Patents

Literature

408results about "Furnace heating elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

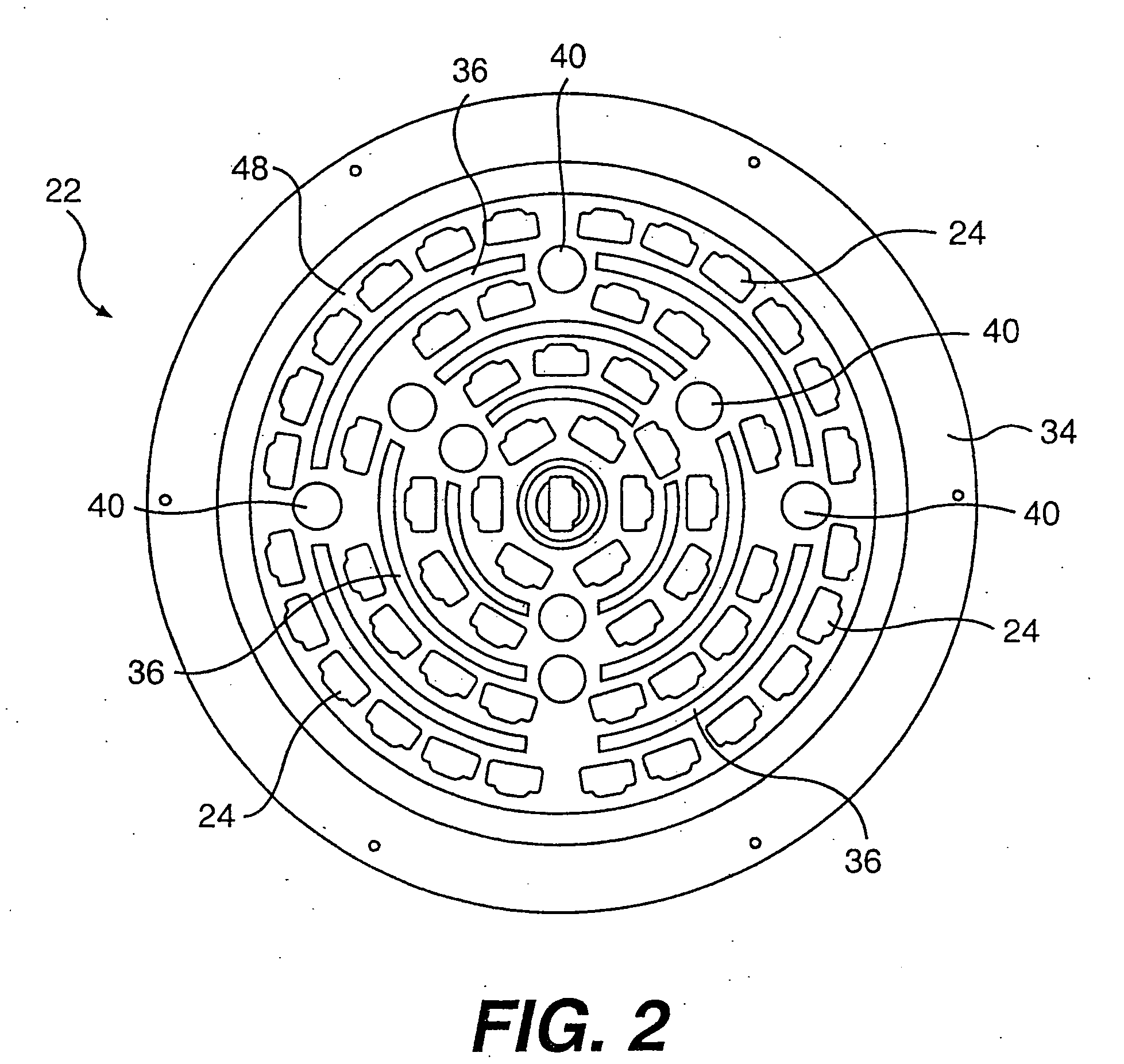

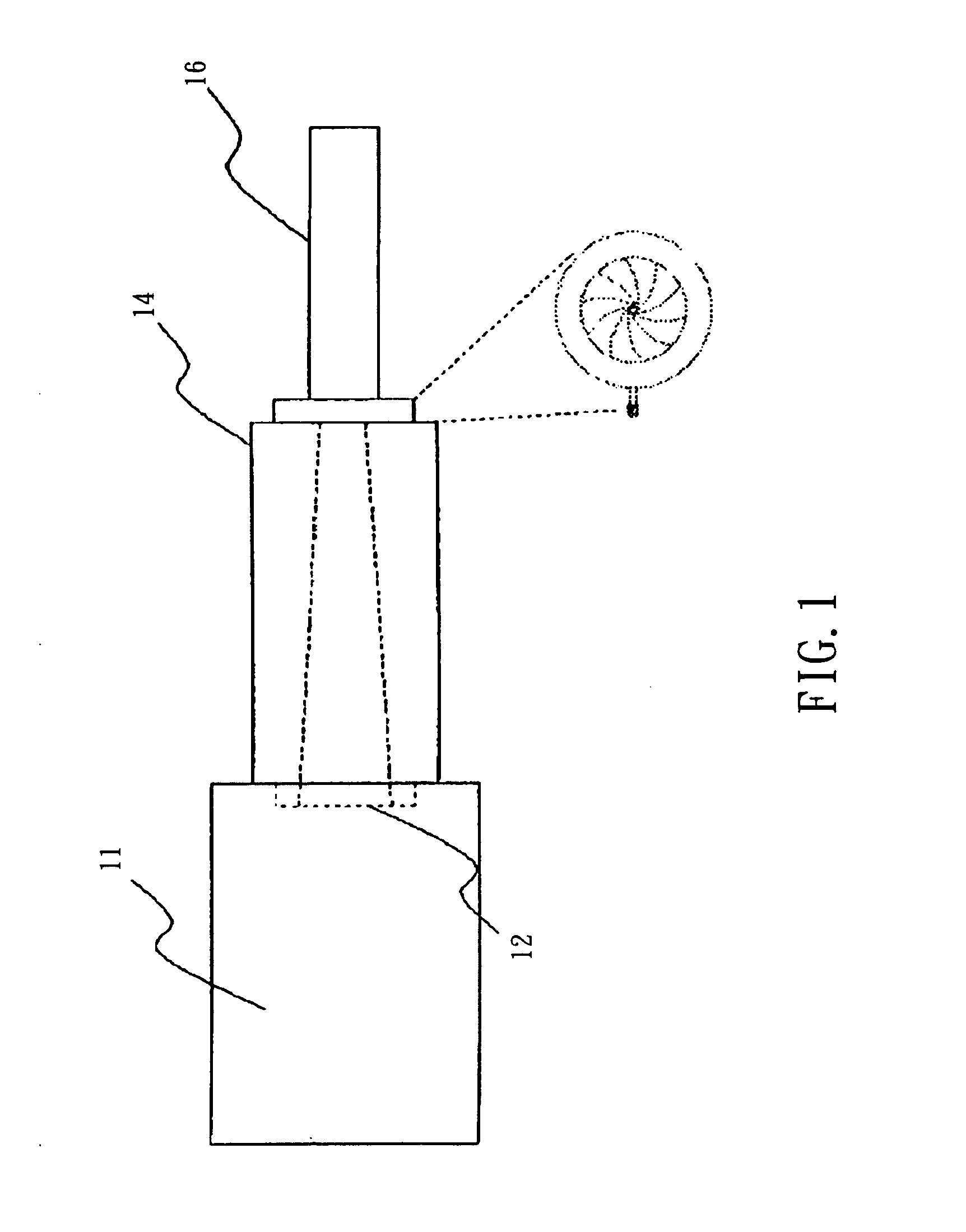

Magnetic rotation transmitting device, hermetic stirring unit, and electric furnace

InactiveUS20050206260A1Dynamo-electric brakes/clutchesRotary stirring mixersElectric arc furnaceMagnetic rotation

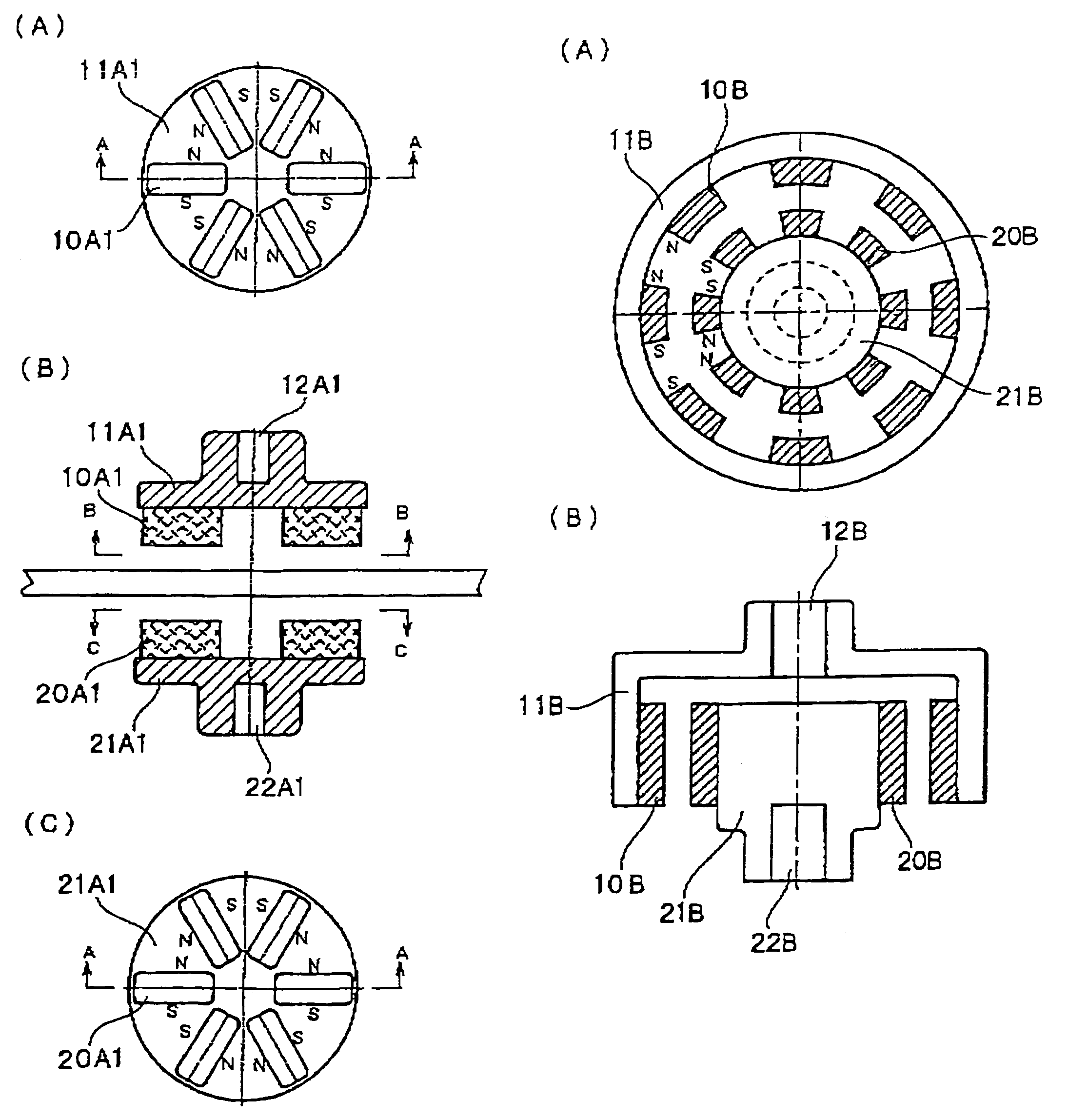

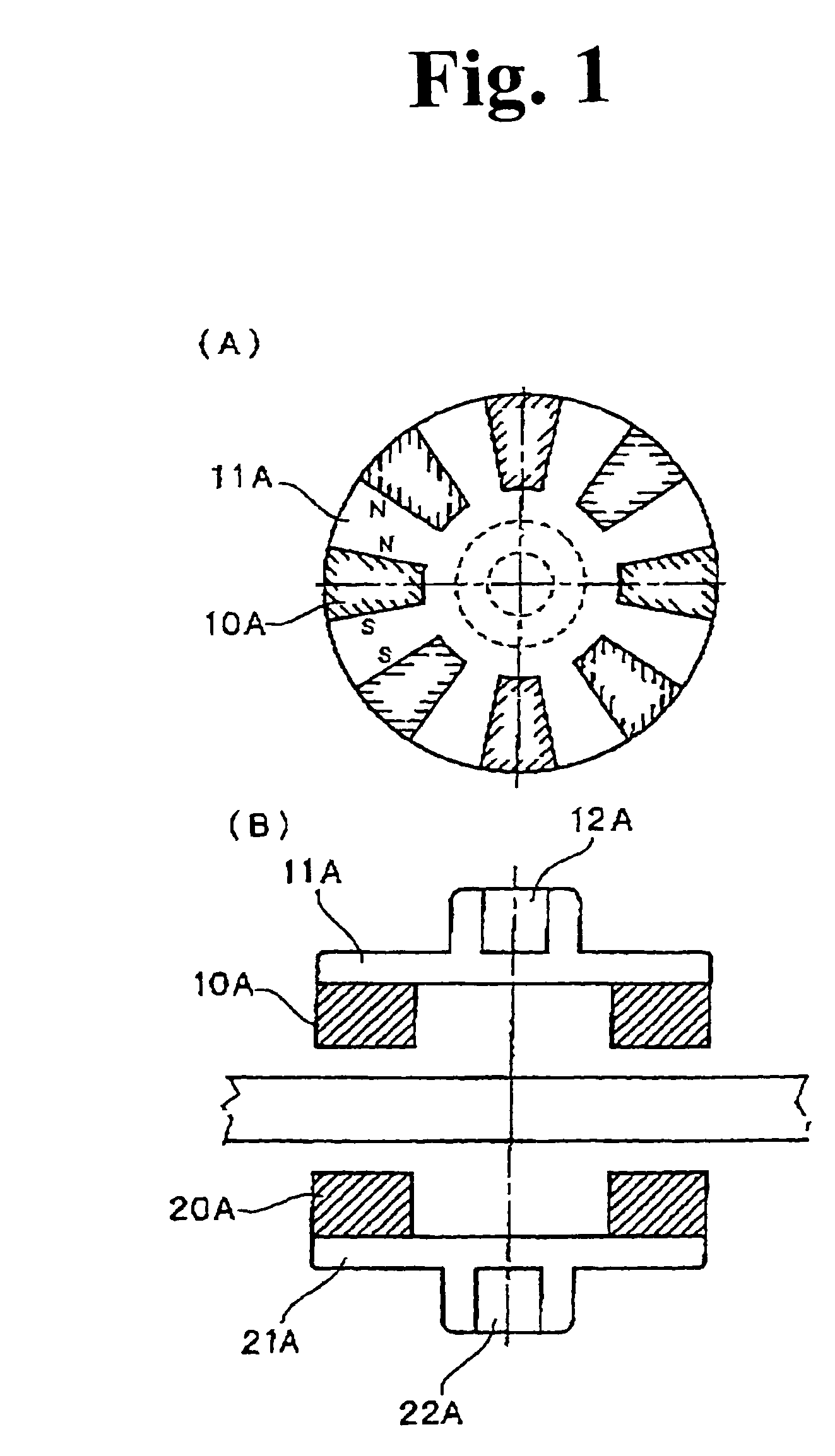

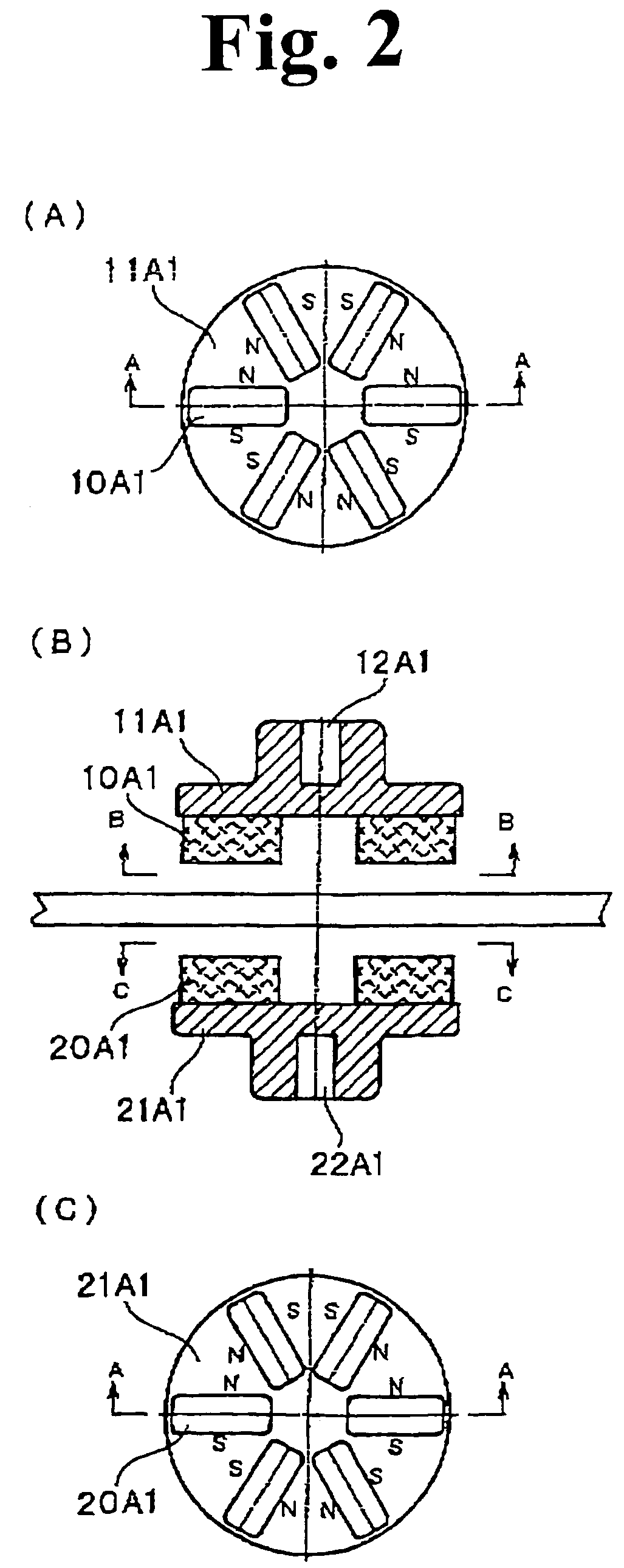

In order to provide a magnetic rotation transmitting device capable of obtaining a large transmitting torque without using a large-sized permanent magnet, in an axial-type magnetic rotation transmitting device, which includes a driving rotation body having one or plural magnetic line(s) in which plural first magnets (10A) are disposed in a circumferential direction on a first disk (11A) at almost equal intervals, a drive source rotationally driving a drive shaft of the driving rotation body, and a driven rotation body having one or plural magnet line(s) in which second magnets (20A) of the same number as the first magnets (10A) are disposed in the circumferential direction on a second disk (21A) at almost equal intervals, symmetrically disposed to, and magnetically coupled with the driving rotation body with a magnetic coupling gap and, which utilizes a magnetic operation and which allows the driven rotation body to rotate by rotationally driving the drive shaft by means of the drive source, the first magnet (10A) has a N-magnetic pole portion and a S-magnetic pole portion, and an extended surface of a boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driving center line as being a rotation center line of the driving rotation body, the second magnet (20A) has the N-magnetic pole portion and the S-magnetic pole portion, and the extended surface of the boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driven center line as being the rotation center line of the driven rotation body, adjacent and facing surfaces of the first magnets (10A) adjacent to each other on the first disk (11A) are disposed so that magnetic pole faces having the same polarity make pairs, and adjacent and facing surfaces of the second magnets (20A) adjacent to each other on the second disk (21A) are disposed so that the magnetic pole faces having the same polarity make pairs.

Owner:MAGUNEO

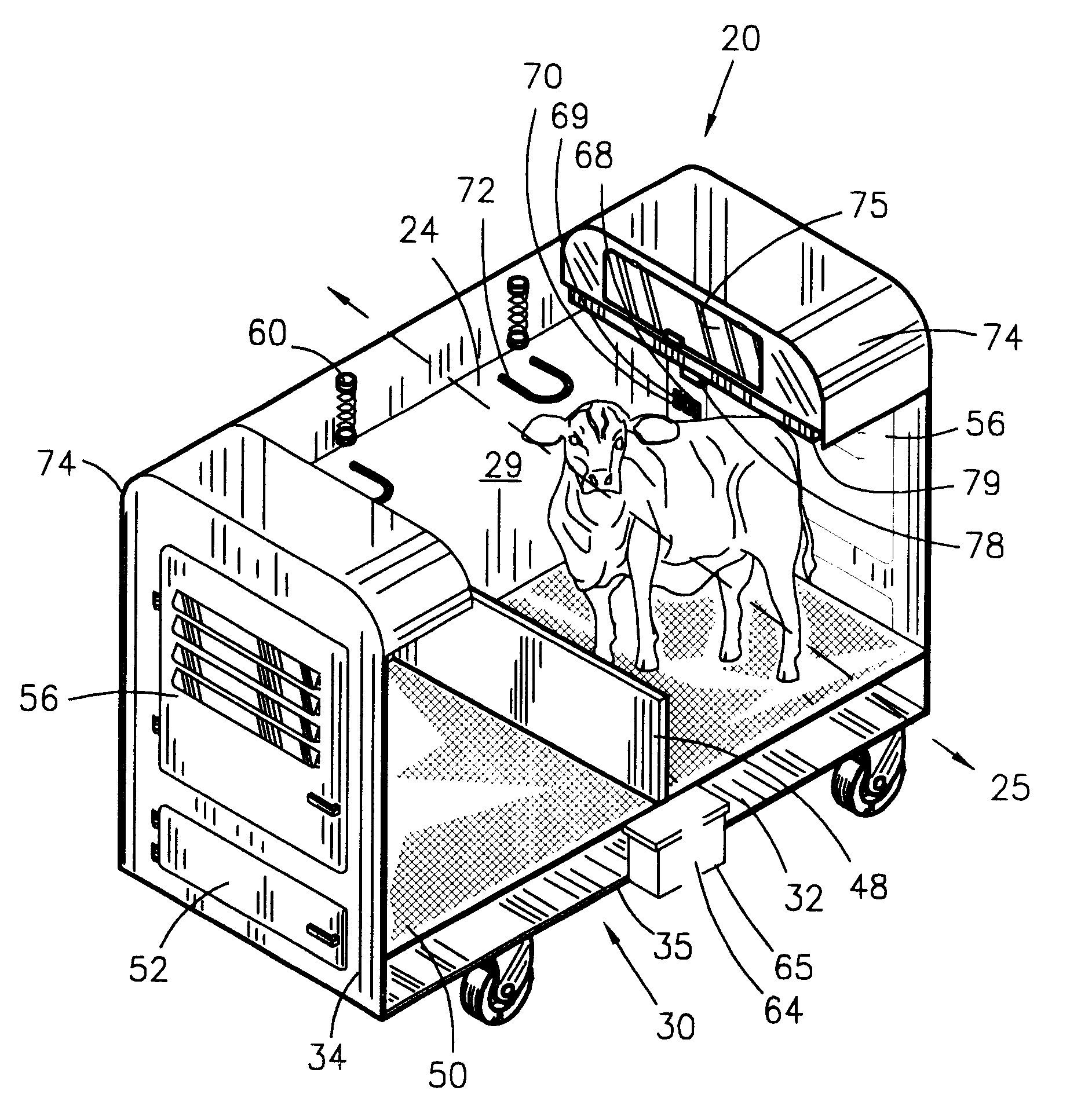

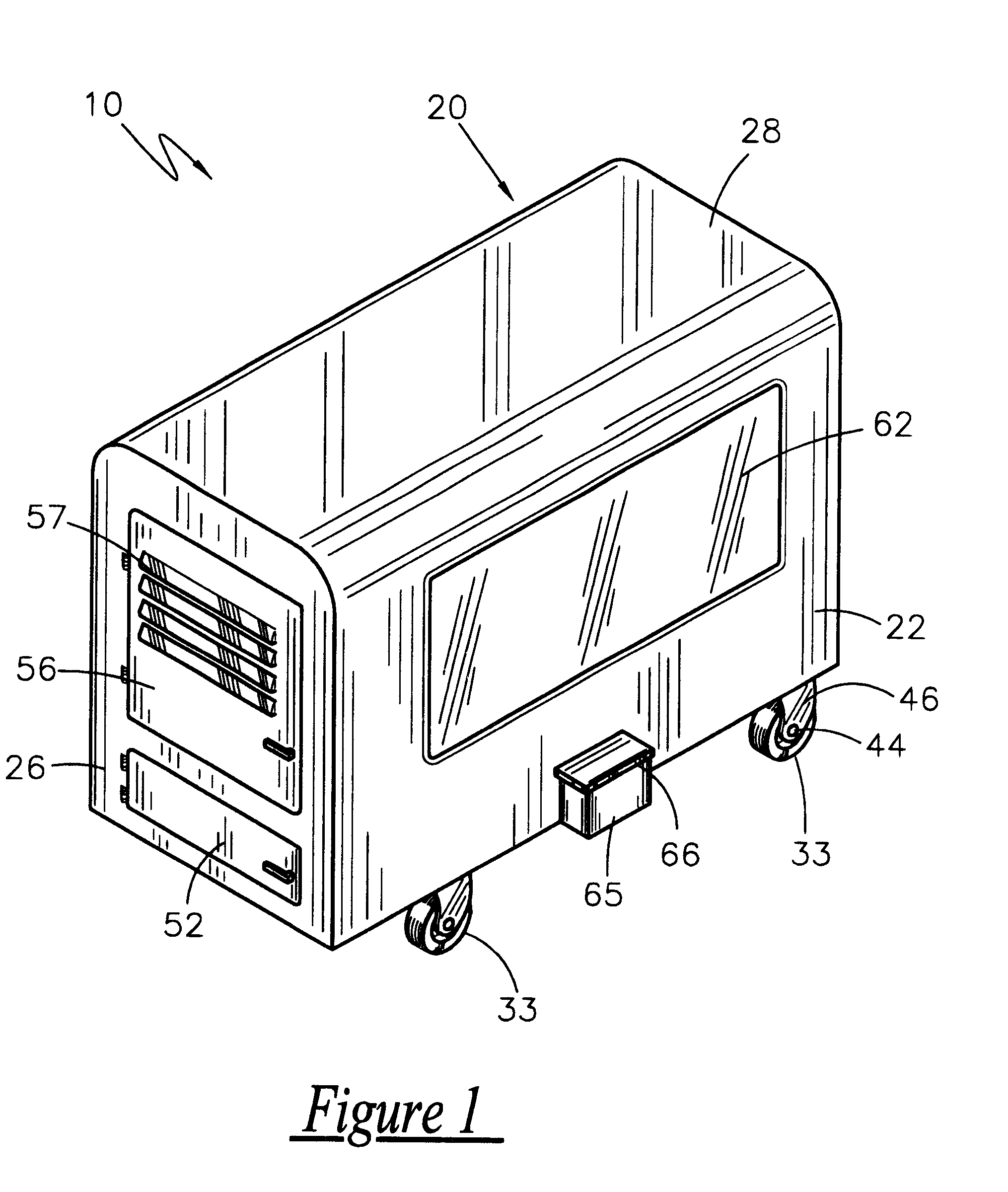

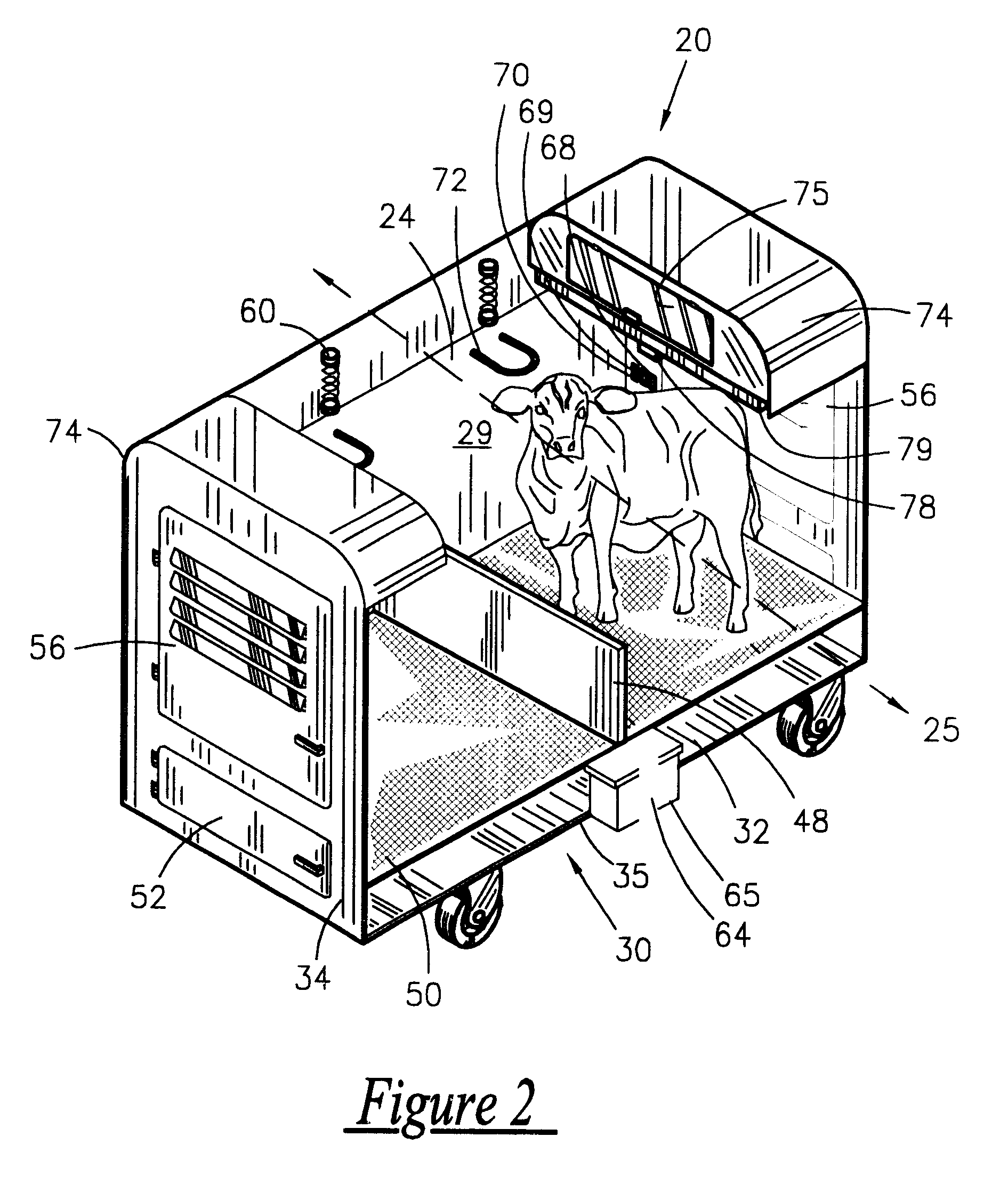

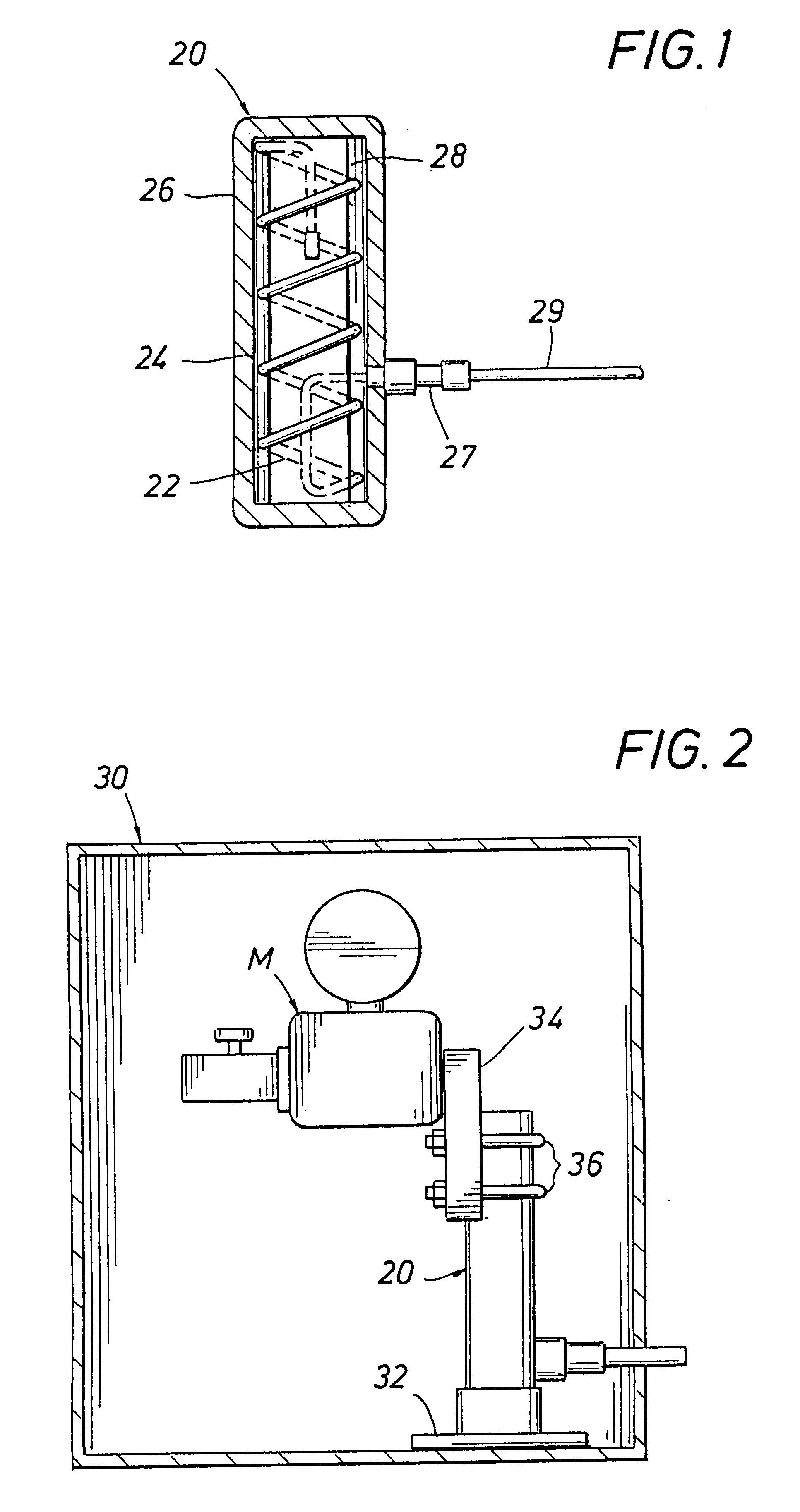

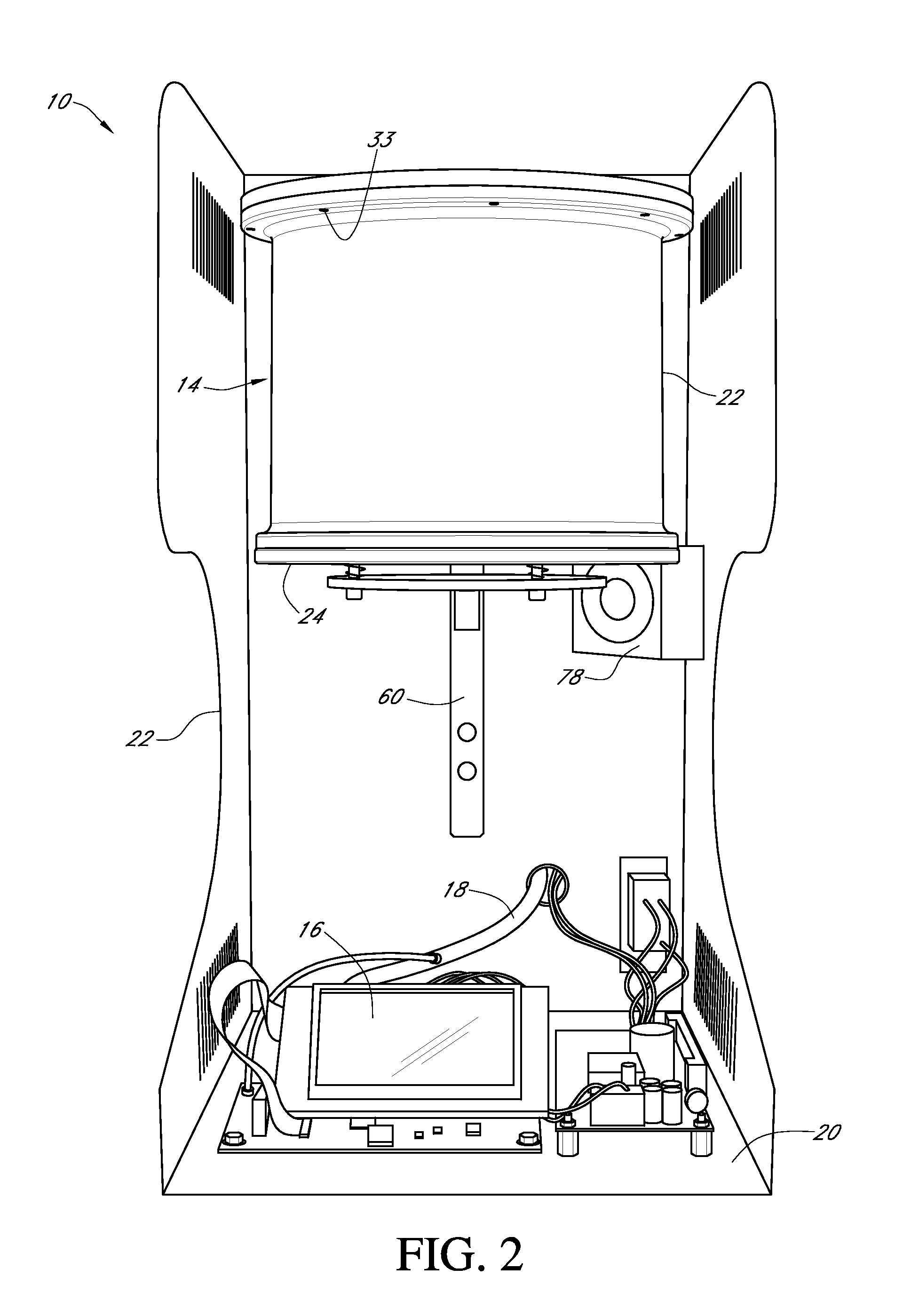

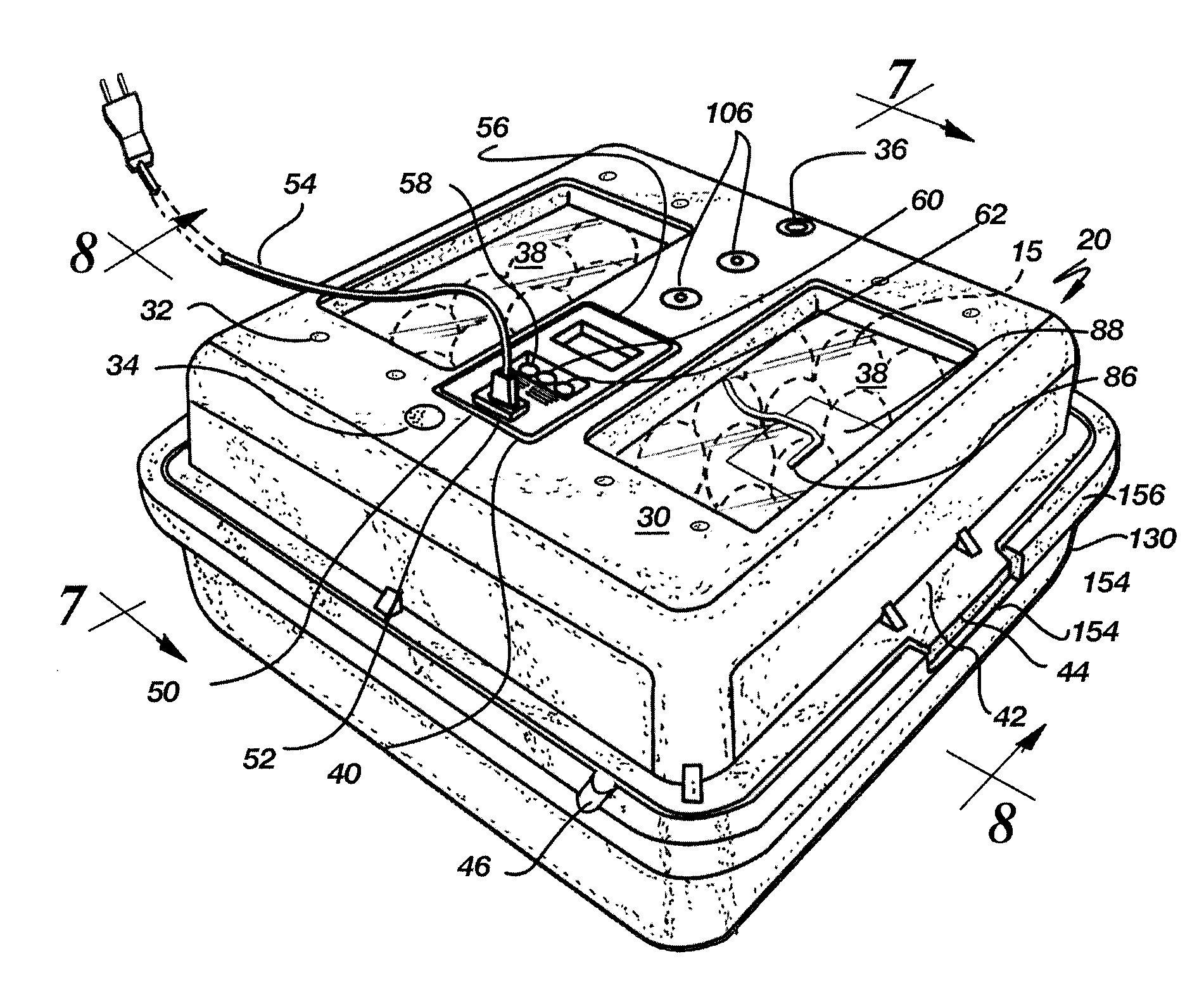

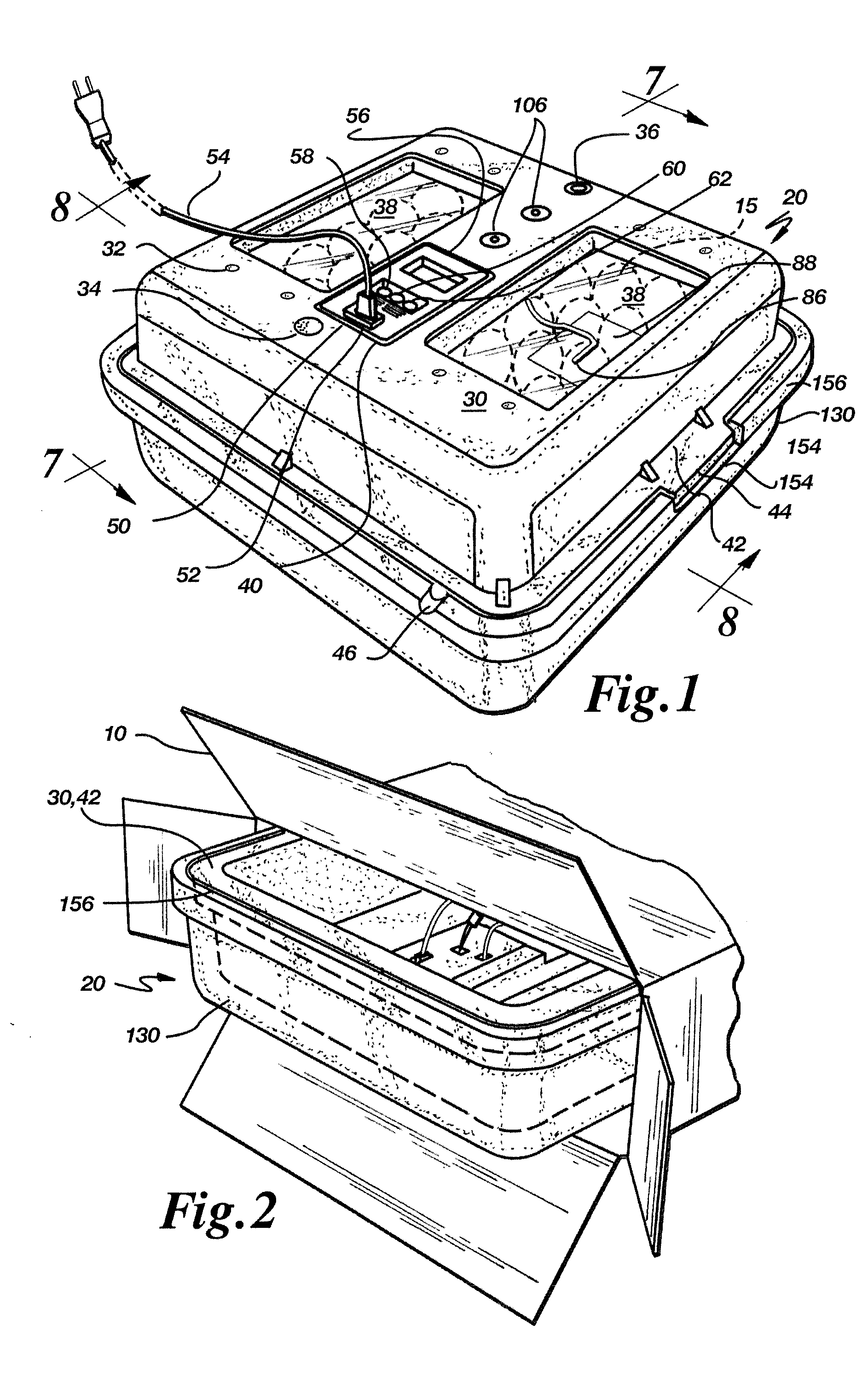

Livestock incubator

InactiveUS6425347B1Easy to cleanDomestic stoves or rangesElectrical heating fuelAnimal scienceDraft animals

A portable livestock incubating device is provided formed of a rectangular container having and incubating volume forming an incubating chamber defined by the zone within the incubating volume. Each each end wall further includes an access door hingedly attached to an upper portion above a clean out door for providing ingress and egress of livestock. Each access door has an exhaust vent located at an upper portion whereby heated air, generated via an electric heater within said the incubating chamber exhausts therethrough. A base with wheels mounted thereon for facilitating transportation of the portable livestock incubating device.

