorable for realizing real disposable usage.

Owner:ZHEJIANG KANGKANG MEDICAL DEVICES

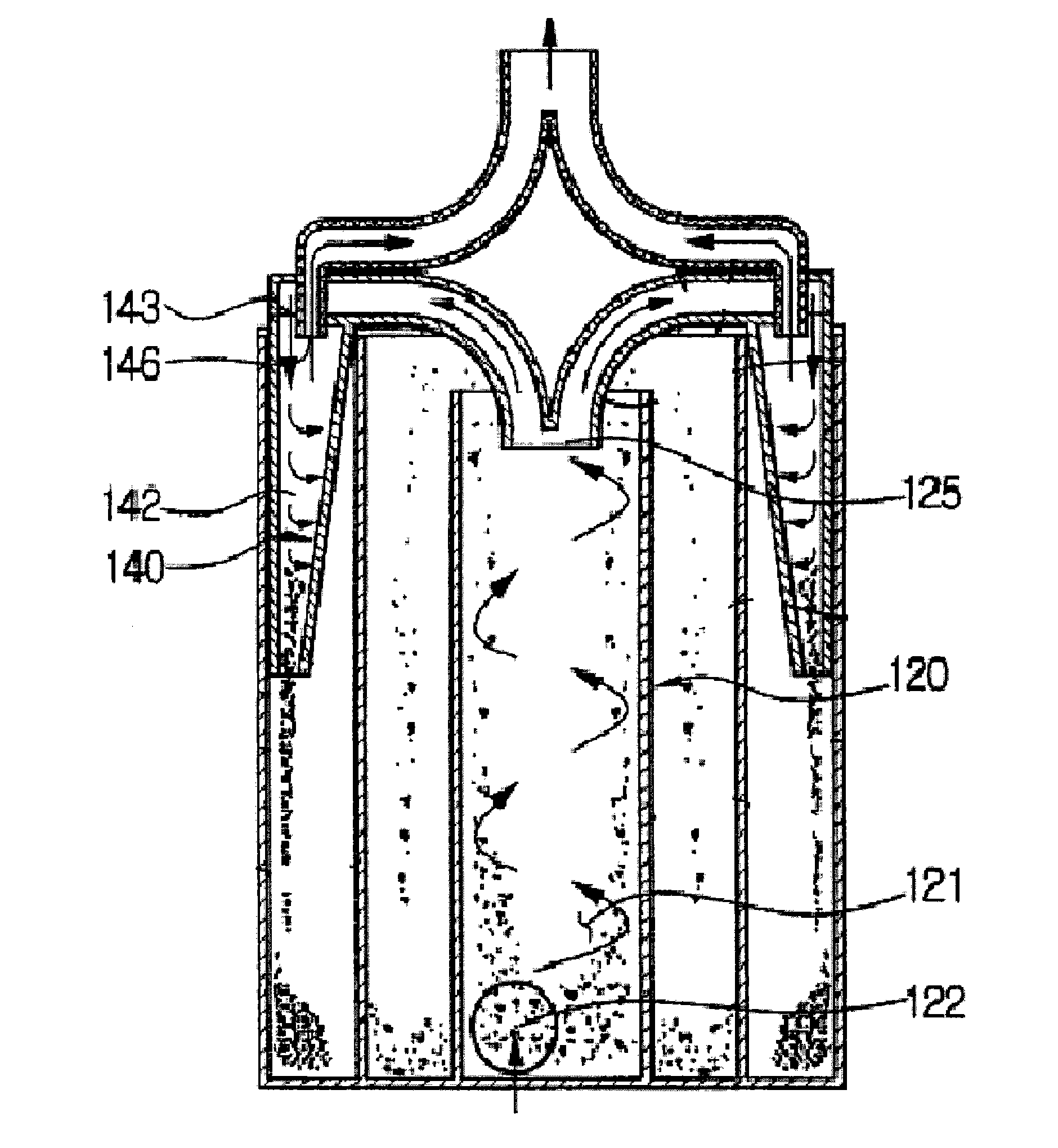

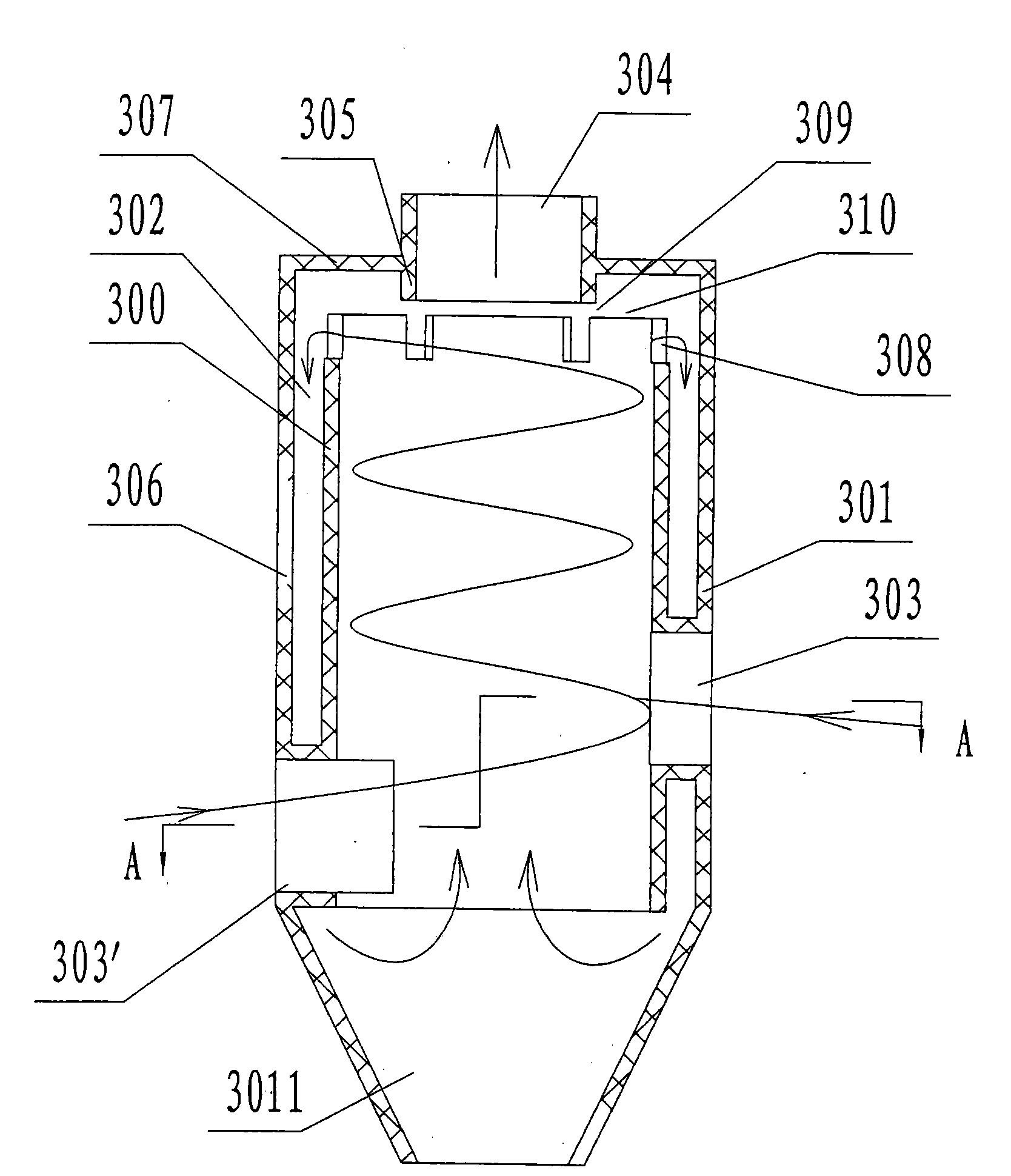

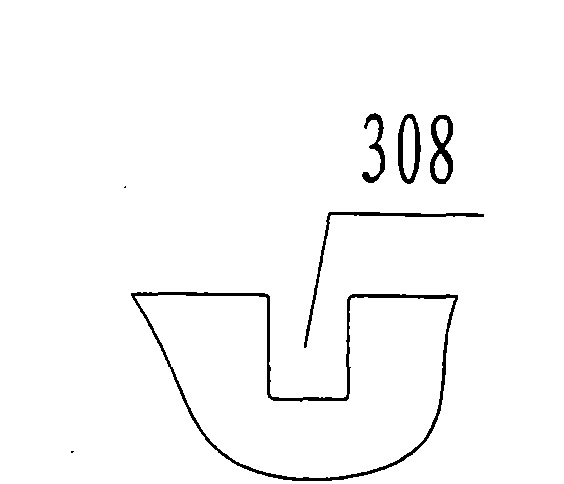

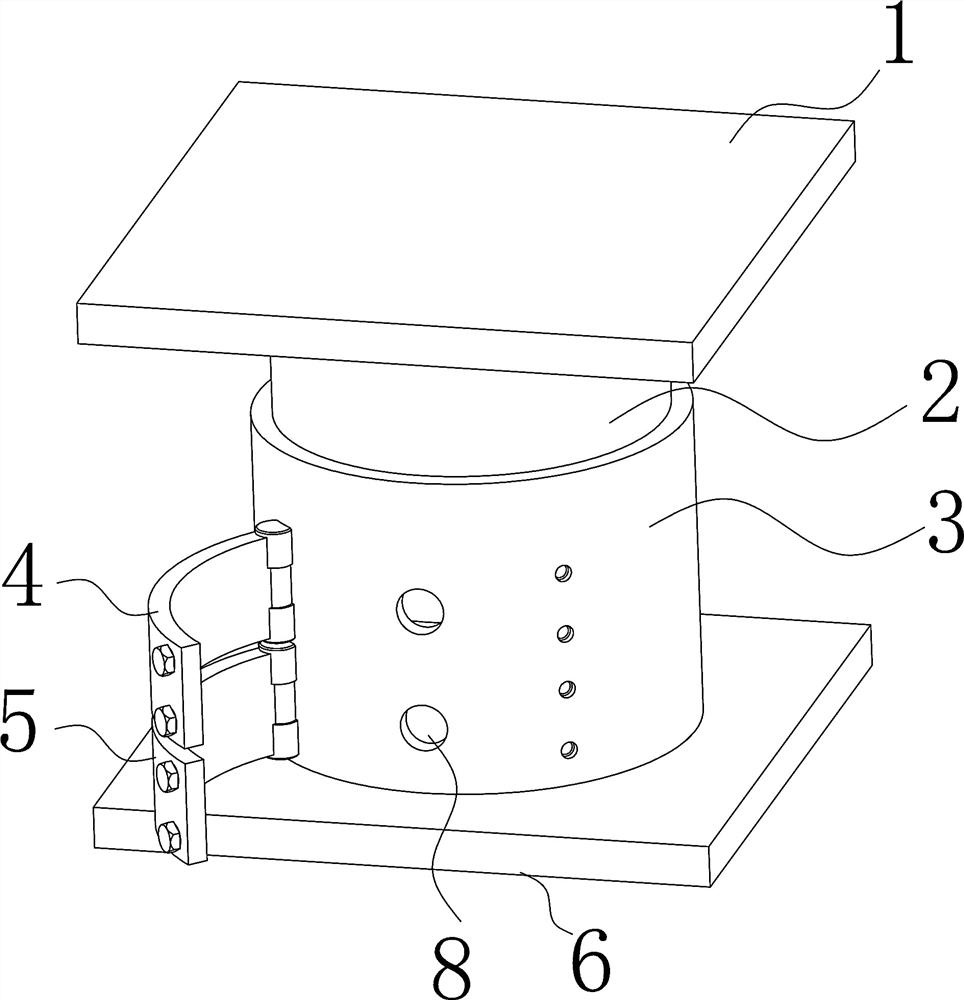

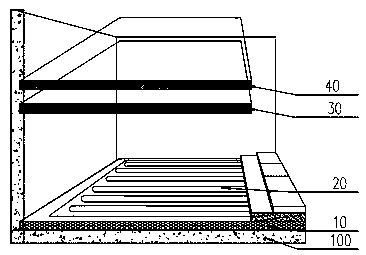

Cyclone separator, cyclone separation device and vacuum cleaner having cyclone separation device

ActiveCN101653345AShort flow pathReduce shear stressSuction filtersReversed direction vortexCycloneCyclonic separation

The invention discloses a cyclone separator, which comprises an inner cylinder body (300) and an outer cylinder body (301), wherein an annular gap (302) is preserved between the outer wall of the inner cylinder and the inner wall of the outer cylinder; the lower end of the inner cylinder is an open end; the lower end of the outer cylinder is a closed end; the wall of the outer cylinder is provided with an air inlet (303); the upper end of the outer cylinder is provided air outlets (304); a return part is arranged between the upper end of the inner cylinder and the air outlet; an air flow enters the cyclone separator from the air inlet on the lower end of the outer cylinder along a tangential direction; one part of an air flow obtained after separation is discharged from the air outlet and the other part of the air flow obtained after separation passes through the annular gap from the return part to be separated again; and the returning air flow obtained after separation enters the inner cylinder to be mixed with a fresh incoming air flow for another time of separation. The invention also relates to a cyclone separation device consisting of the cyclone separator and a vacuum cleaner having the cyclone separation device. The vacuum cleaner of the invention is simple in structure and short in flow path of a single-separation air flow, realizes backflow and circulation and greatly improves separation efficiency while saving energy and protecting environment.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

