Heat processing furnace and vertical-type heat processing apparatus

A heat treatment device, heat treatment furnace technology, applied in the direction of heating devices, furnaces, furnace types, etc., can solve the problems of not ensuring the gap between heating parts, durability reduction, difficulty in rapid cooling, etc., to achieve the effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

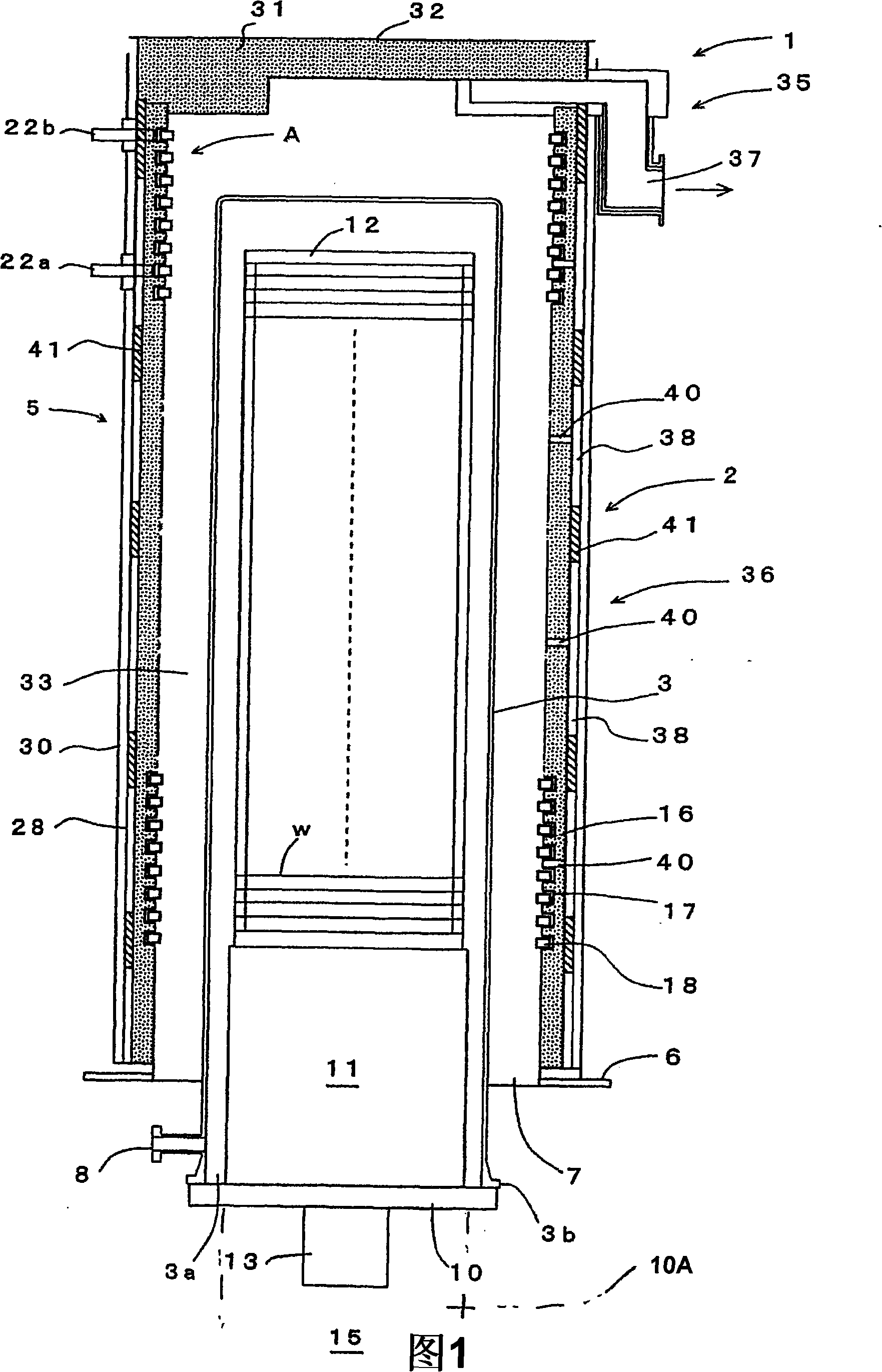

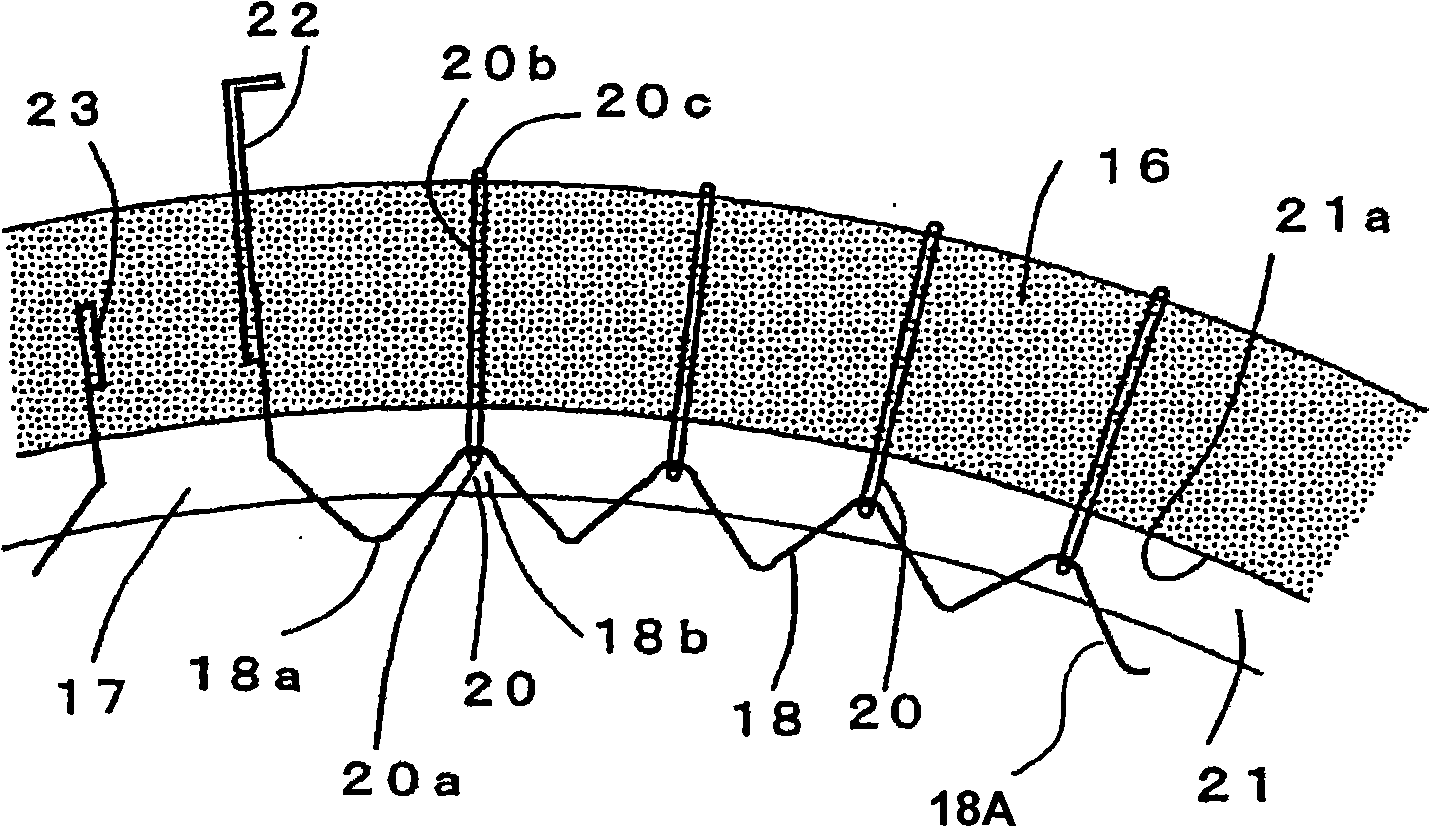

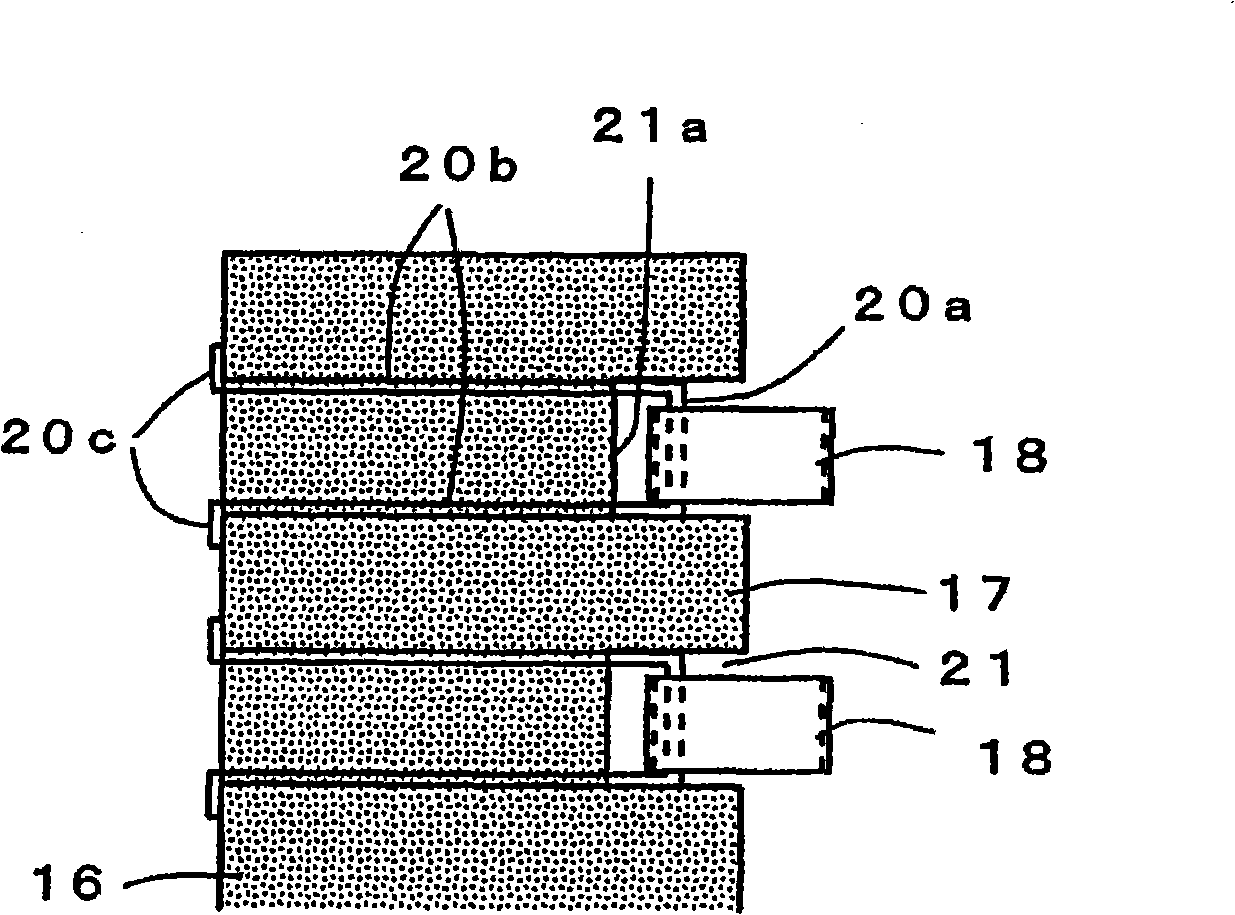

[0049] Hereinafter, the best mode for carrying out the present invention will be described in detail based on the drawings. Fig. 1 is a longitudinal sectional view schematically showing a vertical heat treatment apparatus as an embodiment of the present invention, figure 2 is an enlarged cross-sectional view showing part A of FIG. 1 , image 3 is an enlarged longitudinal sectional view showing part A, Figure 4 is a plan view showing the heating element, Figure 5 It is a side view showing a heating member.

[0050] In FIG. 1 , reference numeral 1 represents a vertical heat treatment apparatus as one of semiconductor manufacturing apparatuses, and this heat treatment apparatus 1 has a structure capable of accommodating a plurality of objects to be processed (such as semiconductor wafers w) at a time, and performing oxidation, diffusion, and reduction thereof. Vertical heat treatment furnace 2 for heat treatment such as pressure CVD. This heat treatment furnace 2 includes:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com