Owner:BOGNER DANIEL G +1

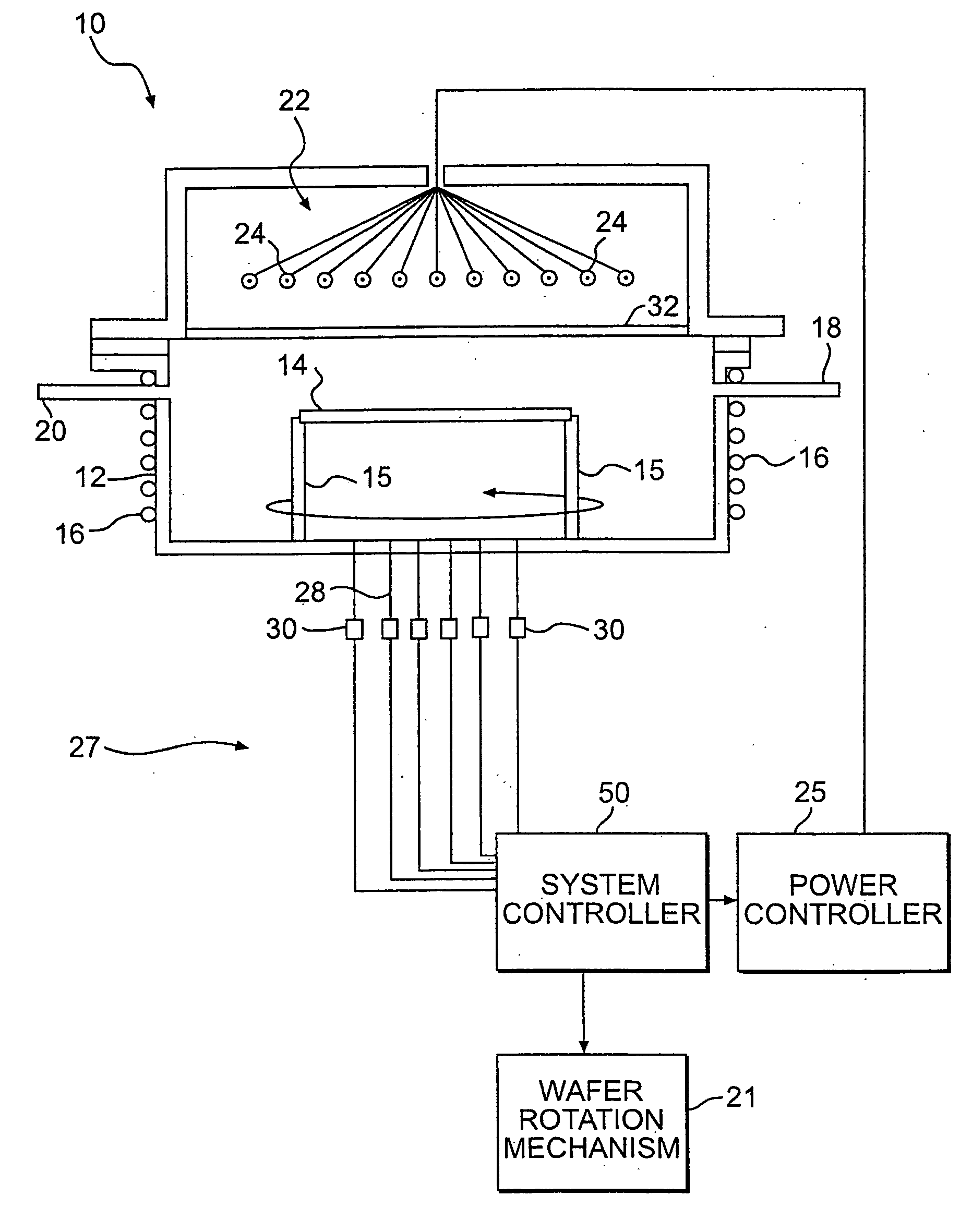

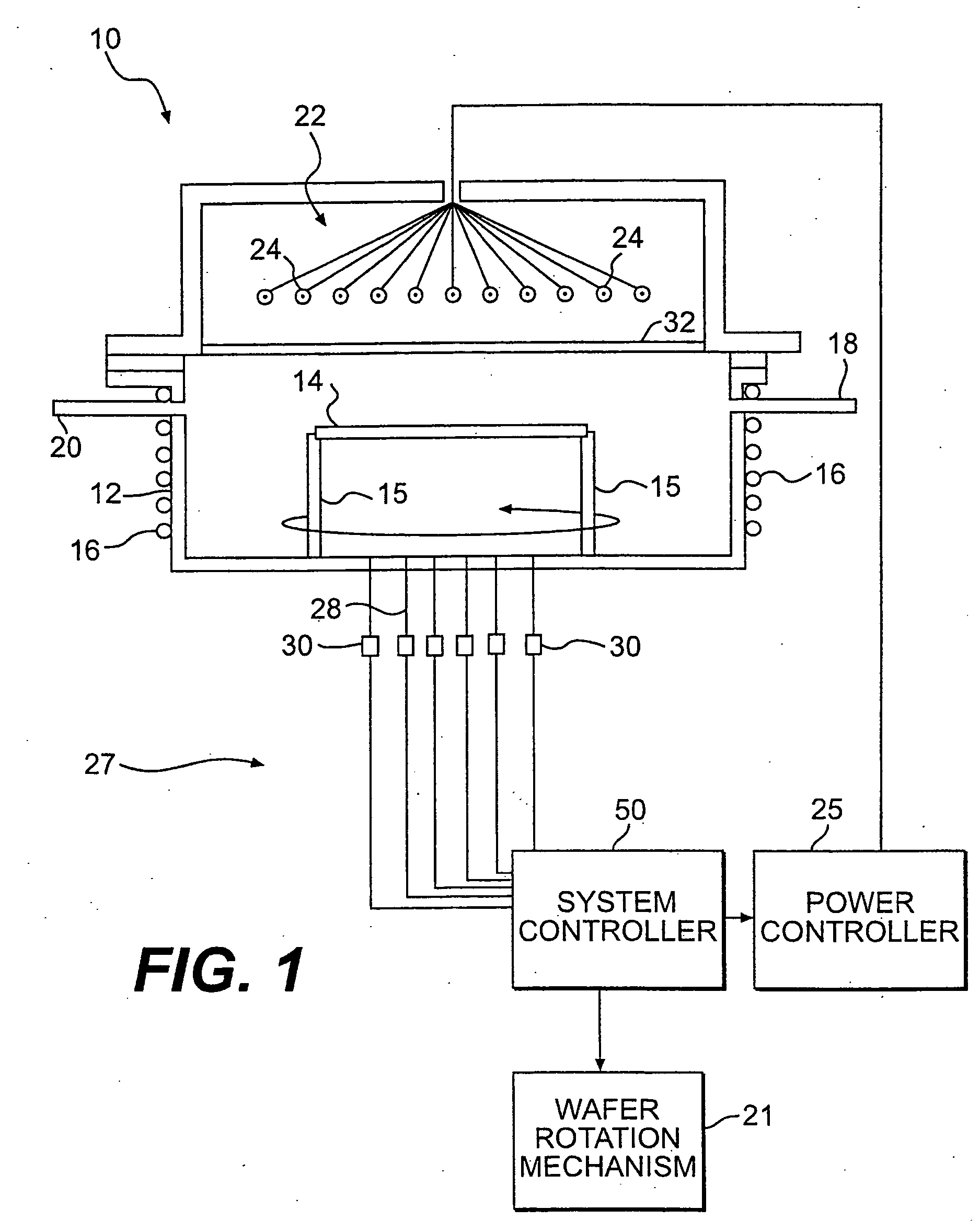

Heating device for heating semiconductor wafers in thermal processing chambers

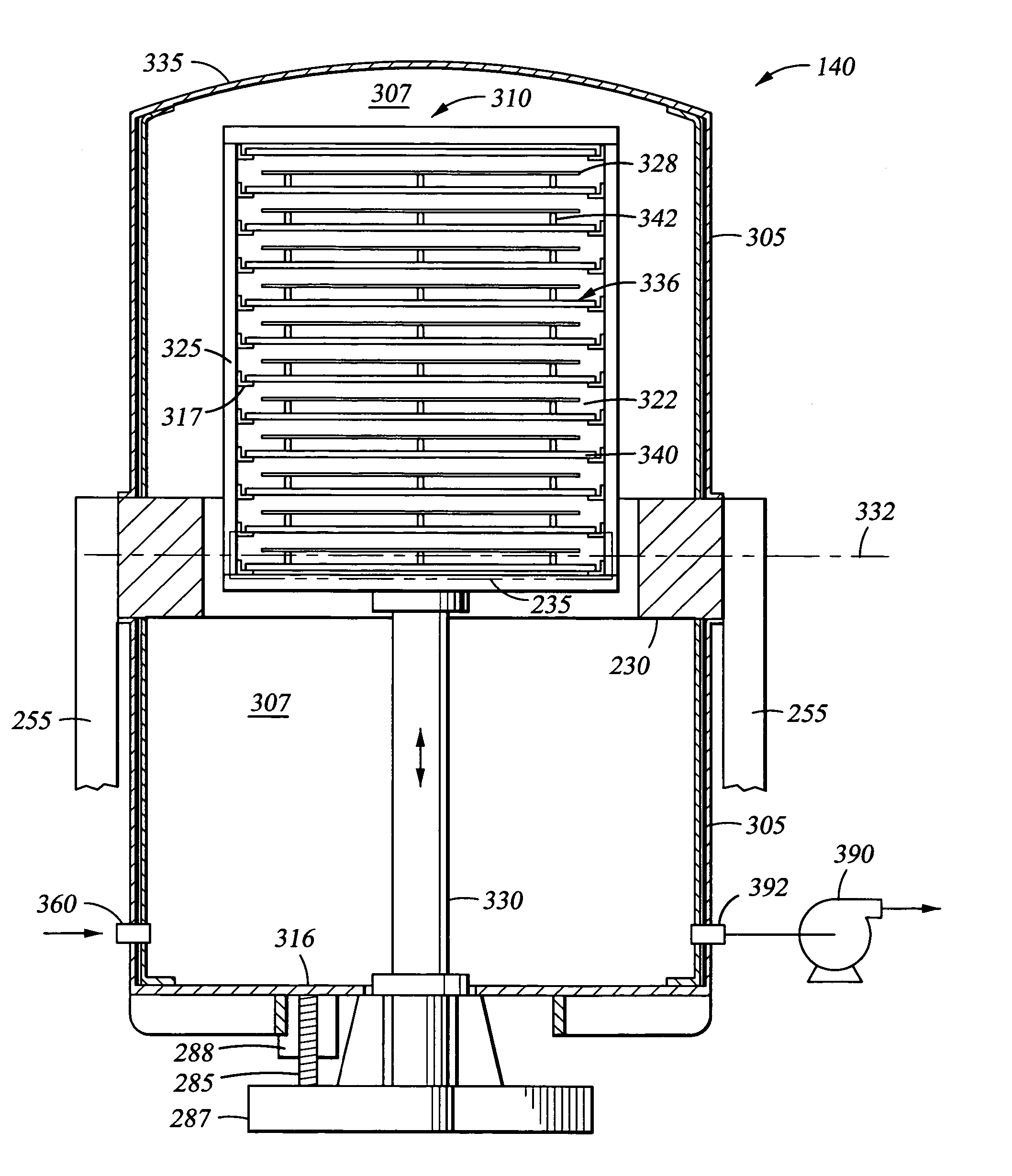

InactiveUS20050008351A1Easy to control timeImprove the level ofDrying solid materials with heatMuffle furnacesLight energyEngineering

An apparatus for heat treating semiconductor wafers is disclosed. The apparatus includes a heating device which contains an assembly of light energy sources for emitting light energy onto a wafer. The light energy sources can be placed in various configurations. In accordance with the present invention, tuning devices which are used to adjust the overall irradiance distribution of the light energy sources are included in the heating device. The tuning devices can be either active sources of light energy or passive sources which reflect, refract or absorb light energy. For instance, in one embodiment, the tuning devices can comprise a lamp spaced from a focusing lens designed to focus determined amounts of light energy onto a particular location of a wafer being heated.

Owner:MATTSON TECHNOLOGY +1

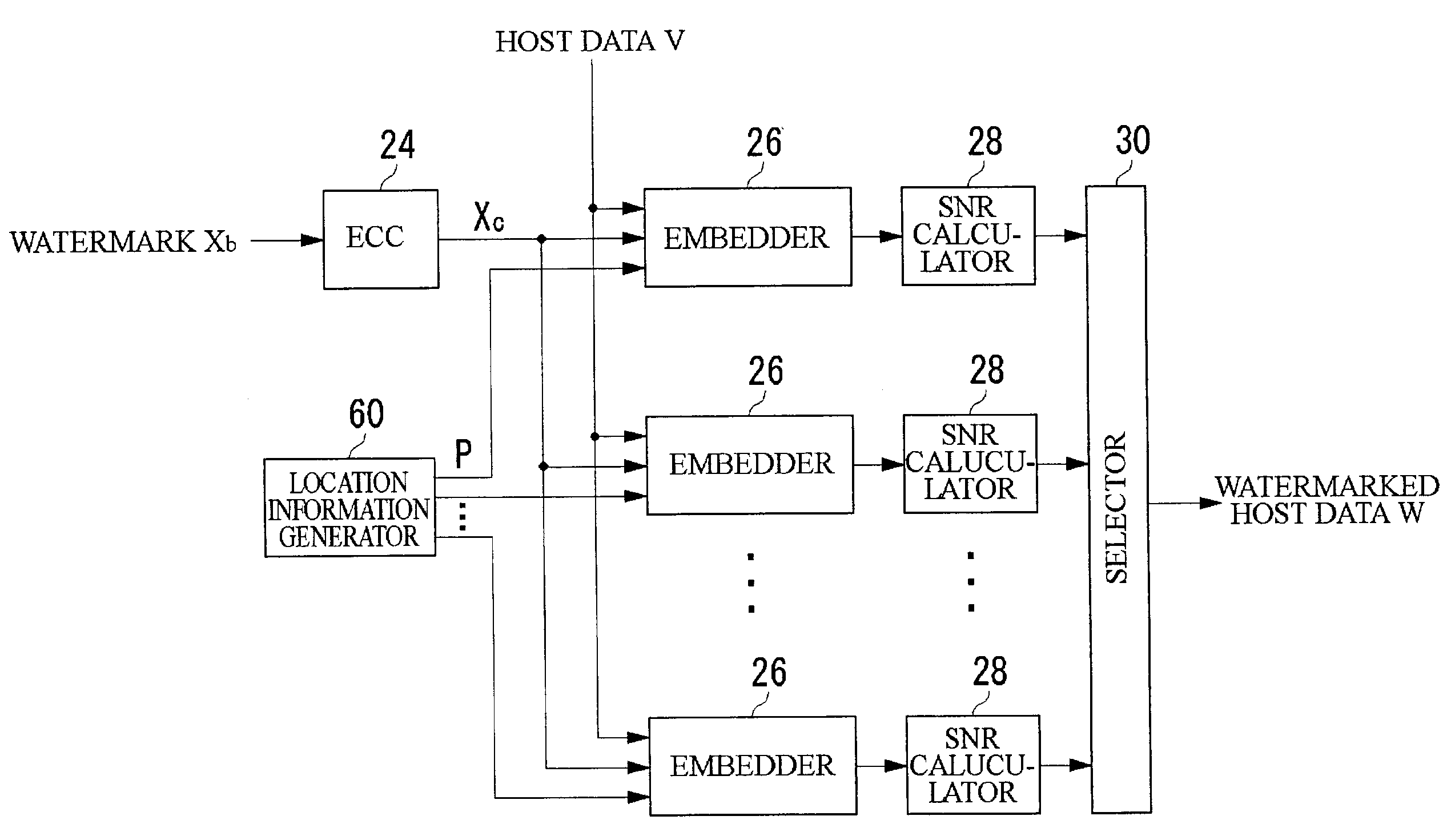

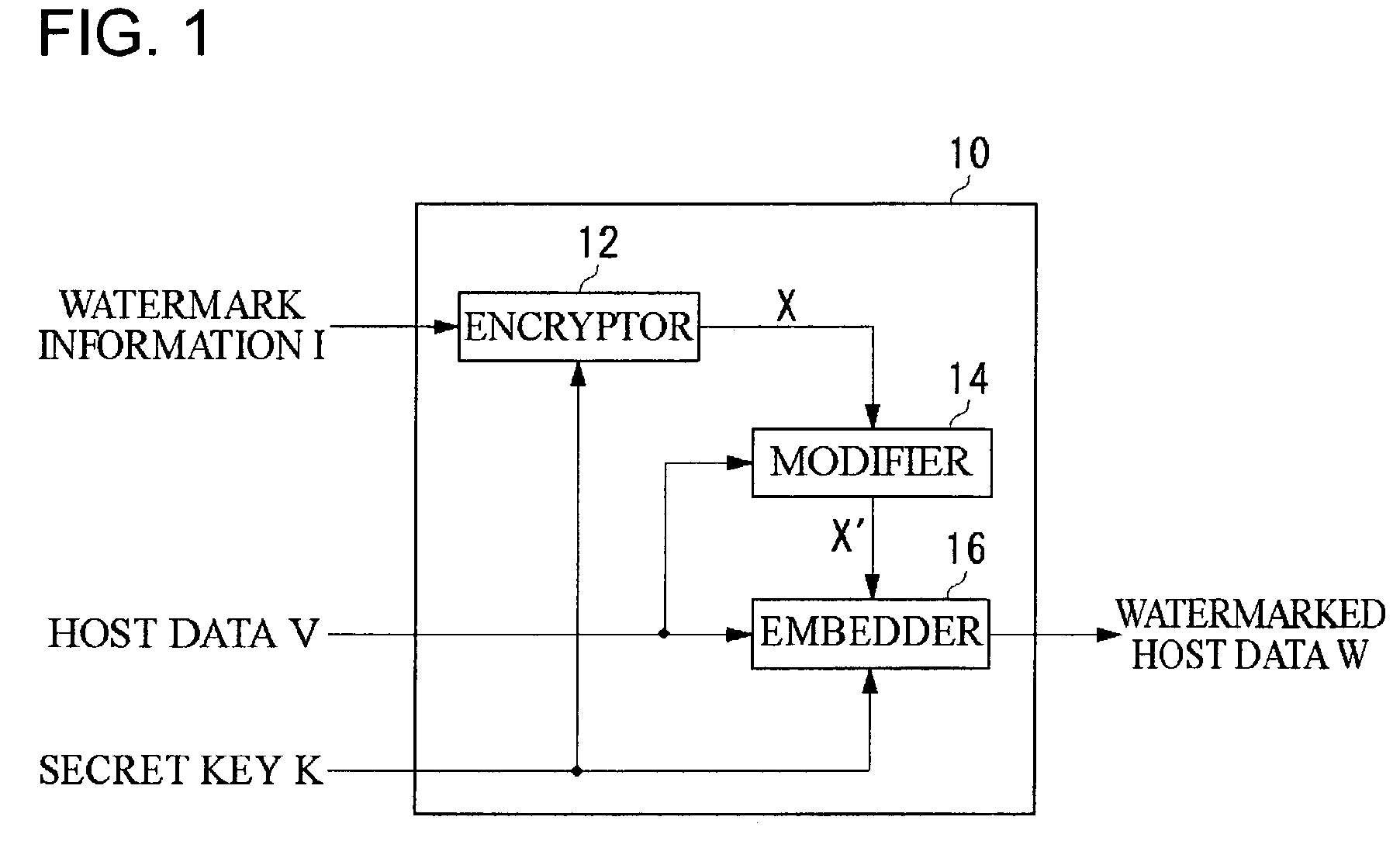

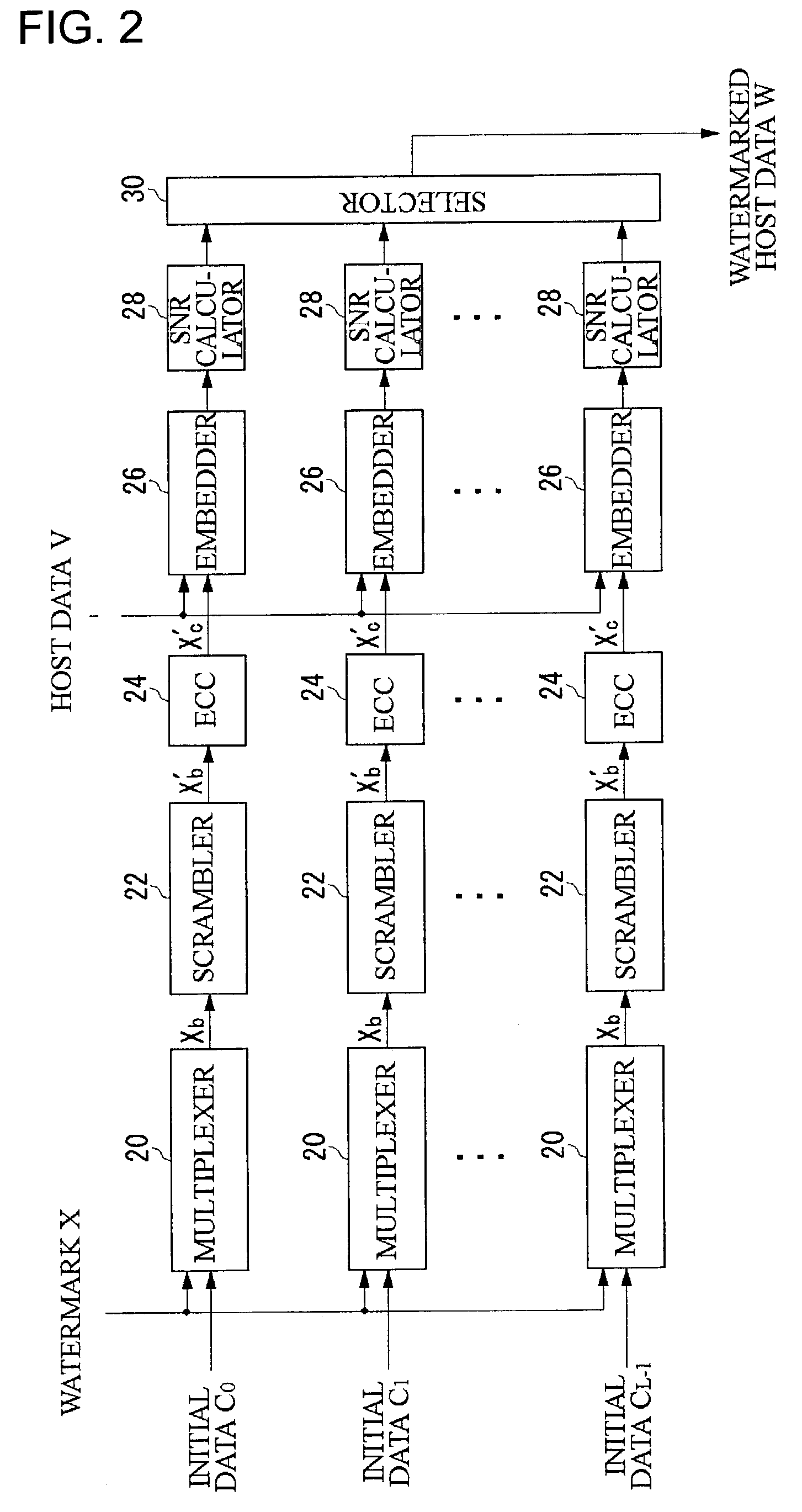

Digital watermarking system using scrambling method

ActiveUS7487356B2High degree of robustnessReduce detection error rateUser identity/authority verificationCharacter and pattern recognitionSignal-to-noise ratio (imaging)Multiplexer

An encoding apparatus that embeds a watermark in host data is provided. A multiplexer generates a plurality of bit sequences by adding initial data to the head of the watermark. A scrambler scrambles a plurality of the bit sequences respectively and generates a plurality of scrambled watermarks. An embedder embeds a plurality of the scrambled watermarks in the host data and generates a plurality of candidate watermarked host data. A signal-to-noise ratio calculator evaluates the robustness of the watermarks hidden in the respective candidate watermarked host data. A selector selects one candidate that has the highest level of the robustness as a final watermarked host data.