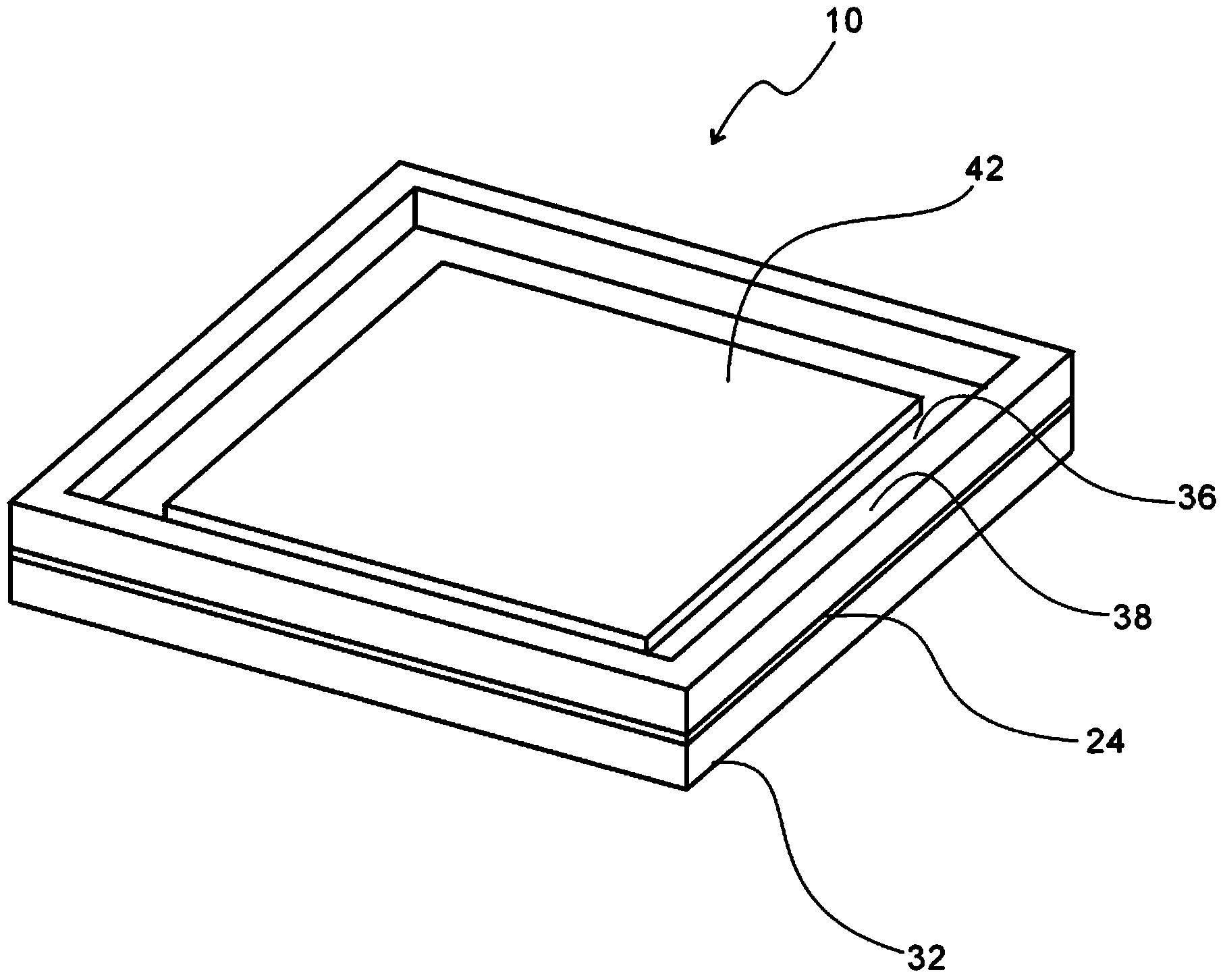

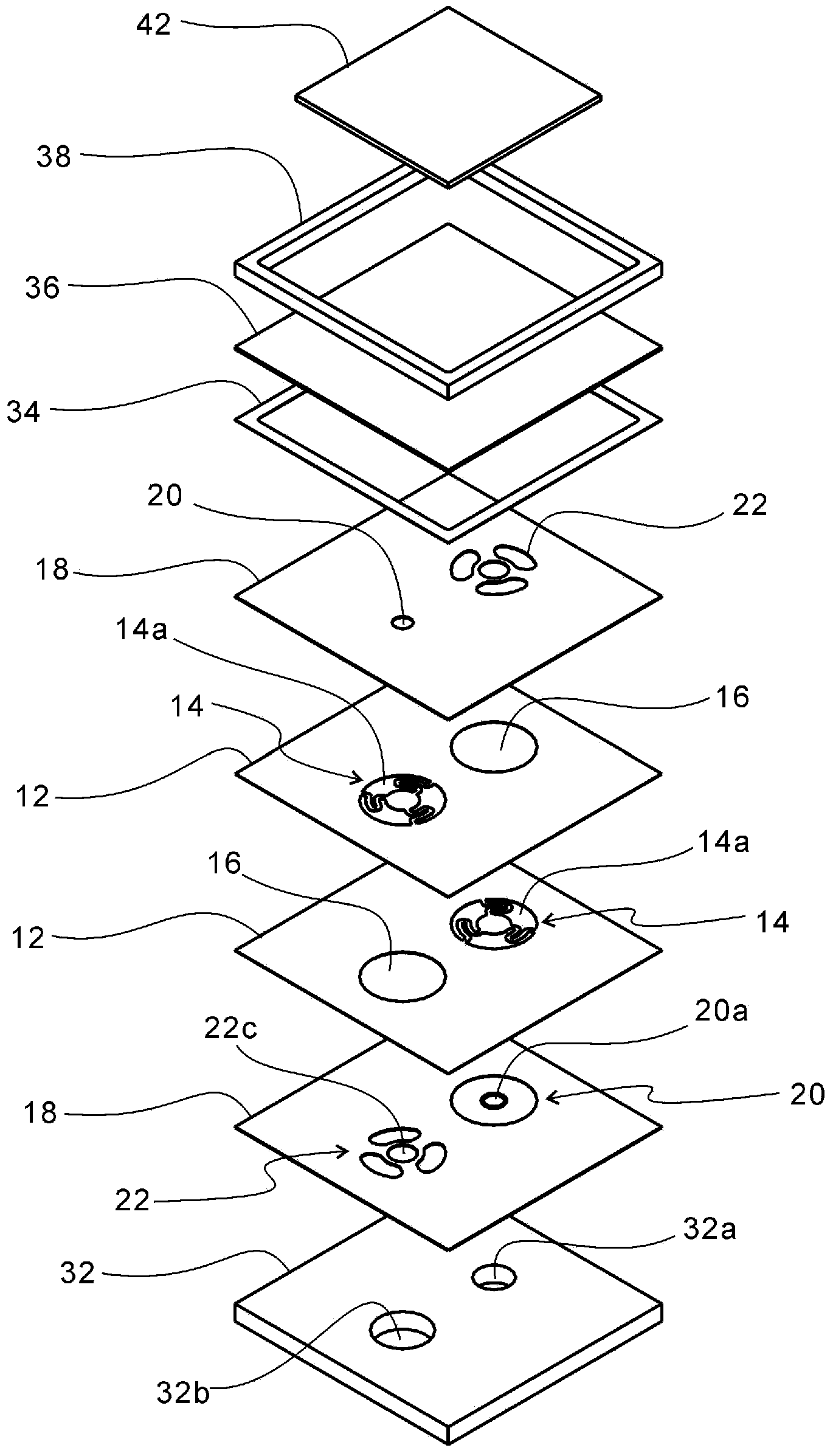

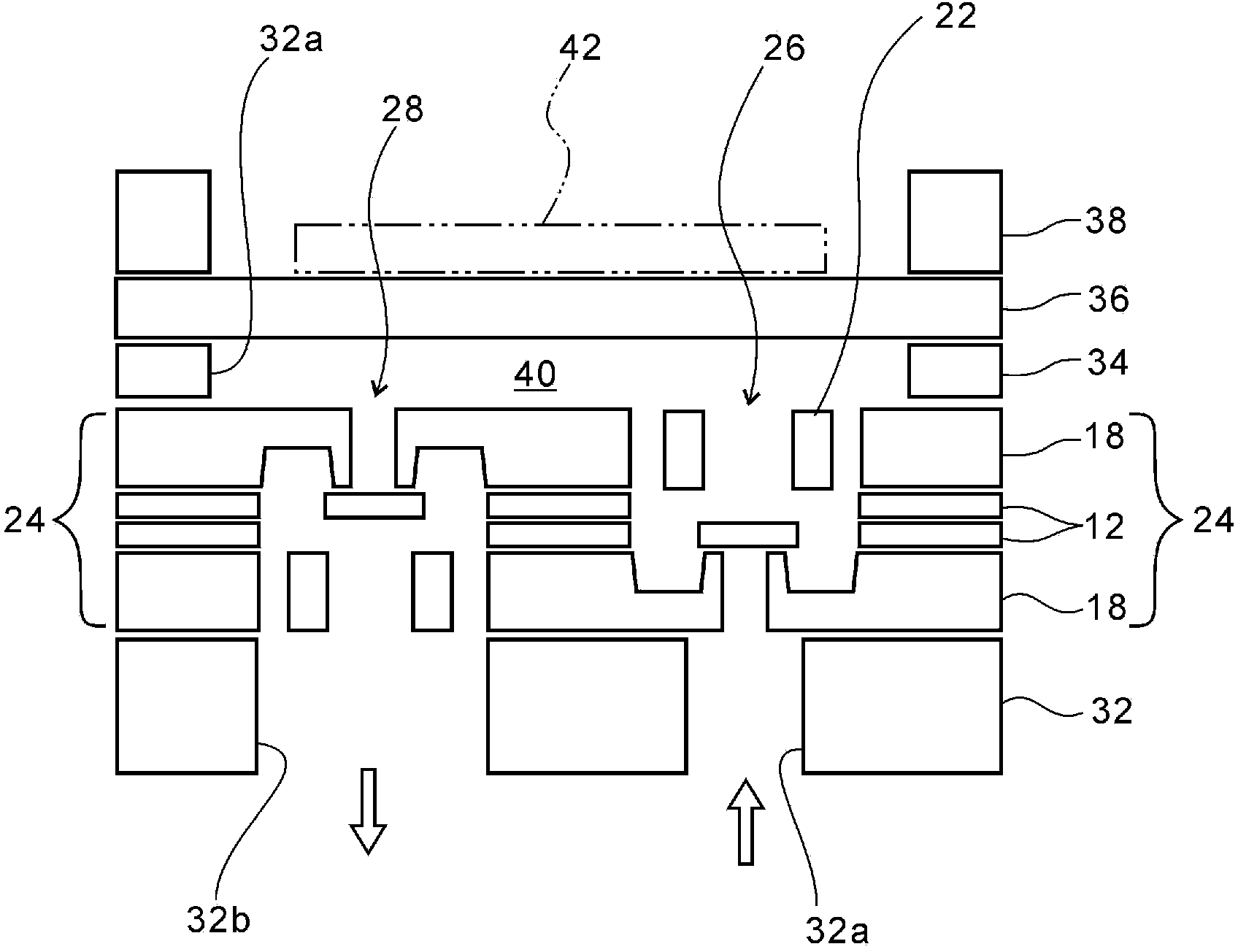

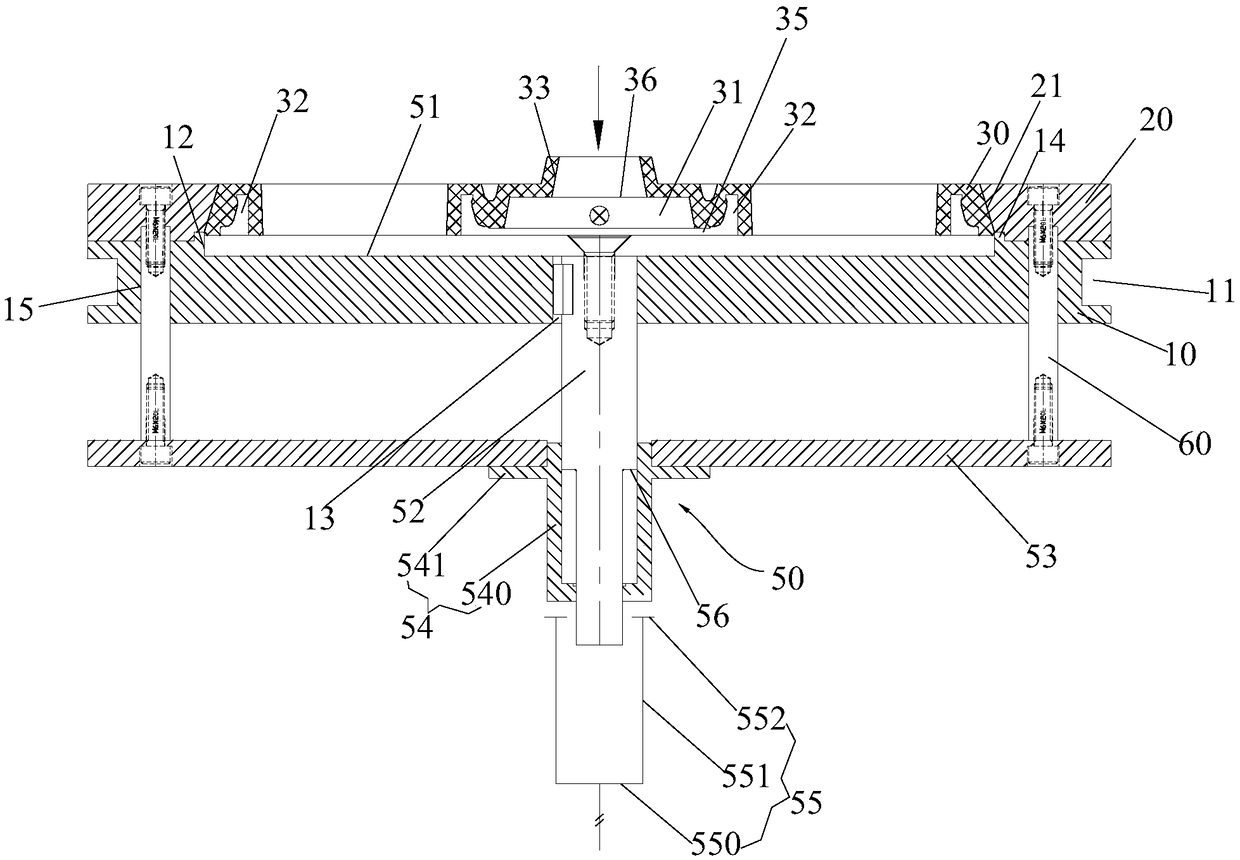

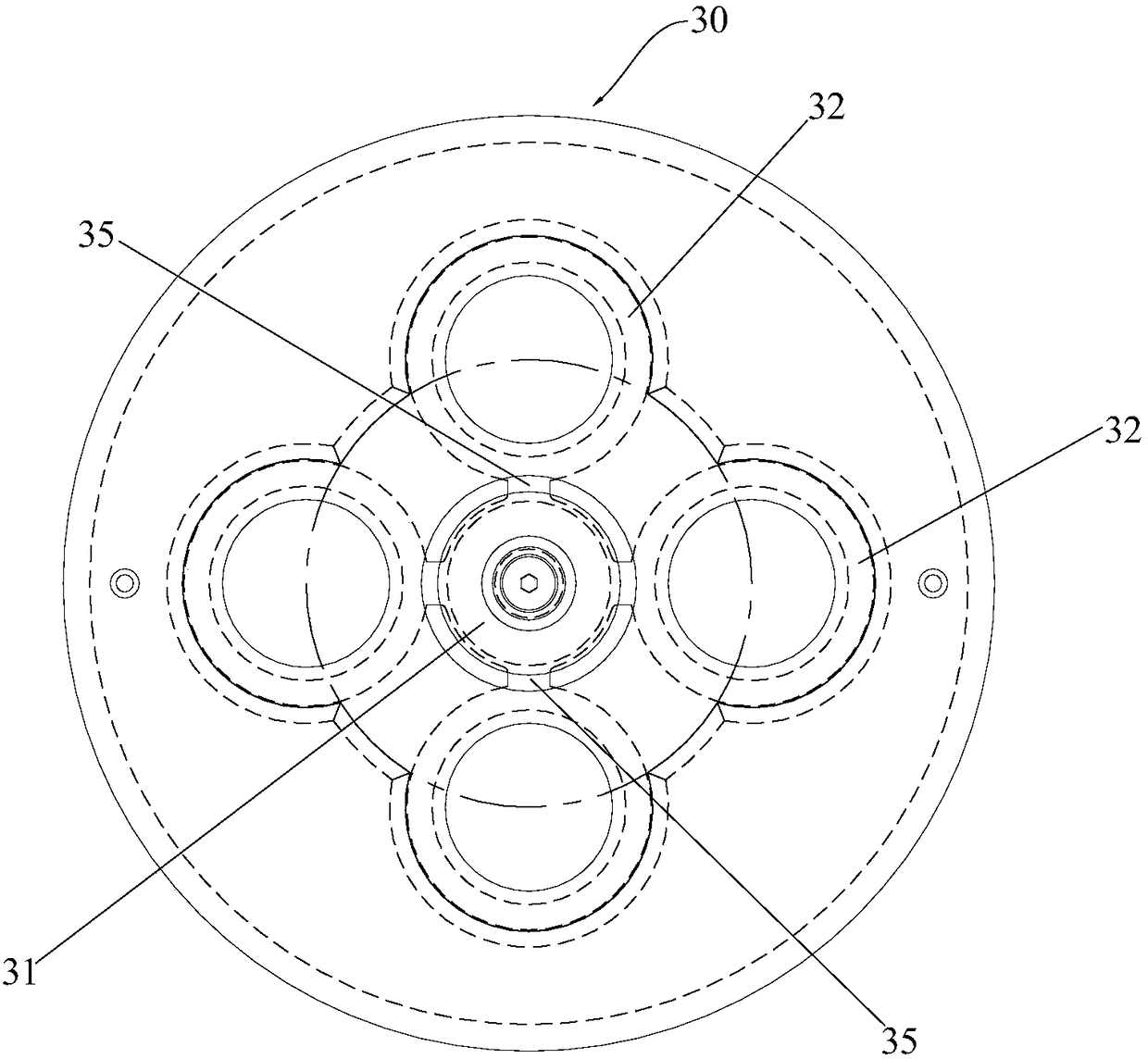

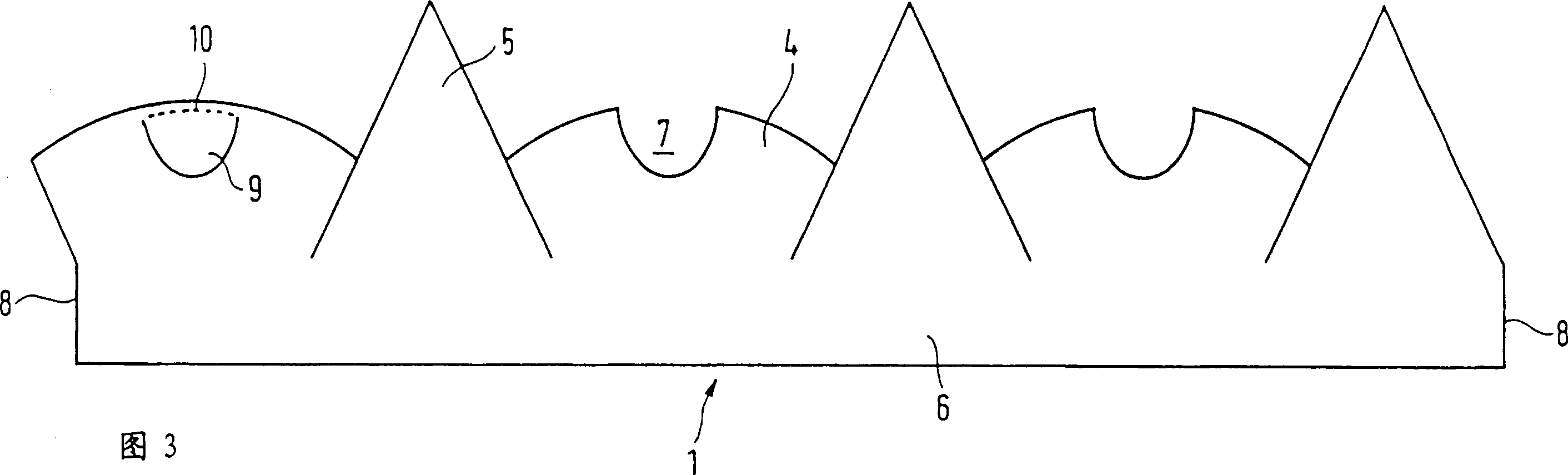

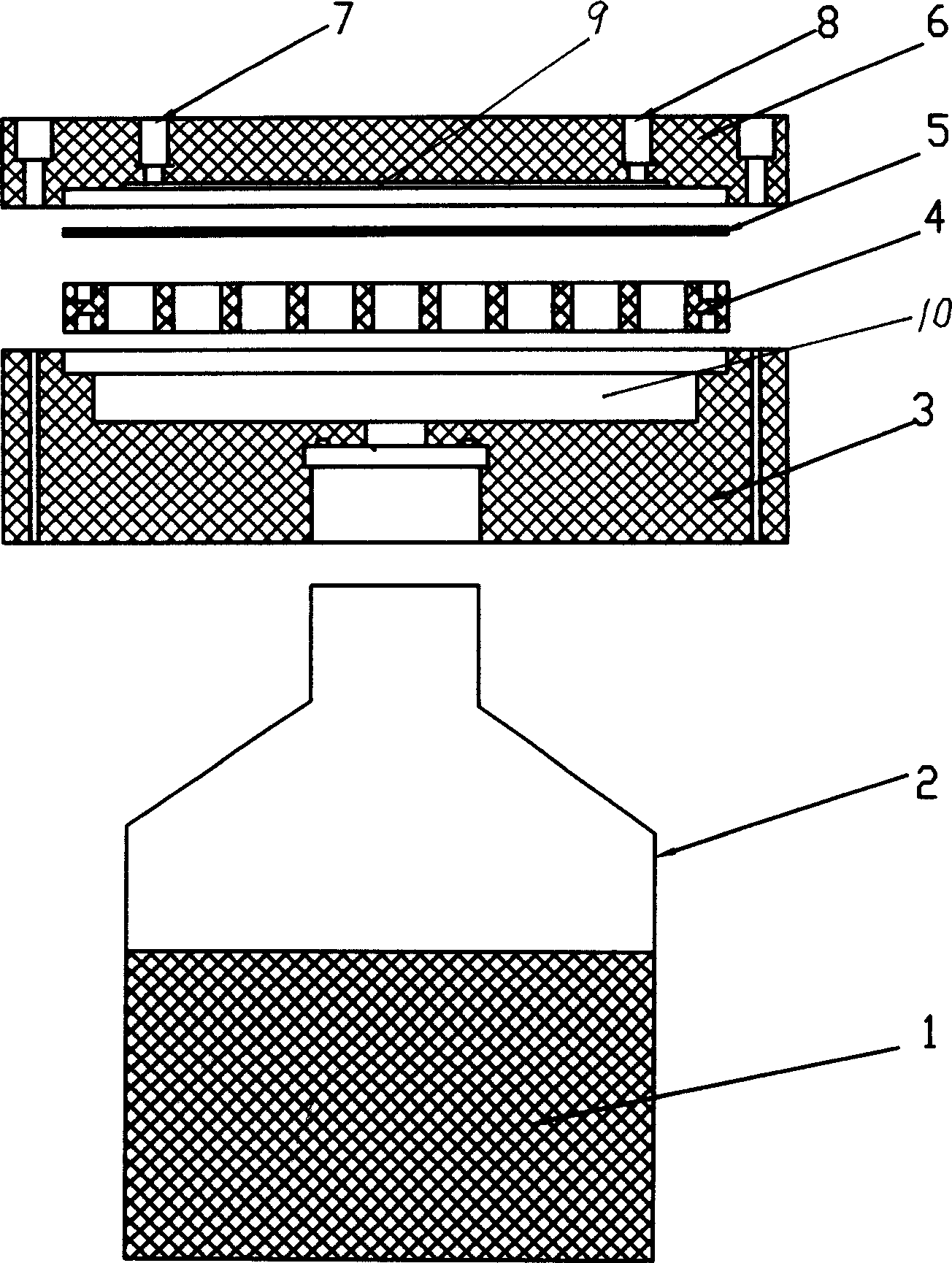

Microdiaphragm pump

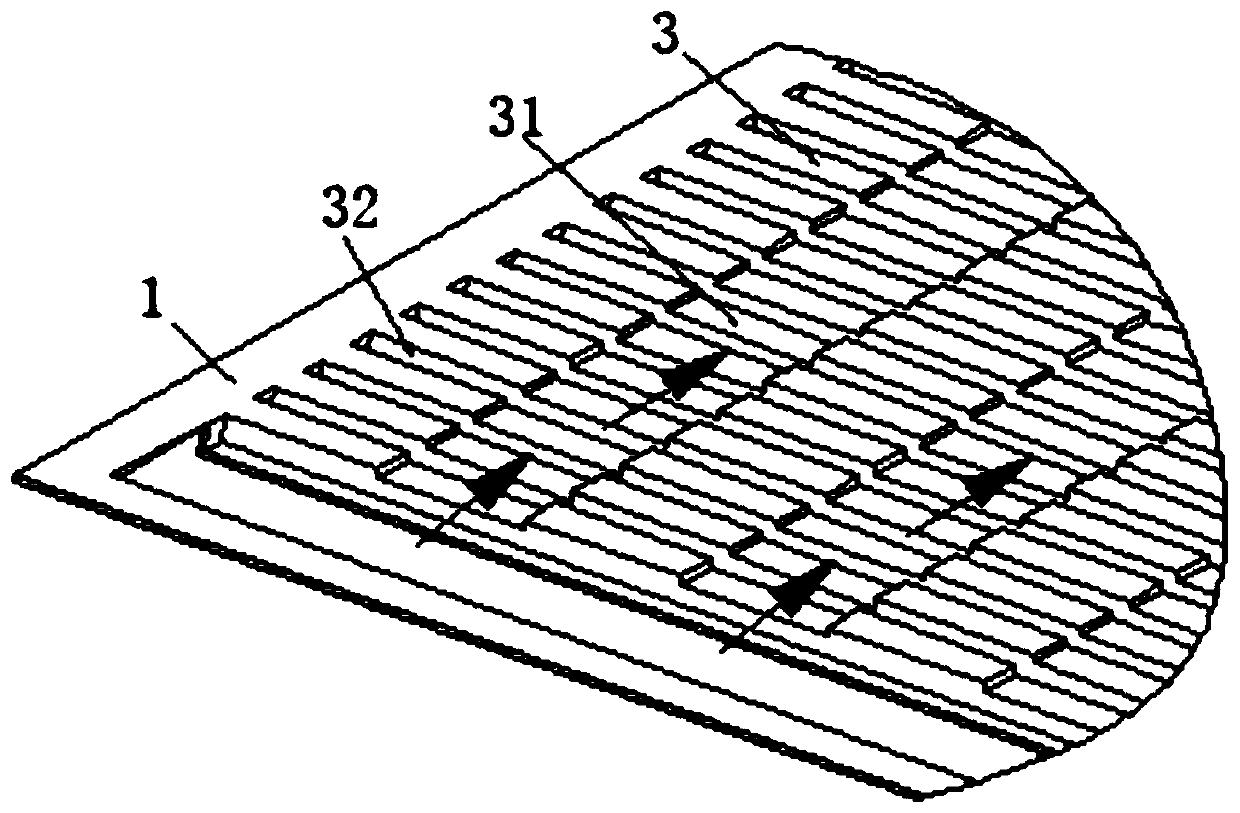

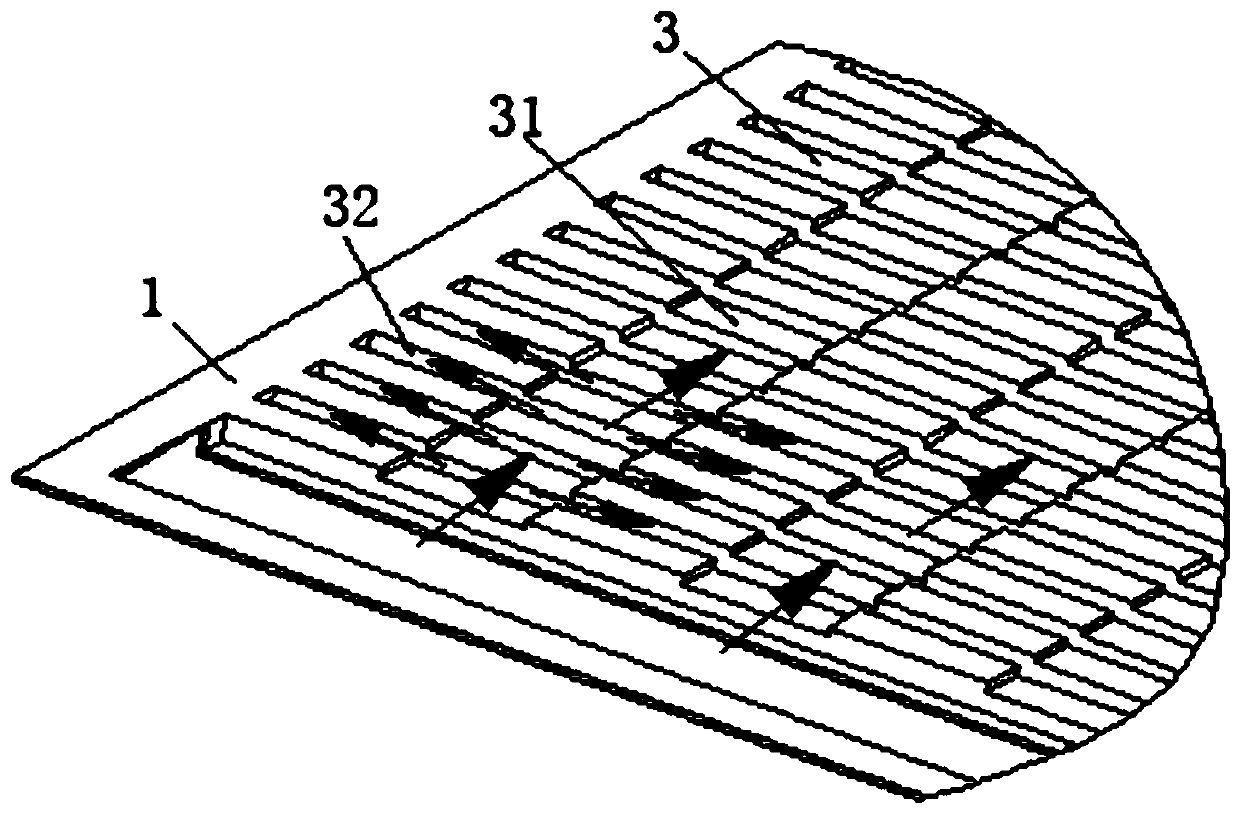

InactiveCN103906923AIncrease volume changeSleekPositive displacement pump componentsWorking fluid for enginesDiaphragm pumpInlet valve

A microdiaphragm pump having a diaphragm chamber in contact with one side of an intake valve and one side of a discharge valve. The microdiaphragm includes two valve plate sheets 12, in each of which a valve plate 14 of one of an intake valve 26 and a discharge valve 28 and a flow path aperture 16 that provides a passage of the other valve are formed and which are laminated in directions that are opposite from each other; two valve seat sheets 18, which are laminated to the laminate and in which valve seats 20 and valve stoppers 22 are formed; a base plate 32; a frame 34; a diaphragm 36; and a drive element 42. The microdiaphragm pump has extremely small external dimensions and provides high productivity, high flow control accuracy, a smooth operation, large suction and discharge forces, and high reliability.

