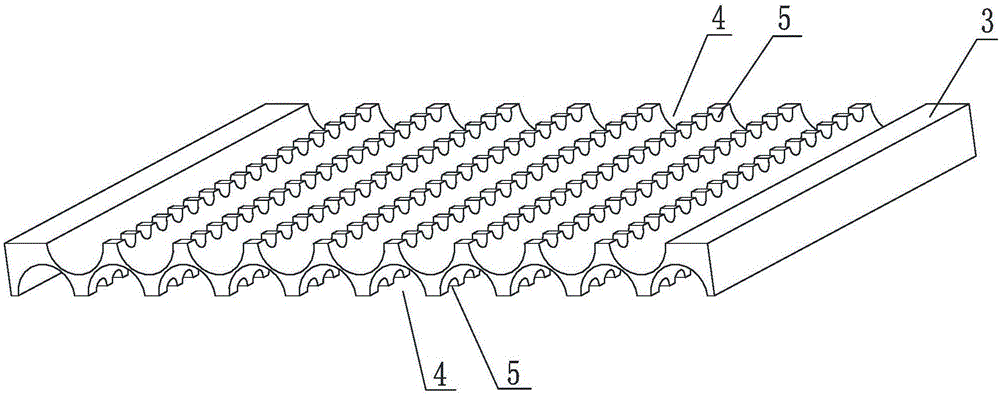

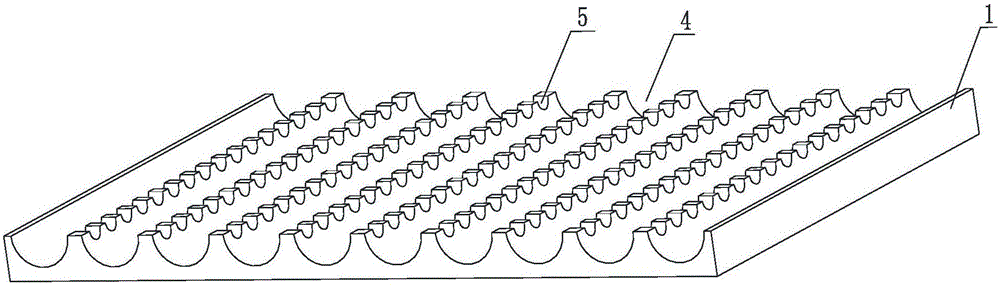

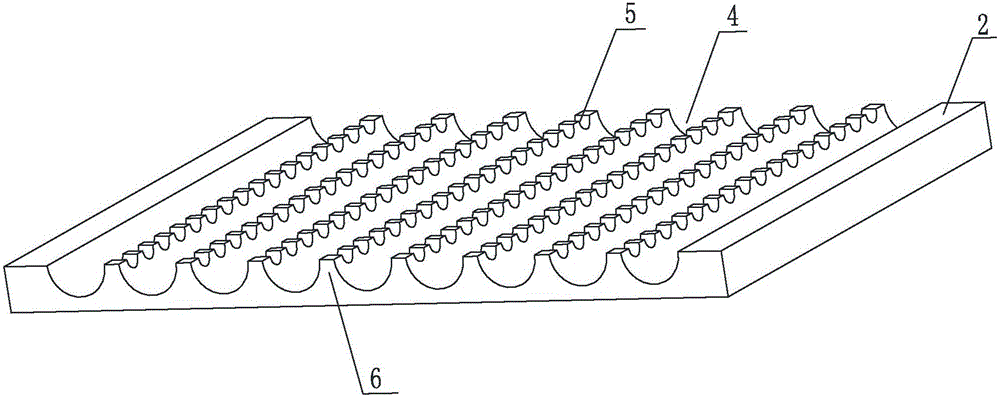

Compact and efficient heat exchanger core and welding fixture thereof

A technology for welding tooling and heat exchangers, which is applied to indirect heat exchangers, heat exchanger types, welding equipment, etc. Excellent high temperature and high pressure performance, improving yield and reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In view of the fact that the high temperature resistance and heat transfer efficiency of the existing printed circuit board heat exchanger are not high enough and still need to be improved, and the existing welding tooling cannot meet the assembly accuracy during welding and the pressure requirements required for diffusion welding, the core The heating and cooling of the body is greatly affected by the tooling, which affects the welding quality. The present invention designs a compact and high-efficiency heat exchanger core, and the heat exchanger prepared by using the heat exchanger core has high heat exchange efficiency and compactness, can serve under high temperature and high pressure, and is suitable for use in special occasions . At the same time, the present invention designs an assembly and welding integrated tooling for the heat exchanger core, which solves the problems of poor assembly accuracy during diffusion welding, difficulty in obtaining stable pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com