Owner:SANYO ELECTRIC CO LTD

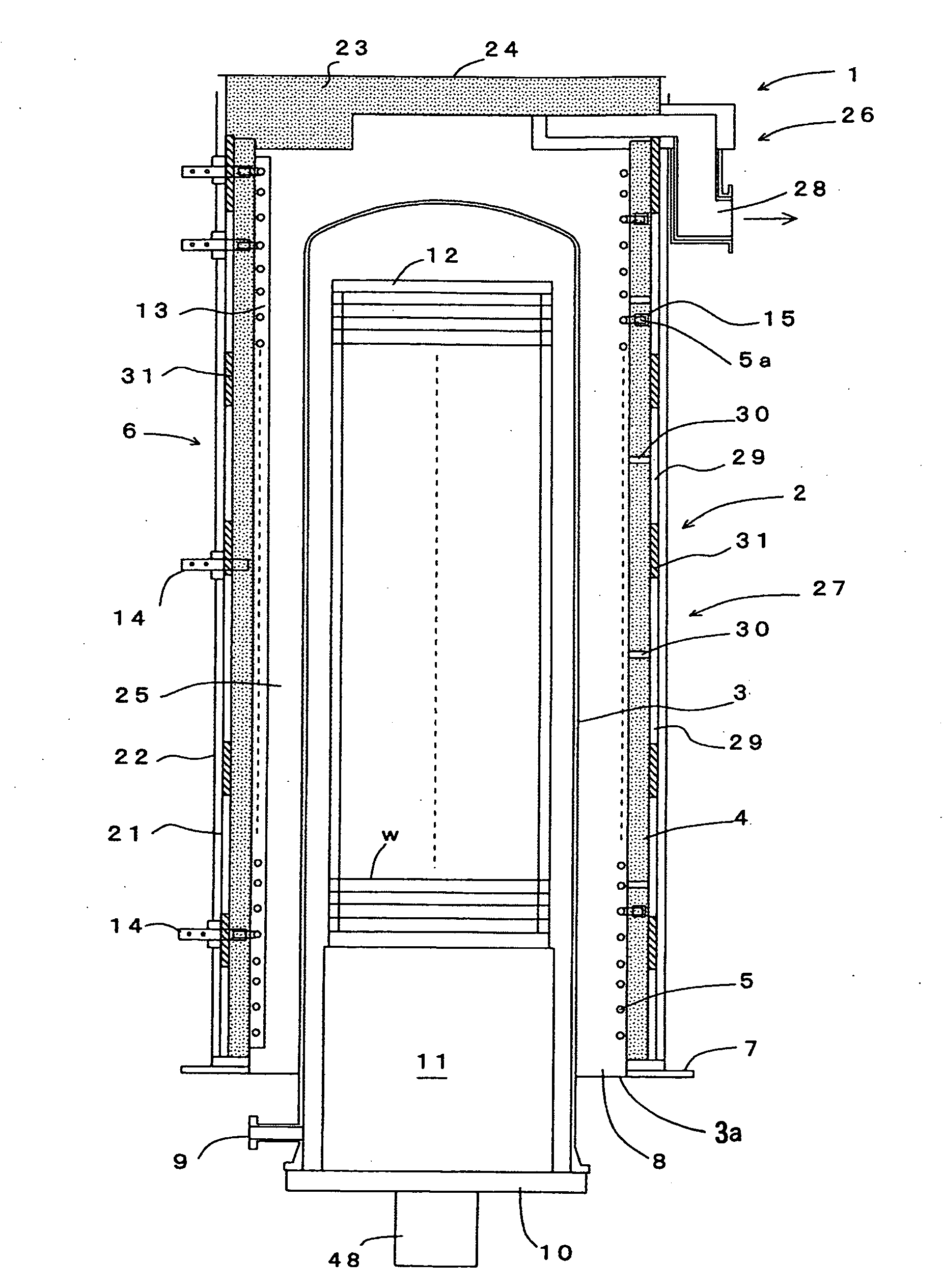

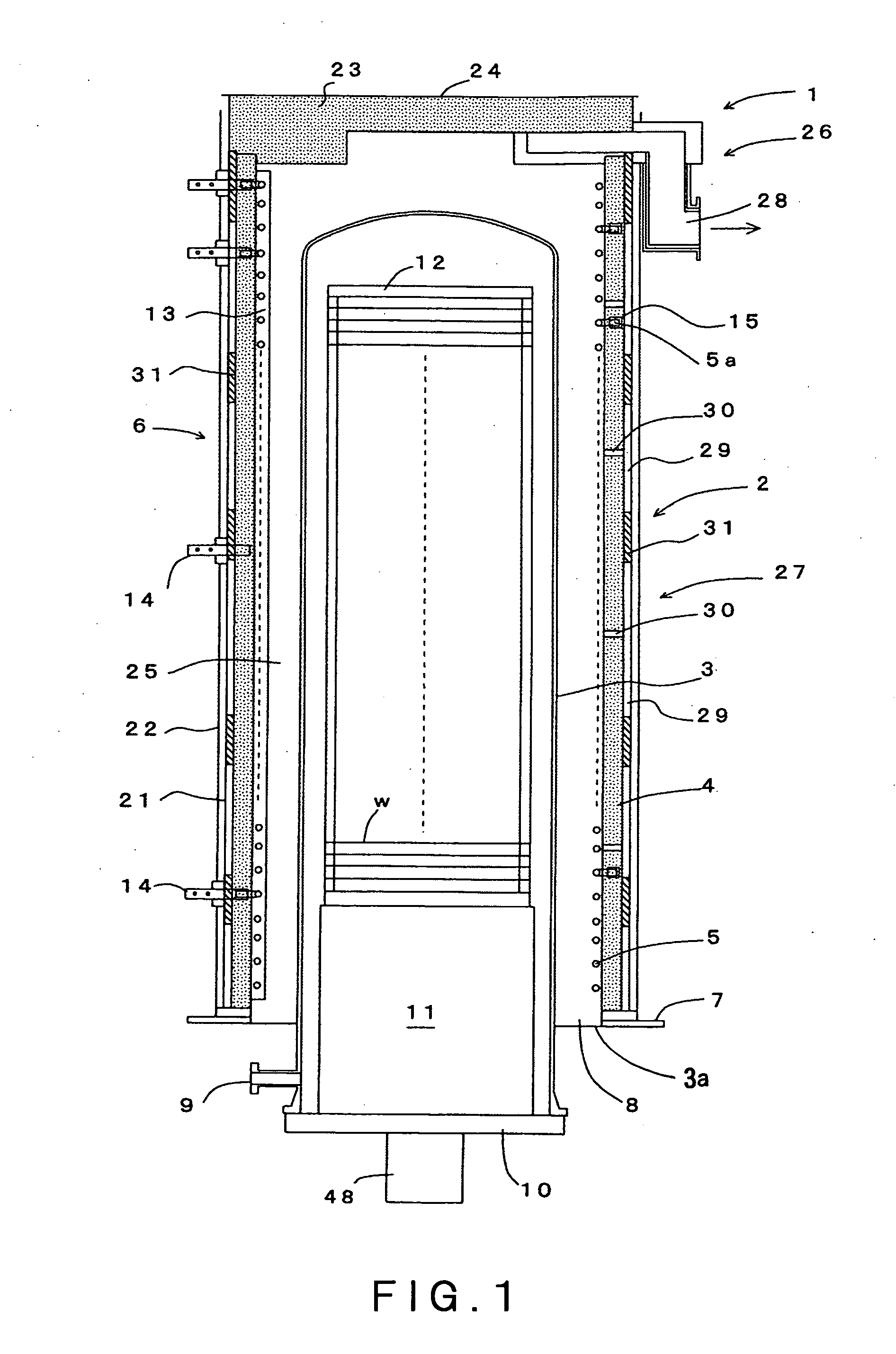

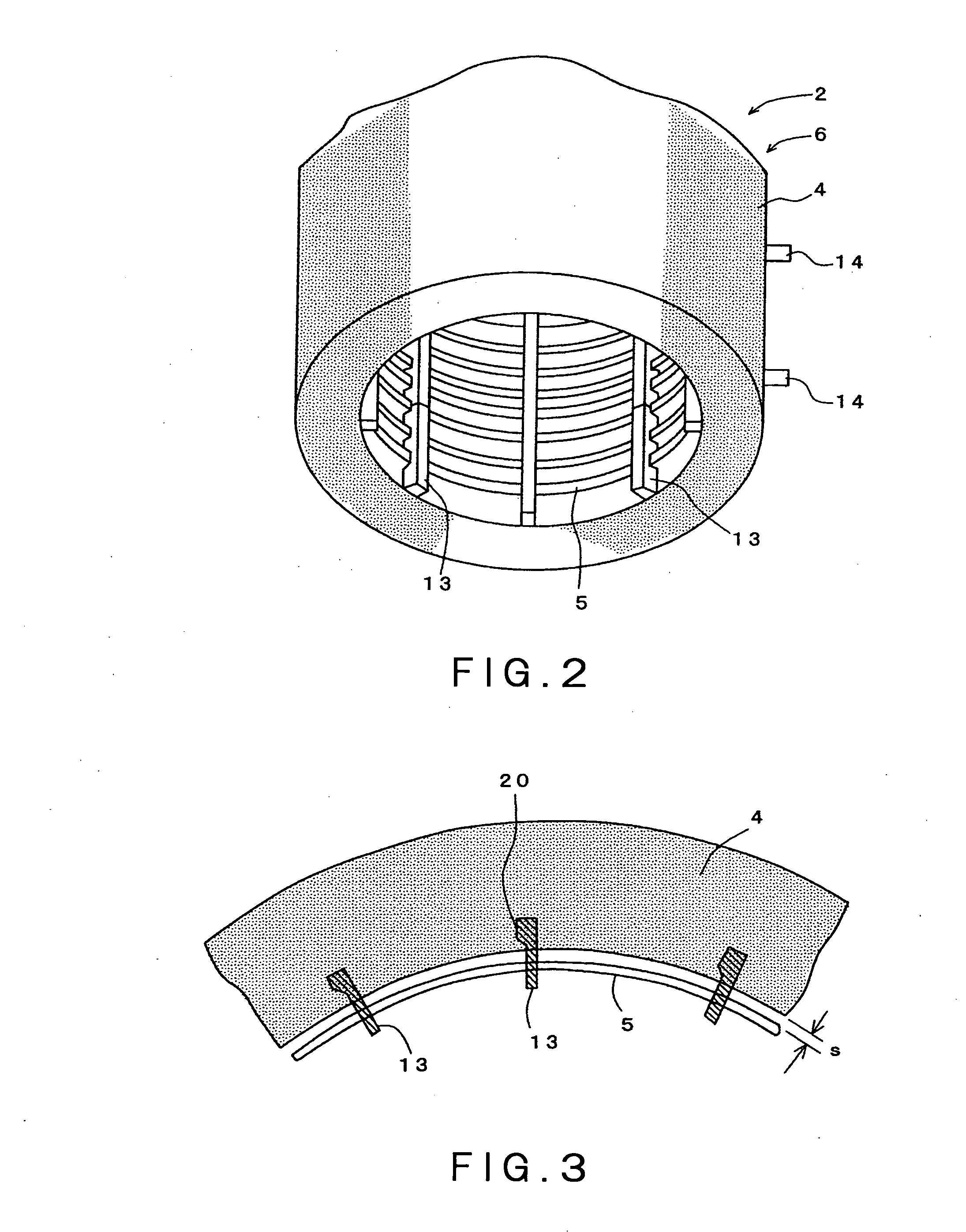

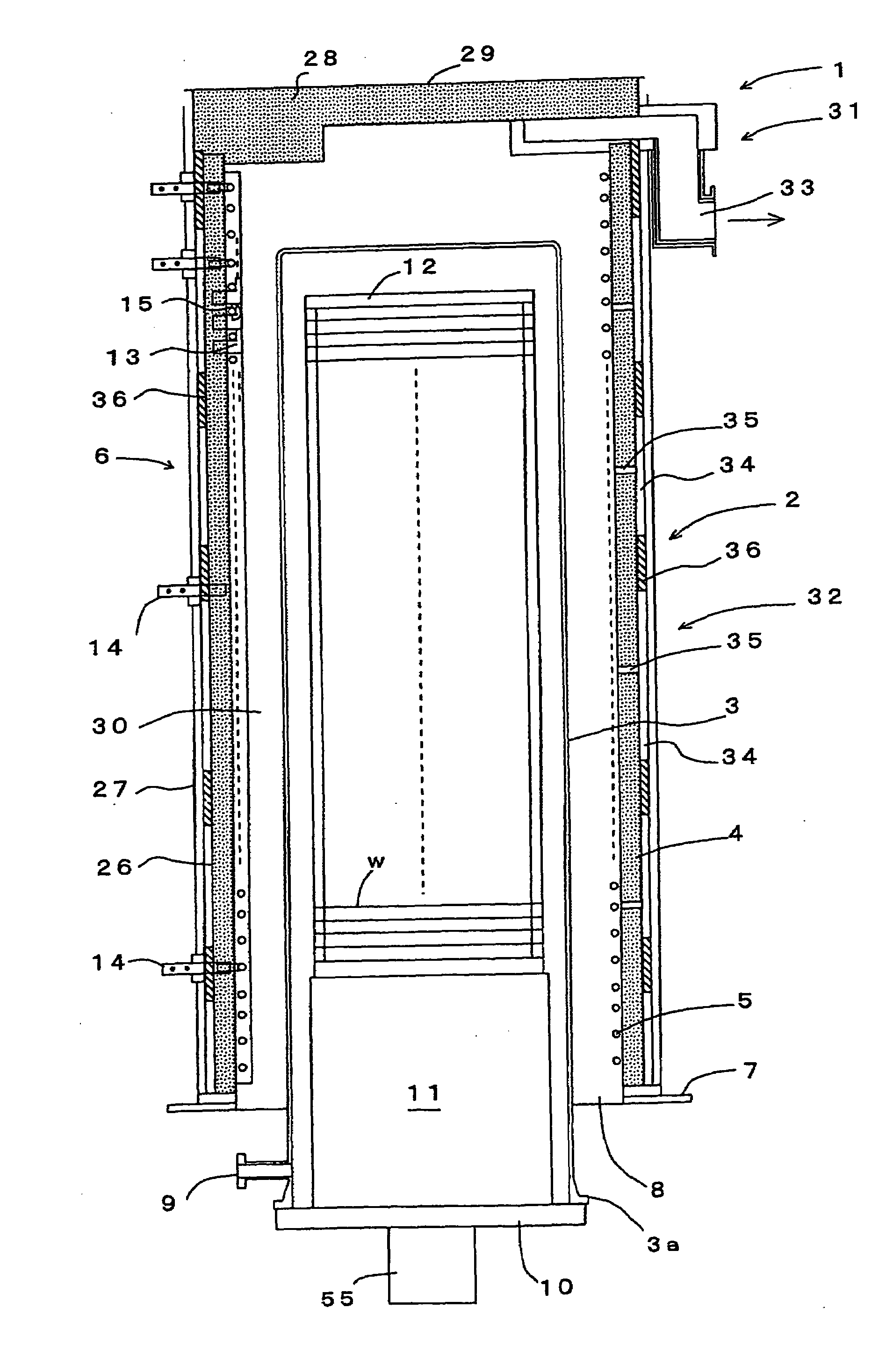

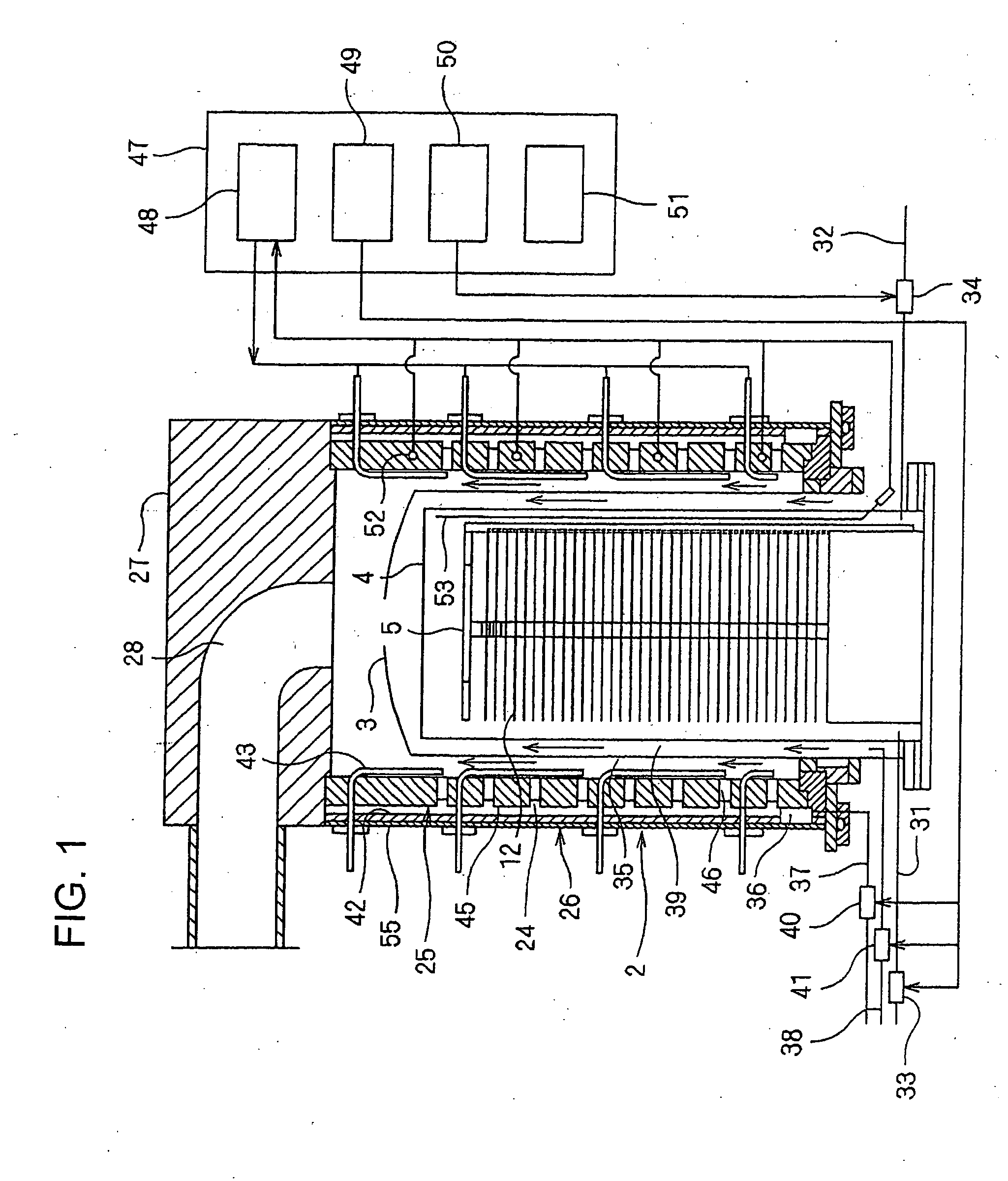

Heat processing furnace and method of manufacturing the same

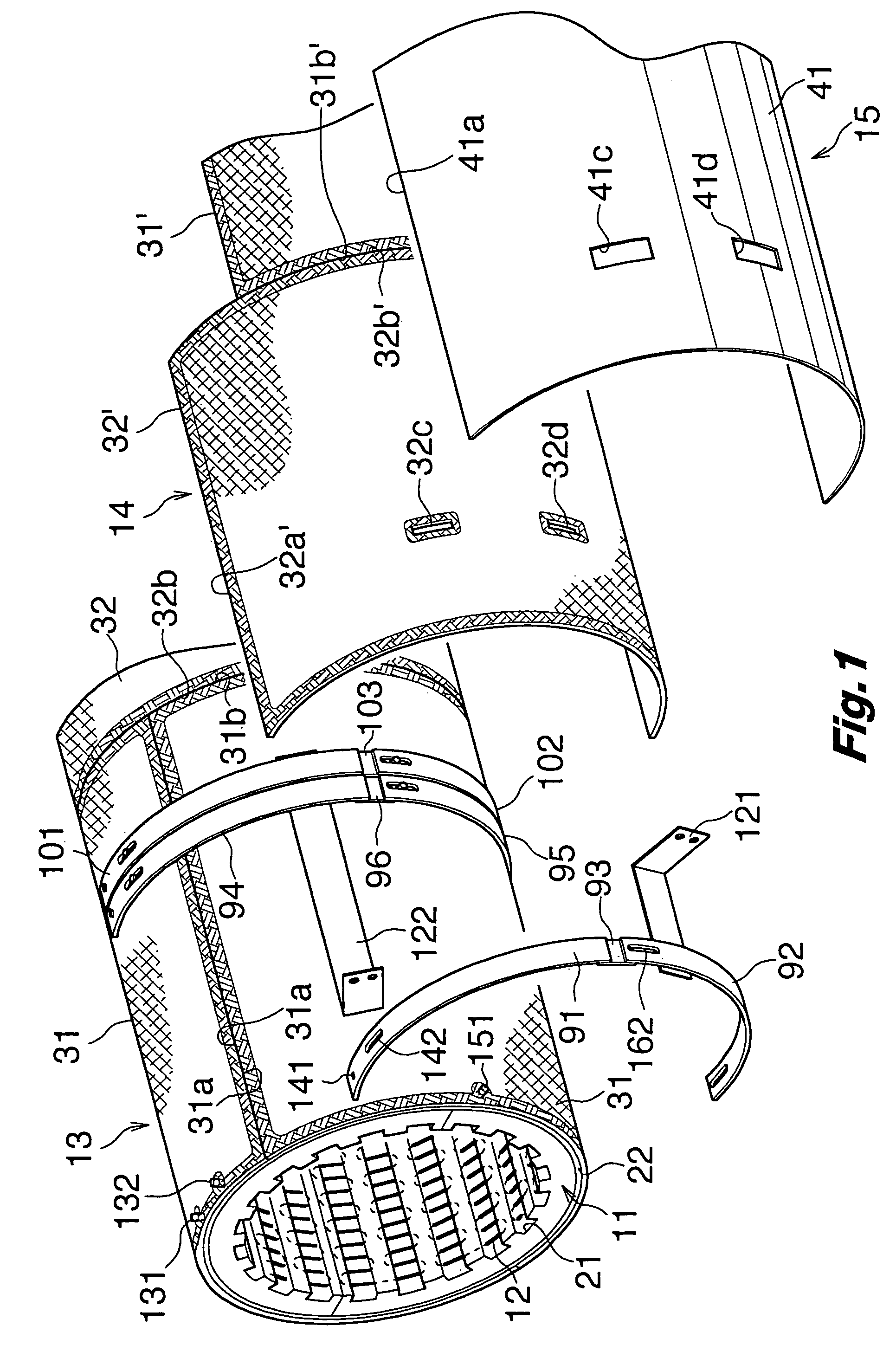

ActiveUS20080296282A1Increased durabilityReduce frictional resistanceOhmic-resistance electrodesRotary drum furnacesCurve shapeEngineering

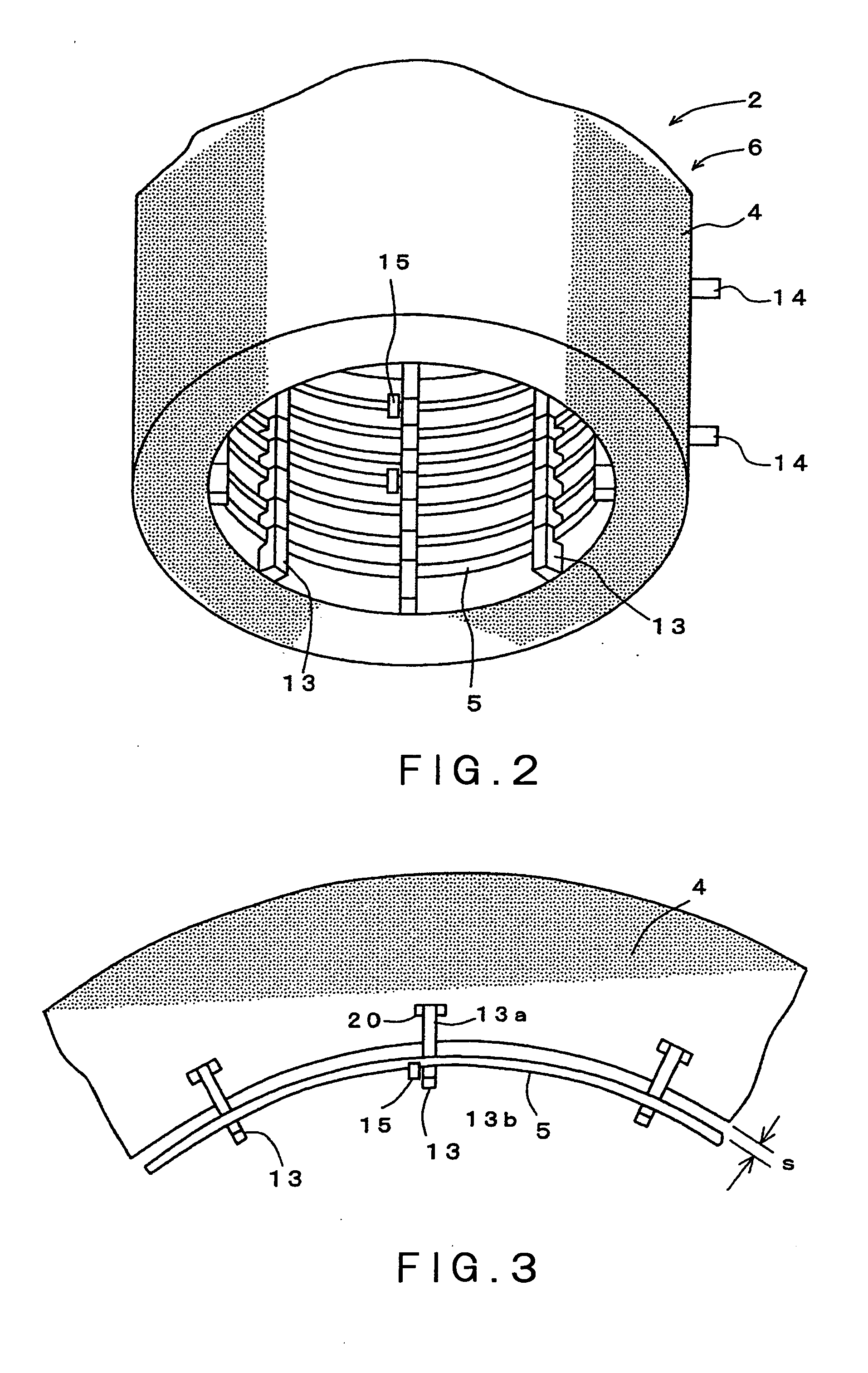

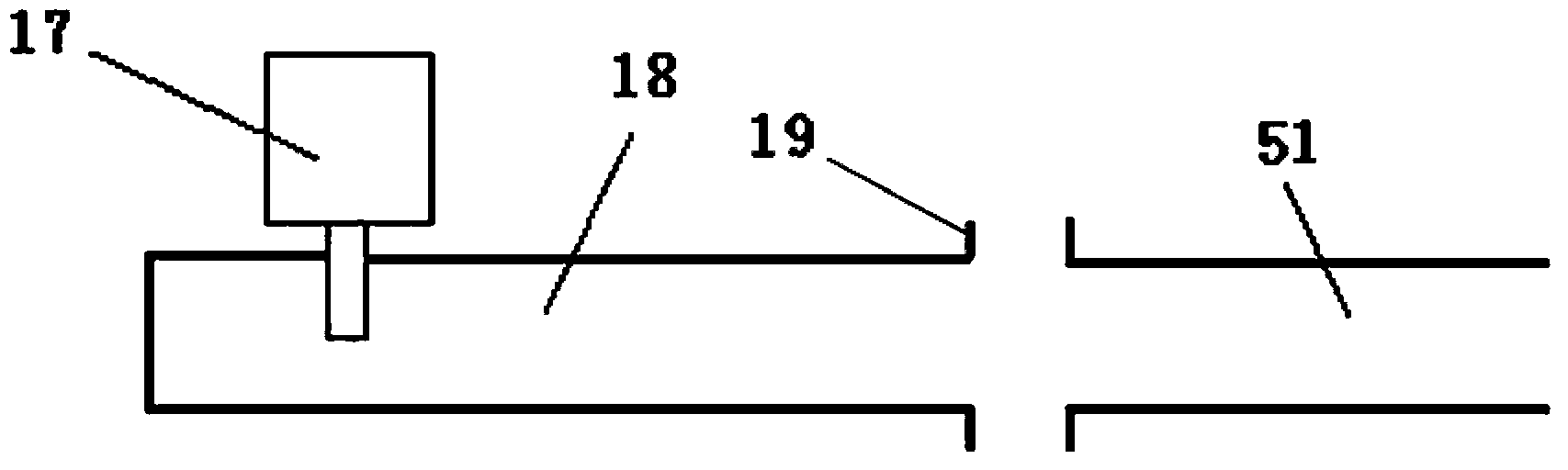

The object of the present invention is to reduce a frictional resistance which is generated between a support member and a heating resistor when the heating resistor is thermally expanded and thermally shrunk, whereby generation of a permanent deformation of the heating resistor caused by a residual stress thereof can be restrained, to thereby improve the durability. A heat processing furnace comprises: a processing vessel 3 capable of accommodating an object to be processed w and subjecting the object to be processed w to a heat process; a cylindrical heat insulation member 4 surrounding the processing vessel 3; a helical heating resistor 5 arranged along an inner peripheral surface of the heat insulation member 4; a support member 13 disposed on the inner peripheral surface of the heat insulation member 4 in parallel with an axial direction thereof, for supporting the heating resistor 5 at predetermined pitches along the axial direction; and a plurality of terminal plates 14 axially arranged on an outside of the heating resistor 5 at suitable intervals therebetween, the terminal plates 14 radially passing through the heat insulation member 4 so as to be extended outside. The support member 13 includes a base part 17 positioned on an inside of the heating resistor 5, and a plurality of support pieces 18 extending radially outward from the base part through spaces between adjacent portions of the heating resistor 5 so as to support the heating resistor 5, the support member 13 being formed to have a comb-like shape. An upper surface part of each of the support pieces 18 is formed to have a curved shape in order to reduce a frictional resistance generated when the heating resistor 5 is moved upon a thermal expansion and a thermal shrinkage thereof.

Owner:TOKYO ELECTRON LTD

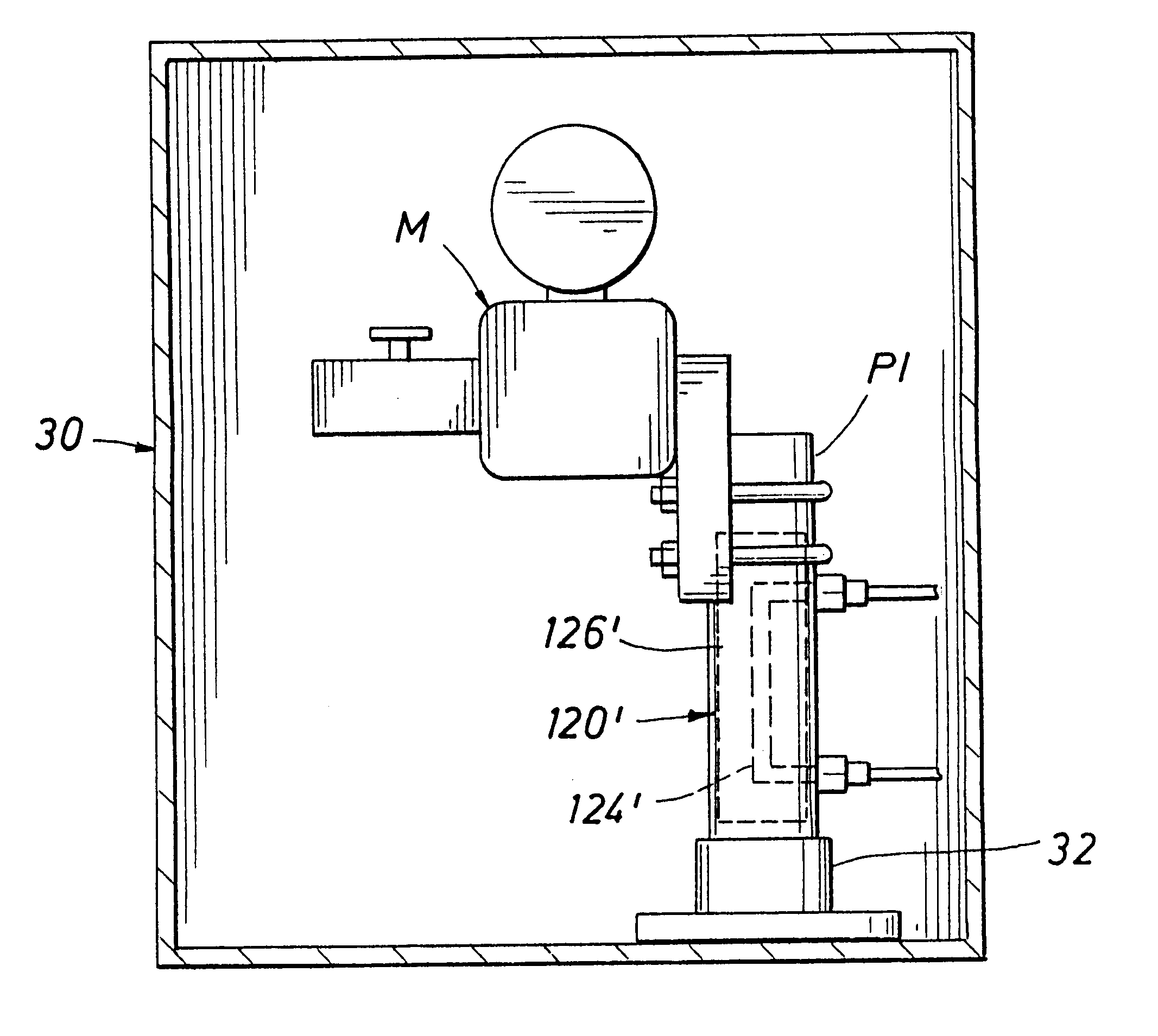

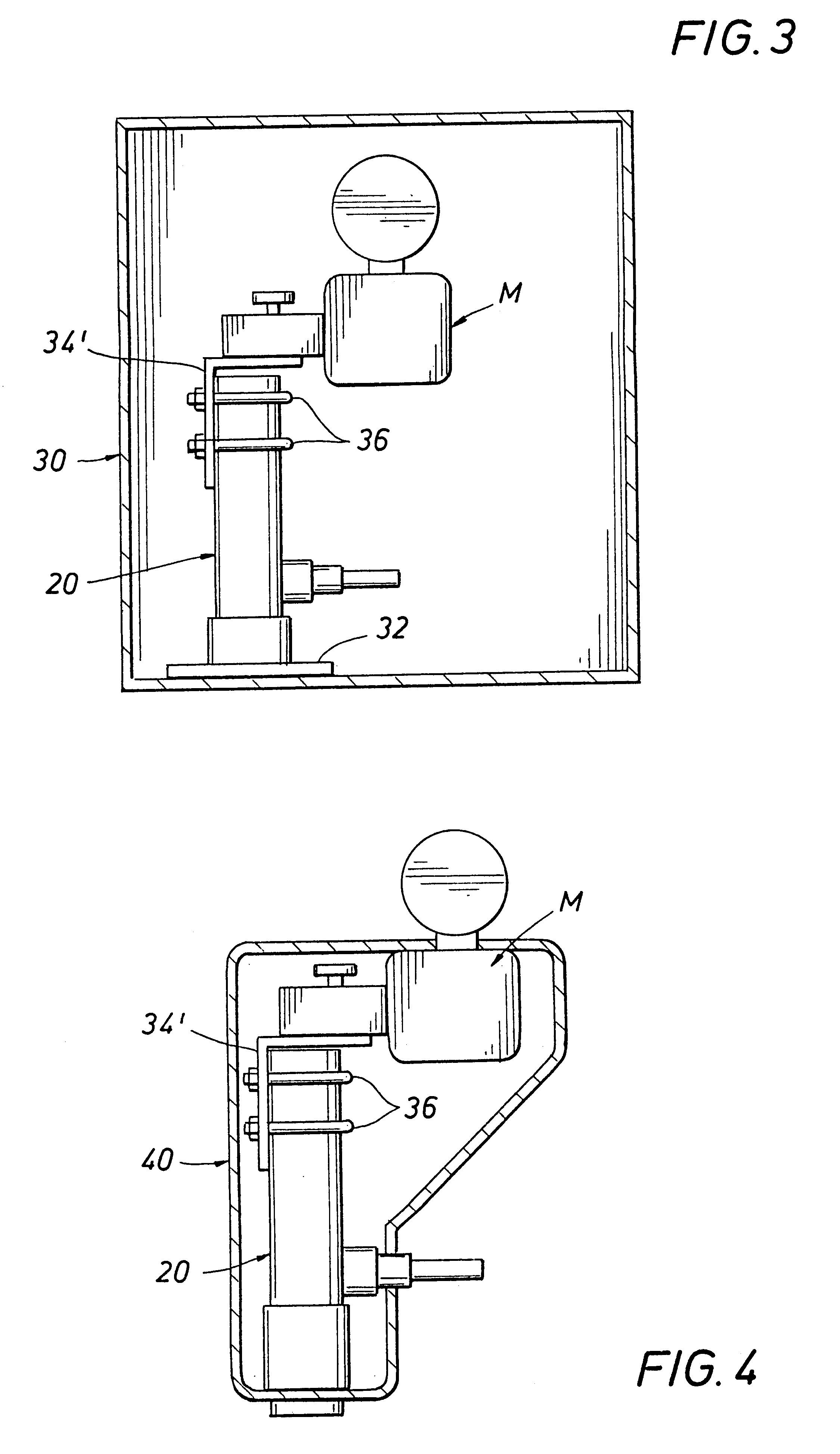

Pipe stand instrument heater and mounting system

InactiveUS6196297B1Improve heat transfer performanceReduced Power RequirementsPipe heating/coolingFluid pressure measurementInstrumentation

A pipe stand instrument heater system heats an instrument within an enclosure supported by a pipe stand. The heater system includes a housing mounted to the pipe stand and a heater unit in the housing. A bracket is provided for mounting the instrument to the housing. The heater unit can be powered by electric, steam or other fluids.

Owner:INTERTEC INSTR

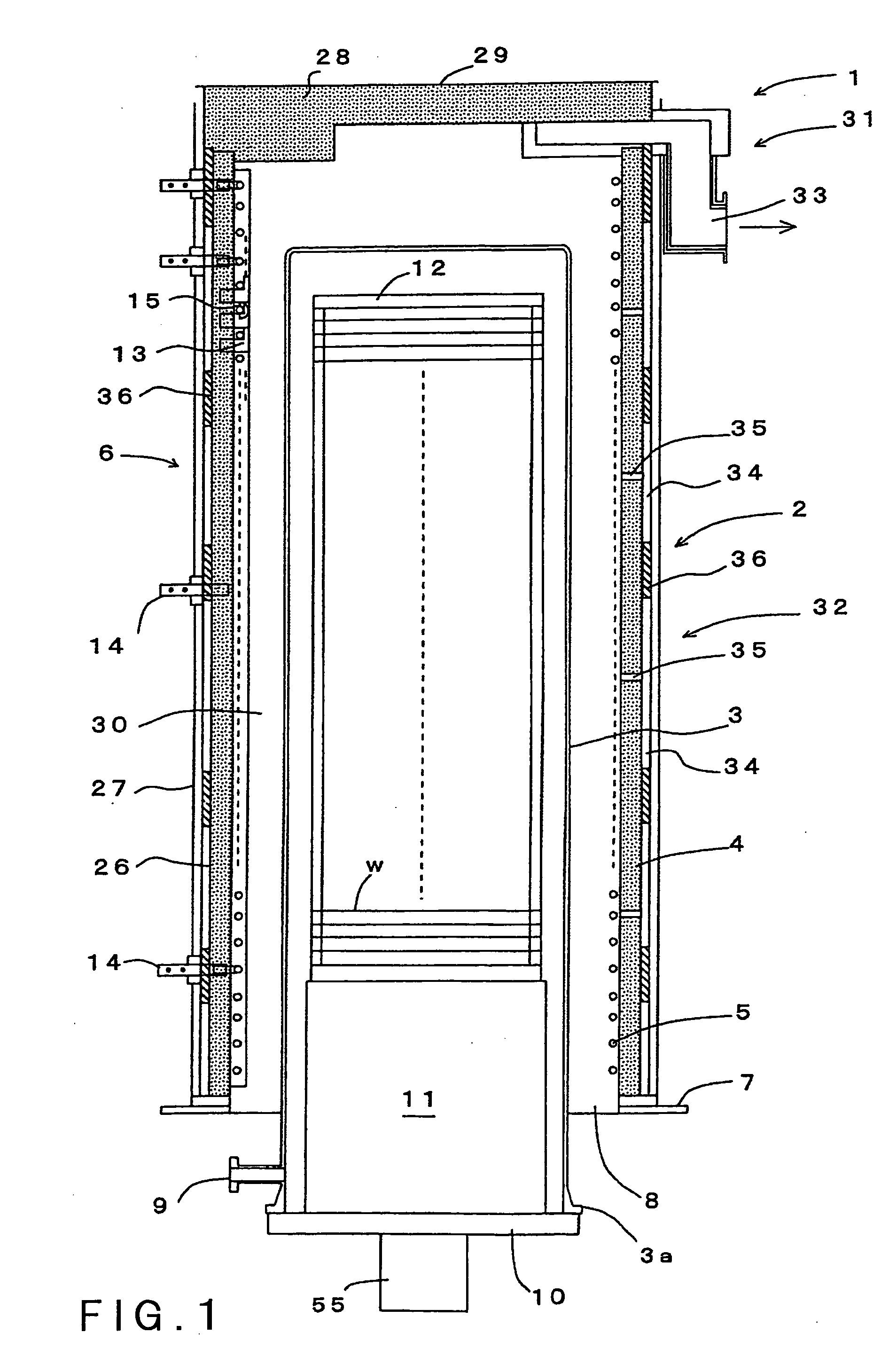

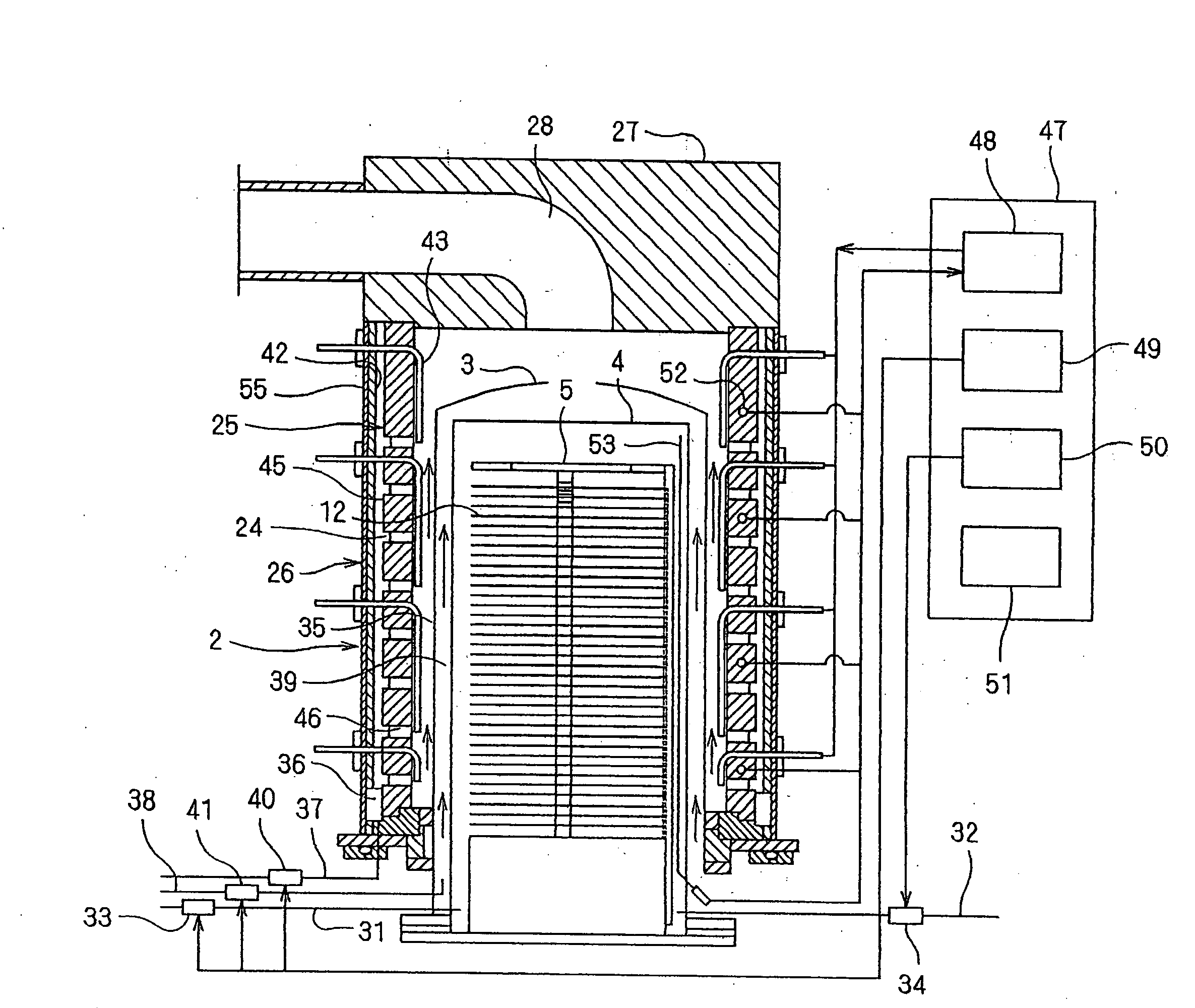

Thermal processing furnace

ActiveUS20090194521A1Increased durabilityMuffle furnacesOhmic-resistance electrodesEngineeringHeat treated

A thermal processing furnace comprises: a tubular heat insulation member 4 surrounding a processing vessel 3 for receiving and thermally processing an object to be processed w; a heating resistor 5 helically arranged on an inner circumferential surface of the heat insulation member 4; and a support member 13 disposed on the inner circumferential surface of the heat insulation member 4, the support member 13 supporting the heating resistor 5 such that the heating resistor 5 can be thermally expanded and thermally shrunk. The thermal processing furnace further comprises: a movement prevention member 15 disposed on the heating resistor 5 to be in contact with one side surface of the support member 13 so as to prevent a downward movement of the heating resistor 5.

Owner:TOKYO ELECTRON LTD

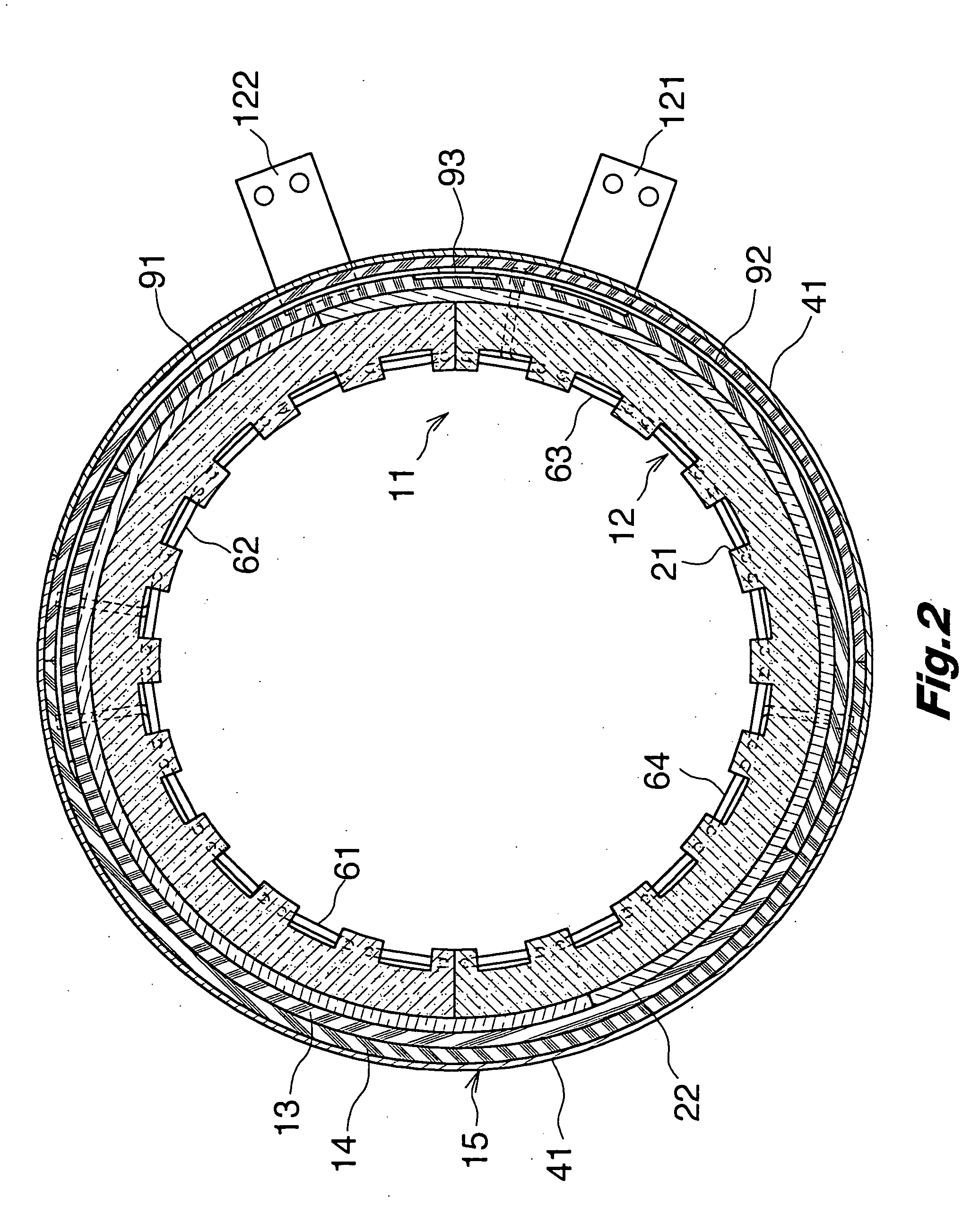

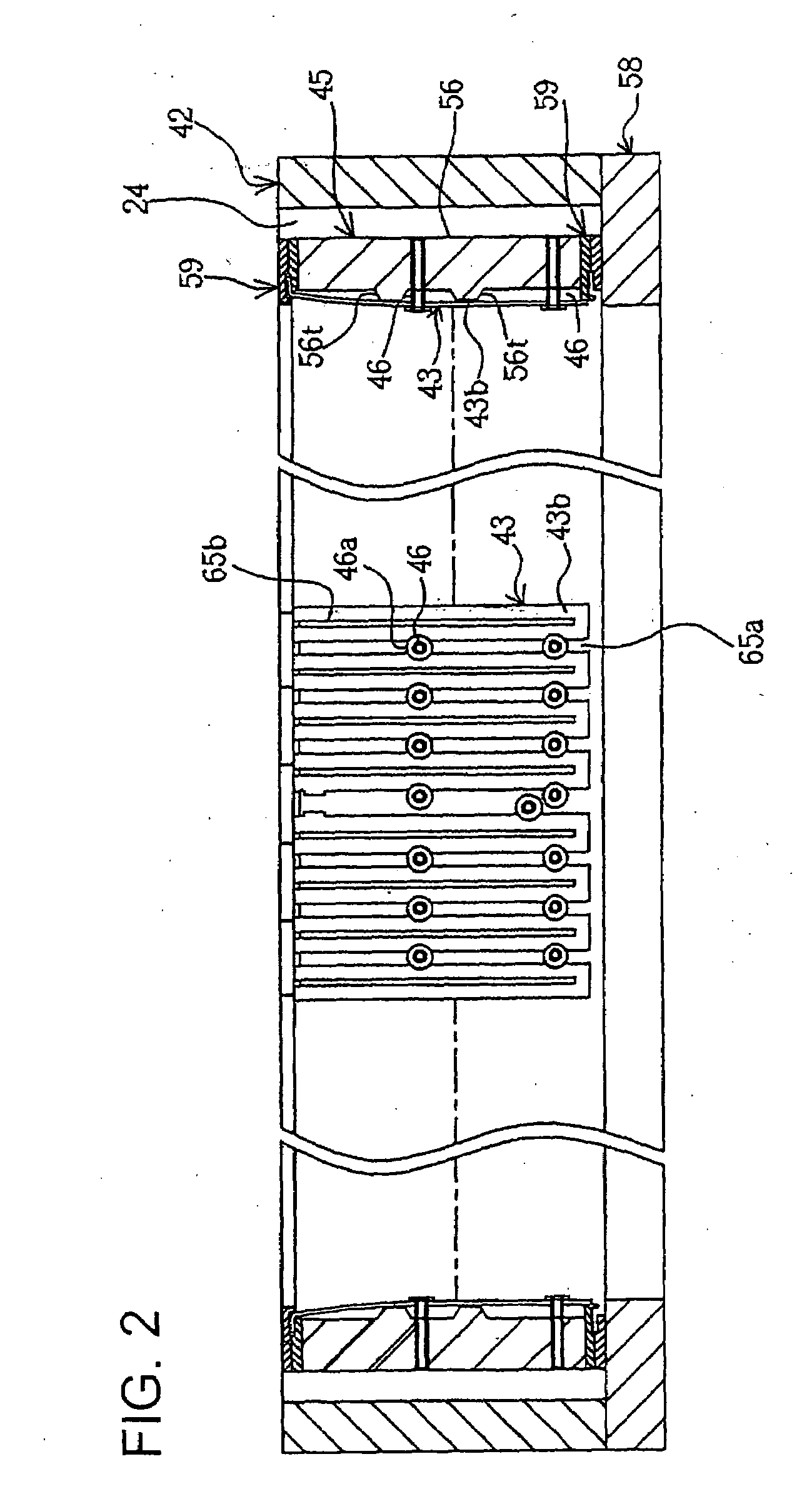

Electric heater for thermal treatment furnace

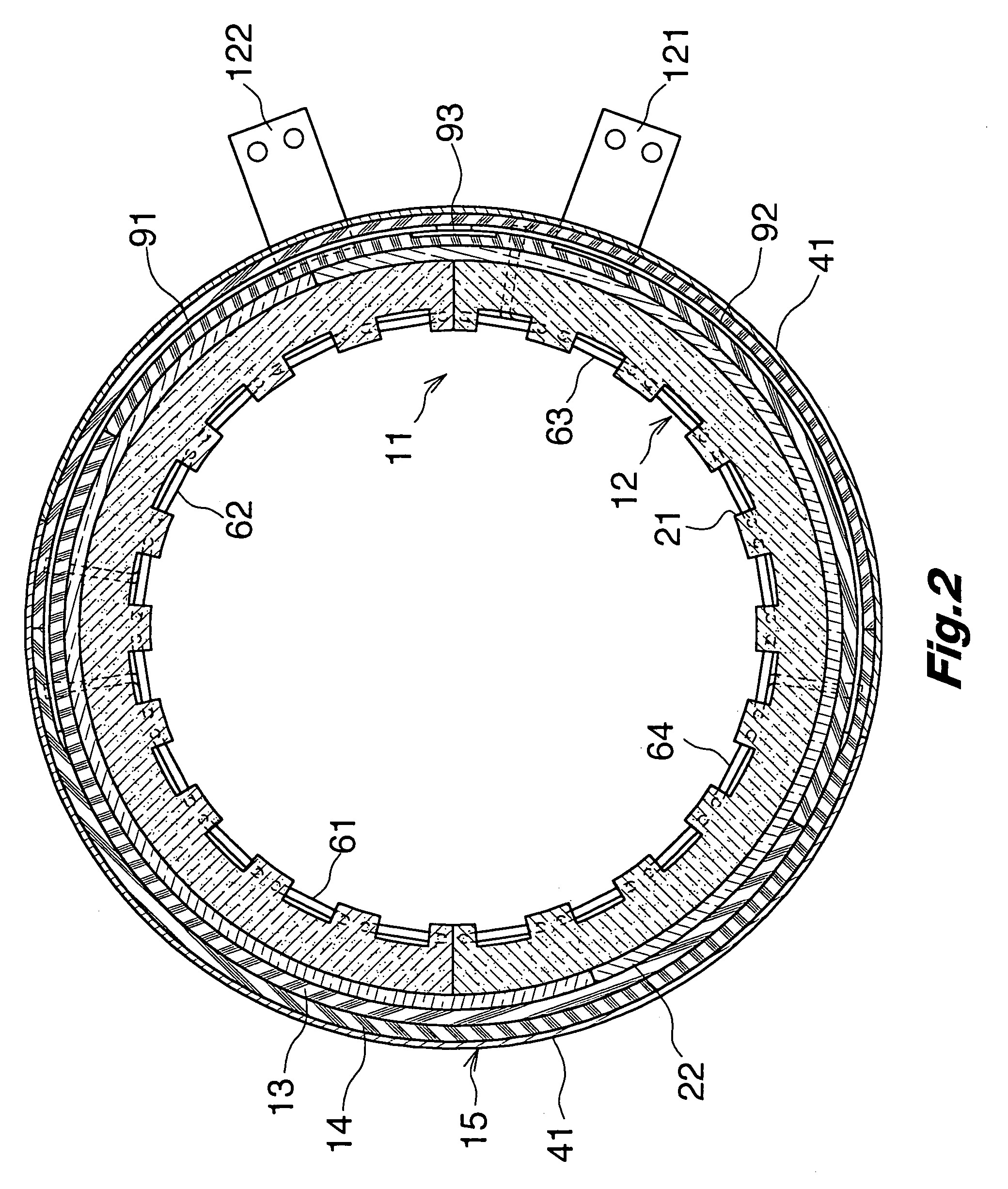

InactiveUS20050069014A1Improve thermal stabilityUnfavorable influence can be preventedSemiconductor/solid-state device manufacturingHeating element shapesThermal insulationEngineering

A heating element (12) made of metal wire is installed at an internal circumferential surface of a cylindrical main thermal insulation body (11) of an electric heater according to the present invention. The heating element (12) comprises a plurality of resistance heat emitting portions (61)-(64)(71)-(74)(81)-(84) as segments along its length direction. The resistance heat emitting portions (61)-(64)(71)-(74)(81)-(84) are connected in parallel.