Owner:KIKUCHI SEISAKUSHO CO LTD

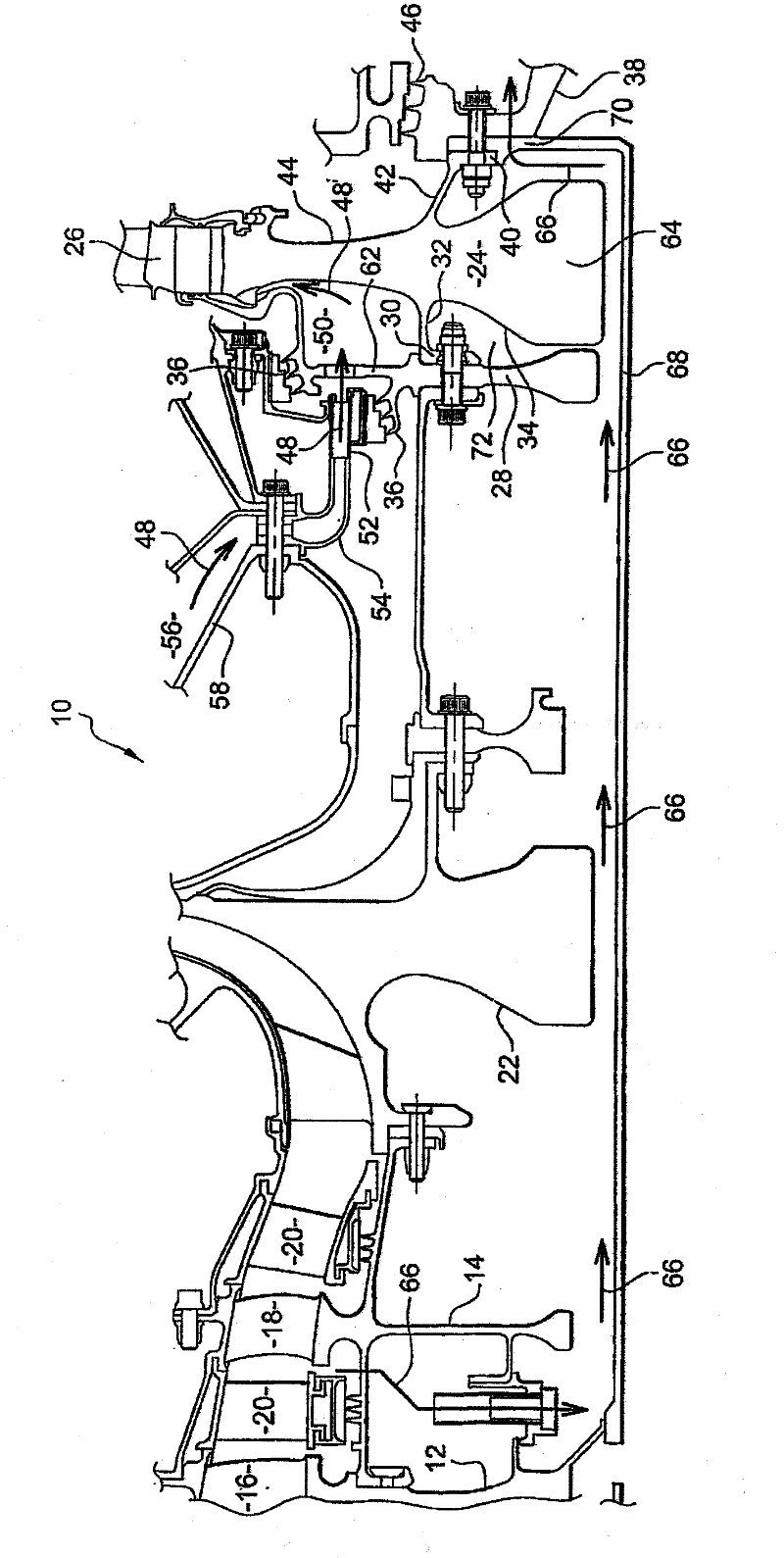

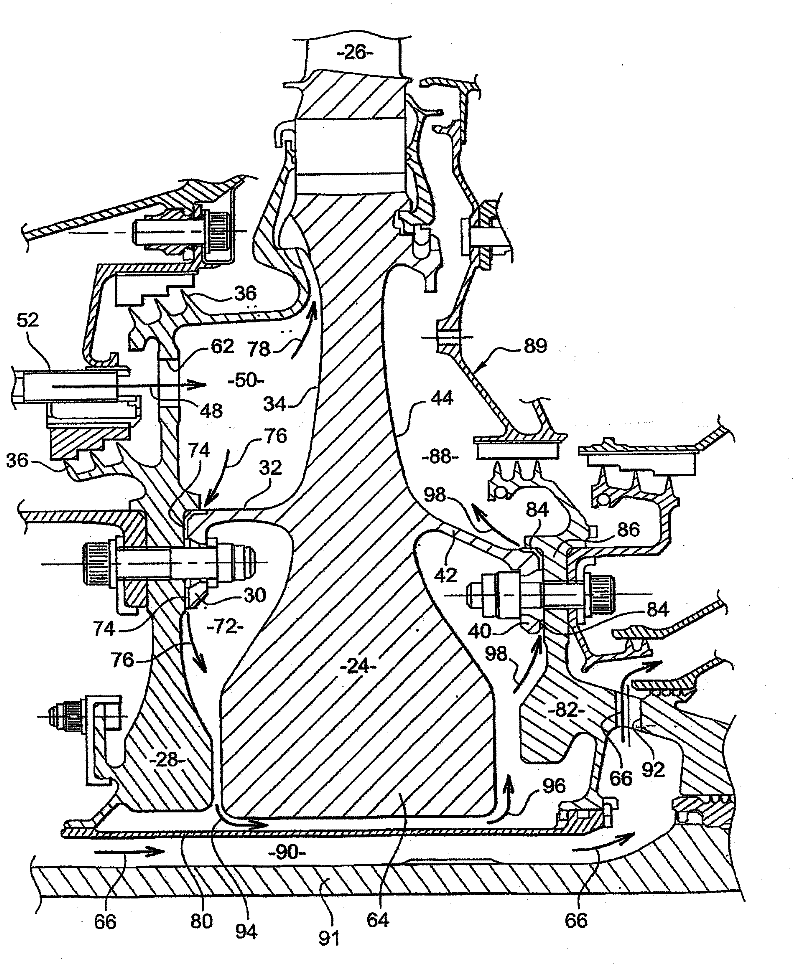

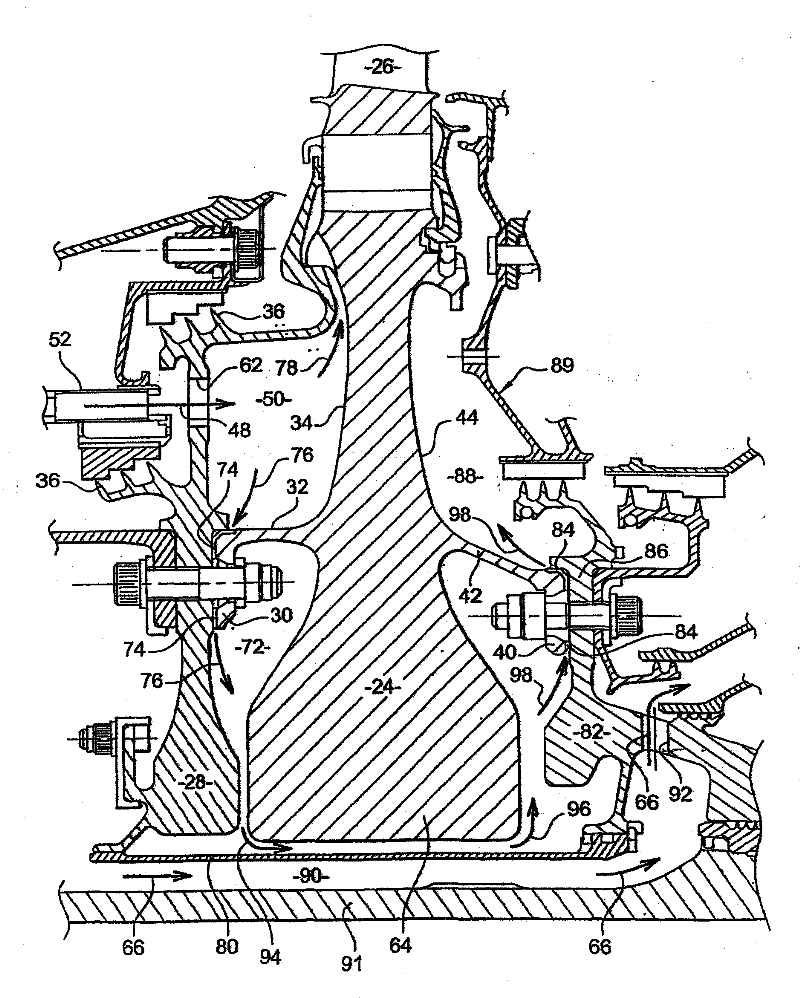

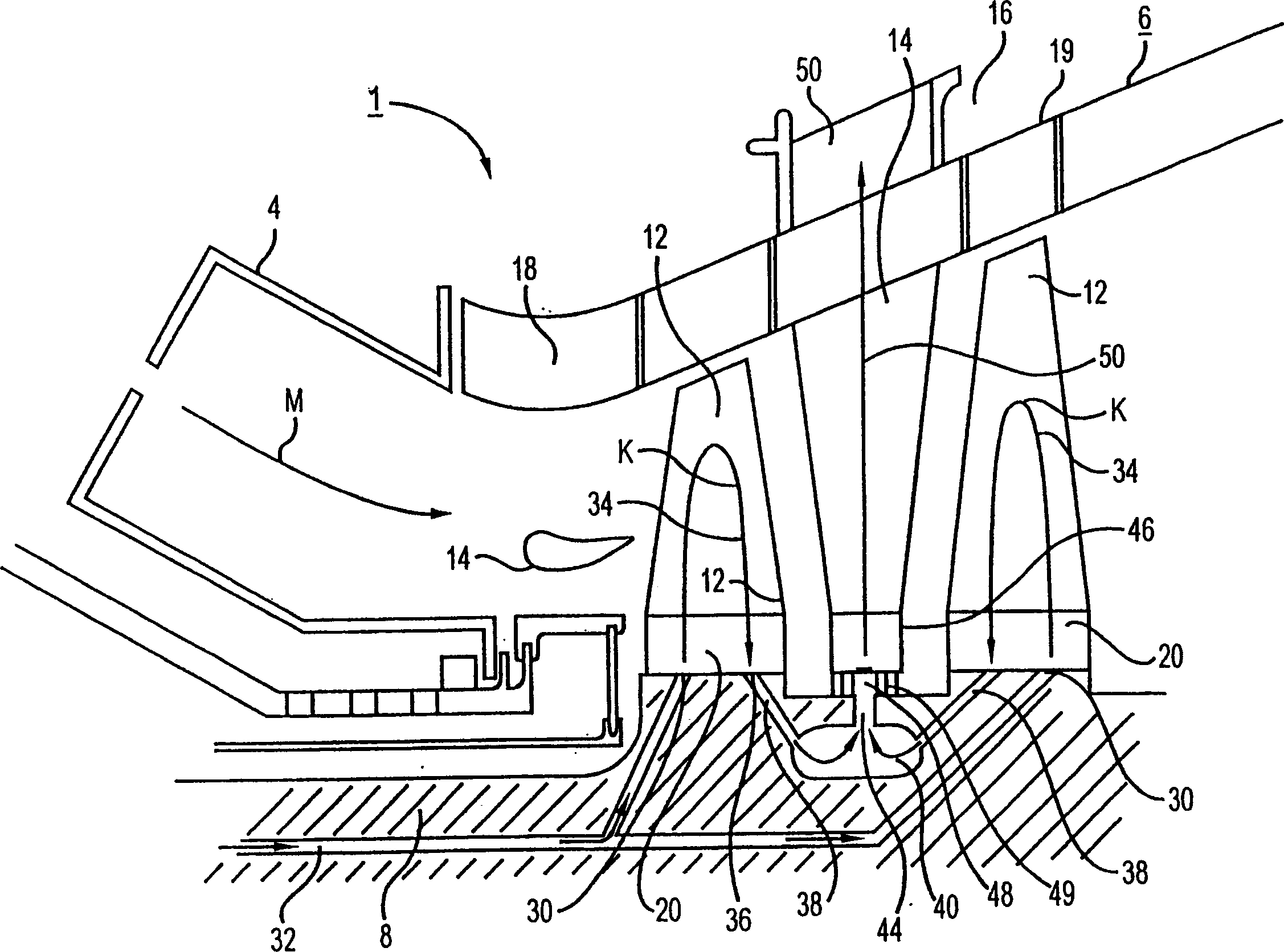

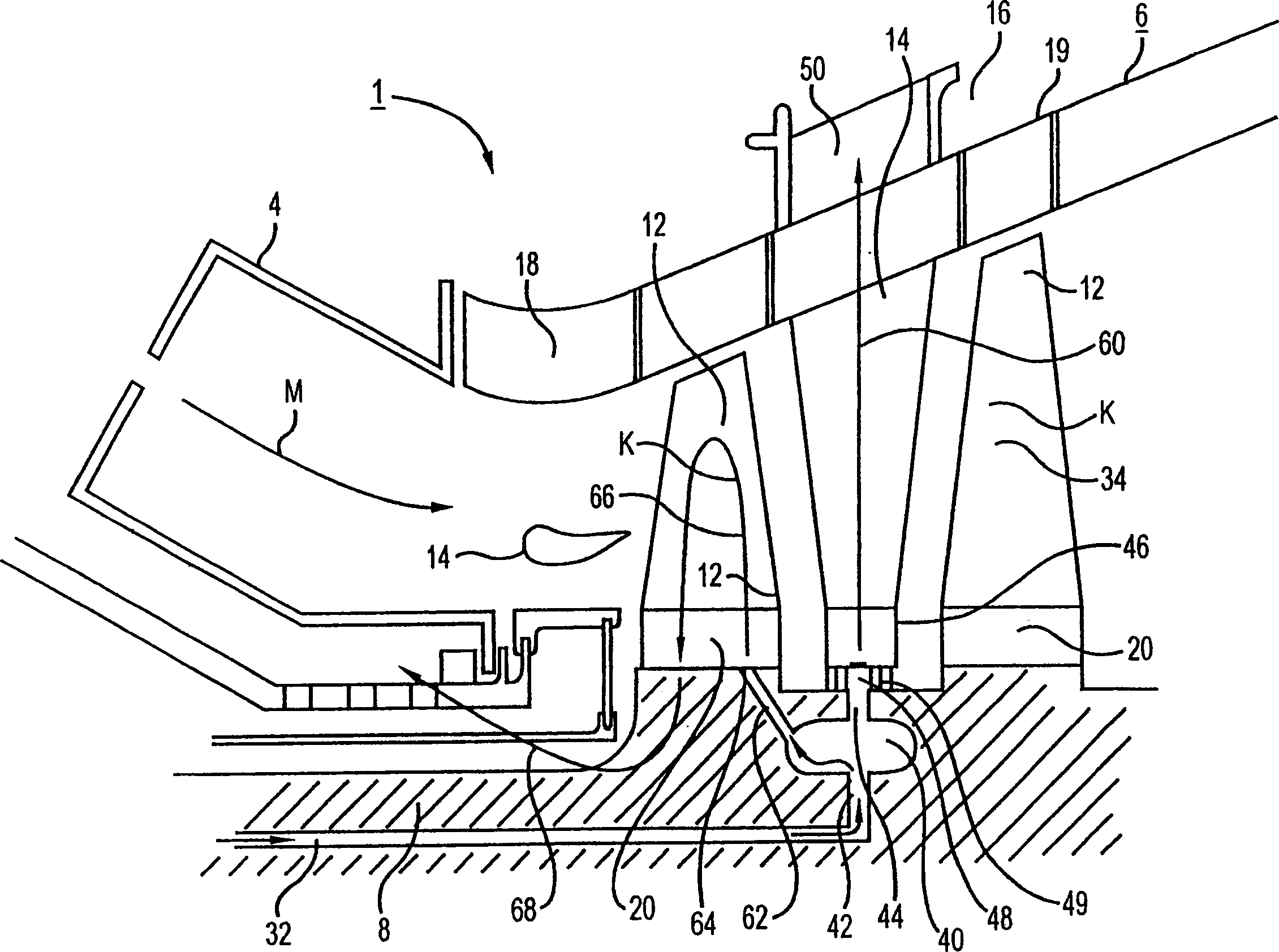

Ventilation of a high-pressure turbine in a turbomachine

InactiveCN102187062AShort flow pathNo delayEngine fuctionsTurbine/propulsion engine coolingHigh pressureTurbine

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

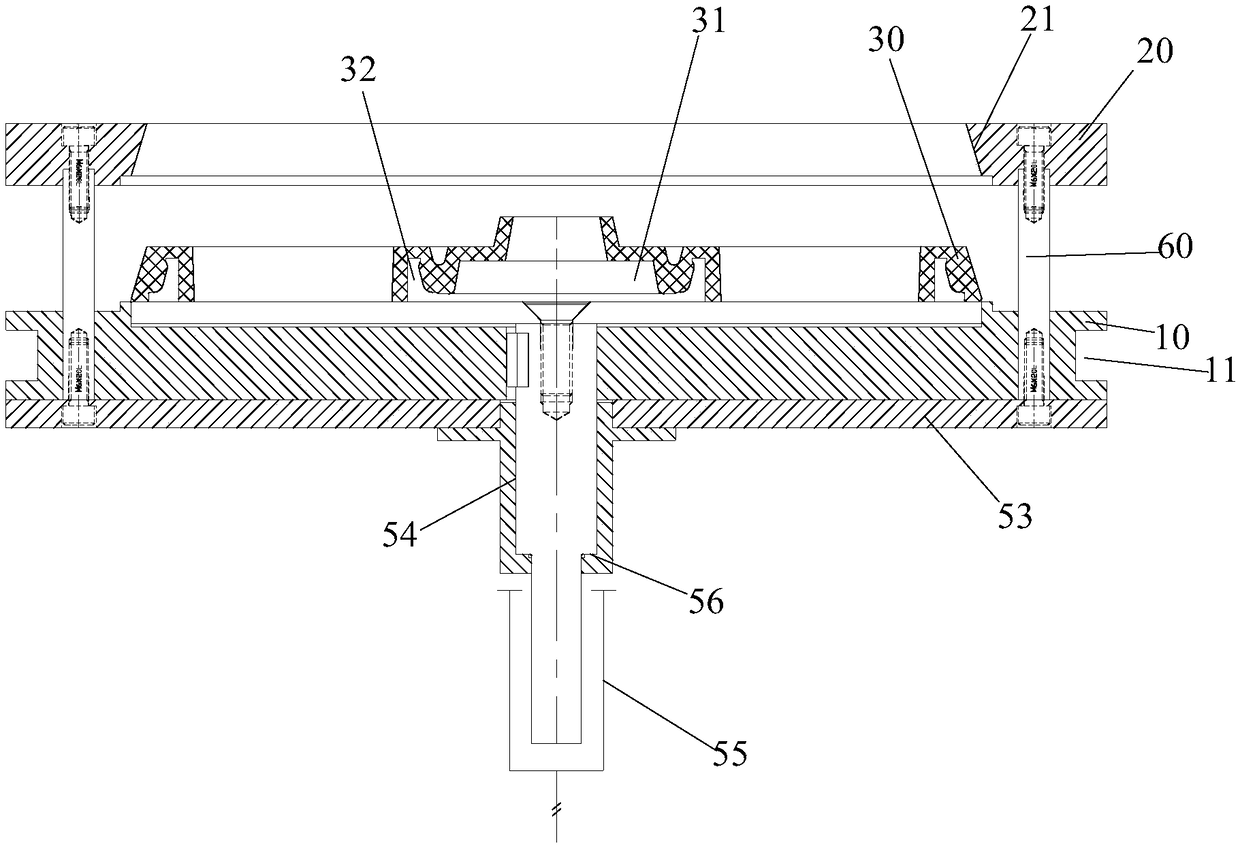

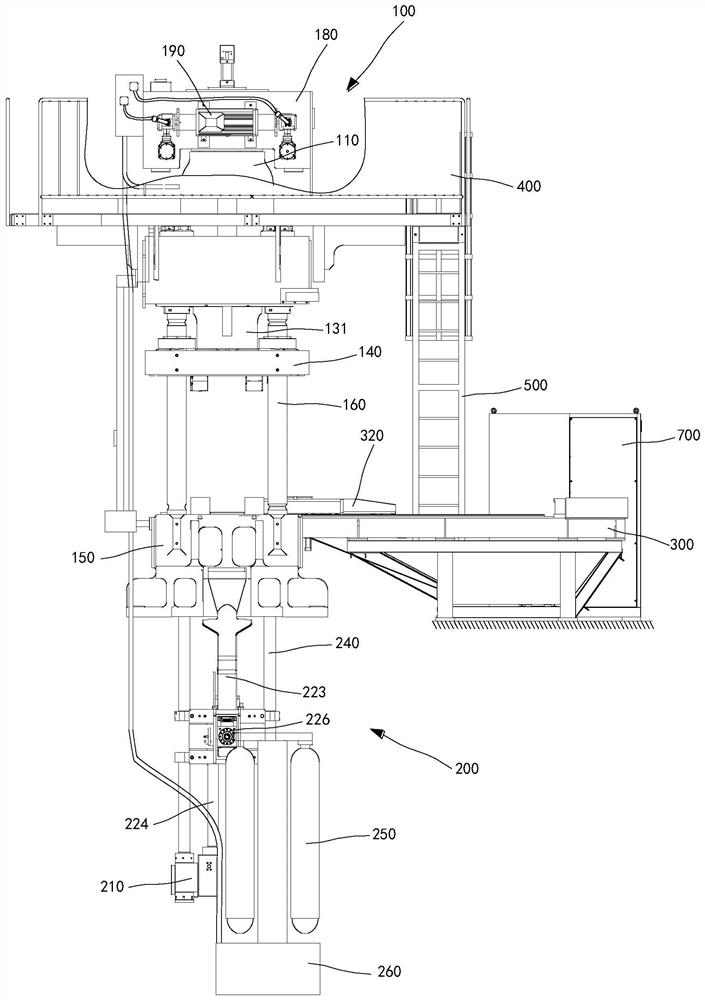

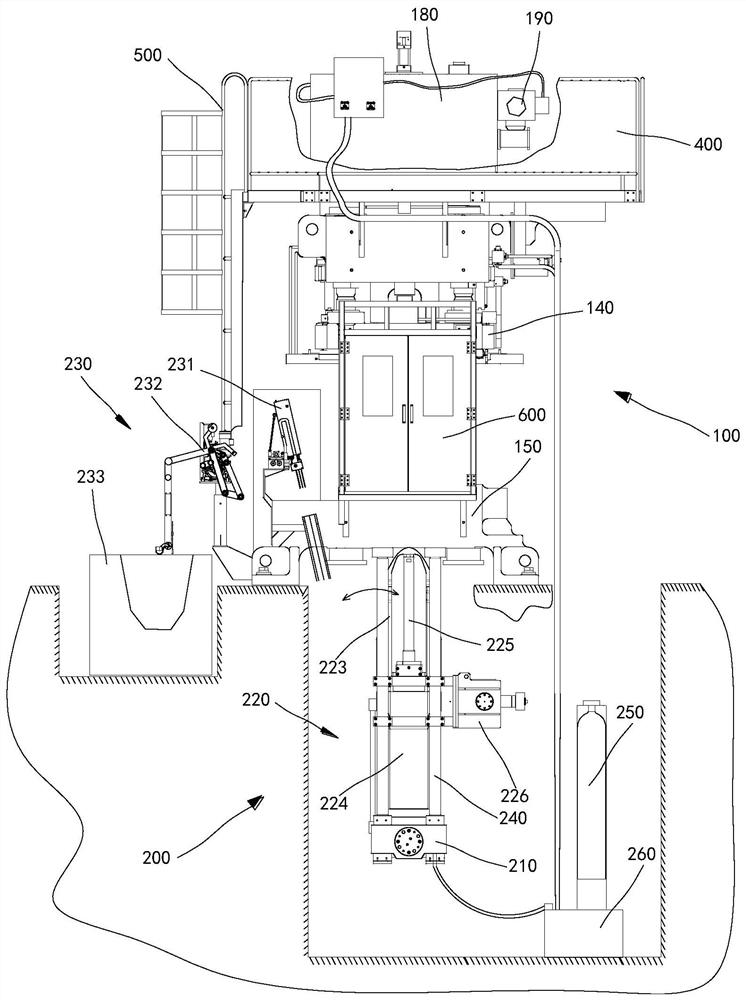

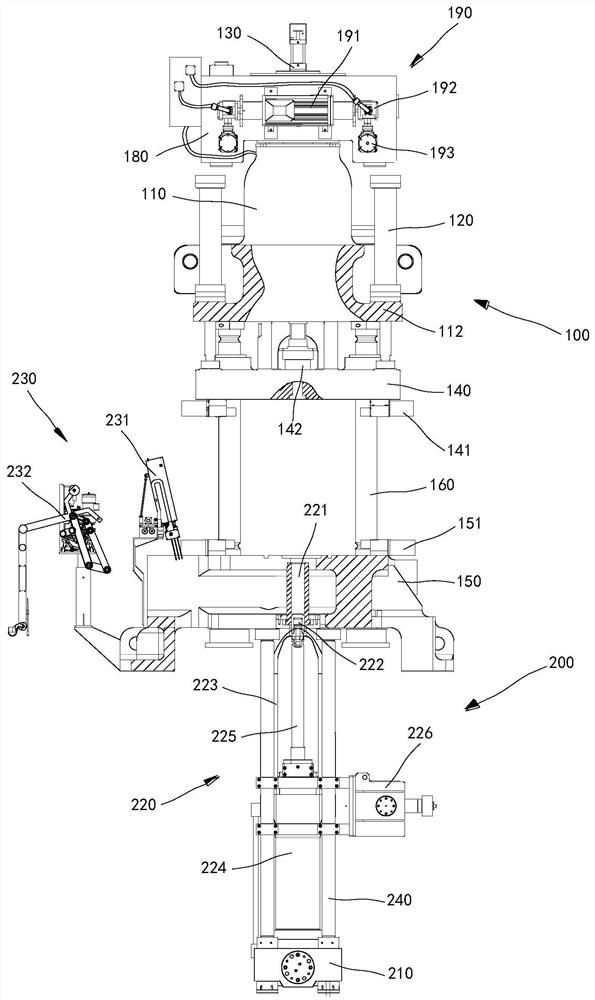

Casting device and casting method thereof

The invention provides a casting device and a casting method thereof. The casting device comprises a centrifugal lower mold, a centrifugal upper mold, a sand mold, a mold jacking device and a centrifugal machine, wherein an accommodating cavity is formed in the centrifugal lower mold; a guide bar is arranged at the position, on the outer side of the accommodating cavity, of the centrifugal lower mold; a cavity for accommodating the sand mold is formed in the centrifugal upper mold; a feeding pouring gate is formed in the bottom surface of the sand mold; a sprue is formed in the top surface ofthe feeding pouring gate; at least two annular casting cavities are formed in the periphery of the feeding pouring gate; each casting cavity sinks inwards from the bottom surface of the sand mold; each casting cavity is provided with a connecting channel communicating to the feeding pouring gate; the mold jacking device comprises a stripping plate arranged in the accommodating cavity, a jacking shaft connected under the stripping plate, a mold jacking plate arranged below the centrifugal lower mold and driving equipment arranged below the mold jacking plate. Two ends of the guide bar are separately fixed to the centrifugal upper mold and the mold jacking plate. The casting method comprises the following steps: stretching the mold jacking device out; retracting the mold jacking device; carrying out centrifugal casting; jacking the mold; pushing out a forming body; and removing the centrifugal pressure casting pouring gate. A casting manufactured by the casting device is uniform in tissue, and defects such as airholes are reduced.

