Hydraulic camshaft adjuster, and method for operating the hydraulic camshaft adjuster

A camshaft adjuster, hydraulic technology, applied in the direction of machine/engine, engine lubrication, engine components, etc., can solve problems such as expensive and troublesome, and achieve the effect of reducing the risk of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

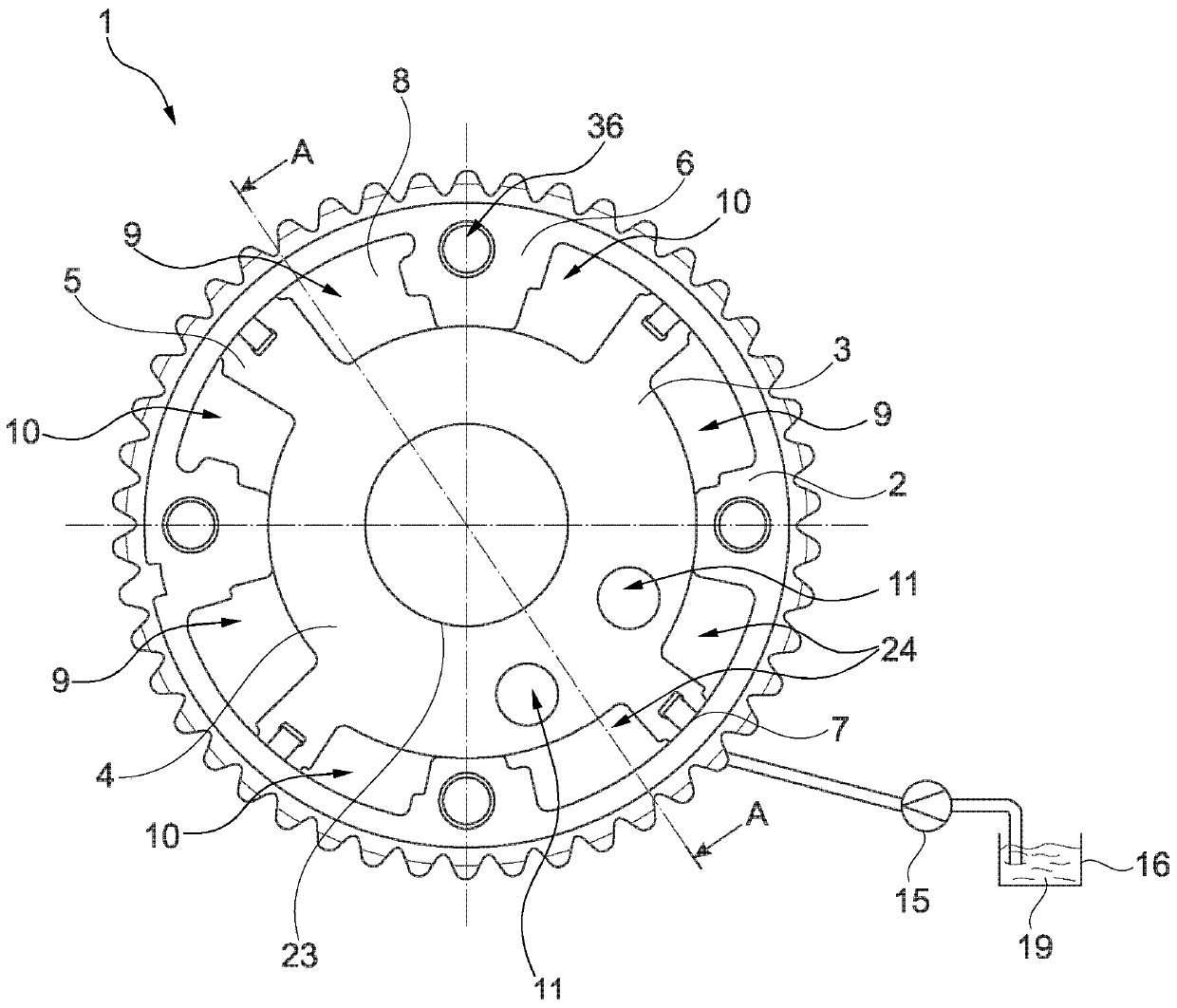

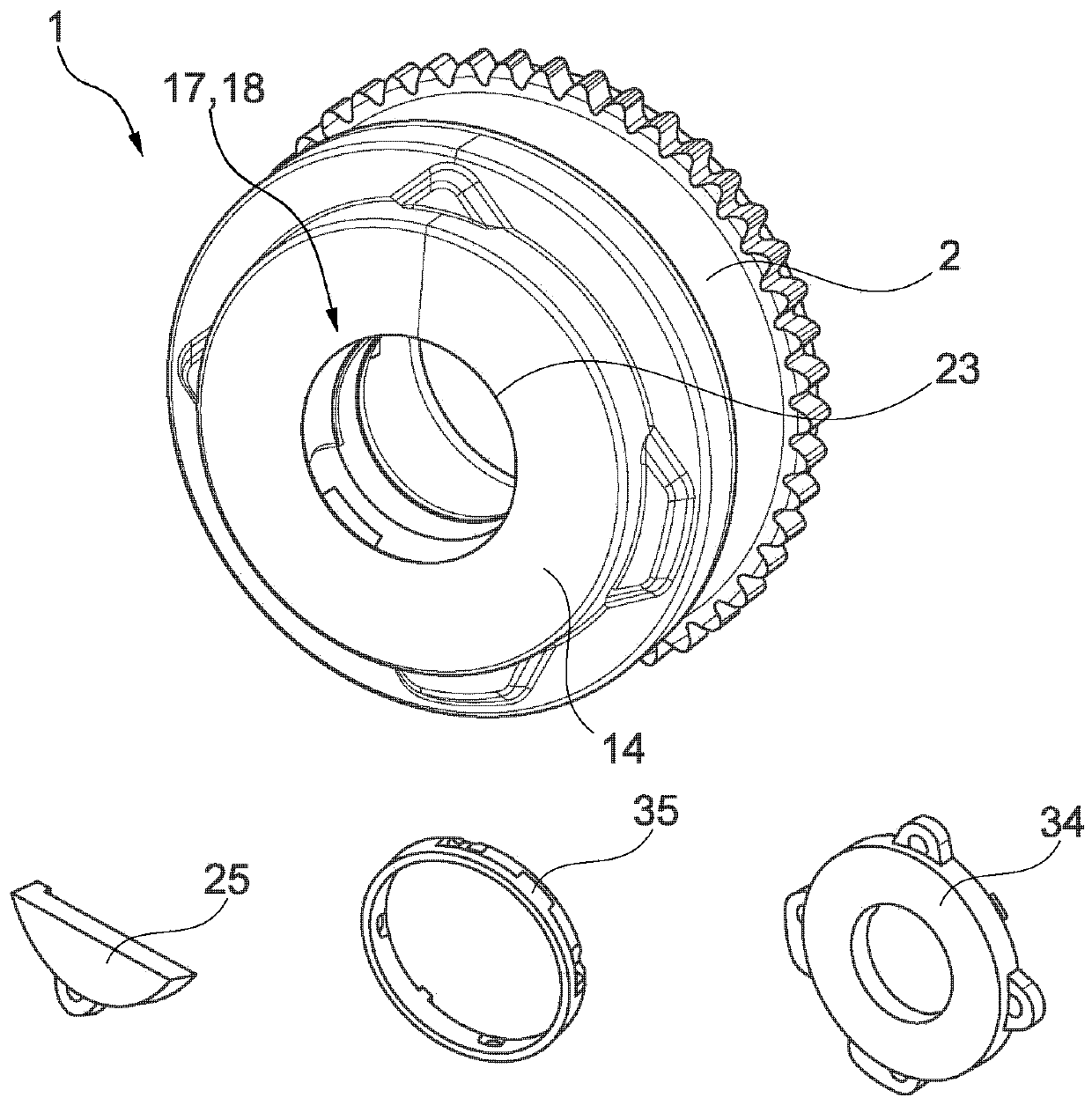

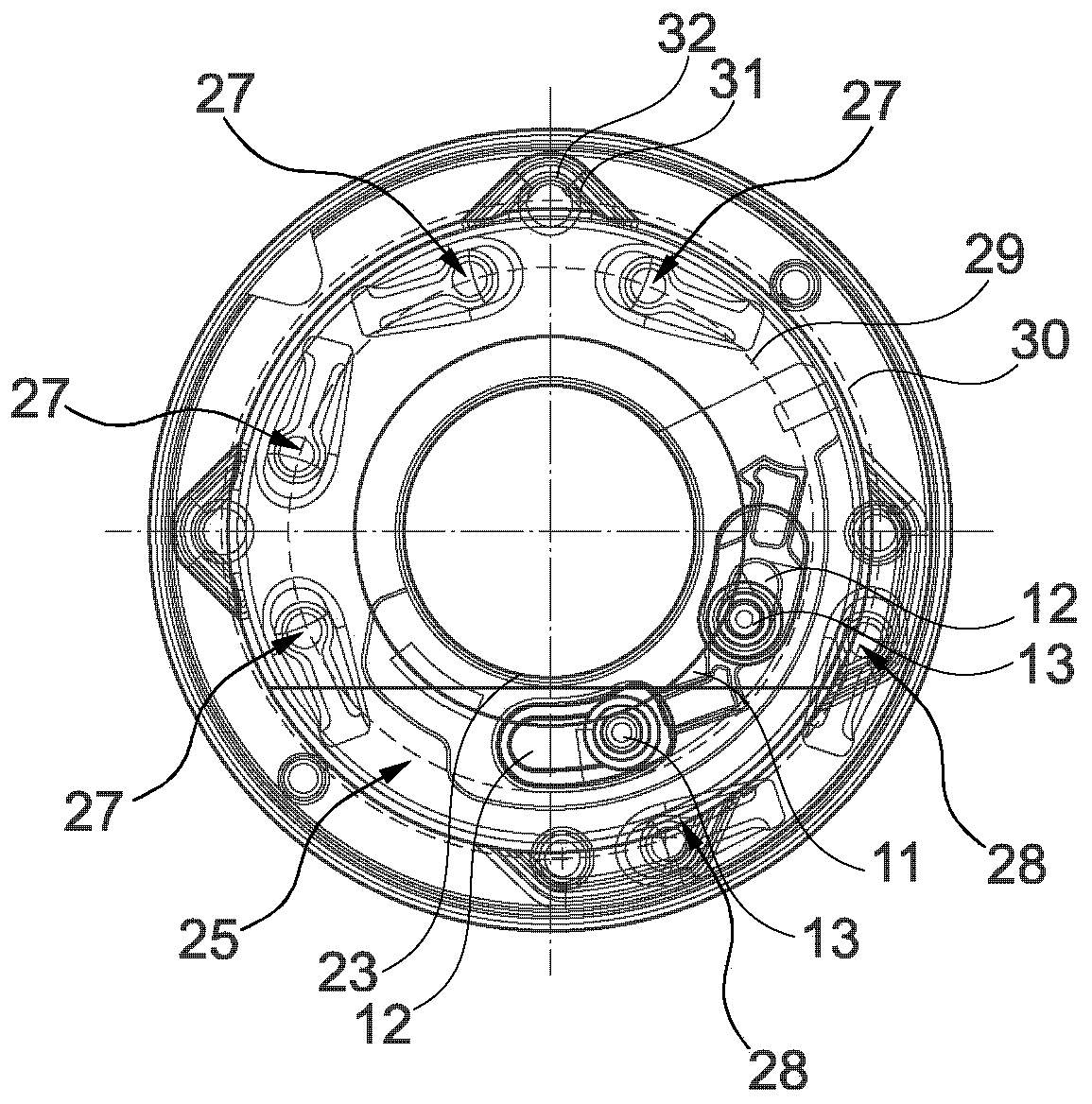

[0028] exist figure 1 An exemplary embodiment of a hydraulic camshaft adjuster 1 according to the invention is shown in FIG. 1 , which is used for adjusting the valve timing of an internal combustion engine. exist figure 1 The hydraulic camshaft adjuster 1 shown schematically in the figure is configured in a known manner as a vane adjuster and comprises a stator 2 that can be driven by the crankshaft of the internal combustion engine, not shown here, and a The camshaft is connected to the rotor 3 in a rotationally fixed manner. The rotor 3 has a rotor hub 4 from which a plurality of blades 5 extend in radial direction. In the illustration shown, a hydraulic camshaft adjuster 1 is shown with a stator 2 and a rotor 3 in section. The stator 2 has webs 6 which divide the annular space between the stator 2 and the rotor 3 into pressure chambers 8 . The pressure chambers 8 are divided by the vanes 5 of the rotor 3 into two groups of working chambers 9 , 10 with different directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com