Owner:KOYO THERMO SYST CO LTD

Glass manufacturing apparatus, a structural member thereof and method for heating the structural member by conduction heating

A hollow tubular body for molten glass in which local-overheating is reduced at the time of conduction heating. The hollow tubular body has a platinum or platinum alloy hollow tube, used for conduction heating, wherein a platinum or platinum alloy ring electrode is joined to the outer circumference of the hollow tube, a lead-out electrode is joined to an outer edge of the ring electrode, and a thick portion is provided in at least the joint portion closest to the lead-out electrode, of the ring electrode and in the vicinity thereof.

Owner:ASAHI GLASS CO LTD

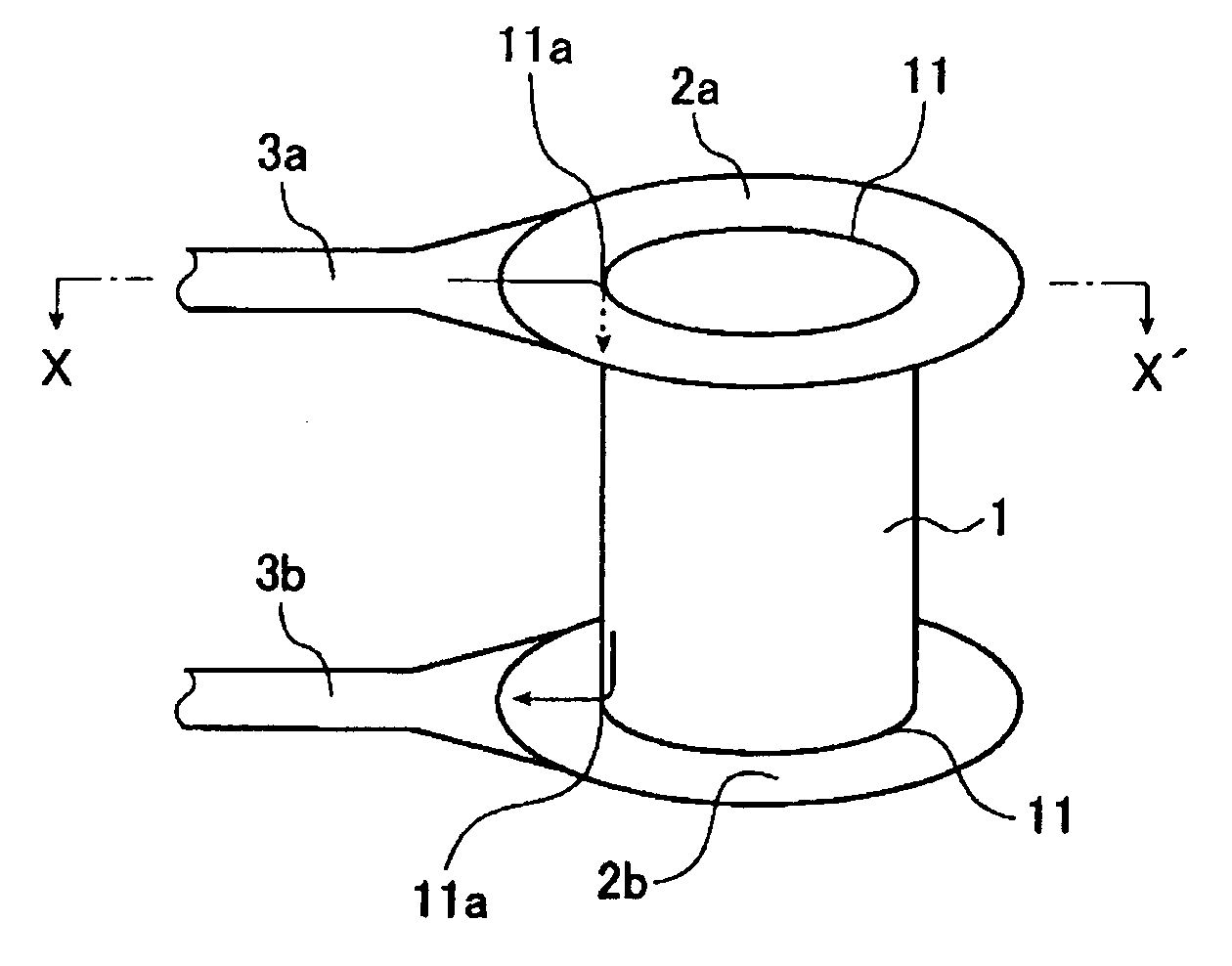

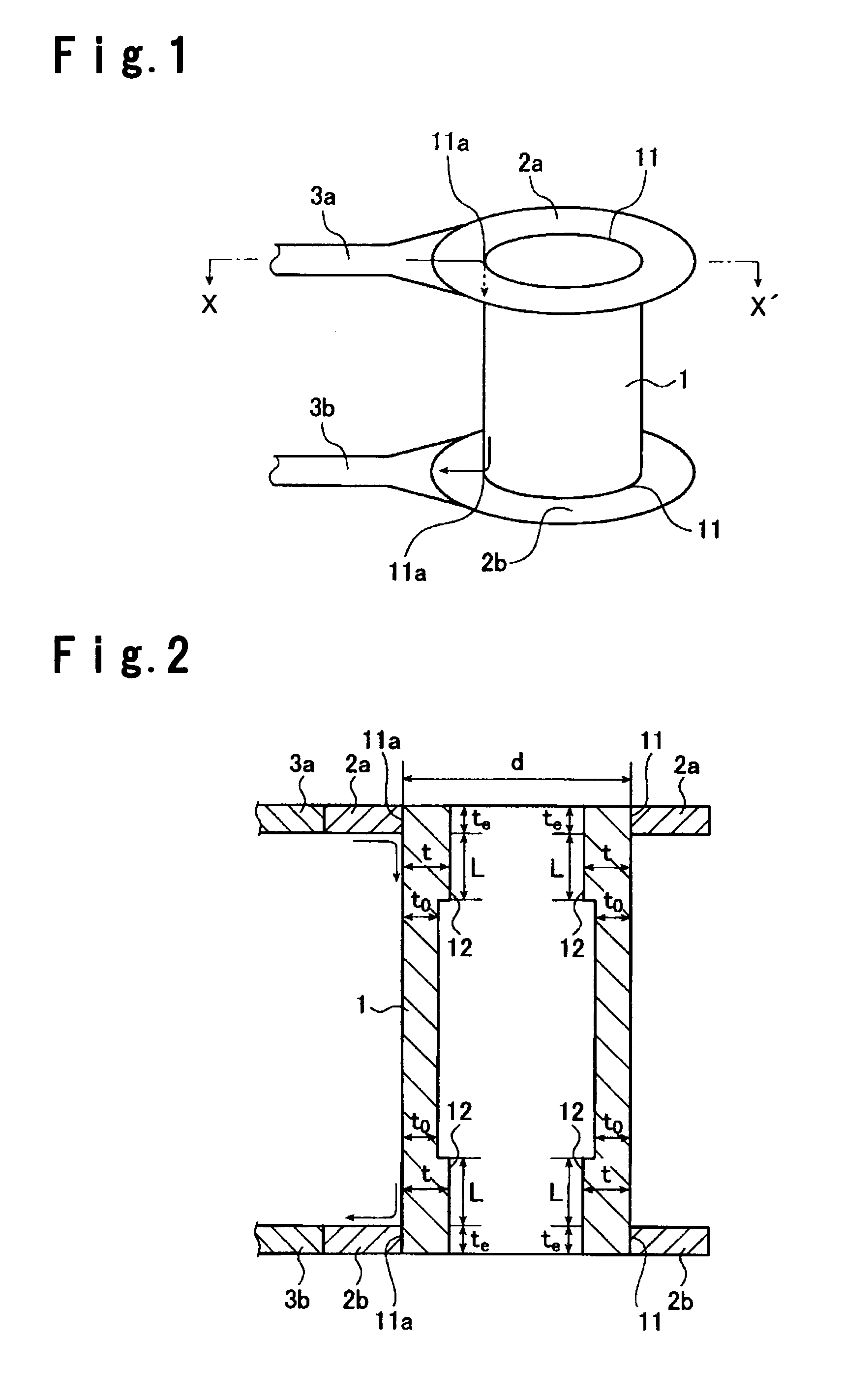

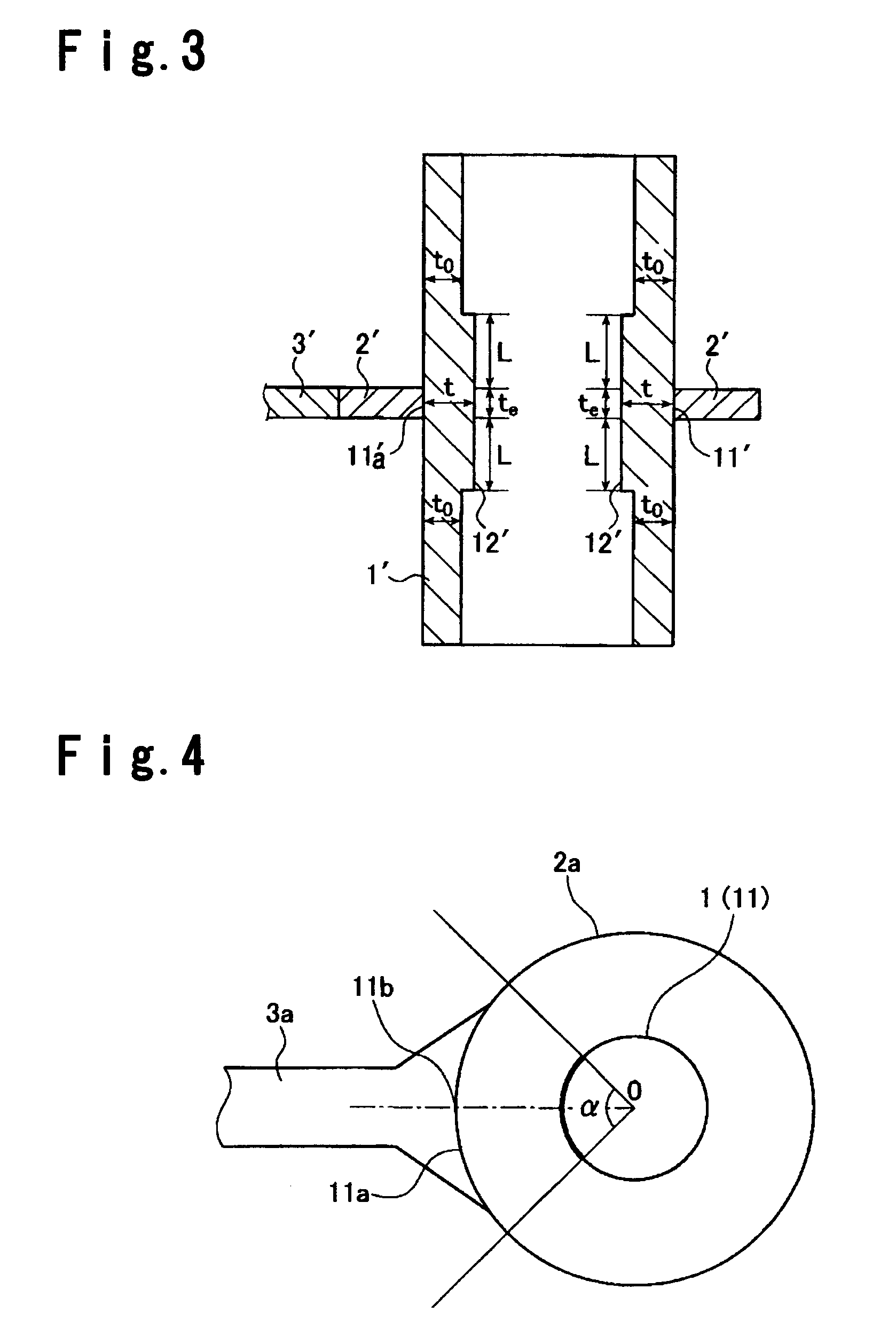

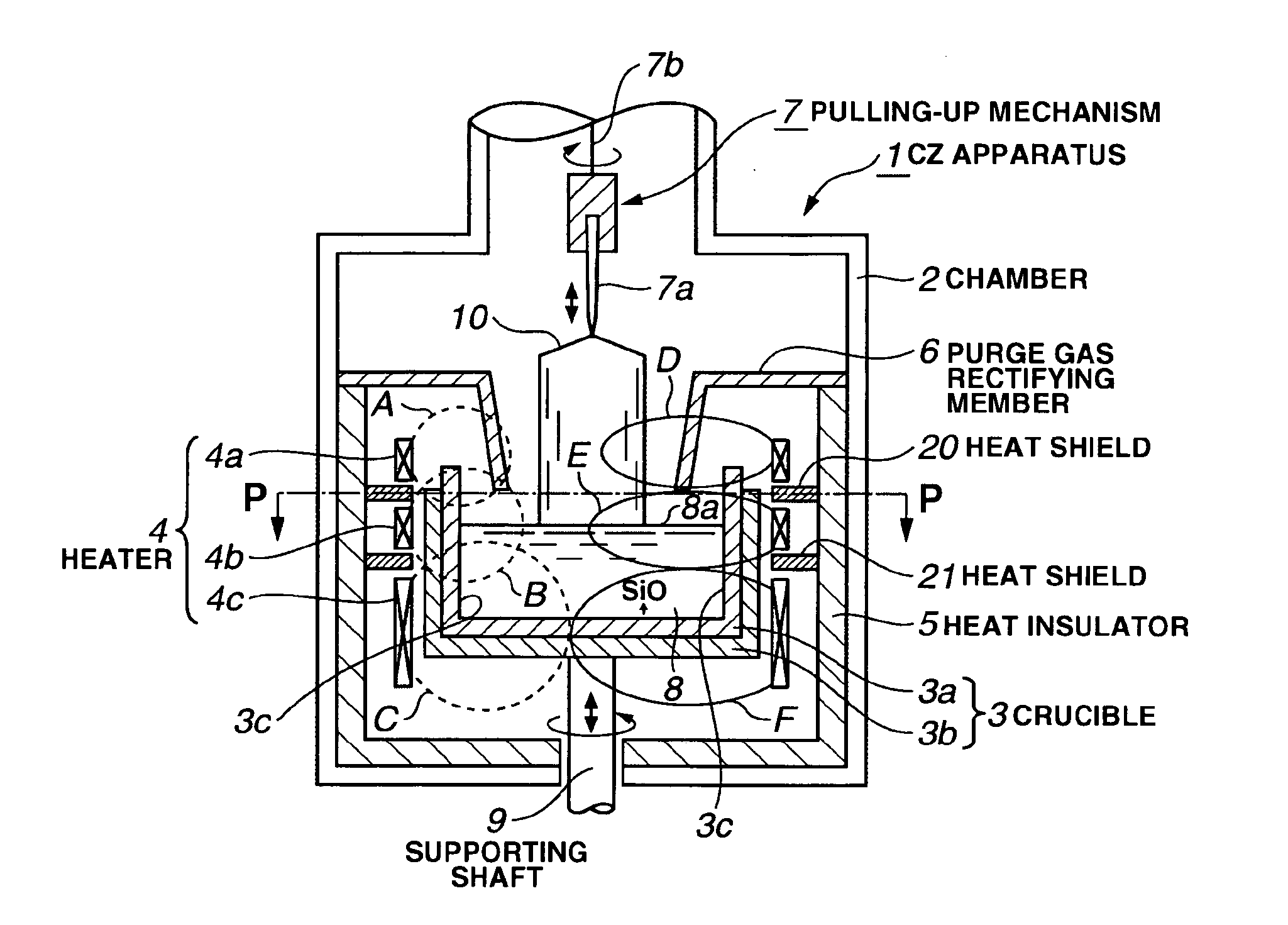

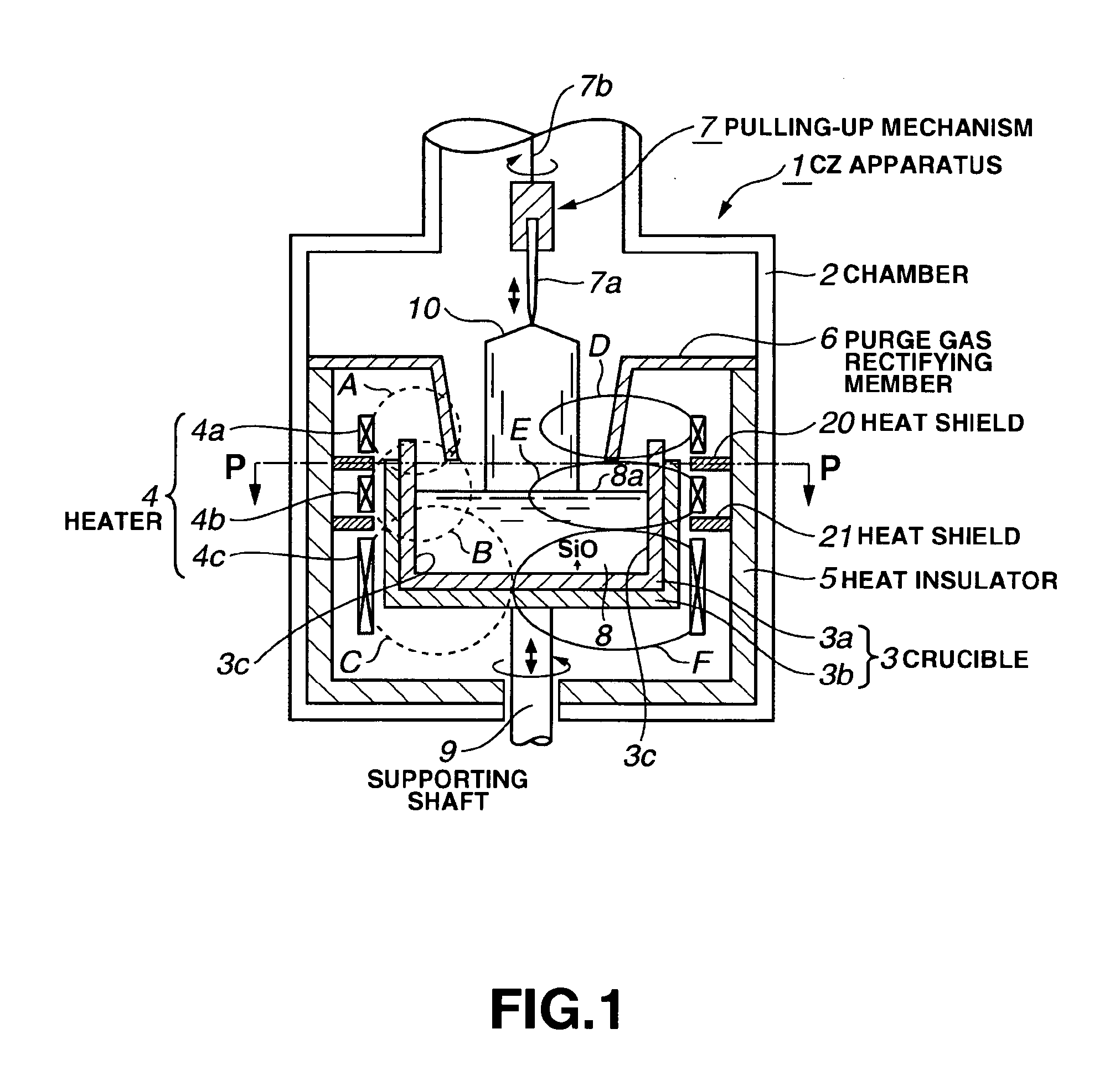

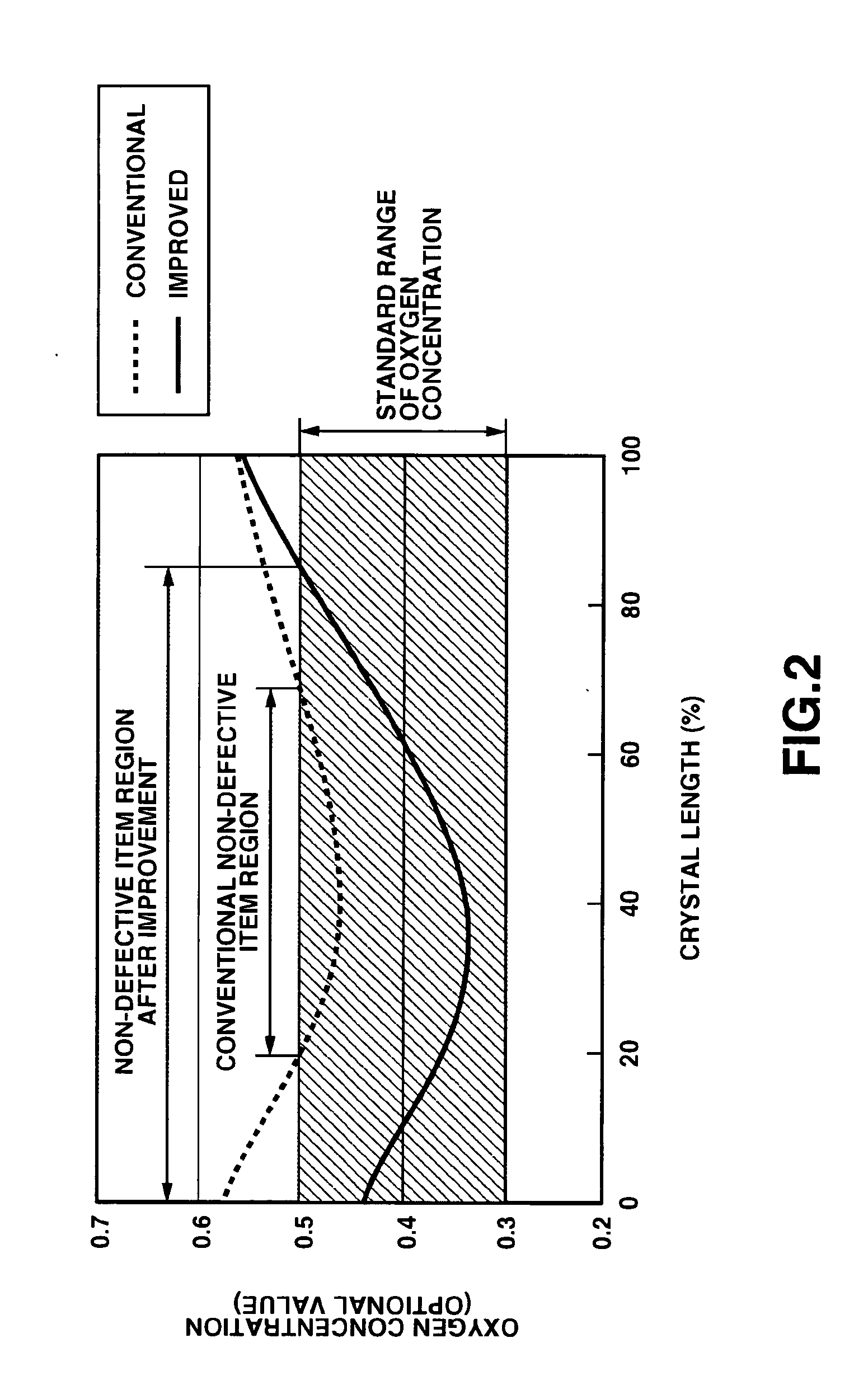

Semiconductor Single Crystal Manufacturing Apparatus and Graphite Crucible

ActiveUS20070215038A1Improve directionalityImprove directivityPolycrystalline material growthBy zone-melting liquidsSingle crystalEngineering

A semiconductor single crystal manufacturing apparatus which can manufacture a single crystal of high oxygen concentration to that of low oxygen concentration within a prescribed standard range of oxygen concentration, as a wafer material for semiconductor integrated circuits, with a high yield, is provided. Heat shields 20, 21 are provided in the entire annular area between respective adjacent heaters of the heaters 4a, 4b, 4c for heating the crucible 3 from the outside periphery side. By using the heat shields 20, 21 for localizing the respective heating regions for the heaters to actively control the temperature distribution for the crucible 3 and melt 8 in the crucible, a single crystal of high oxygen concentration to that of low oxygen concentration can be manufactured within a prescribed standard range of oxygen concentration with a high yield.

Owner:SUMCO TECHXIV

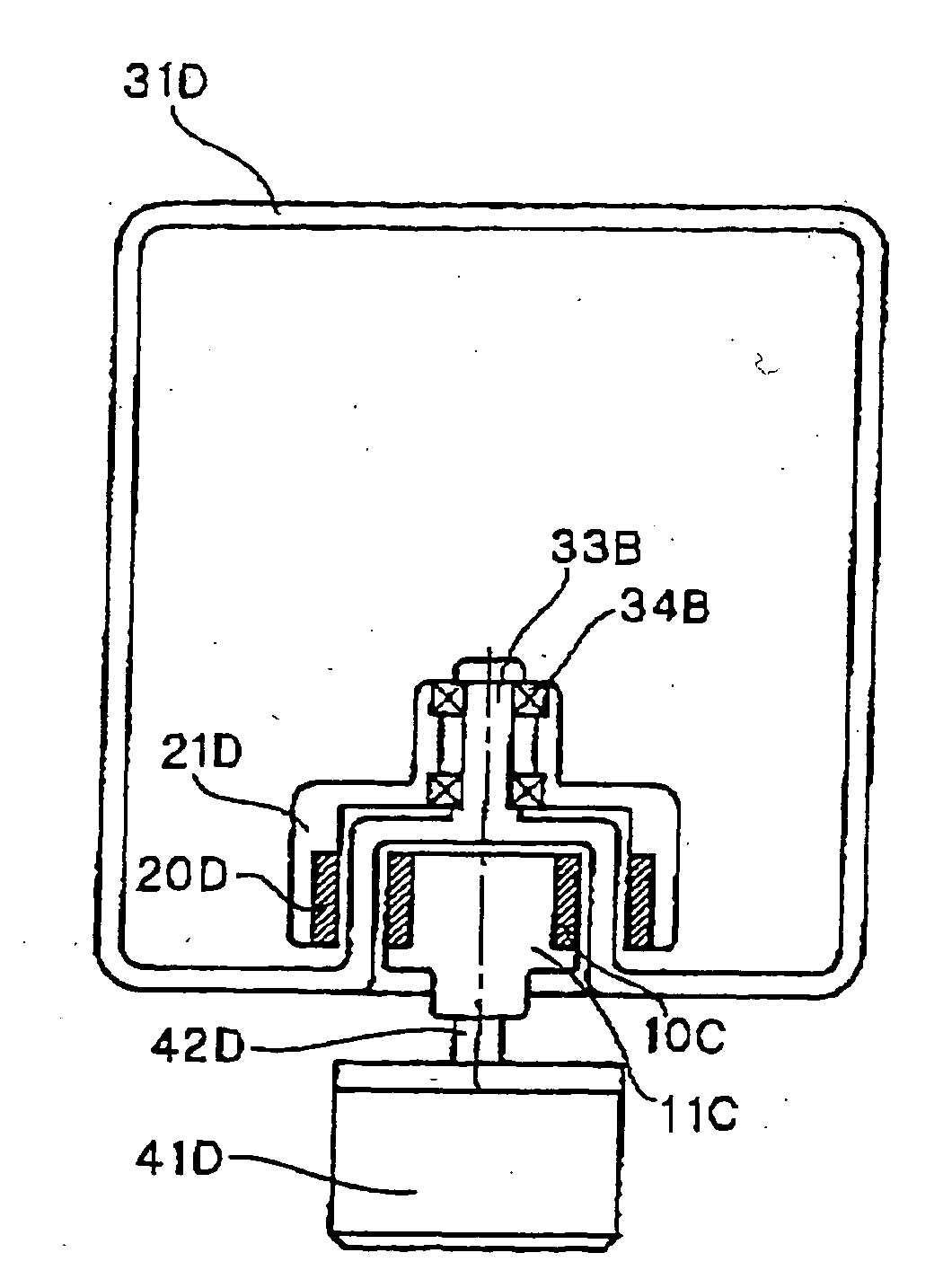

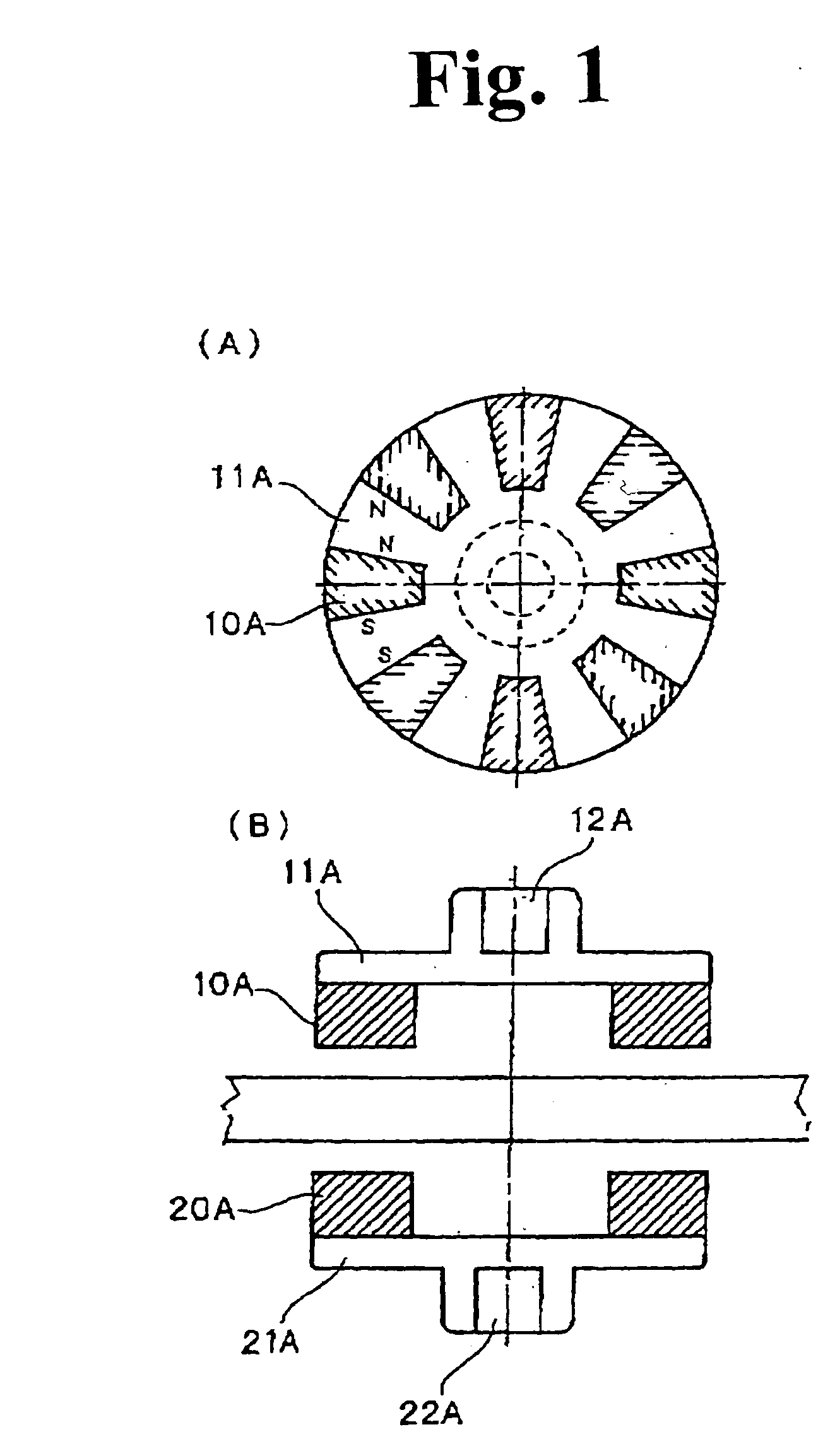

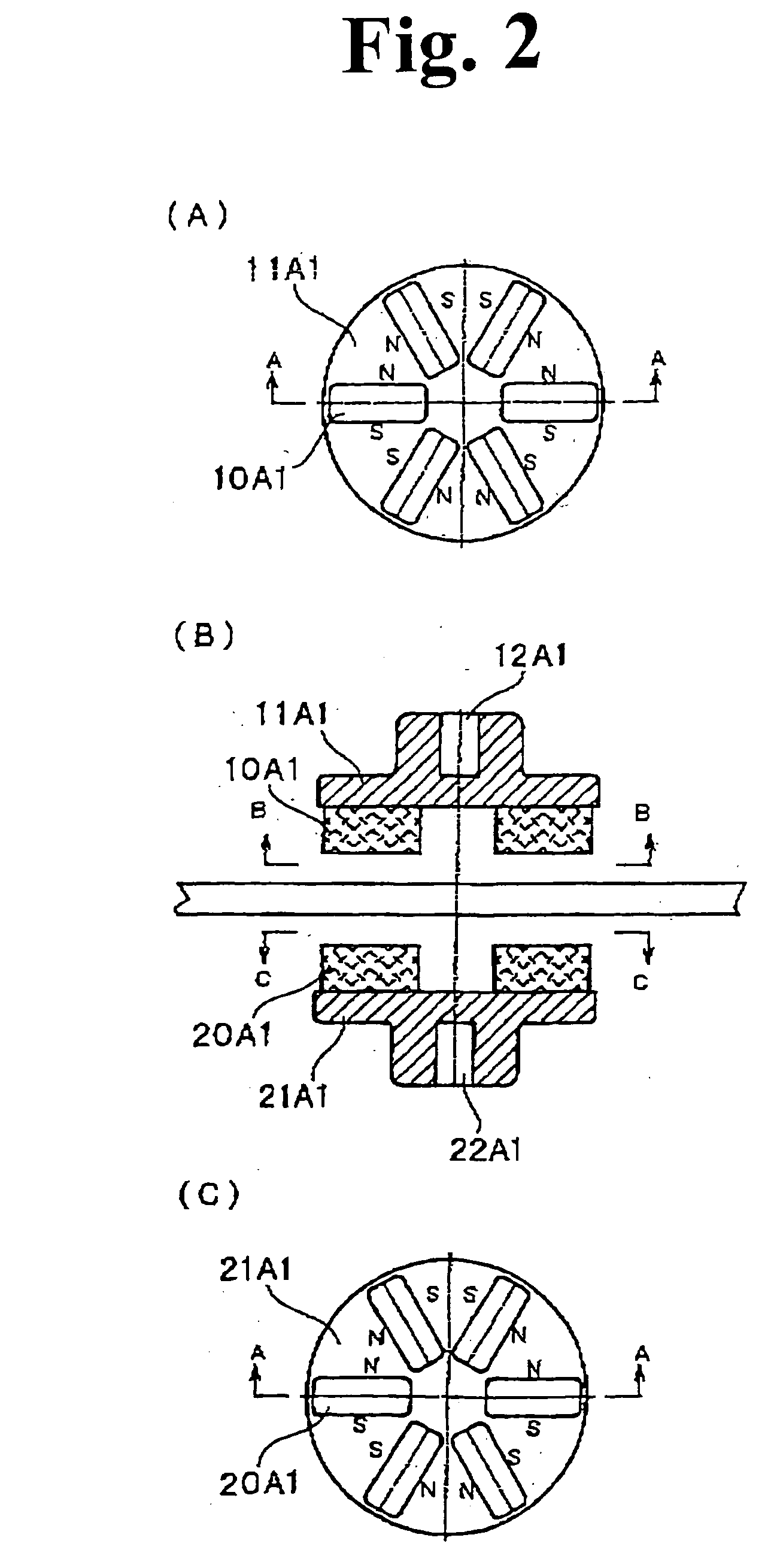

Magnetic rotation transmitting device, hermetic stirring unit, and electric furnace

InactiveUS7112904B2Dynamo-electric brakes/clutchesRotary stirring mixersMagnetic rotationElectric arc furnace

In order to provide a magnetic rotation transmitting device capable of obtaining a large transmitting torque without using a large-sized permanent magnet, in an axial-type magnetic rotation transmitting device, which includes a driving rotation body having one or plural magnetic line(s) in which plural first magnets (10A) are disposed in a circumferential direction on a first disk (11A) at almost equal intervals, a drive source rotationally driving a drive shaft of the driving rotation body, and a driven rotation body having one or plural magnet line(s) in which second magnets (20A) of the same number as the first magnets (10A) are disposed in the circumferential direction on a second disk (21A) at almost equal intervals, symmetrically disposed to, and magnetically coupled with the driving rotation body with a magnetic coupling gap and, which utilizes a magnetic operation and which allows the driven rotation body to rotate by rotationally driving the drive shaft by means of the drive source, the first magnet (10A) has a N-magnetic pole portion and a S-magnetic pole portion, and an extended surface of a boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driving center line as being a rotation center line of the driving rotation body, the second magnet (20A) has the N-magnetic pole portion and the S-magnetic pole portion, and the extended surface of the boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driven center line as being the rotation center line of the driven rotation body, adjacent and facing surfaces of the first magnets (10A) adjacent to each other on the first disk (11A) are disposed so that magnetic pole faces having the same polarity make pairs, and adjacent and facing surfaces of the second magnets (20A) adjacent to each other on the second disk (21A) are disposed so that the magnetic pole faces having the same polarity make pairs.

Owner:MAGUNEO

Chamber for uniform substrate heating

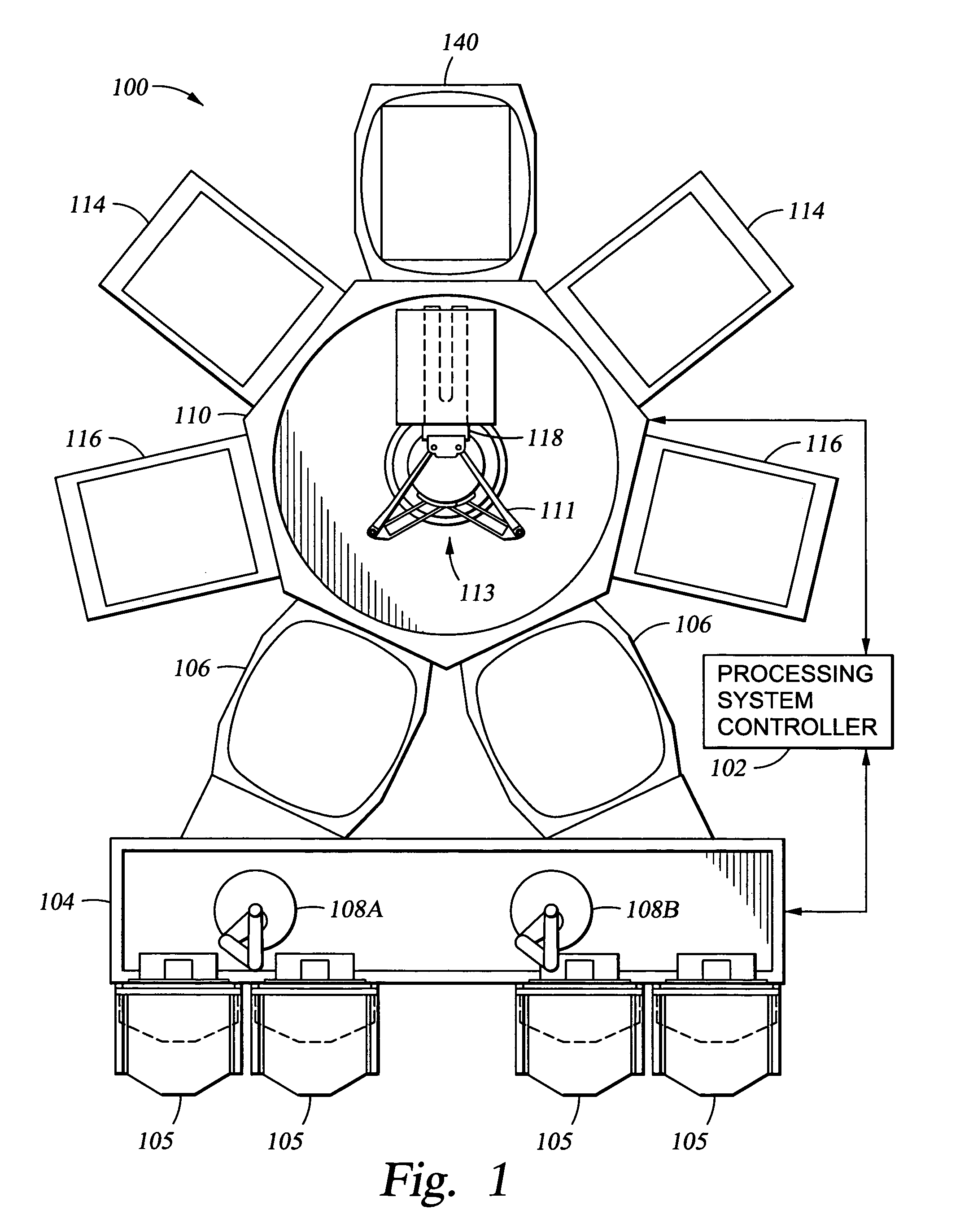

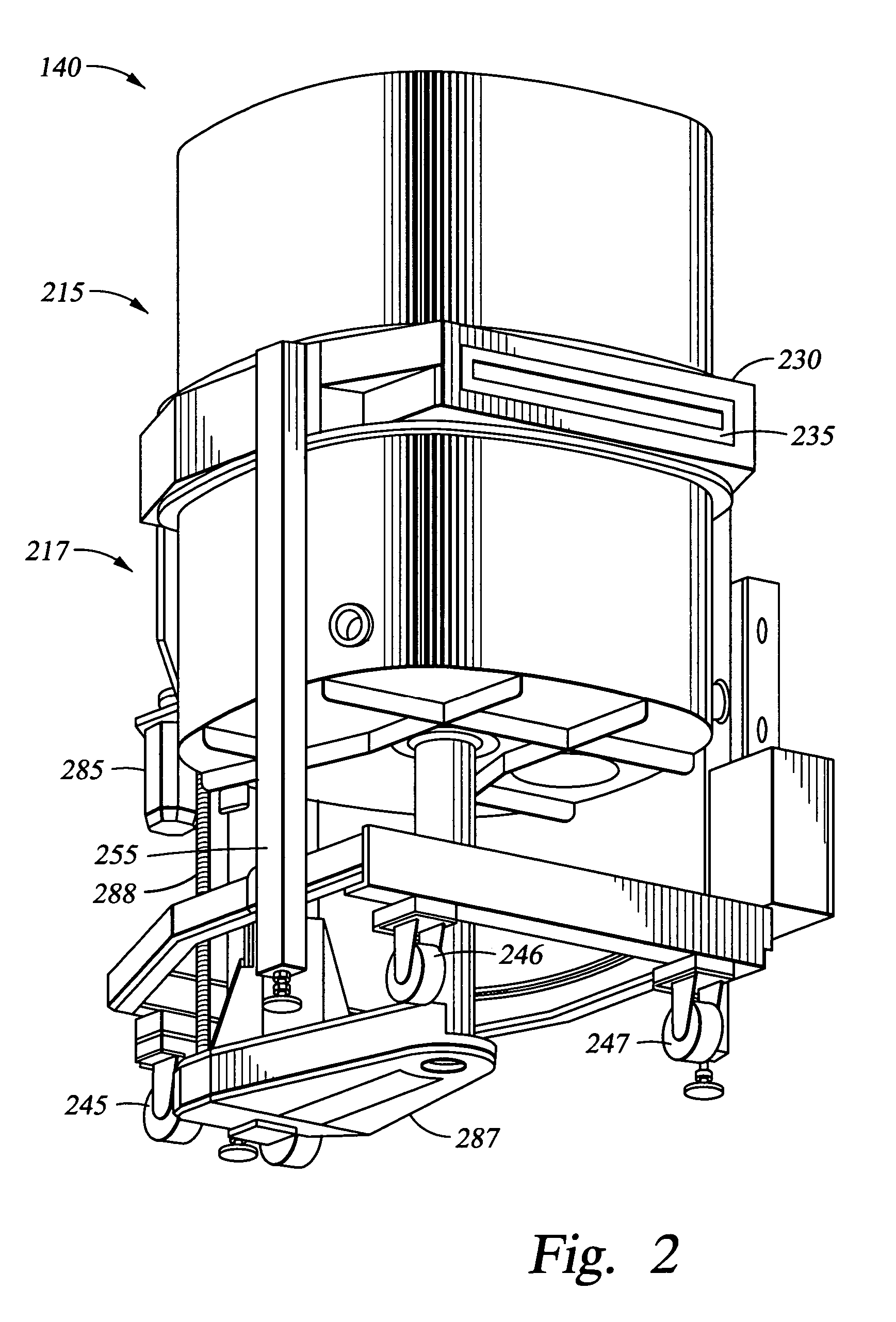

Embodiments of the invention generally provide an apparatus and a method for providing a uniform thermal profile to a plurality of substrates during heat processing. In one embodiment, a cassette containing one or more heated substrate supports is moveably disposed within a heating chamber having an about uniform thermal profile therein to more uniformly heat the substrates.