Owner:YANTAI SHUANGYUAN GENERAL PARTS

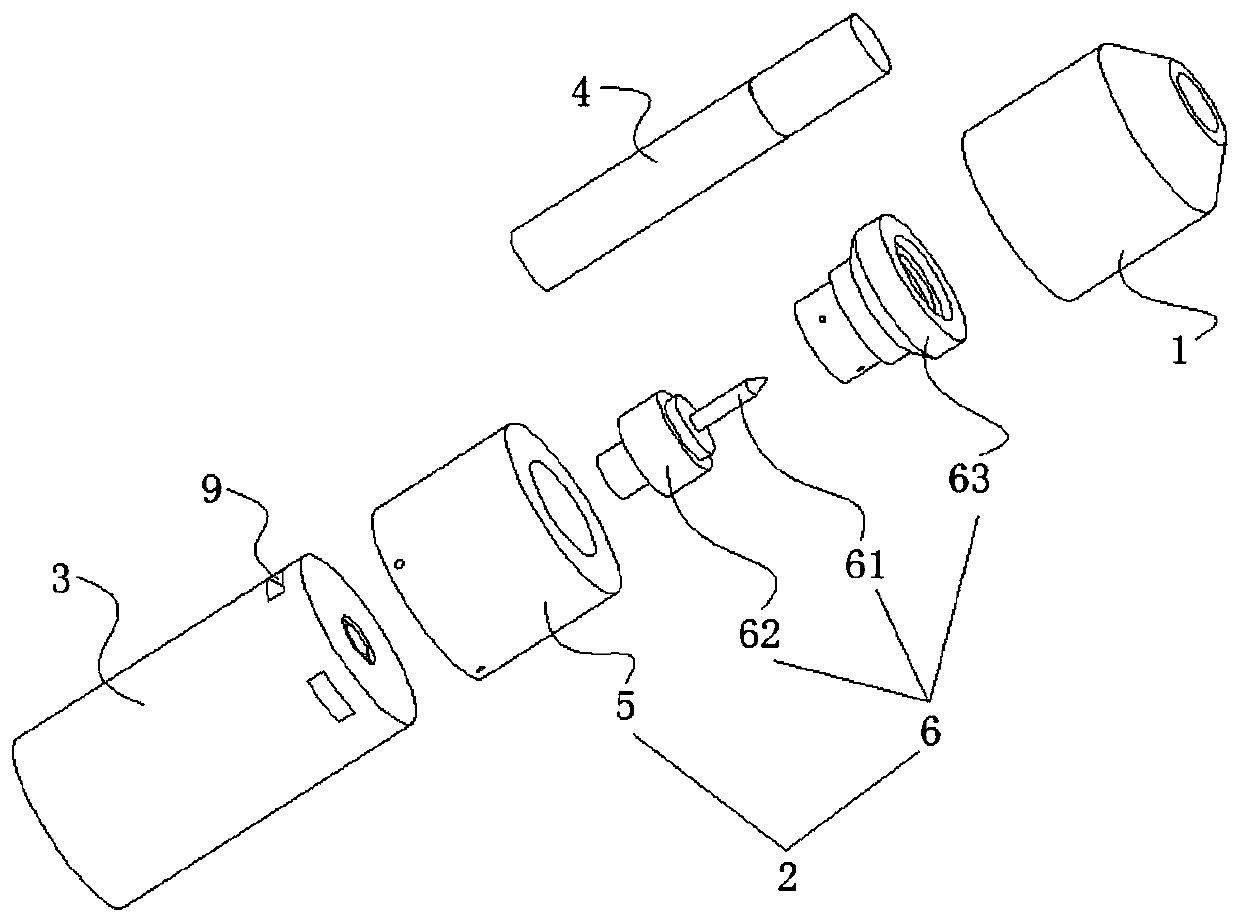

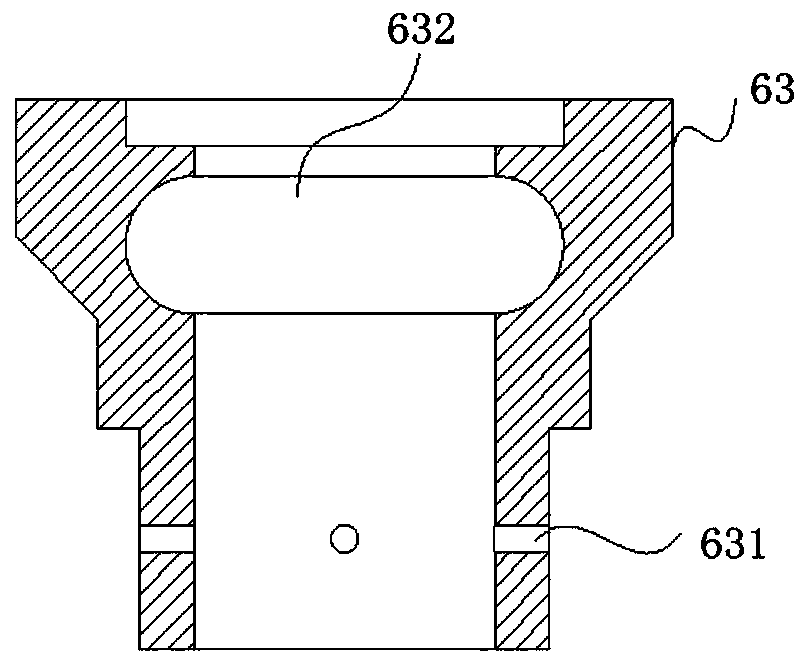

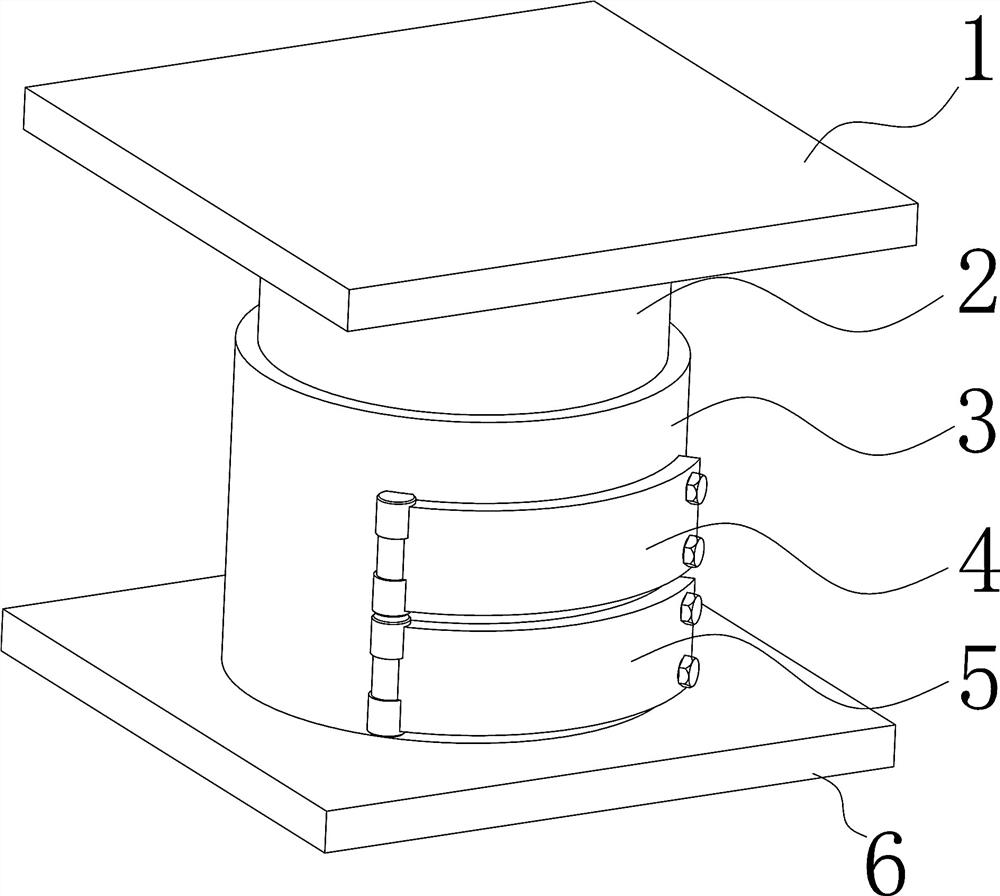

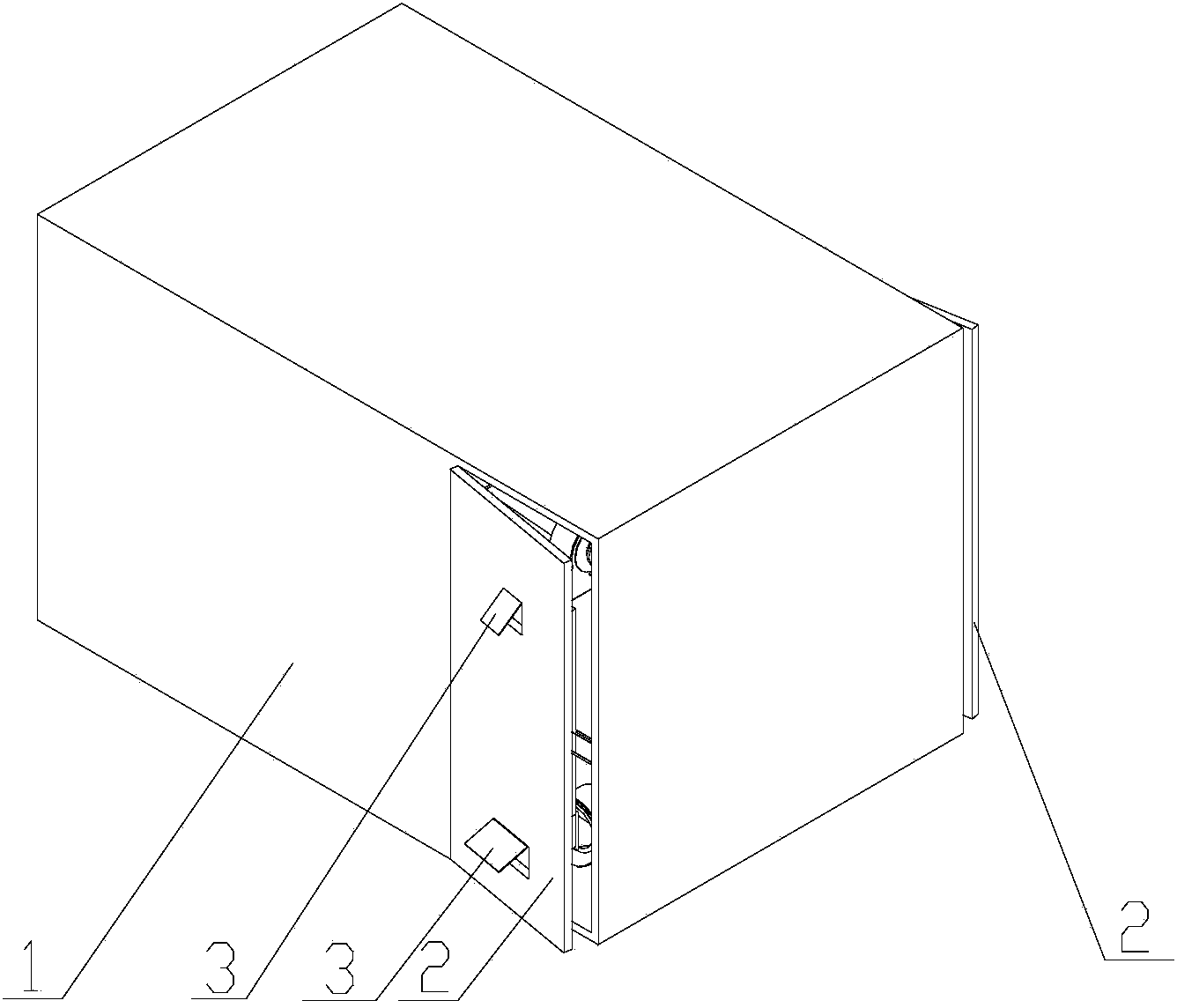

Cigarette heating device

Owner:CHINA TOBACCO GUANGDONG IND

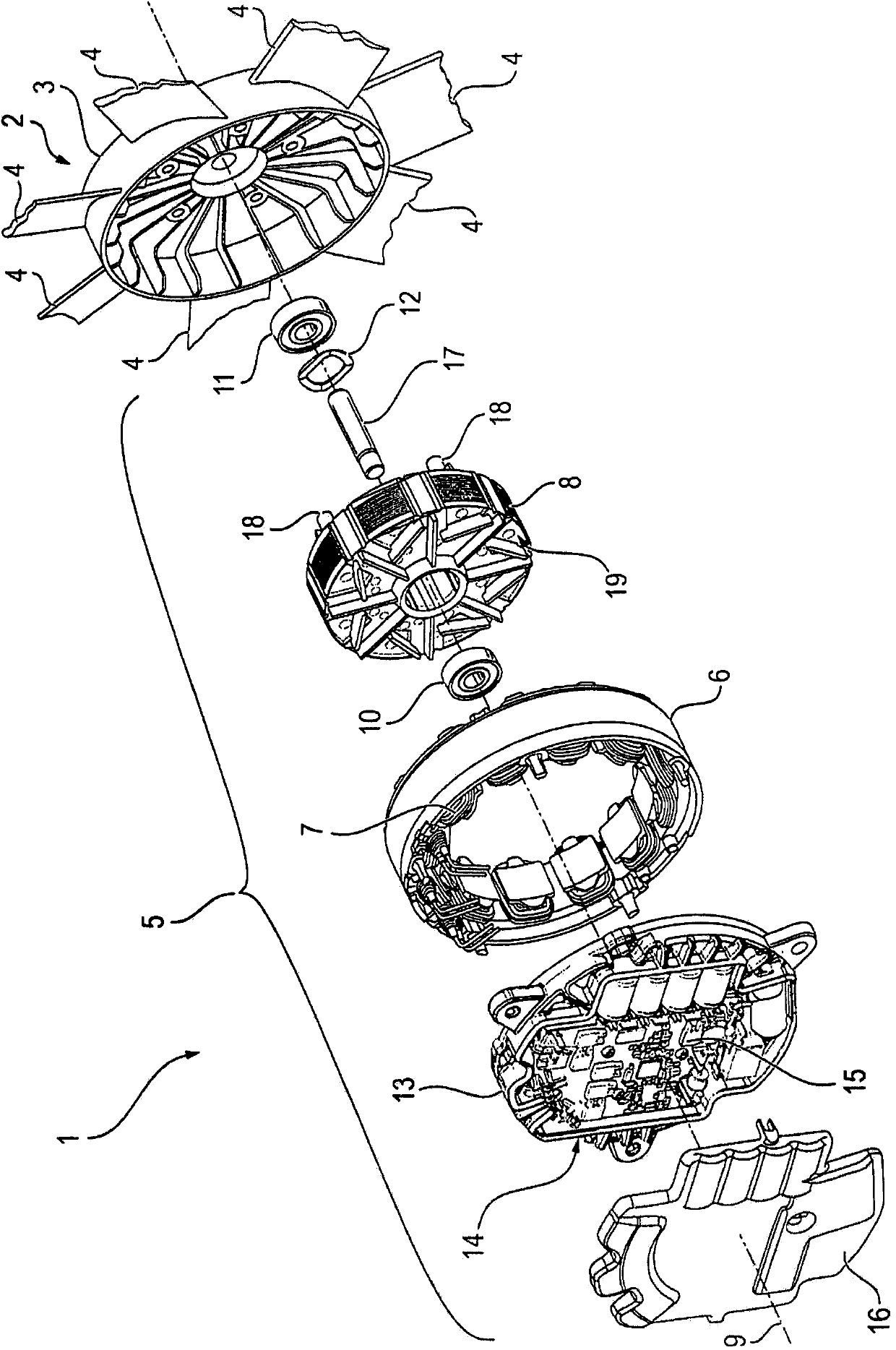

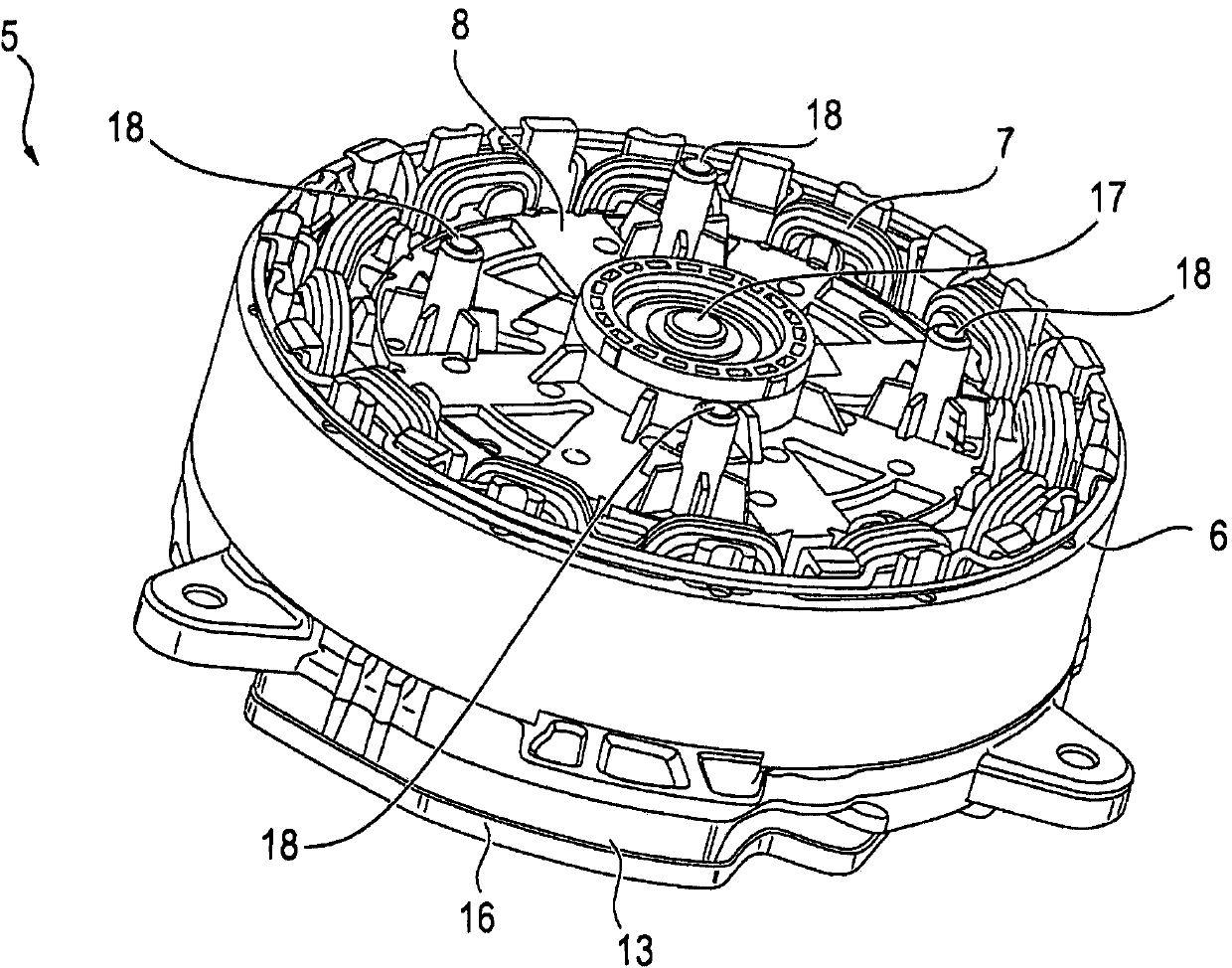

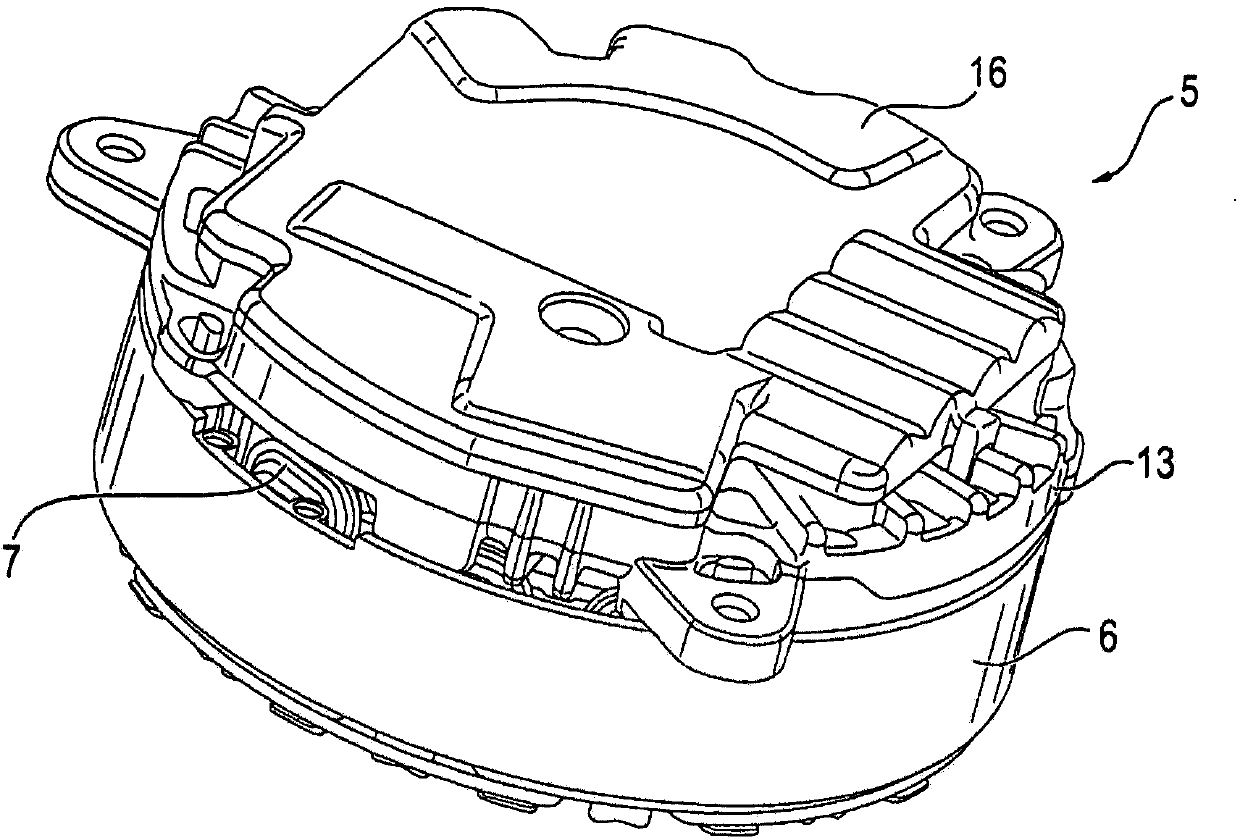

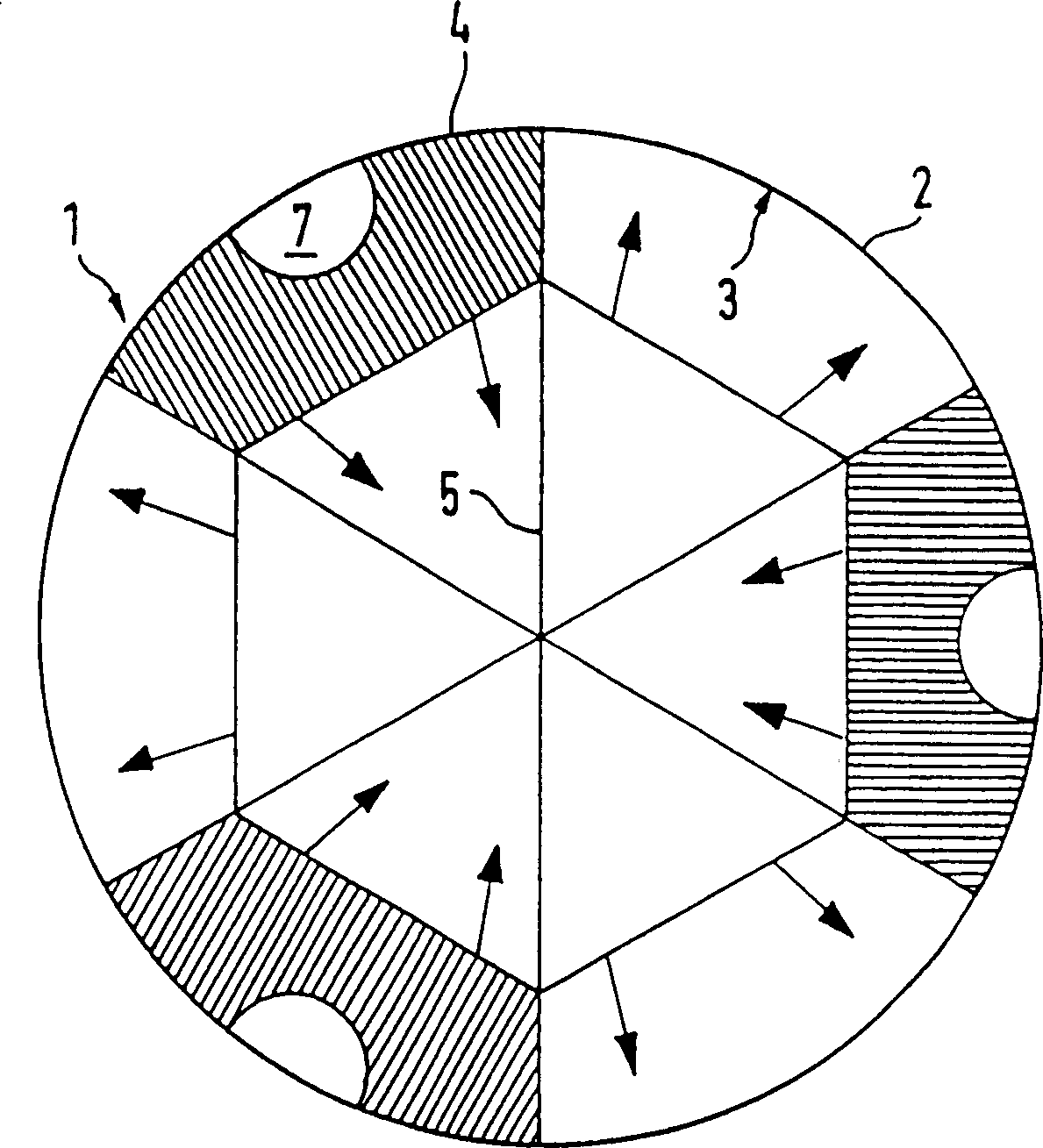

Breathing electric motor

ActiveCN103797693AResistance to the formation of temperature gradientsShort flow pathAssociation with control/drive circuitsWindingsEngineeringMechanical engineering

The invention relates to an electric motor (5) that has efficient self-cooling. The electric motor (5) comprises a rotor (8) that is rotatably mounted with respect to a stator (6). On a first sub-segment (23a) of an end face (19) of the rotor (8), a first air-guiding contour (20a) is formed that, during rotation of the rotor (8) in a reference rotation direction (R), generates an outwardly directed air flow (S). On a second sub-segment (23b) of the same end face (19), a second air-guide contour (20b) is formed that, during rotation of the rotor (8) in a reference rotation direction (R), generates an inwardly directed air flow (S).

