Ventilation of a high-pressure turbine in a turbomachine

A technology of high-pressure turbines and turbines, which is applied in the cooling of turbines/propulsion devices, cooling of engines, mechanical equipment, etc. It can solve problems such as unbalanced pressure and difficult control of turbines, and achieve the goal of reducing weight, reducing risks, and increasing service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

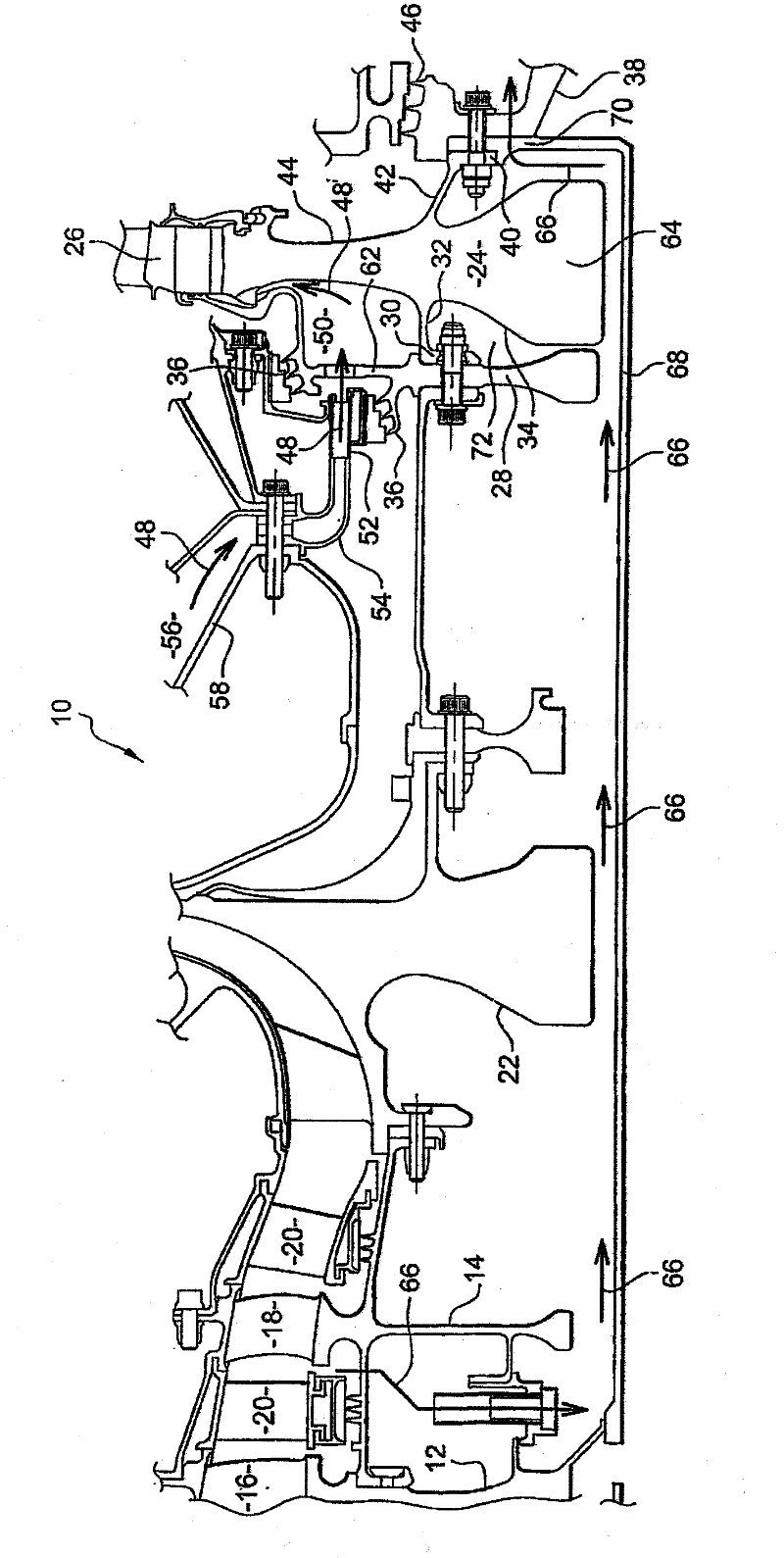

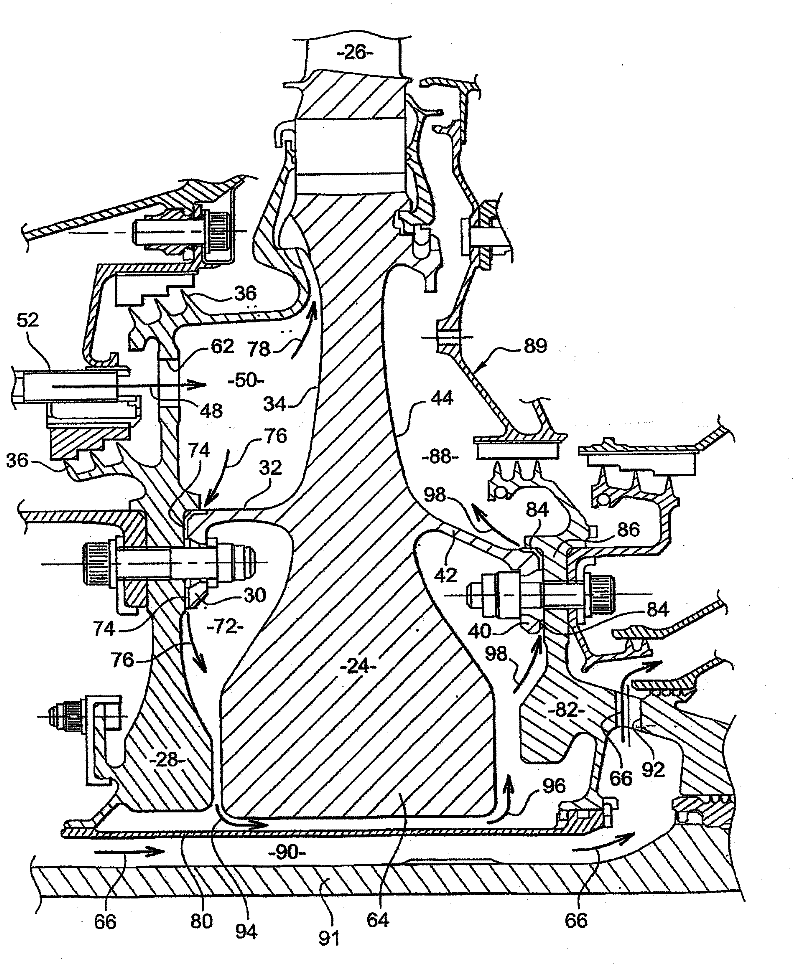

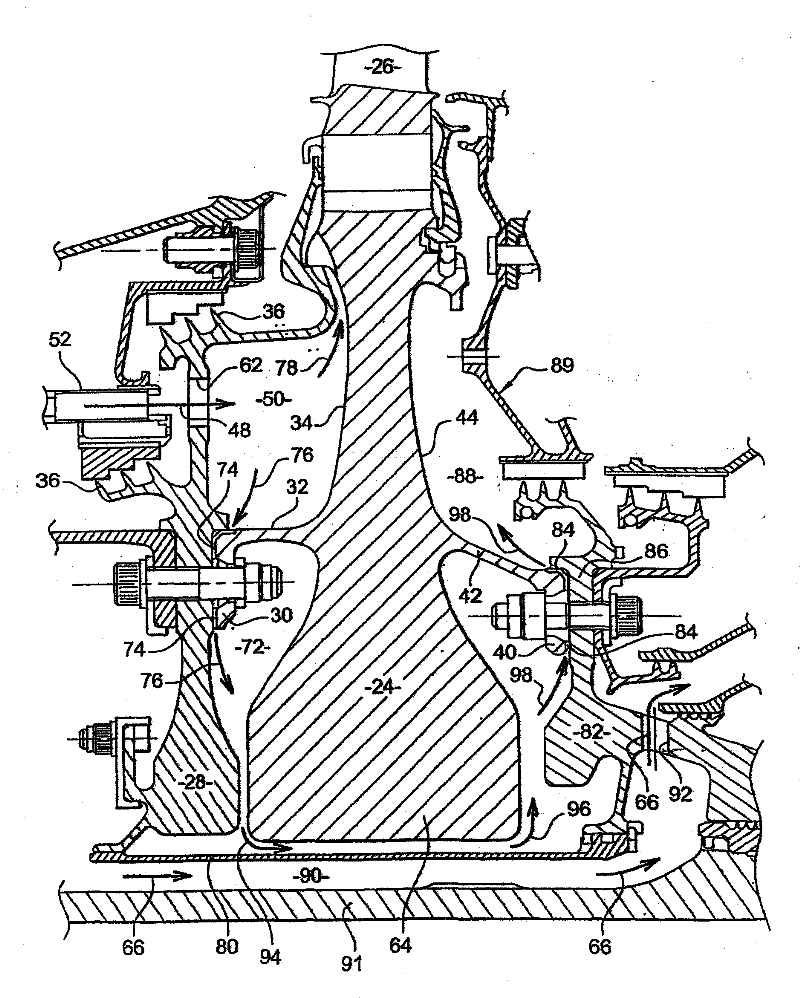

[0042] figure 1 A twin-rotor aircraft turbojet engine 10 of known type is shown, notably comprising (from upstream to downstream) a high-pressure compressor, a combustion chamber and a high-pressure turbine.

[0043] The high pressure compressor comprises a rotor consisting of disks 12, 14 with blades 16, 18 between which a stator stage 20 is placed for directing the flow of air through the compressor. The high-pressure compressor is provided with a centrifugal impeller 22 at its outlet for delivering compressed air to the combustion chamber.

[0044] The high-pressure turbine basically comprises a rotor disk 24 with blades 26 extending within the flow section of the combustion gases exiting the combustion chamber for the purpose of extracting mechanical energy from the gas flow in order to transmit rotational power to the high-pressure turbine and Rotor of high pressure compressor. Around the blades 26 of the rotor disk are sector-shaped sealing rings (not shown) which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com