Owner:APPLIED MATERIALS INC

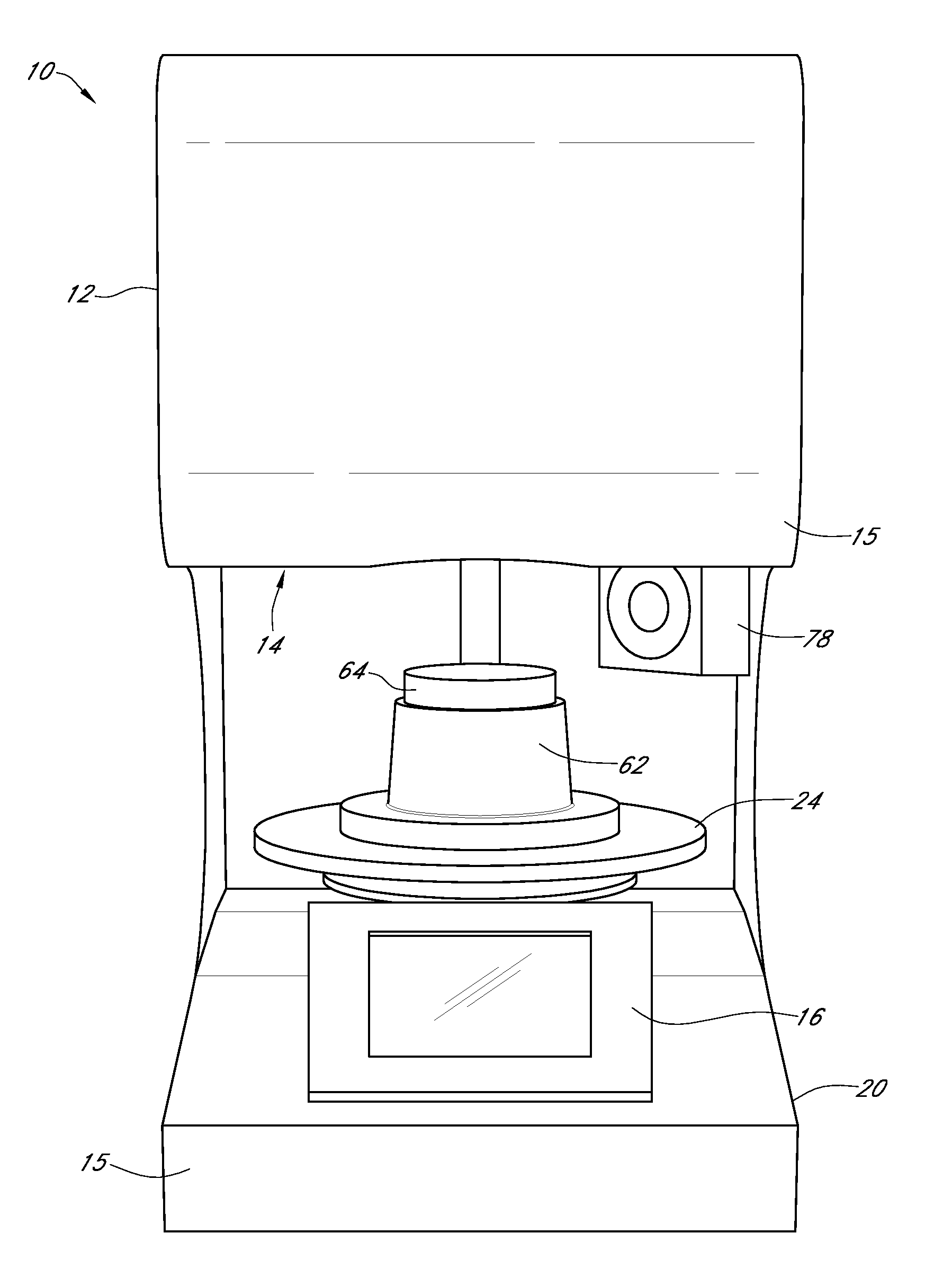

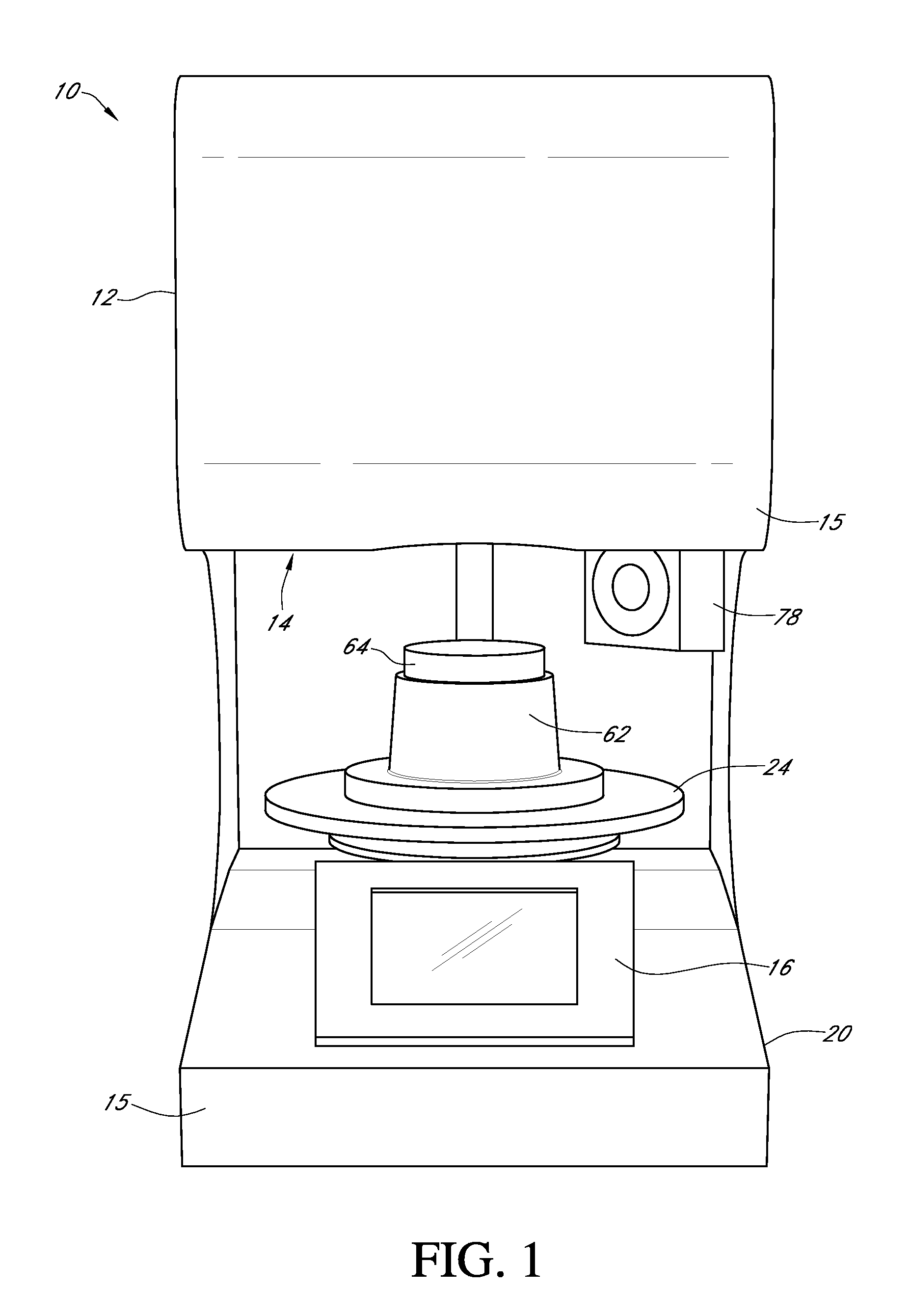

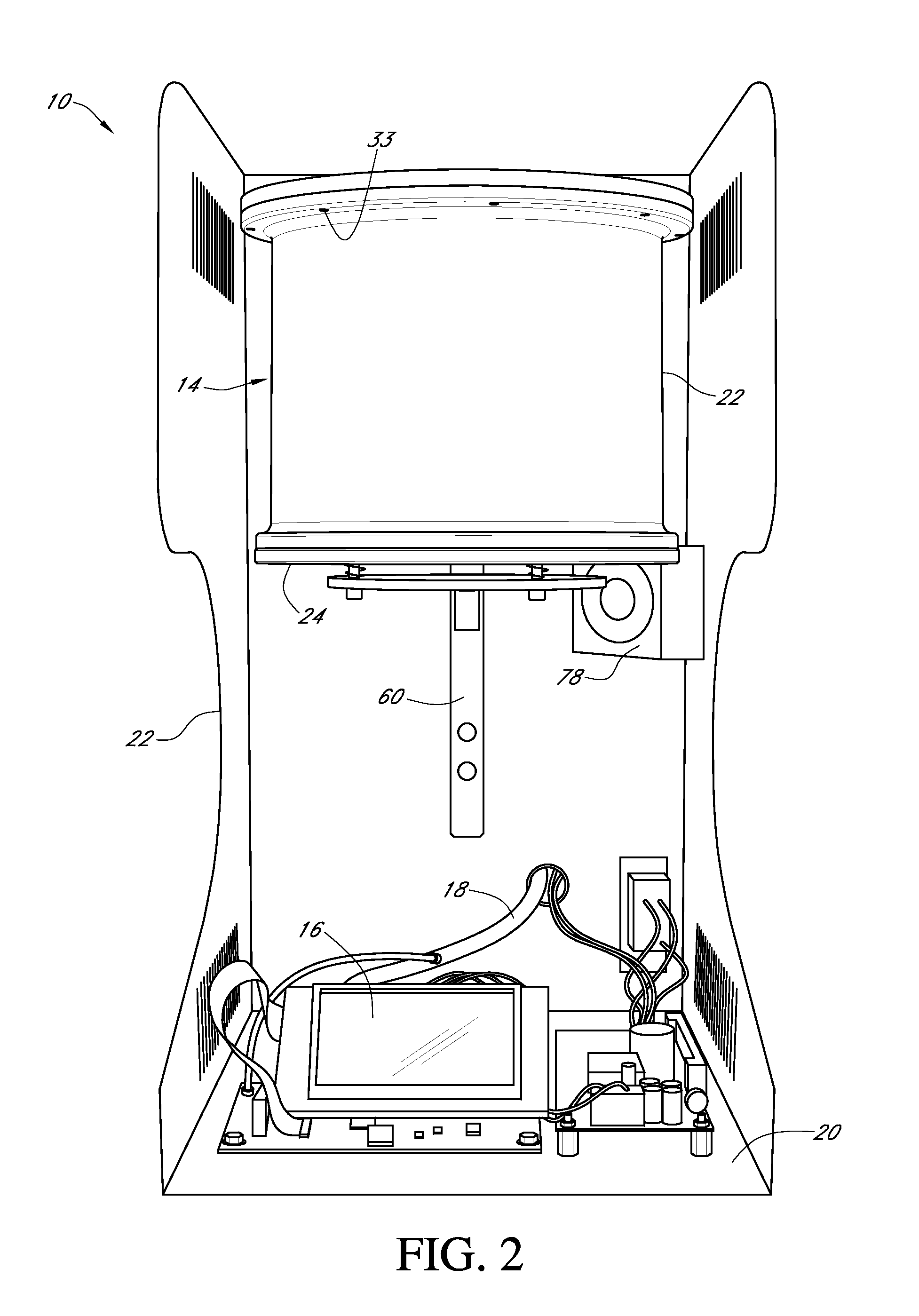

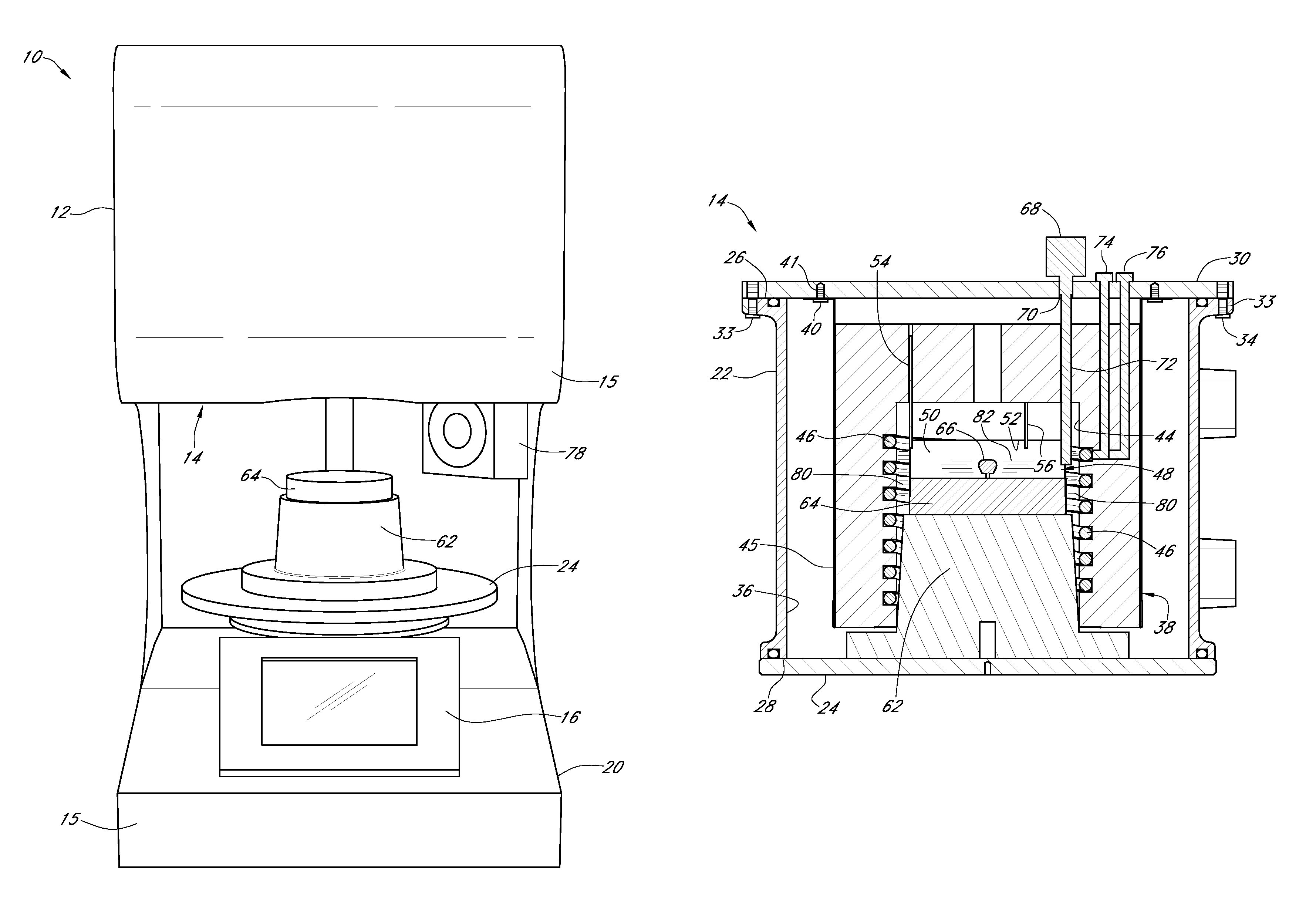

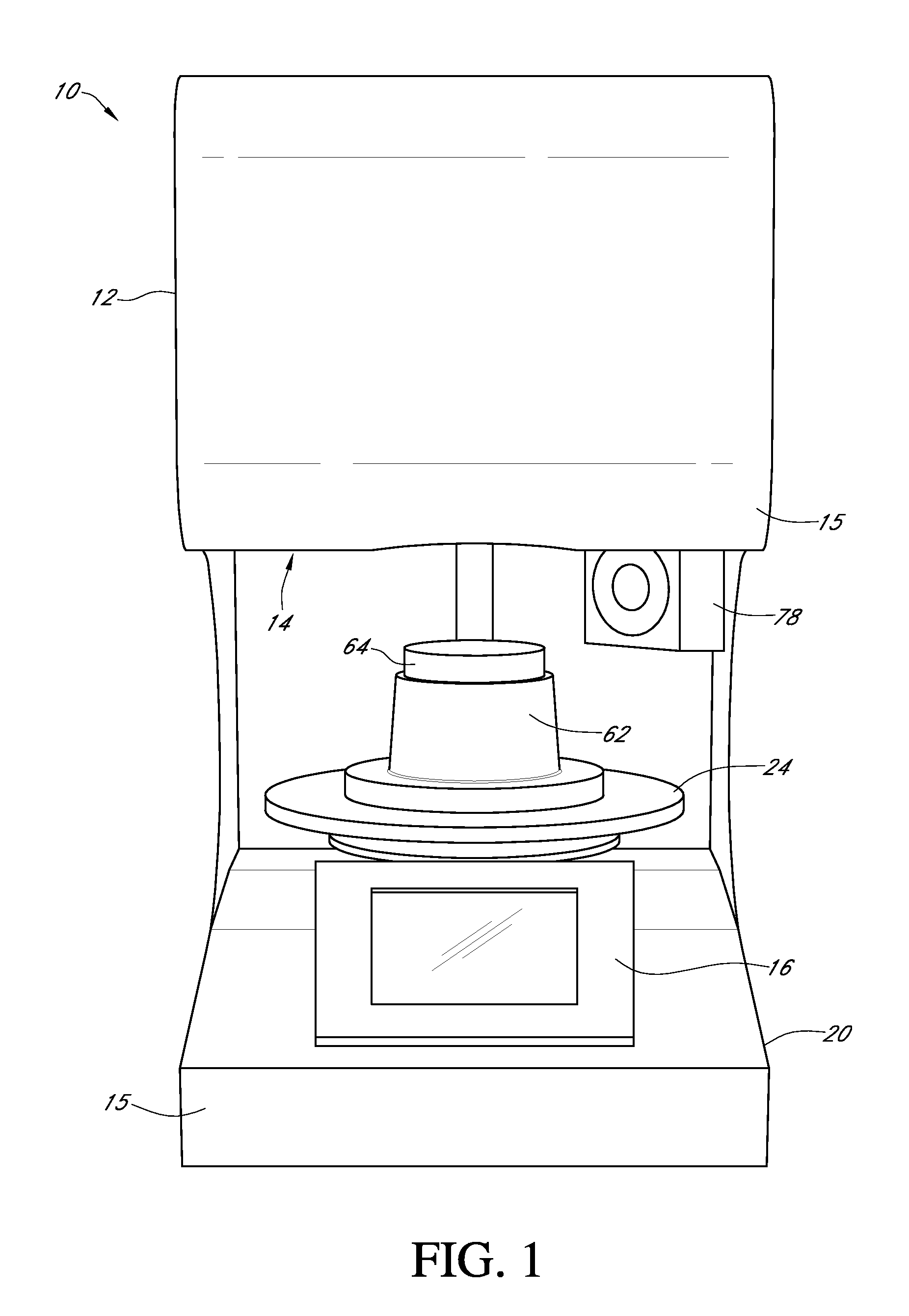

Vacuum Oven

A vacuum oven or vacuum furnace is disclosed having a heat distribution sleeve that conforms to the shape of an interior heating chamber. The heat distribution sleeve may be of generally annular shape, like a ring, and located in a substantially regularly spaced and offset relationship from a heating element located within walls adjacent the interior heating chamber. The heat distribution sleeve includes a thermal conductive material which absorbs and re-radiates heat emitted from the heating element, thereby providing more consistent and regular radiation fields for heating treating a work piece that is loaded on a work holding tray and, upon the vacuum oven being in an operational position, the work piece is located within the furnace chamber.

Owner:IBEX DENTAL TECH

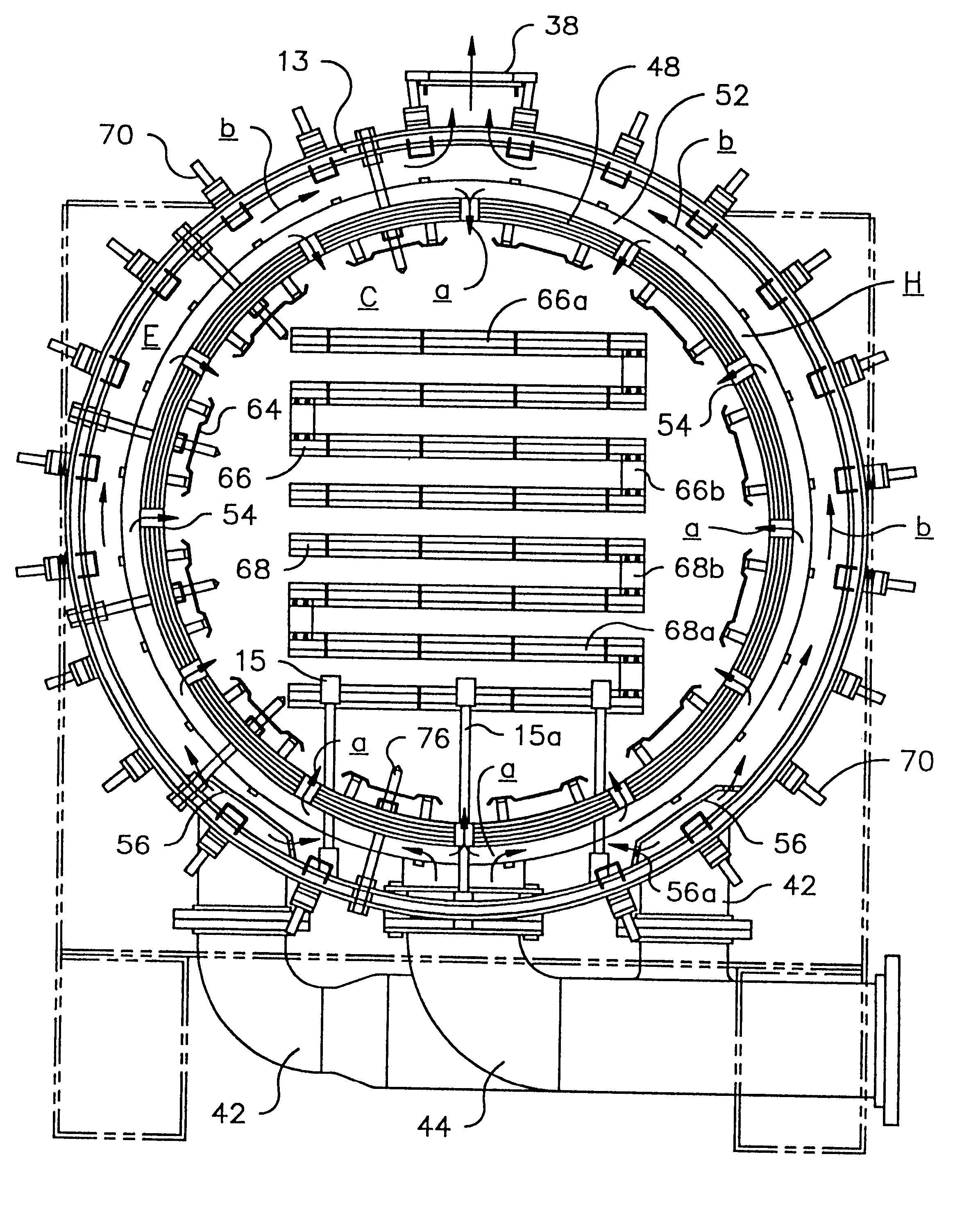

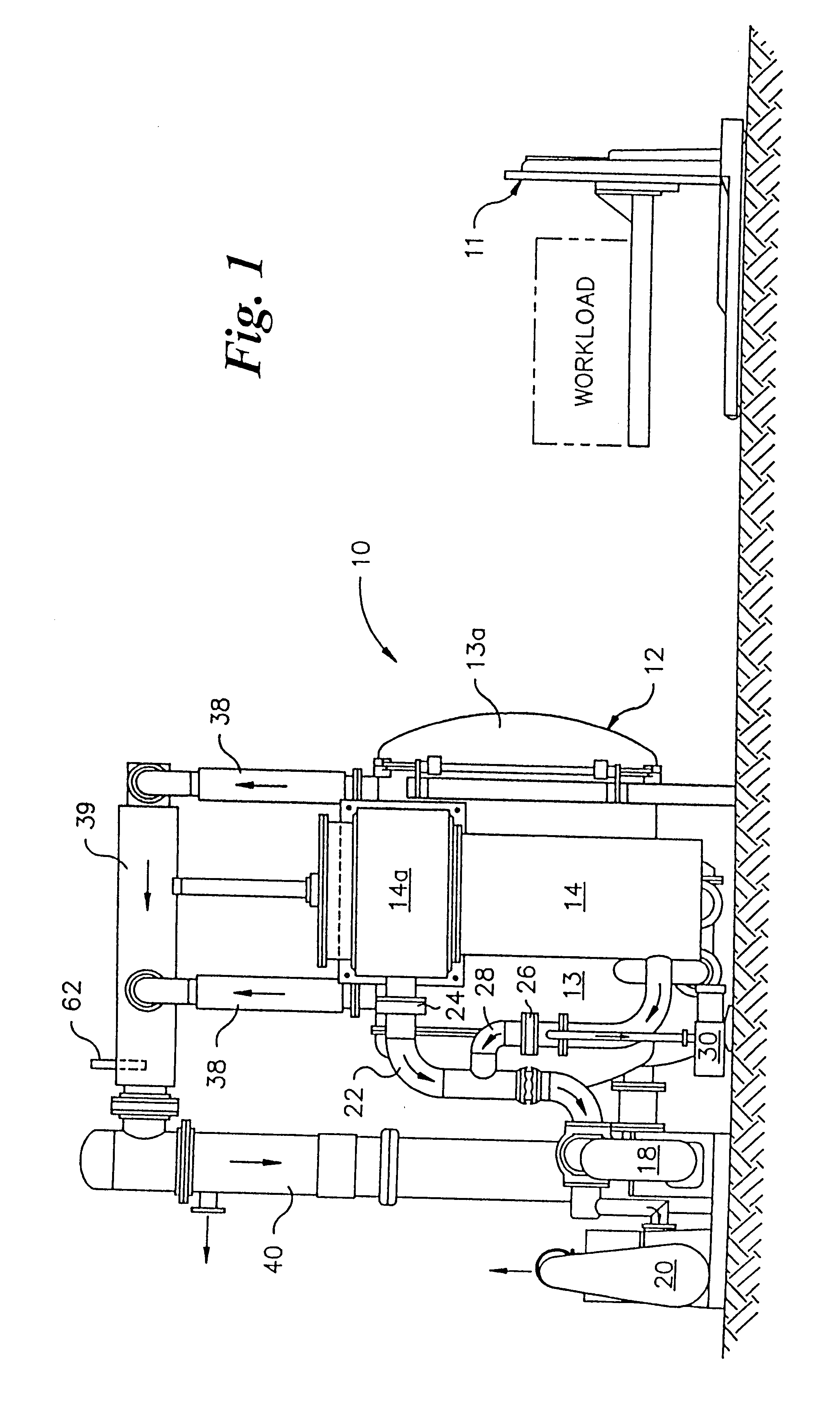

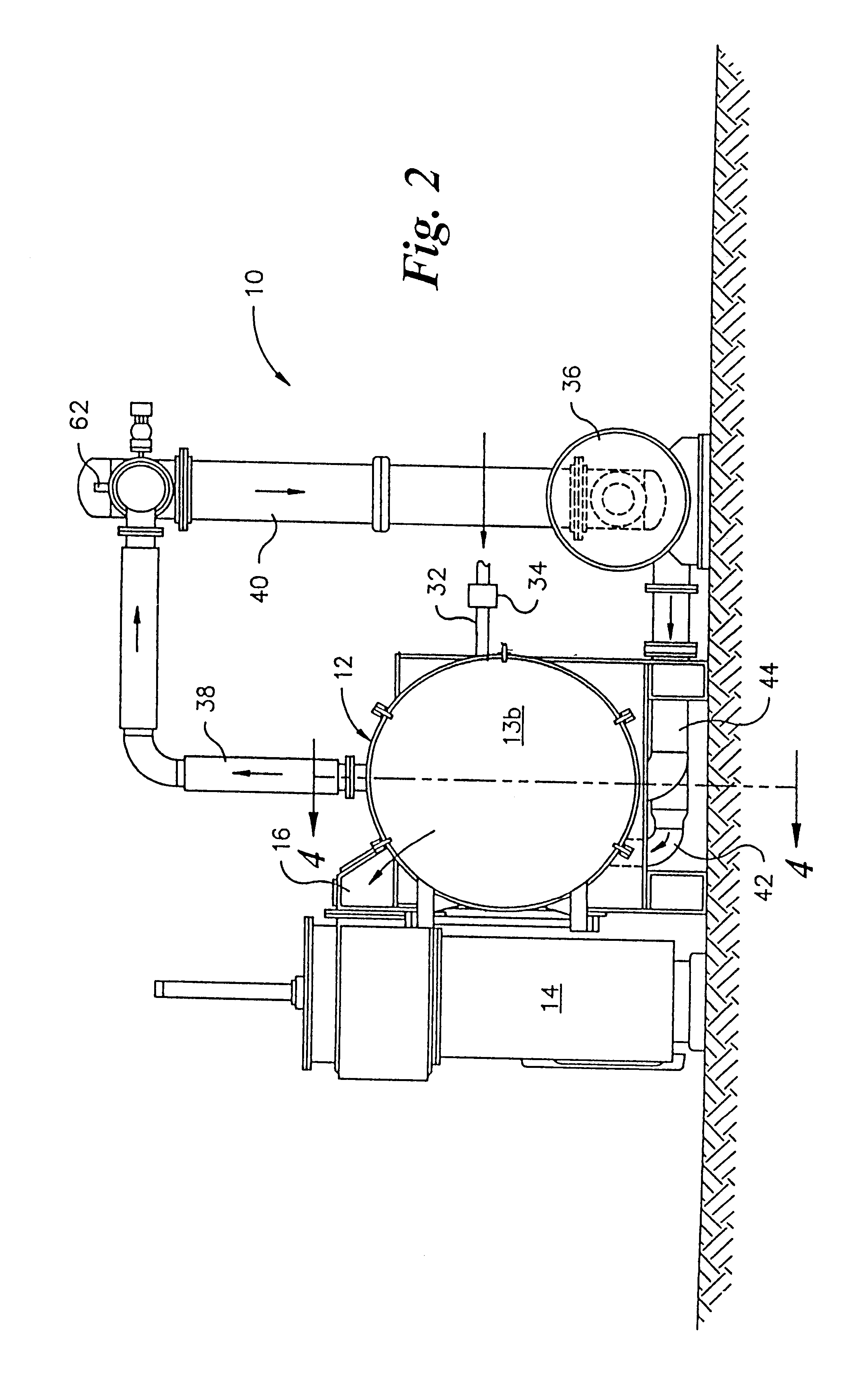

High temperature vacuum furnace

InactiveUS6349108B1Improve uniformityEffective dispersionMuffle furnacesMaintainance of heating chambersEngineeringDirect radiation

An electric resistance high temperature vacuum furnace having radiant heating units evenly spaced around the sides and ends of the furnace hot zone. Pairs of units are automatically regulated both radially and longitudinally according to the temperature required by the workload in the hot zone. The units each comprise parallel aligned elements electrically connected in series at their one ends. Each element has lengthwise surfaces angularly disposed from each other to form a beam structure of high section modulus for stiffness and resistance to sagging. Also, the angles of the element surfaces facing a heat-reflective assembly substantially enable all of the energy radiated toward the assembly to be reflected into the hot zone in addition to the direct radiation from the surfaces facing the hot zone. The furnace includes a re-circulating cooling system for rapid cooling of the furnace and workload. An inert cooling fluid bypasses the hot zone, passing instead around the outside of the heat assembly and through a heat exchanger until the circulated fluid temperature drops below the maximum tolerated by all component parts in the cooling system, after which the fluid passes directly through the hot zone.

Owner:PVT

Vacuum oven

A vacuum oven or vacuum furnace is disclosed having a heat distribution sleeve that conforms to the shape of an interior heating chamber. The heat distribution sleeve may be of generally annular shape, like a ring, and located in a substantially regularly spaced and offset relationship from a heating element located within walls adjacent the interior heating chamber. The heat distribution sleeve includes a thermal conductive material which absorbs and re-radiates heat emitted from the heating element, thereby providing more consistent and regular radiation fields for heating treating a work piece that is loaded on a work holding tray and, upon the vacuum oven being in an operational position, the work piece is located within the furnace chamber.

Owner:IBEX DENTAL TECH

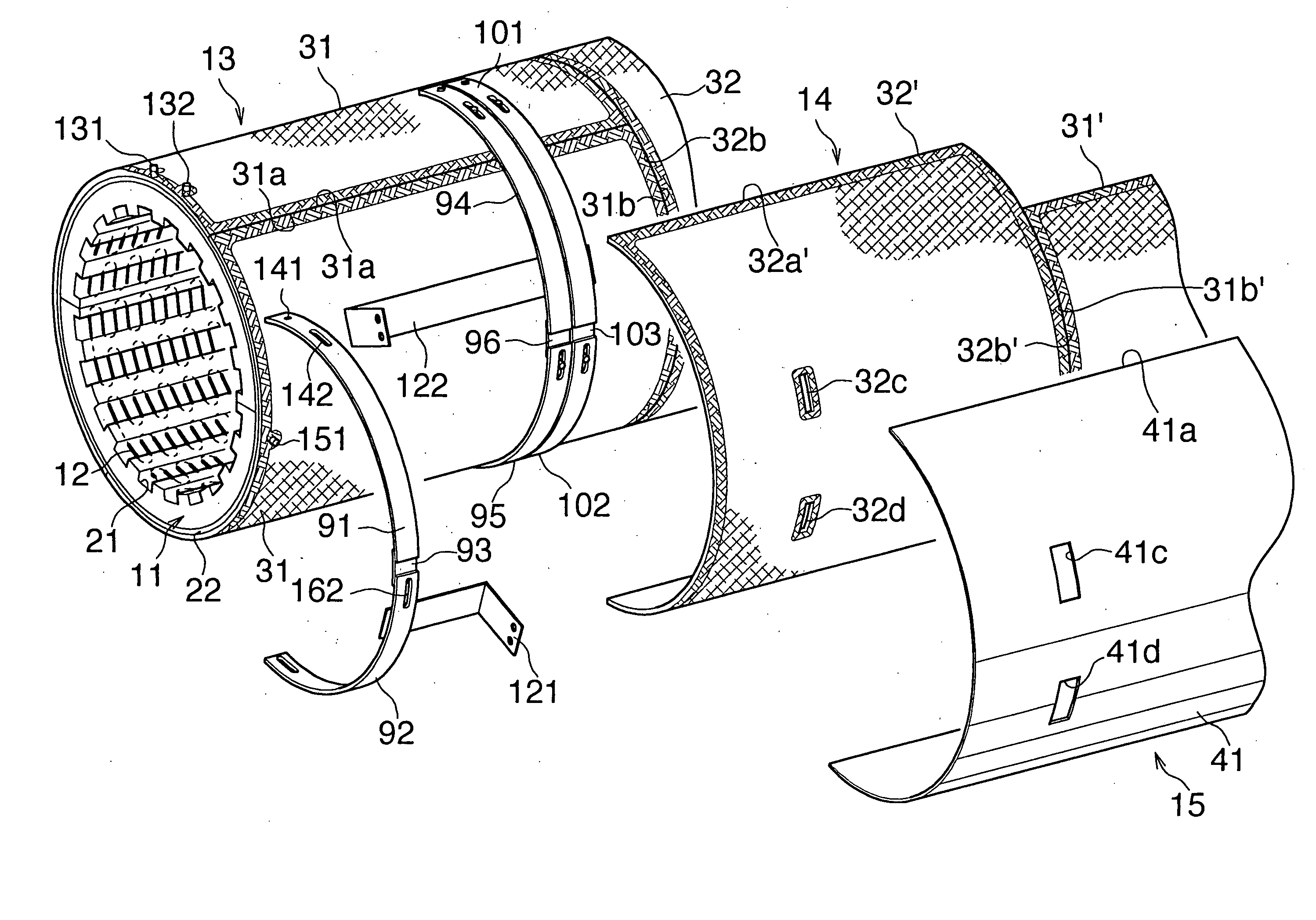

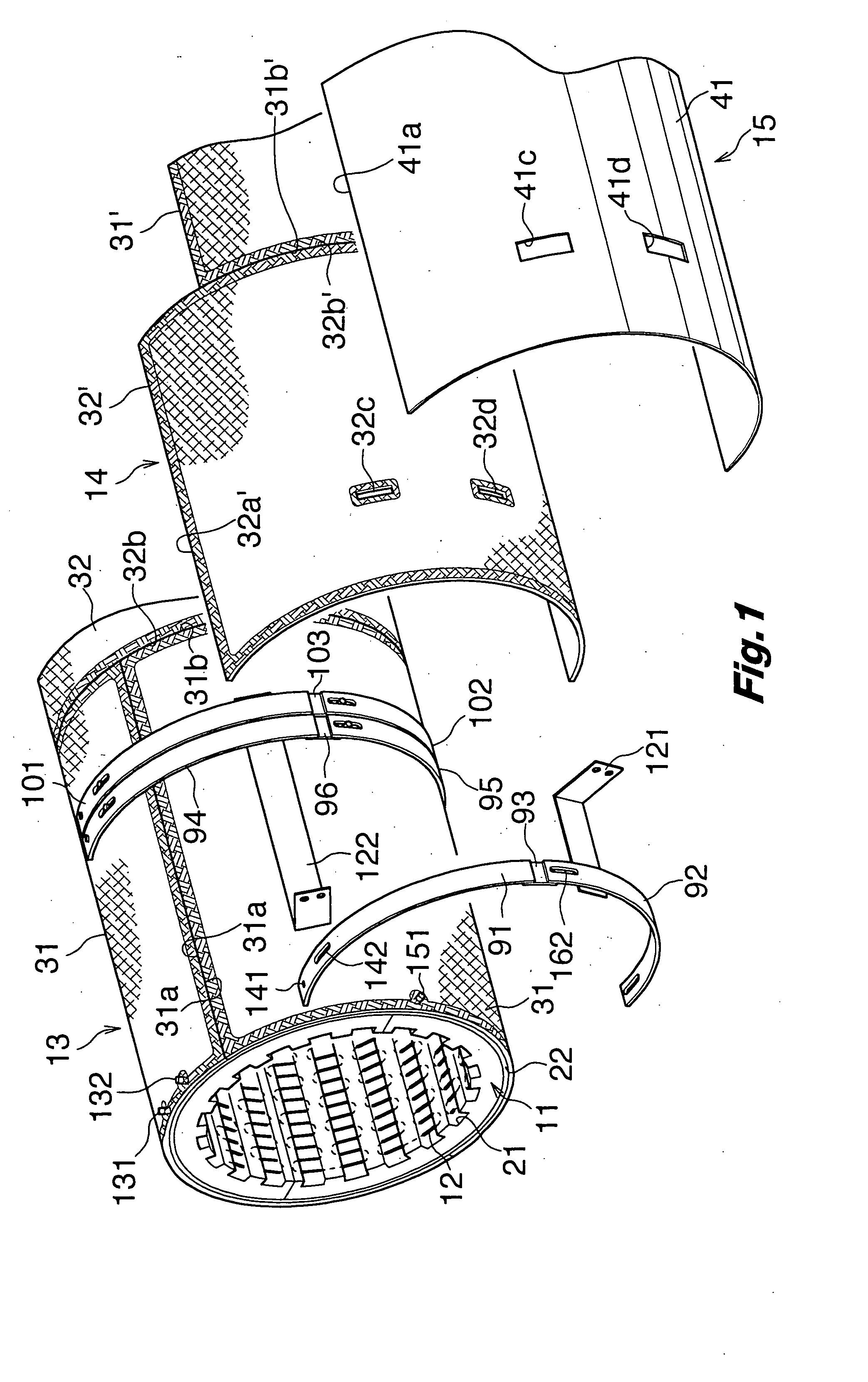

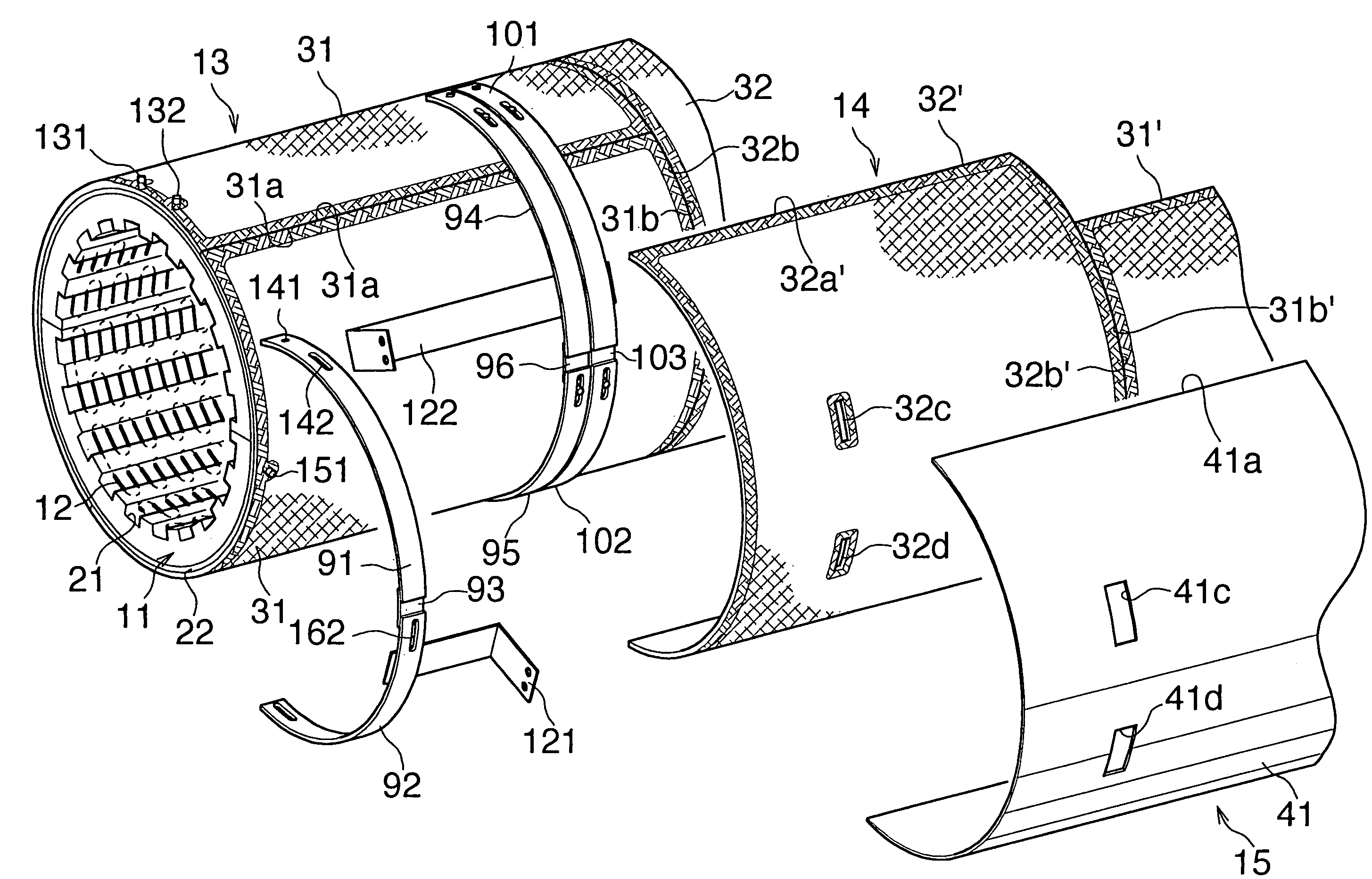

Substrate processing apparatus, heating apparatus for use in the same, method of manufacturing semiconductors with those apparatuses, and heating element supporting structure

ActiveUS20090035948A1Baking ovenSemiconductor/solid-state device manufacturingSemiconductorChemical engineering

A substrate treating device comprising a treatment chamber for storing and treating substrates and a heating device having a heating element and a heat insulator and heating the substrates in the treatment chamber by the heating element. The heating element is so formed that only its one end is held by a holding part, and a projection projected to the treatment chamber side at the intermediate part of the heating element and positioned in proximity to or in contact with the heating element is formed on the heat insulator. A pin with an enlarged part is passed through the heating element and the heat insulator at the intermediate part of the heating element and The enlarged part is positioned in proximity to or in contact with the heating element. The plurality of projections may be formed on the heat insulator and the pins may be disposed between these plurality of projections.

