Plate type heat exchanger and plate type laminated sheet thereof

A technology of heat exchange plates and laminations, which is applied in the direction of heat exchangers, indirect heat exchangers, heat exchange equipment, etc., and can solve the problems of reducing heat exchange efficiency, uneven flow of refrigerant or refrigerant, and the overall size of plate laminations. Unreasonable and other problems, to achieve the effect of improving heat transfer performance, reducing flow resistance, and increasing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

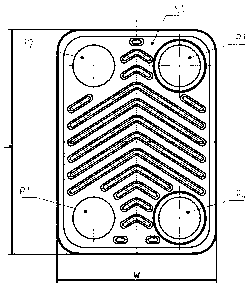

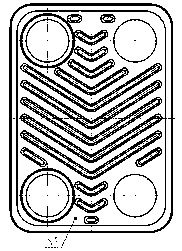

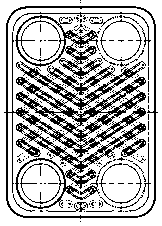

[0026] The core of the present invention is to provide a plate laminate of a plate heat exchanger. By designing and optimizing the structural parameters of the laminate, the uniformity of the refrigerant flow from the inlet pipe P1 to the outlet pipe P2 is ensured, thereby improving the heat exchange performance; at the same time, In the circulation channel surrounded by adjacent laminations, since the hotter refrigerant flows from the inlet pipe P3 to the outlet pipe P4, the flow path is relatively short, thereby reducing the flow resistance and increasing the flow rate, thereby improving the heat exchange efficiency and reducing the The power consumption of the water pump in the cooling subsystem.

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the following in conjunction with the attached figure 1 -14 and specific embodiment are described in further detail to the present invention.

[0028] A plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com