S-shaped composite furnace wire and processing method thereof

A serpentine and furnace wire technology, applied in furnace heating elements and other directions, can solve problems such as lack of mechanical equipment, inability to meet large-scale production, and difficulty in meeting product technical requirements, and achieve the effect of extending service life and improving processing convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

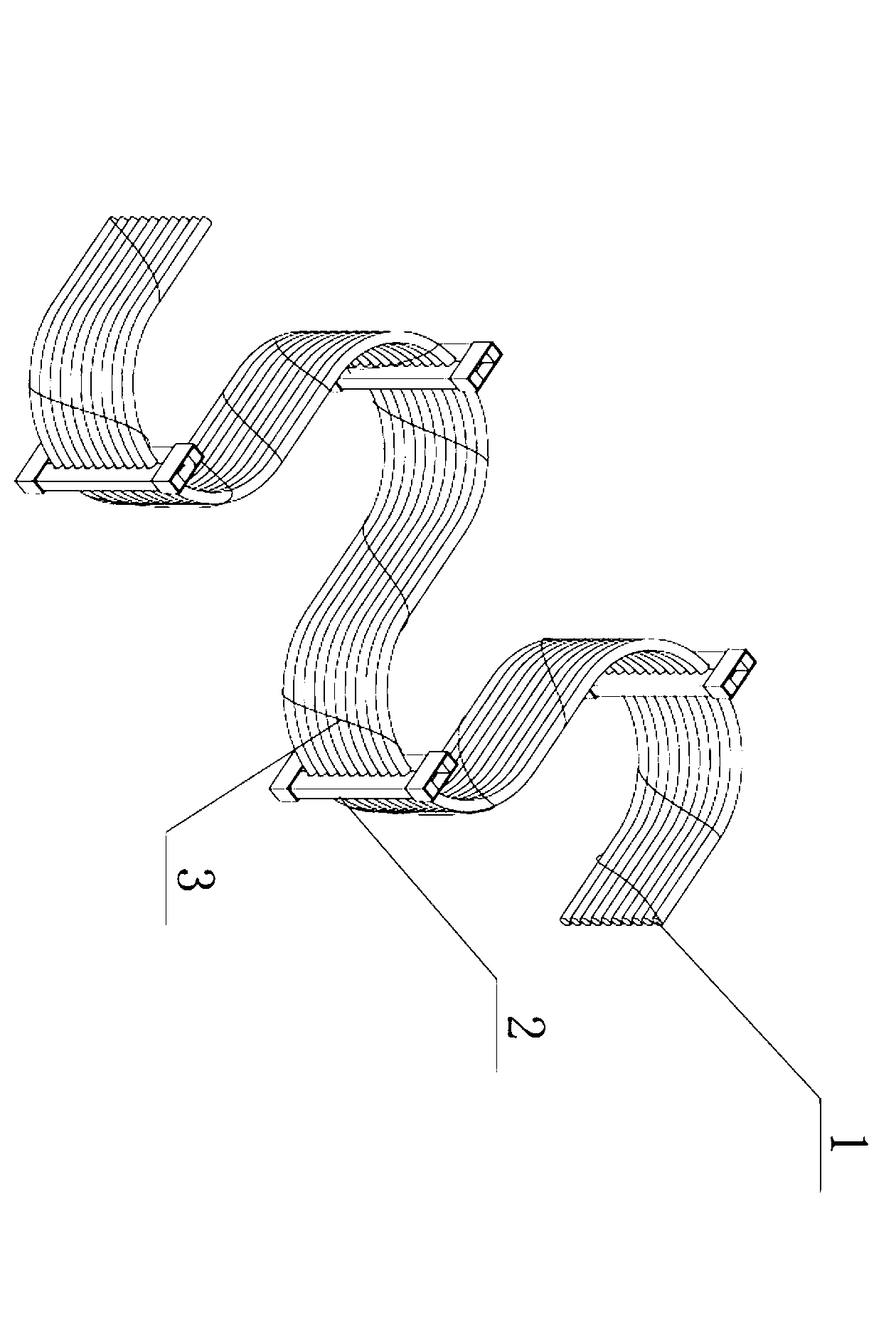

[0021] Such as figure 1 As shown, the serpentine composite furnace wire of the present invention is composed of a serpentine electrothermal alloy wire 1 , a metal clip 2 and a winding wire 3 . Several electrothermal alloy wires 1 with the same cross-section folded into a serpentine shape are stacked and fixed at the crest by a metal clip 2; the metal clip 2 can be a separate metal casting, a stamping part, or a U-shaped single metal clip The winding wire 3 is a heat-resistant metal wire that meets the binding strength requirements of the electrothermal alloy wire 1 in high temperature working state.

[0022] The processing method of serpentine composite furnace wire of the present invention comprises the following steps:

[0023] 1. Processing serpentine electric heating alloy wire

[0024] Use a snake spring machine to fold the electric heating alloy wire 1 into a meandering snake shape;

[0025] 2. Processing metal clips

[0026] The metal clip 2 is made into split metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com