Owner:KOKUSA ELECTRIC CO LTD +1

High temperature heating element for preventing contamination of a work piece

InactiveUS20080041836A1Accurately closely controlledAccurately determineMuffle furnacesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceWorking temperature

A modular heating element that facilitates removal and replacement without disassembly of a furnace provides a precisely controllable process temperature in the range 1000-1400 degrees centigrade. The configuration of the heating element is linear rather than coiled, and the temperature is monitored directly by measuring the electrical resistance of KANTHAL®, or other like Fe Cr Al wire encased in an aluminum ceramic sleeve that provides mechanical support and seals the heating element wire against oxidation, thereby increasing operational temperature and prolonging service life.

Owner:SOLAICX

Radiation apparatus with capability of preventing heat convection

ActiveUS20090139975A1Improve high temperature stabilityAvoid heatRadiation pyrometryMuffle furnacesTemperature differenceEngineering

The present invention provides a radiation apparatus with capability of preventing heat convection, which comprises a blackbody furnace having a cavity therein and an air pressure adjusting unit. The air pressure adjusting unit coupled to the blackbody furnace for adjusting the air pressure of the open end of the cavity according to the temperature difference between the cavity and the outside environment. By means of the design of the present invention, it is capable of preventing heat convection between the cavity and the outside environment by utilizing the air pressure adjusting unit for controlling the air pressure status around the open end of cavity such that the blackbody furnace is stable for services of calibrations and tests.

Owner:IND TECH RES INST

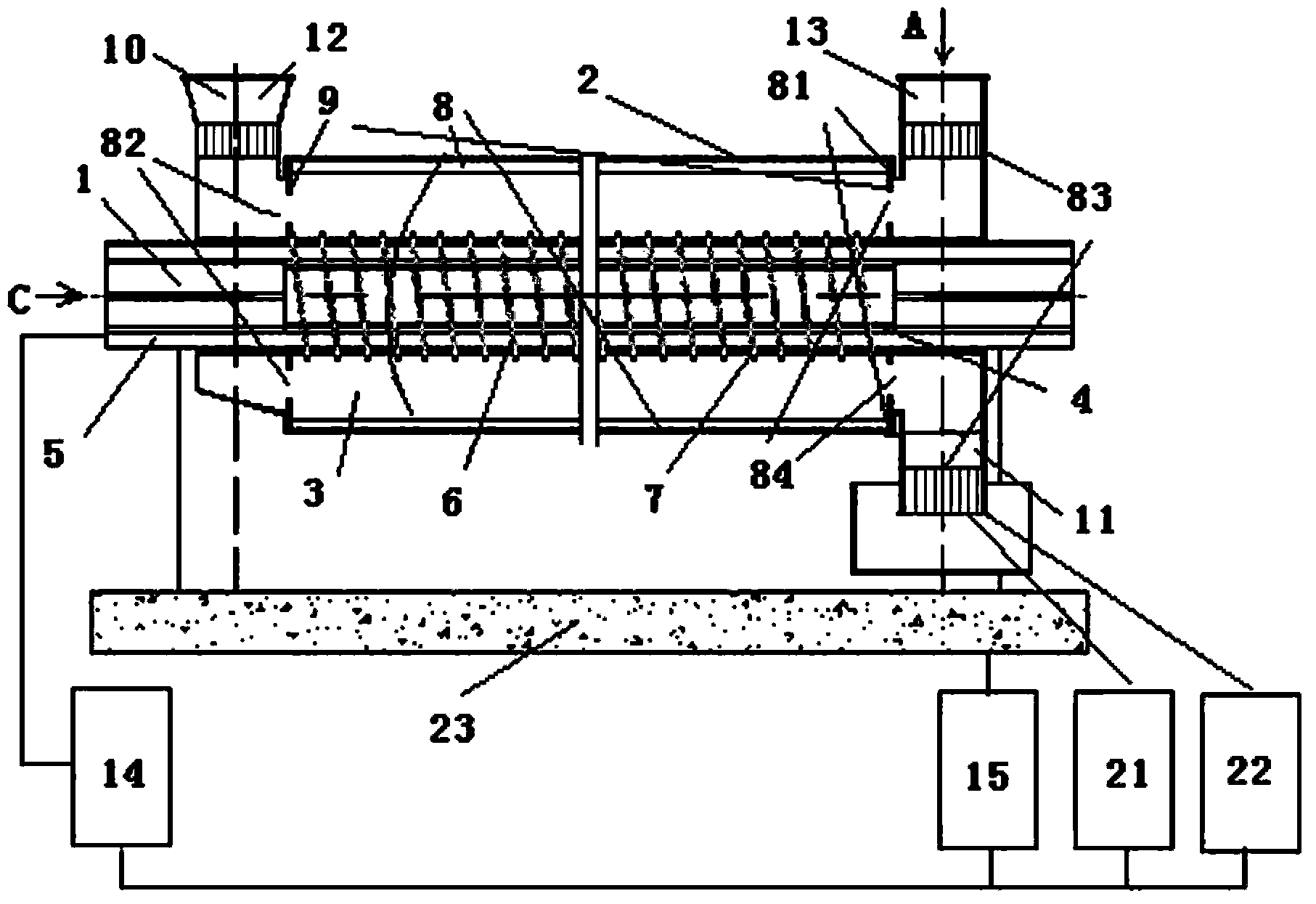

Microwave heating device

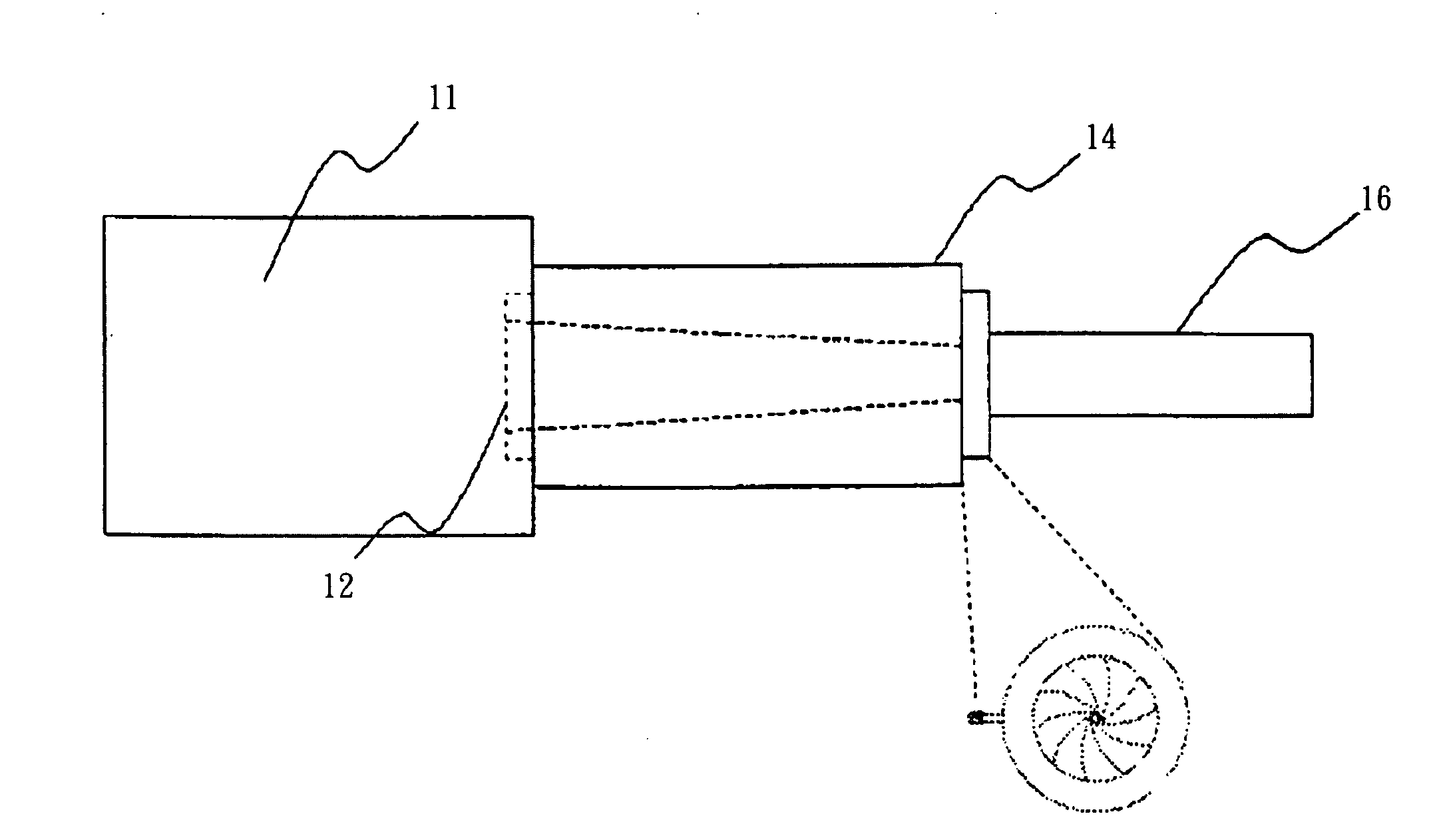

ActiveCN103813498APrevent escapeEnsure safetyMicrowave heatingFurnace heating elementsMicrowave powerWaveguide flange

The invention relates to a microwave heating device, wherein heating and drying of the microwave heating device are performed through industrial microwaves. According to the novel microwave heating device, intercoupling of a plurality of magnetrons is avoided due to the novel microwave power transmission and energy feedback mode and accordingly the output power and efficiency of the magnetrons is improved, the service life and the reliability of the magnetrons are improved, and accordingly the production is improved, the maintenance cost of the device is reduced, and energy resources are greatly saved. The microwave heating device comprises a rotatable metal outer cylinder and a metal inner cylinder which is provided with a microwave power radiation source; a coaxial annular chamber is formed in the metal outer cylinder; a supporting tube is arranged in the annular chamber; the supporting tube is provided with at least one microwave gap antenna group; the microwave gap antenna group is formed by a plurality of microwave gap antennas which are uniformly arranged surrounding the angular direction of the supporting tube; a waveguide exciter is connected with the microwave gap antennas through a waveguide flange plate; the microwave magnetrons are inserted into the waveguide exciter.

Owner:上海明光电子科技有限公司

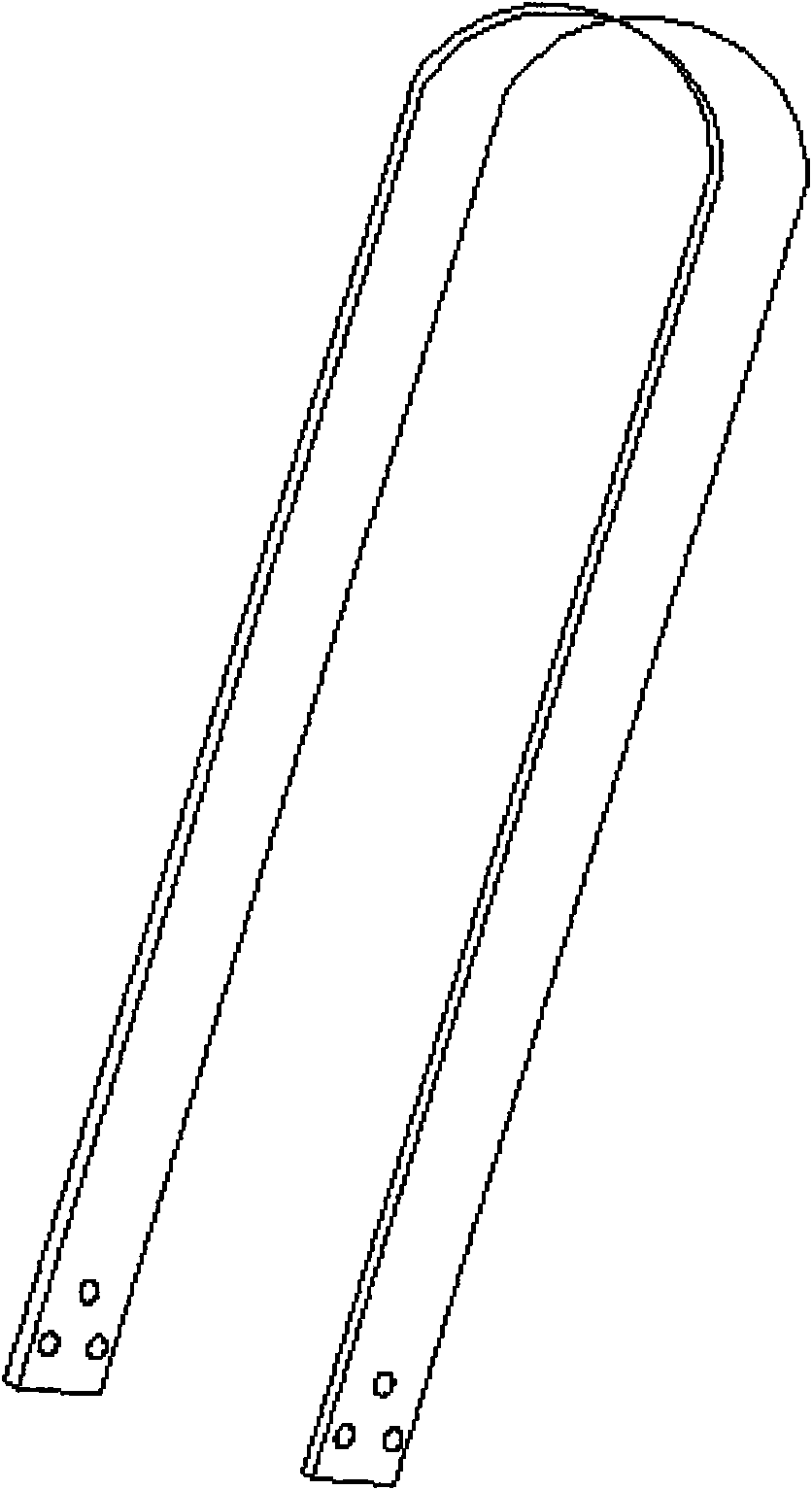

U-shaped heating element of silicon tetrachloride hydrogenation furnace and manufacturing process thereof

InactiveCN101541111AHigh in fiberThermally matched wellLiquid surface applicatorsFurnace heating elementsCorrosionHeating element

The invention provides a U-shaped heating element of a silicon tetrachloride hydrogenation furnace and a manufacturing process thereof. The U-shaped heating element of the silicon tetrachloride hydrogenation furnace consists of a green body, a matrix and a silicon carbide surface coating, wherein, the green body is prepared from 2D (two-dimensional) carbon fiber laminated fabric or quasi-3D (three-dimensional) carbon fiber needle felt with the weight not less than 50% of the total weight of the product; the matrix is composed of impregnated carbon and CVD-based (chemical vapor deposition) carbon, wherein, the content of the CVD-based carbon is not more than 30% of the total weight of the green body and the matrix; the material density of the heating element is higher than or equal to 1.3g / cm3; and the thickness of the silicon carbide surface coating is 10 to 100 mum. The U-shaped heating element of the silicon tetrachloride hydrogenation furnace has the advantages of high corrosion and erosion resistance, long service life and high reliability.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

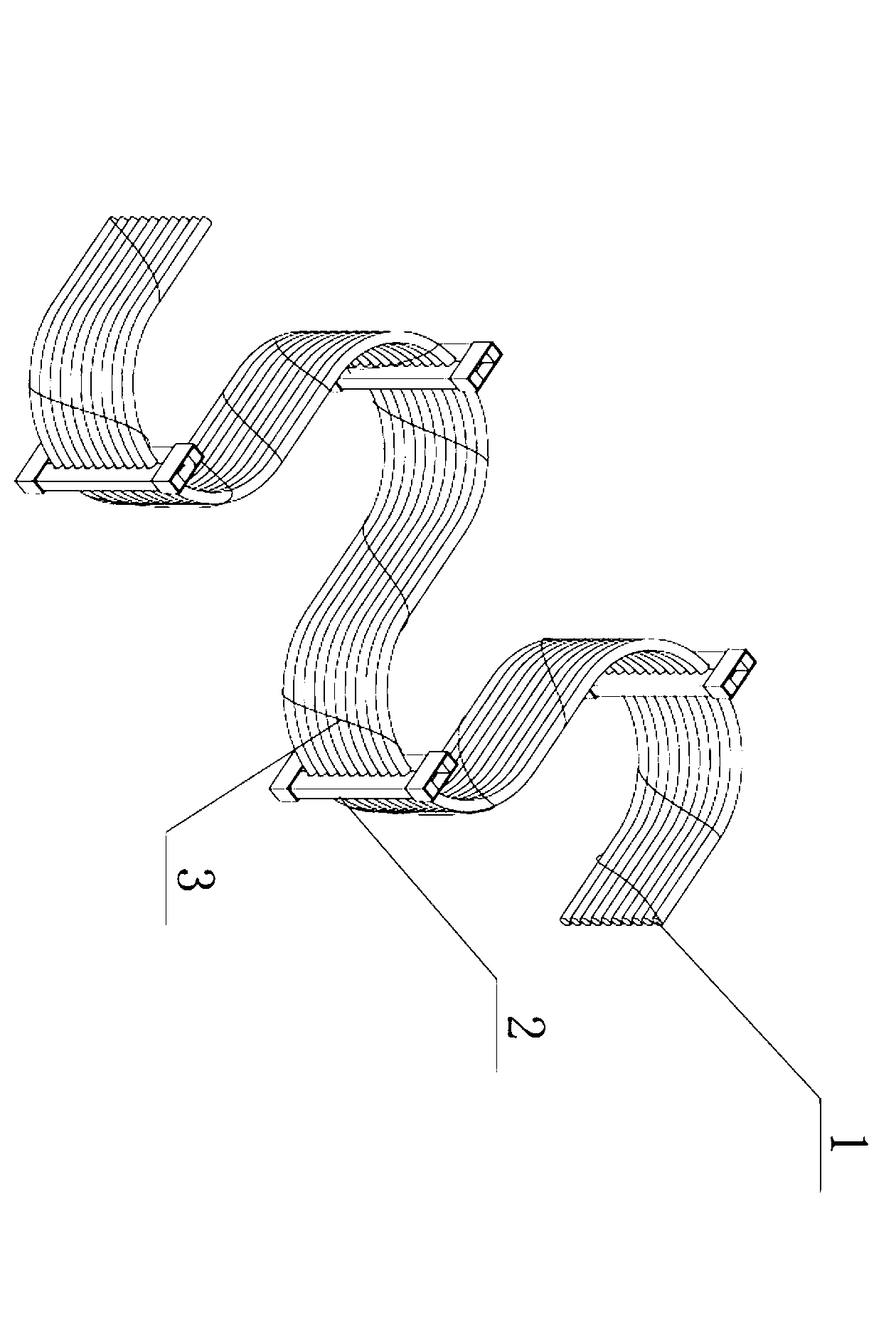

S-shaped composite furnace wire and processing method thereof

InactiveCN103313447ASolve the technical problems of inconvenient processing and incapable of large-scale productionImproved ease of processingFurnace heating elementsAlloyMetal

The invention relates to an S-shaped composite furnace wire and a processing method thereof. The S-shaped composite furnace wire is formed by combining S-shaped electric heating alloy wires, metal clamps and a twined wire, wherein a plurality of S-shaped electric heating alloy wires with the same section are overlapped to form a circuitous curved S-shaped flat band, the twined wire is arranged on the S-shaped flat band for fixing, and the wave crests of the S-shaped flat band are fixed by the metal clamps. The processing method of the S-shaped composite furnace wire comprises the following steps: processing the S-shaped electric heating alloy wires, processing the metal clamps, and assembling the S-shaped flat band. The S-shaped composite furnace wire has the advantages that the processing convenience and the installation reliability of the electric heating wires are increased, and the service life is prolonged.

Owner:朱建新

Electric heater for thermal treatment furnace

InactiveUS7003014B2High currentReduce weightSemiconductor/solid-state device manufacturingHeating element shapesThermal insulationEngineering

A heating element (12) made of metal wire is installed at an internal circumferential surface of a cylindrical main thermal insulation body (11) of an electric heater according to the present invention. The heating element (12) comprises a plurality of resistance heat emitting portions (61)–(64) (71)–(74) (81)–(84) as segments along its length direction. The resistance heat emitting portions (61)–(64) (71)–(74) (81)–(84) are connected in parallel.

Owner:KOYO THERMO SYST CO LTD

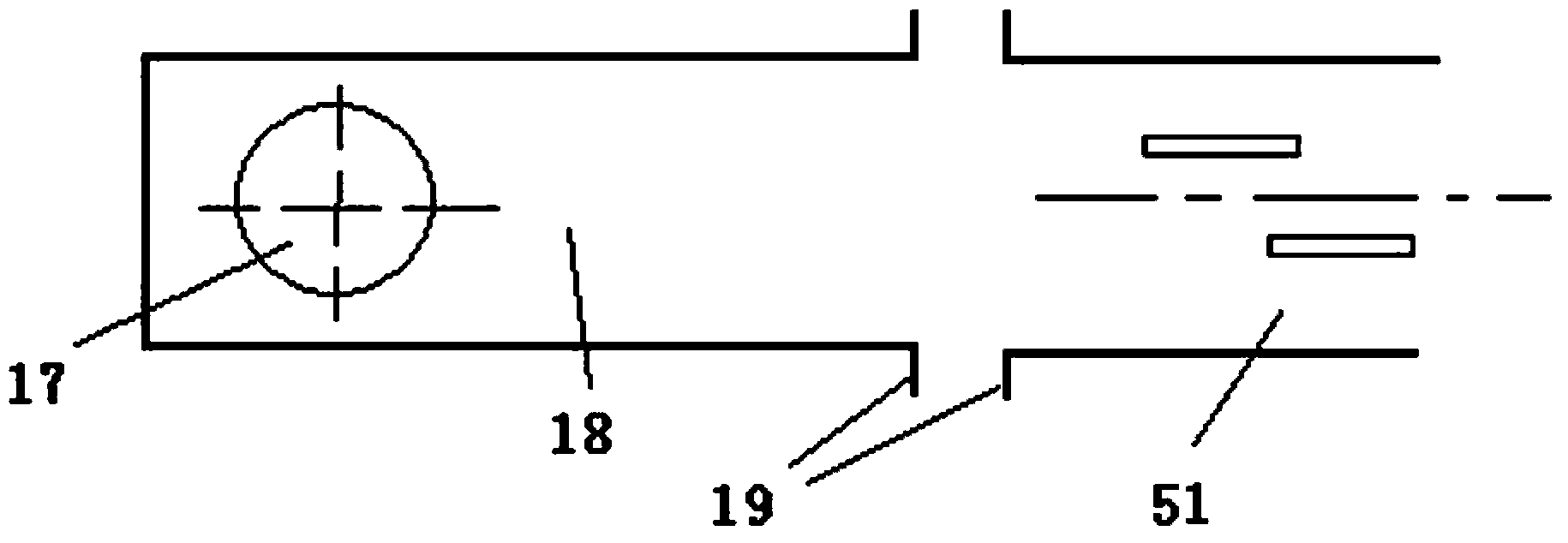

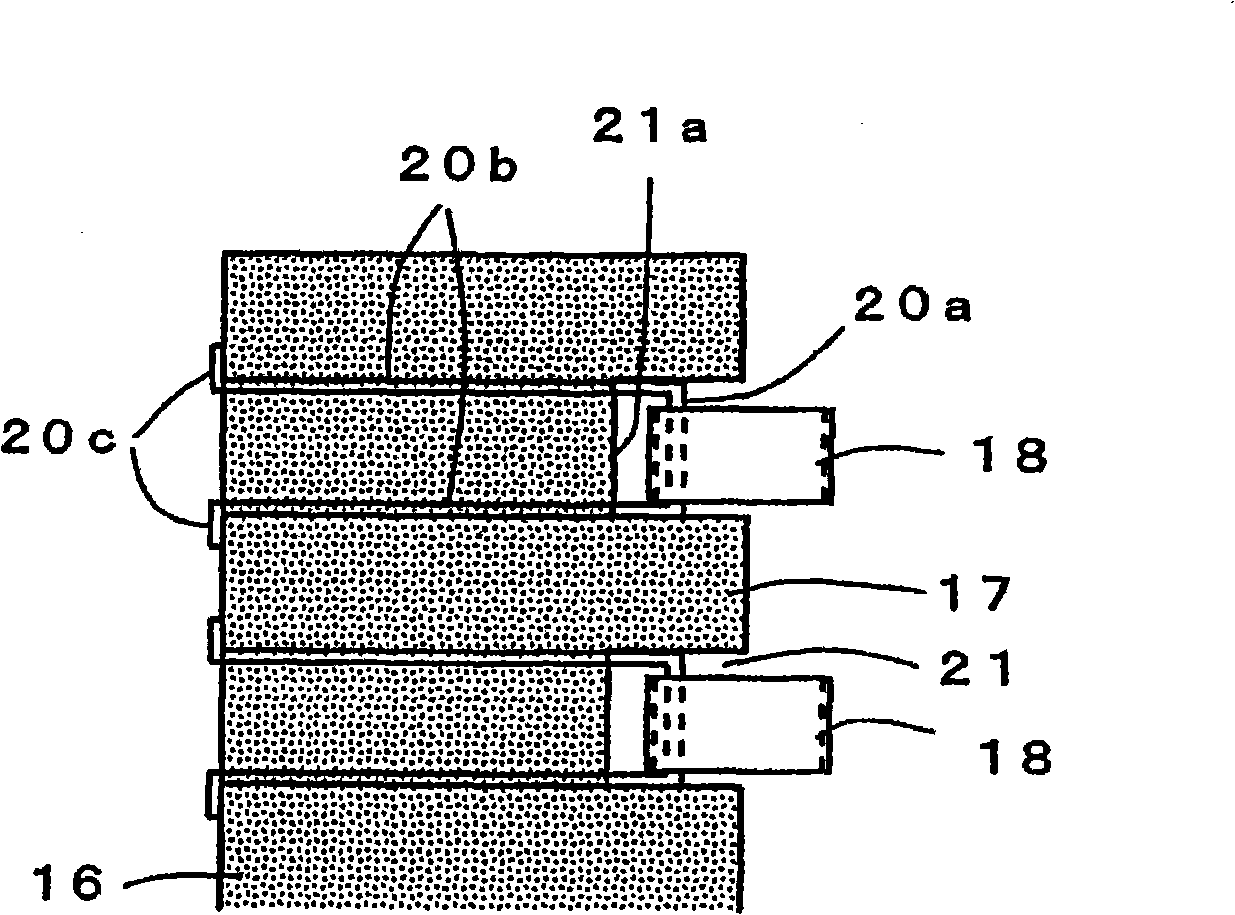

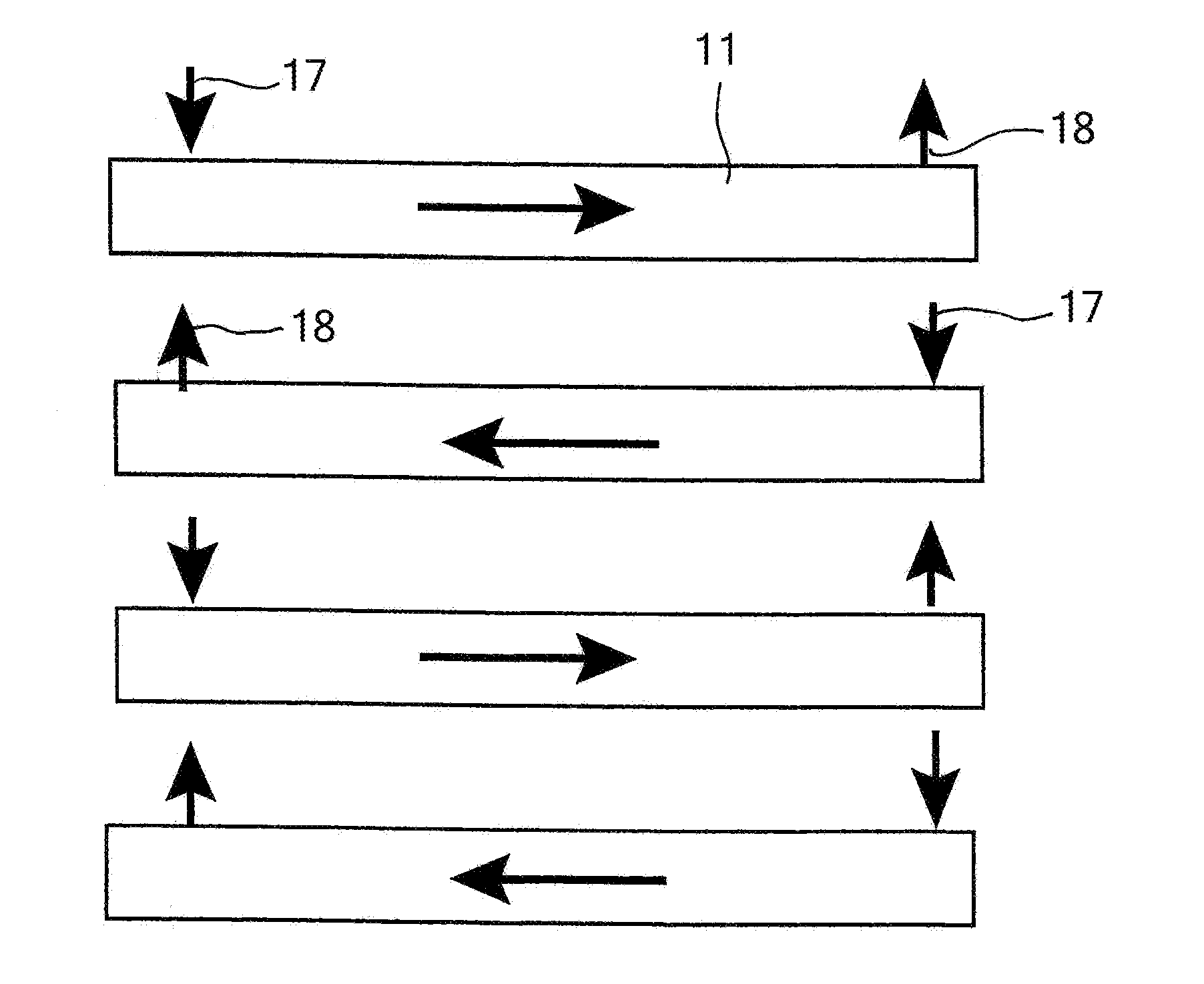

Heat processing furnace and vertical-type heat processing apparatus

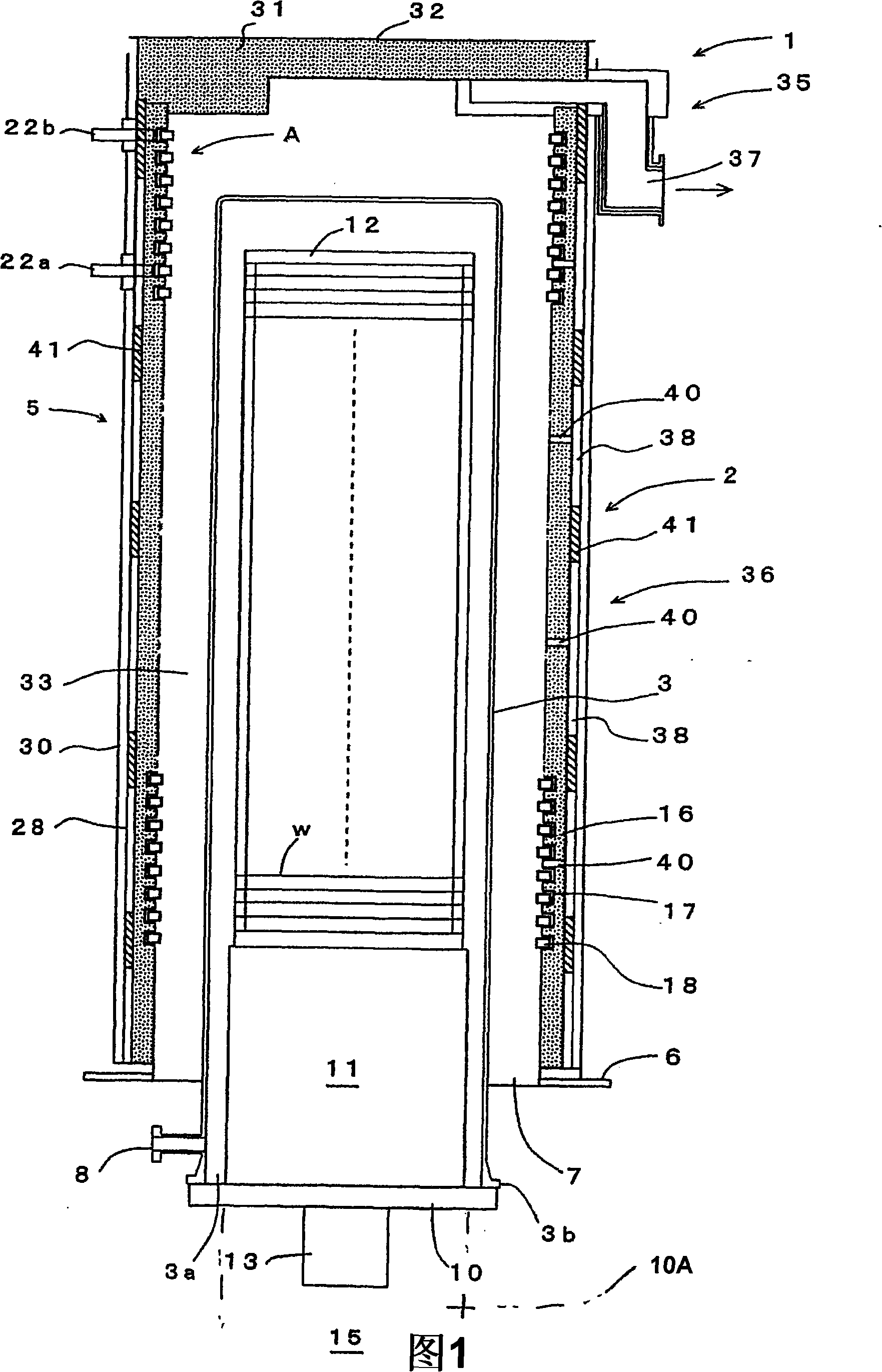

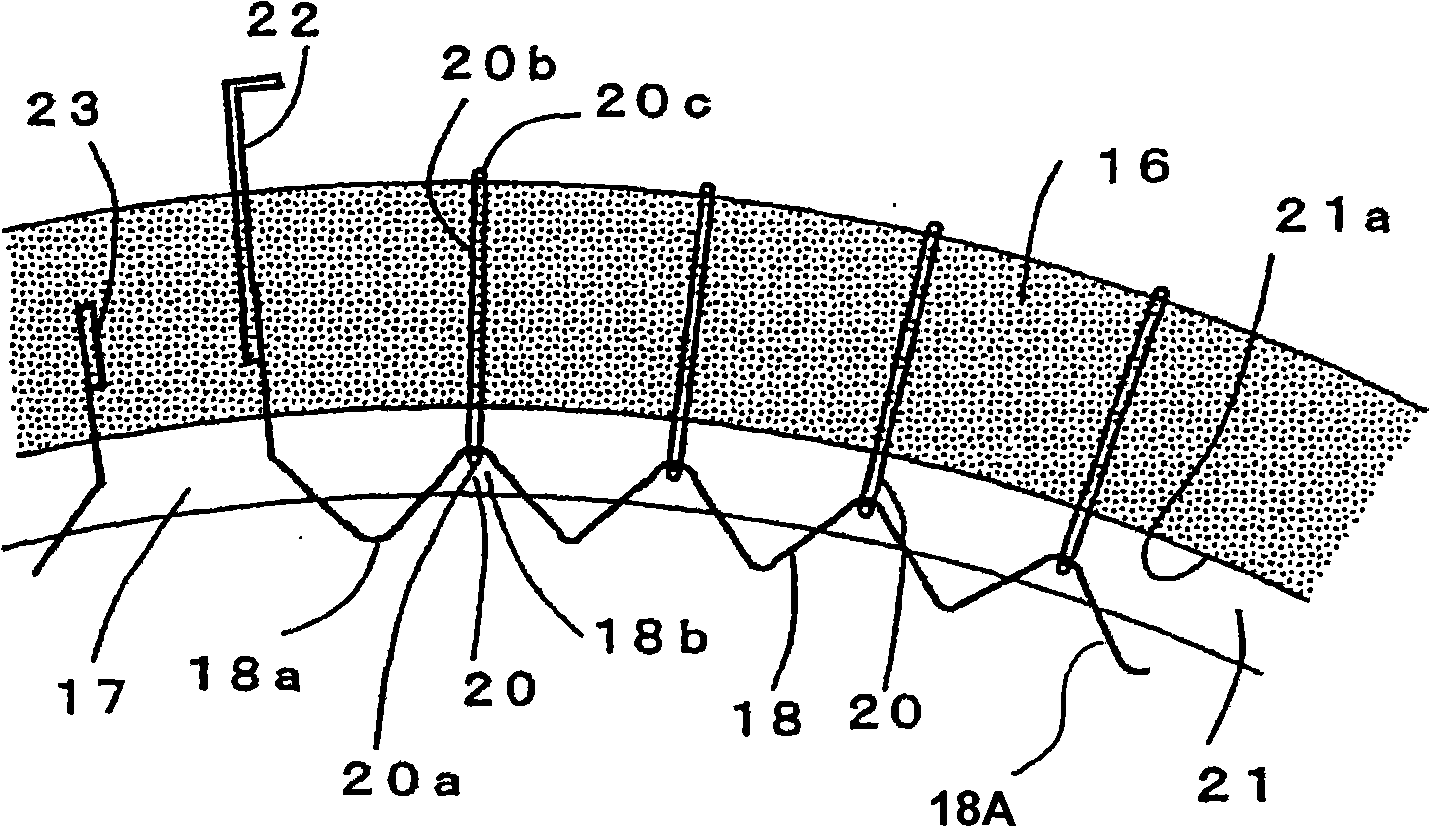

ActiveCN101312123ARapid heating and coolingIncreased durabilitySemiconductor/solid-state device manufacturingFurnace typesEngineeringResistor

The invention provides a heat processing furnace and a vertical heat processing device capable of quickly increasing and decreasing a temperature, while achieving improvement in durability. A heat processing furnace (2) comprises: a processing vessel (3) for accommodating an object to be processed (w) and performing thereto a heat process; and a cylindrical heater (5) disposed to surround an outer circumference of the processing vessel (3), for heating the object to be processed (w). The heater (5) includes a cylindrical heat insulating member (16), and heating resistors (18) arranged along an inner circumferential surface of the heat insulating member (16). Each of the heating resistors (18) is formed of a strip-shaped member that is bent into a waveform having peak portions and trough portions. Pin members (20) are arranged in the heat insulating member (16) at suitable intervals therebetween, the pin members (20) holding the heating resistor (18) such that the heating resistor (18) is movable in a radial direction of the heater.