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

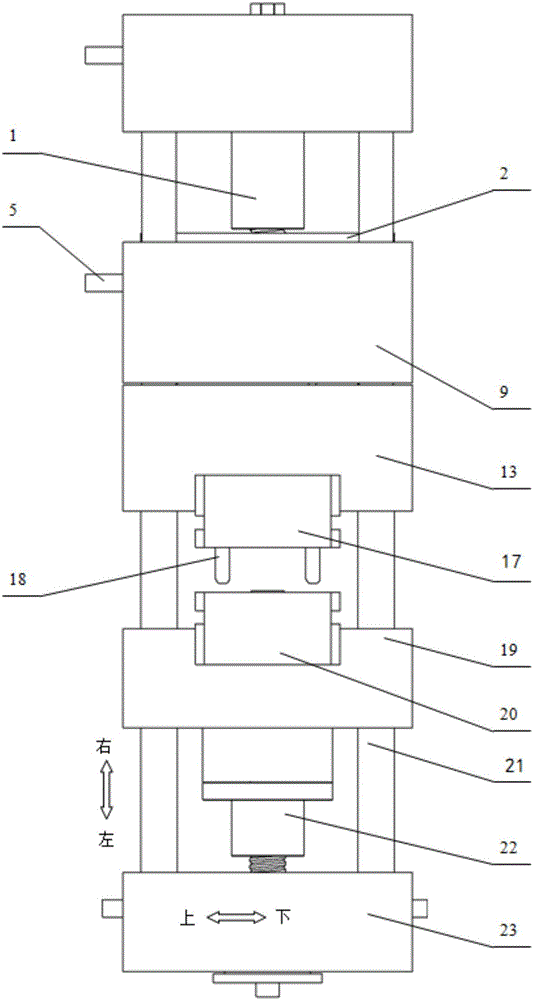

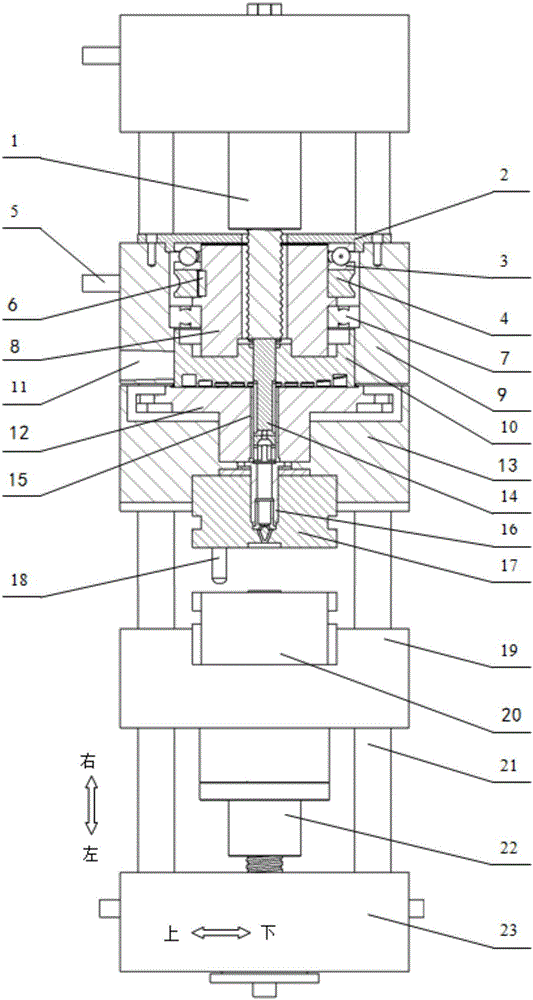

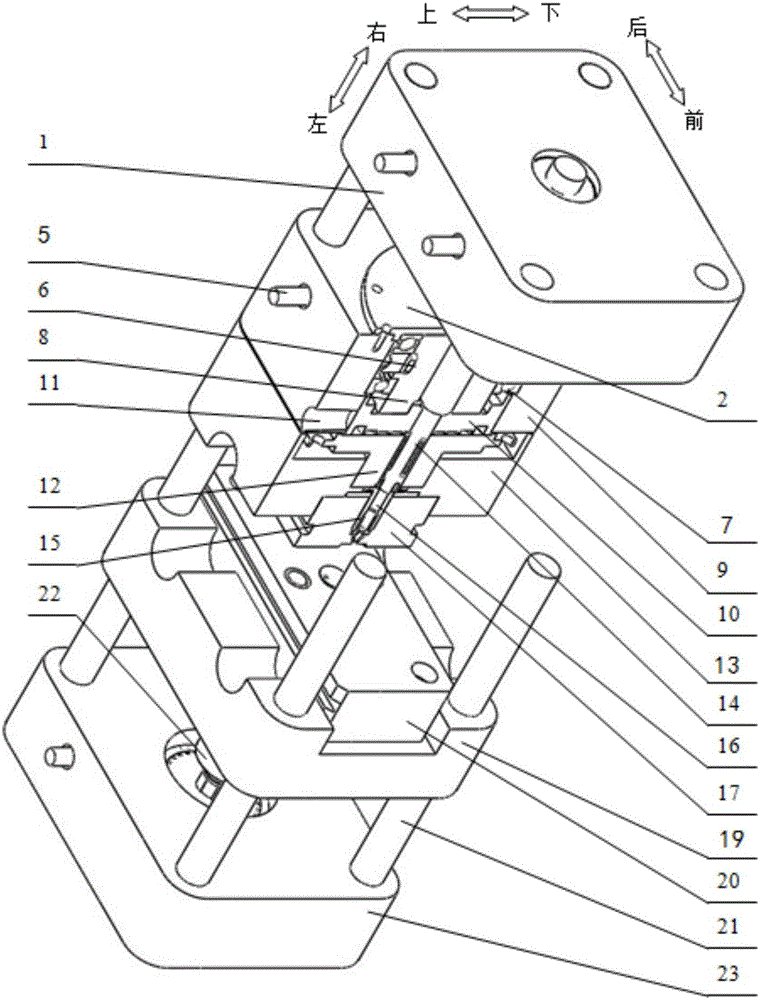

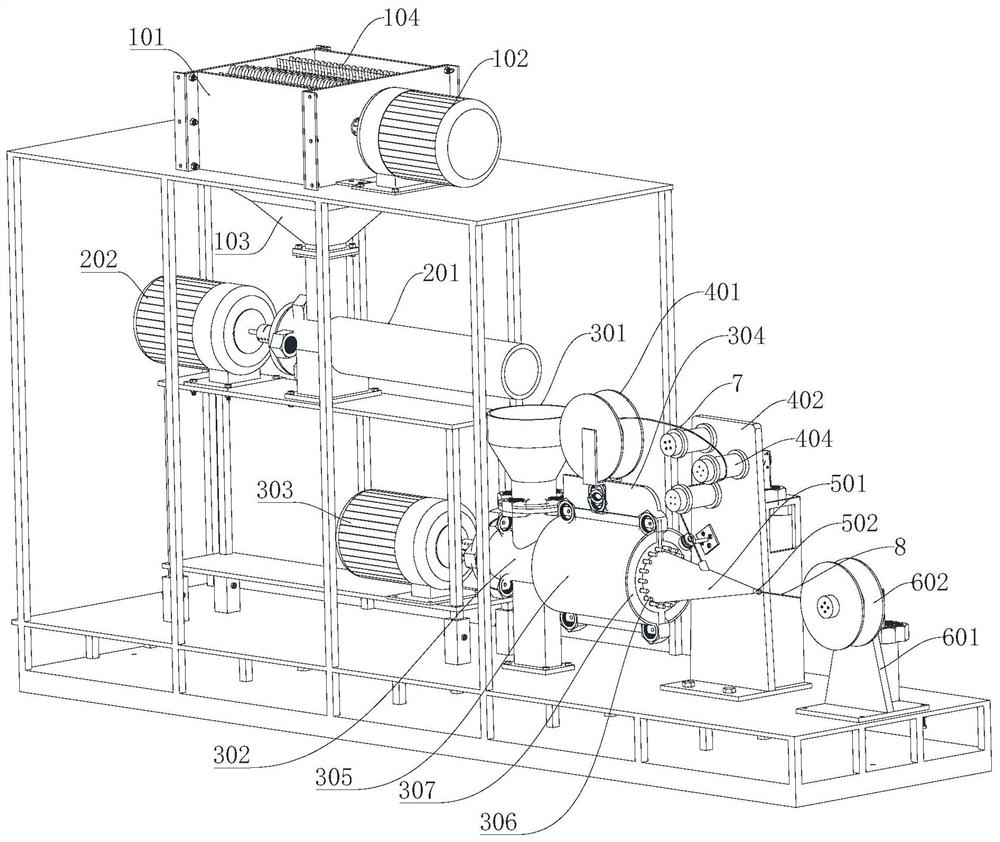

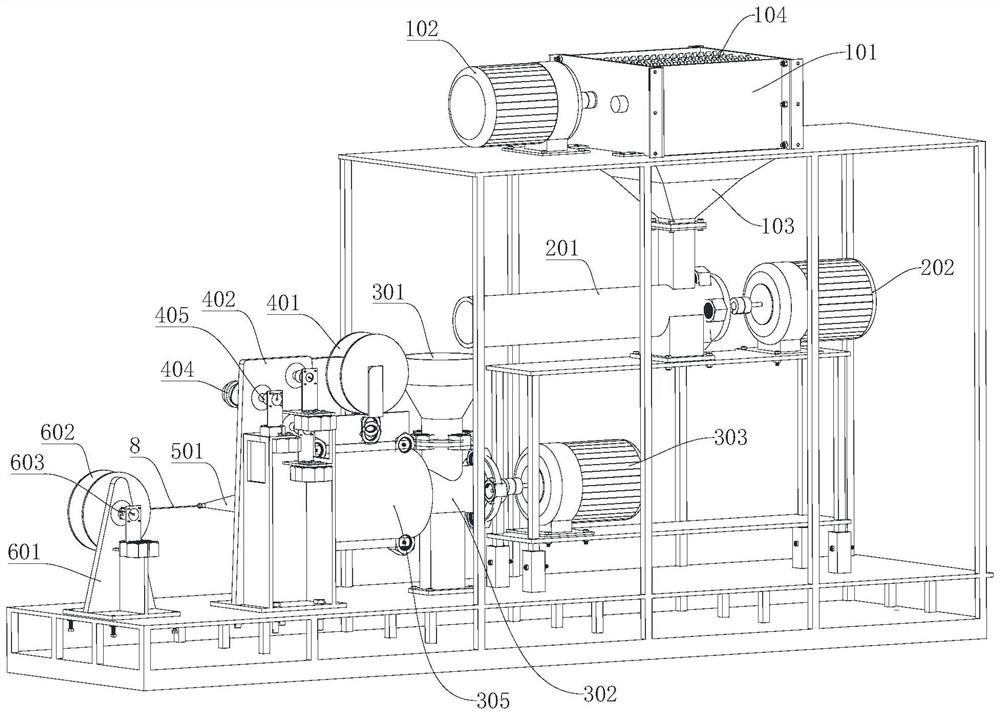

Miniature injection molding machine with injection molding and plasticizing in coaxial line design

ActiveCN106626286AImprove transmission efficiencySimple supporting structureThermal insulationCoaxial line

The invention discloses a miniature injection molding machine with injection molding and plasticizing in coaxial line design. The miniature injection molding machine comprises an injection molding drive device, a grinding disc plasticizing device, a mold, a mold combination drive device and a clamping plate which are sequentially arranged on pull rods in a penetrating manner. The four pull rods penetrate four holes in each of the injection molding drive device, a base body, a fixed mold plate and the clamping plate in the whole machine, and the injection molding drive device, the base body, the fixed mold plate and the clamping plate are fixedly mounted on the specific positions of the pull rods, the four pull rods penetrate four holes in a movable mold plate, but the movable mold plate can move left and right on the four pull rods for achieving mold opening and mold closing. The miniature injection molding machine is simple and compact in structure, small in occupied space and more smooth in forming action; and melting charge plasticized by the miniature injection molding machine with injection and plasticizing in coaxial line design is directly gathered in a sleeve and is injected through a piston, the melting charge flowing path is short, thermal insulation of the melting charge is facilitated, and the quality of injection molding products can be guaranteed.

Owner:ZHEJIANG UNIV

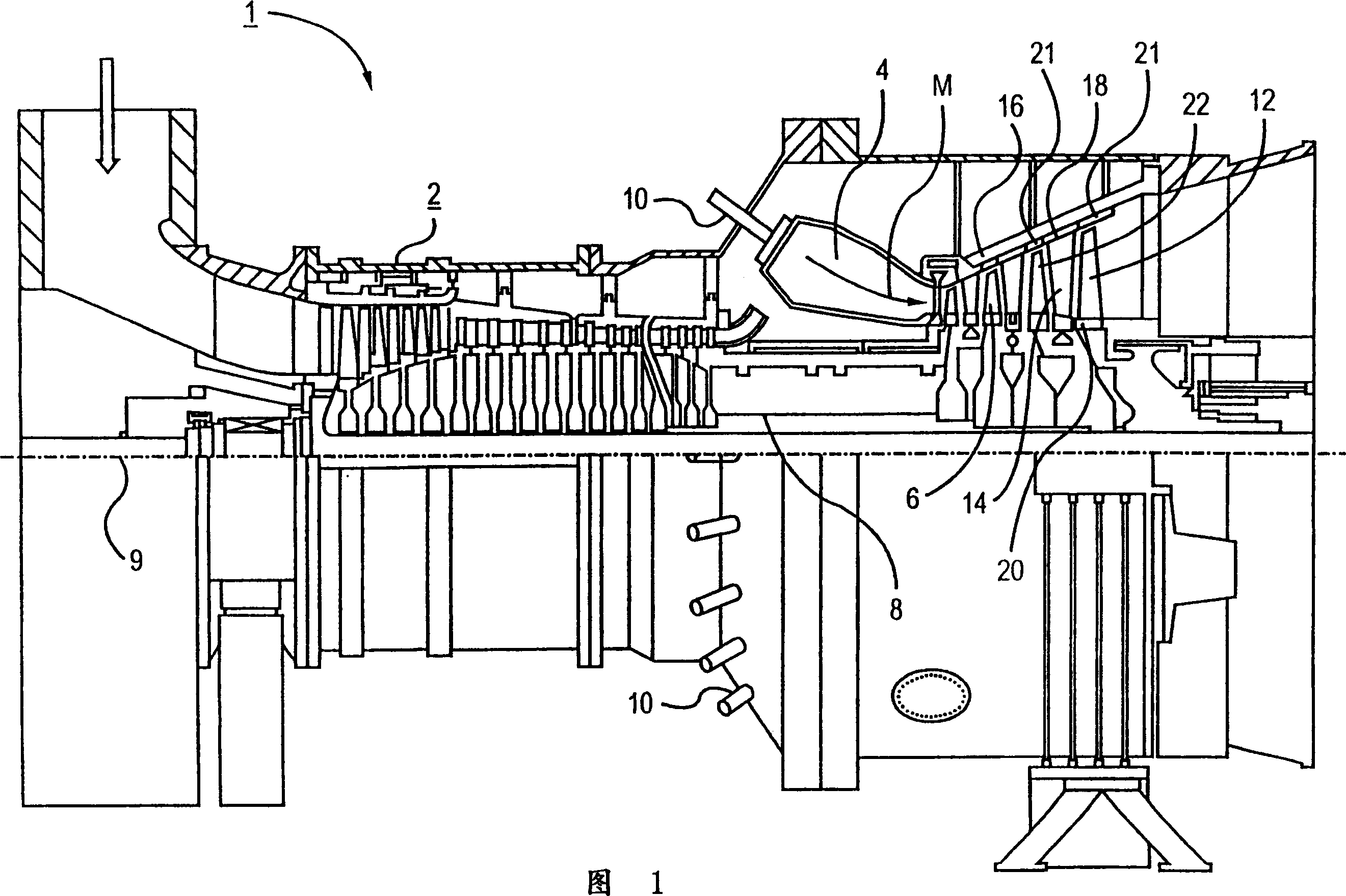

Gas turbine

InactiveCN1380487AShort flow pathEasy dischargeEngine fuctionsTurbine/propulsion engine coolingTurbine bladeGas turbines

In a turbine (1) with several working blades assembled on the turbine shaft (8) assembled into a working blade group and several guide blades (14) connected to the turbine casing assembled into a guide blade group, in order to Particularly high efficiency is achieved in the case of a simple and reliable cooling of the turbine blades (12), (14). According to the invention, at least some of the guide vanes (14) have a coolant inlet (48) at their free end facing the turbine shaft (8).

Owner:SIEMENS AG

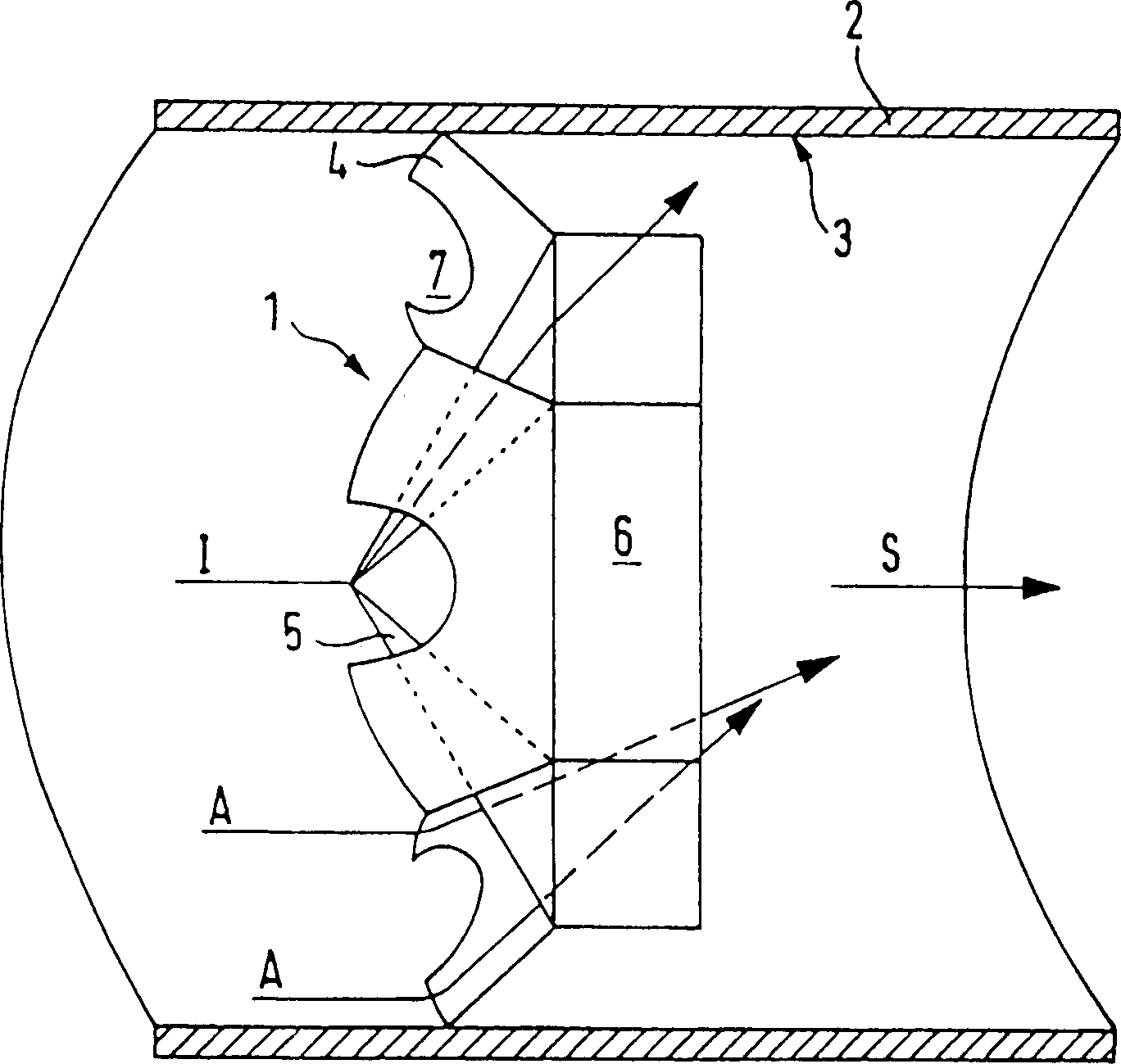

Mixer element for fluid that is guided in pipe

InactiveCN1148511CProtects against heat-induced damageUniform temperature distributionFlow mixersExhaust apparatusEngineeringInternal combustion engine

The invention relates to a mixer element (1) for a fluid that is guided in a pipe (2), especially a mixer element that is used in the exhaust pipe of an internal combustion engine. Parts of the outer current A that is adjacent to the inner surface (3) of the pipe (2) are guided towards the interior by means of an outer guide section (4) and at the same time and in an approximately common plane parts of the inner current I are guided towards the exterior by means of an inner guide section (5). The use of the entire inner surface (3) of the pipe (2) for the purpose of cooling is preferably guaranteed by at least one opening (7) that is provided in the outer guide surface (4). The invention provides a simple means for obtaining a homogeneous temperature distribution and good cooling of a fluid that is guided in a pipe. The inventive mixer element (1) is especially distinguished from known mixer elements by its compact construction.

Owner:EMITEC EMISSIONSTECHNIK

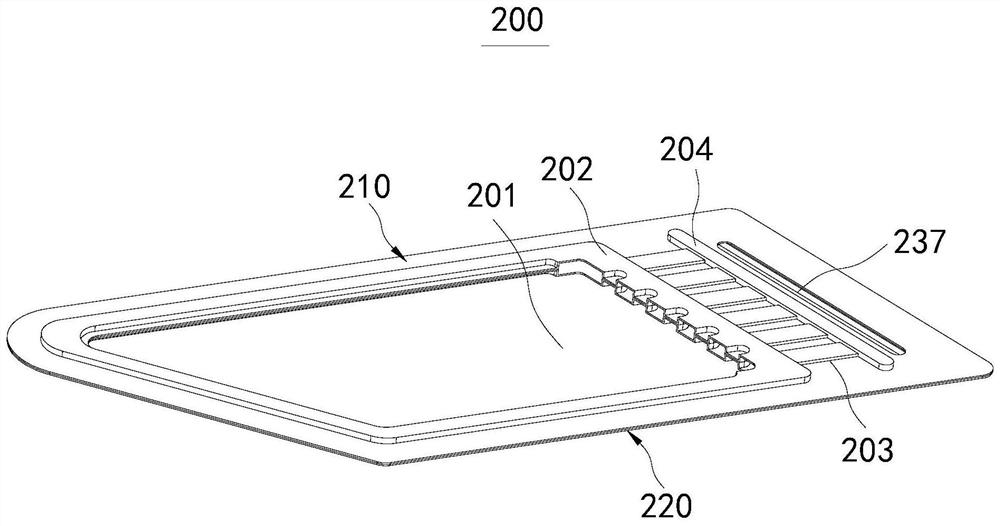

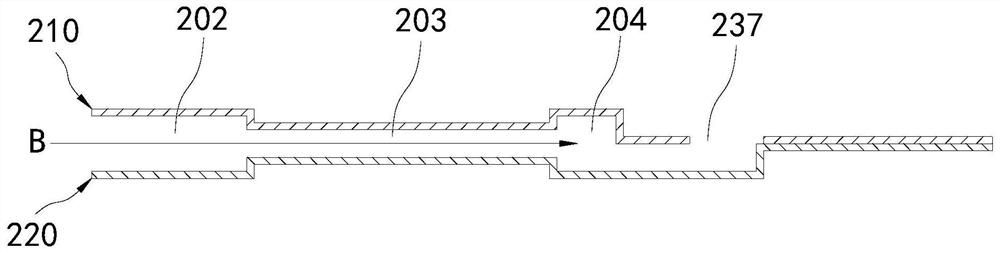

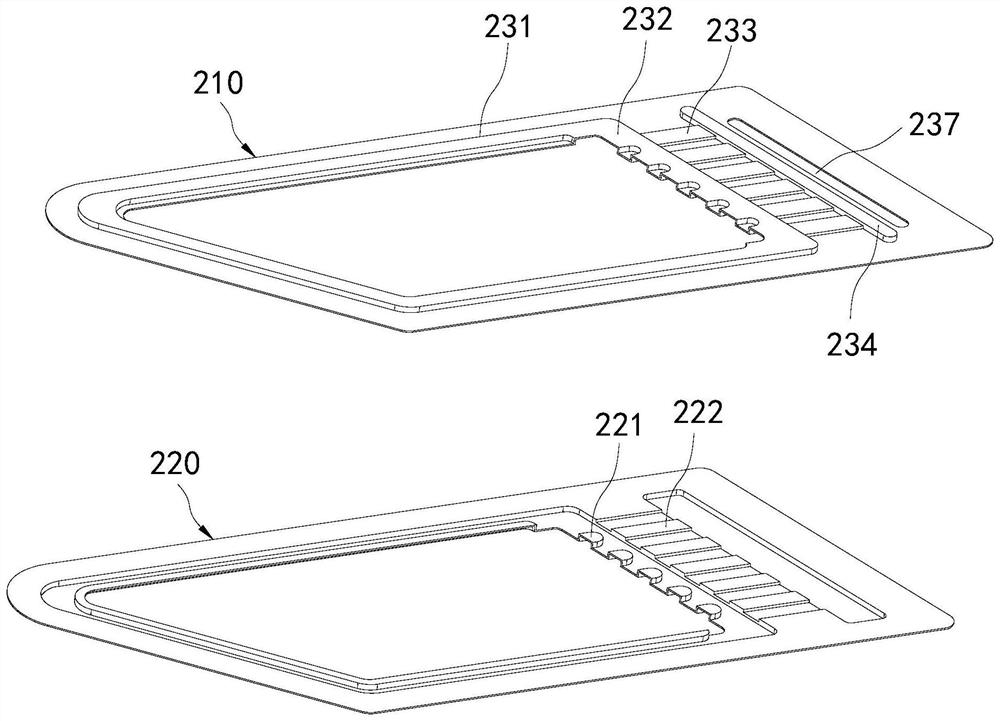

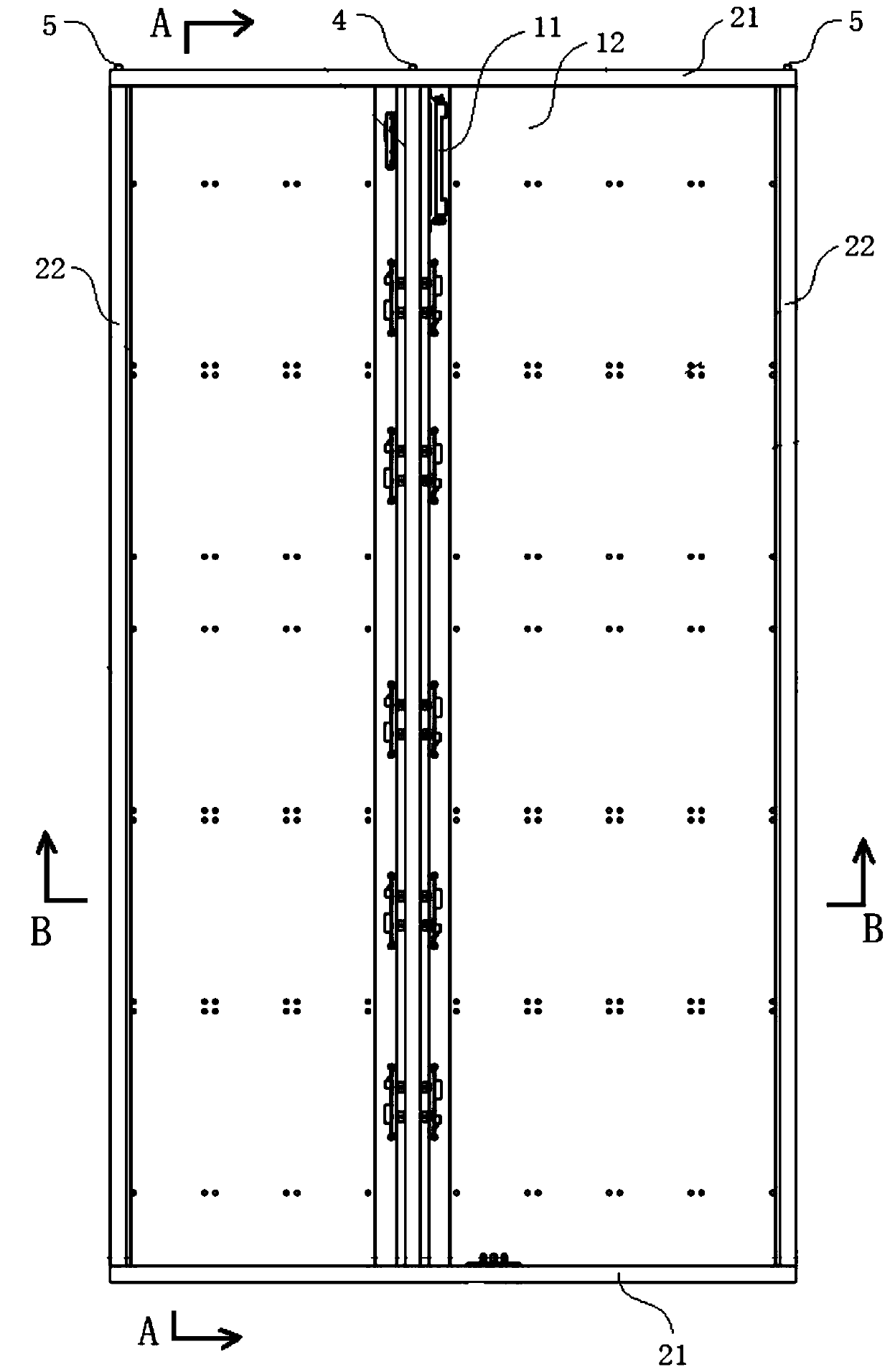

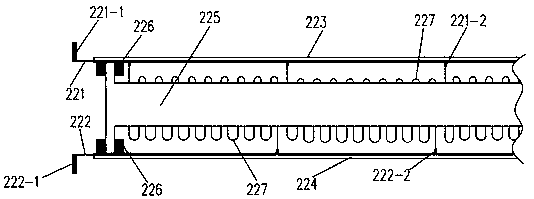

Bipolar plate fluid inlet and outlet area, bipolar plate and fuel cell

PendingCN111668507AShort flow pathIncrease the proportion of effective areaFinal product manufactureFuel cellsFuel cellsMechanical engineering

The invention relates to the technical field of fuel cell manufacturing, in particular to a bipolar plate fluid inlet and outlet area, a bipolar plate and a fuel cell. The bipolar plate fluid inlet and outlet area comprises a first monopolar plate and a second monopolar plate which are arranged in an attached mode. A first cavity, a middle cavity, a flow channel cavity and a second cavity are formed between the first monopole plate and the second monopole plate. The first cavity, the middle cavity, the flow channel cavity and the second cavity are sequentially communicated. According to the bipolar plate fluid inlet and outlet area, fluid can directly flow into a distribution area of a polar plate flow field in the inlet area and directly flow out of the distribution area of the polar plate flow field in the outlet area, overturning is not needed, the flowing path of the fluid is shorter, the pressure loss is smaller, and the proportion of the effective area of the bipolar plate is increased.

