Stiffness-variable surgical manipulator, surgical instrument and operation method of surgical instrument

A surgical device and variable stiffness technology, applied in the field of medical devices, can solve the problems of inability to use in a narrow space, large noise and structural size, and large overall structure, and achieve the effects of simple structure, high degree of automation, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

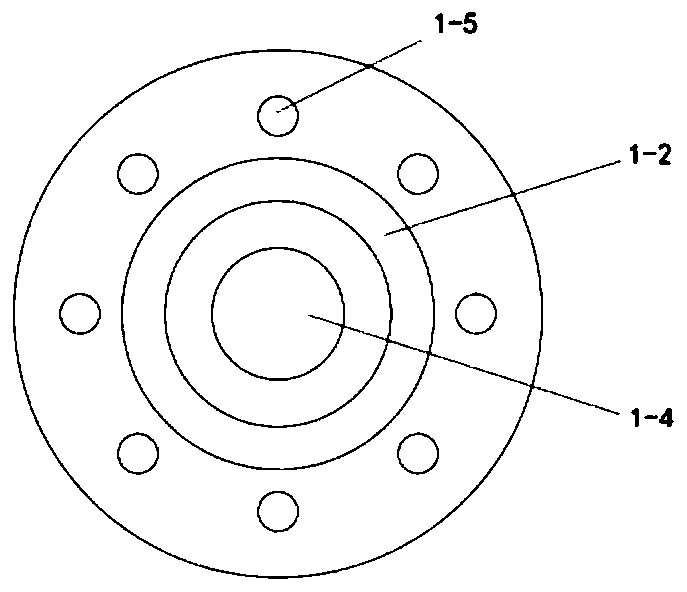

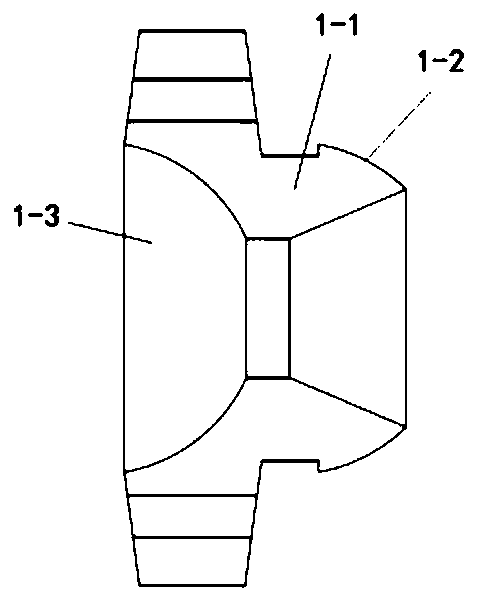

[0043] This embodiment discloses a surgical device, which includes a base plate, a mechanical arm support is provided on one side of the base plate, and the mechanical arm support is fixedly connected to one end of the variable stiffness surgical mechanical arm described in Embodiment 1 through bolts. Specifically, the joint of the surgical manipulator with variable stiffness used to connect with the support of the manipulator is connected with a flange connection plate 7, and the flange connection plate is fixedly connected with the support of the manipulator through bolts.

[0044] Two first driving mechanisms are arranged on the bottom plate, the first driving mechanism adopts a steering gear, the steering gear is fixed on the support plate, the support plate and the bottom plate are fixedly connected by bolts, and the output shaft of the steering gear is connected to the turntable , the two ropes in one group of the variable stiffness surgical manipulator pass through the s...

Embodiment 3

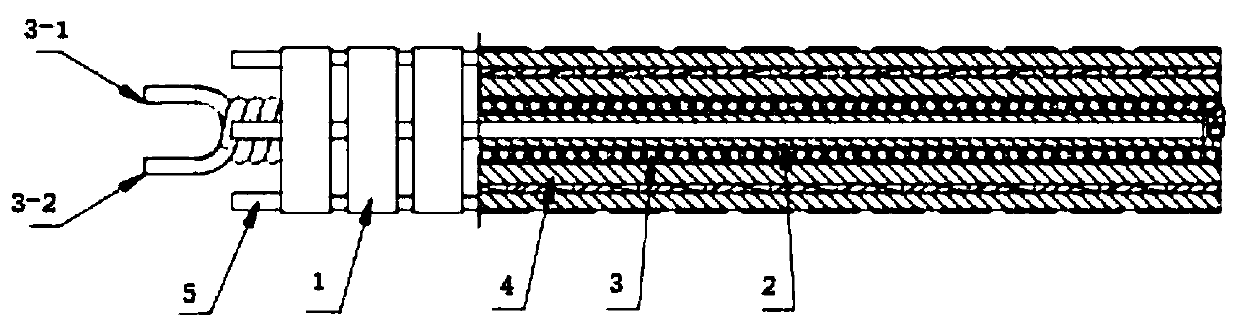

[0050] This embodiment discloses a surgical device, such as Figure 5-6 As shown, in this embodiment, the variable stiffness surgical manipulator includes a first manipulator part and a second manipulator part, and the number of its ropes is eight, a total of four groups of ropes, wherein two groups of ropes (four ropes) Pass through all the joints of the first mechanical arm and the second mechanical arm, and be fixedly connected with the joints at the end of the second mechanical arm. The other two sets of ropes (the other four ropes) only pass through the first mechanical arm and are connected with Joint fixed connection of the end of the first mechanical arm part (for connecting the end of the second mechanical arm part), wherein the first mechanical arm part is used to connect with the mechanical arm support 6, and the end of the second mechanical arm part is used for To connect the surgical instruments, the strings passing only through the first mechanical arm and the st...

Embodiment 4

[0059] This embodiment discloses a working method of a surgical device: input the motion path of the end of the mechanical arm to the controller in advance according to the surgical target position, connect the required surgical instruments to the end of the surgical mechanical arm with variable stiffness, and connect the flexible temperature control tube The positive and negative poles of the power supply are respectively connected to the water inlet and the water outlet. The flexible metal tube generates heat after being energized, and heats the variable stiffness tube made of PET plastic material. After heating to a certain temperature, the variable stiffness tube produces a phase change. , changing from rigidity to flexibility. At this time, the second motor works to drive the variable-stiffness surgical manipulator to move forward as a whole. While moving forward, the steering gear works together to work according to the movement path set by the controller to retract or rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com