Owner:TOKYO ELECTRON LTD

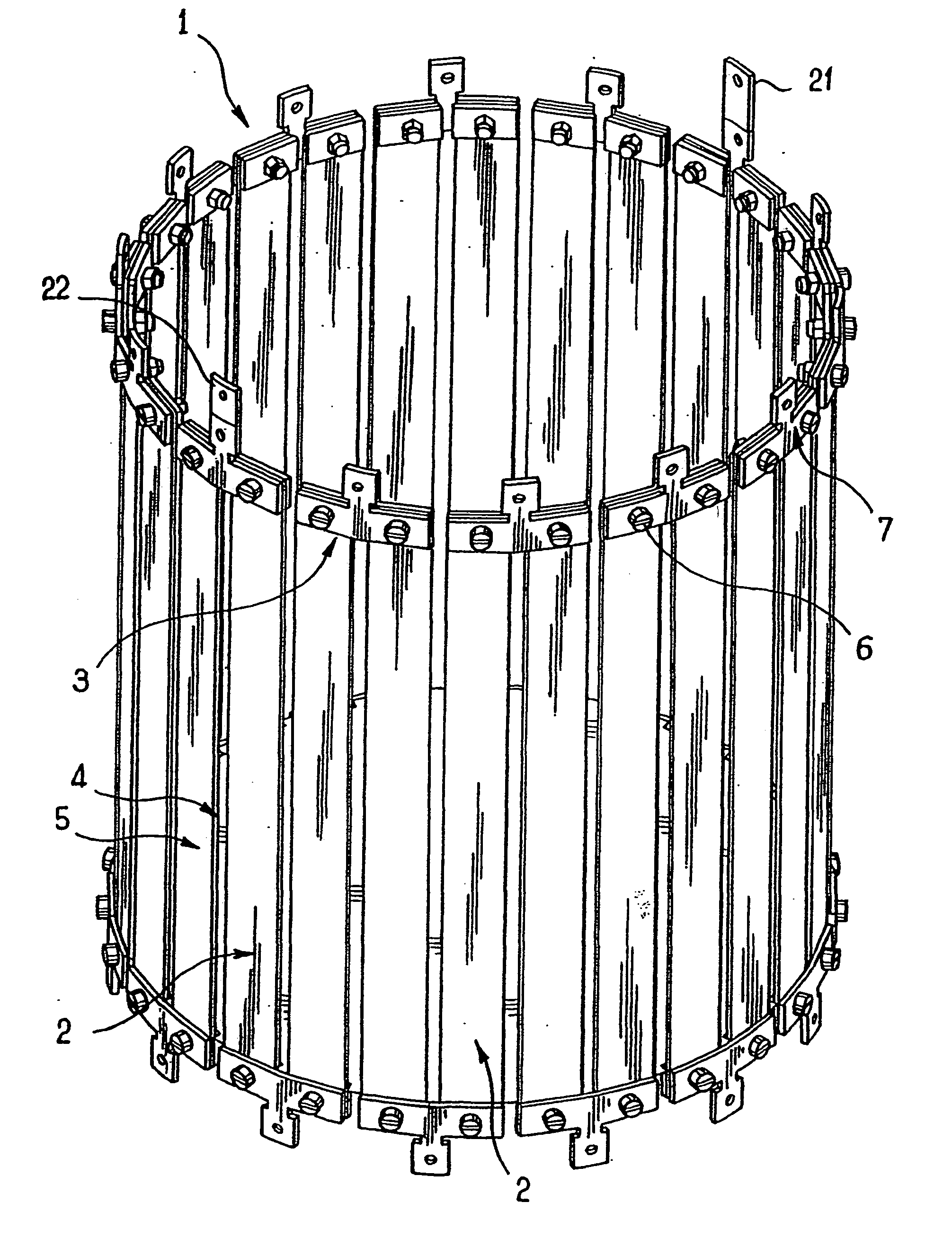

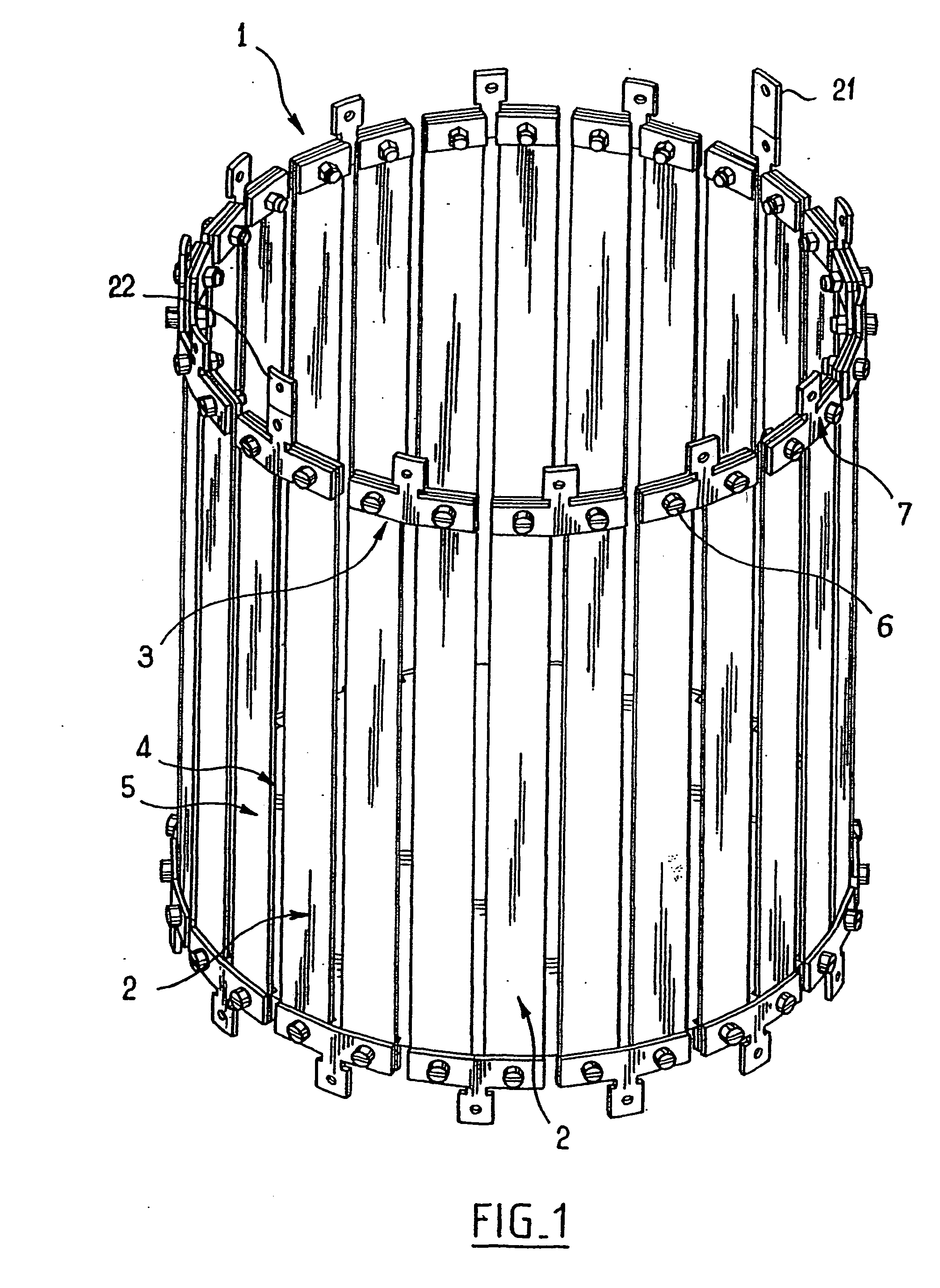

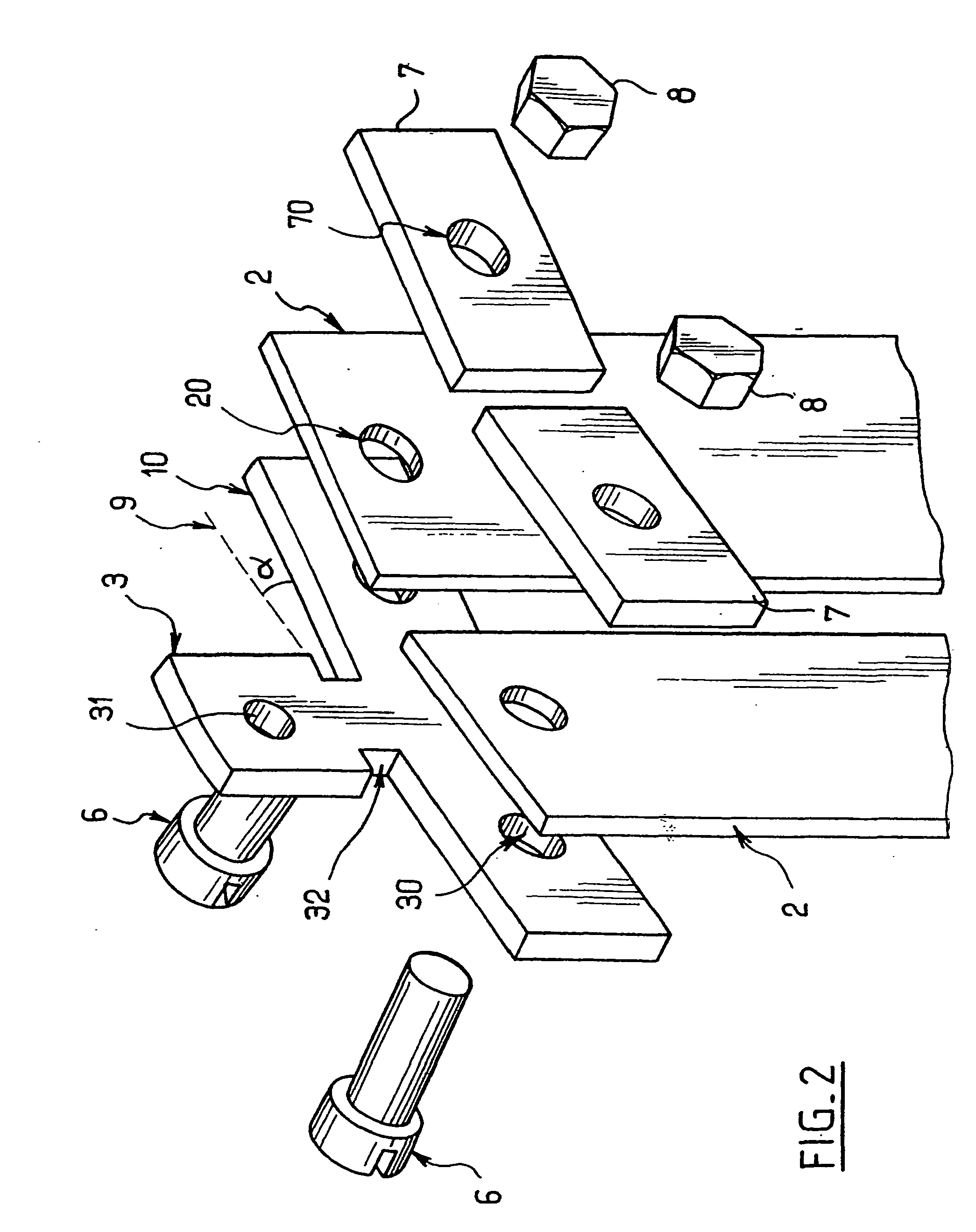

Made to the structure of a graphite resistance furnace

InactiveUS20040238526A1Heater elementsSulfur/selenium/tellurium active ingredientsGraphiteElectrical current

The invention relates to a high-temperature heater device (1) including at least one heater element (2), and current leads (20, 21) for powering the heater element(s) (2), said device being characterized in that it operates in any position, and in that each of the heater elements comprises at least one thin graphite strip (2) connected at its ends to the current leads by means of refractory conductive connection elements (3) made of molybdenum.

Owner:CENT NAT DE LA RECHERCHE SCI

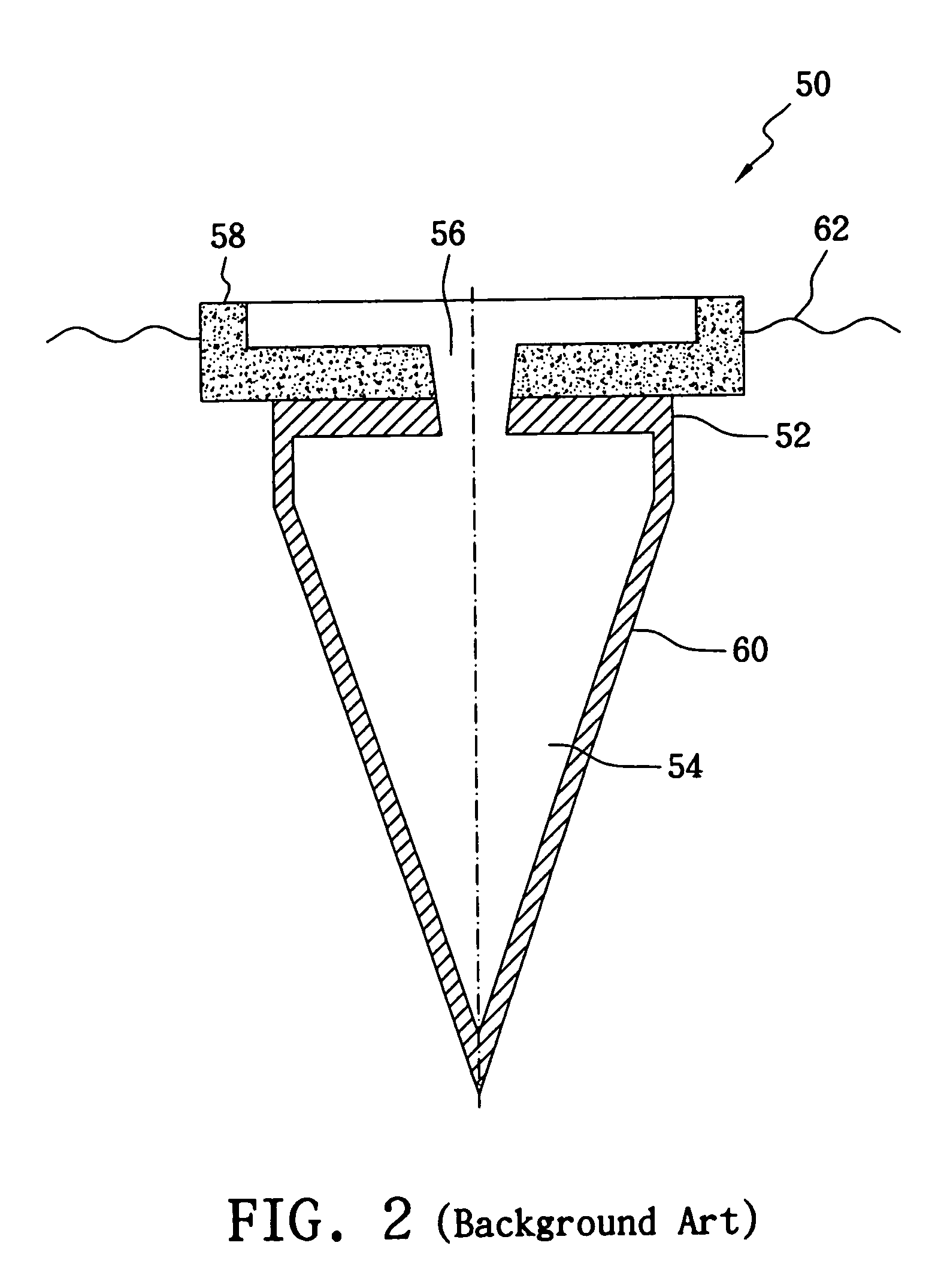

Vacuum cleaning structure for electrode furnace

ActiveUS20120213244A1Increase airflow turbulenceImprove cleaning qualityChemical analysis using combustionFurnace typesCrucibleEngineering

An electrode for a resistance analytical furnace has a crucible-engaging surface and an end spaced from the crucible-engaging surface having a plurality of grooves formed therein. A manifold mounted on the end of the electrode defines a dust recovery plenum and includes an outlet communicating with the plenum for coupling to a vacuum source to remove debris from the electrode. The improved electrode and electrode cleaning manifold positioned on the electrode provides a turbulent airflow for removal of dust and debris from an analytical furnace.

Owner:LECO CORPORATION

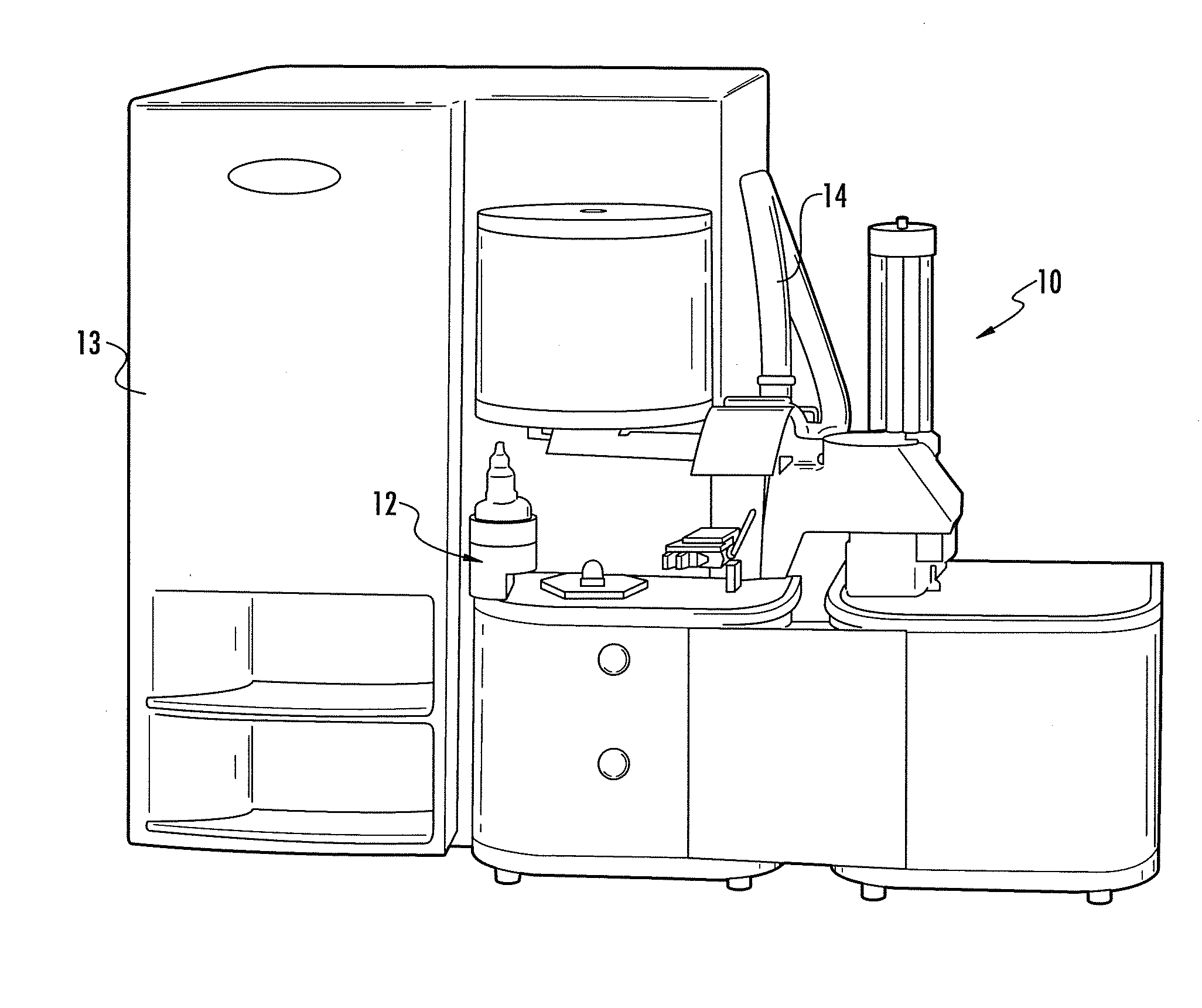

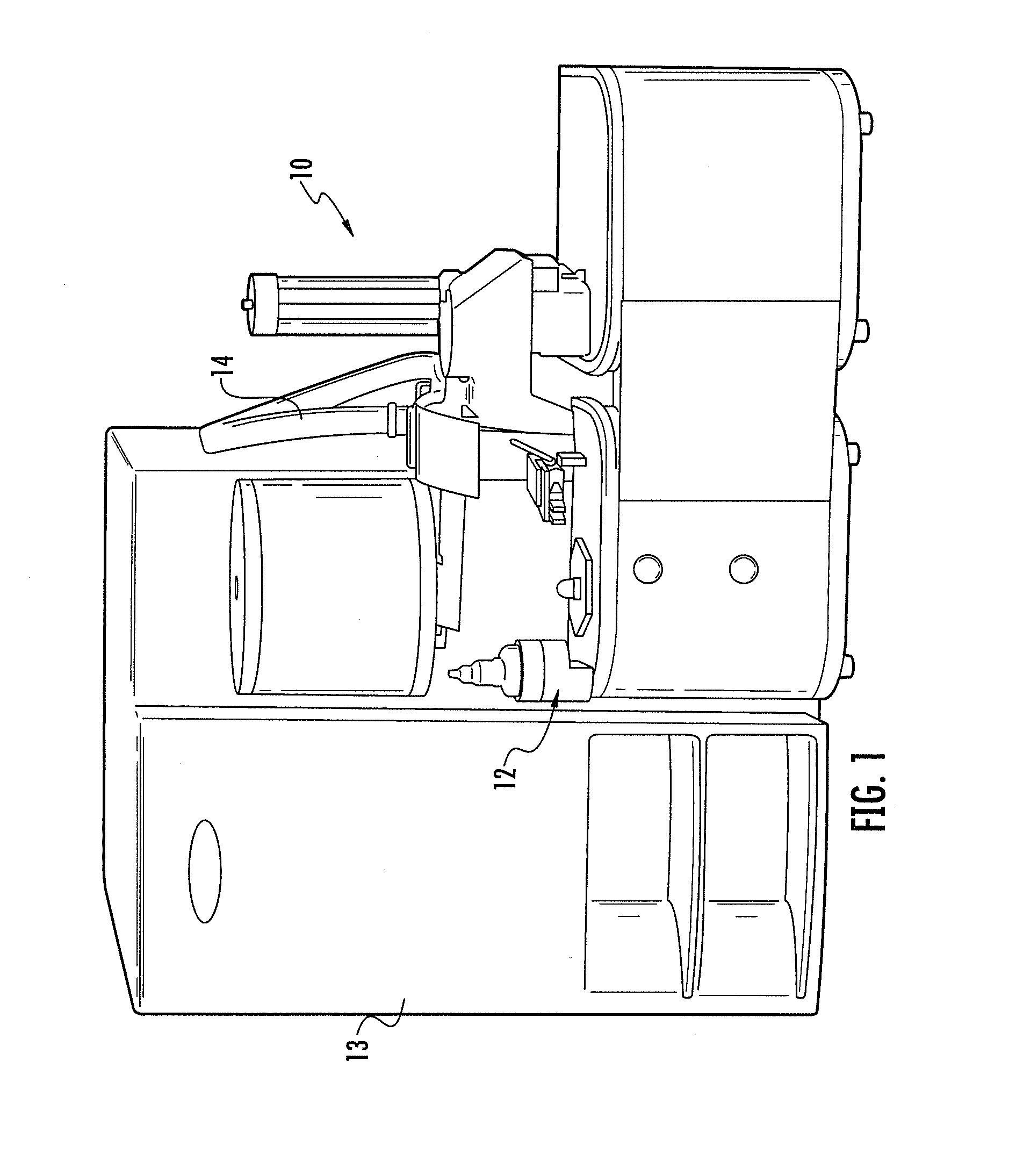

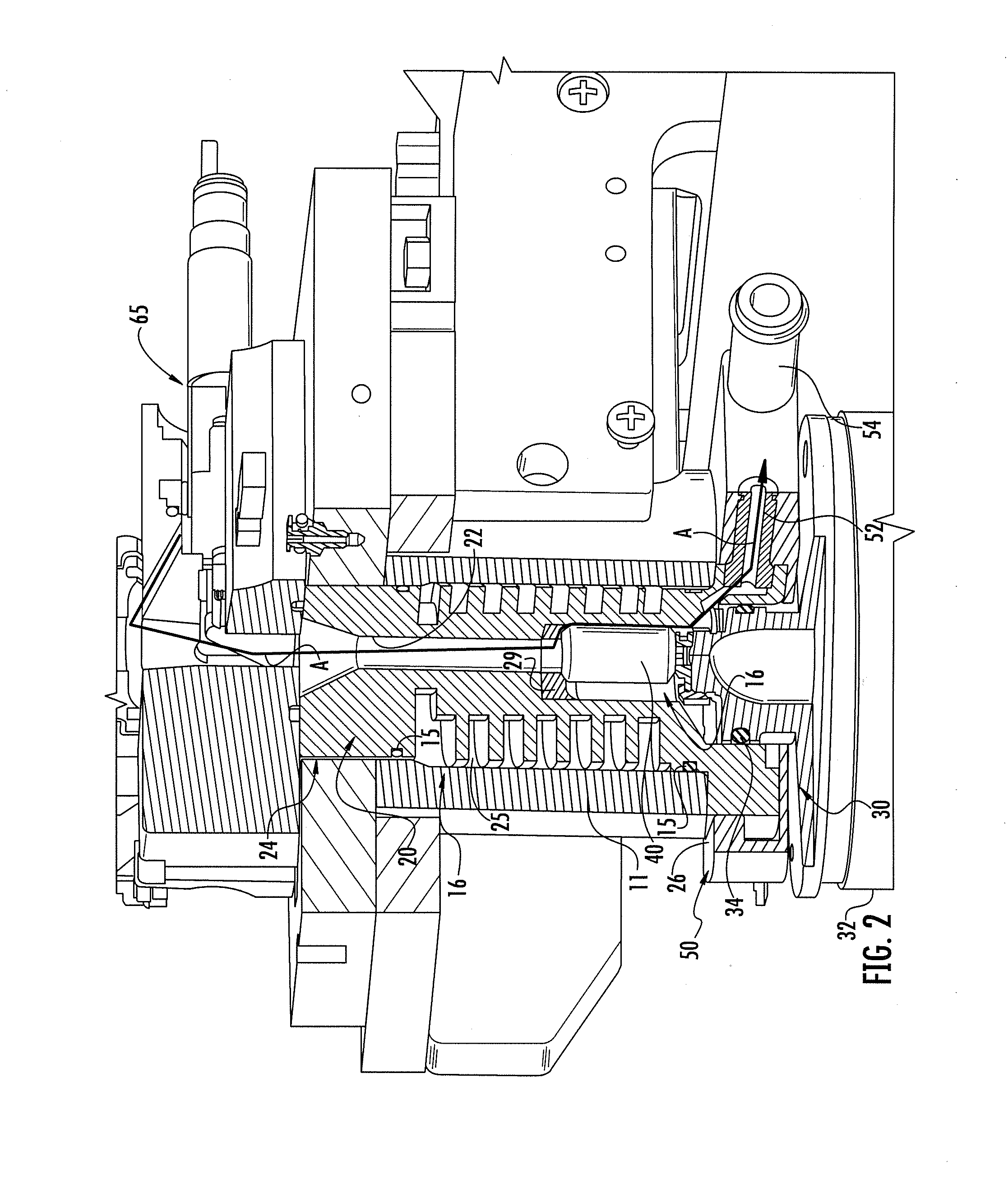

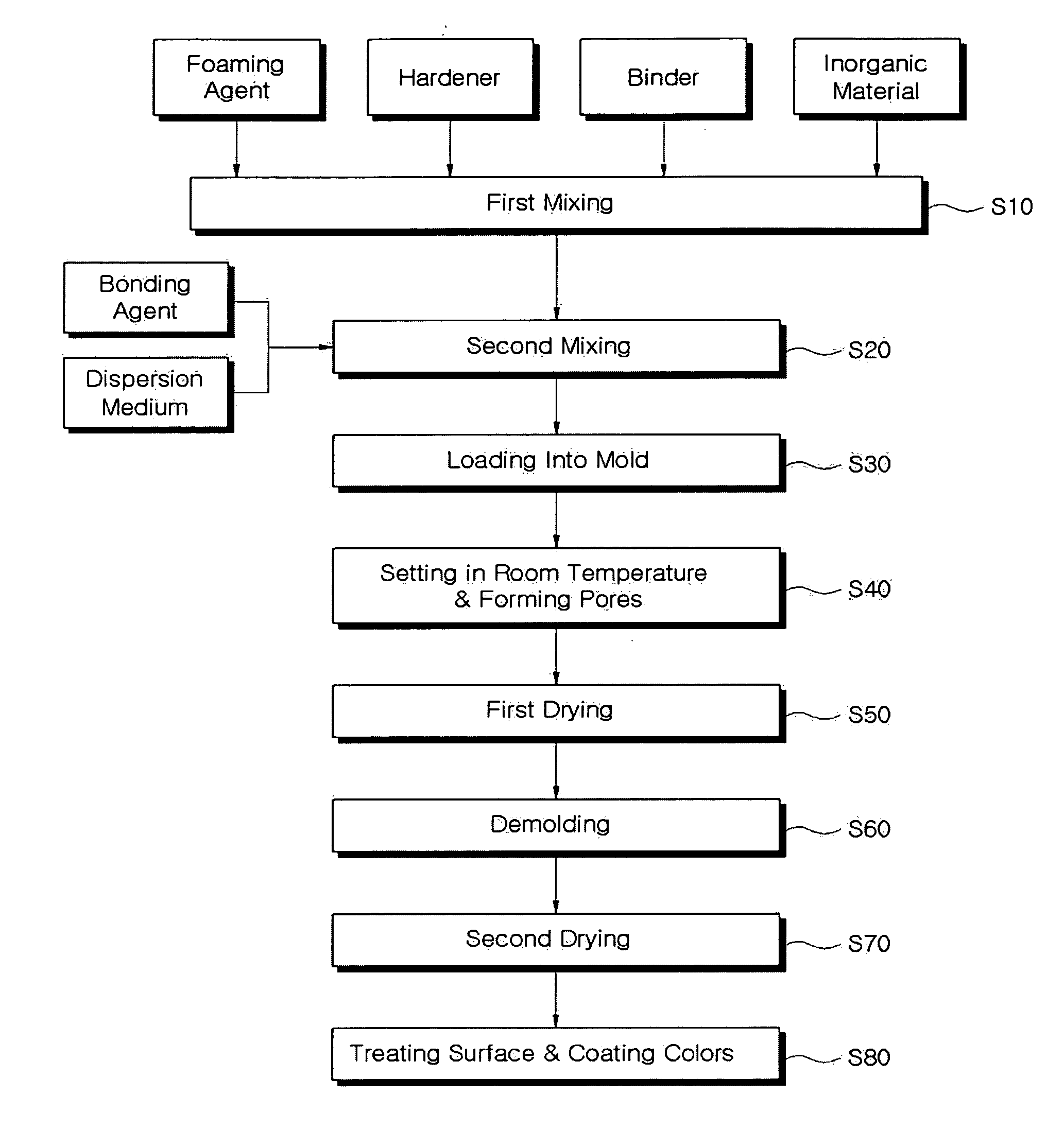

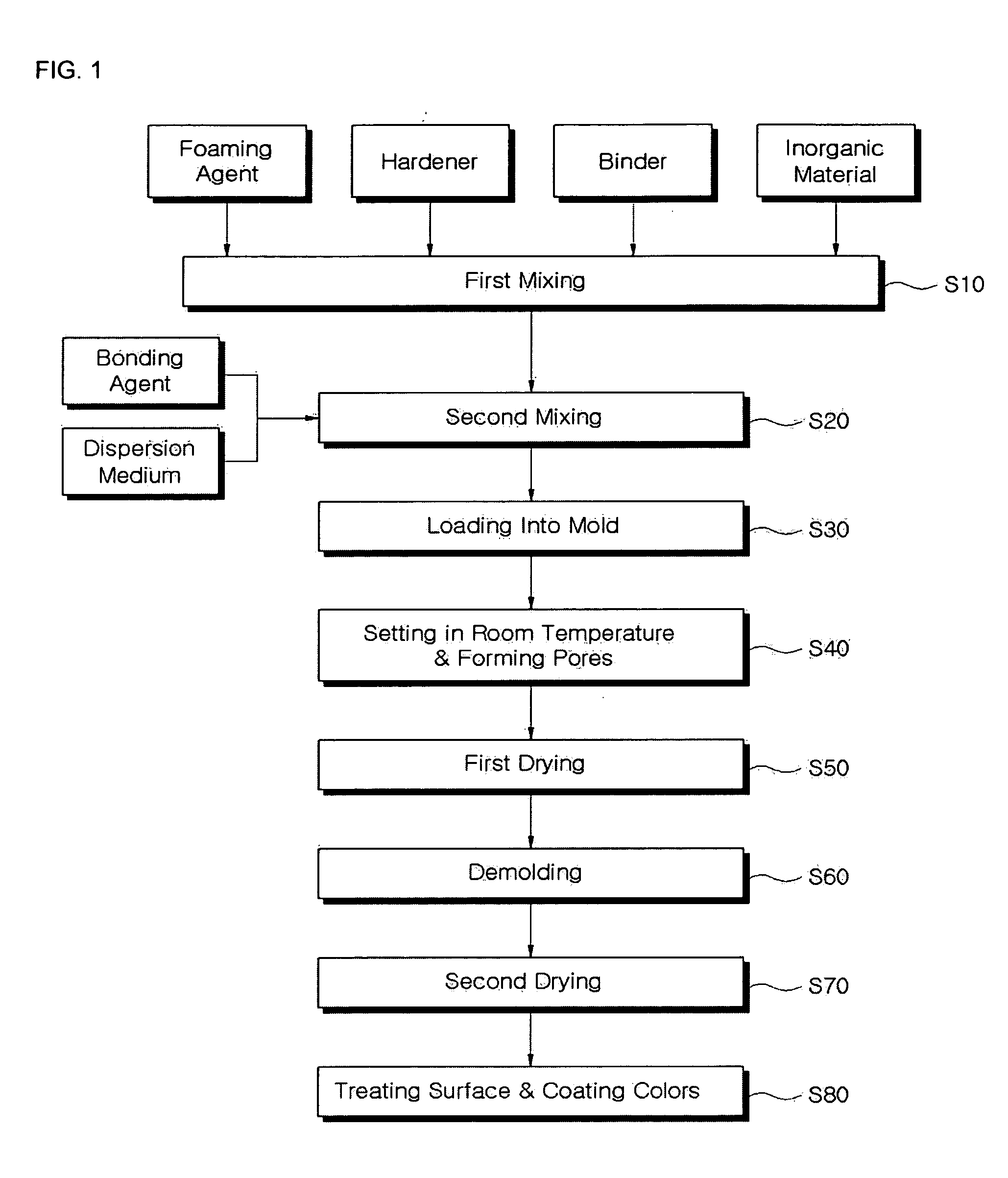

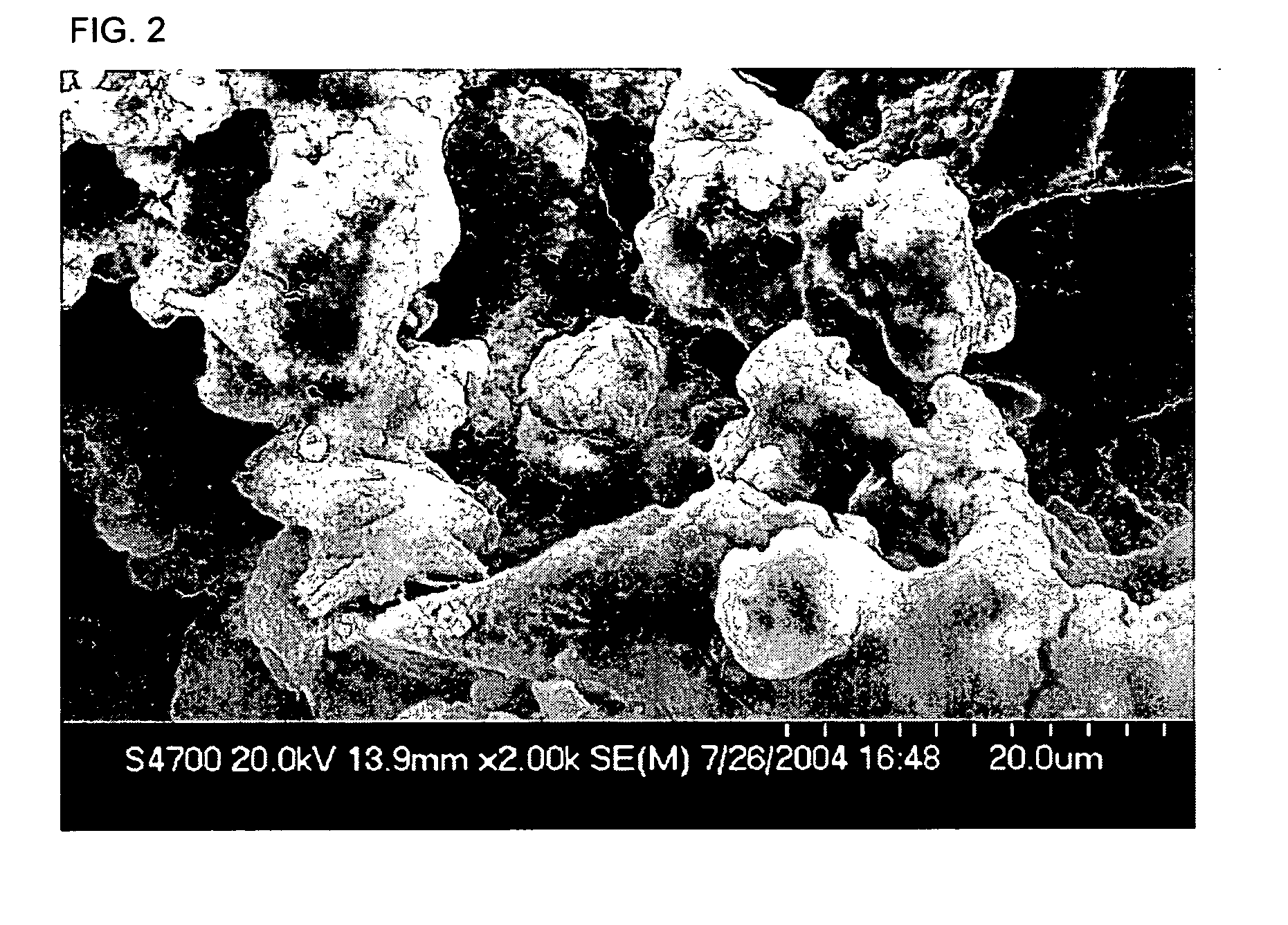

Porous ceramic heating element and method of manufacturing thereof

InactiveUS20070003750A1High bonding strengthAccelerating formation of foamIncandescent ignitionMaintainance of heating chambersFoaming agentMetallurgy

The present invention provides a porous ceramic heating element wherein 0.08 to 1.00 wt % of a foaming agent is added in 99.00 to 99.92 wt % of a mixture of an inorganic material, a binder, a conductive material, a hardener, a bonding agent and a dispersion medium and mixed with the mixture. According to the porous ceramic heating element, the bonding strength of porous foam formed in the ceramic heating element becomes strong, thereby providing an effect that the entire structure is hardened.