Owner:北京新研创能科技有限公司

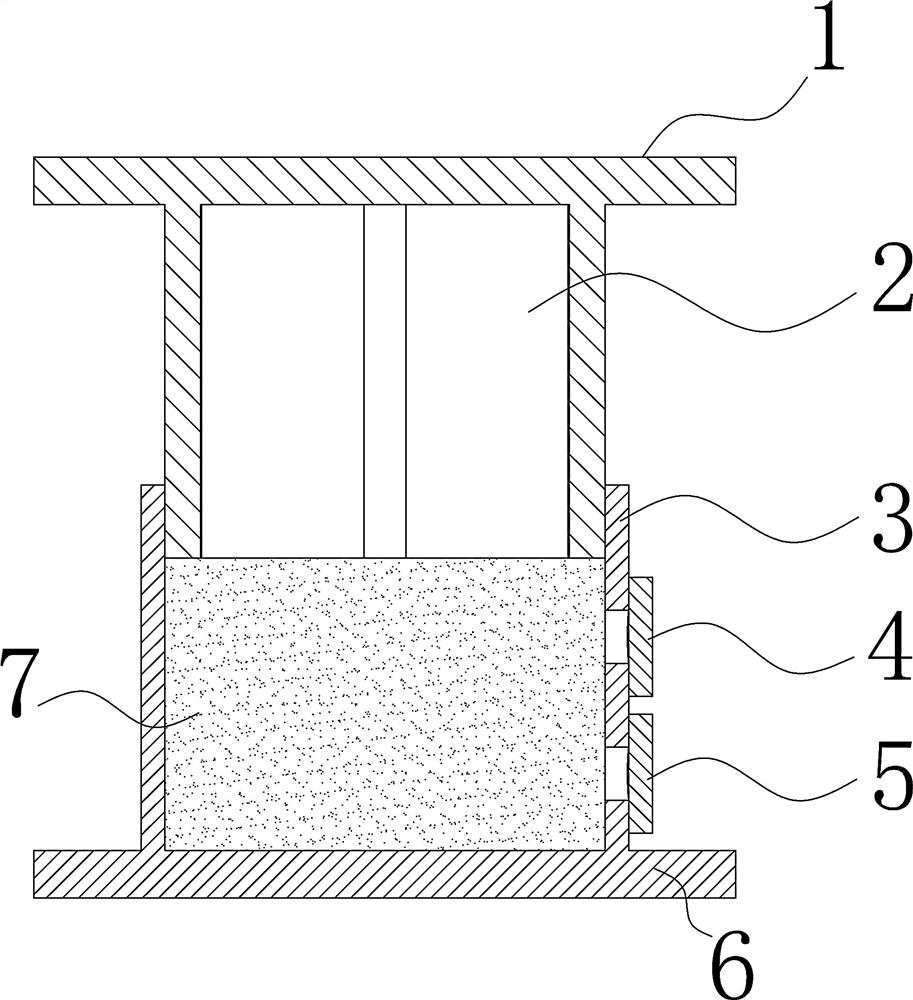

Gradable unloading sand box

InactiveCN112554562AShort flow pathLower the elevationBridge erection/assemblyBuilding material handlingElectric machineryStructural engineering

Owner:中交二航局第一工程有限公司

Double-sided flow field for polar plate for improving material distribution uniformity of fuel cell

The invention relates to a double-sided flow field for a polar plate for improving the material distribution uniformity of a fuel cell, the polar plate is formed by stamping a stainless steel flat plate, grooves sunken towards the inside of the plate surface are formed in the front surface and the back surface of the stainless steel plate, and ridges protruding towards the outside of the plate surface are arranged on the back surface corresponding to the grooves; and the reverse flow field is formed by sequentially arranging a column of flow fields or more than two columns of flow fields whichare sequentially arranged at intervals by long-strip-shaped bulges from top to bottom. The flow field is suitable for a thin plate stamping process, multi-stage disturbing fluid is arranged on the front face and the back face, and material distribution uniformity is good; the parallel arrangement structure improves the mass transfer efficiency; and mass transfer strengthening effect under the ridges of the parallelogram groove group is good.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Vertical squeeze casting machine

The invention relates to the technical field of casting equipment, and discloses a vertical squeeze casting machine. The machine comprises a mold opening and closing device and an injection device, the mold opening and closing device comprises a rear mold plate, a fixed mold plate, a movable mold plate, an opening and closing assembly and a liquid filling assembly, in the casting process, the opening and closing assembly drives the movable mold plate to conduct mold closing or mold opening, and rapid mold locking is achieved; and in the mold closing state, the liquid filling assembly can conduct pressurization mold locking on the movable mold plate, the opening and closing assembly and the liquid filling assembly are separately controlled, the mold opening and closing time is greatly shortened, and the production efficiency is improved. The injection device comprises a base, an injection assembly and a feeding assembly, the fixed mold plate is provided with a liquid inlet in butt jointwith the injection assembly, and the injection assembly reciprocates between the feeding assembly and the liquid inlet. The feeding assembly independently provides molten metal for the injection assembly, then the injection assembly injects the molten metal into a metal impression to complete casting, the flowing path is short, gas is located on the molten metal, the gas entrapment phenomenon isreduced through injection from bottom to top, and the product quality is improved.

Owner:广州楚河工业设计合伙企业(有限合伙)

Radar transmitting cabin capable of rapid heating

ActiveCN104023504AHeating fastShort working temperature timeCooling/ventilation/heating modificationsRadarCentrifugal fan

The invention relates to a radar transmitting cabin capable of rapid heating. The radar transmitting cabin comprises a shelter body which is provided with a cabin door. The cabin door is provided with two outer ventilation doors. Two rectangular electronic cabinet groups are disposed side by side inside the cabin body. The top and bottom of each electronic cabinet group are respectively provided with a heat radiation air-duct which is communicated with the electronic cabinet group. Same ends of the two heat radiation air-ducts are respectively connected with a centrifugal fan. Upper and lower centrifugal fans are communicated with each other through a heating air-duct, inside which at least a heater is arranged. Junctions between the heating air-duct and the two centrifugal fans are respectively provided with an inner air door. During heating, the heat radiation air-ducts and the centrifugal fans are fully utilized, and heated air flows circularly in the ducts to rapidly heat devices in the electronic cabinets. Flow velocity of hot air is high; flow path is short; heating rate is fast; time for an electronic device to reach an appropriate operating temperature is short; and radar start-up is fast.

Owner:BEIJING INST OF RADIO MEASUREMENT

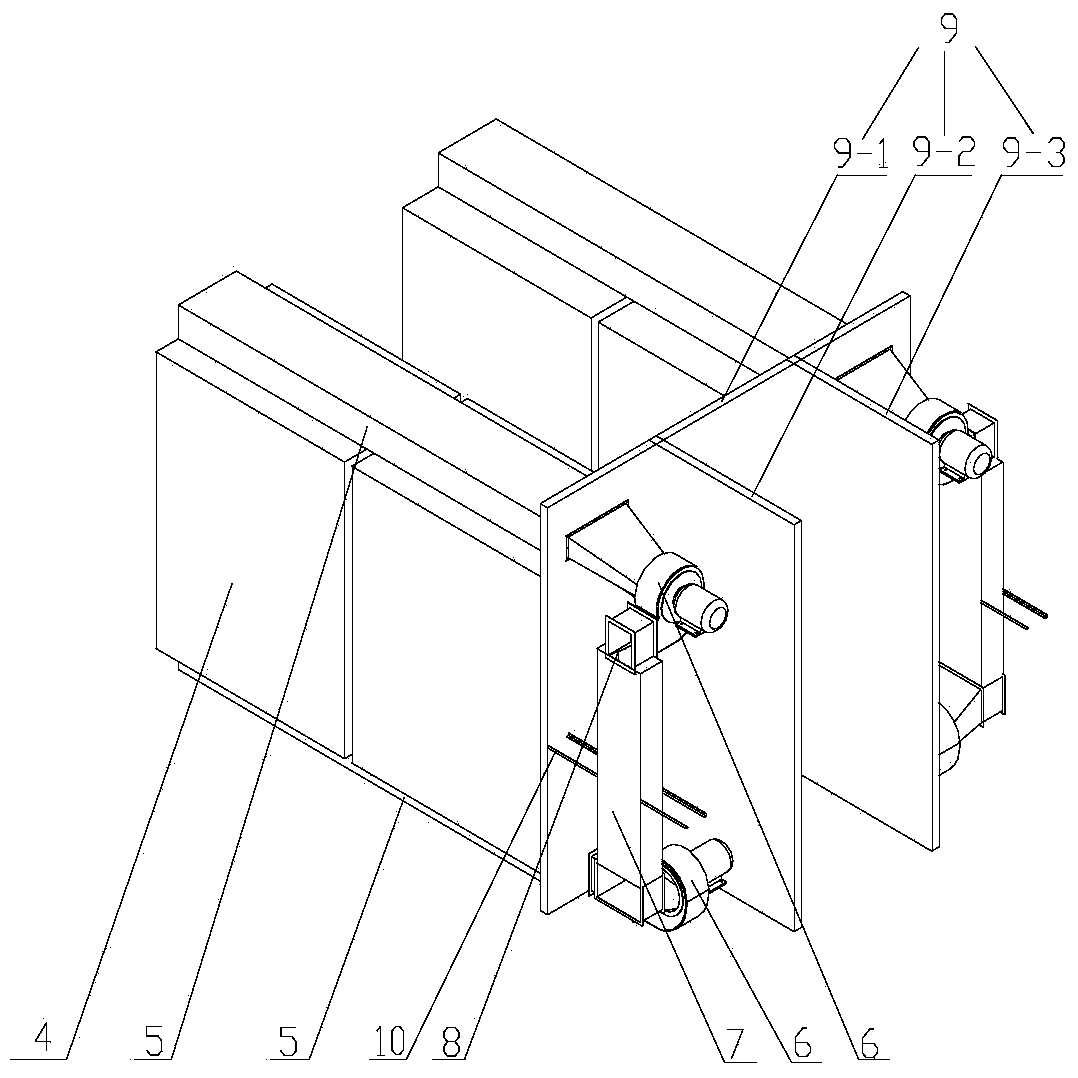

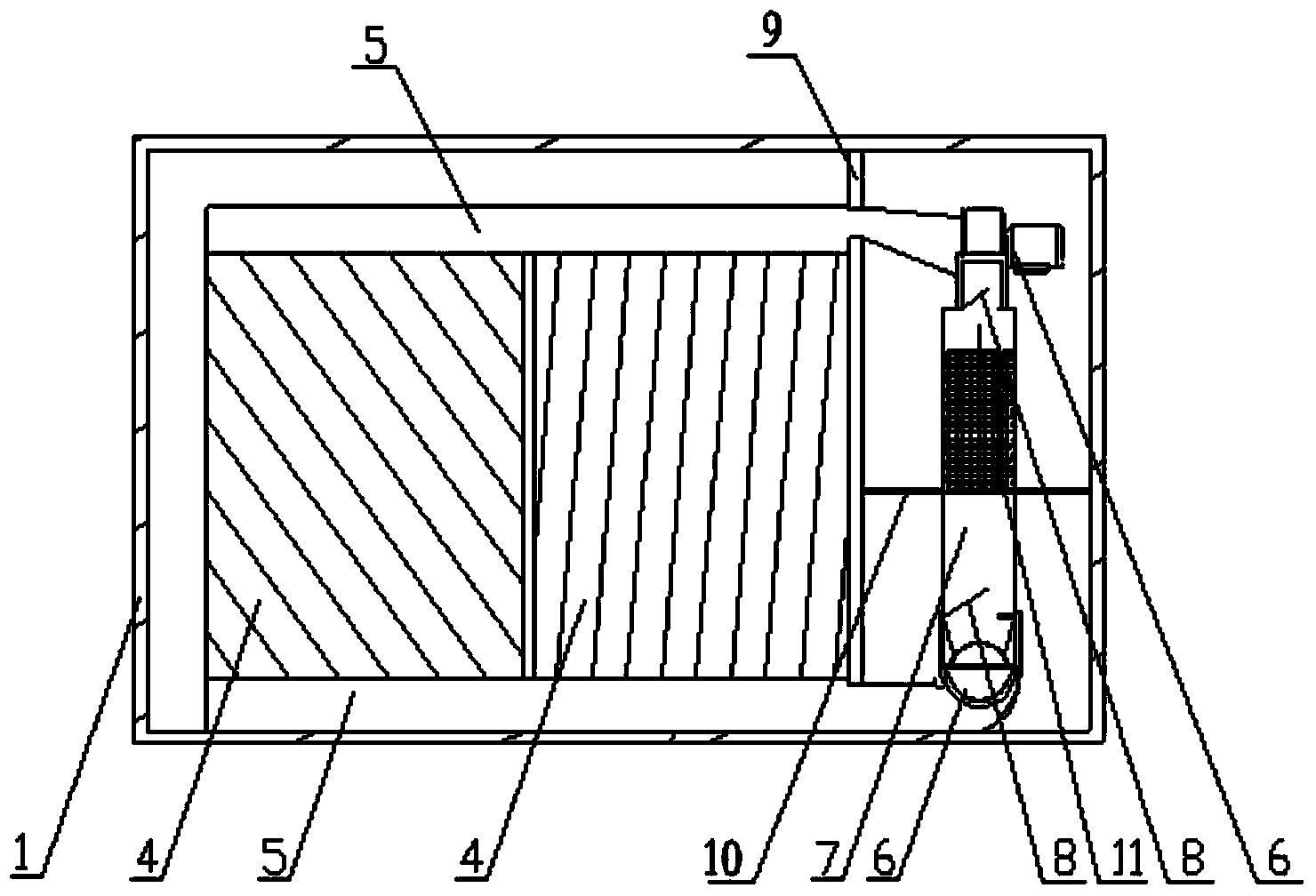

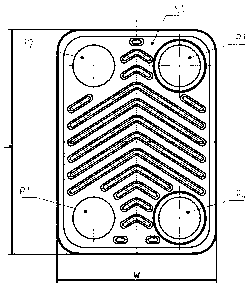

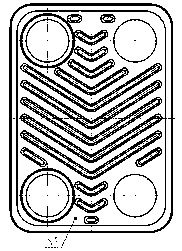

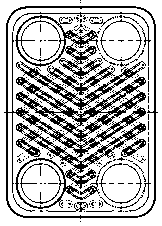

Plate type heat exchanger and plate type laminated sheet thereof

PendingCN108645256AGuaranteed uniformityReduce power consumptionLaminated elementsStationary plate conduit assembliesEngineeringPlate fin heat exchanger

The invention discloses a plate type heat exchanger and a plate type laminated sheet of the plate type heat exchanger. The laminated sheet is provided with a p1 and a p2 are an inlet and an outlet holes, a p3 and a p4 are two isolation angle holes, adjacent laminations are oppositely arranged, and every pair of adjacent laminations is subjected to staggered heat exchange. If the n plate S1 and then +1 plate S2 flow refrigerant in a flowing region, the n-1 plateS1 and the n plate S2 region and the n+1 plate S1 region and the n+2 plate S2 region flow refrigerating fluid, and vice versa. Wherein, n is greater than or equal to 2, and n is an integer. Optimization lamination structure parameters are designed through design, so that the heat exchange performance is improved from the inlet pipeP1 to the outlet pipe P2, meanwhile, the flow path is shorter, therefore the flow resistance is reduced, so that the flow rate is increased, the heat exchange efficiency is further improved, and the power consumption of the water pump in the cooling sub-system can be reduced.

Owner:JIANGXI XINDIAN AUTOMOBILE AIR CONDITIONING SYST

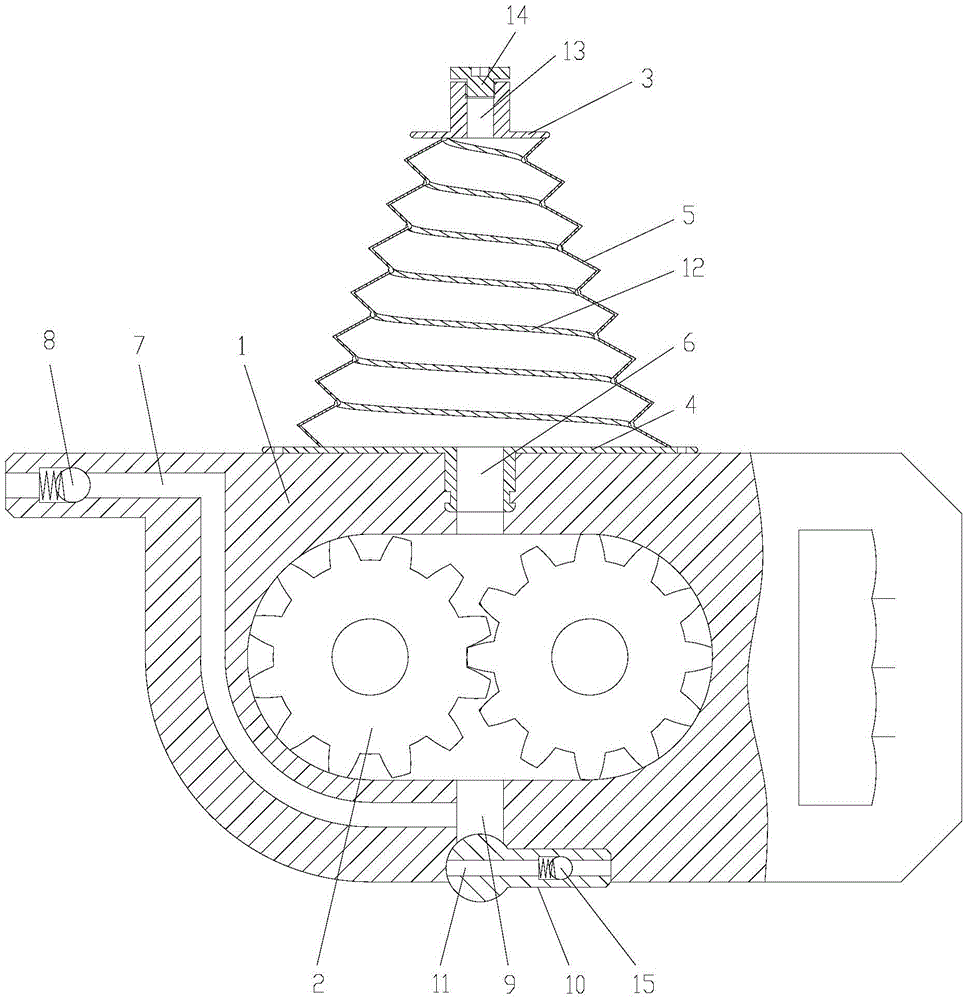

Grease injection device

InactiveCN105485502AShort grease flow pathFat injection resistance is smallEngine lubricationInjection devicePetroleum engineering

The invention discloses a grease injection device which comprises a device shell, two gears arranged in an inner cavity of the shell to form a gear pump structure and a grease bag fixed to the device shell and communicated with an oil suction cavity in the device shell. The grease bag comprises an upper connecting plate, a lower connecting plate and a tapered bag body fixed between the upper connecting plate and the lower connecting plate. The lower connecting plate is provided with an oil outlet for making an inner cavity of the tapered bag body communicated with the oil suction cavity of the device shell. According to the grease injection device, the grease bag and a pump body are combined into a whole, the grease flow path is short, the grease injection resistance is small, use is convenient, labor is saved, the grease in the tapered grease bag of the structure is fully sucked out conveniently, and the grease utilization rate can be increased.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

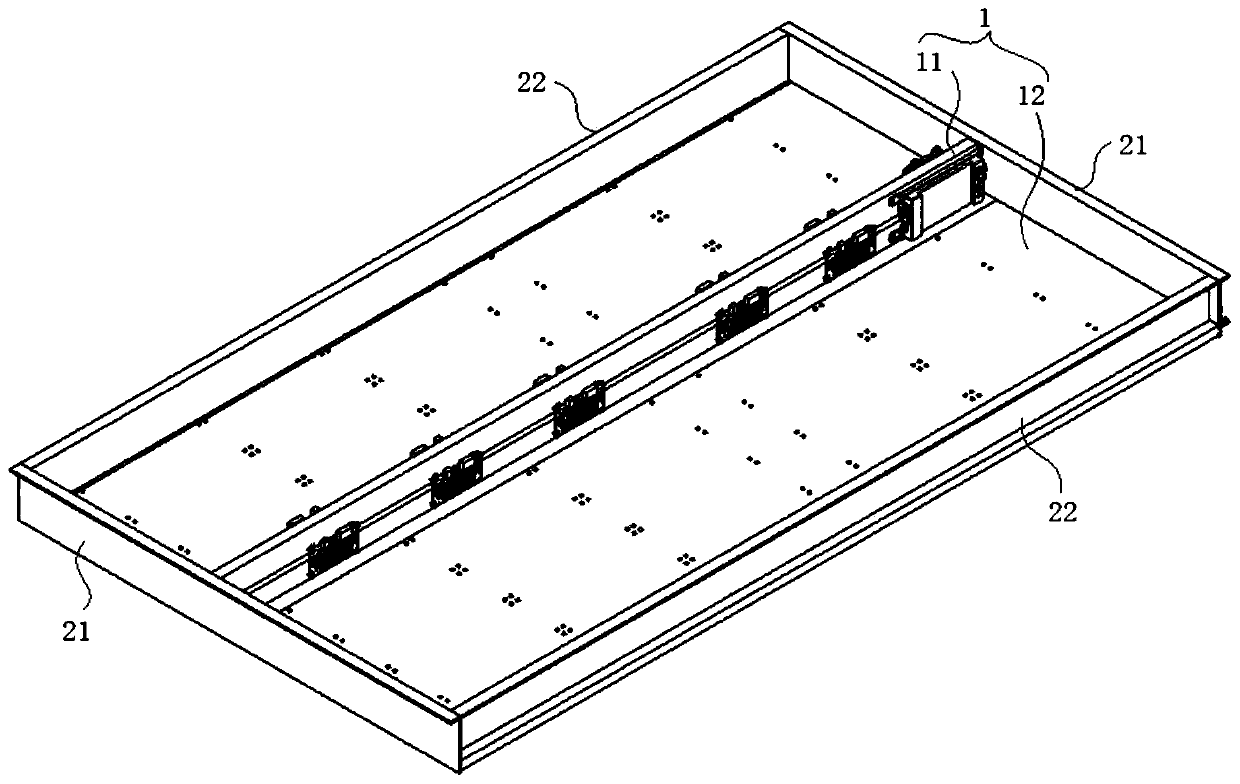

Power cell casing and power cell

InactiveCN110165109AReduce weightReduce volumeSecondary cellsCell component detailsInlet channelWater channel

The invention relates to a power cell casing and a power cell. The power cell casing is used for receiving a cell or a cell unit. The power cell casing is provided with a chamber structure for flowingof heat exchange liquid, wherein the chamber structure includes at least one water inlet channel and at least two water outlet channels extending in a longitudinal direction and multiple cooling water channels extending in a lateral direction, in the lateral direction, one water inlet channel is arranged between two adjacent water outlet channels, a set of heat exchange water channels is arrangedbetween the water inlet channel and the adjacent water outlet channel, each set of heat exchange water channels includes multiple heat exchange water channels, the multiple heat exchange water channels in the same set are in fluid communication in parallel between the water inlet channels and the adjacent water outlet channels, the casing includes a bottom plate used for fixing the cell or the cell unit, at least the water inlet channel and the heat exchange water channels are disposed on the bottom plate, and multiple turbulent structures spaced apart in the longitudinal direction are constructed in the water inlet channels. The power cell casing is advantaged in that the power cell casing can be both lightweight and with the heat exchange function for the single cell or the cell unit.

Owner:CH AUTO TECH CORP CO LTD

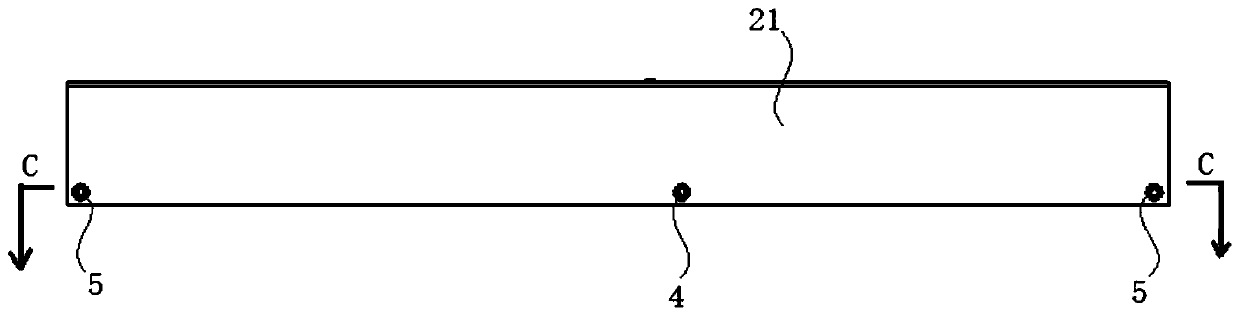

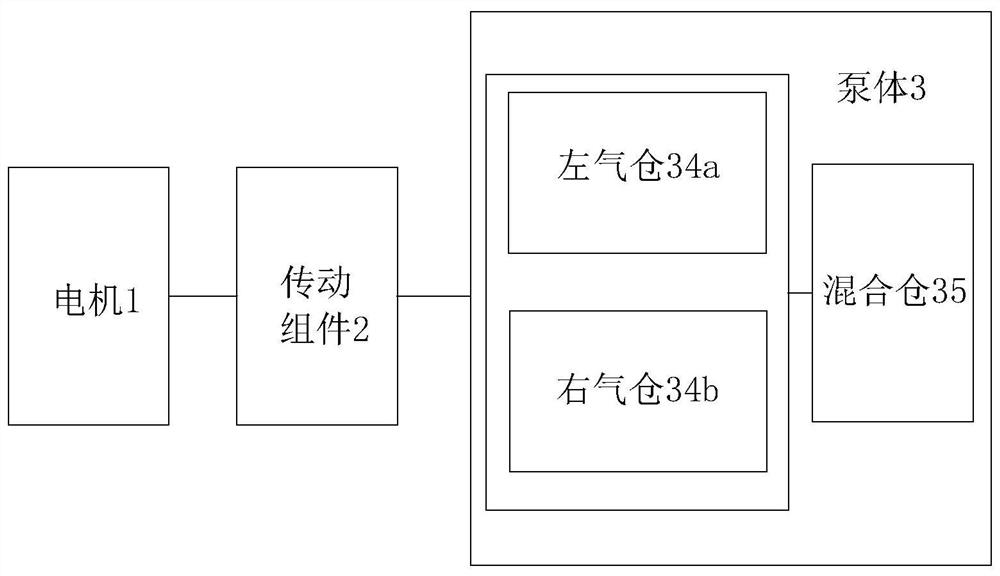

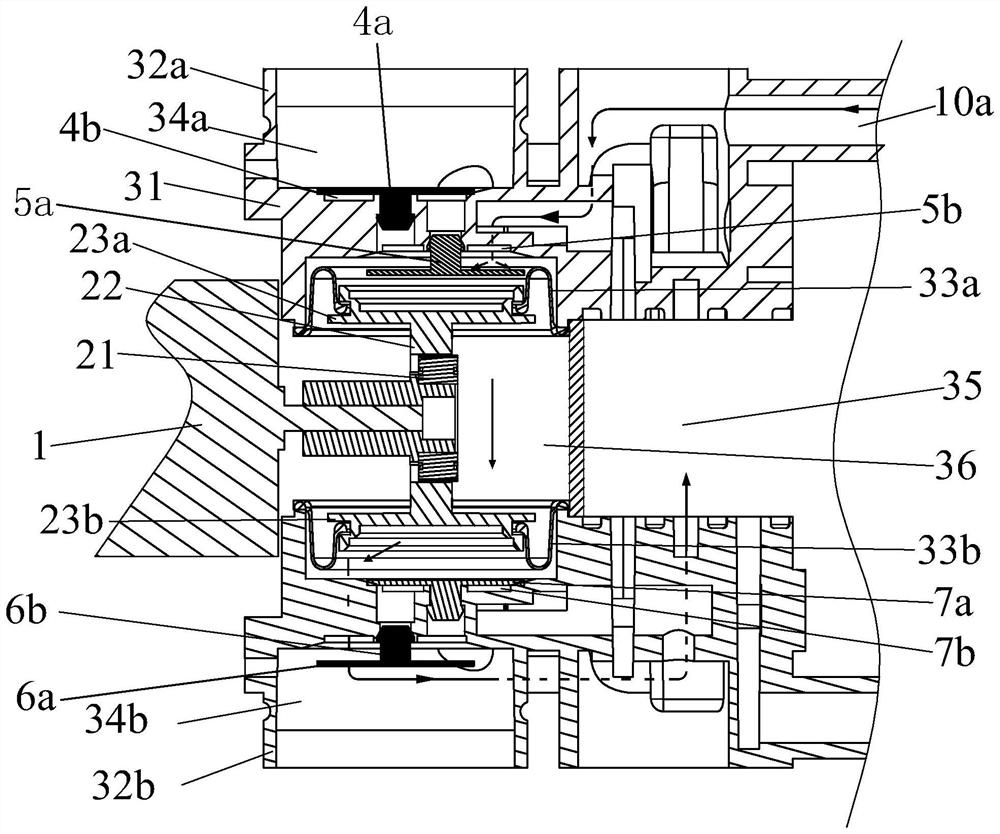

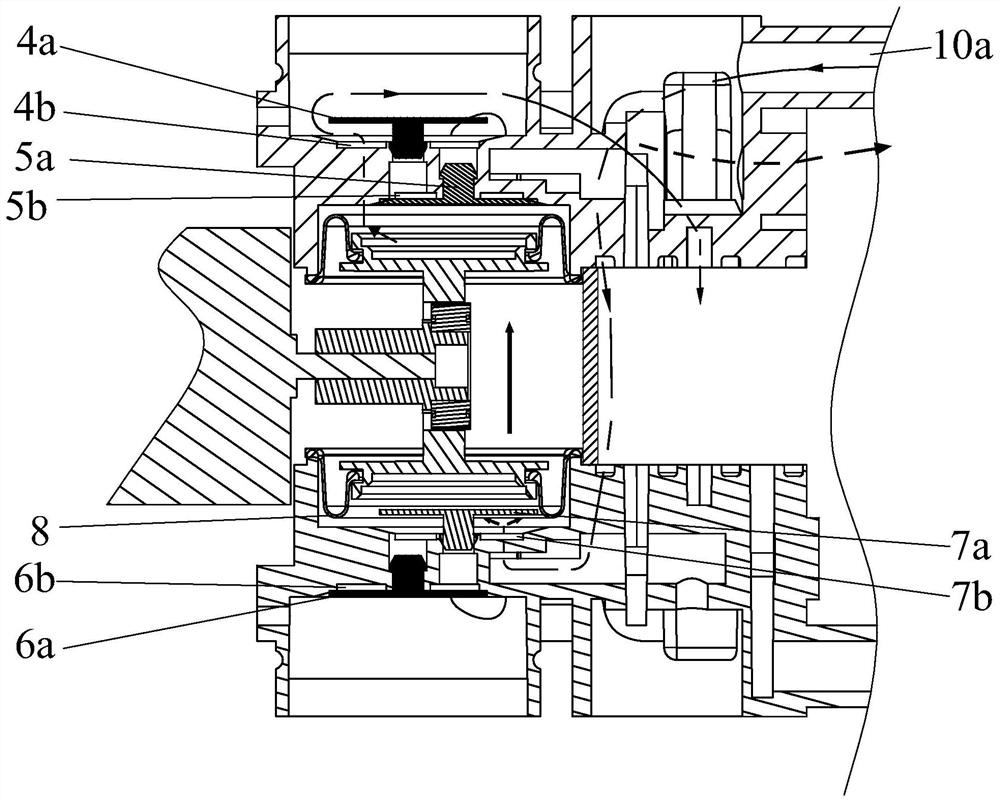

Miniature diaphragm pump with precise flow adjusting device

PendingCN114320857ASolve the problem of periodic traffic fluctuationsHigh measurement accuracyPositive displacement pump componentsWithdrawing sample devicesPhysicsElectric machinery

The invention discloses a miniature diaphragm pump with a precise flow adjusting device. The miniature diaphragm pump comprises a motor, a transmission assembly and a pump body. The pump body comprises a middle shell, a left shell, a right shell, a left diaphragm piece, a right diaphragm piece, a left air bin, a right air bin and a mixing bin, the left diaphragm piece is arranged between the middle shell and the left shell, the right diaphragm piece is arranged between the middle shell and the right shell, the middle shell is provided with a working bin, the left shell is provided with the left air bin, and the right shell is provided with the right air bin; the transmission assembly, the left diaphragm piece and the right diaphragm piece are arranged in the working bin, the motor sequentially drives the left diaphragm piece and the right diaphragm piece to reciprocate through the transmission assembly, external gas is sequentially squeezed into the left gas bin and the right gas bin, and gas in the left gas bin and the right gas bin flows into the mixing bin and then is output to the flow adjusting device through the mixing bin. The flow adjusting device comprises an adjusting motor, a speed adjusting assembly and an adjusting device, and the adjusting device is used for adjusting the flow. The miniature diaphragm pump is stable in flow, wide in measuring range and high in measuring precision.

Owner:SHENZHEN AMAE INSTR

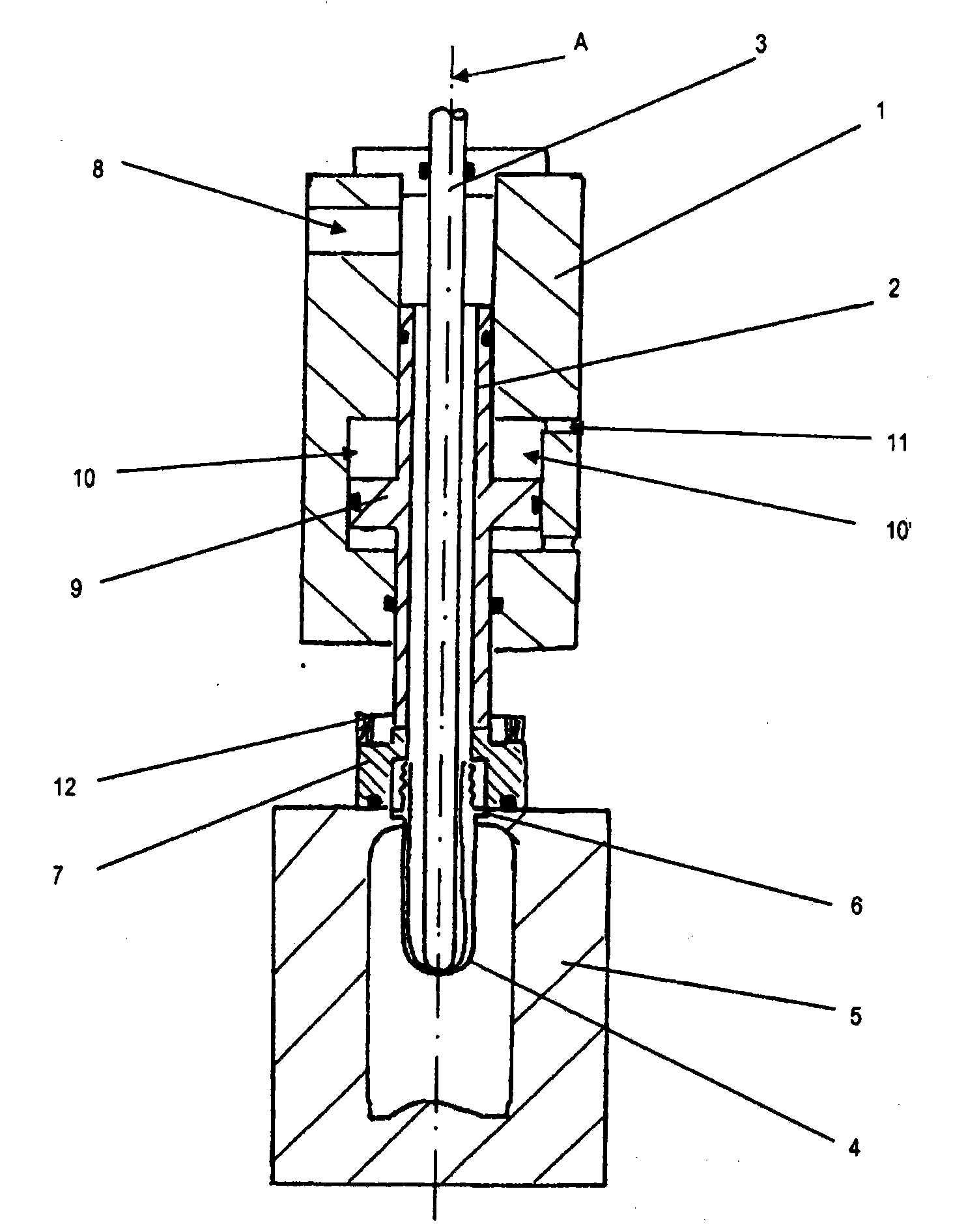

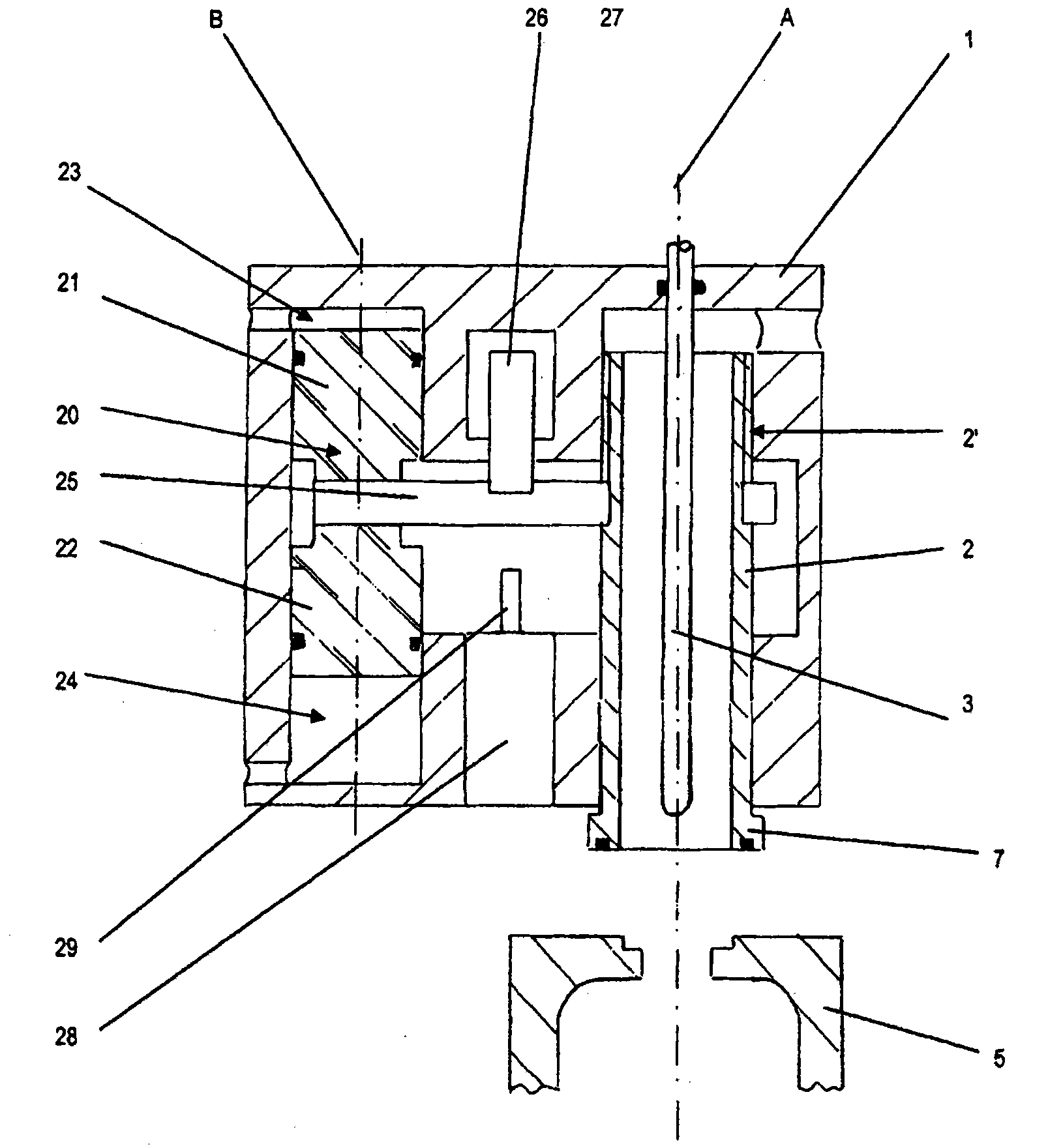

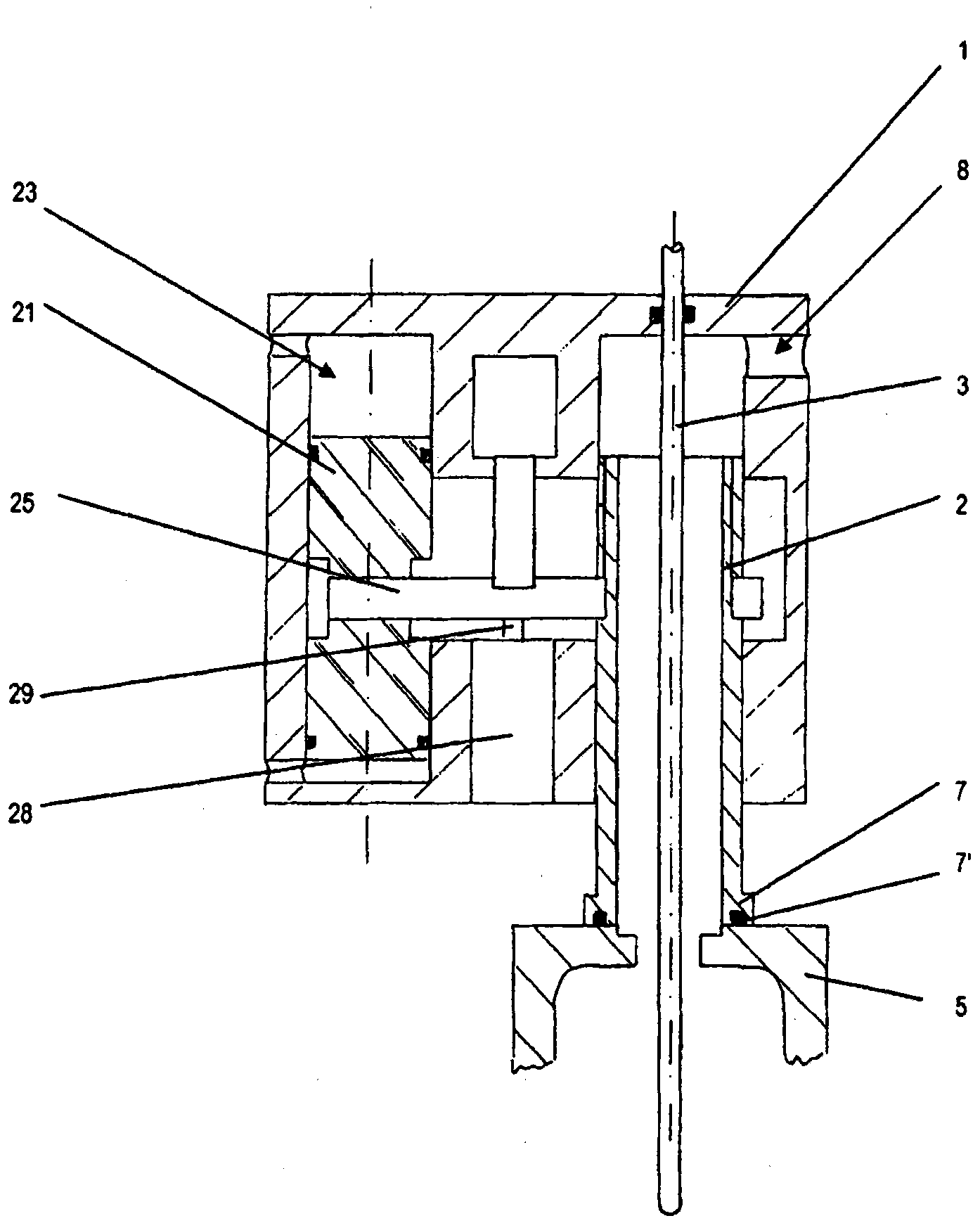

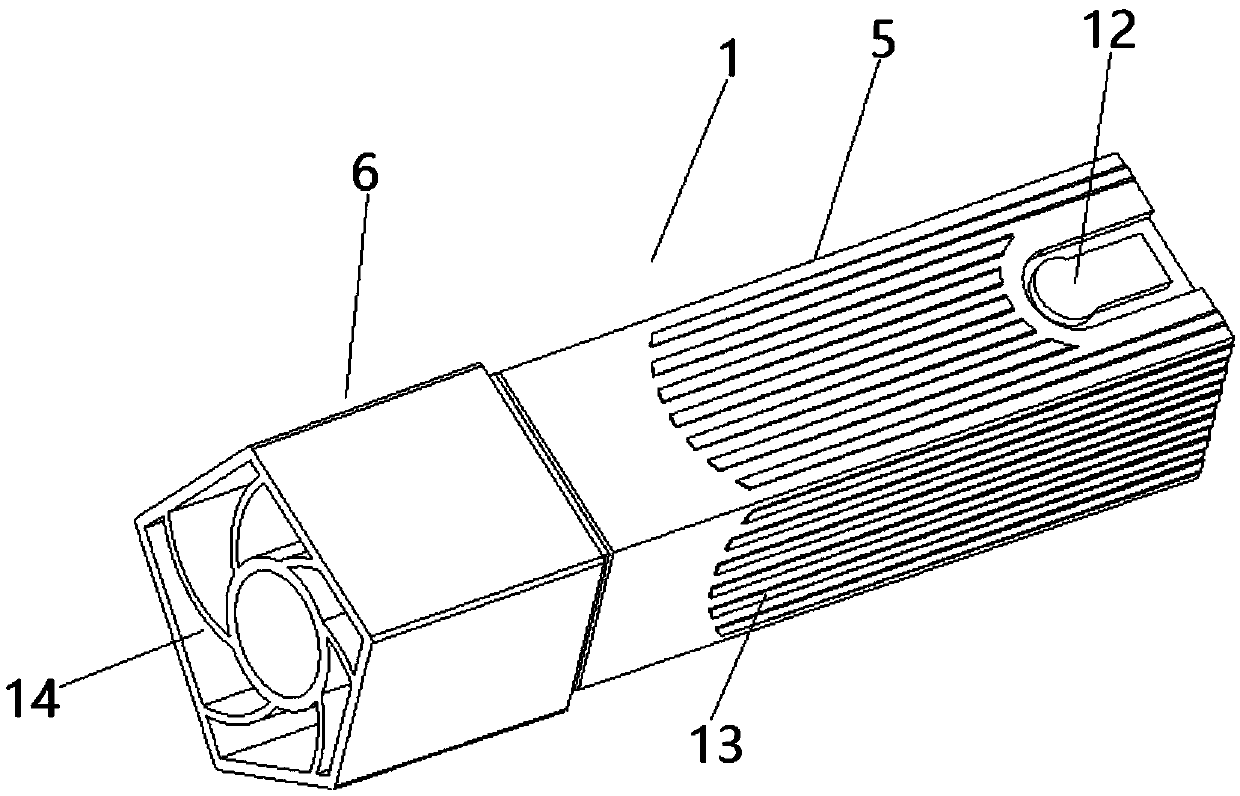

Device for injecting compressed air into a blow mold

The invention relates to a device for injecting compressed air into a parison, having an injection cylinder, having a hollow shaft (2) arranged inside the housing (1) of the injection cylinder in a manner so as to be displaceable along its longitudinal axis (A), one end of said hollow shaft projecting out of the housing (1) and provided with a connection head (7) for a tight connection to the parison, and having a stretching rod (3) arranged coaxially to the hollow shaft (2) in the interior of the hollow shaft (2) and displaceable coaxially with the hollow shaft (2). A double piston (21, 22) is arranged axially parallel to the hollow shaft (2). The double piston (21, 22) is connected to the hollow shaft (2) by a connection lug (25) and thereby moves the hollow shaft along its longitudinal axis (A) between a lower and an upper end position. The drive of the hollow shaft (2) therefore takes place not coaxially, but rather from the side via a piston axis (B) arranged parallel to the longitudinal axis (A) of the hollow shaft (2). In this way, the functioning of the air supply via the hollow shaft (2) and the movement of the coaxially arranged stretching rod (3) is separated from the drive of the hollow shaft (2).

Owner:오이겐자이츠아게

Device for detecting analyte in liquid sample

PendingCN110967478AEasy to collectEasy to detectAnalysis material containersWithdrawing sample devicesAnalyteEngineering

The invention discloses a device for detecting an analyte in a liquid sample. The device comprises a cup body, a first receiving zone for receiving a liquid sample; a flow guide channel through whicha sample can be added or collected. The flow guide channel is communicated with the first receiving area, and the bottom surface of the flow guide channel is an inclined surface. The first receiving area and the flow guide channel are arranged in the cup body. The device further comprises a secondary sampling port. The flow guide channel is a groove. A second receiving area is arranged in the groove. The second receiving area comprises a corner area used for collecting secondary samples. The invention also discloses a use method of the device for detecting the analyte in the liquid sample. Thedevice can be used for detecting the existence or quantity of analytes in a liquid sample, and can still detect the liquid sample under the condition that the liquidity of the liquid sample is extremely poor and / or the sample amount is extremely small, and an operator can conveniently suck the liquid sample to carry out secondary confirmation detection.