Owner:KIM CHANGHEE +1

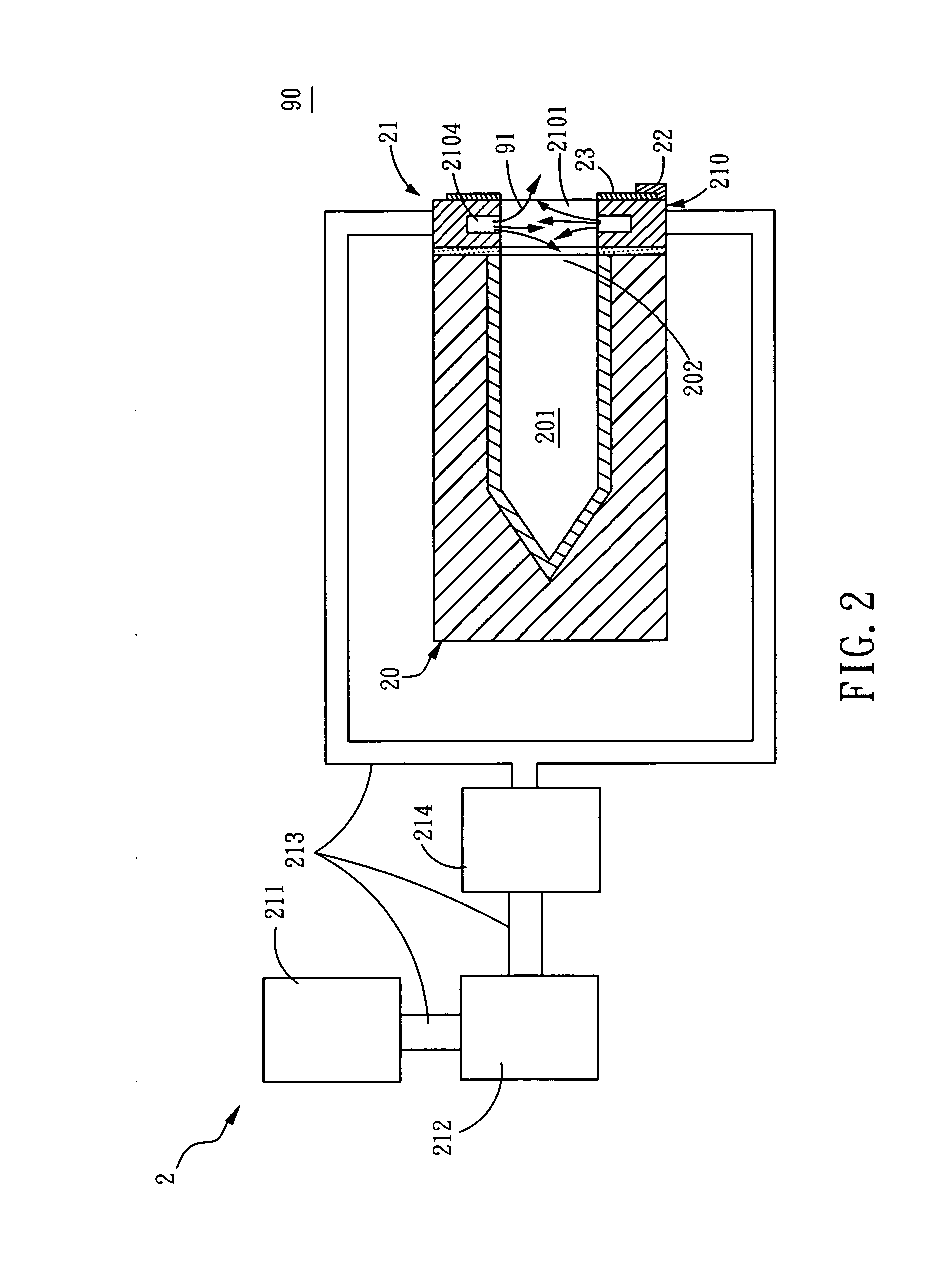

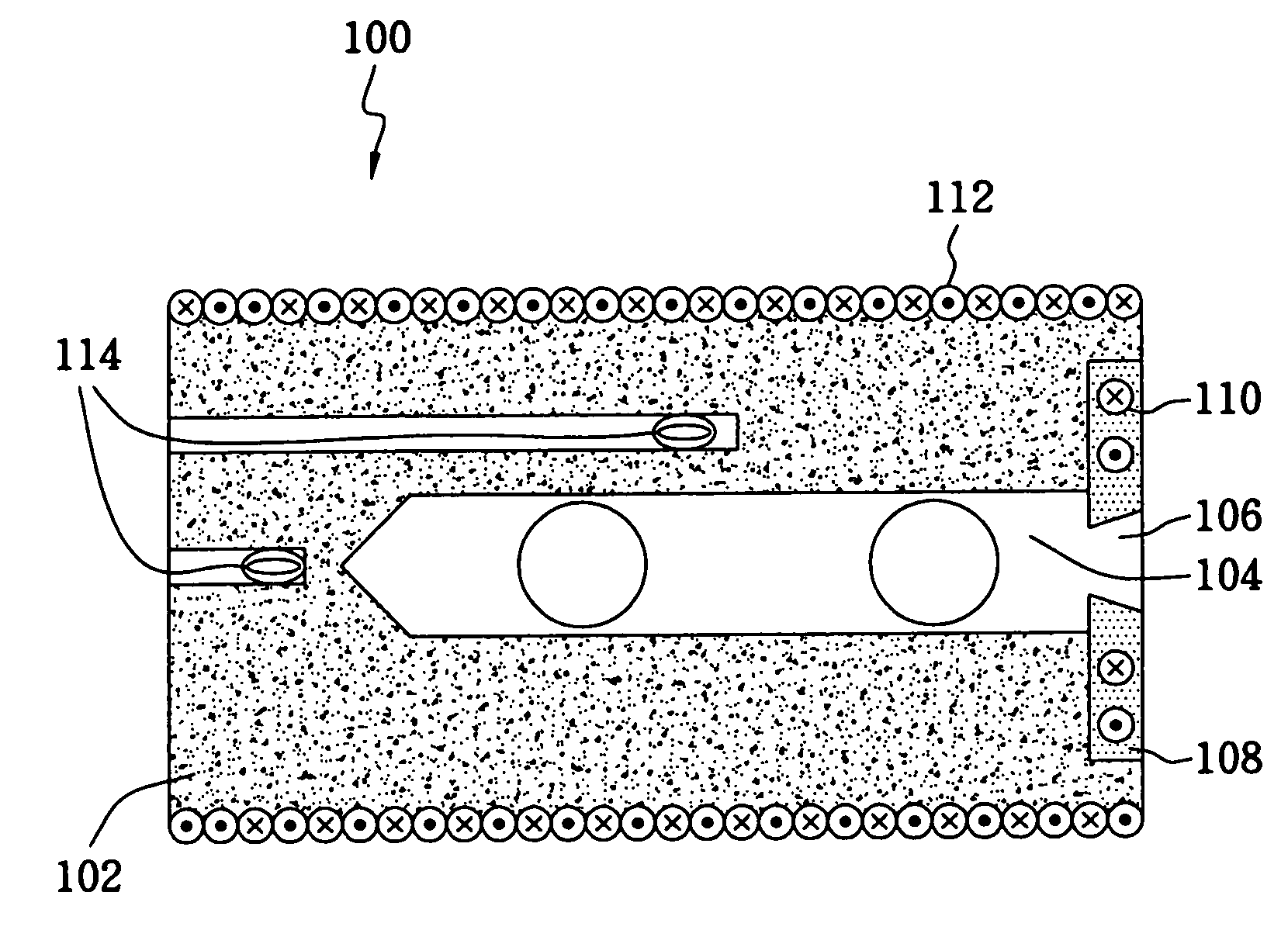

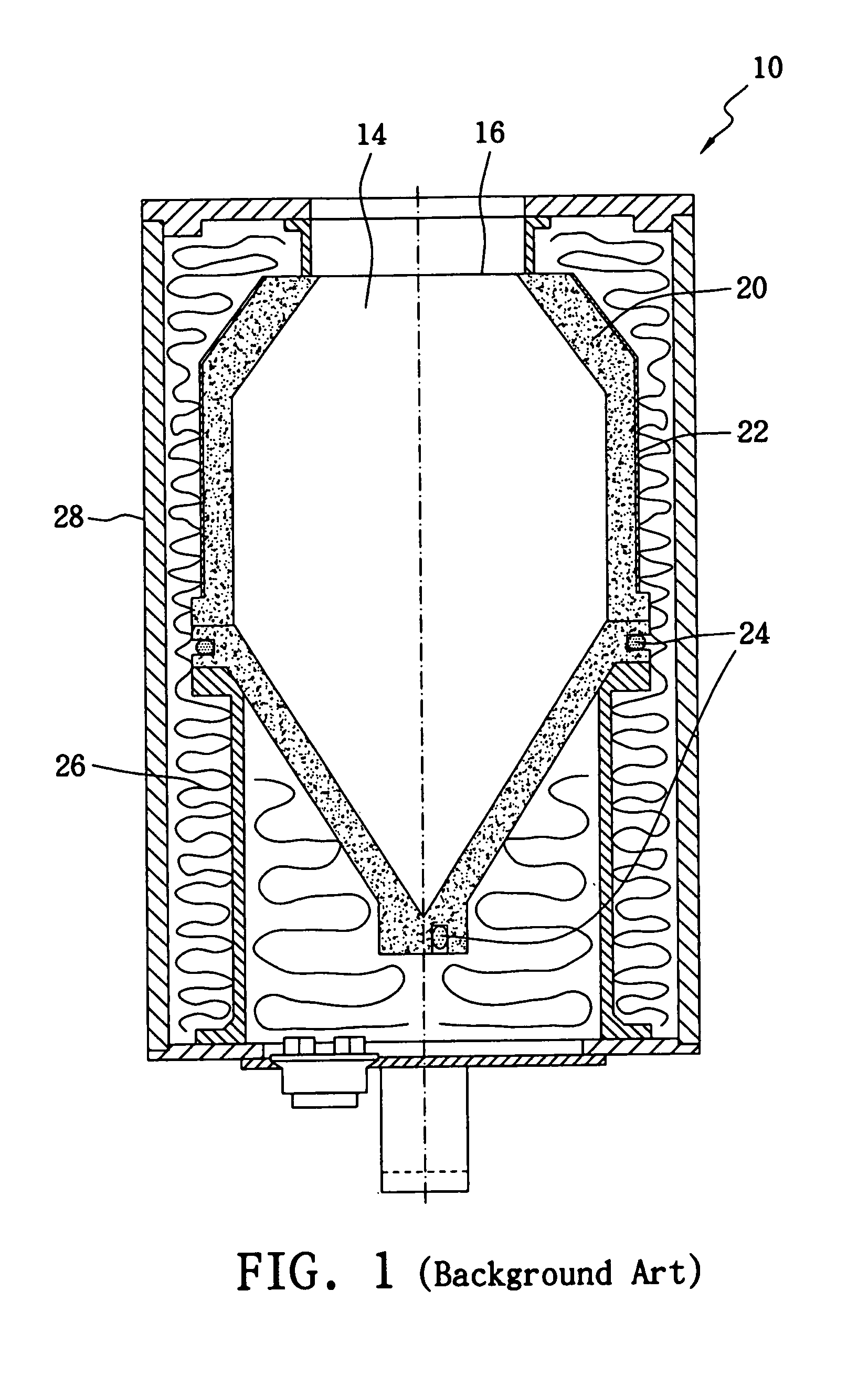

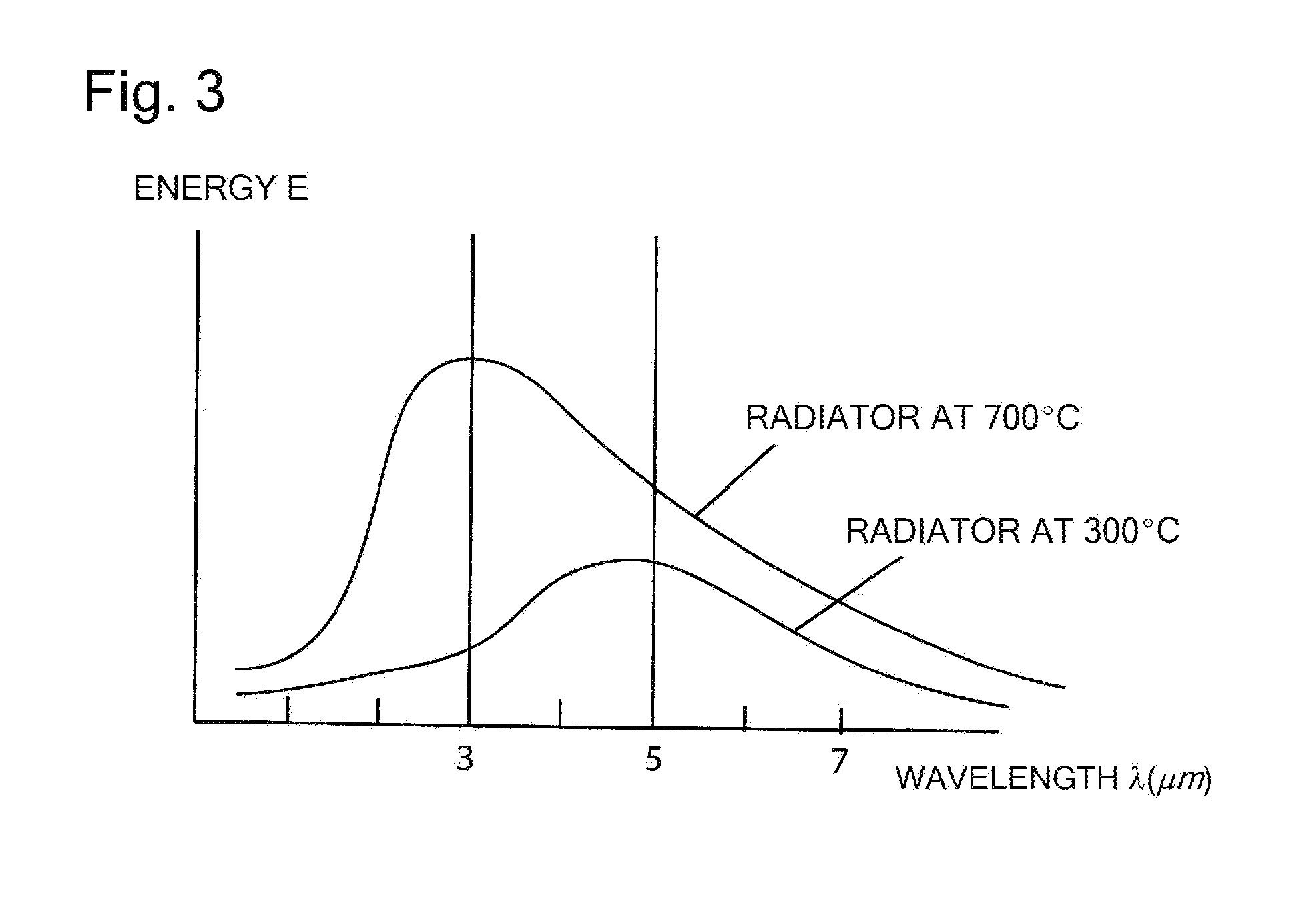

Portable blackbody furnace

ActiveUS7148450B2Improve stabilityImprove uniformityBaking ovenMaintainance of heating chambersMetallurgyJoule

The present invention discloses a portable blackbody furnace comprising a metallic body, a cylindrical cavity with a tapered end in the metallic body, a shielding plate positioned at an open end of the cylindrical cavity, at least a first heaters positioned in the shielding plate, a plurality of second heaters positioned around the metallic body, and a plurality of thermometers positioned in the metallic body. Preferably, the heat capacity of the metallic body is larger than 200 Joules / K, and has radial thickness larger than 5 mm. There are grooves formed on the outer wall of the metallic body, and the second heaters are heating wires embedded inside the grooves. In addition, the flow direction of the current between two adjacent heating wires is opposite to eliminate the magnetic field generated from the current flow.

Owner:IND TECH RES INST

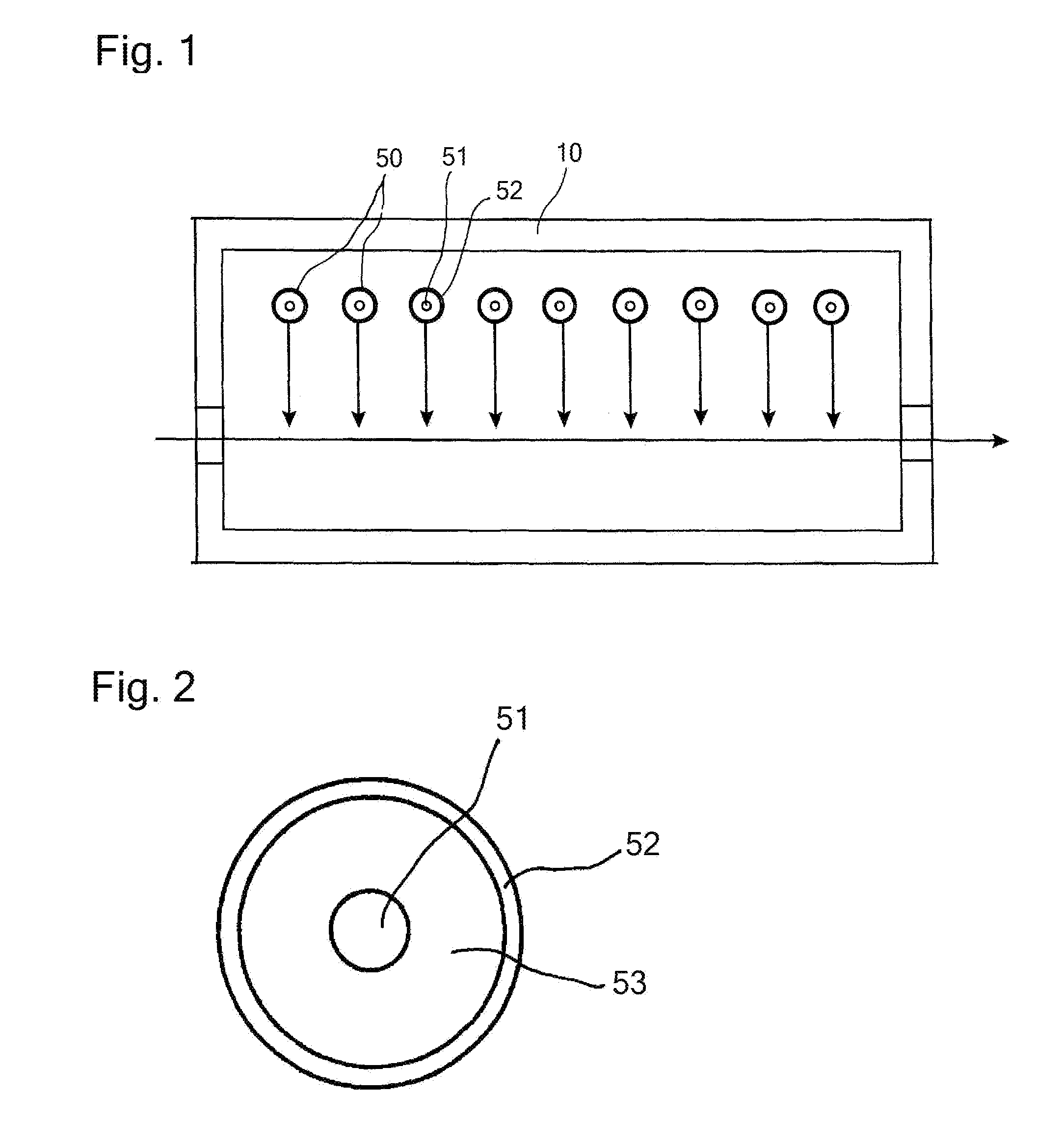

Coated film drying furnace

ActiveUS20120328272A1Sufficient drynessEfficient dryingDrying solid materials with heatCell electrodesOrganic solventHydrogen

A coated film drying furnace for drying a coated film inside a furnace body by conveying the coated film therein, the coated film having an absorption spectrum for electromagnetic waves of 3.5 μm or less and having hydrogen bonds, such as an electrode coated film for lithium ion battery. Infrared heaters provided inside a furnace body have outer circumferences of filaments concentrically covered by tubes that function as a low pass filter, and have a structure in which a fluid flow passage is formed at 16 between the plurality of tubes. Due to this, a temperature rise in the furnace is controlled so as to prevent explosion of an organic solvent vapor, and the coated film is efficiently heated and dried by intensively radiating near infrared rays of 3.5 μm or less that have superior ability to cut off the intermolecular hydrogen bonds onto a work.

Owner:NGK INSULATORS LTD

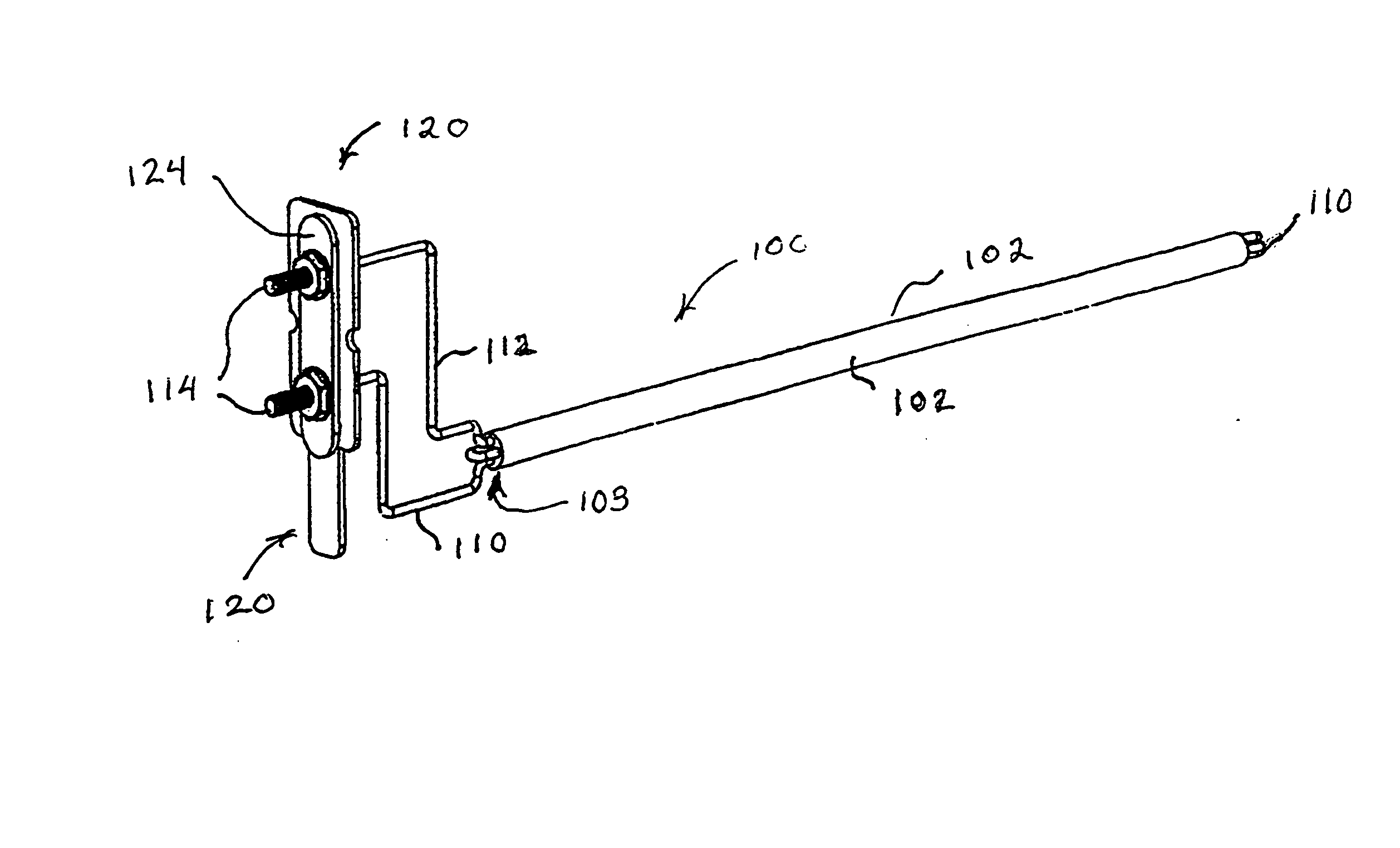

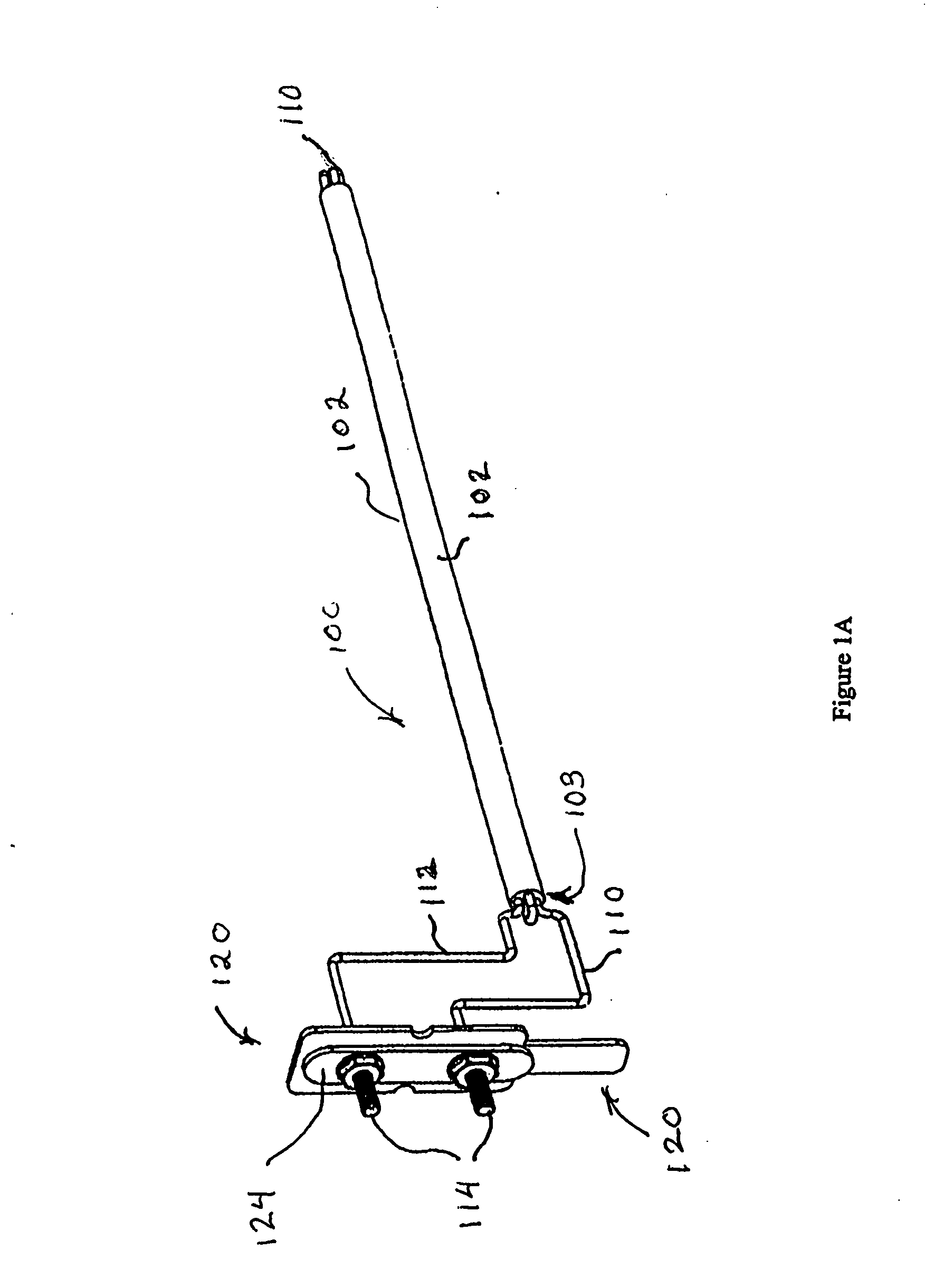

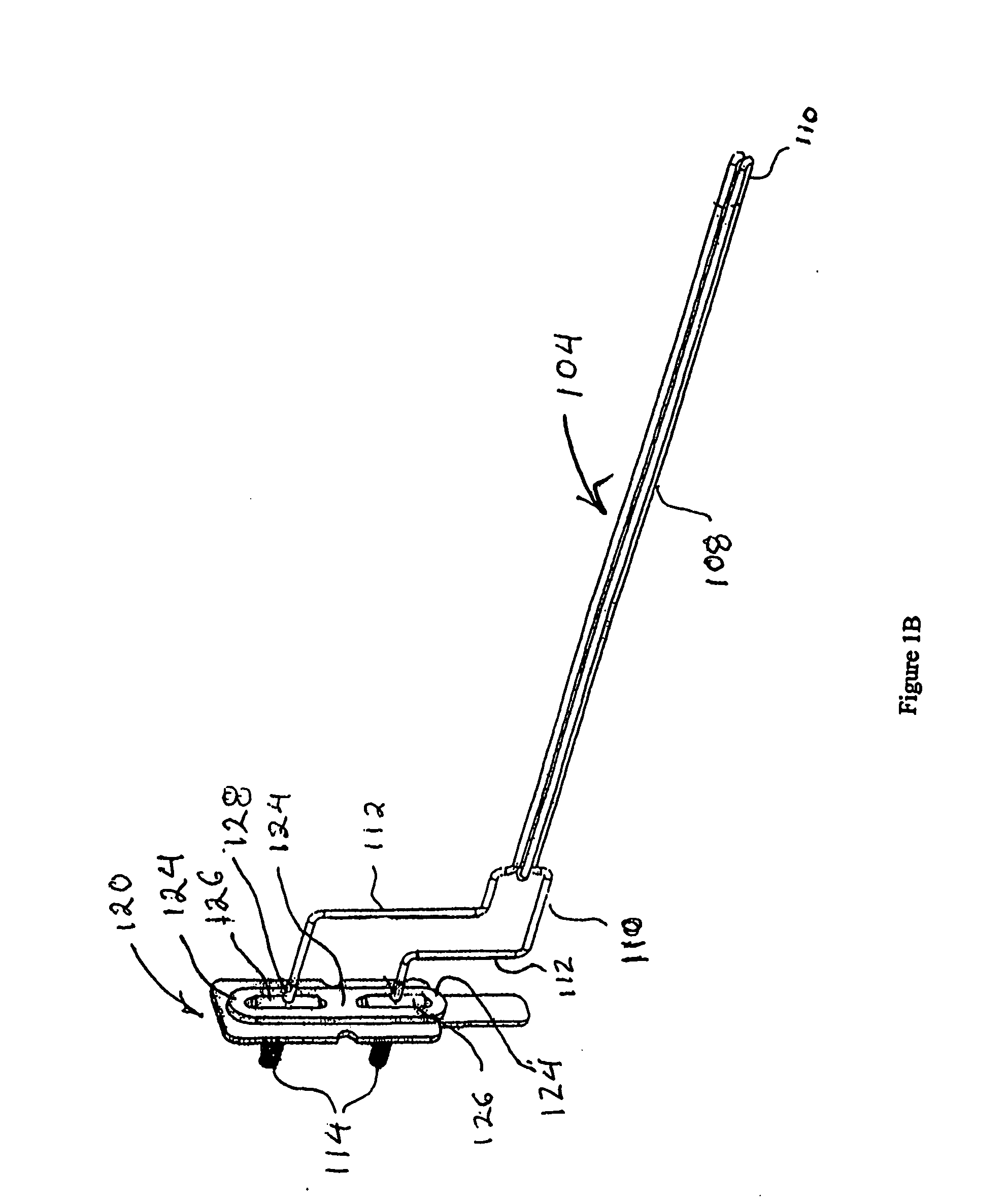

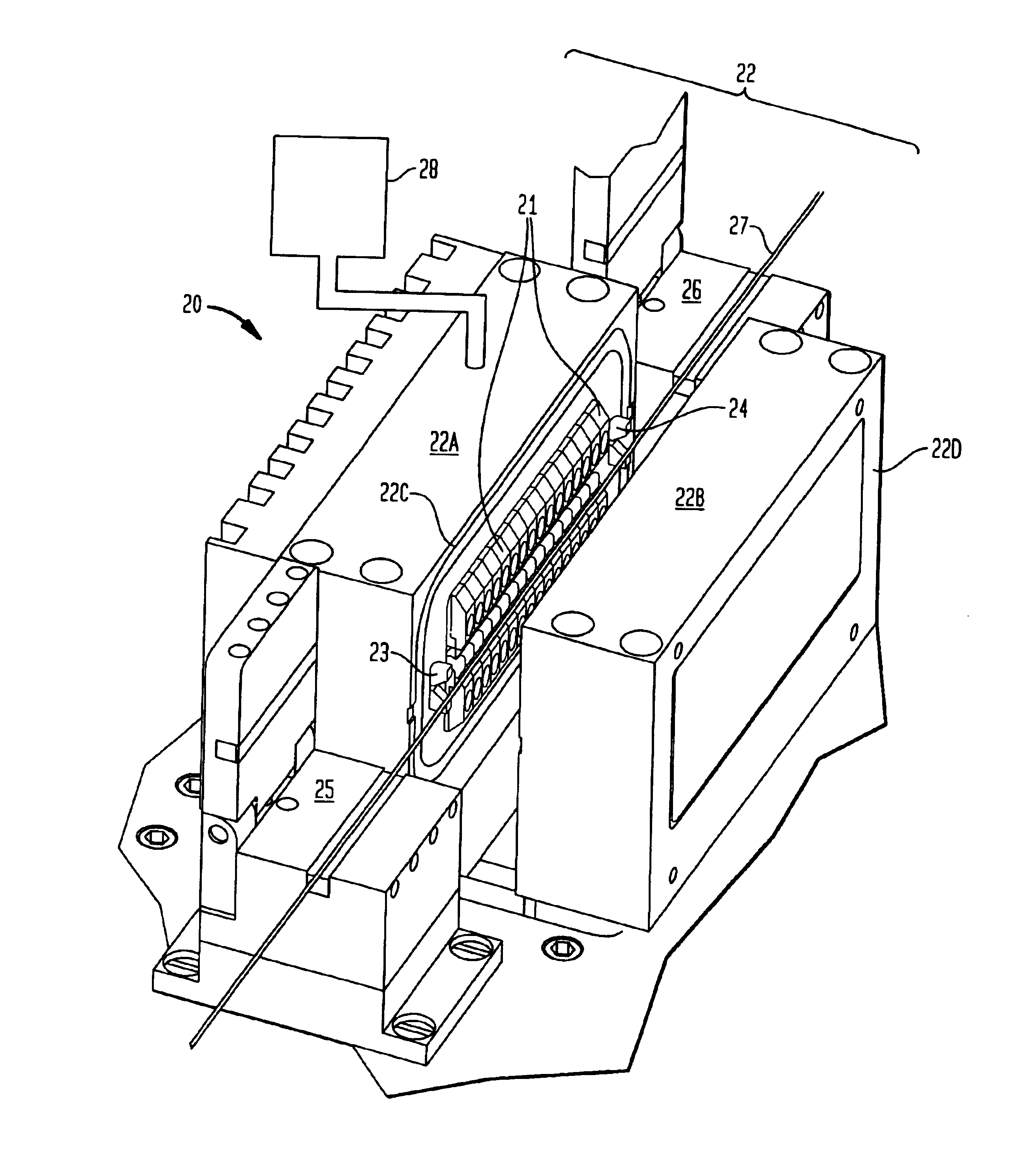

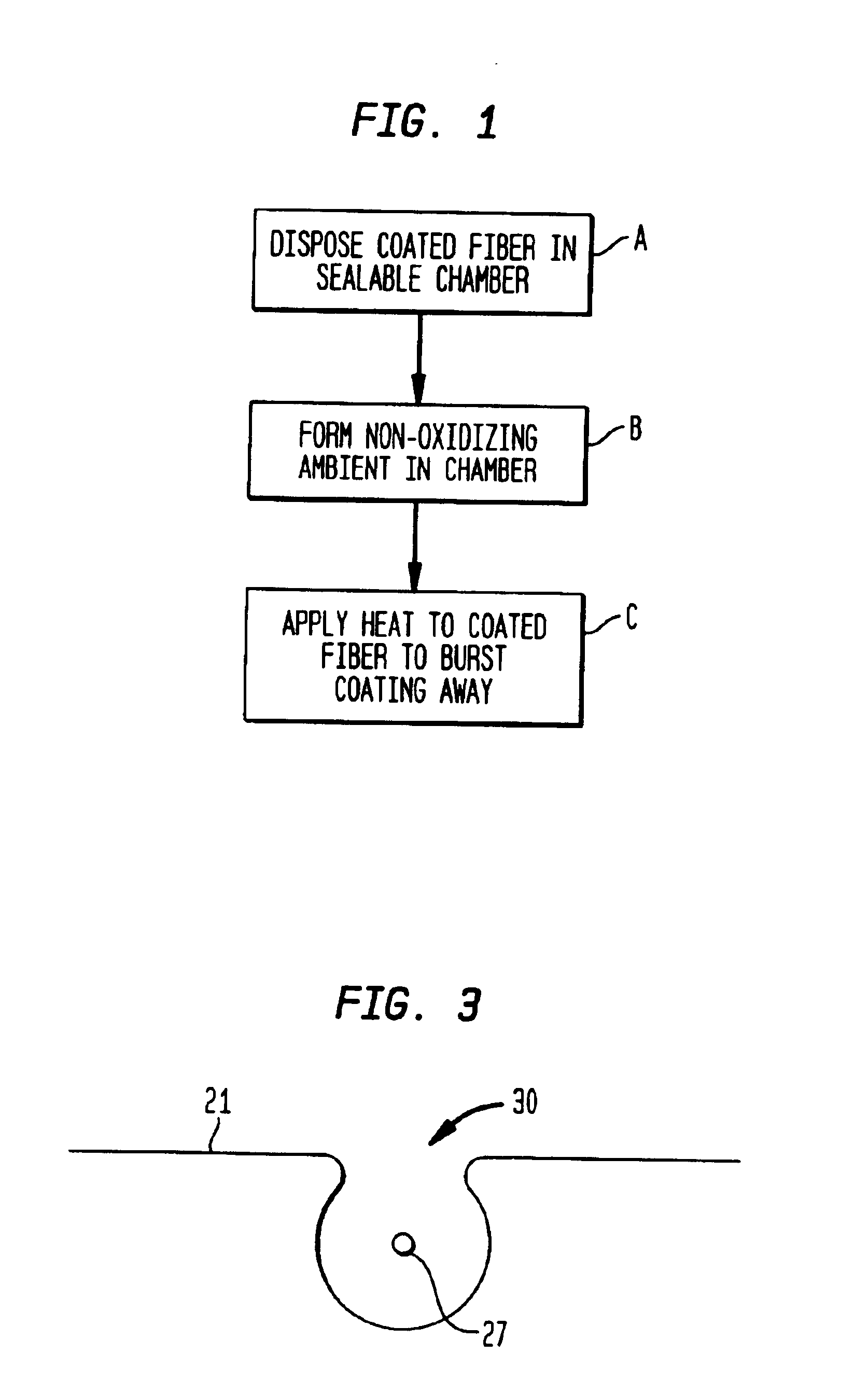

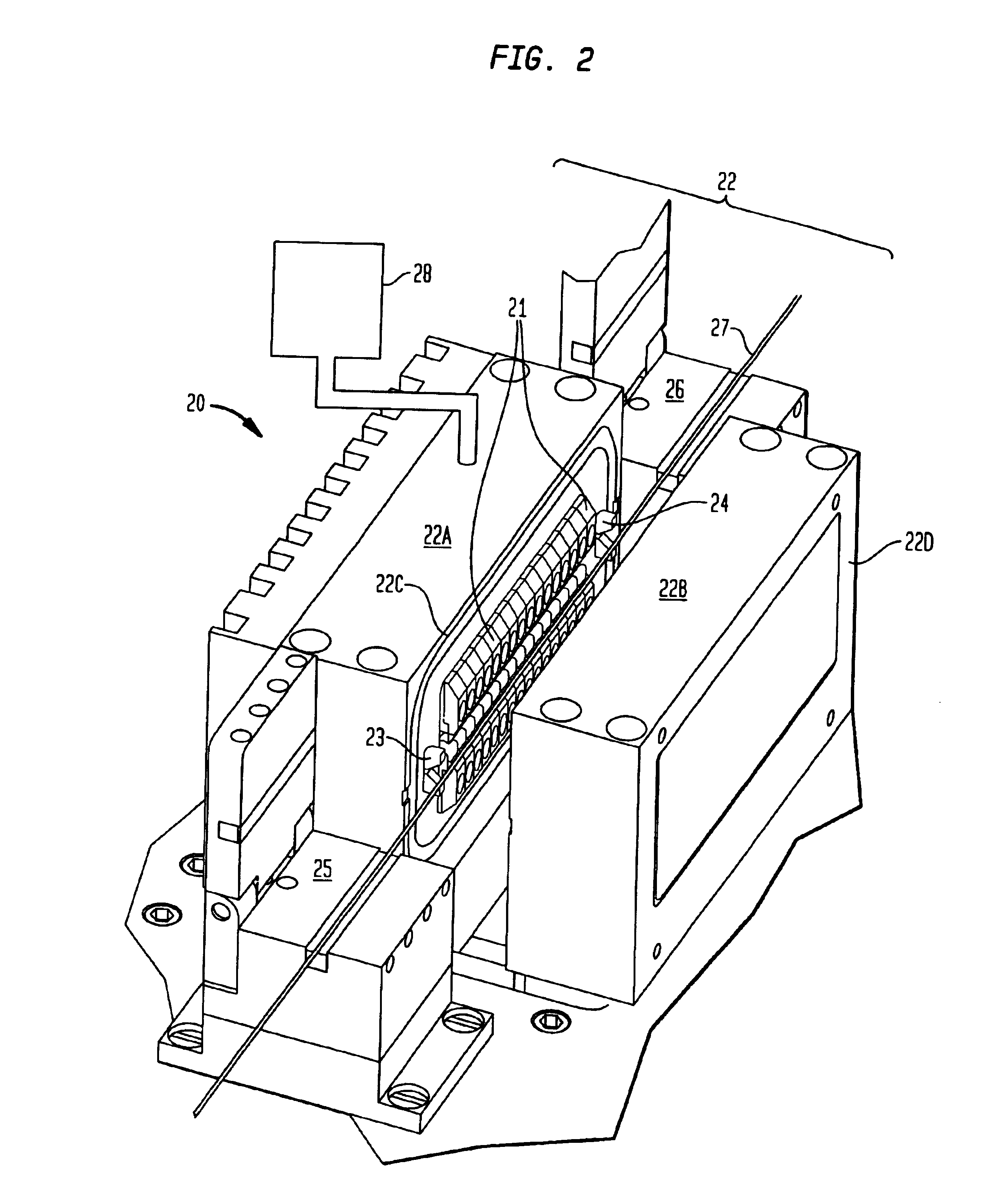

Method and apparatus for removing polymeric coatings from optical fiber in a non-oxidizing environment

In accordance with the invention, the polymeric coating is removed from a coated optical fiber by disposing the fiber within a non-oxidizing environment and applying sufficient heat to volatilize at least a portion of the polymeric coating. The result is that the coating material bursts from the fiber, yielding a clean glass surface virtually free of surface flaws. In a preferred embodiment the non-oxidizing environment is inert gas and the heat is provided by resistive filament heaters.

Owner:THORLABS INC

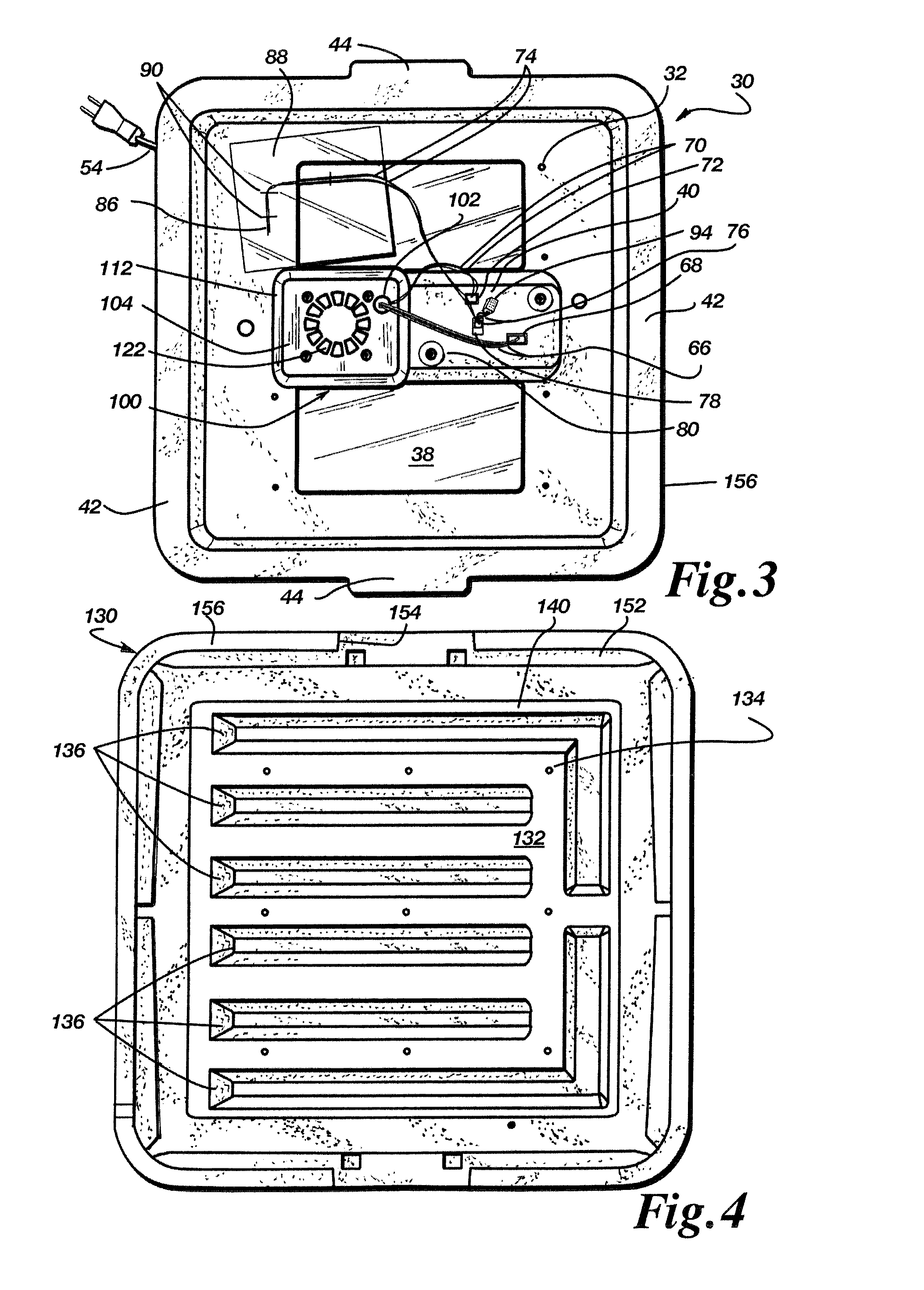

Egg incubator

InactiveUS20160135434A1Environment is restrictiveHigh productElectric heating systemAir heatersMoisture sensorDigital control

An insulated egg incubator having a base pan with a bottom into which eggs are placed for incubation until hatching. Water channels are evenly disbursed in the bottom of the base pan for adding water and humidity to the incubator. A plastic molded screen is located in the base pan above the water channels to support the eggs. A top lid of a smaller dimension than the base pan is provided for completely nesting upside down into the base pan for shipping of the incubator. A window is in the top lid for viewing within the incubator. An insulated heater with a plastic fan assembly is mounted to the inside of the top lid. A digital control unit is mounted in the top lid with a rectifier connected to and controlling the on-off modes of the heater and the fan. A thermistor is provided inside the top lid and connected to the control unit placeable on the eggs for displaying the temperature within the incubator at the top of the eggs and inputting temperature readings to the control unit for operation of the heater. A humidity sensor is located inside the top lid and connected to the control unit for displaying the humidity within the incubator. A power cord with a plug is provided for connection and supply of electrical power to the control unit.

Owner:MILLER MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com