Owner:ZHEJIANG ORIENT GENE BIOTECH

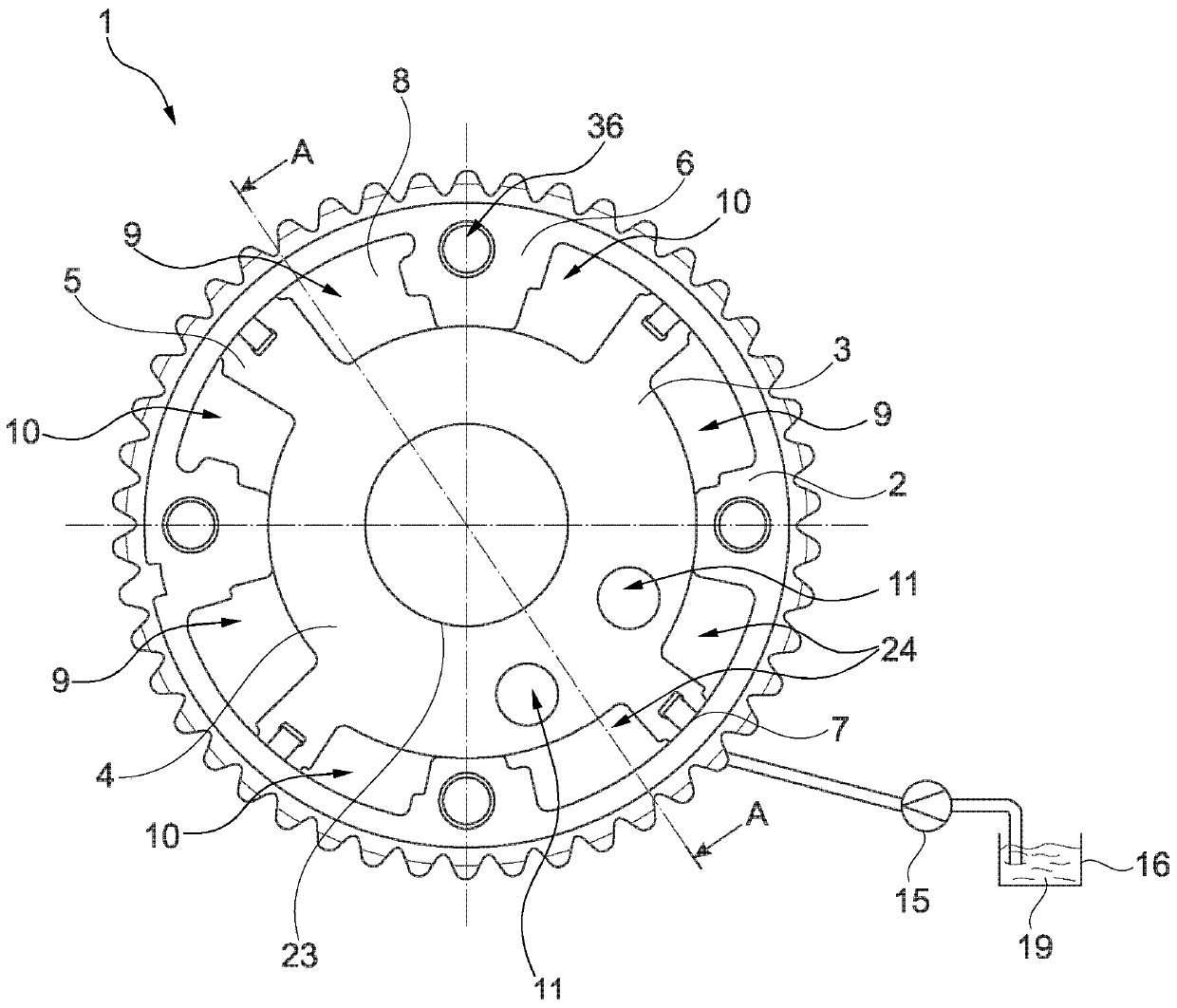

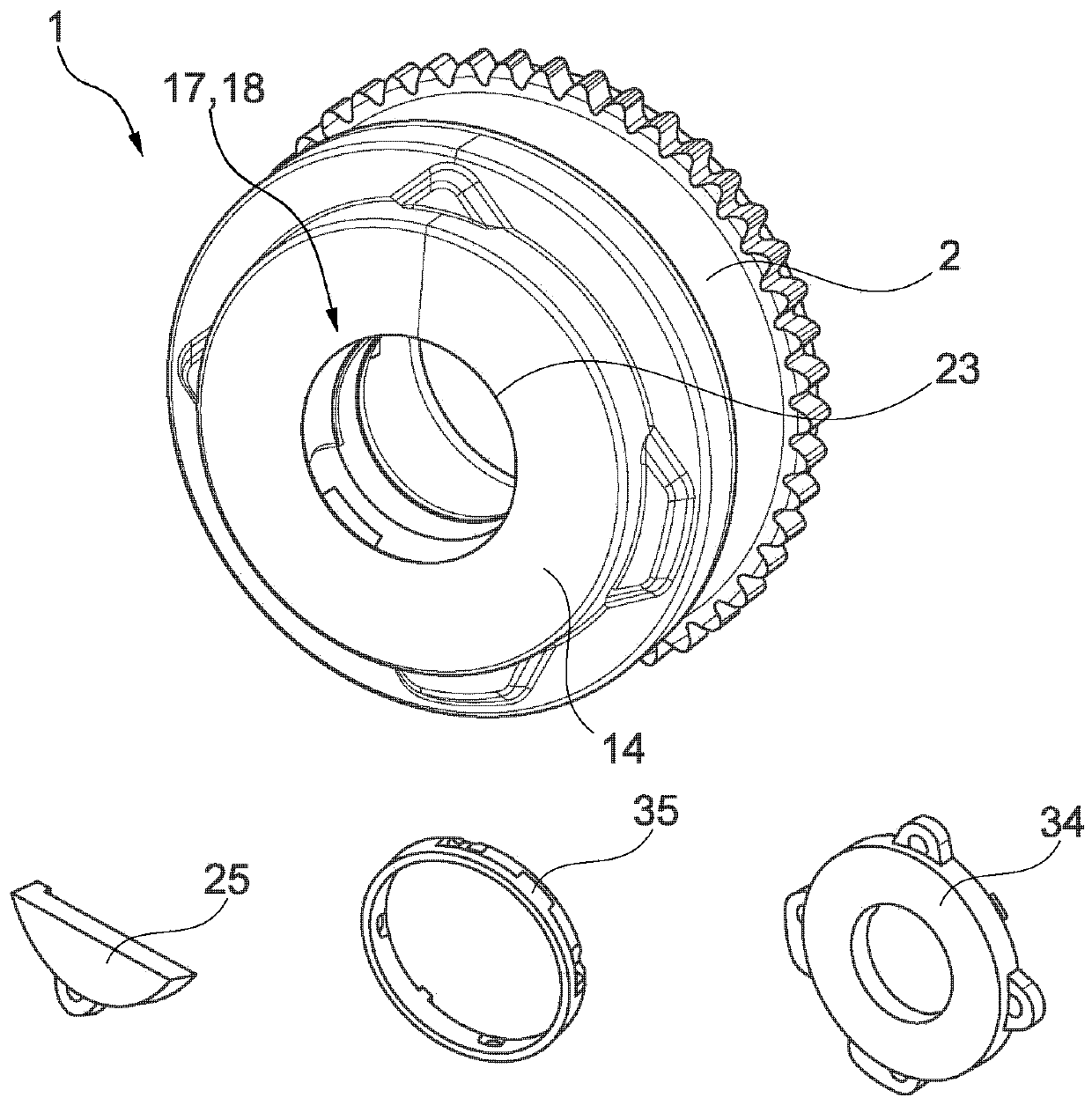

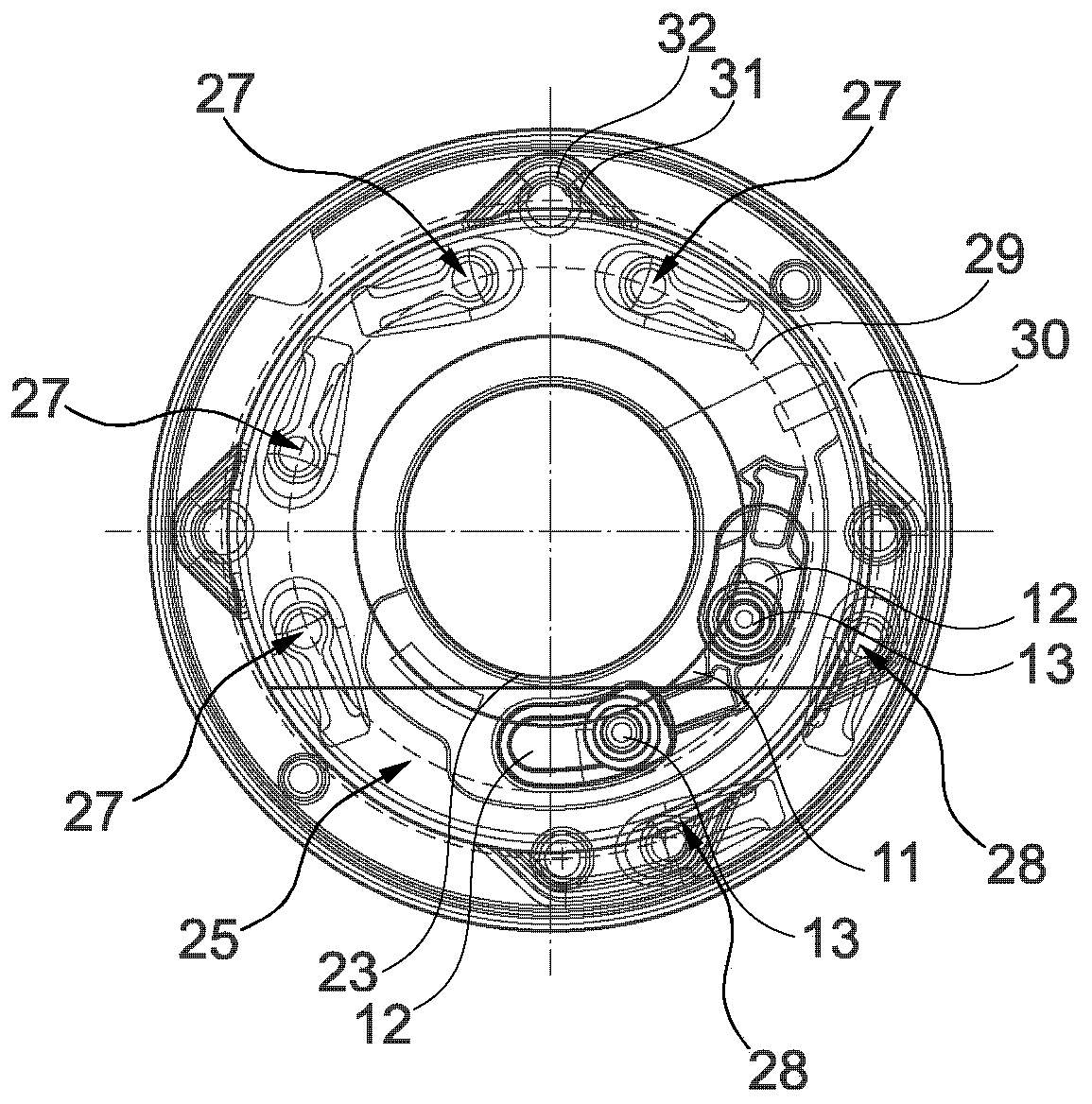

Hydraulic camshaft adjuster, and method for operating the hydraulic camshaft adjuster

ActiveCN110730856AEnsure pressure medium supplyEasy to twistValve arrangementsMachines/enginesEngineeringInternal combustion engine

The invention relates to a hydraulic camshaft adjuster (1) for adjusting the control time of gas exchange valves of an internal combustion engine, comprising a stator (2) which can be synchronously rotated by the crankshaft of the internal combustion engine, and a rotor (3) which is mounted so as to rotate with the stator (2), and which can synchronously rotate with the camshaft, several ribs (6)being provided on the stator (2), the ribs dividing an annular chamber (7) between the stator (2) and the rotor (3) into a plurality of pressure chambers (8), wherein the rotor (3) comprises a rotor hub (4) and a plurality of vanes (5) extending radially outward from the rotor hub (3), the pressure chamber (8) being divided into two groups of working chambers (9, 10) having a different direction of work and being impinged upon by respectively a pressure medium (19) upstream or downstream in a pressure medium circuit, and comprising a central locking mechanism (11) for locking the rotor (3) ina central position, wherein the hydraulic camshaft adjuster (1) is connected at least partially to a front side (20, 21) by a cover (17, 18), wherein a reservoir (14) for storing the pressure medium (19) is formed in one of the covers (17, 18). The cover (17, 18) comprises an overflow opening (23) through which the pressure medium (19) can exit in the axial direction from the hydraulic camshaft adjuster (1), and wherein the reservoir (14) is dimensioned in relation to the overflow opening (23) such that when the hydraulic camshaft adjuster (1) is at a standstill, a pressure medium (25) remainsat the bottom in the reservoir (14), which ensures the pressure medium is supplied to the return valve (28) of the central locking mechanism (11) when the hydraulic camshaft adjuster (1) is running.The invention also relates to a method for operating said type of camshaft adjuster (1).

Owner:SCHAEFFLER TECH AG & CO KG

Air-cooled hydrogen fuel cell based on single metal polar plate and electric pile

InactiveCN111048801ACompact structureImprove power densityFuel cell heat exchangeCollectors/separatorsChemical physicsElectrical battery

The invention provides an air-cooled hydrogen fuel cell based on a single metal polar plate. The fuel cell comprises a metal polar plate and a reaction flow channel, the metal polar plate is the single metal polar plate, one side of the metal polar plate is provided with a cathode gas reaction flow channel and a cooling medium flow channel, the cathode gas reaction flow channel and the cooling medium flow channel are the same flow channel, and the other side of the metal polar plate is provided with an anode gas reaction flow channel. The structure and the system of the fuel cell are more compact, power density of the cell is improved, the cathode reaction gas flow channel provides excessive reaction gases, oxygen needed by reaction is provided, heat generated by reaction of the fuel cellis cooled, the structure of the fuel cell is simplified, welding of bipolar plates is avoided, and complexity of the fuel cell is simplified. An electric pile comprises a single cell, and the single cell is the air-cooled hydrogen fuel cell based on the single metal polar plate.

Owner:GREE ELECTRIC APPLIANCES INC

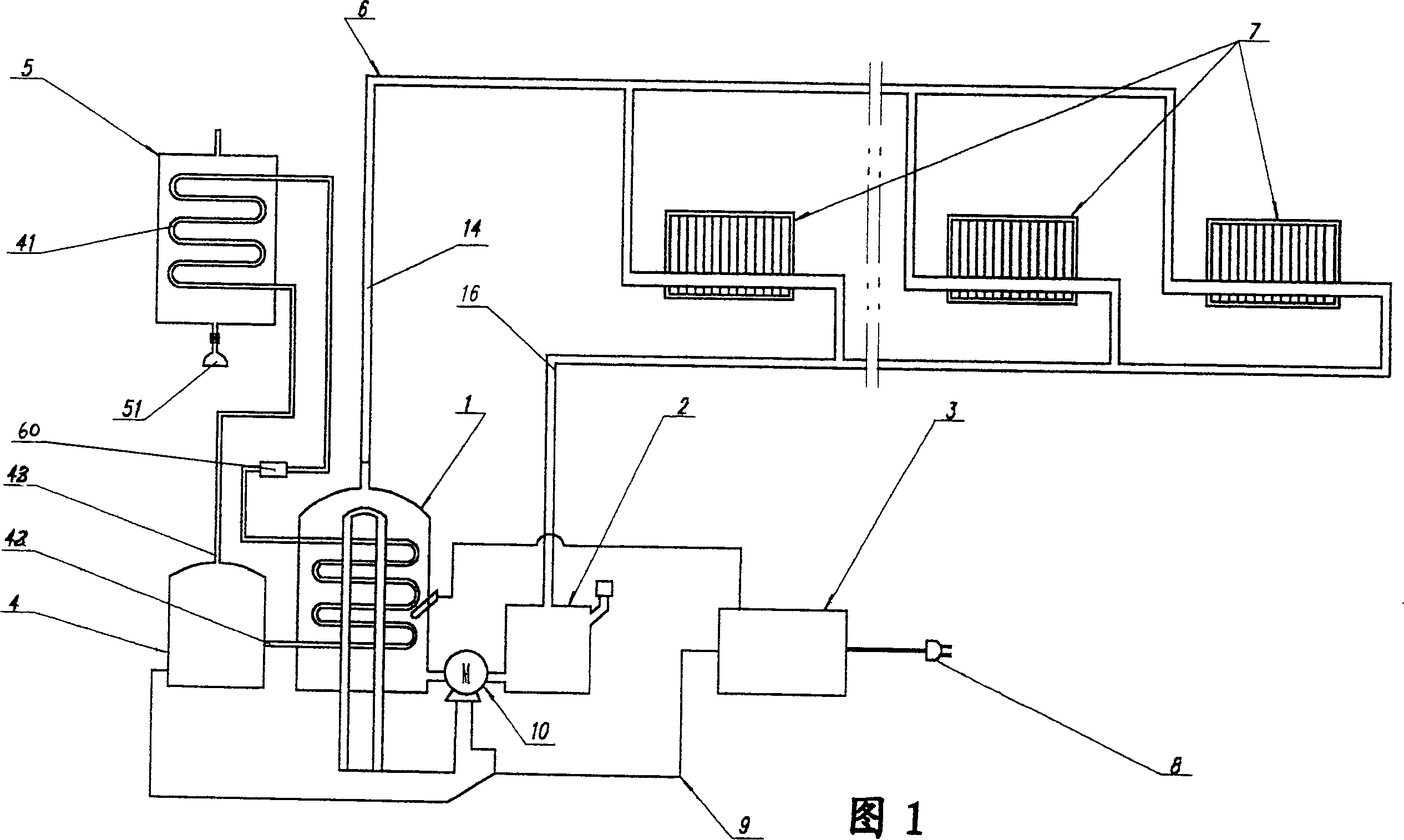

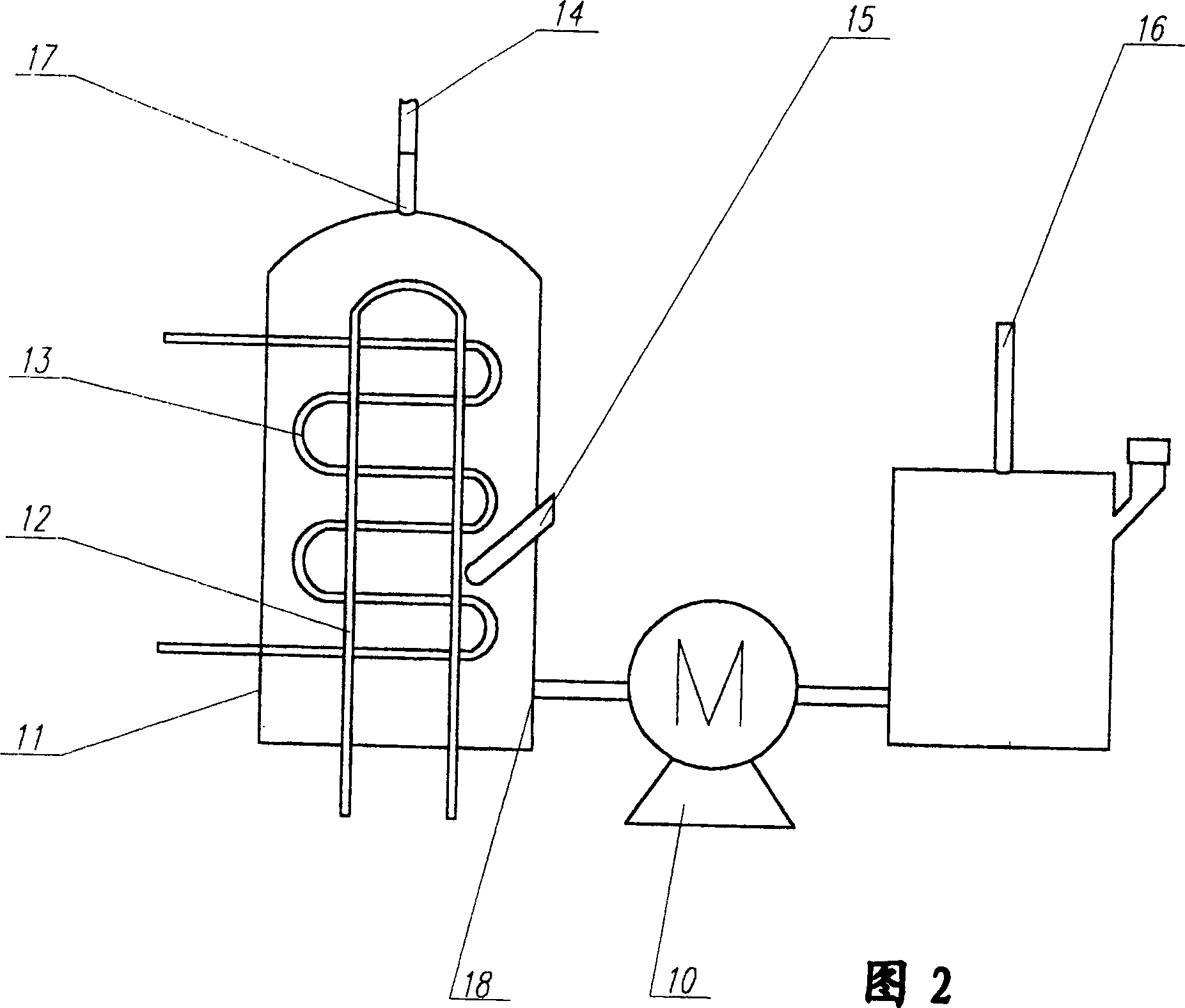

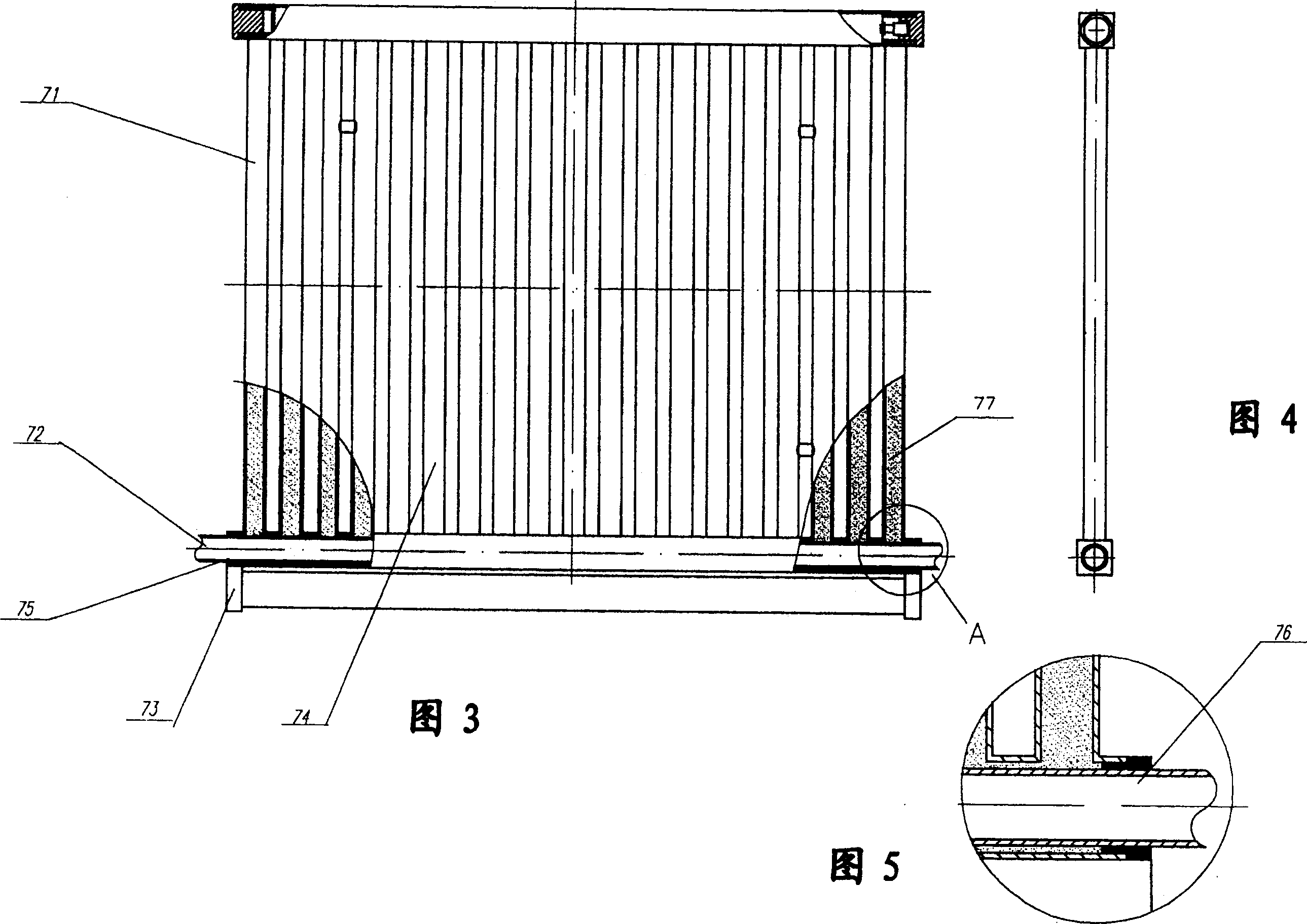

Indoor air temp adjusting system

InactiveCN1328558CReduce weightHeating fastHeating and refrigeration combinationsLithium bromideEngineering

Owner:邓明善

heart assist device

ActiveCN105561412BReduce energy consumptionImprove efficiencyControl devicesIntravenous devicesSurgeryCardiac Ventricle

Owner:深圳市华畅医疗创新有限公司

Liquid flow alkalization method and alkalization device

InactiveCN1971281AChange flow rateShort flow pathChemical methods analysisDiisopropylamine dichloroacetateEngineering

A liquid flow basification method and basification device are disclosed which belong to the technique field of chemical analysis. The volatile gas of strong base solution of the diisopropylamine dichloroacetate which penetrates the microporous polytetrafluoroethylene film is mixed with the flowing liquid to realize the auto basification of the liquid, and changes the flow speed to control the PH value. Said device contains: basification bottle and basification pool, the microporous polytetrafluoroethylene is mounted flatwise between the base plate and upper cover, the bore diameter is 20-100 mum, the imports and exports of liquid, flow cavity, basification bottle and the base plate are connected hermetically with the upper cover. The invention is used for the basification of liquid in the chemical analysis, flow circuit short, save time, save agent, avoid the cross contamination and improve the precision of analysis; and the device is simple in structure, easy to disassemble, convenient to maintain and clean, and good utilization effect.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

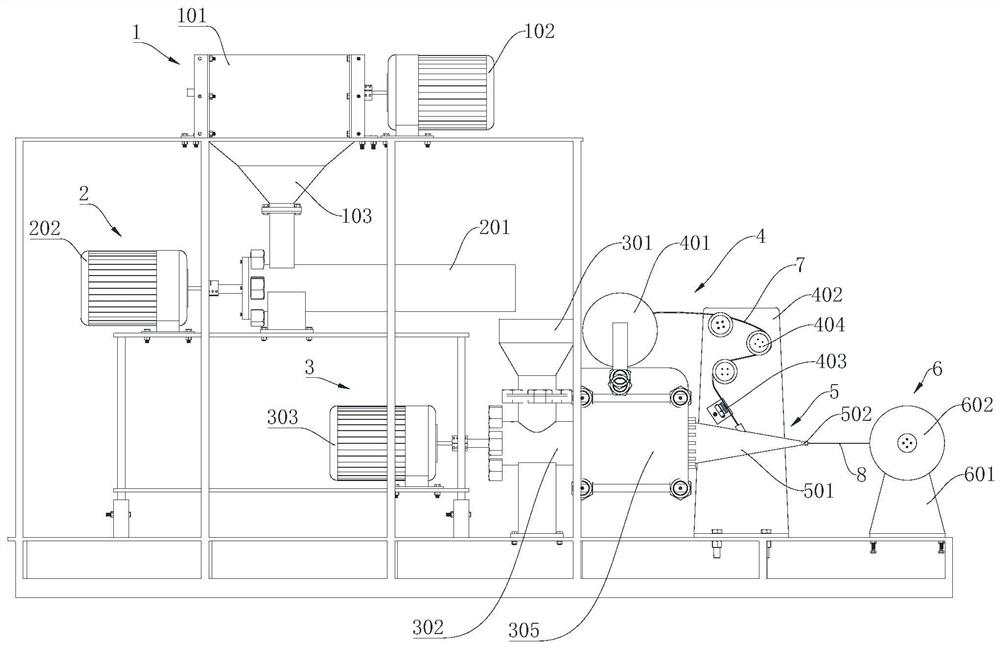

Continuous fiber reinforced composite wire manufacturing equipment

ActiveCN112936806ASimple structureShort flow pathPlastic recyclingCoatingsFiber-reinforced compositeMechanical engineering

The invention provides continuous fiber reinforced composite wire manufacturing equipment. The continuous fiber reinforced composite wire manufacturing equipment comprises a crushing mechanism, a conveying mechanism, a melting mechanism, a wire feeding mechanism, an extruding mechanism and a wire collecting mechanism; the conveying mechanism is in butt joint with the crushing mechanism, and is used for conveying crushed raw materials; the melting mechanism is in butt joint with the conveying mechanism, and is used for heating the crushed raw materials to form molten basal bodies; the wire feeding mechanism is used for conveying continuous fibers; the extruding mechanism is provided with a first shell in the shape of a conical cylinder; a large end of the first shell is directly in butt joint with an outlet of the melting mechanism, and a nozzle is arranged at a small end; a fiber inlet for enabling the continuous fibers to enter is formed in the side wall of the first shell; and the wire collecting mechanism is used for collecting continuous fiber reinforced composite wires sprayed out by the nozzle. According to the continuous fiber reinforced composite wire manufacturing equipment, the design difficulty of the nozzle is reduced, and meanwhile, optimization of the overall structure of the equipment is facilitated.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Electric heating wire seat

PendingCN111407105AHigh resistivityImprove insulation performanceStoolsFurnace heating elementsInsulation layerEngineering

The invention provides an electric heating wire seat. The electric heating wire seat comprises a seat body and an electric heating wire module embedded in the seat body, the electric heating wire module comprises a plate body, an electric heating wire module body fixedly arranged on the plate body and a heat insulation layer, the heat insulation layer is fixedly arranged on the lower surface of the plate body, a cavity with an upper opening is formed in the seat body, the electric heating wire module body is fixedly arranged in the cavity, the heat insulation layer makes contact with the cavity bottom of the cavity, and a decorative surface layer is installed at the upper opening of the cavity. The electric heating wire module is used for heating the seat body and the decorative surface layer after being electrified, a pressure sensor is arranged on the decorative surface layer, the pressure sensor is electrically connected with a processor, the processor is electrically connected witha controller, the controller is electrically connected with the electric heating wire module, and the controller controls the working condition of the electric heating wire module. The decorative surface layer is heated through the electric heating wires, and the comfort of a user is improved.

Owner:CHINA NORTHWEST ARCHITECTURE DESIGN & RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com